Metal-Assisted Chemical Etching for Anisotropic Deep Trenching of GaN Array

Abstract

:1. Introduction

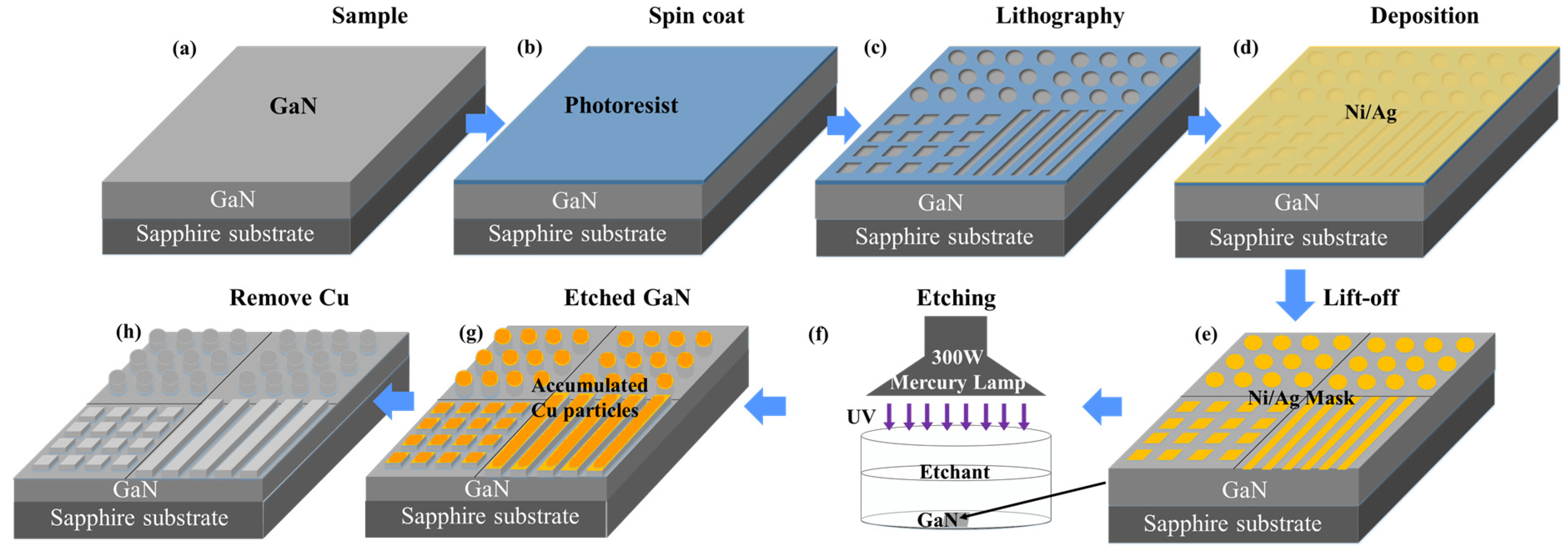

2. Materials and Methods

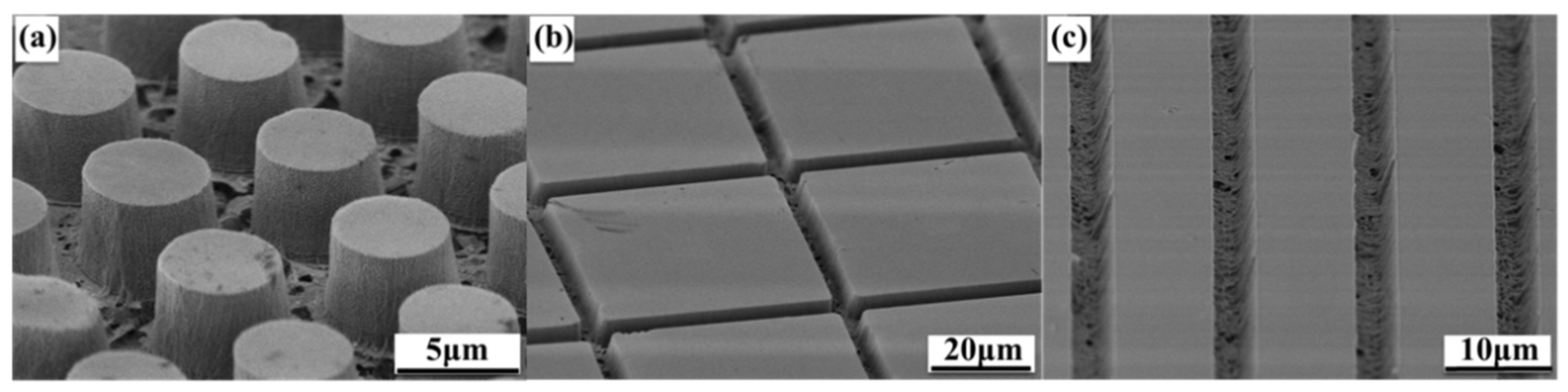

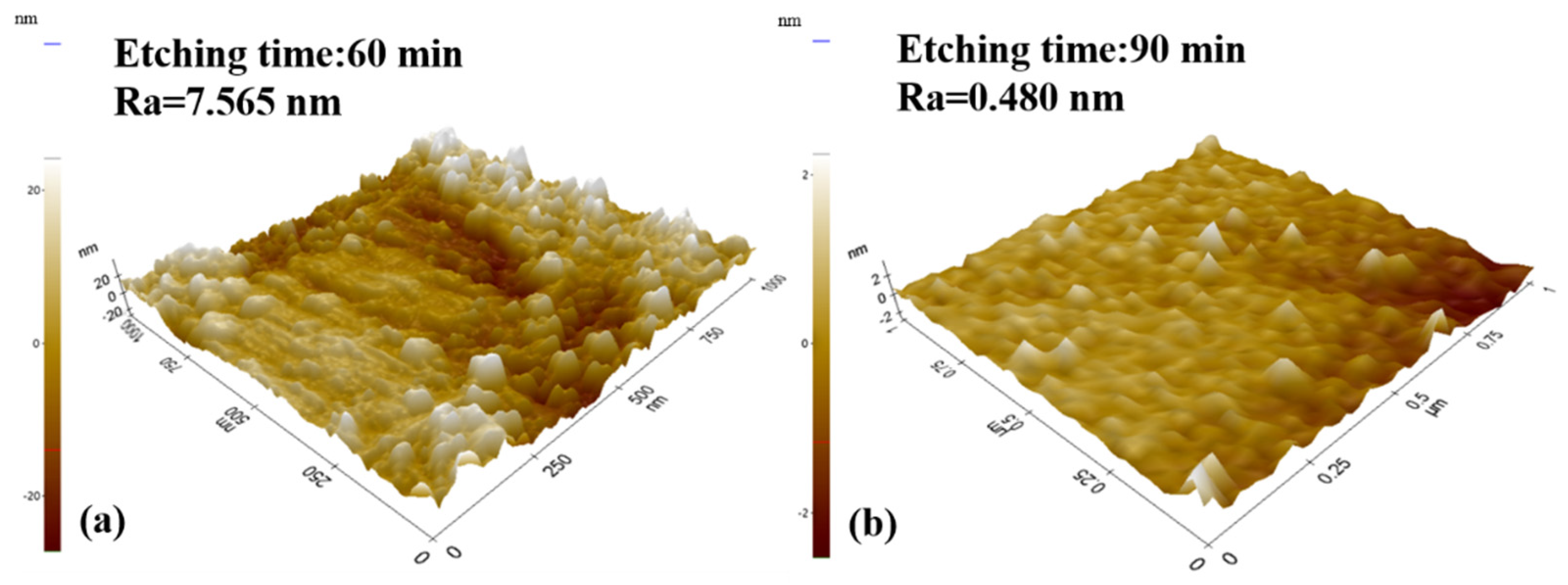

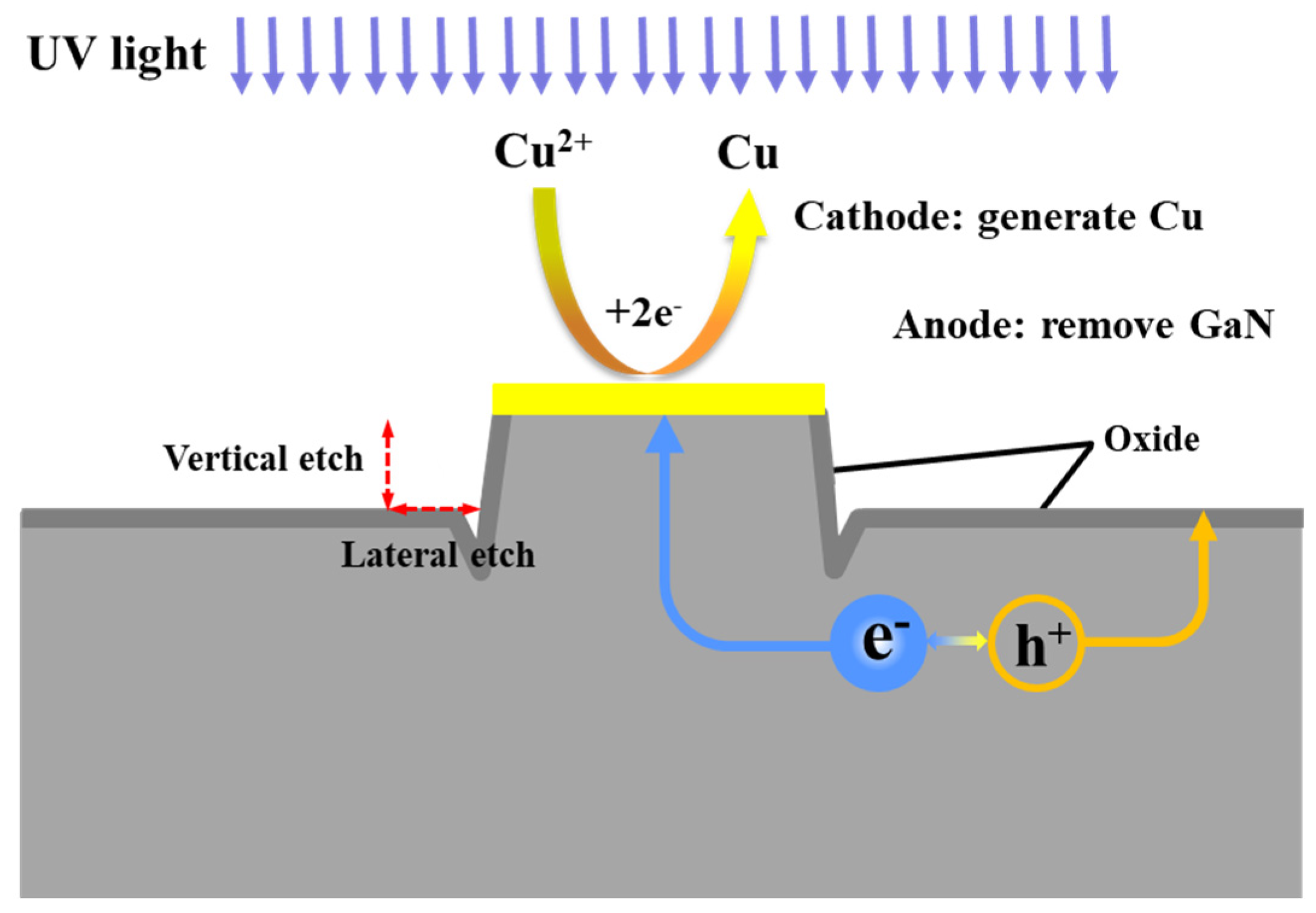

3. Results and Discussion

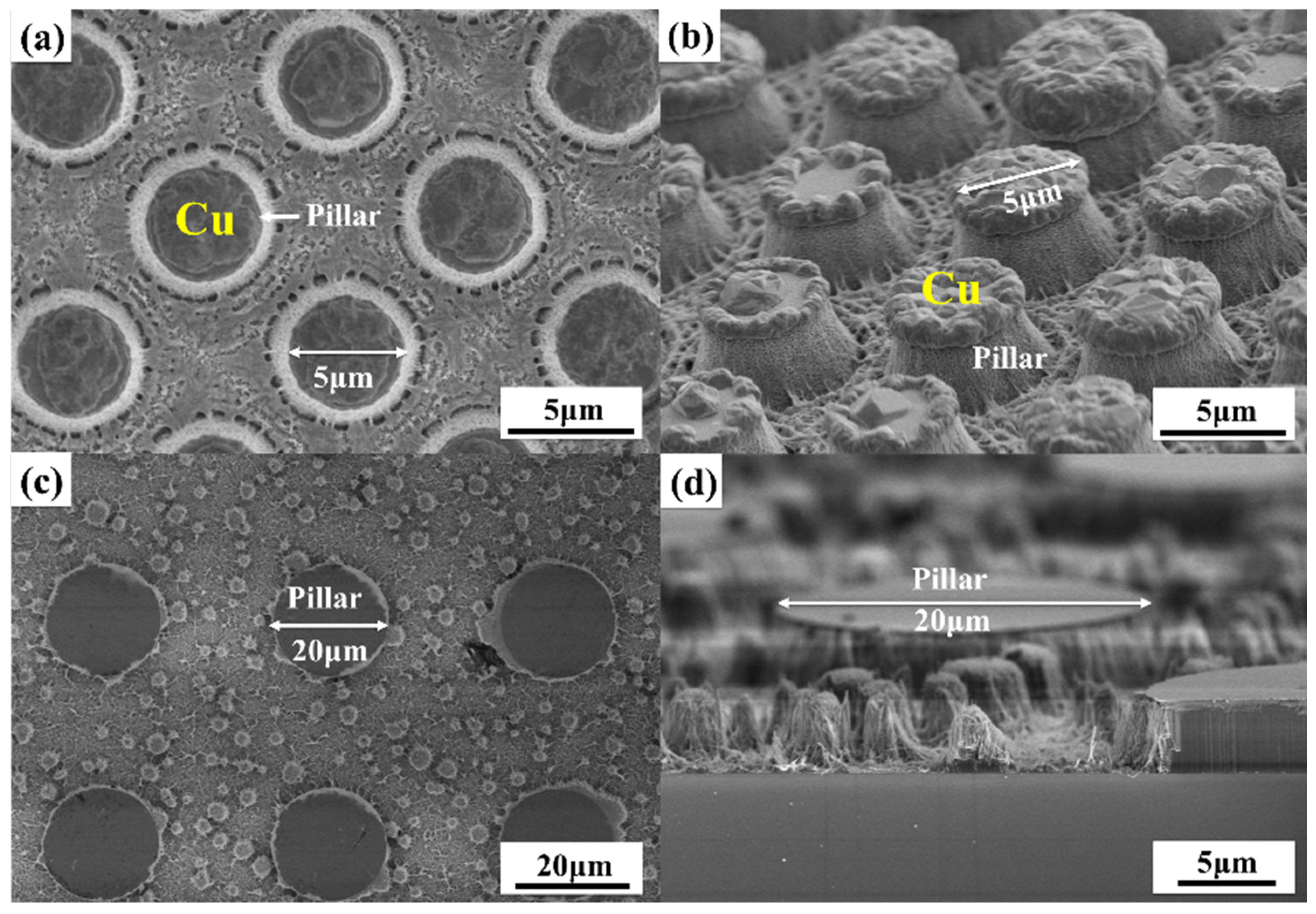

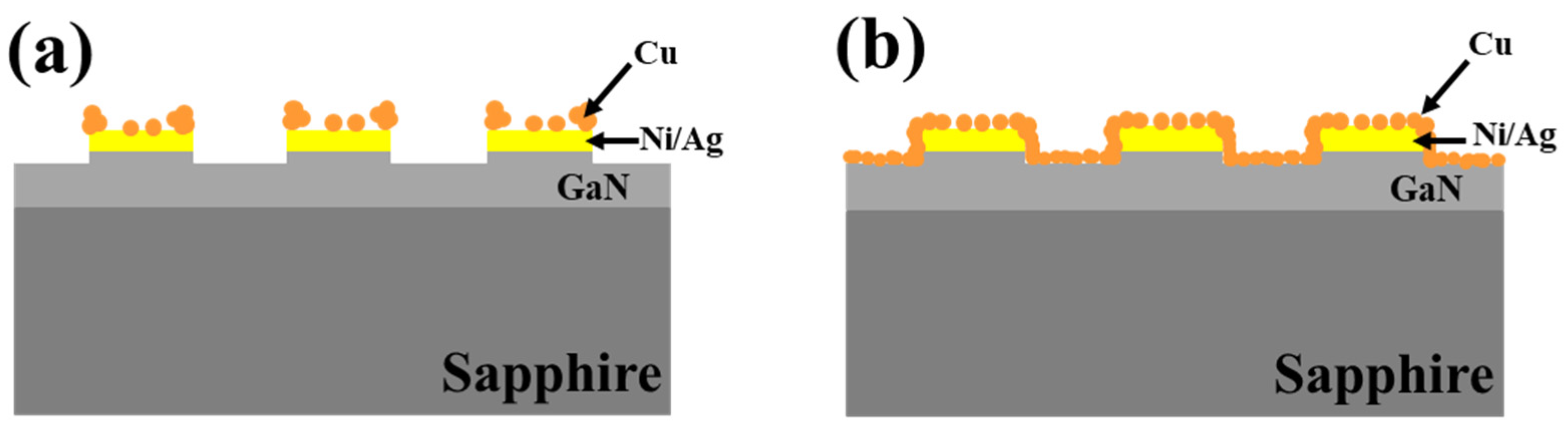

3.1. Selection of Mask Materials

3.2. Effect of HF Concentration on GaN MacEtch

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, S.; Yuan, G.; Wang, Q.; Liu, W.; Zhang, S.; Liu, Z.; Wang, J.; Li, J. Morphology control of c-Si via facile copper-assisted chemical etching: Managements on etch end-points. Appl. Surf. Sci. 2019, 489, 776. [Google Scholar] [CrossRef]

- Toor, F.; Miller, J.B.; Davidson, L.M.; Duan, W.; Jura, M.P.; Yim, J.; Forziati, J.; Black, M.R. Metal assisted catalyzed etched (MACE) black Si: Optics and device physics. Nanoscale 2016, 8, 15448. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Geyer, N.; Werner, P.; de Boor, J.; Gosele, U. Metal-assisted chemical etching of silicon: A review. Adv. Mater. 2011, 23, 285. [Google Scholar] [CrossRef] [PubMed]

- Wilhelm, T.S.; Wang, Z.; Baboli, M.A.; Yan, J.; Preble, S.F.; Mohseni, P.K. Ordered AlxGa1–xAs Nanopillar Arrays via Inverse Metal-Assisted Chemical Etching. ACS Appl. Mater. Interfaces 2018, 10, 27488. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Mohseni, P.K.; Song, Y.; Ishihara, T.; Li, X. Inverse metal-assisted chemical etching produces smooth high aspect ratio InP nanostructures. Nano Lett. 2015, 15, 641. [Google Scholar] [CrossRef] [PubMed]

- Geng, X.; Duan, B.K.; Grismer, D.A.; Zhao, L.; Bohn, P.W. Monodisperse GaN nanowires prepared by metal-assisted chemical etching with in situ catalyst deposition. Electrochem. Commun. 2012, 19, 39. [Google Scholar] [CrossRef]

- Miwa, K.; Komatsu, Y.; Toguchi, M.; Horikiri, F.; Fukuhara, N.; Narita, Y.; Ichikawa, O.; Isono, R.; Tanaka, T.; Sato, T. Self-termination of contactless photo-electrochemical (PEC) etching on aluminum gallium nitride/gallium nitride heterostructures. Appl. Phys. Express 2020, 13, 026508. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.R.; Hou, F.; Wang, Z.G.; Zhang, S.H.; Pan, G.B. Photoelectrochemical etching of gallium nitride surface by complexation dissolution mechanism. Appl. Surf. Sci. 2017, 410, 332. [Google Scholar] [CrossRef]

- Horikiri, F.; Fukuhara, N.; Ohta, H.; Asai, N.; Narita, Y.; Yoshida, T.; Mishima, T.; Toguchi, M.; Miwa, K.; Ogami, H.; et al. Thermal-assisted contactless photoelectrochemical etching for GaN. Appl. Phys. Express 2020, 13, 046501. [Google Scholar] [CrossRef]

- Asoh, H.; Suzuki, Y.; Ono, S. Metal-assisted chemical etching of GaAs using Au catalyst deposited on the backside of a substrate. Electrochim. Acta 2015, 183, 8. [Google Scholar] [CrossRef]

- Kong, L.; Song, Y.; Kim, J.D.; Yu, L.; Wasserman, D.; Chim, W.K.; Chiam, S.Y.; Li, X. Damage-Free Smooth-Sidewall InGaAs Nanopillar Array by Metal-Assisted Chemical Etching. ACS Nano 2017, 11, 10193. [Google Scholar] [CrossRef] [PubMed]

- Najar, A.; Shafa, M.; Anjum, D. Synthesis, optical properties and residual strain effect of GaN nanowires generated via metal-assisted photochemical electroless etching. RSC Adv. 2017, 7, 21697. [Google Scholar] [CrossRef] [Green Version]

- Horikiri, F.; Fukuhara, N.; Ohta, H.; Asai, N.; Narita, Y.; Yoshida, T.; Mishima, T.; Toguchi, M.; Miwa, K.; Sato, T. Simple wet-etching technology for GaN using an electrodeless photo-assisted electrochemical reaction with a luminous array film as the UV source. Appl. Phys. Express 2019, 12, 031003. [Google Scholar] [CrossRef] [Green Version]

- Tong, X.W.; Kong, W.Y.; Wang, Y.Y.; Zhu, J.M.; Luo, L.B.; Wang, Z.H. High-Performance Red-Light Photodetector Based on Lead-Free Bismuth Halide Perovskite Film. ACS Appl. Mater. Interfaces 2017, 9, 18977. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Zhou, K.; Sun, Q.; Liu, J.; Feng, M.; Li, Z.; Zhou, Y.; Zhang, L.; Li, D.; Zhang, S.; et al. Room-temperature continuous-wave electrically injected InGaN-based laser directly grown on Si. Nat. Photonics 2016, 10, 595. [Google Scholar] [CrossRef]

- Gao, J.; Jin, Y.; Hao, Y.; Xie, B.; Wen, C.P.; Shen, B.; Wang, M. Gate-Recessed Normally OFF GaN MOSHEMT With High-Temperature Oxidation/Wet Etching Using LPCVD Si3N4 as the Mask. IEEE Trans. Electron Dev. 2018, 65, 1728. [Google Scholar] [CrossRef]

- Sun, Y.; Kang, X.; Zheng, Y.; Wei, K.; Li, P.; Wang, W.; Liu, X.; Zhang, G. Optimization of Mesa Etch for a Quasi-Vertical GaN Schottky Barrier Diode (SBD) by Inductively Coupled Plasma (ICP) and Device Characteristics. Nanomaterials 2020, 10, 657. [Google Scholar] [CrossRef] [Green Version]

- Kochetkov, F.M.; Neplokh, V.; Mastalieva, V.A.; Mukhangali, S.; Vorob’ev, A.A.; Uvarov, A.V.; Komissarenko, F.E.; Mitin, D.M.; Kapoor, A.; Eymery, J.; et al. Stretchable Transparent Light-Emitting Diodes Based on InGaN/GaN Quantum Well Microwires and Carbon Nanotube Films. Nanomaterials 2021, 11, 1503. [Google Scholar] [CrossRef]

- Zhang, M.R.; Jiang, Q.M.; Zhang, S.H.; Wang, Z.G.; Hou, F.; Pan, G.B. Fabrication of gallium nitride nanowires by metal-assisted photochemical etching. Appl. Surf. Sci. 2017, 422, 216. [Google Scholar] [CrossRef]

- Aravindh, S.A.; Xin, B.; Mitra, S.; Roqan, I.S.; Najar, A. GaN and InGaN nanowires prepared by metal-assisted electroless etching: Experimental and theoretical studies. Results Phys. 2020, 19, 103428. [Google Scholar] [CrossRef]

- Huygens, I.M.; Strubbe, K.; Gomes, W.P. Electrochemistry and Photoetching of n-GaN. J. Electrochem. Soc. 2000, 147, 1797. [Google Scholar] [CrossRef]

- Zhuang, D.; Edgar, J.H. Wet etching of GaN, AlN, and SiC: A review. Mater. Sci. Eng. R 2005, 48, 1. [Google Scholar] [CrossRef]

- Wang, Q.; Yuan, G.; Zhao, S.; Liu, W.; Liu, Z.; Wang, J.; Li, J. Metal-assisted photochemical etching of GaN nanowires: The role of metal distribution. Electrochem. Commun. 2019, 103, 66. [Google Scholar] [CrossRef]

- Pearton, S.J.; Zolper, J.C.; Shul, R.J.; Ren, F. GaN: Processing, defects, and devices. J. Appl. Phys. 1999, 86, 1. [Google Scholar] [CrossRef]

- Chen, S.; Wang, L.W. Thermodynamic Oxidation and Reduction Potentials of Photocatalytic Semiconductors in Aqueous Solution. Chem. Mater. 2012, 24, 3659. [Google Scholar] [CrossRef] [Green Version]

- Geng, X.; Duan, B.K.; Grismer, D.A.; Zhao, L.; Bohn, P.W. Catalyst and processing effects on metal-assisted chemical etching for the production of highly porous GaN. Semicond. Sci. Technol. 2013, 28, 065001. [Google Scholar] [CrossRef]

- Sujatha, K.; Israel, S.; Anzline, C.; Devi, R.N.; Sheeba, R.A.J.R. X-ray derived experimental charge density distribution in GaF3 and VF3 solid systems. Phys. B Condens. Matter 2016, 496, 74. [Google Scholar] [CrossRef]

- Horikiri, F.; Ohta, H.; Asai, N.; Narita, Y.; Yoshida, T.; Mishima, T. Excellent potential of photo-electrochemical etching for fabricating high-aspect-ratio deep trenches in gallium nitride. Appl. Phys. Express 2018, 11, 091001. [Google Scholar] [CrossRef]

- Mokhov, D.V.; Berezovskaya, T.N.; Nikitina, E.V.; Shubina, K.Y.; Mizerov, A.M.; Bouravleuv, A.D. Metal-Assisted Photochemical Etching of N- and Ga-Polar GaN Epitaxial Layers. Semiconductors 2019, 53, 1717. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Zhou, K.; Zhao, S.; Yang, W.; Zhang, H.; Yan, W.; Huang, Y.; Yuan, G. Metal-Assisted Chemical Etching for Anisotropic Deep Trenching of GaN Array. Nanomaterials 2021, 11, 3179. https://doi.org/10.3390/nano11123179

Wang Q, Zhou K, Zhao S, Yang W, Zhang H, Yan W, Huang Y, Yuan G. Metal-Assisted Chemical Etching for Anisotropic Deep Trenching of GaN Array. Nanomaterials. 2021; 11(12):3179. https://doi.org/10.3390/nano11123179

Chicago/Turabian StyleWang, Qi, Kehong Zhou, Shuai Zhao, Wen Yang, Hongsheng Zhang, Wensheng Yan, Yi Huang, and Guodong Yuan. 2021. "Metal-Assisted Chemical Etching for Anisotropic Deep Trenching of GaN Array" Nanomaterials 11, no. 12: 3179. https://doi.org/10.3390/nano11123179

APA StyleWang, Q., Zhou, K., Zhao, S., Yang, W., Zhang, H., Yan, W., Huang, Y., & Yuan, G. (2021). Metal-Assisted Chemical Etching for Anisotropic Deep Trenching of GaN Array. Nanomaterials, 11(12), 3179. https://doi.org/10.3390/nano11123179