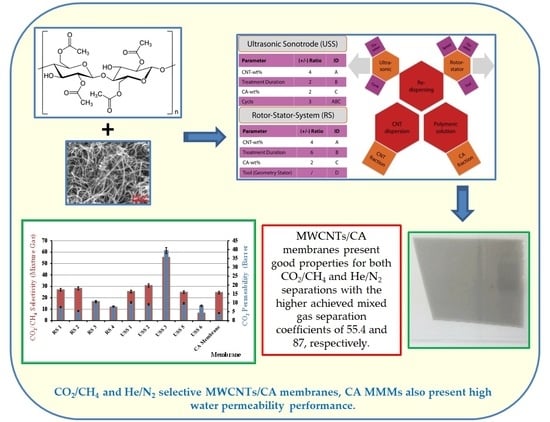

CO2/CH4 and He/N2 Separation Properties and Water Permeability Valuation of Mixed Matrix MWCNTs-Based Cellulose Acetate Flat Sheet Membranes: A Study of the Optimization of the Filler Material Dispersion Method

Abstract

1. Introduction

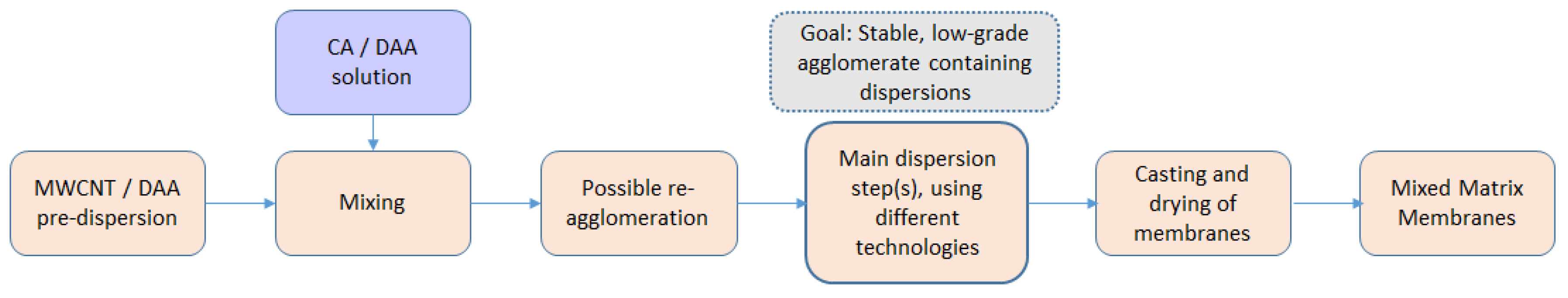

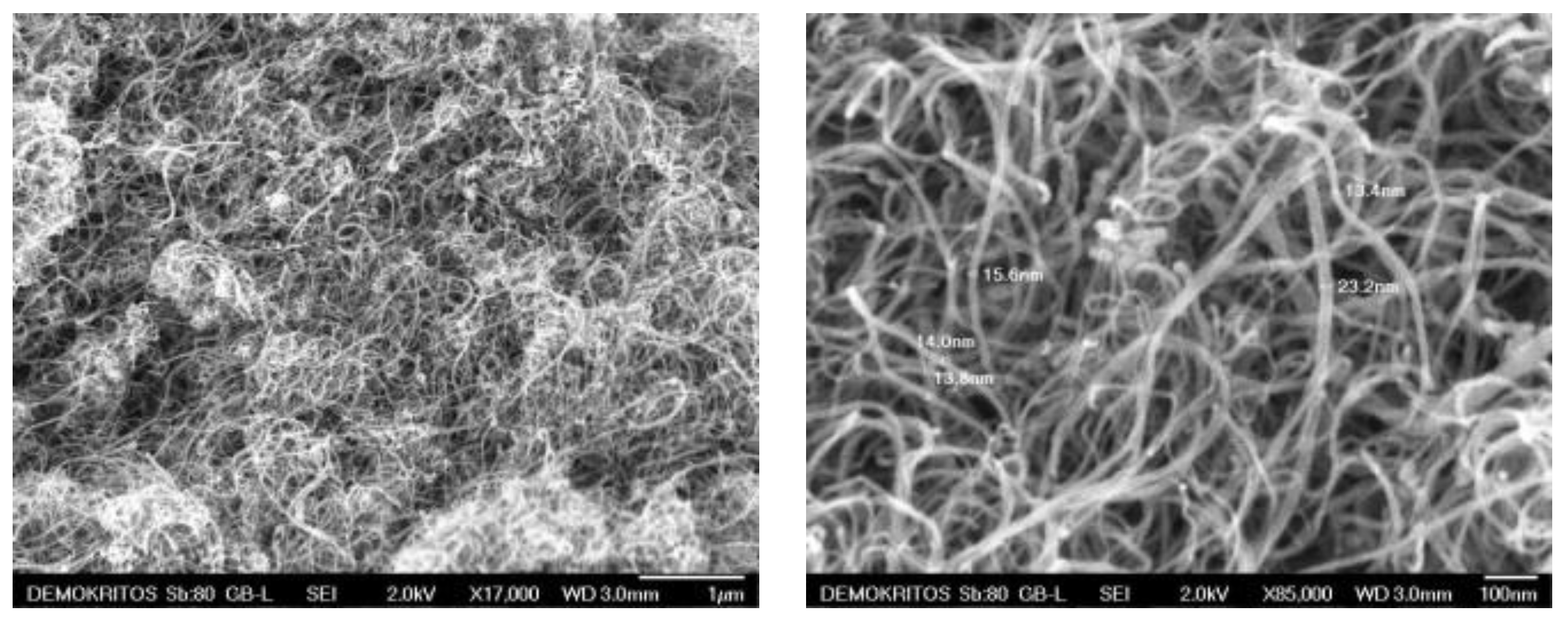

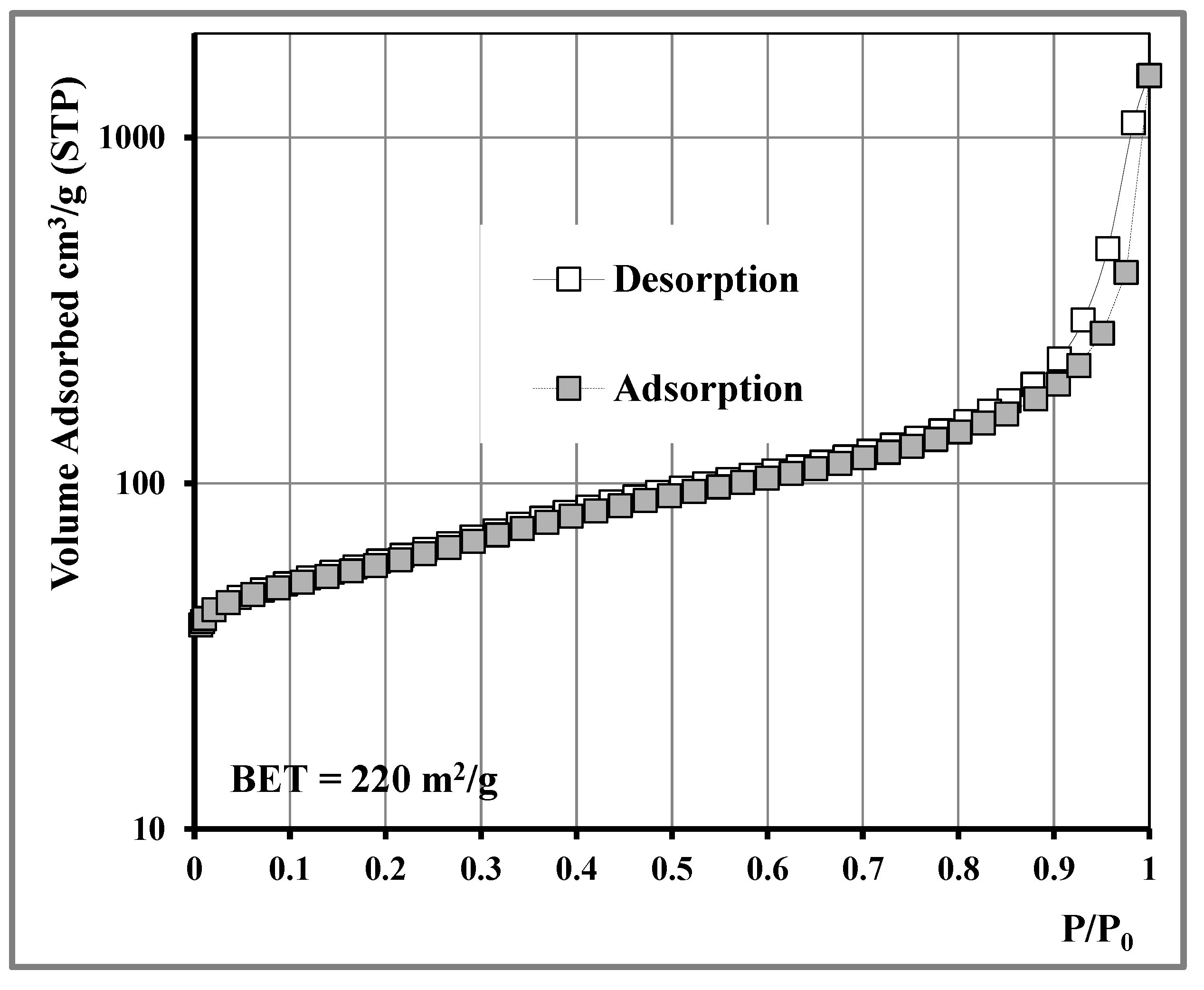

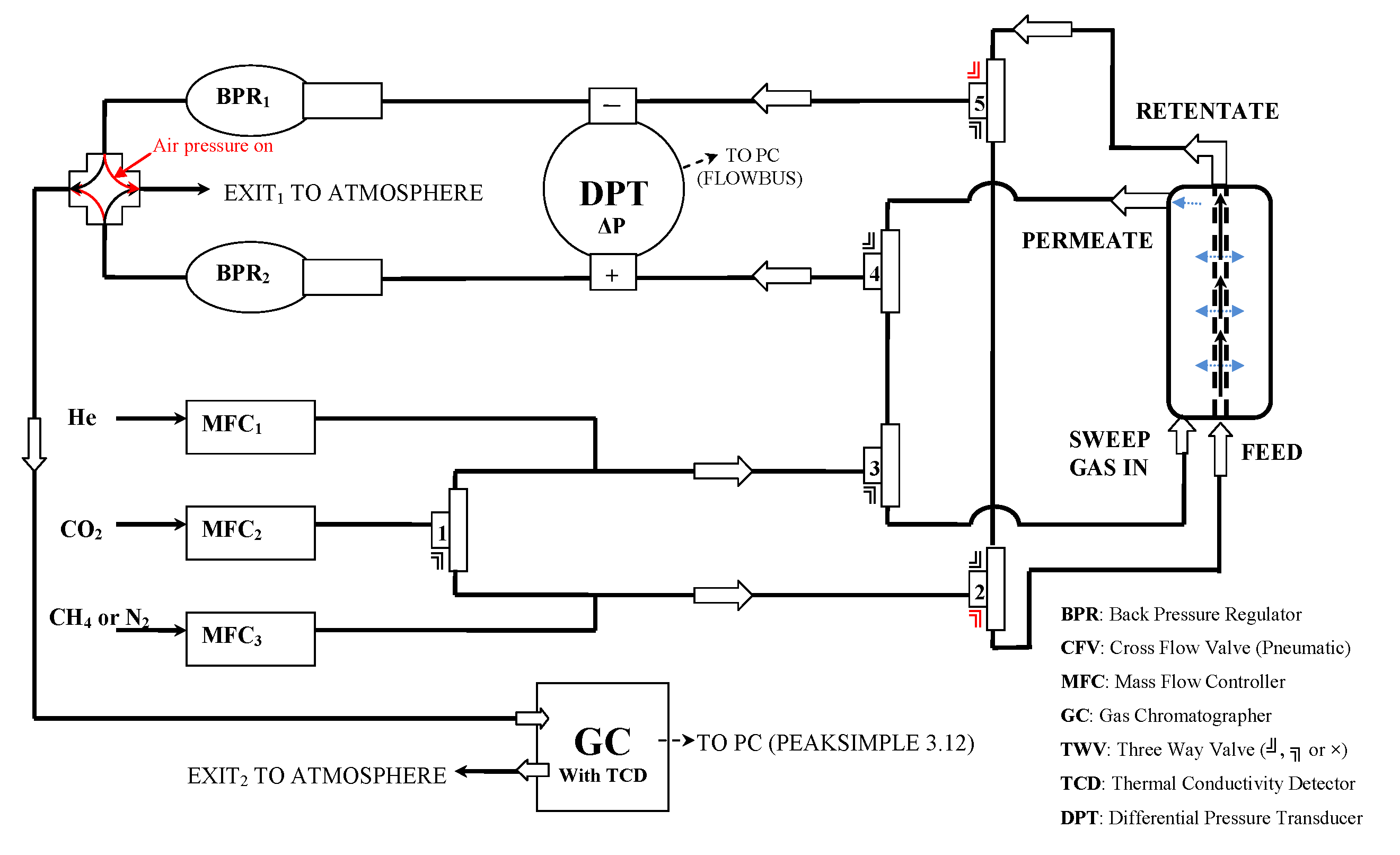

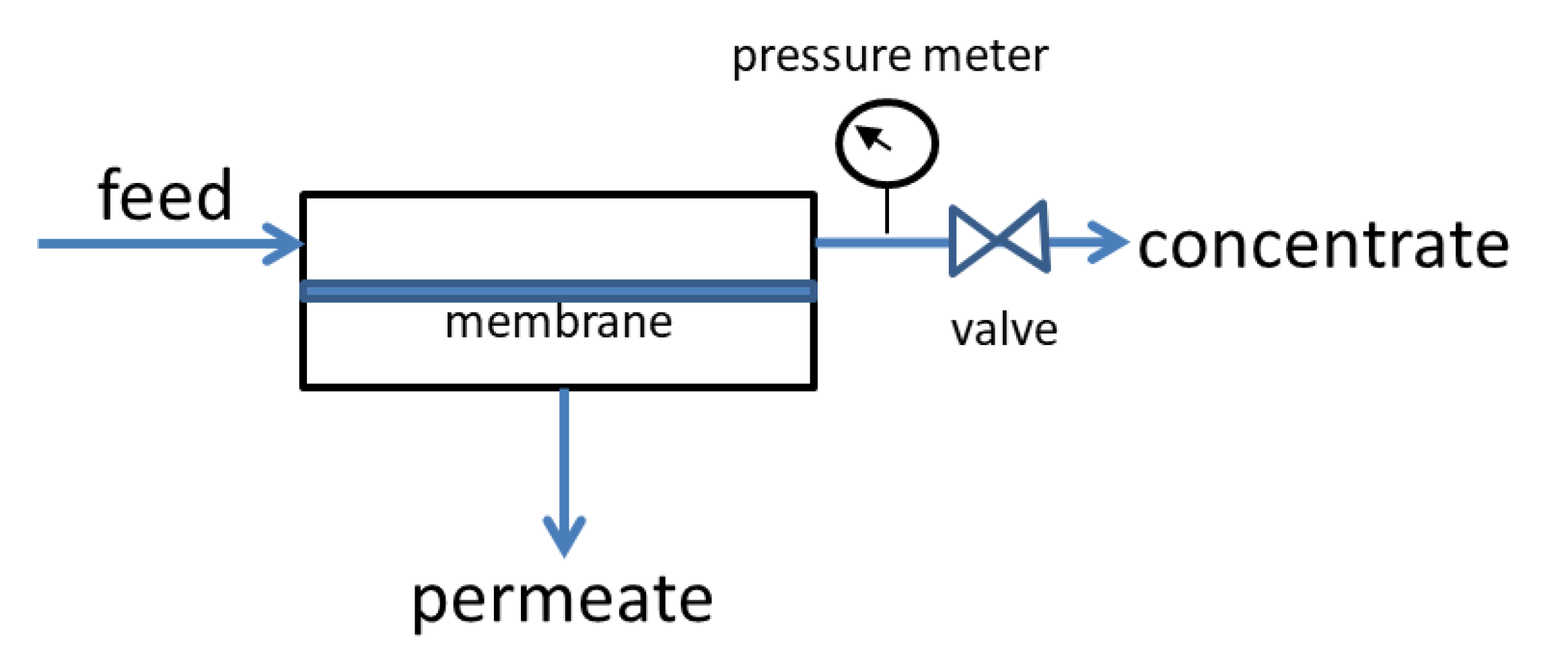

2. Materials and Methods

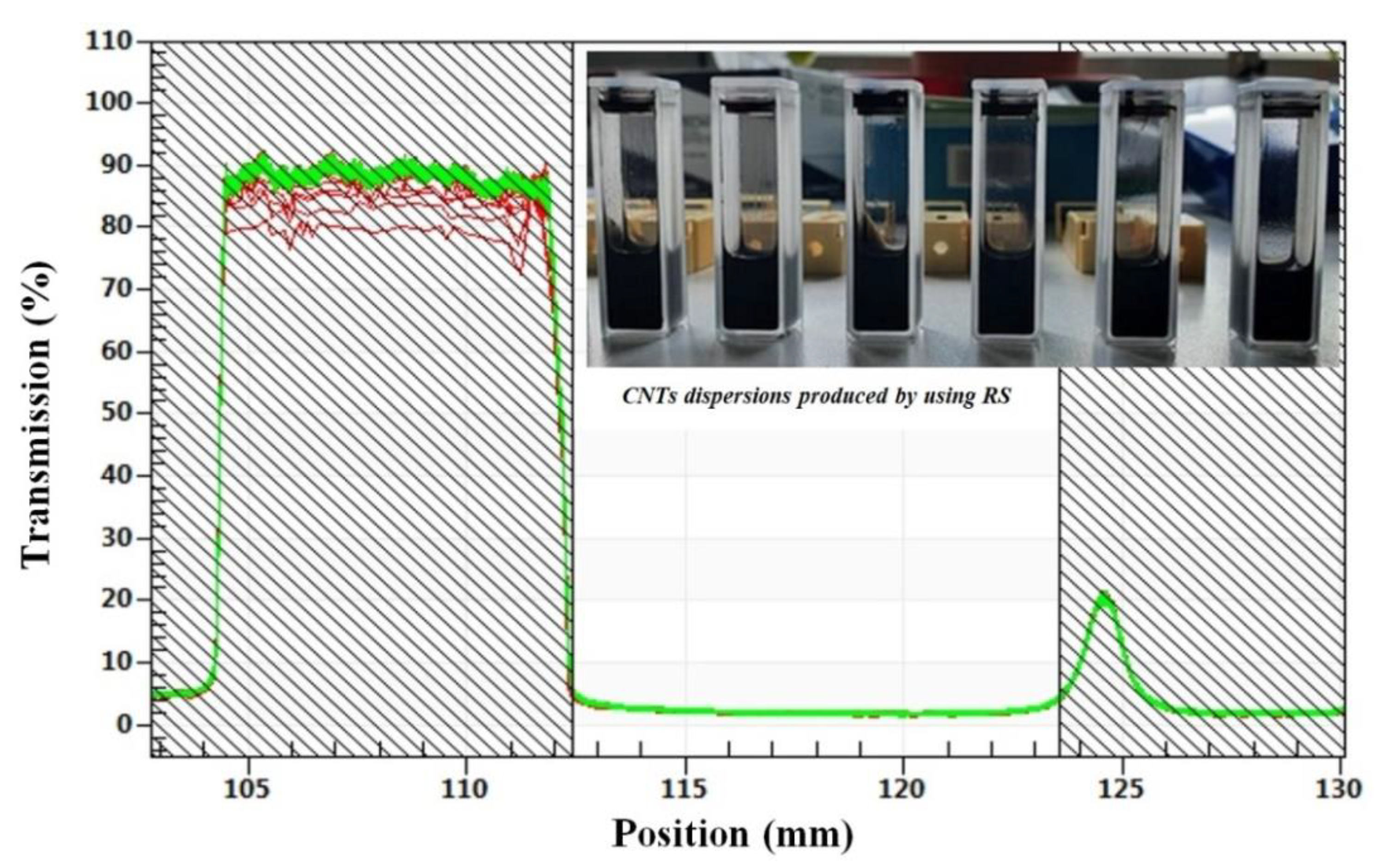

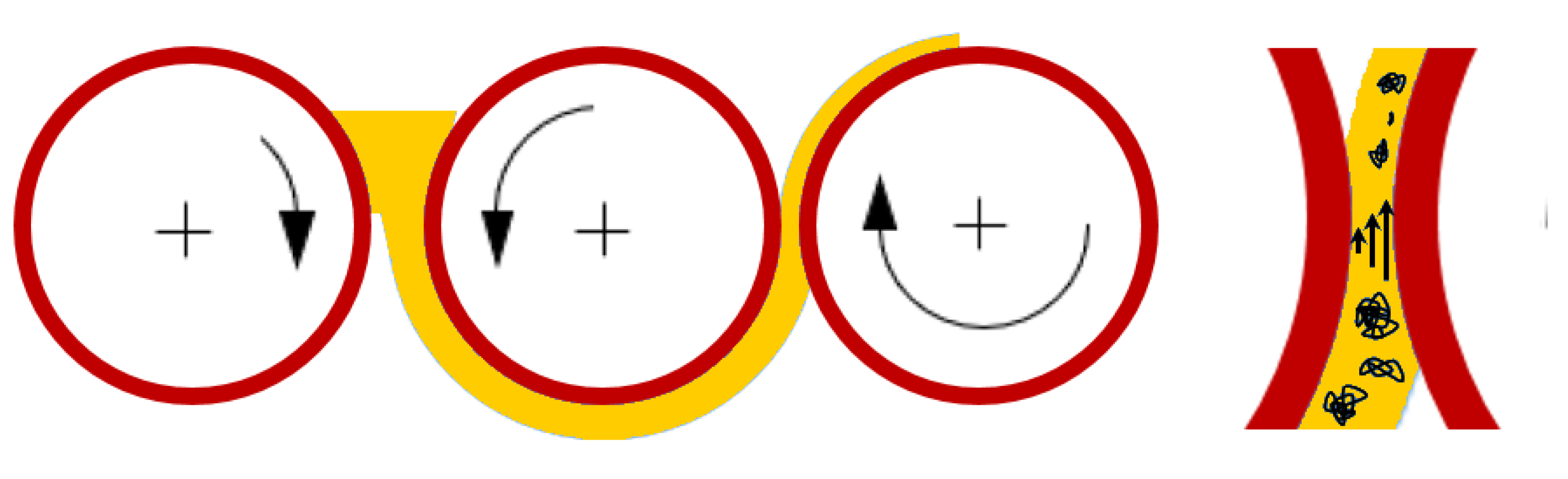

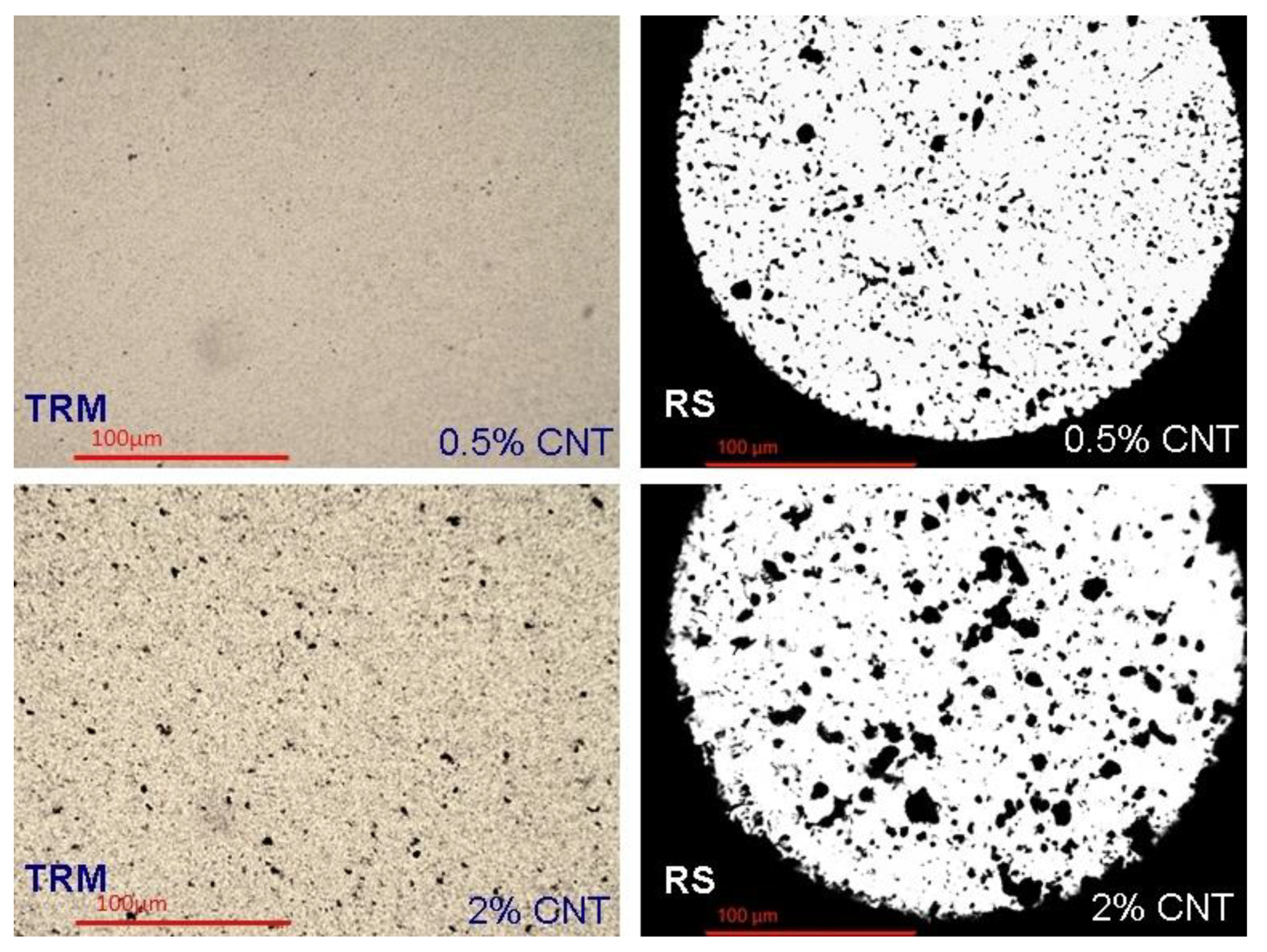

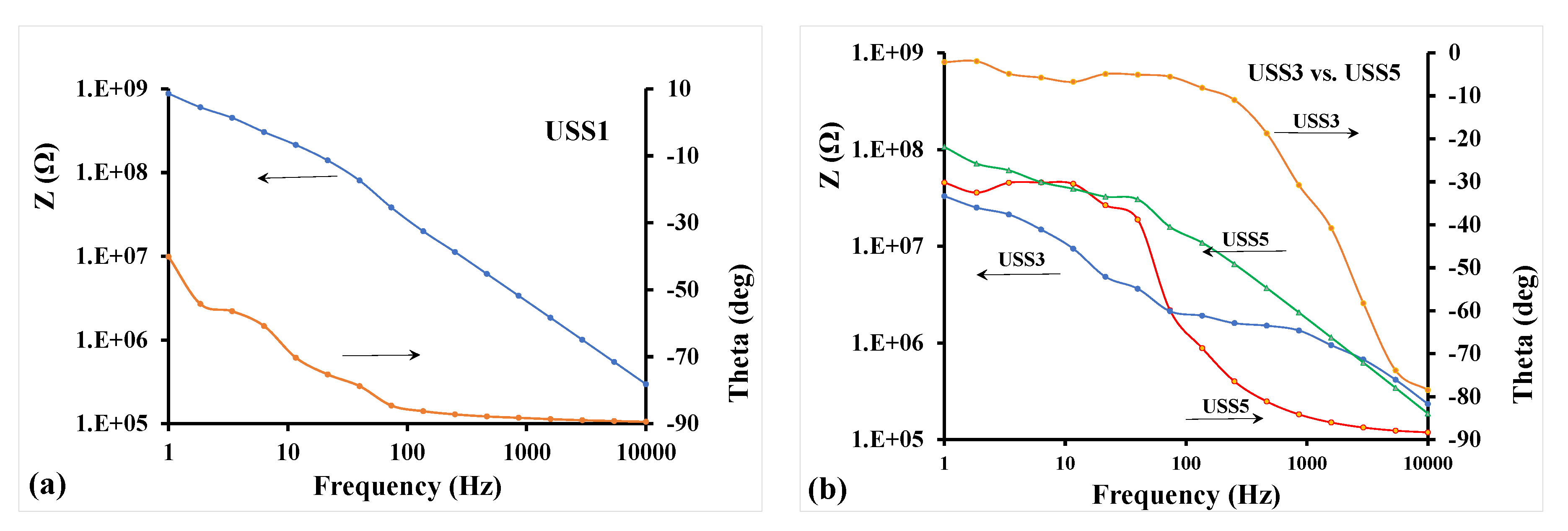

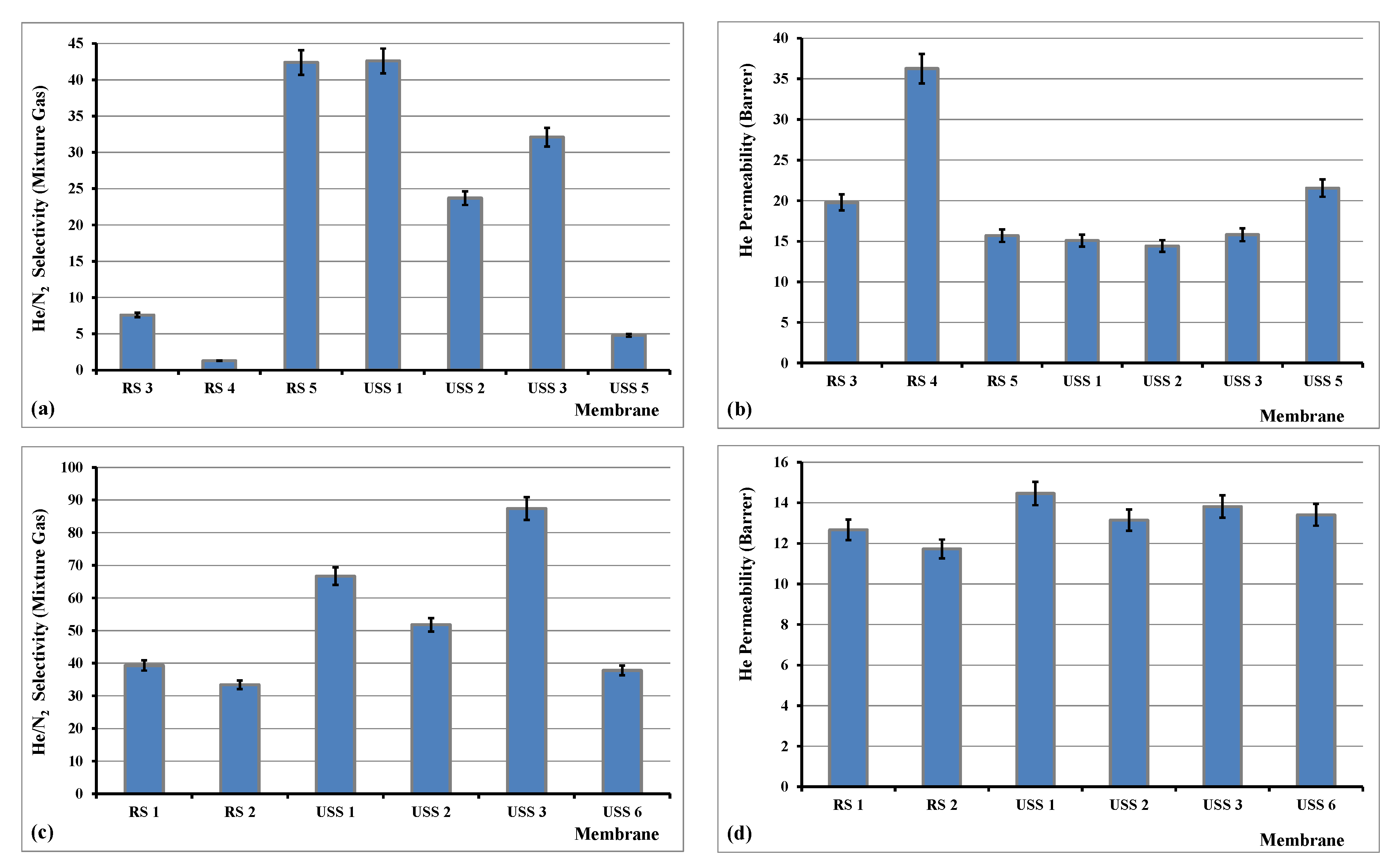

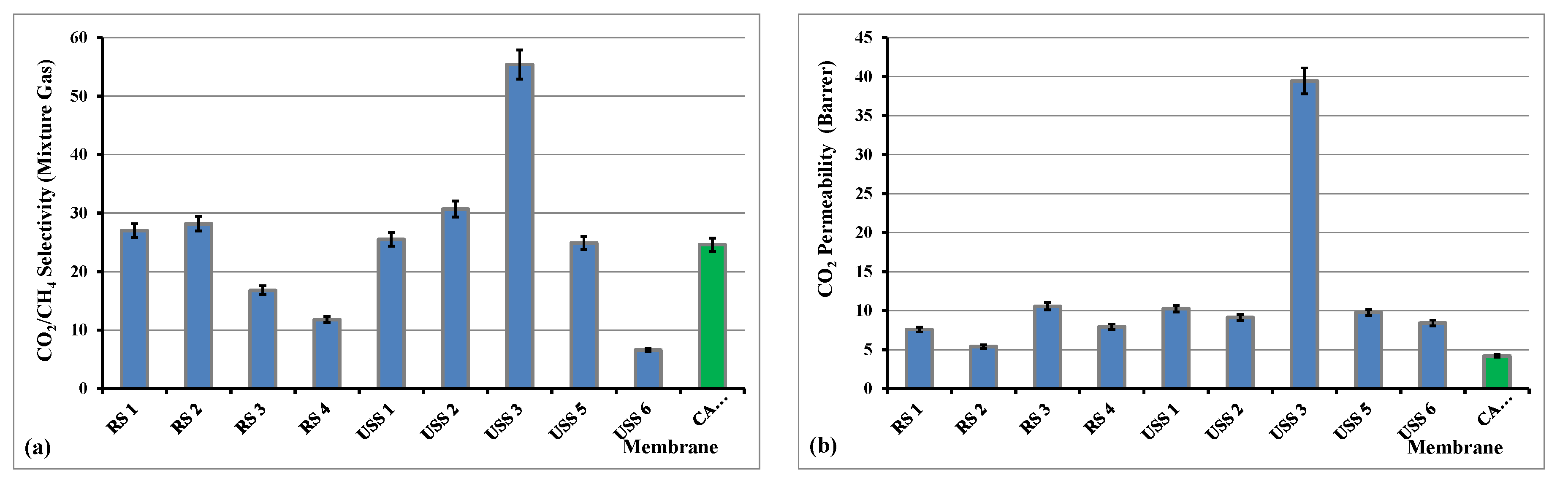

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gudmundsson, J.S. Natural Gas Sweetening & Effect of Declining Pressure. In TPG4140 Project Report; NTNU: Trondheim, Norway, 2013. [Google Scholar]

- George, G.; Bhoria, N.; AlHallaq, S.; Abdala, A.; Mittal, V. Polymer membranes for acid gas removal from natural gas. Sep. Purif. Technol. 2016, 158, 333–356. [Google Scholar] [CrossRef]

- Shibata, T. Cellulose acetate in separation technology. Macromol. Symp. 2004, 208, 353–369. [Google Scholar] [CrossRef]

- Dunweg, G.; Lother, S.; Wolfgang, A. Dialysis Membrane Made of Cellulose Acetate. U.S. Patent 5,403,485, 4 April 1995. [Google Scholar]

- Hayama, M.; Yamamoto, K.; Kohori, F.; Sakai, K.J. How polysulfone dialysis membranes containing polyvinylpyrrolidone achieve excellent biocompatibility? Membr. Sci. 2004, 234, 41–49. [Google Scholar] [CrossRef]

- Qin, J.J.; Oo, M.H.; Cao, Y.M.; Lee, L.S. Development of a LCST membrane forming system for cellulose acetate ultrafiltration hollow fiber. Sep. Purif. Technol. 2005, 42, 291–295. [Google Scholar] [CrossRef]

- Zularisam, A.W.; Ismail, A.F.; Salim, M.R.; Sakinah, M.; Ozaki, H. The effects of natural organic matter (NOM) fractions on fouling characteristics and flux recovery of ultrafiltration membranes. Desalination 2007, 212, 191–208. [Google Scholar] [CrossRef]

- Shibutani, T.; Kitaura, T.; Ohmukai, Y.; Maruyama, T.; Nakatsuka, S.; Watabe, T.; Matsuyama, H. Membrane fouling properties of hollow fiber membranes prepared from cellulose acetate derivatives. J. Membr. Sci. 2011, 376, 102–109. [Google Scholar] [CrossRef]

- Favvas, E.P. Chapter, Nanomaterials and their Applicability as Membranes’ Fillers. In Innovations in Nanomaterials; Imran, A.B., Shapter, J., Eds.; Nova Science Publ.: New York, NY, USA, 2015; pp. 105–153. [Google Scholar]

- Ahmad, A.L.; Jawad, Z.A.; Low, S.C.; Zein, S.H.S. A cellulose acetate/multi-walled carbon nanotube mixed matrix membrane for CO2/N2 separation. J. Membr. Sci. 2014, 451, 55–66. [Google Scholar] [CrossRef]

- Mubashir, M.; Fong, Y.Y.; Leng, C.T.; Keong, L.K. Optimization of spinning parameters on the fabrication of NH2-MIL-53(Al)/cellulose acetate (CA) hollow fiber mixed matrix membrane for CO2. Sep. Purif. Technol. 2019, 215, 32–43. [Google Scholar] [CrossRef]

- Rashid, M.H.; Farrukh, S.; Javed, S.; Hussain, A.; Fan, X.; Ali, S.; Ayoub, M. Synthesis and gas permeation analysis of TiO2 nanotube-embedded cellulose acetate mixed matrix membranes. Chem. Pap. 2020, 74, 821–828. [Google Scholar] [CrossRef]

- Etemadi, H.; Yegani, R.; Seyfollahi, M. The effect of amino functionalized and polyethylene glycol grafted nanodiamond on anti-biofouling properties of cellulose acetate membrane in membrane bioreactor systems. Sep. Purif. Technol. 2017, 177, 350–362. [Google Scholar] [CrossRef]

- Ang, M.B.M.Y.; Macni, C.R.M.; Caparanga, A.R.; Huang, S.-H.; Tsai, H.-A.; Lee, K.-R.; Lai, J.-Y. Mitigating the fouling of mixed-matrix cellulose acetate membranes for oil-1 water separation through modification with polydopamine particles. Chem. Eng. Res. Des. 2020, 159, 195–204. [Google Scholar] [CrossRef]

- Zhao, Y.; Jung, B.T.; Ansaloni, L.; Ho, W.S.H. Multiwalled carbon nanotube mixed matrix membranes containing amines for high pressure CO2/H2 separation. J. Membr. Sci. 2014, 459, 233–243. [Google Scholar] [CrossRef]

- Shen, J.; Zhang, M.; Liu, G.; Guan, K.; Jin, W. Size effects of graphene oxide on mixed matrix membranes for CO2 separation. AIChE 2016, 62, 2843–2852. [Google Scholar] [CrossRef]

- Dai, L.; Chang, D.W.; Baek, J.-B.; Lu, W. Carbon nanomaterials for advanced energy conversion and storage. Small 2012, 23, 1130–1166. [Google Scholar] [CrossRef] [PubMed]

- Jariwala, D.; Sangwan, V.K.; Lauhon, L.J.; Marksa, T.J.; Hersam, M.C. Carbon nanomaterials for electronics, optoelectronics, photovoltaics, and sensing. Chem. Soc. Rev. 2013, 42, 2824–2860. [Google Scholar] [CrossRef]

- Mochalin, V.N.; Shenderova, O.; Ho, D.; Gogotsi, Y. The properties and applications of nanodiamonds. Nat. Nanotech. 2012, 7, 11–23. [Google Scholar] [CrossRef]

- Kim, J.; Van Der Bruggen, B. The use of nanoparticles in polymeric and ceramic membrane structures: Review of manufacturing procedures and performance improvement for water treatment. Environ. Pollut. 2010, 158, 2335–2349. [Google Scholar] [CrossRef]

- Karkhanechi, H.; Kazemian, H.; Nazockdast, H.; Mozdianfard, M.R.; Bidoki, S.M. Fabrication of Homogenous Polymer-Zeolite Nanocomposites as Mixed-Matrix Membranes for Gas Separation. Chem. Eng. Technol. 2012, 35, 885–892. [Google Scholar] [CrossRef]

- Favvas, E.P.; Stefanopoulos, K.L.; Nolan, J.W.; Papageorgiou, S.K.; Mitropoulos, A.C.; Lairez, D. Mixed Matrix Hollow Fiber Membranes with enhanced gas permeation properties. Sep. Purif. Technol. 2014, 132, 336–345. [Google Scholar] [CrossRef]

- Moore, T.T.; Mahajan, R.; Vu, D.Q.; Koros, W.J. Hybrid membrane materials comprising organic polymers with rigid dispersed phases. AICHE J. 2004, 50, 311–321. [Google Scholar] [CrossRef]

- Buonomenna, M.G.; Yave, W.; Golemme, G. Some approaches for high performance polymer based membranes for gas separation: Block copolymers, carbon molecular sieves and mixed matrix membranes. RSC Adv. 2012, 2, 10745–10773. [Google Scholar] [CrossRef]

- Zahid, M.; Rashid, A.; Akram, S.; Rehan, Z.A.; Razzaq, W. A Comprehensive Review on Polymeric Nano-Composite Membranes for Water Treatment. J. Membr. Sci. Technol. 2018, 8, 1000179. [Google Scholar] [CrossRef]

- Pereira, C.M.C.; Nóvoa, P.; Martins, M.; Forero, S.; Hepp, F. Characterization of carbon nanotube 3D-structures infused with low viscosity epoxy resin system. Compos. Struct. 2010, 92, 2252–2257. [Google Scholar] [CrossRef]

- Schweiss, R.; Steeb, M.; Wilde, P.M.; Schubert, T. Enhancement of proton exchange membrane fuel cell performance by doping microporous layers of gas diffusion layers with multiwall carbon nanotubes. J. Power Sources 2012, 220, 79–83. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. IUPAC Technical Report. Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar]

- Sapalidis, A.A.; Katsaros, F.K.; Steriotis, T.A.; Kanellopoulos, N.K. Properties of Poly(vinyl alcohol)—Bentonite Clay Nanocomposite Films in Relation to Polymer–Clay Interactions. J. Appl. Polym. Sci. 2012, 123, 1812–1821. [Google Scholar] [CrossRef]

- Jin, H.; Huang, Y.; Wang, X.; Yu, P.; Luo, Y. Preparation of modified cellulose acetate membranes using functionalized multi-walled carbon nanotubes for forward osmosis. Des. Water Treat. 2015, 57, 7166–7174. [Google Scholar] [CrossRef]

- Liao, Y.; Loh, C.-H.; Tian, M.; Wang, R.; Fane, A.G. Progress in electrospun polymeric nanofibrous membranes for water treatment: Fabrication, modification and applications. Prog. Polym. Sci. 2018, 77, 69–94. [Google Scholar] [CrossRef]

- O’Dwyer, M.J.; Maistros, G.M.; James, S.W.; Tatam, R.P.; Partridge, I.K. Relating the state of cure to the real-time internal strain development in a curing composite using in-fibre Bragg gratings and dielectric sensors. Meas. Sci. Technol. 1998, 9, 1153–1158. [Google Scholar] [CrossRef]

- Bekas, D.G.; Gkikas, G.; Maistros, G.M.; Paipetis, A.S. On the use of dielectric spectroscopy for the real time assessment of the dispersion of carbon nanotubes in epoxy. RSC Adv. 2016, 6, 78838–78845. [Google Scholar] [CrossRef]

- Dimou, A.-E.; Sakellariou, I.; Maistros, G.M.; Alexopoulos, N.D. Study of Reduced Graphene Oxide Dispersions via Electrical Impedance Spectroscopy. Procedia Struct. Integr. 2020, 28, 1679–1685. [Google Scholar] [CrossRef]

- Haussinger, P.; Glathaar, R.; Rhode, W.; Kick, H.; Benkmann, C.; Weber, J.; Wunschel, H.-J.; Stenke, V.; Leicht, E.; Stenger, H. Noble Gases. In Ullmann’s Encyclopedia of Industrial Chemistry; John Wiley and Sons: Hoboken, NJ, USA, 2011; pp. 392–448. [Google Scholar]

- Committee on the Impact of Selling the Federal Helium Reserve. The Impact of Selling the Federal Helium Reserve; National Academy Press: Washington, DC, USA, 2000. [Google Scholar]

- Scholes, C.A.; Ghosh, U.K. Review of Membranes for Helium Separation and Purification. Membranes 2017, 7, 9. [Google Scholar] [CrossRef] [PubMed]

- Favvas, E.P.; Katsaros, F.K.; Papageorgiou, S.K.; Sapalidis, A.A.; Mitropoulos, A.C. A Review of the Latest Development of Polyimide based Membranes for CO2 Separations. React. Funct. Polym. 2017, 120, 104–130. [Google Scholar] [CrossRef]

- Scholes, C.A.; Tao, W.X.; Stevens, G.W.; Kentish, S.E. Sorption of methane, nitrogen, carbon dioxide and water in matrimid 5218. J. Appl. Polym. Sci. 2010, 117, 2284–2289. [Google Scholar] [CrossRef]

- Dong, G.; Lia, H.; Chen, V. Challenges and opportunities for mixed-matrix membranes for gas separation. J. Mater. Chem. A 2013, 1, 4610–4630. [Google Scholar] [CrossRef]

- Karousos, D.S.; Lei, L.; Lindbråthen, A.; Sapalidis, A.A.; Kouvelos, E.P.; He, X.; Favvas, E.P. Cellulose-based carbon hollow fiber membranes for high-pressure mixed gas separation of CO2/CH4 and CO2/N2. Sep. Purif. Technol. 2020, 253, 117473. [Google Scholar] [CrossRef]

- Gantzel, P.K.; Merten, U. Gas separations with high-flux cellulose acetate membranes. Ind. Eng. Chem. Process Des. Dev. 1970, 9, 331–332. [Google Scholar] [CrossRef]

- Syrtsova, D.A.; Kharitonov, A.P.; Teplyakov, V.V.; Koops, G.-H. Improving gas separation properties of polymeric membranes based on glassy polymers by gas phase fluorination. Desalination 2004, 163, 273–279. [Google Scholar] [CrossRef]

- Kim, S.; Pechar, T.W.; Marand, E. Poly(imide siloxane) and carbon nanotube mixed matrix membranes for gas separation. Desalination 2006, 192, 330–339. [Google Scholar] [CrossRef]

- Favvas, E.P.; Romanos, G.E.; Papageorgiou, S.K.; Katsaros, F.K.; Mitropoulos, A.C.; Kanellopoulos, N.K. A Methodology for the morphological and physicochemical characterisation of asymmetric carbon hollow fiber membranes. J. Membr. Sci. 2011, 375, 113–123. [Google Scholar] [CrossRef]

- Favvas, E.P.; Heliopoulos, N.S.; Papageorgiou, S.K.; Mitropoulos, A.C.; Kapantaidakis, G.C.; Kanellopoulos, N.K. Helium and hydrogen selective carbon hollow fiber membranes: The effect of pyrolysis isothermal time. Sep. Purif. Technol. 2015, 142, 176–181. [Google Scholar] [CrossRef]

- Sazali, N.; Salleh, W.N.W.; Ismail, A.F.; Ismail, N.H.; Aziz, F.; Yusof, N.; Hasbullah, H. Effect of stabilization temperature during pyrolysis process of P84 co-polyimide-based tubular carbon membrane for H2/N2 and He/N2 separations. IOP Conf. Ser. Mater. Sci. Eng. 2018, 342, 012027. [Google Scholar] [CrossRef]

- Sazali, N.; Salleh, W.N.W.; Ismail, A.F.; Kadirgama, K.; Othman, F.E.C. P84 Co-Polyimide Based-Tubular Carbon Membrane: Effect of Heating Rates on Helium Separations. Solid State Phenom. 2018, 280, 308–311. [Google Scholar] [CrossRef]

- Ma, X.; Li, Y.S.; Wei, X.; Kniep, J. Ultrathin Carbon Molecular Sieve Membrane for Propylene/Propane separation. AIChE 2016, 62, 491–499. [Google Scholar] [CrossRef]

- Nikolaeva, D.; Azcune, I.; Tanczyk, M.; Warmuzinski, K.; Jaschik, M.; Sandru, M.; Dahl, P.I.; Genua, A.; Loïs, S.; Sheridan, E.; et al. The performance of affordable and stable cellulose-based poly-ionic membranes in CO2/N2 and CO2/CH4 gas separation. J. Membr. Sci. 2018, 564, 552–561. [Google Scholar] [CrossRef]

- Vengatesan, M.; Wahab, M.A.; Kuppireddy, S.; Kakosimos, G.; Abdalla, O.; Favvas, E.; Reinalda, D.; Geuzebroek, F.; Abdala, A.; Karanikolos, G. Metal-Organic Framework—Based Mixed Matrix Membranes for Carbon Dioxide Separation: Recent Advances and Future Directions. Front. Chem. 2020, 8, 534. [Google Scholar]

- Kohl, A.L.; Nielsen, R.B. (Eds.) Chapter 2—Alkanolamines for hydrogen sulfide and carbon dioxide removal. In Gas Purification, 5th ed.; Gulf Professional Publishing: Houston, TX, USA, 1997; pp. 40–186. [Google Scholar]

- Luis, P.; Van Gerven, T.; Van der Bruggen, B. Recent developments in membrane-based technologies for CO2 capture. Prog. Energy Combus. Sci. 2012, 38, 419–448. [Google Scholar] [CrossRef]

- Adewole, J.K.; Ahmad, A.L.; Ismail, S.; Leo, C.P. Current challenges in membrane separation of CO2 from natural gas: A review. Int. J. Greenh. Gas Control 2013, 17, 46–65. [Google Scholar] [CrossRef]

- Baker, R.W. Future directions of membrane gas separation technology. Ind. Eng. Chem. Res. 2002, 41, 1393–1411. [Google Scholar] [CrossRef]

- Baker, R.W. Membrane gas-separation: Applications. In Membrane Operations: Innovative Separations and Transformations; Drioli, E., Giorno, L., Eds.; Wiley-VCH Verlag GmbH & CoKGaA: Weinheim, Germany, 2009. [Google Scholar]

- Bernardo, P.; Drioli, E.; Golemme, G. Membrane Gas Separation: A Review / State of the Art. Ind. Eng. Chem. Res. 2009, 48, 4638–4663. [Google Scholar] [CrossRef]

- Yeom, C.K.; Lee, S.H.; Lee, J.M. Study of Transport of Pure and Mixed CO2/N2 Gases through Polymeric Membranes. J. Appl. Polym. Sci. 1999, 78, 179–189. [Google Scholar] [CrossRef]

- Scholes, C.A.; Bacus, J.; Chen, G.Q.; Tao, W.X.; Li, G.; Qader, A.; Stevens, G.W.; Kentish, S.E. Pilot plant performance of rubbery polymeric membranes for carbon dioxide separation from syngas. J. Membr. Sci. 2012, 389, 470–477. [Google Scholar] [CrossRef]

- Favvas, E.P.; Figoli, A.; Castro-Munoz, R.; Fila, V.; He, X. Chapter 1st “Polymeric membrane materials for CO2 separations”. In Current Trends and Future Developments on (Bio-) Membranes, 1st ed.; Carbon Dioxide Separation/Capture by Using Membranes; Elsevier: Amsterdam, The Netherlands, 2018; pp. 3–50. ISBN 9780128136454. [Google Scholar]

- Achoundong, C.S.K.; Bhuwania, N.; Burgess, S.K.; Karvan, O.; Johnson, J.R.; Koros, W.J. Silane Modification of Cellulose Acetate Dense Films as Materials for Acid Gas Removal. Macromolecules 2013, 46, 5584–5594. [Google Scholar] [CrossRef]

- Yi, S.; Ghanem, B.; Liu, Y.; Pinnau, I.; Koros, W.J. Ultraselective glassy polymer membranes with unprecedented performance for energy-efficient sour gas separation. Sci. Adv. 2019, 5, eaaw5459. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Yavari, M. Upper bound of polymeric membranes for mixed-gas CO2/CH4 separations. J. Membr. Sci. 2015, 475, 101–109. [Google Scholar] [CrossRef]

- Jeon, Y.-W.; Shin, M.-S. Separation of biogas using newly prepared cellulose acetate hollow fiber membranes. Energy Procedia 2017, 136, 219–224. [Google Scholar] [CrossRef]

- Pak, S.-H.; Jeon, Y.-W.; Shin, M.-S.; Koh, H.C. Preparation of Cellulose Acetate Hollow-Fiber Membranes for CO2/CH4 Separation. Environ. Eng. Sci. 2015, 33, 1–8. [Google Scholar]

- Mubashir, M.; Yeong, Y.F.; Lau, K.K.; Chew, T.L. Effect of spinning conditions on the fabrication of cellulose acetate hollow fiber membrane for CO2 separation from N2 and CH4. Polym. Test. 2019, 73, 1–11. [Google Scholar] [CrossRef]

- Mubashir, M.; Fong, Y.Y.; Leng, C.T.; Keong, L.K. Enhanced Gases Separation of Cellulose Acetate Membrane Using N-Methyl-1-2 Pyrrolidone as Fabrication Solvent. Int. J. Autom. Mech. Eng. 2018, 15, 4978–4986. [Google Scholar] [CrossRef]

- Salehi, A.A.; Ghannadi-Maragheh, M.; Torab-Mostaedi, M.; Torkaman, R.; Asadollahzadeh, M. A review on the water-energy nexus for drinking water production from humid air. Renew. Sust. Energy Rev. 2020, 120, 109627. [Google Scholar] [CrossRef]

- Antoniou, M.K.; Sapalidis, A.; Sideratou, Z. Functionalization of Carbon-Based Additives. In Membrane Desalination: From the Nanoscale to Real World Applications; Sapalidis, A.A., Ed.; CRC Press/Taylor and Francis Group: Abington, UK, 2021; pp. 91–123. ISBN 9780367030797. [Google Scholar]

- Yin, J.; Zhu, G.; Deng, B. Multi-walled carbon nanotubes (MWNTs)/polysulfone (PSU) mixed matrix hollow fiber membranes for enhanced water treatment. J. Membr. Sci. 2013, 437, 237–248. [Google Scholar] [CrossRef]

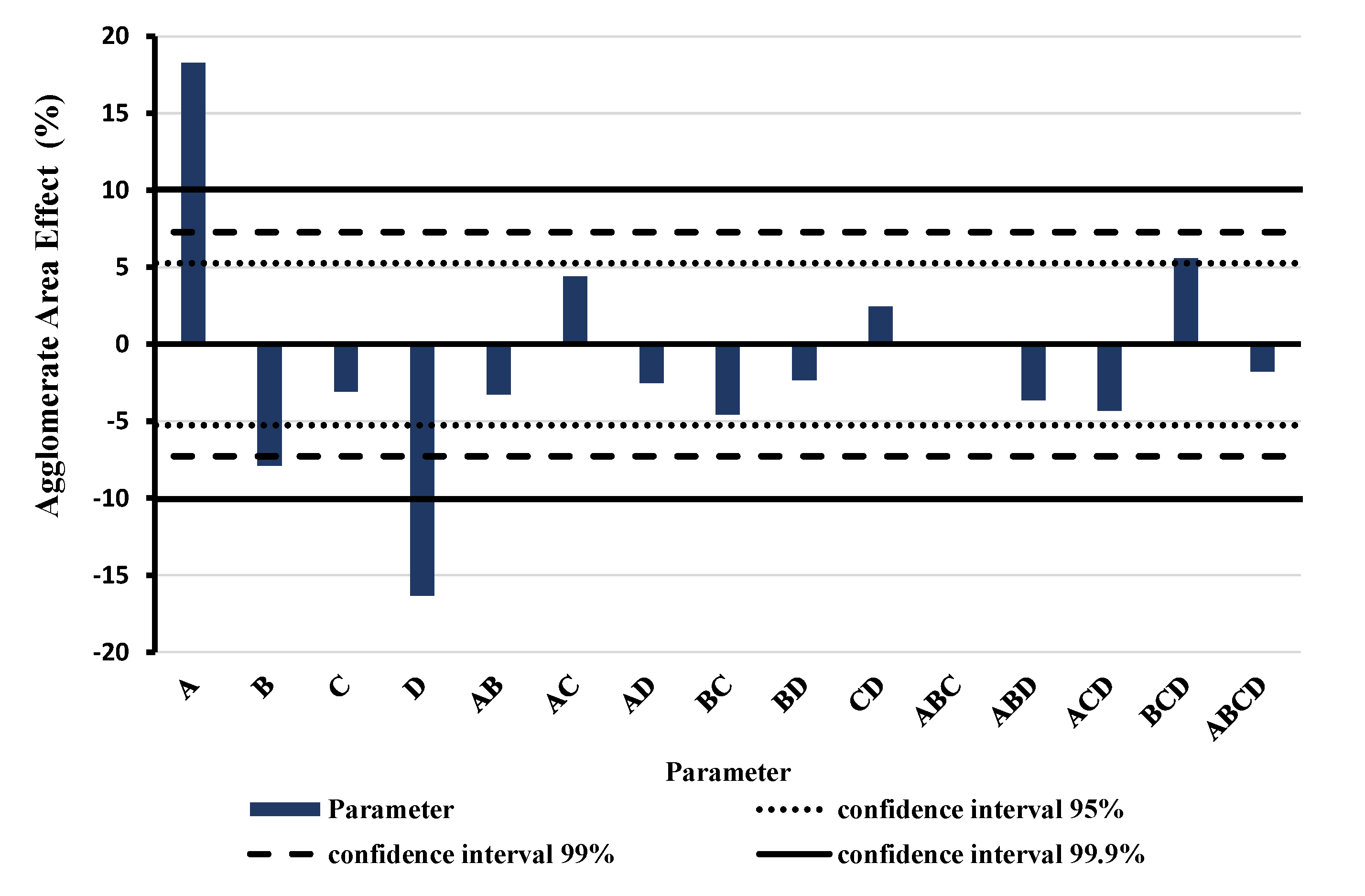

| Parameter | - | + |

|---|---|---|

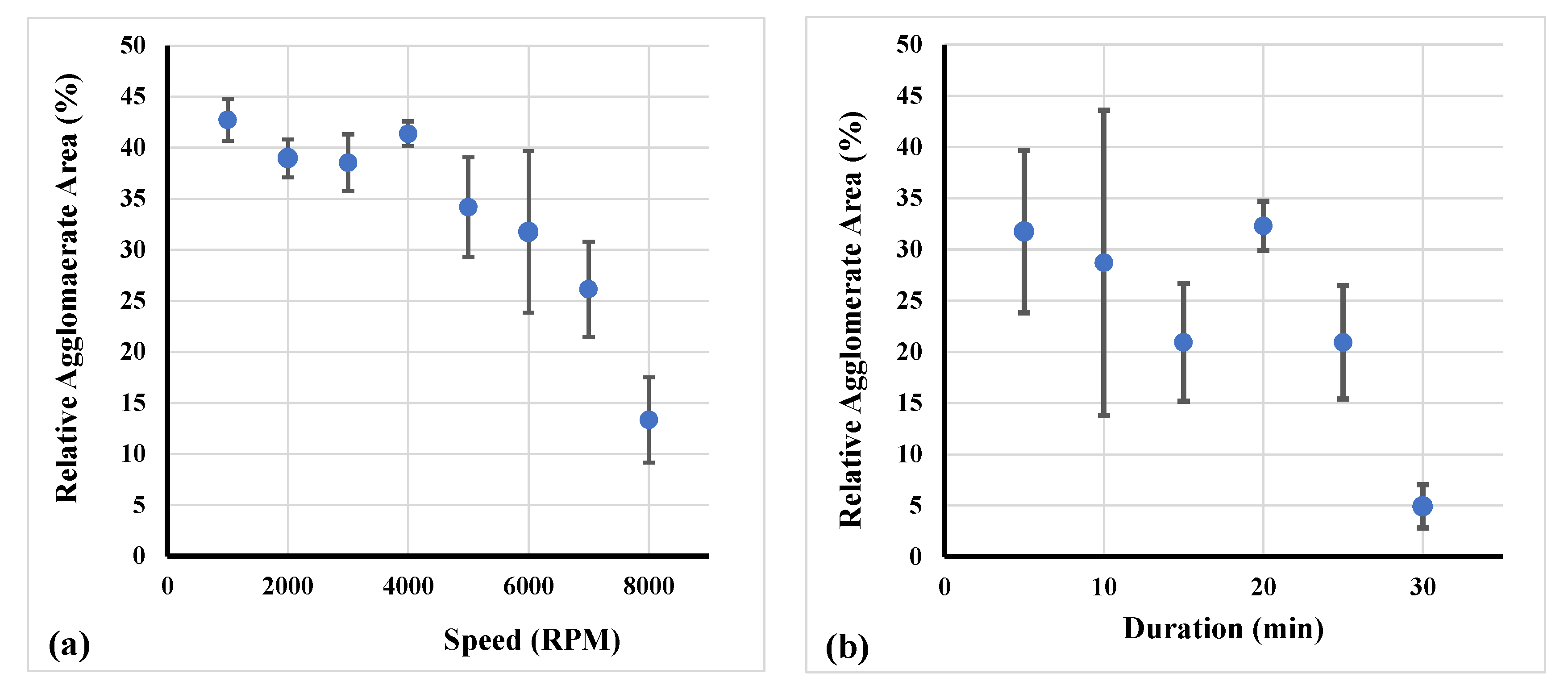

| Treatment duration (min) | 5 | 30 |

| Revolution speed (min−1) | 2000 | 6000 |

| Tool (geometry stator) | Emulsor screen (ES) | General purpose disintegrating head (MUSS) |

| MWCNTs weight concentration (%) * | 0.5 | 2 |

| CA weight concentration (%) | 5 | 10 |

| Parameter | - | + |

|---|---|---|

| Treatment duration (min) | 2.5 | 5 |

| Cycle (%) | 30 | 100 |

| MWCNTs weight concentration (%) * | 0.5 | 2 |

| CA weight concentration (%) | 5 | 10 |

| Parameter | Value |

|---|---|

| Roll gap (µm) | 10 |

| Revolution speed (min−1) | 450 |

| Roll temperature (°C) | 24 |

| MWCNTs weight concentration (%) * | 0.5–2 |

| CA weight concentration (%) | 10 |

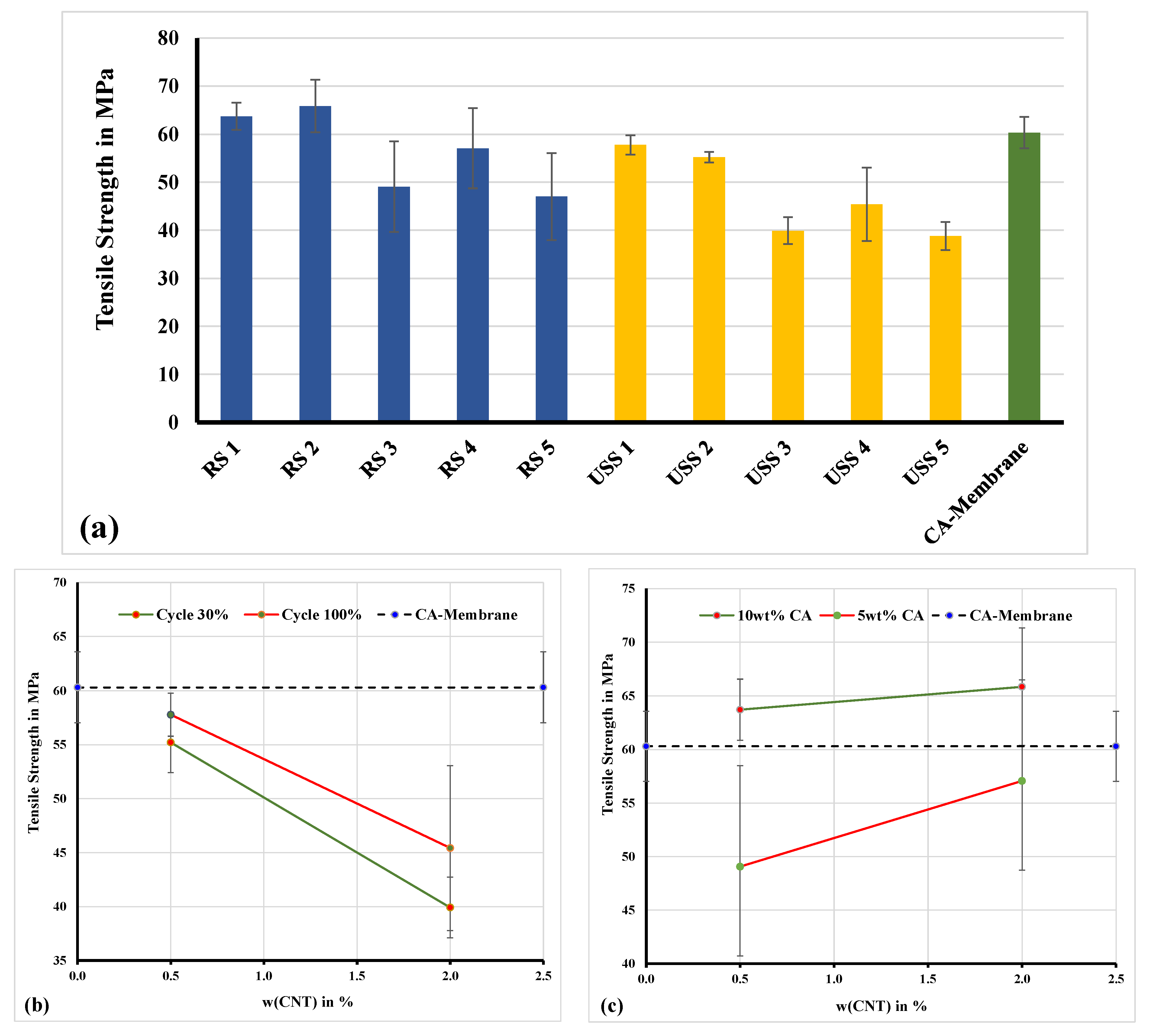

| Samples Prepared by Rotor-Stator System | |||||

| Sample | Method | CA Concentration (%) | MWCNTs Concentration (%) | Revolution Speed (min−1) | Duration (min) |

| RS1 | RS (ES) | 10 | 0.5 | 6000 | 30 |

| RS2 | RS (MUSS) | 10 | 2.0 | 6000 | 30 |

| RS3 | RS (MUSS) | 5 | 0.5 | 6000 | 30 |

| RS4 | RS (ES) | 5 | 2.0 | 6000 | 30 |

| RS5 | RS (MUSS) | 5 | 0.5 | 2000 | 5 |

| Samples Prepared by Ultrasonification | |||||

| Sample | Method | CA Concentration (%) | MWCNTs Concentration (%) | Cycle (%) | Duration (min) |

| USS1 | USS | 5.0 | 0.5 | 100 | 2.5 |

| USS2 | USS | 10.0 | 0.5 | 30 | 2.5 |

| USS3 | USS | 10.0 | 2.0 | 30 | 5 |

| USS4 | USS | 10.0 | 2.0 | 100 | 2.5 |

| USS5 | USS | 5.0 | 2.0 | 100 | 5 |

| USS6 | USS | 10.0 | 0.5 | 100 | 5 |

| USS7 | USS | 10.0 | 2.0 | 100 | 2.5 |

| Sample | Water Permeability (L/(h·m2·bar)) | Water Permeability Decrease (%) |

|---|---|---|

| CA-Membrane | 109 | -- |

| RS1 | 36 | 67 |

| RS2 | 38 | 65 |

| USS1 | 23 | 79 |

| USS2 | 27 | 75 |

| USS3 | 12 | 89 |

| USS6 | 19 | 83 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Esser, T.; Wolf, T.; Schubert, T.; Benra, J.; Forero, S.; Maistros, G.; Barbe, S.; Theodorakopoulos, G.V.; Karousos, D.S.; Sapalidis, A.A.; et al. CO2/CH4 and He/N2 Separation Properties and Water Permeability Valuation of Mixed Matrix MWCNTs-Based Cellulose Acetate Flat Sheet Membranes: A Study of the Optimization of the Filler Material Dispersion Method. Nanomaterials 2021, 11, 280. https://doi.org/10.3390/nano11020280

Esser T, Wolf T, Schubert T, Benra J, Forero S, Maistros G, Barbe S, Theodorakopoulos GV, Karousos DS, Sapalidis AA, et al. CO2/CH4 and He/N2 Separation Properties and Water Permeability Valuation of Mixed Matrix MWCNTs-Based Cellulose Acetate Flat Sheet Membranes: A Study of the Optimization of the Filler Material Dispersion Method. Nanomaterials. 2021; 11(2):280. https://doi.org/10.3390/nano11020280

Chicago/Turabian StyleEsser, Tobias, Tobias Wolf, Tim Schubert, Jan Benra, Stefan Forero, George Maistros, Stéphan Barbe, George V. Theodorakopoulos, Dionysios S. Karousos, Andreas A. Sapalidis, and et al. 2021. "CO2/CH4 and He/N2 Separation Properties and Water Permeability Valuation of Mixed Matrix MWCNTs-Based Cellulose Acetate Flat Sheet Membranes: A Study of the Optimization of the Filler Material Dispersion Method" Nanomaterials 11, no. 2: 280. https://doi.org/10.3390/nano11020280

APA StyleEsser, T., Wolf, T., Schubert, T., Benra, J., Forero, S., Maistros, G., Barbe, S., Theodorakopoulos, G. V., Karousos, D. S., Sapalidis, A. A., & Favvas, E. P. (2021). CO2/CH4 and He/N2 Separation Properties and Water Permeability Valuation of Mixed Matrix MWCNTs-Based Cellulose Acetate Flat Sheet Membranes: A Study of the Optimization of the Filler Material Dispersion Method. Nanomaterials, 11(2), 280. https://doi.org/10.3390/nano11020280