XRD Evaluation of Wurtzite Phase in MBE Grown Self-Catalyzed GaP Nanowires

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of GaP NW Arrays

2.2. Structural Characterization

2.3. X-ray Diffraction Studies

3. Results and Discussion

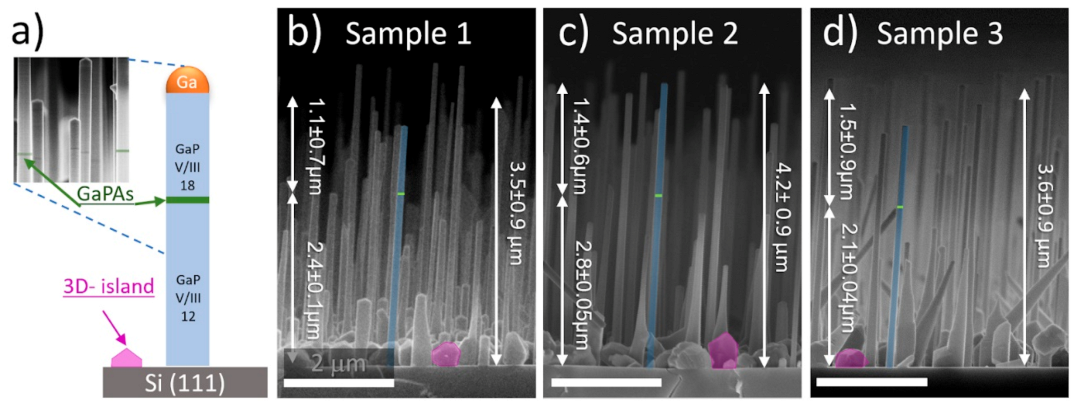

3.1. NW Morphology and Structure

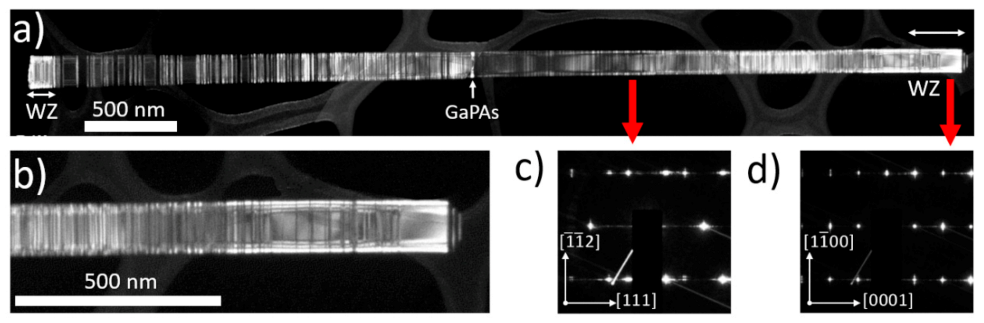

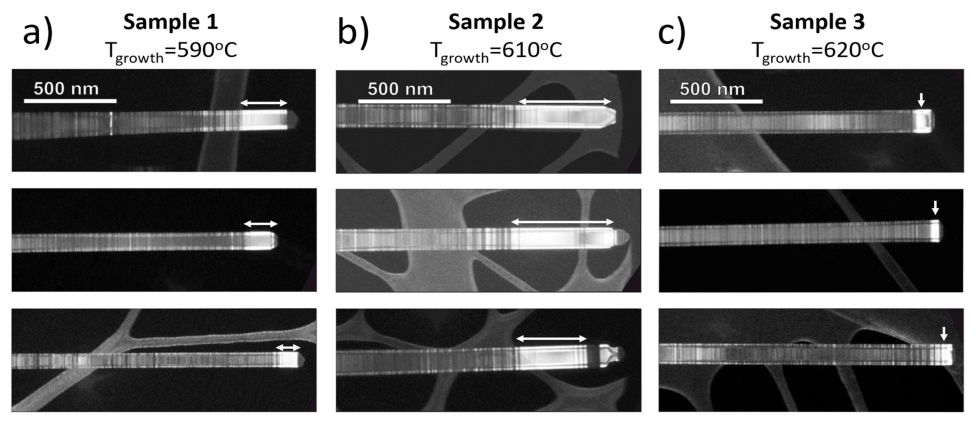

3.2. TEM Study

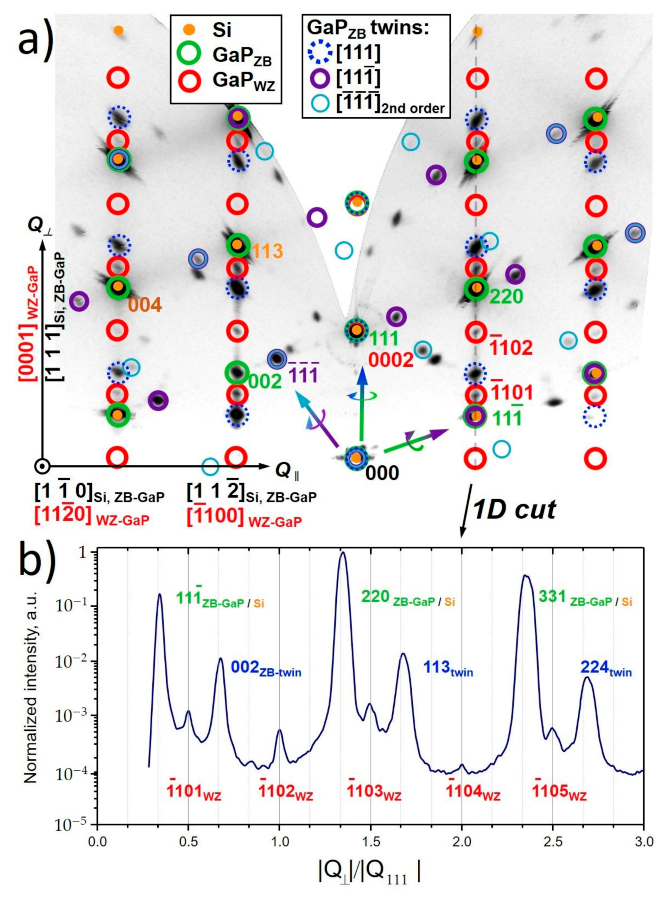

3.3. XRD Study

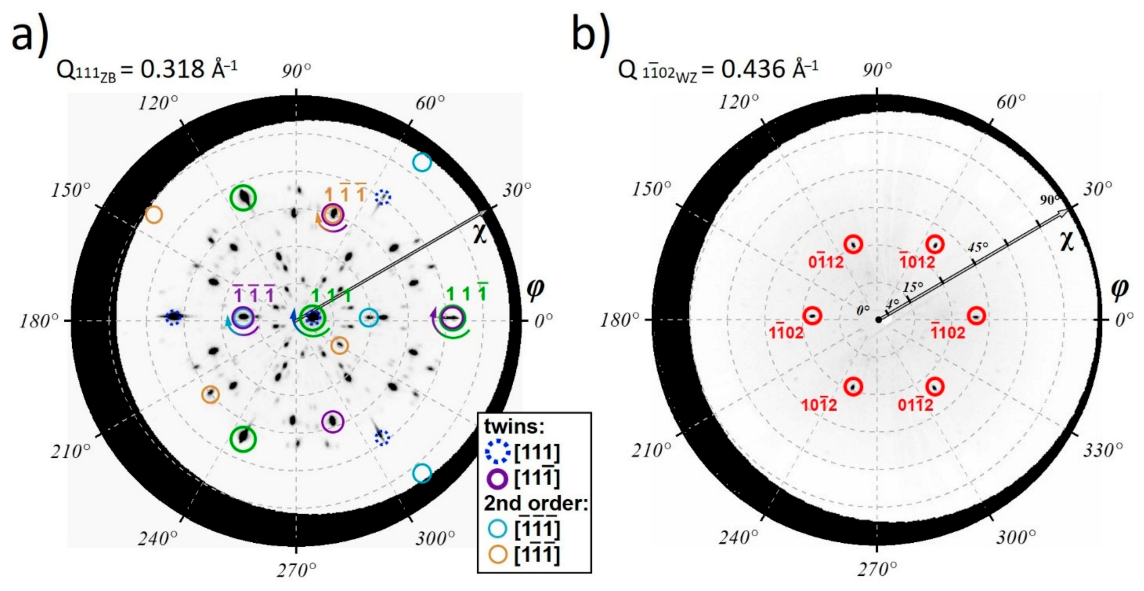

3.3.1. XRD Reciprocal Space Mapping

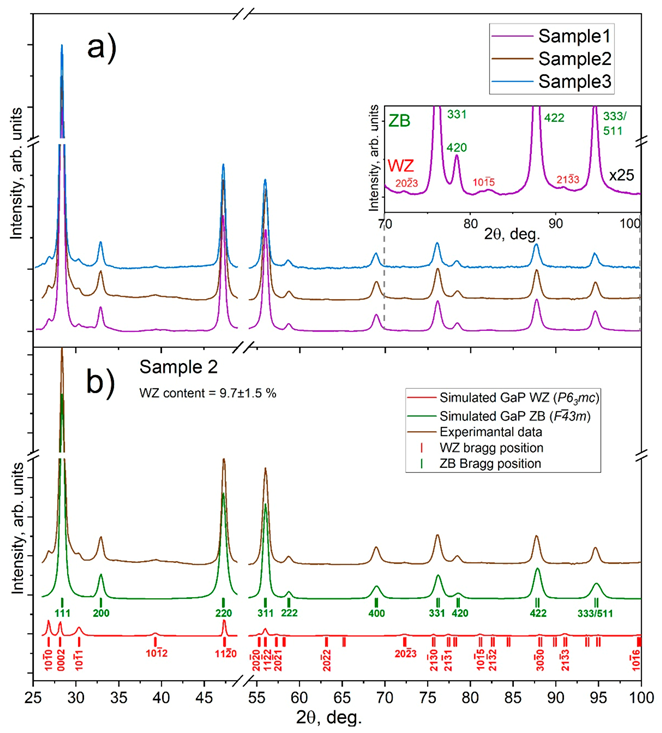

3.3.2. Quantitative Phase Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jacobsson, D.; Panciera, F.; Tersoff, J.; Reuter, M.C.; Lehmann, S.; Hofmann, F.P.S.; Dick, K.A.; Ross, F.M. Interface dynamics and crystal phase switching in GaAs nanowires. Nature 2016, 531, 317–322. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Panciera, F.; Baraissov, Z.; Patriarche, G.; Dubrovskii, V.G.; Glas, F.; Travers, L.; Mirsaidov, U.; Harmand, J.-C. Phase Selection in Self-catalyzed GaAs Nanowires. Nano Lett. 2020, 20, 1669–1675. [Google Scholar] [CrossRef] [PubMed]

- Gudovskikh, A.; Zelentsov, K.; Baranov, A.; Kudryashov, D.; Morozov, I.; Nikitina, E.; Kleider, J.-P. Study of GaP/Si Heterojunction Solar Cells. Energy Procedia 2016, 102, 56–63. [Google Scholar] [CrossRef]

- Bolshakov, A.D.; Fedorov, V.V.; Sibirev, N.V.; Fetisova, M.V.; Moiseev, E.I.; Kryzhanovskaya, N.V.; Koval, O.Y.; Ubyivovk, E.V.; Mozharov, A.M.; Cirlin, G.E.; et al. Growth and Characterization of GaP/GaPAs Nanowire Heterostructures with Controllable Composition. Phys. Status Solidi (RRL) Rapid Res. Lett. 2019, 13, 1900350. [Google Scholar] [CrossRef]

- Henry, C.H. Limiting efficiencies of ideal single and multiple energy gap terrestrial solar cells. J. Appl. Phys. 1980, 51, 4494–4500. [Google Scholar] [CrossRef]

- Pikhtin, A.N.; Hegazy, H.H. Fundamental absorption edge of semiconductor alloys with the direct-gap energy-band structure. Semiconductors 2009, 43, 1259–1266. [Google Scholar] [CrossRef]

- Halder, N.N.; Kelrich, A.; Cohen, S.; Ritter, D. Pure wurtzite GaP nanowires grown on zincblende GaP substrates by selective area vapor liquid solid epitaxy. Nanotechnology 2017, 28, 465603. [Google Scholar] [CrossRef] [Green Version]

- Assali, S.S.; Lähnemann, J.; Vu, T.T.T.; Jöns, K.D.; Gagliano, L.L.; Verheijen, M.M.; Akopian, N.N.; Bakkers, E.P.A.M.; Haverkort, J.E.M. Crystal Phase Quantum Well Emission with Digital Control. Nano Lett. 2017, 17, 6062–6068. [Google Scholar] [CrossRef]

- Breuer, S.; Pfüller, C.; Flissikowski, T.; Brandt, O.; Grahn, H.T.; Geelhaar, L.; Riechert, H. Suitability of Au- and Self-Assisted GaAs Nanowires for Optoelectronic Applications. Nano Lett. 2011, 11, 1276–1279. [Google Scholar] [CrossRef]

- Da Silva, B.C.; Couto, O.D.D.; Obata, H.T.; De Lima, M.M.; Bonani, F.D.; De Oliveira, C.E.; Sipahi, G.M.; Iikawa, F.; Cotta, M.A. Optical Absorption Exhibits Pseudo-Direct Band Gap of Wurtzite Gallium Phosphide. Sci. Rep. 2020, 10, 1–7. [Google Scholar] [CrossRef]

- Assali, S.S.; Zardo, I.I.; Plissard, S.S.; Kriegner, D.; Verheijen, M.M.; Bauer, G.; Meijerink, A.; Belabbes, A.; Bechstedt, F.; Haverkort, J.E.M.; et al. Direct Band Gap Wurtzite Gallium Phosphide Nanowires. Nano Lett. 2013, 13, 1559–1563. [Google Scholar] [CrossRef]

- Gagliano, L.; Belabbes, A.; Albani, M.; Assali, S.; Verheijen, M.A.; Miglio, L.; Bechstedt, F.; Haverkort, J.E.M.; Bakkers, E.P.A.M. Pseudodirect to Direct Compositional Crossover in Wurtzite GaP/InxGa1–xP Core–Shell Nanowires. Nano Lett. 2016, 16, 7930–7936. [Google Scholar] [CrossRef]

- Im, H.S.; Park, K.; Kim, J.; Kim, D.; Lee, J.; Lee, J.A.; Park, J.; Ahn, J.-P. Strain Mapping and Raman Spectroscopy of Bent GaP and GaAs Nanowires. ACS Omega 2018, 3, 3129–3135. [Google Scholar] [CrossRef]

- Maliakkal, C.B.; Gokhale, M.; Parmar, J.; Bapat, R.D.; Chalke, B.A.; Ghosh, S.; Bhattacharya, A. Growth, structural and optical characterization of wurtzite GaP nanowires. Nanotechnology 2019, 30, 254002. [Google Scholar] [CrossRef]

- Huang, K.; Zhang, Z.; Zhou, Q.; Liu, L.; Zhang, X.; Kang, M.; Zhao, F.; Lu, X.; Gao, X.; Liu, J. Silver catalyzed gallium phosphide nanowires integrated on silicon andin situAg-alloying induced bandgap transition. Nanotechnology 2015, 26, 255706. [Google Scholar] [CrossRef]

- Bolshakov, A.D.; Mozharov, A.M.; Sapunov, G.A.; Fedorov, V.V.; Dvoretckaia, L.N.; Mukhin, I.S. Theoretical modeling of the self-catalyzed nanowire growth: Nucleation- and adsorption-limited regimes. Mater. Res. Express 2017, 4, 125027. [Google Scholar] [CrossRef]

- Tambe, M.J.; Ren, S.; Gradečak, S. Effects of Gold Diffusion on n-Type Doping of GaAs Nanowires. Nano Lett. 2010, 10, 4584–4589. [Google Scholar] [CrossRef]

- Perea, D.E.; Allen, J.E.; May, S.J.; Wessels, B.W.; Seidman, D.N.; Lauhon, L.J. Three-Dimensional Nanoscale Composition Mapping of Semiconductor Nanowires. Nano Lett. 2006, 6, 181–185. [Google Scholar] [CrossRef]

- Assali, S.; Greil, J.; Zardo, I.; Belabbes, A.; De Moor, M.W.A.; Koelling, S.; Koenraad, P.M.; Bechstedt, F.; Bakkers, E.P.A.M.; Haverkort, J.E.M. Optical study of the band structure of wurtzite GaP nanowires. J. Appl. Phys. 2016, 120, 044304. [Google Scholar] [CrossRef] [Green Version]

- Akopian, N.; Patriarche, G.; Liu, L.; Harmand, J.-C.; Zwiller, V. Crystal Phase Quantum Dots. Nano Lett. 2010, 10, 1198–1201. [Google Scholar] [CrossRef]

- Kumagai, M.; Chuang, S.L.; Ando, H. Analytical solutions of the block-diagonalized Hamiltonian for strained wurtzite semiconductors. Phys. Rev. B 1998, 57, 15303–15314. [Google Scholar] [CrossRef]

- Takagi, Y.; Furukawa, Y.; Wakahara, A.; Kan, H. Lattice relaxation process and crystallographic tilt in GaP layers grown on misoriented Si(001) substrates by metalorganic vapor phase epitaxy. J. Appl. Phys. 2010, 107, 63506. [Google Scholar] [CrossRef]

- Létoublon, A.; Guo, W.; Cornet, C.; Boulle, A.; Véron, M.; Bondi, A.; Durand, O.; Rohel, T.; Dehaese, O.; Chevalier, N.; et al. X-ray study of antiphase domains and their stability in MBE grown GaP on Si. J. Cryst. Growth 2011, 323, 409–412. [Google Scholar] [CrossRef]

- Rietveld, H.M. Line profiles of neutron powder-diffraction peaks for structure refinement. Acta Crystallogr. 1967, 22, 151–152. [Google Scholar] [CrossRef]

- Okumura, H.; Akane, T.; Tsubo, Y.; Matsumoto, S. Comparison of Conventional Surface Cleaning Methods for Si Molecular Beam Epitaxy. J. Electrochem. Soc. 1997, 144, 3765–3768. [Google Scholar] [CrossRef]

- Zi, Y.; Suslov, S.; Yang, C. Understanding Self-Catalyzed Epitaxial Growth of III–V Nanowires toward Controlled Synthesis. Nano Lett. 2017, 17, 1167–1173. [Google Scholar] [CrossRef]

- Suturin, S.M.; Korovin, A.M.; Fedorov, V.V.; Valkovsky, G.A.; Tabuchi, M.; Sokolov, N.S. An advanced three-dimensional RHEED mapping approach to the diffraction study of Co/MnF2/CaF2/Si(001) epitaxial heterostructures. J. Appl. Crystallogr. 2016, 49, 1532–1543. [Google Scholar] [CrossRef]

- Suturin, S.M.; Fedorov, V.V.; Korovin, A.M.; Sokolov, N.S.; Nashchekin, A.V.; Tabuchi, M. Epitaxial Ni nanoparticles on CaF2(001), (110) and (111) surfaces studied by three-dimensional RHEED, GIXD and GISAXS reciprocal-space mapping techniques. J. Appl. Crystallogr. 2017, 50, 830–839. [Google Scholar] [CrossRef]

- Suturin, S.M.; Fedorov, V.V.; Korovin, A.M.; Valkovskiy, G.A.; Konnikov, S.G.; Tabuchi, M.; Sokolov, N.S. A look inside epitaxial cobalt-on-fluorite nanoparticles with three-dimensional reciprocal space mapping using GIXD, RHEED and GISAXS. J. Appl. Crystallogr. 2013, 46, 874–881. [Google Scholar] [CrossRef] [Green Version]

- McCusker, L.B.; Von Dreele, R.B.; Cox, D.E.; Louër, D.; Scardi, P. Rietveld refinement guidelines. J. Appl. Crystallogr. 1999, 32, 36–50. [Google Scholar] [CrossRef] [Green Version]

- Furman, J.; Gundiah, G.; Page, K.; Pizarro, N.; Cheetham, A. Local structure and time-resolved photoluminescence of emulsion prepared YAG nanoparticles. Chem. Phys. Lett. 2008, 465, 67–72. [Google Scholar] [CrossRef]

- Makiura, R.; Yonemura, T.; Yamada, T.; Yamauchi, M.; Ikeda, R.; Kitagawa, H.; Kato, K.; Takata, M. Size-controlled stabilization of the superionic phase to room temperature in polymer-coated AgI nanoparticles. Nat. Mater. 2009, 8, 476–480. [Google Scholar] [CrossRef] [PubMed]

- Rietveld, H.M. A profile refinement method for nuclear and magnetic structures. J. Appl. Crystallogr. 1969, 2, 65–71. [Google Scholar] [CrossRef]

- Roisnel, T.; Rodríquez-Carvajal, J. WinPLOTR: A Windows Tool for Powder Diffraction Pattern Analysis. Mater. Sci. Forum 2001, 378–381, 118–123. [Google Scholar] [CrossRef] [Green Version]

- Popović, S. Quantitative Phase Analysis by X-ray Diffraction—Doping Methods and Applications. Crystals 2020, 10, 27. [Google Scholar] [CrossRef] [Green Version]

- Clavier, N.; Szenknect, S.; Costin, D.T.; Mesbah, A.; Ravaux, J.; Poinssot, C.; Dacheux, N. Purification of uranothorite solid solutions from polyphase systems. J. Nucl. Mater. 2013, 441, 73–83. [Google Scholar] [CrossRef]

- Wenk, H.-R.; Lutterotti, L.; Kaercher, P.; Kanitpanyacharoen, W.; Miyagi, L.; Vasin, R. Rietveld texture analysis from synchrotron diffraction images. II. Complex multiphase materials and diamond anvil cell experiments. Powder Diffr. 2014, 29, 220–232. [Google Scholar] [CrossRef] [Green Version]

- Mazzoni, A.; Conconi, M.S. Study of carbonitriding reactions of zirconia. Synthesis of Zr(C,N,O) phases and β-type zirconium oxynitrides. Ceram. Int. 2004, 30, 23–29. [Google Scholar] [CrossRef]

- Koval, O.Y.; Fedorov, V.V.; Bolshakov, A.D.; Fedina, S.V.; Kochetkov, F.M.; Neplokh, V.; Sapunov, G.A.; Dvoretckaia, L.N.; Kirilenko, D.A.; Shtrom, I.V.; et al. Structural and Optical Properties of Self-Catalyzed Axially Heterostructured GaPN/GaP Nanowires Embedded into a Flexible Silicone Membrane. Nanomaterials 2020, 10, 2110. [Google Scholar] [CrossRef]

- Tersoff, J. Stable Self-Catalyzed Growth of III–V Nanowires. Nano Lett. 2015, 15, 6609–6613. [Google Scholar] [CrossRef]

- Zhuang, Q.D.; Anyebe, E.A.; Sánchez, A.M.; Rajpalke, M.K.; Veal, T.D.; Zhukov, A.; Robinson, B.J.; Anderson, F.; Kolosov, O.; Fal’Ko, V. Graphitic platform for self-catalysed InAs nanowires growth by molecular beam epitaxy. Nanoscale Res. Lett. 2014, 9, 321. [Google Scholar] [CrossRef] [Green Version]

- Plante, M.; Lapierre, R. Growth mechanisms of GaAs nanowires by gas source molecular beam epitaxy. J. Cryst. Growth 2006, 286, 394–399. [Google Scholar] [CrossRef]

- Sibirev, N.V.; Fedorov, V.V.; Kirilenko, D.A.; Ubiyvovk, E.V.; Berdnikov, Y.S.; Bolshakov, A.D.; Mukhin, I.S. Study of Wurtzite Crystal Phase Stabilization in Heterostructured Ga(As,P) Nanowires. Semiconductors 2020, 54, 1862–1865. [Google Scholar] [CrossRef]

- Akiyama, T.; Nakamura, K.; Ito, T. Structural stability and electronic structures of InP nanowires: Role of surface dangling bonds on nanowire facets. Phys. Rev. B 2006, 73, 235308. [Google Scholar] [CrossRef]

- Akiyama, T.; Sano, K.; Nakamura, K.; Ito, T. An Empirical Potential Approach to Wurtzite-Zinc-Blende Polytypism in Group III-V Semiconductor Nanowires. Jpn. J. Appl. Phys. 2006, 45, L275–L278. [Google Scholar] [CrossRef]

- Dubrovskii, V.G.; Sibirev, N.V.; Halder, N.N.; Ritter, D. Classification of the Morphologies and Related Crystal Phases of III–V Nanowires Based on the Surface Energy Analysis. J. Phys. Chem. C 2019, 123, 18693–18701. [Google Scholar] [CrossRef]

- Hijazi, H.; Dubrovskii, V.G.; Monier, G.; Gil, E.; Leroux, C.; Avit, G.; Trassoudaine, A.; Bougerol, C.; Castellucci, D.; Robert-Goumet, C.; et al. Influence of Silicon on the Nucleation Rate of GaAs Nanowires on Silicon Substrates. J. Phys. Chem. C 2018, 122, 19230–19235. [Google Scholar] [CrossRef]

- Henke, B.L.; Gullikson, E.M.; Davis, J.C. X-Ray Interactions: Photoabsorption, Scattering, Transmission, and Reflection at E = 50–30,000 eV, Z = 1–92. At. Data Nucl. Data Tables 1993, 54, 181–342. [Google Scholar] [CrossRef] [Green Version]

- Bao, J.; Bell, D.C.; Capasso, F.; Wagner, J.B.; Mårtensson, T.; Trägårdh, J.; Samuelson, L. Optical Properties of Rotationally Twinned InP Nanowire Heterostructures. Nano Lett. 2008, 8, 836–841. [Google Scholar] [CrossRef]

- Foster, L.M. A Lattice Parameter Criterion for Miscibility Gaps in the III–V and II–VI Pseudobinary Solid Solutions. J. Electrochem. Soc. 1974, 121, 1662–1665. [Google Scholar] [CrossRef]

- Huy, V.P.H.; So, S.; Kim, I.T.; Hur, J. Self-healing gallium phosphide embedded in a hybrid matrix for high-performance Li-ion batteries. Energy Storage Mater. 2021, 34, 669–681. [Google Scholar] [CrossRef]

- Persson, K. Materials Data on GaP (SG:186) by Materials Project. 2014. Available online: https://materialsproject.org/materials/mp-8882/ (accessed on 29 September 2020).

- Lazarev, S.; Göransson, D.J.O.; Borgström, M.; Messing, M.E.; Xu, H.Q.; Dzhigaev, D.; Yefanov, O.M.; Bauer, S.; Baumbach, T.; Feidenhans, R.; et al. Revealing misfit dislocations in InAsxP1−x-InP core–shell nanowires by x-ray diffraction. Nanotechnology 2019, 30, 505703. [Google Scholar] [CrossRef]

| Sample | Lattice Parameter a WZ, Å | Lattice Parameter c WZ, Å | WZ Content, % | Tgrowth, °C |

|---|---|---|---|---|

| Sample 1 | 3.840 | 6.349 | ~8.1 ± 0.93 | 590 |

| Sample 2 | 3.839 | 6.344 | ~9.7 ± 1.5 | 610 |

| Sample 3 | 3.839 | 6.345 | ~6.4 ± 1.14 | 620 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koval, O.Y.; Fedorov, V.V.; Bolshakov, A.D.; Eliseev, I.E.; Fedina, S.V.; Sapunov, G.A.; Udovenko, S.A.; Dvoretckaia, L.N.; Kirilenko, D.A.; Burkovsky, R.G.; et al. XRD Evaluation of Wurtzite Phase in MBE Grown Self-Catalyzed GaP Nanowires. Nanomaterials 2021, 11, 960. https://doi.org/10.3390/nano11040960

Koval OY, Fedorov VV, Bolshakov AD, Eliseev IE, Fedina SV, Sapunov GA, Udovenko SA, Dvoretckaia LN, Kirilenko DA, Burkovsky RG, et al. XRD Evaluation of Wurtzite Phase in MBE Grown Self-Catalyzed GaP Nanowires. Nanomaterials. 2021; 11(4):960. https://doi.org/10.3390/nano11040960

Chicago/Turabian StyleKoval, Olga Yu., Vladimir V. Fedorov, Alexey D. Bolshakov, Igor E. Eliseev, Sergey V. Fedina, Georgiy A. Sapunov, Stanislav A. Udovenko, Liliia N. Dvoretckaia, Demid A. Kirilenko, Roman G. Burkovsky, and et al. 2021. "XRD Evaluation of Wurtzite Phase in MBE Grown Self-Catalyzed GaP Nanowires" Nanomaterials 11, no. 4: 960. https://doi.org/10.3390/nano11040960

APA StyleKoval, O. Y., Fedorov, V. V., Bolshakov, A. D., Eliseev, I. E., Fedina, S. V., Sapunov, G. A., Udovenko, S. A., Dvoretckaia, L. N., Kirilenko, D. A., Burkovsky, R. G., & Mukhin, I. S. (2021). XRD Evaluation of Wurtzite Phase in MBE Grown Self-Catalyzed GaP Nanowires. Nanomaterials, 11(4), 960. https://doi.org/10.3390/nano11040960