A Short Review on the Electrochemical Performance of Hierarchical and Nitrogen-Doped Activated Biocarbon-Based Electrodes for Supercapacitors

Abstract

1. Introduction

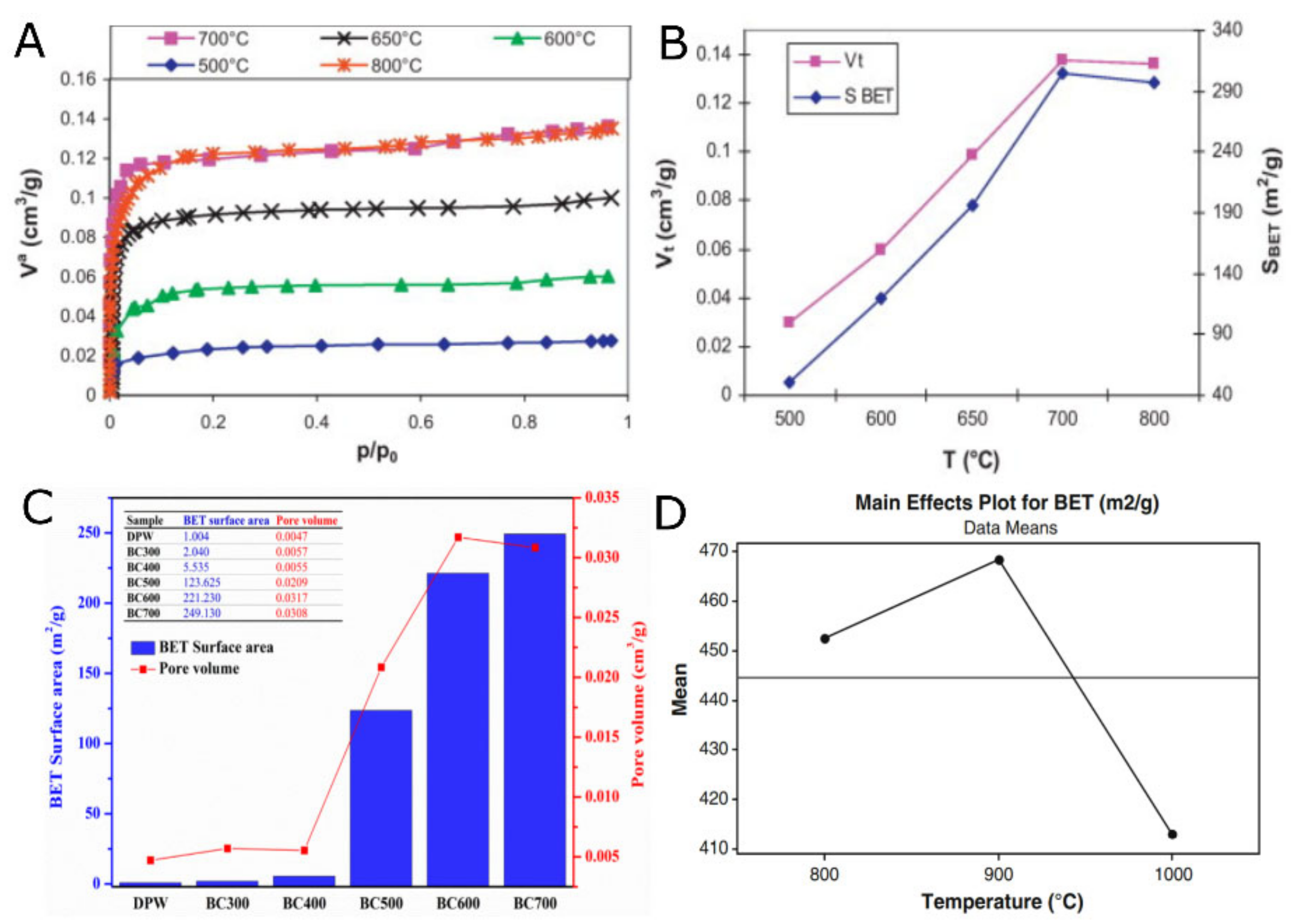

2. Effect of the Pyrolysis and Experimental Conditions on the AC and CE Properties

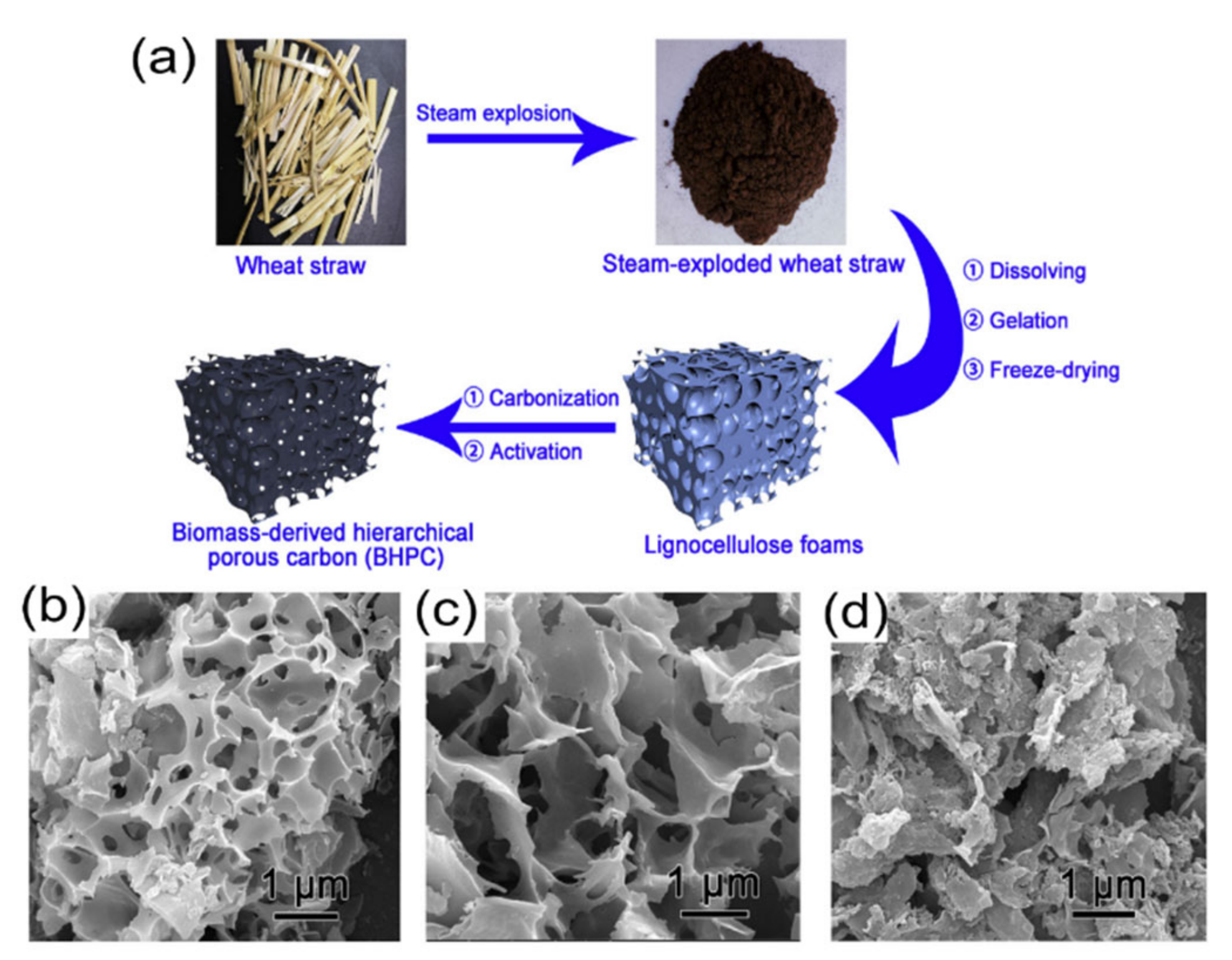

3. Biomass-Based Electrodes for Supercapacitors

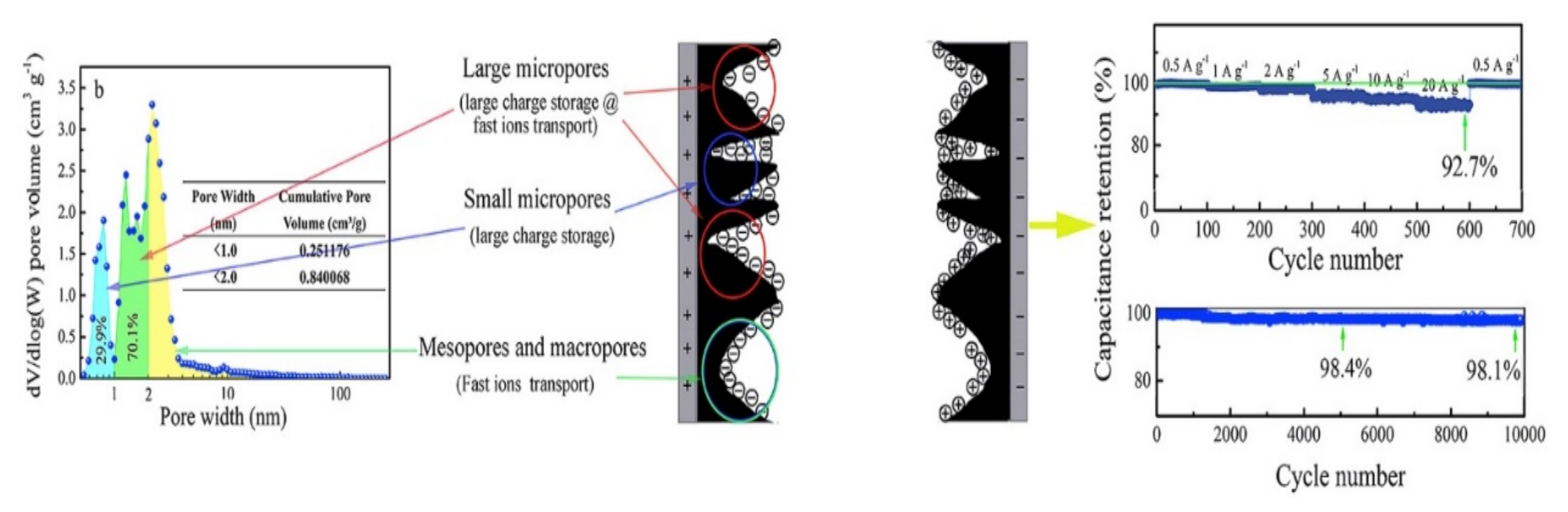

4. Effect of the Pore Structure on the Electrochemical Properties of the CEs

5. Heteroatom Doping in Porous Electrodes

6. Effect of Hierarchically Porous and N-Doped Structures on Electrochemical Performance of Electrodes

7. Challenges and Future Perspectives

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Pandey, G. Biomass-based bio-electro fuel cells based on carbon electrodes: An alternative source of renewable energy. SN Appl. Sci. 2019, 1, 408. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, Q. Recent Progress in Multivalent Metal (Mg, Zn, Ca, and Al) and Metal-Ion Rechargeable Batteries with Organic Materials as Promising Electrodes. Small 2019, 15, 1805061. [Google Scholar] [CrossRef]

- Wang, K.; Bi, R.; Huang, M.; Lv, B.; Wang, H.; Li, C.; Wu, H.; Zhang, Q. Porous Cobalt Metal−Organic Frameworks as Active Elements in Battery−Supercapacitor Hybrid Devices. Inorg. Chem. 2020, 59, 6808–6814. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Srimuk, P.; Fleischmann, S.; Su, X.; Hatton, T.A.; Presser, V. Redox-electrolytes for non-flow electrochemical energy storage: A critical review and best practice. Progress Mat. Sci. 2019, 101, 46–89. [Google Scholar] [CrossRef]

- Simon, P.; Gogotsi, Y.; Dunn, B. Where do batteries end and supercapacitors begin? Science 2014, 343, 1210–1211. [Google Scholar] [CrossRef]

- Miller, J.R.; Burke, A.F. Electrochemical capacitors: Challenges and opportunities for real-world applications. Electrochem. Soc. Interface 2008, 17, 53. [Google Scholar] [CrossRef]

- Zhao, Y.; Dong, C.; Sheng, L.; Xiao, Z.; Jiang, L.; Li, X.; Jiang, M.; Shi, J. Heteroatom-Doped Pillared Porous Carbon Architectures with Ultrafast Electron and Ion Transport Capabilities under High Mass Loadings for High-Rate Supercapacitors. ACS Sustain. Chem. Eng. 2020, 8, 8664–8674. [Google Scholar] [CrossRef]

- dos Reis, G.S.; Larsson, S.H.; de Oliveira, H.P.; Thyrel, M.; Claudio Lima, E. Sustainable Biomass Activated Carbons as Electrodes for Battery and Supercapacitors—A Mini-Review. Nanomaterials 2020, 10, 1398. [Google Scholar] [CrossRef]

- Li, Y.; Zheng, K.; Ali Shan, S.A.; Huang, Y.; Tian, Y.; Cheng, J.; Zhang, J. Winter-jujube-derived carbon with self-doped heteroatoms and a hierarchically porous structure for high-performance supercapacitors. RSC Adv. 2017, 7, 43356–43365. [Google Scholar]

- Zhang, Y.L.; Sun, C.; Tang, Z.S. High specific capacitance and high energy density supercapacitor electrodes enabled by porous carbon with multilevel pores and self-doped heteroatoms derived from Chinese date. Diam. Relat. Mater. 2019, 97, 107455. [Google Scholar] [CrossRef]

- Hu, X.; Li, J.; Zhang, Y.; Wu, Q.; Xia, G. Heteroatoms (N-, Si-) self-doped spongy carbon derived from wild fungus sharia bambusicola as electrode materials for supercapacitors. Chem. Phys. 2019, 525, 110383. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, X.; Liang, Z.; Wang, C.; Sui, Y.; Zheng, B.; Ye, Y.; Ma, W.; Zhao, Q.; Qin, C. B/P/N/O co-doped hierarchical porous carbon nanofiber self-standing film with high volumetric and gravimetric capacitance performances for aqueous supercapacitors. Electrochim. Acta 2020, 337, 135800. [Google Scholar] [CrossRef]

- Yan, D.; Guo, D.C.; Lu, A.H.; Dong, X.L.; Li, W.C. One-pot synthesis of unique skin-tissue-bone structured porous carbons for enhanced supercapacitor performance. J. Colloid Interface Sci. 2019, 557, 519–527. [Google Scholar] [CrossRef] [PubMed]

- Thue, P.S.; Umpierres, C.S.; Lima, E.C.; Lima, D.R.; Machado, F.M.; Reis, G.S.d.; Silva, R.S.; Pavan, F.A.; Tran, H.N. Single-step pyrolysis for producing magnetic activated carbon from tucumã (Astrocaryum aculeatum) seed and nickel(II) chloride and zinc(II) chloride. Application for removal of nicotinamide and propranolol. J. Hazard. Mat. 2020, 398, 122903. [Google Scholar] [CrossRef]

- Reis, G.S.d.; Adebayo, M.A.; Lima, E.C.; Sampaio, C.H.; Prola, L.D.T. Activated carbon from sewage sludge for preconcentration of copper. Anal. Lett. 2016, 49, 541–555. [Google Scholar] [CrossRef]

- Reis, G.S.D.; Wilhelm, M.; Silva, T.C.A.; Rezwan, K.; Sampaio, C.H.; Lima, E.C.; Souza, S.M.A.G.U. The use of the design of experiments for the evaluation of the production of surface rich activated carbon from sewage sludge via microwave and conventional pyrolysis. Appl. Therm. Eng. 2016, 93, 590–597. [Google Scholar] [CrossRef]

- Kasperiski, F.M.; Lima, E.C.; Umpierres, C.S.; Reis, G.S.d.; Thue, P.S.; Lima, D.R.; Dias, S.L.P.; Saucier, C.; da Costa, J.B. Production of porous activated carbons from Caesalpinia ferrea seed pod wastes: Highly efficient removal of captopril from aqueous solutions. J. Clean. Prod. 2018, 197, 919–929. [Google Scholar] [CrossRef]

- Cunha, M.R.; Lima, E.C.; Cimirro, N.F.G.M.; Thue, P.S.; Dias, S.L.P.; Gelesky, M.A.; Dotto, G.L.; Reis, G.S.d.; Pavan, F.A. Conversion of Eragrostis plana Nees leaves to activated carbon by microwave-assisted pyrolysis for the removal of organic emerging contaminants from aqueous solutions. Environ. Sci. Pollut. Res. 2018, 25, 23315–23327. [Google Scholar] [CrossRef] [PubMed]

- Lua, A.C.; Yang, T. Effects of vacuum pyrolysis conditions on the characteristics of activated carbons derived from pistachio-nut shells. J. Colloid Interface Sci. 2005, 290, 505–513. [Google Scholar] [CrossRef]

- Nuithitikul, K.; Srikhun, S.; Hirunpraditkoon, S. Influences of pyrolysis condition and acid treatment on properties of durian peel-based activated carbon. Bioresour. Technol. 2010, 101, 426–429. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.-F.; Chiueh, P.-T.; Kuan, W.-H.; Lo, S.-L. Microwave pyrolysis of lignocellulosic biomass: Heating performance and reaction kinetics. Energy 2016, 100, 137–144. [Google Scholar]

- Bouchelta, C.; Medjram, M.S.; Zoubida, M.; Chekkat, F.A.; Ramdane, N.; Bellat, J.-P. Effects of pyrolysis conditions on the porous structure development of date pits activated carbon. J. Anal. Appl. Pyrolysis 2012, 94, 215–222. [Google Scholar] [CrossRef]

- Ahmad, M.; Lee, S.S.; Dou, X.; Mohan, D.; Sung, J.-K.; Yang, J.E.; Ok, Y.S. Effects of pyrolysis temperature on soybean stover- and peanut shell-derived biochar properties and TCE adsorption in watery. Bioresour. Technol. 2012, 118, 536–544. [Google Scholar] [CrossRef] [PubMed]

- Elnour, A.Y.; Alghyamah, A.A.; Shaikh, H.M.; Poulose, A.M.; Al-Zahrani, S.M.; Anis, A.; Al-Wabel, M.-I. Effect of Pyrolysis Temperature on Biochar Microstructural Evolution, Physicochemical Characteristics, and Its Influence on Biochar/Polypropylene Composites. Appl. Sci. 2019, 9, 1149. [Google Scholar] [CrossRef]

- Soltani, S.M.; Yazdi, S.K.; Hosseini, S. Effects of pyrolysis conditions on the porous structure construction of mesoporous charred carbon from used cigarette filters. Appl. Nanosci. 2014, 4, 551–569. [Google Scholar] [CrossRef]

- Okonkwo, C.A.; Lv, T.; Hong, W.; Li, G.; Huang, J.; Deng, J.; Jia, L.; Wu, M.; Liu, H.; Guo, M. The synthesis of micro mesoporous carbon derived from nitrogen-rich spirulina extract impregnated castor shell based on biomass self-doping for highly efficient supercapacitor electrodes. J. Alloys Compd. 2020, 825, 154009. [Google Scholar] [CrossRef]

- Song, X.; Ma, X.; Li, Y.; Ding, L.; Jiang, R. Tea waste-derived microporous active carbon with enhanced double-layer supercapacitor behaviors. Appl. Surface Sci. 2019, 487, 189–197. [Google Scholar] [CrossRef]

- Sun, L.; Tian, C.; Li, M.; Meng, X.; Wang, L.; Wang, R.; Yin, J.; Fu, H. From coconut shell to porous graphene-like nanosheets for high-power supercapacitors. J. Mater. Chem. A 2013, 1, 6462–6470. [Google Scholar] [CrossRef]

- Zhao, B.; O’Connor, D.; Zhang, J.; Peng, T.; Shen, Z.; Tsang, D.C.W.; Hou, D. Effect of pyrolysis temperature, heating rate, and residence time on rapeseed stem derived biochar. J. Clean. Prod. 2018, 174, 977–987. [Google Scholar] [CrossRef]

- Hou, J.; Jiang, K.; Tahir, M.; Wu, X.; Idrees, F.; Shen, M.; Cao, C. Tunable porous structure of carbon nanosheets derived from puffed rice for high energy density supercapacitors. J. Power Sources 2017, 371, 148–155. [Google Scholar] [CrossRef]

- Gao, Y.; Yue, Q.; Gao, B.; Li, A. Insight into activated carbon from different kinds of chemical activating agents: A review. Sci. Total Environ. 2020, 746, 141094. [Google Scholar] [CrossRef] [PubMed]

- Bedia, J.; Peñas-Garzón, M.; Gómez-Avilés, A.; Rodriguez, J.J.; Belver, C. Review on Activated Carbons by Chemical Activation with FeCl3. J. Carbon Res. 2020, 6, 21. [Google Scholar] [CrossRef]

- Danish, M.; Ahmad, T. A review on the utilization of wood biomass as a sustainable precursor for activated carbon production and application. Renew. Sustain. Energ. Rev. 2018, 87, 1–21. [Google Scholar] [CrossRef]

- Peng, L.; Cai, Y.; Luo, Y.; Yuan, G.; Huang, J.; Hu, C.; Dong, H.; Xiao, Y.; Liang, Y.; Liu, Y.; et al. Bio-inspired highly crumpled porous carbons with multidirectional porosity for high rate performance electrochemical supercapacitors. ACS Sustain. Chem. Eng. 2018, 6, 12716–12726. [Google Scholar] [CrossRef]

- Cunha, M.R.; Lima, E.C.; Lima, D.R.; da Silva, R.S.; Thue, P.S.; Seliem, M.K.; Sher, F.; dos Reis, G.S.; Larsson, S.H. Removal of captopril pharmaceutical from synthetic pharmaceutical-industry wastewaters: Use of activated carbon derived from Butia catarinensis. J. Environ. Chem. Eng. 2020, 8, 104506. [Google Scholar] [CrossRef]

- Niu, J.; Shao, R.; Liang, J.; Dou, M.; Li, Z.; Huang, Y.; Wang, F. Biomass-derived mesopore-dominant porous carbons with large specific surface area and high defect density as high-performance electrode materials for Li-ion batteries and supercapacitors. Nano Energy 2017, 36, 322–330. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, D.; Zhang, Y.; He, J.; Wang, Y.; Wang, K.; Xu, Y.; Li, H.; Wang, Y. Biomass-derived microporous carbon with large micropore size for high-performance supercapacitors. J. Power Sources 2020, 448, 227396. [Google Scholar] [CrossRef]

- Gou, G.; Huang, F.; Jiang, M.; Li, J.; Zhou, Z. Hierarchical porous carbon electrode materials for supercapacitor developed from wheat straw cellulosic foam. Renew. Energy 2020, 149, 208–216. [Google Scholar] [CrossRef]

- Xu, D.; Hu, W.; Sun, X.N.; Cui, P.; Chen, X.Y. Redox additives of Na2MoO4 and KI: Synergistic effect and the improved capacitive performances for carbon-based supercapacitors. J. Power Sources 2017, 341, 448–456. [Google Scholar] [CrossRef]

- Jiang, C.; Yakaboylu, G.A.; Yumak, T.; Zondlo, J.W.; Sabolsky, E.M.; Wang, J. Activated carbons prepared by indirect and direct CO2 activation of lignocellulosic biomass for supercapacitor electrodes. Renew. Energy 2020, 155, 38–52. [Google Scholar] [CrossRef]

- Yakaboylu, G.A.; Jiang, C.; Yumak, T.; Zondlo, J.W.; Wang, J.; Sabolsky, E.M. Engineered hierarchical porous carbons for supercapacitor applications through chemical pretreatment and activation of biomass precursors. Renew. Energy 2021, 163, 276–287. [Google Scholar] [CrossRef]

- Kang, D.; Liu, Q.; Gu, J.; Su, Y.; Zhang, W.; Zhang, D. “Egg-Box”-Assisted Fabrication of Porous Carbon with Small Mesopores for High-Rate Electric Double Layer Capacitors. ACS Nano 2015, 9, 11225–11233. [Google Scholar] [CrossRef]

- Liu, J.; Min, S.; Wang, F.; Zhang, Z. Biomass-derived three-dimensional porous carbon membrane electrode for high-performance aqueous supercapacitors: An alternative of powdery carbon materials. J. Power Sources 2020, 466, 228347. [Google Scholar] [CrossRef]

- Chen, H.; Liu, D.; Shen, Z.; Bao, B.; Zhao, S.; Wu, L. Functional biomass carbons with a hierarchical porous structure for supercapacitor electrode materials. Electrochim. Acta 2015, 180, 241–251. [Google Scholar] [CrossRef]

- Tian, W.; Gao, Q.; Tan, Y.; Li, Z. Unusual, interconnected graphitized carbon nanosheets as the electrode of a high-rate ionic liquid-based supercapacitor. Carbon 2017, 119, 287–295. [Google Scholar] [CrossRef]

- Guo, F.; Jiang, X.; Jia, X.; Liang, S.; Qian, L.; Rao, Z. Synthesis of biomass carbon electrode materials by bimetallic activation for the application in supercapacitors. J. Electroanal. Chem. 2019, 844, 105–115. [Google Scholar] [CrossRef]

- Sevilla, M.; Diez, N.; Ferrero, G.A.; Fuertes, A.B. Sustainable supercapacitor electrodes produced by the activation of biomass with sodium thiosulfate. Energy Storage Mater. 2019, 18, 356–365. [Google Scholar] [CrossRef]

- Liang, X.; Liu, R.; Wu, X. Biomass waste-derived functionalized hierarchical porous carbon with high gravimetric and volumetric capacitances for supercapacitors. Microporous Mesoporous Mater. 2021, 310, 110659. [Google Scholar] [CrossRef]

- Zhou, X.; Li, H.; Yang, J. Biomass-derived activated carbon materials with plentiful heteroatoms for high-performance electrochemical capacitor electrodes. J. Energy Chem. 2016, 25, 35–40. [Google Scholar] [CrossRef]

- Ren, M.; Jia, Z.; Tian, Z.; Lopez, D.; Cai, J.; Titirici, M.M.; Jorge, A.B. High-performance n-doped carbon electrodes obtained via hydrothermal carbonization of macroalgae for supercapacitor applications. ChemElectroChem 2018, 5, 2686–2693. [Google Scholar] [CrossRef]

- Cao, Q.; Zhang, Y.; Chen, J.; Zhu, M.; Yang, C.; Guo, H.; Song, Y.; Li, Y.; Zhou, J. Electrospun biomass-based carbon nanofibers as high-performance supercapacitors. Ind. Crops Prod. 2020, 148, 112181. [Google Scholar] [CrossRef]

- Divya, P.; Rajalakshmi, R. Renewable, low cost green functional mesoporous electrodes from Solanum lycopersicum leaves for supercapacitors. J Energy Storage 2020, 27, 101149. [Google Scholar] [CrossRef]

- Wang, L.; Li, Z.; Yan, S.; Yu, X.; Ma, Y.; Ma, L. Modifying the microstructure of algae-based active carbon and modelling supercapacitors using artificial neural networks. RSC Adv. 2019, 9, 14797. [Google Scholar] [CrossRef]

- Cai, Y.; Luo, Y.; Dong, H.; Zhao, X.; Xiao, Y.; Liang, Y.; Hu, H.; Liu, Y.; Zheng, M. Hierarchically porous carbon nanosheets derived from Moringa oleifera stem as electrode material for high-performance electric double-layer capacitors. J. Power Sources 2017, 353, 260–269. [Google Scholar] [CrossRef]

- Zheng, L.H.; Chen, M.H.; Liang, S.X.; Lü, Q.F. Oxygen-rich hierarchical porous carbon derived from biomass waste-kapok flower for supercapacitor electrode. Diam. Relat. Mat. 2021, 113, 108267. [Google Scholar] [CrossRef]

- Jain, A.; Ghosh, M.; Krajewski, M.; Kurungot, S.; Michalsk, M. Biomass-derived activated carbon material from native European deciduous trees as an inexpensive and sustainable energy material for supercapacitor application. J. Energy Storage 2021, 34, 102178. [Google Scholar] [CrossRef]

- Vinayagam, M.; Babu, R.S.; Sivasamy, A.; Barros, A.L.F. Biomass-derived porous activated carbon from Syzygium cumini fruit shells and Chrysopogon zizanioides roots for high-energy-density symmetric supercapacitors. Biomass Bioenergy 2020, 143, 105838. [Google Scholar] [CrossRef]

- Sun, Y.; Xue, J.; Dong, S.; Zhang, Y.; An, Y.; Ding, B.; Zhang, T.; Dou, H.; Zhang, X. Biomass-derived porous carbon electrodes for high-performance supercapacitors. J. Mater. Sci. 2020, 55, 5166–5176. [Google Scholar] [CrossRef]

- Jung, S.M.; Mafra, D.L.; Lin, C.-T.; Jung, H.Y.; Kong, J. Controlled porous structures of graphene aerogels and their effect on supercapacitor performance. Nanoscale 2015, 7, 3486–4393. [Google Scholar] [CrossRef]

- Zhang, D.; Han, M.; Wang, B.; Li, Y.; Lei, L.; Wang, K.; Wang, Y.; Zhang, L.; Feng, H. Superior supercapacitors based on nitrogen and sulfur co-doped hierarchical porous carbon: Excellent rate capability and cycle stability. J. Power Sources 2017, 358, 112–120. [Google Scholar] [CrossRef]

- Chmiola, T.; Yushin, G.; Gogotsi, Y.; Portet, C.; Simon, P.; Taberna, P.L. Anomalous increase in carbon capacitance at pore sizes less than 1 nanometer. Science 2006, 313, 1760–1763. [Google Scholar] [CrossRef]

- Zhou, M.; Pu, F.; Wang, Z.; Guan, S. Nitrogen-doped porous carbons through KOH activation with superior performance in supercapacitors. Carbon 2014, 68, 185–194. [Google Scholar] [CrossRef]

- Kim, H.-K.; Lee, M.S.; Lee, S.-Y.; Choi, Y.-W.; Jeong, N.-J.; Kim, C.S. High power density of reverse electrodialysis with pore-filling ion exchange membranes and a highopen-area spacer. J. Mater. Chem. A 2015, 3, 16302. [Google Scholar]

- Miao, L.; Duan, H.; Wang, Z.; Lv, Y.; Xiong, W.; Zhu, D.; Gan, L.; Li, L.; Liu, M. Improving the pore-ion size compatibility between poly(ionic liquid)- derived carbons and high-voltage electrolytes for high energy-power supercapacitors. Chem. Eng. J. 2020, 382, 122945. [Google Scholar] [CrossRef]

- Li, X.; Zhang, H.; Mai, Z.; Zhang, H.; Vankelecom, I. Ion exchange membranes for vanadium redox flow battery (VRB) applications. Energy Environ. Sci. 2011, 4, 1147–1160. [Google Scholar] [CrossRef]

- Olivares-Marín, M.; Aklalouch, M.; Tonti, D. Combined Influence of Meso- and Macroporosity of Soft-Hard Templated Carbon Electrodes on the Performance of Li-O2 Cells with Different Configurations. Nanomaterials 2019, 9, 810. [Google Scholar] [CrossRef] [PubMed]

- Bokhari, S.W.; Siddique, A.H.; Pan, H.; Li, Y.; Imtiaz, M.; Chen, Z.; Zhu, S.M.; Zhang, D. Nitrogen doping in the carbon matrix for Li-ion hybrid supercapacitors: State of the art, challenges and future prospective. RSC Adv. 2017, 7, 18926–18936. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, S.; Tang, J.; Pan, L.; Eguchi, M.; Na, J.; Yamauchi, Y. Nitrogen-doped nanostructured carbons: A new material horizon for water desalination by capacitive deionization. EnergyChem 2020, 2, 100043. [Google Scholar] [CrossRef]

- Gopalakrishnan, A.; Badhulika, S. Effect of self-doped heteroatoms on the performance of biomass-derived carbon for supercapacitor applications. J. Power Sources 2020, 480, 228830. [Google Scholar] [CrossRef]

- Wan, Z.; Sun, Y.; Tsang, D.C.W.; Khan, E.; Yip, A.C.K.; Ng, Y.H.; Rinklebe, J.; Ok, Y.S. Customised fabrication of nitrogen-doped biochar for environmental and energy applications. Chem. Eng. J. 2020, 401, 126136. [Google Scholar] [CrossRef]

- Zhu, C.; Li, H.; Fu, S.; Du, D.; Lin, Y. Highly efficient nonprecious metal catalysts towards oxygen reduction reaction based on three-dimensional porous carbon nanostructures. Chem. Soc. Rev. 2016, 45, 517–531. [Google Scholar] [CrossRef]

- Geng, D.; Yang, S.; Zhang, Y.; Yang, J.; Liu, J.; Li, R.; Sham, T.-K.; Sun, X.; Ye, S.; Knights, S. Nitrogen doping effects on the structure of graphene. Appl. Surf. Sci. 2011, 257, 9193–9198. [Google Scholar] [CrossRef]

- Xu, X.; Pan, L.; Liu, Y.; Lu, T.; Sun, Z. Enhanced capacitive deionization performance of graphene by nitrogen doping. J. Colloid Interface Sci. 2015, 445, 143–150. [Google Scholar] [CrossRef]

- Deng, J.; Li, J.; Song, S.; Zhou, Y.; Li, L. Electrolyte-dependent supercapacitor performance on nitrogen-doped porous bio-carbon from gelatin. Nanomaterials 2020, 10, 353. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Liu, Y.-X.; Li, Y.; Deng, B.W.; Yin, B.; Yang, M.B. Design of compressible and elastic N-doped porous carbon nanofiber aerogels as binder-free supercapacitor electrodes. J. Mater. Chem. A 2020, 8, 17257–17265. [Google Scholar] [CrossRef]

- He, G.; Yang, G.; Song, Y.; Wang, L. Biomass Juncus Derived Nitrogen-Doped Porous Carbon Materials for Supercapacitor and Oxygen Reduction Reaction. Front. Chem. 2020, 8, 226. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.F.; Zhang, X.D.; Liang, H.W.; Kong, M.; Guan, Q.F.; Chen, P.; Wu, Z.Y.; YU, S.H. Synthesis of nitrogen-doped porous carbon nanofibers as an efficient electrode material for supercapacitors. ACS Nano 2012, 6, 7092–7102. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Yang, W.; Kong, L.; Song, A.; Qin, X. Facile synthesis of nitrogen-doped porous carbon for high-performance supercapacitors. RSC Adv. 2017, 7, 55257–55263. [Google Scholar] [CrossRef]

- Zou, B.X.; Wang, Y.; Huang, X.; Lu, Y. Hierarchical N- and O-Doped porous carbon composites for high-performance supercapacitors. J. Nanomater. 2018, 2018, 8945042. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, H.; Bai, J.; Xu, M.; Luo, C.; Yang, L.; Bai, L.; Wei, D.; Wang, W.; Yang, H. N-doped hierarchically porous carbon derived from grape marcs for high-performance supercapacitors. J. Alloys Compd. 2021, 854, 157207. [Google Scholar] [CrossRef]

- Sun, S.; Han, F.; Wu, X.; Fan, Z. One-step synthesis of biomass-derived O, N-codoped hierarchical porous carbon with the high surface area for supercapacitors. Chin. Chem. Lett. 2020, 31, 2235–2238. [Google Scholar] [CrossRef]

- Ahmed, S.; Rafat, M.; Ahmed, A. Nitrogen doped activated carbon derived from orange peel for supercapacitor application. Adv. Nat. Sci: Nanosci. Nanotechnol. 2018, 9, 035008. [Google Scholar] [CrossRef]

- Lin, G.; Ma, R.; Zhou, Y.; Liu, Q.; Dong, X.; Wang, J. KOH activation of biomass-derived nitrogen-doped carbons for supercapacitor and electrocatalytic oxygen reduction. Electrochim. Acta 2018, 261, 49–57. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, Z.; Ying, C.; Zhong, W. Facile synthesis of high nitrogen-doped content, mesopore-dominate biomass-derived hierarchical porous graphitic carbon for high-performance supercapacitors. Electrochim. Acta 2020, 334, 135615. [Google Scholar] [CrossRef]

- Liang, J.-Y.; Wang, C.-C.; Lu, S.-Y. Glucose-derived nitrogen-doped hierarchical hollow nest-like carbon nanostructures from a novel template-free method as an outstanding electrode material for supercapacitors. J. Mater. Chem. A 2015, 3, 24453–24462. [Google Scholar] [CrossRef]

- Wei, H.; Chen, J.; Fu, N.; Cheny, H.; Lin, H.; Han, S. Biomass-derived nitrogen-doped porous carbon with superior capacitive performance and high CO2 capture capacity. Electrochimi. Acta 2018, 266, 161–169162. [Google Scholar] [CrossRef]

- Wang, S.; Dong, L.; Li, Z.; Lin, N.; Xu, H.; Gao, S. Sustainable supercapacitors of nitrogen-doping porous carbon-based on cellulose nanocrystals and urea. Int. J. Biol. Macromol. 2020, 164, 4095–4103. [Google Scholar] [CrossRef]

- Yang, S.; Yang, W.; Song, A.; Gao, L.; Su, L.; Shao, G. Supercapacitance of nitrogen-sulfur-oxygen co-doped 3D hierarchical porous carbon in aqueous and organic electrolyte. J. Power Sources 2017, 359, 556–567557. [Google Scholar] [CrossRef]

- Gao, F.; Shao, G.; Qu, J.; Lv, L.; Li, Y.; Wu, M. Tailoring of porous and nitrogen-rich carbons derived from hydrochar for high-performance supercapacitor electrodes. Electrochim. Acta 2015, 155, 201–208. [Google Scholar] [CrossRef]

- Wen, Y.; Chi, L.; Wenelska, K.; Wen, X.; Chen, X.; Mijowska, E. Eucalyptus derived heteroatom-doped hierarchical porous carbons as electrode materials in supercapacitors. Sci. Rep. 2020, 10, 14631. [Google Scholar] [CrossRef]

- Jiang, M.; Yu, X.; Gao, R.; Yang, T.; Xu, Z.; Cao, L. Fabrication of Biomass-Derived N, S Co-doped Carbon with Hierarchically Porous Architecture for High-Performance Supercapacitor. NANO Brief Rep. Rev. 2020, 15, 2050096. [Google Scholar] [CrossRef]

- Ma, G.; Yang, Q.; Sun, K.; Peng, H.; Ran, F.; Zhao, X.; Lei, Z. Nitrogen-doped porous carbon derived from biomass waste for high-performance supercapacitor. Bioresource Technol. 2015, 197, 137–142. [Google Scholar] [CrossRef] [PubMed]

- Zou, K.; Deng, Y.; Chen, J.; Qian, Y.; Yang, Y.; Li, Y.; Chen, G. Hierarchically porous nitrogen-doped carbon derived from the activation of agriculture waste by potassium hydroxide and urea for high-performance supercapacitors. J. Power Sources 2018, 378, 579–588. [Google Scholar] [CrossRef]

- Yan, G.; Lin, J.; Liu, P.; Zhao, Z.; Lian, J.; Chang, W.; Yao, L.; Liu, Y.; Lin, H.; Han, S. Preparation of nitrogen-doped porous carbons for high-performance supercapacitor using biomass of waste lotus stems. RSC Adv. 2018, 8, 6806–6813. [Google Scholar] [CrossRef]

- Song, P.; Shen, X.P.; He, X.M.; Feng, K.H.; Kong, L.R.; Ji, Z.Y.; Zhai, L.Z.; Zhu, G.X.; Zhang, D.Y. Cellulose-derived nitrogen-doped hierarchically porous carbon for high-performance supercapacitors. Cellulose 2019, 26, 1195–1208. [Google Scholar] [CrossRef]

- Demir, M.; Saraswat, S.K.; Gupta, R.B. Hierarchical nitrogen-doped porous carbon derived from lecithin for high-performance supercapacitors. RSC Adv. 2017, 7, 42430. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Y.; Peng, Y.; Wang, Y.; Wang, N.; Wang, J.; Zhao, J. Nitrogen-doped biomass-based hierarchical porous carbon with large mesoporous volume for application in energy storage. Chem. Eng. J. 2018, 348, 850–859. [Google Scholar] [CrossRef]

- Hu, Y.; Tong, X.; Zhuo, H.; Zhong, L.; Peng, X.; Wang, S.; Sun, R. 3D hierarchical porous N-doped carbon aerogel from renewable cellulose: An attractive carbon for high-performance supercapacitor electrodes and CO2 adsorption. RSC Adv. 2016, 6, 15788–15795. [Google Scholar] [CrossRef]

- Lia, J.; Luo, F.; Lin, T.; Yang, J.; Yang, S.; He, D.; Xiao, D.; Liu, W. Pomelo peel-based N, O-codoped hierarchical porous carbon material for supercapacitor application. Chem. Phys. Lett. 2020, 753, 137597. [Google Scholar] [CrossRef]

| Biomass Precursor | Pyrolysis Method and Optimal Condition | SSA (m2 g−1) | GSC (F g−1) | Current Density (A g−1) | Specific Energy (Wh kg−1) | Power Density (W kg−1) | Capacitance Retention (%) | Rate Capability | Electrolyte | Ref |

|---|---|---|---|---|---|---|---|---|---|---|

| Winter jujube | Pre-carbonized at 400 °C and further pyrolyzed at 800 °C for 2 h with KOH | 2286.2 | 341 | 0.5 | 30.9 | 8.9 | 96.5 | 76% at 20 A g−1 | 1 M H2SO4 | [9] |

| Chinese date | Pyrolyzed at 700 °C and further pyrolyzed at 500, 600, and 700 °C with KOH. | 1940.7 | 518 | 0.5 | 18.5 | 373.8 | 98.9 | - | Na2SO4 | [10] |

| Chinese date | Pyrolyzed at 700 °C and further pyrolyzed at 500, 600, and 700 °C with KOH. | 1940.7 | 518 | 0.5 | 51.3 | 767.8 | 90.2 | - | Et4NBF4 | [10] |

| Wild fungus | Pre-carbonized at 400 °C and further pyrolyzed at 800 °C for 2 h with KOH | 339 | 0.5 | - | - | 98 | 75% up to 50 A g−1 | 6 M KOH | [11] | |

| Puffed rice | Pre-carbonized at 500 °C and further pyropyrolyzed at 850 °C for 1 h with KOH | 3326 | 218 | 80 | 104 | 53 | 71 | - | 6 M KOH | [30] |

| Seaweed | Carbonized in vacuum at 600–900°C for 3 h and further pyrolyzed at 750 °C for 2 h with KOH | 3270 | 425 | 0.1 | 42 | 390 | - | 91% at 2.0 A g−1 | 1 M H2SO4 | [42] |

| Cattle bone | Pyrolyzed at 1100 °C for 1 h and washed HCl | 2096 | 258 | 5.0 | 109.9 | 4400 | 96.4 | EMIM-BF4 | [36] | |

| Flaxseed residue | Pyrolyzed at 700 °C and further pyrolyzed at and 700 °C with KOH (1:4). | 3230 | 369 | 0.5 | 61.2 | 468.8 | 98.1 | - | 6 M KOH | [37] |

| Straw residues | Pre-carbonized at 400 °C for 3 h and further pyrolyzed at 600 °C for 1h with KOH | 772 | 226.2 | 0.5 | - | - | 78.4 | - | 6 M KOH | [38] |

| Bamboo residues | Pyrolyzed at 750 °C for 1 h and further pyrolyzed at 750 °C for 1 h with KOH. | 171.5 | 281 | 0.2 | 37.8 | 97 | 88 | - | 6 M KOH | [37] |

| Carrot biomass | Pre-carbonized at 260 °C for 6 h and further pyrolyzed at 1000 °C for 2 h | 682 | 161 | 0.2 | 5.6–4.6 | 48.8–5884.4 | 90 | 81.8% at 20 A g−1 | 6 M KOH | [43] |

| castor shell powder | AC pyrolyzed at 800 °C with KOH | 1527 | 365 | 1.0 | 9.14 | 500 | - | - | [26] | |

| Tea leave residue | A mixture of KOH and tea powder (2:1) and pyrolyzed at 900 °C for 60 min | ~912 | 167 | 1.0 | 47.86 | 1580.72 | - | 81.42% at 30 A g−1 | 6 M KOH 1 M Na2SO4 | [27] |

| Coconut shell | Biomass/ZnCl2 ratio 1:3, then pyrolyzed at 900 °C for 1 h. | 1874 | 268 | 1.0 | 11.6 | 210 | 99.5 | 76.9% at 10 A g−1 | 6 M KOH | [28] |

| Bamboo | Biomass/KOH ratio 1:4 and pyrolyzed at 750 °C. | ~172 | 318 | 0.2 | 42.1 | 210 | 99.5 | 76.9% at 10 A g−1 | 1 M H2SO4 | [44] |

| Shaddock skin | Carbonized at 900 °C for 2 h under Ar and further pyrolyzed at 1200 °C for 1h under vacuum | 2327 | 152 | 1.0 | 11 | 5600 | 97.6 | 87% at 100 A g−1 | EMI TFSI + EMI BF4 | [45] |

| Peanut shells | FeCl3/MgCl2 activated sample at 800 °C | 1401.45 | ~247 | 1.0 | 32.7 | 588.3 | 96.3 | 81.8% at 10 A/g | 1 M Na2SO4 | [46] |

| Peanut shells | FeCl3/ZnCl2 activated sample at 800 °C | 1427.81 | ~186 | 1.0 | 22.9 | 523.8 | - | 1 M Na2SO4 | [46] | |

| wood sawdust and tannic acid | Potassium chloride + sodium thiosulfate | 2650 | 200 | - | 47–51 | - | 97–100 | 80% at 40 A g−1 | aqueous electrolyte (H2SO4) | [47] |

| wood sawdust and tannic acid | 2650 | 160 | - | 32–36 | 140 | 97–100 | 75% at 40 A g−1 | Organic electrolyte | [47] | |

| foxtail grass seeds | Biomass was mixed with NaHCO3 and KHCO3 (1:1:1) and pyrolyzed at 700 °C for 2 h. | 358 | 0.5 | 18.2 Wh L− 1 | - | - | 91.2% at 2.0 A g−1 | 6 M KOH | [48] | |

| soybean | Pre-carbonized at 400 °C for 2 h and further pyrolyzed at 750 °C for 2 h with KOH | 2251 | 248 | 0.1 | - | - | 98.75 | 56.7% from 0.1 to 20 A g−1 | 6 M KOH | [49] |

| Macroalgae | Hydrothermal carbonization + conventional pyrolysis with ZnCl2 | ~2000 | 202 | 0.5 | 7 | 3000 | 96 | 90% at 10 A g−1 | 6 M KOH | [50] |

| Biomass-based carbon nanofibers | 320.3 | 0.1 | 30.2 | 400 | 70.6 | - | 6 M KOH | [51] | ||

| Dead plant leaves | Pyrolyzed at 1000 °C in for 5 h in argon air | 325 | 345 | 0.5 | 43.13 | 61.34 | 87.3 | - | 1 M H2SO4 | [52] |

| Flagelliforme algae | Pre-carbonized at 400 °C for 1 h and further pyrolyzed at 700 °C for 2 h with KOH activation | 2760 | 283 | 0.1 | 22 | 80 | 100 | - | 6 M KOH | [53] |

| Moringa oleifera stem | Biomass blended with ZnCl2 (ratio 1:3) in 50 mL of 2 M FeCl3 solution; afterward, pyrolyzed at 800 °C for 2 h under N2, for the last, washed with 2.0 M HCl. | 2250 | 283 | 0.5 | 11.6 | 95 | 82 | - | 1.0 M Na2SO4 1.0 M H2SO4 | [54] |

| kapok flower | Pre-carbonized at 500 °C for 2 h; soaked in 1.0 M HCl. Afterward, blended with KOH (1:4.5) and further pyrolyzed at 700 °C for 2 h. | 1904 | 286.8 | 0.5 | - | - | 97.4 | - | 6 M KOH | [55] |

| Tree residues | Biomass pyrolyzed at Tempretarure between 500–700 °C for 10 min under air. Afterward, the pyrolyzed material was chemically activated with a mixture of HNO3 and H2SO4 (HNO3:H2SO4 = 1:3) | 616 | 24 | 0.25 | 0.53 | 51 | 100 | - | 1.0 M H2SO4 | [56] |

| Syzygium cumini fruit shells | two-step synthesis: (i) carbonization at 700 °C in N2 atmosphere (ii) CO2 activation at 700 °C in N2 atmosphere. | 774 | 294 | 0.5 | 27.22 | 200 | 98 | - | 6 M KOH | [57] |

| Chrysopogon zizanioides roots | two-step synthesis: (i) carbonization at 700 °C in N2 atmosphere (ii) CO2 activation at 700 °C in N2 atmosphere. | 634 | 253 | 0.5 | 16.72 | 200 | 98 | - | 6 M KOH | [57] |

| Quinoa | carbonized for 120 min at 500 °C and further påyrolysed at 800 °C for 2 h with KOH activation. | 2597 | 254 | 0.5 | 22 | 625 | 93 | 75 | 6 M KOH | [58] |

| Quinoa | carbonized for 120 min at 500 °C and further påyrolysed at 800 °C for 2 h with KOH activation. | 2597 | 99.2 | 0.5 | 9.5 | 100 | 93 | 75 | 6 M KOH | [58] |

| Biomass Precursor | N Dopant Precursor | N Content (%) | GSC (F g−1) | Current Density (A g−1) | Capacitance Retention (%) | Ref |

|---|---|---|---|---|---|---|

| Grape marcs | Urea | 2.04 | 446.0 | 0.5 | Up to 95.1 | [80] |

| Alginic acid | Urea | 2.83 | 324 | 1.0 | Up to 91.5 | [81] |

| Orange peel | Melamine | 3.92 | 168 | 0.7 | - | [82] |

| Soybean | Ammonia | 1.37 | 243.2 | 1.0 | 96.5 | [83] |

| Peach gum | Urea | 8.7 | 426 | 0.5 | 97.09 | [84] |

| Glucose | hexamethylenetetramine | - | 322 | 1.0 | 54.0 | [85] |

| Water chestnut | Melamine | 4.89 | 346 | 0.5 | 97.6 | [86] |

| Cellulose | Urea | 7.4 | 570.6 | 1.0 | 99.8 | [87] |

| Hierarchical porous carbon | NH3.H2O + thiourea | 7.63 | 367 | 0.3 | 93.7 | [88] |

| Biomass-derived hydrochar | Melamine | 4.38 | 492 | 0.1 | 98 | [89] |

| Eucalyptus | Ammonium chloride | 359 | 0.5 | 92 | [90] | |

| Coconut shell | thiourea | 4.62 | 360 | 0.1 | 87 | [91] |

| Potato waste | Melamine | 6.2 | 255 | 0.5 | 93.7 | [92] |

| Agricultural waste | Urea | 2.63 | 259.5 | 1.0 | 95 | [93] |

| Waste lotus stems | Urea | 360.5 | 0.5 | 96 | [94] | |

| Cellulose | Urea | 3.0 | 300 | 0.5 | 81 | [95] |

| Lecithin | Urea | 9.2 | 285 | 0.5 | 81.3 | [96] |

| Sugarcane bagasse | polypyrrole | 3.1 | 371 | 0.1 | 71.5 | [97] |

| Cellulose aerogel | Urea | 4.62 | 225 | 0.5 | 81 | [98] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reis, G.S.d.; Oliveira, H.P.d.; Larsson, S.H.; Thyrel, M.; Claudio Lima, E. A Short Review on the Electrochemical Performance of Hierarchical and Nitrogen-Doped Activated Biocarbon-Based Electrodes for Supercapacitors. Nanomaterials 2021, 11, 424. https://doi.org/10.3390/nano11020424

Reis GSd, Oliveira HPd, Larsson SH, Thyrel M, Claudio Lima E. A Short Review on the Electrochemical Performance of Hierarchical and Nitrogen-Doped Activated Biocarbon-Based Electrodes for Supercapacitors. Nanomaterials. 2021; 11(2):424. https://doi.org/10.3390/nano11020424

Chicago/Turabian StyleReis, Glaydson Simões dos, Helinando Pequeno de Oliveira, Sylvia H. Larsson, Mikael Thyrel, and Eder Claudio Lima. 2021. "A Short Review on the Electrochemical Performance of Hierarchical and Nitrogen-Doped Activated Biocarbon-Based Electrodes for Supercapacitors" Nanomaterials 11, no. 2: 424. https://doi.org/10.3390/nano11020424

APA StyleReis, G. S. d., Oliveira, H. P. d., Larsson, S. H., Thyrel, M., & Claudio Lima, E. (2021). A Short Review on the Electrochemical Performance of Hierarchical and Nitrogen-Doped Activated Biocarbon-Based Electrodes for Supercapacitors. Nanomaterials, 11(2), 424. https://doi.org/10.3390/nano11020424