Alkali-Treated Titanium Coated with a Polyurethane, Magnesium and Hydroxyapatite Composite for Bone Tissue Engineering

Abstract

1. Introduction

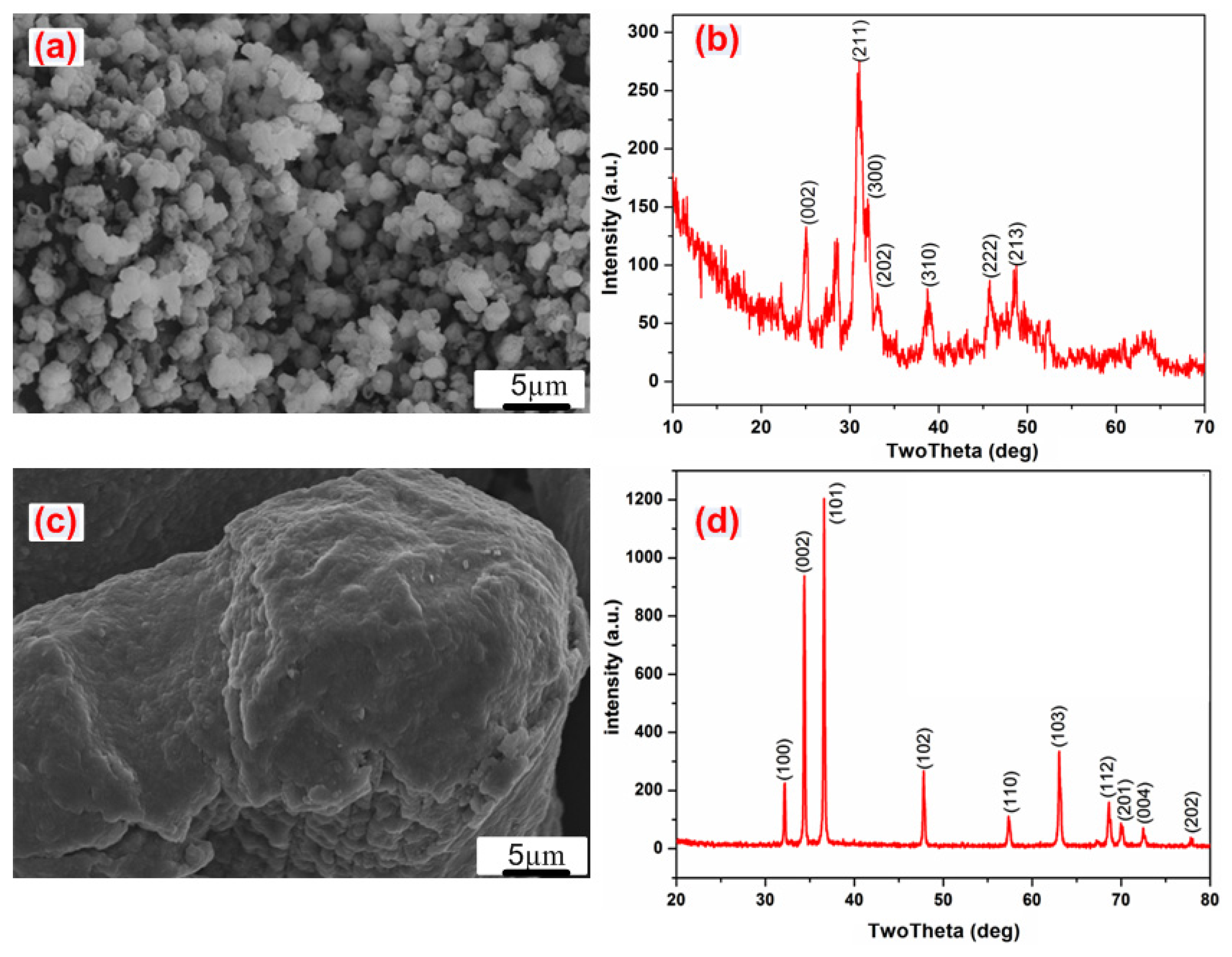

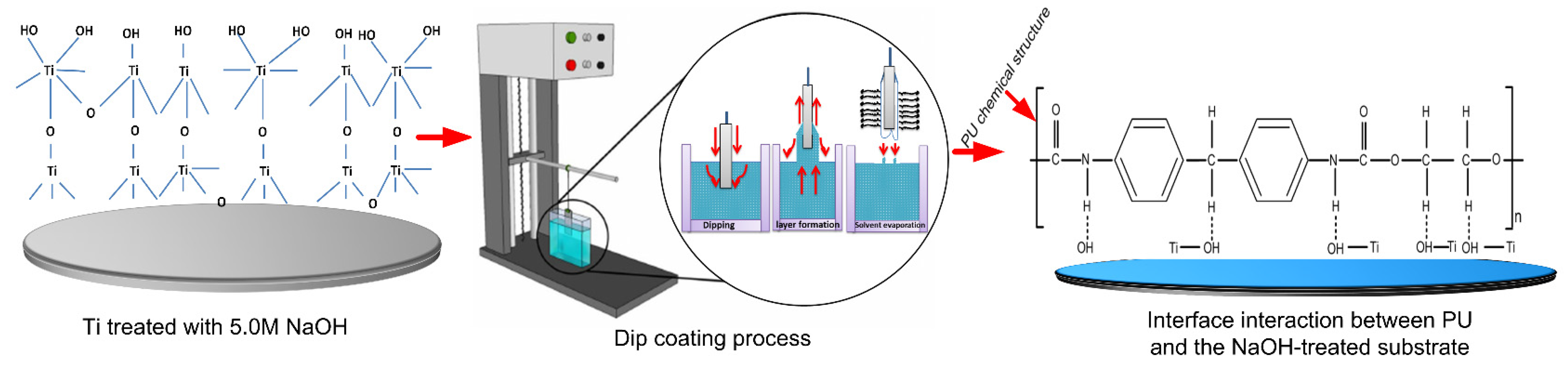

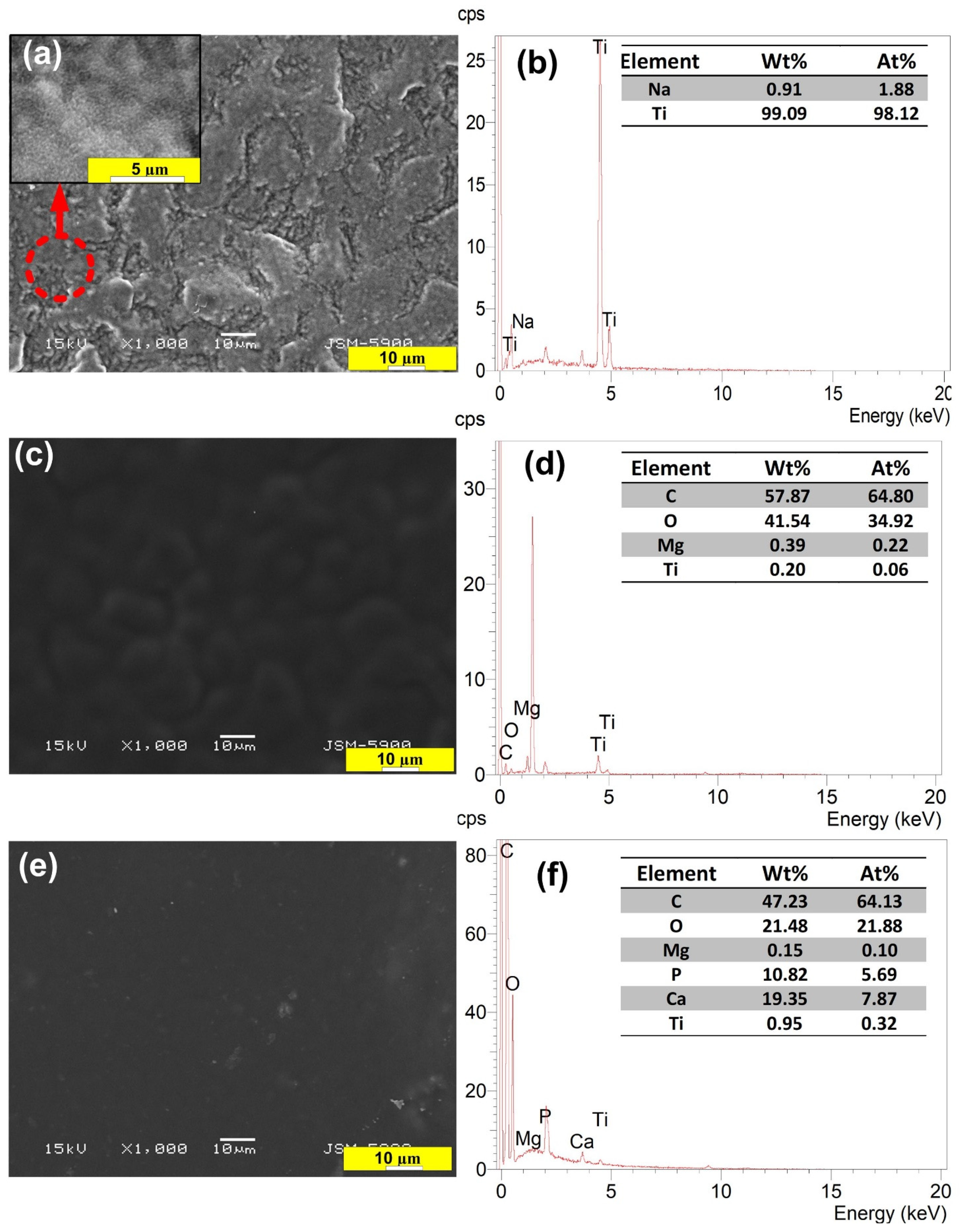

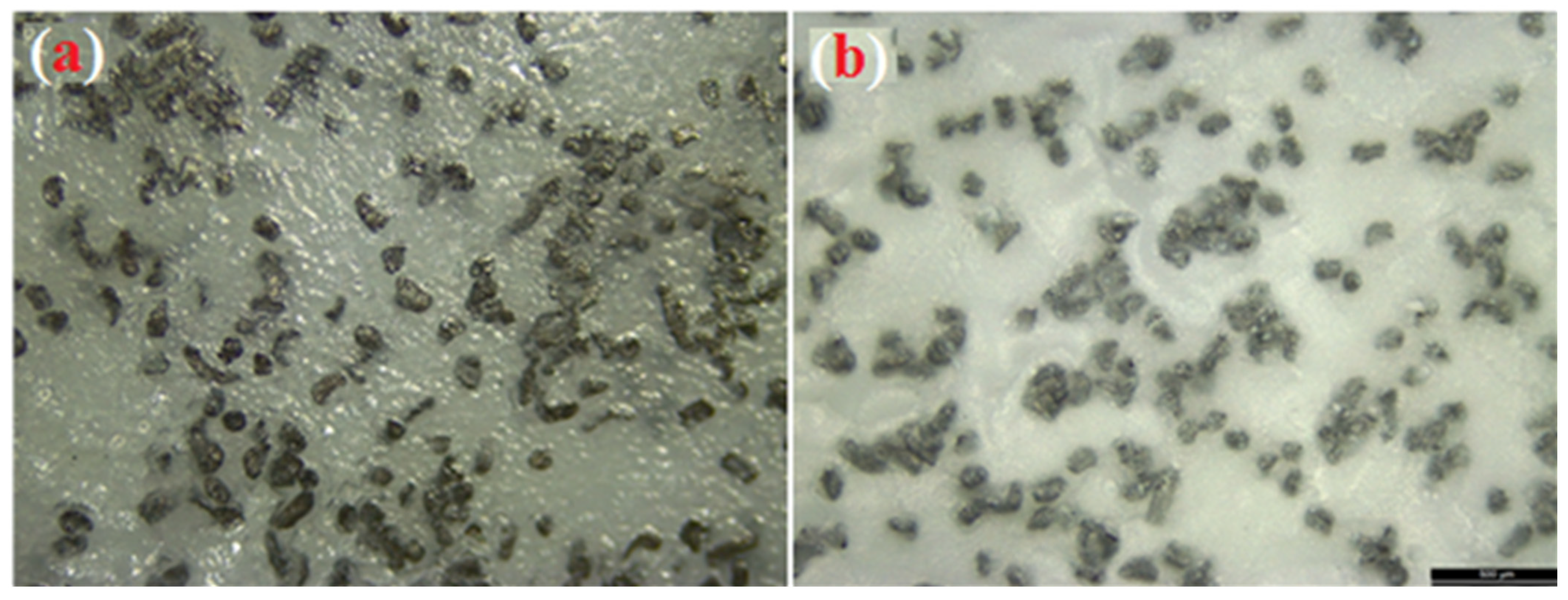

2. Materials and Methods

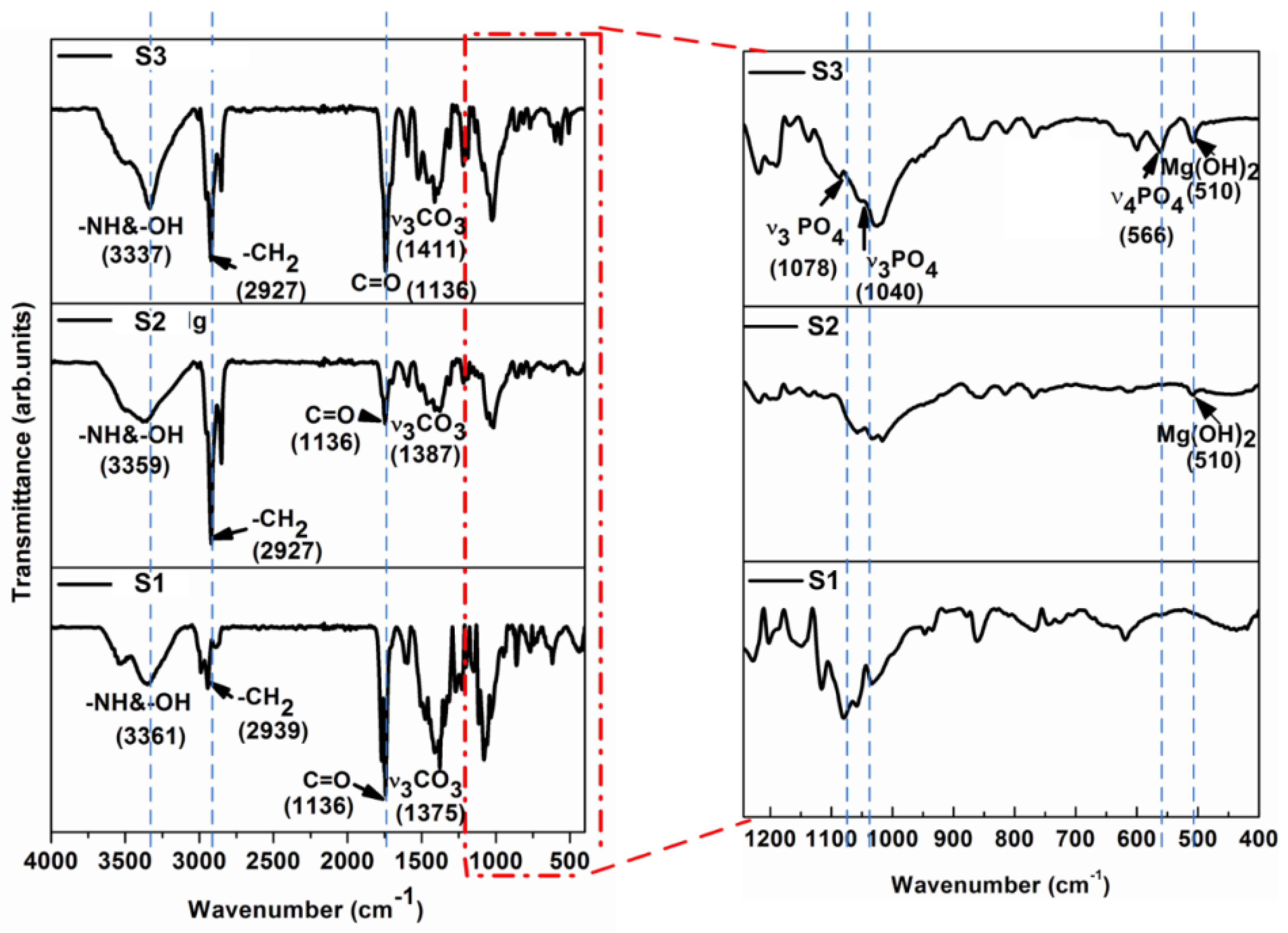

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Park, K.-D.; Lee, B.-A.; Piao, X.-H.; Lee, K.-K.; Park, S.-W.; Oh, H.-K.; Kim, Y.-J.; Park, H.-J. Effect of magnesium and calcium phosphate coatings on osteoblastic responses to the titanium surface. J. Adv. Prosthodont. 2013, 5, 402–408. [Google Scholar] [CrossRef][Green Version]

- Young Kim, S.; kyoung Kim, Y.; song Park, I.; chun Jin, G.; sung Bae, T.; ho Lee, M. Effect of alkali and heat treatments for bioactivity of TiO2 nanotubes. Appl. Surf. Sci. 2014, 321, 412–419. [Google Scholar]

- Roy, P.; Berger, S.; Schmuki, P. TiO2 nanotubes: Synthesis and applications. Angew. Chem. Int. Ed. 2011, 50, 2904–2939. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Agour, M.; Kim, Y.-K.; Lee, M.-H.; Hassan, M.K.; El-Ainin, H.A.; Hamdy, A.S.; Ivanovski, S. Magnesium-particle/polyurethane composite layer coating on titanium surfaces for orthopedic applications. Eur. Polym. J. 2019, 112, 555–568. [Google Scholar] [CrossRef]

- Lim, Y.J.; Oshida, Y.; Andres, C.J.; Barco, M.T. Surface characterizations of variously treated titanium materials. Int. J. Oral Maxillofac. Implants 2001, 16, 333–342. [Google Scholar] [PubMed]

- Lopes, M.A.; Monteiro, F.; Santos, J.; Serro, A.; Saramago, B. Hydrophobicity, surface tension, and zeta potential measurements of glass—Reinforced hydroxyapatite composites. J. Biomed. Mater. Res. 1999, 45, 370–375. [Google Scholar] [CrossRef]

- Webster, T.J.; Ergun, C.; Doremus, R.H.; Siegel, R.W.; Bizios, R. Specific proteins mediate enhanced osteoblast adhesion on nanophase ceramics. J. Biomed. Mater. Res. 2000, 51, 475–483. [Google Scholar] [CrossRef]

- Ferraz, M.; Monteiro, F.; Serro, A.; Saramago, B.; Gibson, I.R.; Santos, J. Effect of chemical composition on hydrophobicity and zeta potential of plasma sprayed HA/CaO–P2O5 glass coatings. Biomaterials 2001, 22, 3105–3112. [Google Scholar] [CrossRef]

- Botelho, C.; Lopes, M.; Gibson, I.R.; Best, S.; Santos, J. Structural analysis of Si-substituted hydroxyapatite: Zeta potential and X-ray photoelectron spectroscopy. J. Mater. Sci. Mater. Med. 2002, 13, 1123–1127. [Google Scholar] [CrossRef] [PubMed]

- Abdal-Hay, A.; Hamdy, A.S.; Khalil, K.A.; Lim, J.H. A novel simple one-step air jet spinning approach for deposition of poly (vinyl acetate)/hydroxyapatite composite nanofibers on Ti implants. Mater. Sci. Eng. C 2015, 49, 681–690. [Google Scholar] [CrossRef]

- Vlacic-Zischke, J.; Hamlet, S.; Friis, T.; Tonetti, M.; Ivanovski, S. The influence of surface microroughness and hydrophilicity of titanium on the up-regulation of TGFβ/BMP signalling in osteoblasts. Biomaterials 2011, 32, 665–671. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Abbasi, N.; Gwiazda, M.; Hamlet, S.; Ivanovski, S. Novel polycaprolactone/hydroxyapatite nanocomposite fibrous scaffolds by direct melt-electrospinning writing. Eur. Polym. J. 2018, 105, 257–264. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Fouad, H.; ALshammari, B.A.; Khalil, K.A. Biosynthesis of bonelike apatite 2D nanoplate structures using fenugreek seed extract. Nanomaterials 2020, 10, 919. [Google Scholar] [CrossRef]

- Porter, A.E.; Taak, P.; Hobbs, L.W.; Coathup, M.J.; Blunn, G.W.; Spector, M. Bone bonding to hydroxyapatite and titanium surfaces on femoral stems retrieved from human subjects at autopsy. Biomaterials 2004, 25, 5199–5208. [Google Scholar] [CrossRef] [PubMed]

- Khalil, K.A.; Kim, S.W.; Dharmaraj, N.; Kim, K.W.; Kim, H.Y. Novel mechanism to improve toughness of the hydroxyapatite bioceramics using high-frequency induction heat sintering. J. Mater. Process. Technol. 2007, 187, 417–420. [Google Scholar] [CrossRef]

- Barakat, N.A.; Khalil, K.; Sheikh, F.A.; Omran, A.; Gaihre, B.; Khil, S.M.; Kim, H.Y. Physiochemical characterizations of hydroxyapatite extracted from bovine bones by three different methods: Extraction of biologically desirable HAp. Mater. Sci. Eng. C 2008, 28, 1381–1387. [Google Scholar] [CrossRef]

- Lin, D.-Y.; Wang, X.-X. Preparation of hydroxyapatite coating on smooth implant surface by electrodeposition. Ceram. Int. 2011, 37, 403–406. [Google Scholar] [CrossRef]

- Szymura-Oleksiak, J.; Ślósarczyk, A.; Cios, A.; Mycek, B.; Paszkiewicz, Z.; Szklarczyk, S.; Stankiewicz, D. The kinetics of pentoxifylline release in vivo from drug-loaded hydroxyapatite implants. Ceram. Int. 2001, 27, 767–772. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, T.; Zhang, J.; Lin, Q.; Jiang, D. Microstructure and mechanical properties of hydroxyapatite obtained by gel-casting process. Ceram. Int. 2008, 34, 359–364. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Barakat, N.A.; Lim, J.K. Hydroxyapatite-doped poly (lactic acid) porous film coating for enhanced bioactivity and corrosion behavior of AZ31 Mg alloy for orthopedic applications. Ceram. Int. 2013, 39, 183–195. [Google Scholar] [CrossRef]

- Wang, C.; Wang, M. Electrochemical impedance spectroscopy study of the nucleation and growth of apatite on chemically treated pure titanium. Mater. Lett. 2002, 54, 30–36. [Google Scholar] [CrossRef]

- Xu, L.; Pan, F.; Yu, G.; Yang, L.; Zhang, E.; Yang, K. In vitro and in vivo evaluation of the surface bioactivity of a calcium phosphate coated magnesium alloy. Biomaterials 2009, 30, 1512–1523. [Google Scholar] [CrossRef] [PubMed]

- Ibasco, S.; Tamimi, F.; Meszaros, R.; Le Nihouannen, D.; Vengallatore, S.; Harvey, E.; Barralet, J.E. Magnesium-sputtered titanium for the formation of bioactive coatings. Acta Biomater. 2009, 5, 2338–2347. [Google Scholar] [CrossRef] [PubMed]

- Huynh, V.; Ngo, N.K.; Golden, T.D. Surface activation and pretreatments for biocompatible metals and alloys used in biomedical applications. Int. J. Biomater. 2019, 2019, 3806504. [Google Scholar] [CrossRef] [PubMed]

- Xuhui, Z.; Lingfang, Y.; Yu, Z.; Xiong, J. Hydroxyapatite coatings on titanium prepared by electrodeposition in a modified simulated body fluid. Chin. J. Chem. Eng. 2009, 17, 667–671. [Google Scholar]

- Rath, P.C.; Besra, L.; Singh, B.P.; Bhattacharjee, S. Titania/hydroxyapatite bi-layer coating on Ti metal by electrophoretic deposition: Characterization and corrosion studies. Ceram. Int. 2012, 38, 3209–3216. [Google Scholar] [CrossRef]

- Cifuentes, S.C.; Gavilán, R.; Lieblich, M.; Benavente, R.; González-Carrasco, J.L. In vitro degradation of biodegradable polylactic acid/magnesium composites: Relevance of Mg particle shape. Acta Biomater. 2016, 32, 348–357. [Google Scholar] [CrossRef]

- Shuai, C.; Li, Y.; Feng, P.; Guo, W.; Yang, W.; Peng, S. Positive feedback effects of Mg on the hydrolysis of poly-l-lactic acid (PLLA): Promoted degradation of PLLA scaffolds. Polym. Test. 2018, 68, 27–33. [Google Scholar] [CrossRef]

- Zimmermann, T.; Ferrandez-Montero, A.; Lieblich, M.; Ferrari, B.; González-Carrasco, J.L.; Müller, W.-D.; Schwitalla, A.D. In vitro degradation of a biodegradable polylactic acid/magnesium composite as potential bone augmentation material in the presence of titanium and PEEK dental implants. Dent. Mater. 2018, 34, 1492–1500. [Google Scholar] [CrossRef] [PubMed]

- Abdal-hay, A.; Dewidar, M.; Lim, J.; Lim, J.K. Enhanced biocorrosion resistance of surface modified magnesium alloys using inorganic/organic composite layer for biomedical applications. Ceram. Int. 2014, 40, 2237–2247. [Google Scholar] [CrossRef]

- Barrere, F.; Van Der Valk, C.; Meijer, G.; Dalmeijer, R.; De Groot, K.; Layrolle, P. Osteointegration of biomimetic apatite coating applied onto dense and porous metal implants in femurs of goats. J. Biomed. Mater. Res. Part. B Appl. Biomater. 2003, 67, 655–665. [Google Scholar] [CrossRef]

- Guelcher, S.A. Biodegradable polyurethanes: Synthesis and applications in regenerative medicine. Tissue Eng. Part. B Rev. 2008, 14, 3–17. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Li, C.; Gong, H.; Jiang, X.; Wang, H.; Li, K. Effects of synthesis conditions on the morphology of hydroxyapatite nanoparticles produced by wet chemical process. Powder Technol. 2010, 2032, 315–321. [Google Scholar] [CrossRef]

- Song, G.; Song, S. A possible biodegradable magnesium implant material. Adv. Eng. Mater. 2007, 9, 298–302. [Google Scholar] [CrossRef]

- Kokubo, T.; Kim, H.-M.; Kawashita, M. Novel bioactive materials with different mechanical properties. Biomaterials 2003, 24, 2161–2175. [Google Scholar] [CrossRef]

- Lu, X.; Wang, Y.-B.; Liu, Y.-R.; Wang, J.-X.; Qu, S.-X.; Feng, B.; Weng, J. Preparation of HA/chitosan composite coatings on alkali-treated titanium surfaces through sol-gel techniques. Mater. Lett. 2007, 61, 3970–3973. [Google Scholar] [CrossRef]

- Cui, W.; Jin, L.; Zhou, L. Surface characteristics and electrochemical corrosion behavior of a pre-anodized microarc oxidation coating on titanium alloy. Mater. Sci. Eng. C 2013, 33, 3775–3779. [Google Scholar] [CrossRef]

- Xie, Y.; Ao, H.; Xin, S.; Zheng, X.; Ding, C. Enhanced cellular responses to titanium coating with hierarchical hybrid structure. Mater. Sci. Eng. C 2014, 38, 272–277. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Gulati, K.; Fernandez-Medina, T.; Qian, M.; Ivanovski, S. In situ hydrothermal transformation of titanium surface into lithium-doped continuous nanowire network towards augmented bioactivity. Appl. Surf. Sci. 2020, 505, 144604. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Amna, T.; Lim, J.K. Biocorrosion and osteoconductivity of PCL/nHAp composite porous film-based coating of magnesium alloy. Solid State Sci. 2012, 18, 131–140. [Google Scholar] [CrossRef]

- Da Conceicao, T.; Scharnagl, N.; Blawert, C.; Dietzel, W.; Kainer, K. Surface modification of magnesium alloy AZ31 by hydrofluoric acid treatment and its effect on the corrosion behaviour. Thin Solid Film. 2010, 518, 5209–5218. [Google Scholar] [CrossRef]

- da Conceição, T.F. Corrosion Protection of Magnesium AZ31 Alloy Sheets by Polymer Coatings. Ph.D. Thesis, Technische Universität, Berlin, Germany, 2011. [Google Scholar]

- Siau, S.; Vervaet, A.; Degrande, S.; Schacht, E.; Van Calster, A. Dip coating of dielectric and solder mask epoxy polymer layers for build-up purposes. Appl. Surf. Sci. 2005, 245, 353–368. [Google Scholar] [CrossRef]

- Fang, H.-W.; Li, K.-Y.; Su, T.-L.; Yang, T.C.-K.; Chang, J.-S.; Lin, P.-L.; Chang, W.-C. Dip coating assisted polylactic acid deposition on steel surface: Film thickness affected by drag force and gravity. Mater. Lett. 2008, 62, 3739–3741. [Google Scholar] [CrossRef]

- Yimsiri, P.; Mackley, M.R. Spin and dip coating of light-emitting polymer solutions: Matching experiment with modelling. Chem. Eng. Sci. 2006, 61, 3496–3505. [Google Scholar] [CrossRef]

- Shukla, A.; Balasubramaniam, R. Effect of surface treatment on electrochemical behavior of CP Ti, Ti–6Al–4V and Ti–13Nb–13Zr alloys in simulated human body fluid. Corros. Sci. 2006, 48, 1696–1720. [Google Scholar] [CrossRef]

- Xue, W.; Liu, X.; Zheng, X.; Ding, C. In vivo evaluation of plasma-sprayed titanium coating after alkali modification. Biomaterials 2005, 26, 3029–3037. [Google Scholar] [CrossRef] [PubMed]

- Abdal-hay, A.; Bartnikowski, M.; Hamlet, S.; Ivanovski, S. Electrospun biphasic tubular scaffold with enhanced mechanical properties for vascular tissue engineering. Mater. Sci. Eng. C 2018, 82, 10–18. [Google Scholar] [CrossRef]

- Burke, M.; Clarke, B.; Rochev, Y.; Gorelov, A.; Carroll, W. Estimation of the strength of adhesion between a thermoresponsive polymer coating and nitinol wire. J. Mater. Sci. Mater. Med. 2008, 19, 1971–1979. [Google Scholar] [CrossRef] [PubMed]

- Catauro, M.; Bollino, F.; Papale, F.; Giovanardi, R.; Veronesi, P. Corrosion behavior and mechanical properties of bioactive sol-gel coatings on titanium implants. Mater. Sci. Eng. C 2014, 43, 375–382. [Google Scholar] [CrossRef]

- Feng, J.; Chen, Y.; Liu, X.; Liu, T.; Zou, L.; Wang, Y.; Ren, Y.; Fan, Z.; Lv, Y.; Zhang, M. In-situ hydrothermal crystallization Mg(OH)2 films on magnesium alloy AZ91 and their corrosion resistance properties. Mater. Chem. Phys. 2013, 143, 322–329. [Google Scholar] [CrossRef]

- Halliday, N.L.; Tomasek, J.J. Mechanical properties of the extracellular matrix influence fibronectin fibril assembly in vitro. Exp. Cell Res. 1995, 217, 109–117. [Google Scholar] [CrossRef]

- Pelham, R.J.; Wang, Y.-L. Cell locomotion and focal adhesions are regulated by substrate flexibility. Proc. Natl. Acad. Sci. USA 1997, 94, 13661–13665. [Google Scholar] [CrossRef]

- Lo, C.-M.; Wang, H.-B.; Dembo, M.; Wang, Y.-L. Cell movement is guided by the rigidity of the substrate. Biophys. J. 2000, 79, 144–152. [Google Scholar] [CrossRef]

- Pattanayak, D.K.; Yamaguchi, S.; Matsushita, T.; Kokubo, T. Nanostructured positively charged bioactive TiO2 layer formed on Ti metal by NaOH, acid and heat treatments. J. Mater. Sci. Mater. Med. 2011, 22, 1803–1812. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, J.; Ruan, Y.C.; Yu, M.K.; O’Laughlin, M.; Wise, H.; Chen, D.; Tian, L.; Shi, D.; Wang, J. Implant-derived magnesium induces local neuronal production of CGRP to improve bone-fracture healing in rats. Nat. Med. 2016, 22, 1160. [Google Scholar] [CrossRef]

- Brown, A.; Zaky, S.; Ray, H.; Sfeir, C. Porous magnesium/PLGA composite scaffolds for enhanced bone regeneration following tooth extraction. Acta Biomater. 2015, 11, 543–553. [Google Scholar] [CrossRef] [PubMed]

- Alvarez-Lopez, M.; Pereda, M.D.; del Valle, J.A.; Fernandez-Lorenzo, M.; Garcia-Alonso, M.C.; Ruano, O.A.; Escudero, M.L. Corrosion behaviour of AZ31 magnesium alloy with different grain sizes in simulated biological fluids. Acta Biomater. 2010, 6, 1763–1771. [Google Scholar] [CrossRef] [PubMed]

| Sample Designation | Description |

|---|---|

| S0 | Alkaline-treated Ti |

| S1 | Plain PU film coated on alkaline-treated Ti |

| S2 | Mg-particle/PU composite film coated on alkaline-treated Ti |

| S3 | Mg- HAp/PU composite film coated on alkaline-treated Ti |

| Samples | Rating of Extent of Adhesion as per ASTM (D3359, 2010) | Percent Area Removed * | Surface Appearance after Adhesion Testing |

|---|---|---|---|

| S2 | 5B | 0% (none) |  |

| S3 | 5B | 0% (none) |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agour, M.; Abdal-hay, A.; Hassan, M.K.; Bartnikowski, M.; Ivanovski, S. Alkali-Treated Titanium Coated with a Polyurethane, Magnesium and Hydroxyapatite Composite for Bone Tissue Engineering. Nanomaterials 2021, 11, 1129. https://doi.org/10.3390/nano11051129

Agour M, Abdal-hay A, Hassan MK, Bartnikowski M, Ivanovski S. Alkali-Treated Titanium Coated with a Polyurethane, Magnesium and Hydroxyapatite Composite for Bone Tissue Engineering. Nanomaterials. 2021; 11(5):1129. https://doi.org/10.3390/nano11051129

Chicago/Turabian StyleAgour, Mahmoud, Abdalla Abdal-hay, Mohamed K. Hassan, Michal Bartnikowski, and Sašo Ivanovski. 2021. "Alkali-Treated Titanium Coated with a Polyurethane, Magnesium and Hydroxyapatite Composite for Bone Tissue Engineering" Nanomaterials 11, no. 5: 1129. https://doi.org/10.3390/nano11051129

APA StyleAgour, M., Abdal-hay, A., Hassan, M. K., Bartnikowski, M., & Ivanovski, S. (2021). Alkali-Treated Titanium Coated with a Polyurethane, Magnesium and Hydroxyapatite Composite for Bone Tissue Engineering. Nanomaterials, 11(5), 1129. https://doi.org/10.3390/nano11051129