Characterization of 3D Printed Yttria-Stabilized Zirconia Parts for Use in Prostheses

Abstract

1. Introduction

2. Materials and Methods

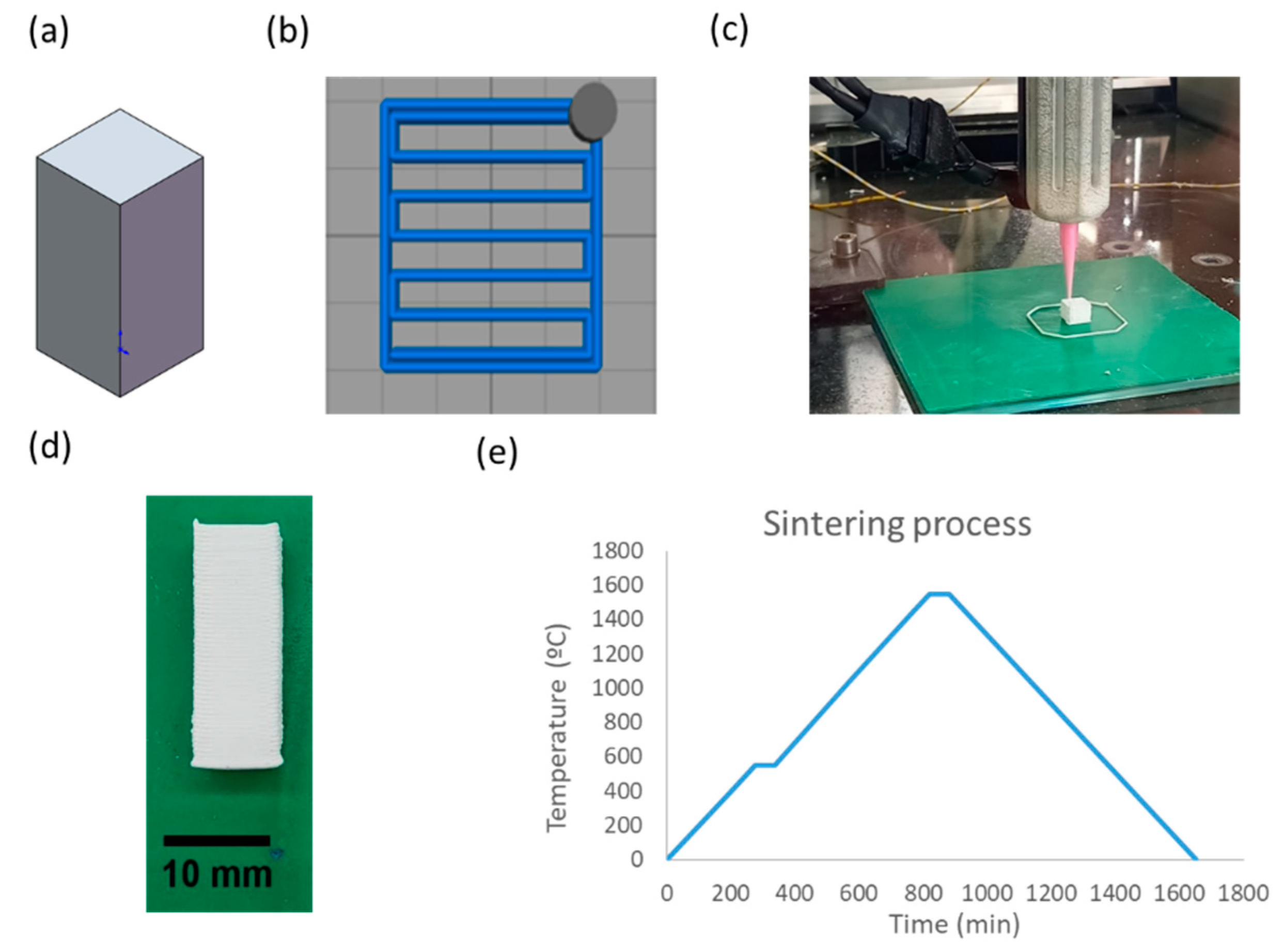

2.1. Zirconia Samples Preparation

2.2. 3D Printing and Sintering Process

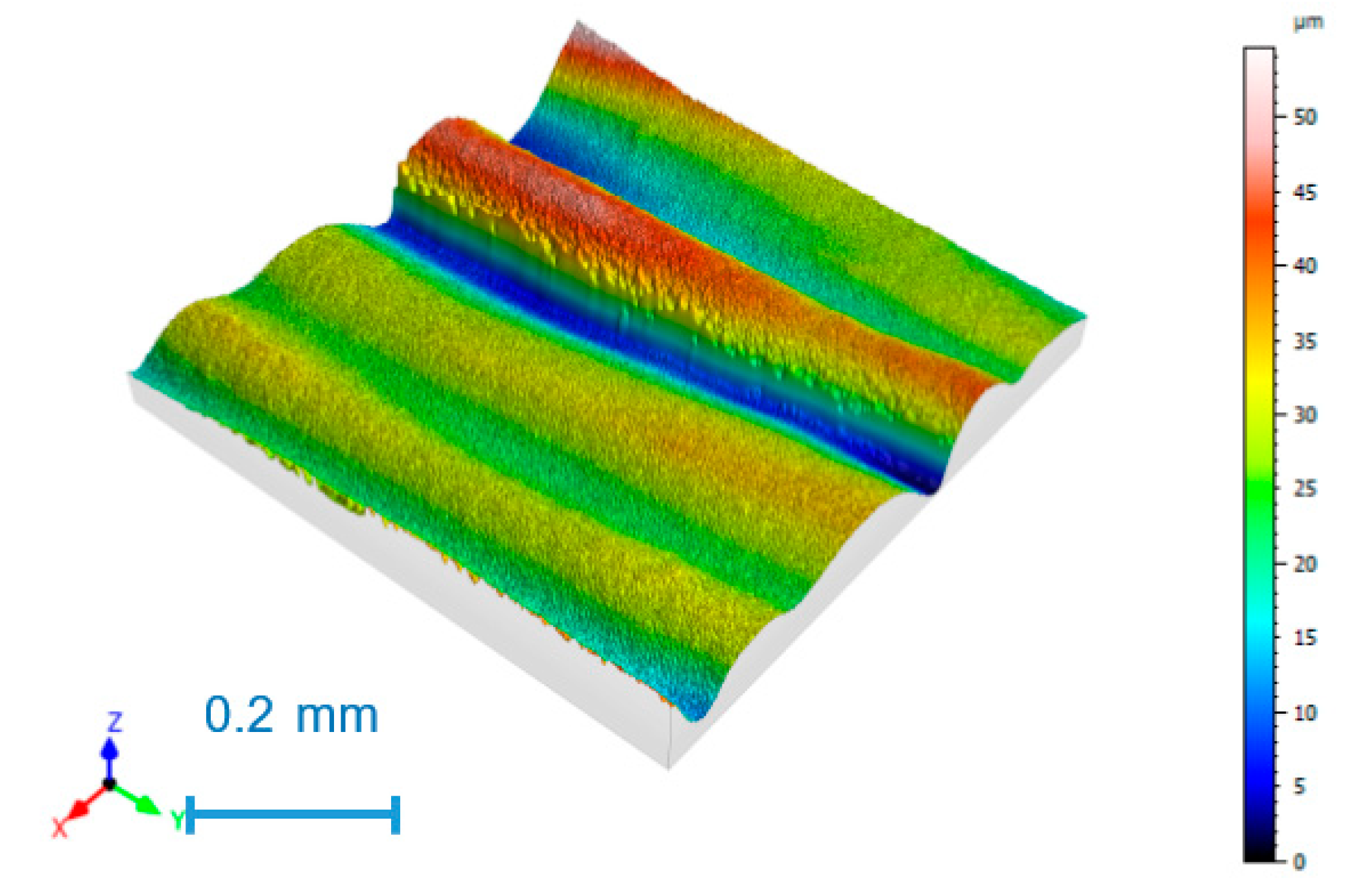

2.3. Areal Surface Roughness

2.4. Shrinkage Measurement

2.5. Total Porosity Measurement

2.6. Mechanical Characterization

2.7. Structural Analysis

3. Results

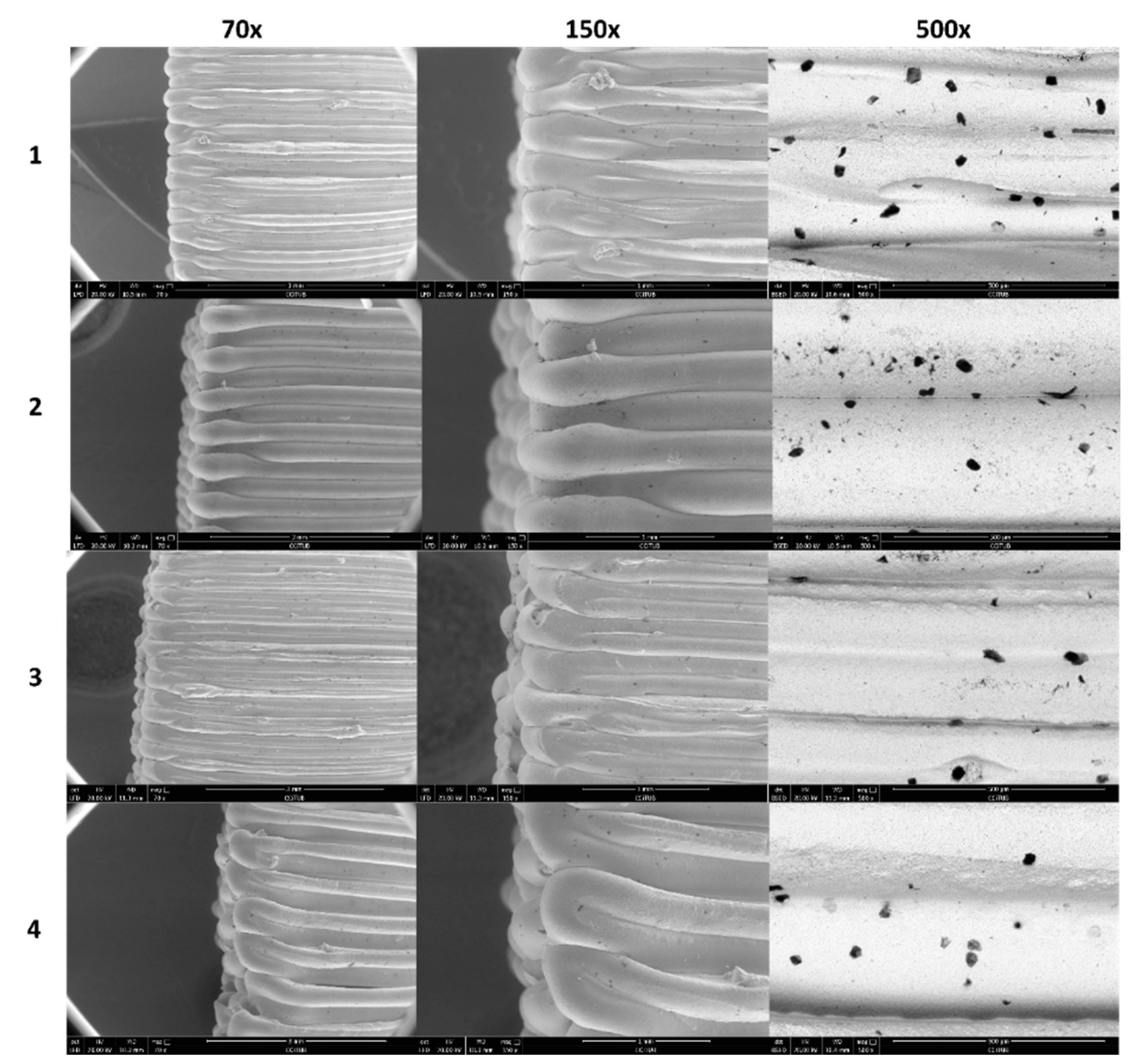

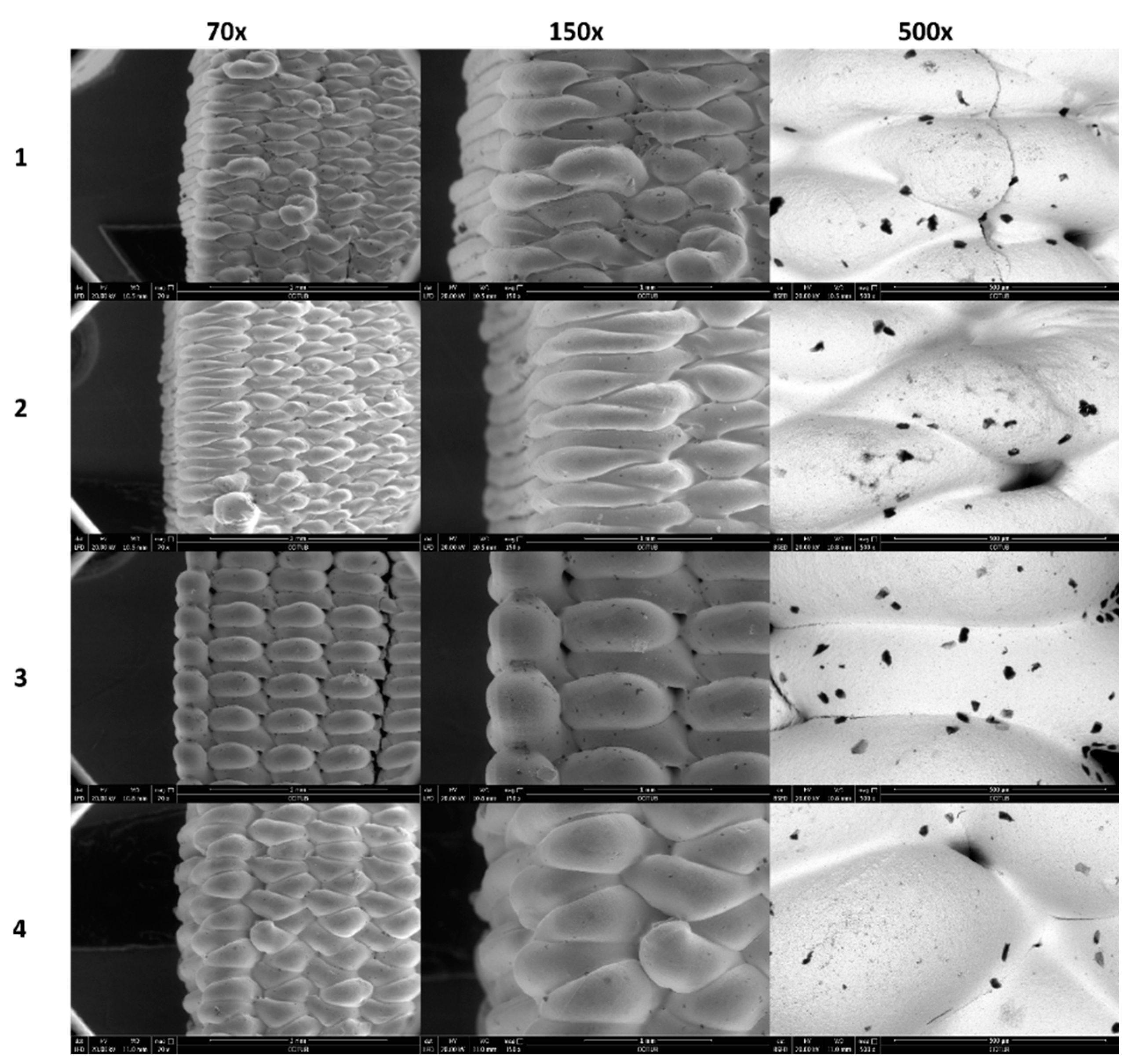

3.1. Surface Roughness

3.2. Shrinkage

3.3. Density and Total Porosity

3.4. Mechanical Strength

3.5. Structural Analysis

4. Discussion

5. Conclusions

- -

- Relatively low Sa values below 10 μm were obtained when combining low layer height and high speed. Layer height is the most important variable affecting roughness in this case.

- -

- Shrinkage in height was higher for samples obtained with high speed, while shrinkage in width was higher for samples with low speed. In all cases, shrinkage values exceeded 19% as is usual in zirconia specimens.

- -

- Total porosity ranged between 12.26% and 24.32%. The lowest mean porosity corresponds to the combination of low layer height and low speed. Layer height was the most influential variable on porosity in this case.

- -

- Compressive strength is directly related to the porosity of the parts. Compressive strength values up to 172 MPa were obtained when low layer height and low speed were employed. Further tests are required, with the use of higher ceramic load and/or higher nozzle diameter. However, the last option would imply the use of higher layer height and thus the surface finish of the lateral would worsen.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Piconi, C.; Maccauro, G. Zirconia as a ceramic biomaterial. Biomaterials 1999, 20, 1–25. [Google Scholar] [CrossRef]

- Helmer, J.D.; Driskell, T.D. Symposium on use of ceramics as surgical implants. In Proceedings of the Research on Bioceramics; Clemson Unviersity: Clemson, SC, USA, 1969. [Google Scholar]

- Garvie, R.C.; Nicholson, P.S. Phase Analysis in Zirconia Systems. J. Am. Ceram. Soc. 1972, 55, 303–305. [Google Scholar] [CrossRef]

- Cristache, C.M.; Burlibaşa, M.; Cristache, G.; Drafta, S.; Popovici, I.A.; Iliescu, A.A.; Zisi, S.; Burlibaşa, L. Zirconia and its biomedical applications. Metal. Int. 2011, 16, 18–23. [Google Scholar]

- Zhang, Y.; Zhu, J.; Wang, Z.; Zhou, Y.; Zhang, X. Constructing a 3D-printable, bioceramic sheathed articular spacer assembly for infected hip arthroplasty. J. Med. Hypotheses Ideas 2015, 9, 13–19. [Google Scholar] [CrossRef][Green Version]

- Kurtz, S.; Ong, K.; Lau, E.; Mowat, F.; Halpern, M. Projections of primary and revision hip and knee arthroplasty in the United States from 2005 to 2030. J. Bone Jt. Surg. Ser. A 2007, 89, 780–785. [Google Scholar] [CrossRef]

- Cao, Y.; Shi, T.; Jiao, C.; Liang, H.; Chen, R.; Tian, Z.; Zou, A.; Yang, Y.; Wei, Z.; Wang, C.; et al. Fabrication and properties of zirconia/hydroxyapatite composite scaffold based on digital light processing. Ceram. Int. 2020, 46, 2300–2308. [Google Scholar] [CrossRef]

- An, S.H.; Matsumoto, T.; Miyajima, H.; Nakahira, A.; Kim, K.H.; Imazato, S. Porous zirconia/hydroxyapatite scaffolds for bone reconstruction. Dent. Mater. 2012, 28, 1221–1231. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Liao, Y.; Wan, Q.; Li, W. Effects of sintering temperature and particle size on the translucency of zirconium dioxide dental ceramic. J. Mater. Sci. Mater. Med. 2011, 22, 2429–2435. [Google Scholar] [CrossRef] [PubMed]

- Gautam, C.; Joyner, J.; Gautam, A.; Rao, J.; Vajtai, R. Zirconia based dental ceramics: Structure, mechanical properties, biocompatibility and applications. Dalton Trans. 2016, 45, 19194–19215. [Google Scholar]

- Bearden, L.J.; Cooke, F.W. Growth inhibition of cultured fibroblasts by cobalt and nickel. J. Biomed. Mater. Res. 1980, 14, 289–309. [Google Scholar] [CrossRef] [PubMed]

- Bergman, M.; Bergman, B.; Söremark, R. Tissue accumulation of nickel released due to electrochemical corrosion of non-precious dental casting alloys. J. Oral Rehabil. 1980, 7, 325–330. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.W.; Moussi, J.; Drury, J.L.; Wataha, J.C. Zirconia in biomedical applications. Expert Rev. Med. Devices 2016, 13, 945–963. [Google Scholar] [CrossRef] [PubMed]

- ISO 13356: 2015. Implants for Surgery—Ceramic Materials Based on Yttria-Stabilized Tetragonal Zirconia (Y-TZP); International Organization for Standardization: Geneva, Switzerland, 2015; p. 24.

- Dall’Ava, L.; Hothi, H.; Di Laura, A.; Henckel, J.; Hart, A. 3D printed acetabular cups for total hip arthroplasty: A review article. Metals 2019, 9, 729. [Google Scholar] [CrossRef]

- ISO/ASTM INTERNATIONAL STANDARD ISO/ASTM 52900 Additive Manufacturing—General Principles—Terminology; International Organization for Standardization: Geneva, Switzerland, 2015; p. 19.

- Coppola, S.; Nasti, G.; Vespini, V.; Ferraro, P. Layered 3D Printing by Tethered Pyro-Electrospinning. Adv. Polym. Technol. 2020, 2020, 1–9. [Google Scholar] [CrossRef]

- D’Lima, D.D.; Lemperle, S.M.; Chen, P.C.; Holmes, R.E.; Colwell, C.W. Bone response to implant surface morphology. J. Arthroplast. 1998, 13, 928–934. [Google Scholar] [CrossRef]

- Muccillo, R.; Muccillo, E.N.S. An experimental setup for shrinkage evaluation during electric field-assisted flash sintering: Application to yttria-stabilized zirconia. J. Eur. Ceram. Soc. 2013, 33, 515–520. [Google Scholar] [CrossRef]

- Li, W.; Ghazanfari, A.; McMillen, D.; Leu, M.C.; Hilmas, G.E.; Watts, J. Characterization of zirconia specimens fabricated by ceramic on-demand extrusion. Ceram. Int. 2018, 44, 12245–12252. [Google Scholar] [CrossRef]

- Yu, T.; Zhang, Z.; Liu, Q.; Kuliiev, R.; Orlovskaya, N.; Wu, D. Extrusion-based additive manufacturing of yttria-partially-stabilized zirconia ceramics. Ceram. Int. 2020, 46, 5020–5027. [Google Scholar] [CrossRef]

- Shao, H.; Zhao, D.; Lin, T.; He, J.; Wu, J. 3D gel-printing of zirconia ceramic parts. Ceram. Int. 2017, 43, 13938–13942. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Domínguez-Fernández, A.; Gómez-Gejo, A. Effect of printing parameters on dimensional error and surface roughness obtained in direct ink writing (DIW) processes. Materials 2020, 13, 2157. [Google Scholar] [CrossRef]

- Léon y León, C.A. New perspectives in mercury porosimetry. Adv. Colloid Interface Sci. 1998, 76–77, 341–372. [Google Scholar] [CrossRef]

- Vitale-Brovarone, C.; Verné, E.; Robiglio, L.; Appendino, P.; Bassi, F.; Martinasso, G.; Muzio, G.; Canuto, R. Development of glass-ceramic scaffolds for bone tissue engineering: Characterisation, proliferation of human osteoblasts and nodule formation. Acta Biomater. 2007, 3, 199–208. [Google Scholar] [CrossRef] [PubMed]

- Radeva, V. Adaptando el método de Arquímedes para determinar las densidades y porosidades de muestras pequeñas de cerámica. Cienc. Soc. 2006, XXXI, 565–585. [Google Scholar] [CrossRef]

- Peng, E.; Wei, X.; Garbe, U.; Yu, D.; Edouard, B.; Liu, A.; Ding, J. Robocasting of dense yttria-stabilized zirconia structures. J. Mater. Sci. 2018, 53, 247–273. [Google Scholar] [CrossRef]

- Rashid, H. Comparing glazed and polished ceramic surfaces using confocal laser scanning microscopy. J. Adv. Microsc. Res. 2012, 7, 208–213. [Google Scholar] [CrossRef]

- Sul, Y.T.; Johansson, C.B.; Petronis, S.; Krozer, A.; Jeong, Y.; Wennerberg, A.; Albrektsson, T. Characteristics of the surface oxides on turned and electrochemically oxidized pure titanium implants up to dielectric breakdown: The oxide thickness, micropore configurations, surface roughness, crystal structure and chemical composition. Biomaterials 2002, 23, 491–501. [Google Scholar] [PubMed]

- Sakthiabirami, K.; Kang, J.H.; Jang, J.G.; Soundharrajan, V.; Lim, H.P.; Yun, K.D.; Park, C.; Lee, B.N.; Yang, Y.P.; Park, S.W. Hybrid porous zirconia scaffolds fabricated using additive manufacturing for bone tissue engineering applications. Mater. Sci. Eng. C 2021, 123, 111950. [Google Scholar] [CrossRef] [PubMed]

- Ziaee, F.; Zebarjad, S.M.; Javadpour, S. Compressive and flexural properties of novel polylactic acid/hydroxyapatite/yttria-stabilized zirconia hybrid nanocomposite scaffold. Int. J. Polym. Mater. Polym. Biomater. 2018, 67, 229–238. [Google Scholar] [CrossRef]

- Osman, R.B.; van der Veen, A.J.; Huiberts, D.; Wismeijer, D.; Alharbi, N. 3D-printing zirconia implants; a dream or a reality? An in-vitro study evaluating the dimensional accuracy, surface topography and mechanical properties of printed zirconia implant and discs. J. Mech. Behav. Biomed. Mater. 2017, 75, 521–528. [Google Scholar]

- Denry, I.; Kelly, J.R. State of the art of zirconia for dental applications. Dent. Mater. 2008, 24, 299–307. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Özcan, M.; Hallmann, L.; Ender, A.; Mehl, A.; Hämmerlet, C.H.F. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin. Oral Investig. 2013, 17, 269–274. [Google Scholar] [CrossRef]

- Hamadouche, M.; Sedel, L. Ceramics in orthopaedics. J. Bone Jt. Surg. Ser. B 2000, 82, 1095–1099. [Google Scholar] [CrossRef]

- Oonishi, H.; Wakitani, S.; Murata, N.; Saito, M.; Imoto, K.; Kim, S.; Matsuura, M. Clinical experience with ceramics in total hip replacement. Clin. Orthop. Relat. Res. 2000, 1, 77–84. [Google Scholar] [CrossRef]

- ISO 25178-6 Geometrical Product Specifications (GPS)-Surface Texture: Areal-Part 6: Classification of Methods for Measuring Surface texture; International Organization for Standardization: Geneva, Switzerland, 2010; p. 11.

- Markandan, K.; Tan, M.T.T.; Chin, J.; Lim, S.S. A novel synthesis route and mechanical properties of Si-O-C cured Yytria stabilised zirconia (YSZ)-graphene composite. Ceram. Int. 2015, 41, 3518–3525. [Google Scholar] [CrossRef]

- Hartcher-O’Brien, J.; Evers, J.; Tempelman, E. Surface roughness of 3D printed materials: Comparing physical measurements and human perception. Mater. Today Commun. 2019, 19, 300–305. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Domínguez-Fernández, A.; Durán-Llucià, R. Influence of print orientation on surface roughness in fused deposition modeling (FDM) processes. Materials 2019, 12, 3834. [Google Scholar] [CrossRef] [PubMed]

- Buj-Corral, I.; Bagheri, A.; Petit-Rojo, O. 3D Printing of Porous Scaffolds with Controlled Porosity and Pore Size Values. Materials 2018, 11, 1532. [Google Scholar] [CrossRef]

- Pérez, M.; Medina-Sánchez, G.; García-Collado, A.; Gupta, M.; Carou, D. Surface quality enhancement of fused deposition modeling (FDM) printed samples based on the selection of critical printing parameters. Materials 2018, 11, 1382. [Google Scholar]

- Peng, T.; Yan, F. Dual-objective Analysis for Desktop FDM Printers: Energy Consumption and Surface Roughness. Procedia CIRP 2018, 69, 106–111. [Google Scholar]

- You, D.H. Optimal printing conditions of PLA printing material for 3D printer. Trans. Korean Inst. Electr. Eng. 2016, 65, 825–830. [Google Scholar] [CrossRef]

- Sykaras, N.; Iacopino, A.M.; Marker, V.A.; Triplett, R.G.; Woody, R.D. Implant materials, designs, and surface topographies. Int. J. Oral Maxillofac. Implant. 2000, 15, 675–690. [Google Scholar]

- Saâdaoui, M.; Khaldoun, F.; Adrien, J.; Reveron, H.; Chevalier, J. X-ray tomography of additive-manufactured zirconia: Processing defects—Strength relations. J. Eur. Ceram. Soc. 2019, 40, 3200–3207. [Google Scholar] [CrossRef]

- Deng, Z.Y.; Yang, J.F.; Beppu, Y.; Ando, M.; Ohji, T. Effect of agglomeration on mechanical properties of porous zirconia fabricated by partial sintering. J. Am. Ceram. Soc. 2002, 85, 1961–1965. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, C.A.; Zhou, J.; Hong, Z. A novel way to fabricate highly porous fibrous YSZ ceramics with improved thermal and mechanical properties. J. Eur. Ceram. Soc. 2012, 32, 2213–2218. [Google Scholar] [CrossRef]

- Christiyan, K.G.J.; Chandrasekhar, U.; Venkateswarlu, K. A study on the influence of process parameters on the Mechanical Properties of 3D printed ABS composite. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012109. [Google Scholar] [CrossRef]

| Experiment Number | Print Speed (mm/s) | Layer Height (mm) |

|---|---|---|

| 1 (3–0.2) | 3 | 0.2 |

| 2 (3–0.4) | 3 | 0.4 |

| 3 (7–0.2) | 7 | 0.2 |

| 4 (7–0.4) | 7 | 0.4 |

| Experiment | Mean Sa (μm) | SD Sa (μm) |

|---|---|---|

| 1 (3–0.2) | 12.4 | 1.7 |

| 2 (3–0.4) | 24.6 | 3.5 |

| 3 (7–0.2) | 9.4 | 2.7 |

| 4 (7–0.4) | 20.2 | 2.9 |

| Experiment | Mean Width (mm) | SD Width (mm) | Mean Height (mm) | SD Height (mm) | Shrinkage in Width (%) | Shrinkage in Height (%) |

|---|---|---|---|---|---|---|

| 1 (3–0.2) | 6.49 | 0.20 | 15.99 | 0.42 | 27.99 | 20.05 |

| 2 (3–0.4) | 6.70 | 0.41 | 16.03 | 0.37 | 25.57 | 19.88 |

| 3 (7–0.2) | 6.96 | 0.41 | 15.24 | 0.56 | 22.70 | 23.80 |

| 4 (7–0.4) | 6.90 | 0.43 | 15.55 | 0.21 | 23.31 | 22.28 |

| Experiment | Mean Weight (g) | SD Weight (g) | Mean Density (g/cm3) | SD Density (g/cm3) | Mean Total Porosity (%) | SD Total Porosity (%) |

|---|---|---|---|---|---|---|

| 1 (3–0.2) | 3.35 | 0.13 | 4.98 | 0.05 | 12.36 | 0.90 |

| 2 (3–0.4) | 3.35 | 0.08 | 4.68 | 0.31 | 17.68 | 5.52 |

| 3 (7–0.2) | 3.21 | 0.43 | 4.25 | 0.38 | 18.84 | 6.77 |

| 4 (7–0.4) | 3.08 | 0.16 | 4.30 | 0.10 | 24.32 | 1.72 |

| Experiment | Compressive Strength (MPa) | SD Compressive Strength (MPa) |

|---|---|---|

| 1 (3–0.2) | 172 | 86 |

| 2 (3–0.4) | 134 | 19 |

| 3 (7–0.2) | 74 | 55 |

| 4 (7–0.4) | 60 | 14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buj-Corral, I.; Vidal, D.; Tejo-Otero, A.; Padilla, J.A.; Xuriguera, E.; Fenollosa-Artés, F. Characterization of 3D Printed Yttria-Stabilized Zirconia Parts for Use in Prostheses. Nanomaterials 2021, 11, 2942. https://doi.org/10.3390/nano11112942

Buj-Corral I, Vidal D, Tejo-Otero A, Padilla JA, Xuriguera E, Fenollosa-Artés F. Characterization of 3D Printed Yttria-Stabilized Zirconia Parts for Use in Prostheses. Nanomaterials. 2021; 11(11):2942. https://doi.org/10.3390/nano11112942

Chicago/Turabian StyleBuj-Corral, Irene, Daniel Vidal, Aitor Tejo-Otero, José Antonio Padilla, Elena Xuriguera, and Felip Fenollosa-Artés. 2021. "Characterization of 3D Printed Yttria-Stabilized Zirconia Parts for Use in Prostheses" Nanomaterials 11, no. 11: 2942. https://doi.org/10.3390/nano11112942

APA StyleBuj-Corral, I., Vidal, D., Tejo-Otero, A., Padilla, J. A., Xuriguera, E., & Fenollosa-Artés, F. (2021). Characterization of 3D Printed Yttria-Stabilized Zirconia Parts for Use in Prostheses. Nanomaterials, 11(11), 2942. https://doi.org/10.3390/nano11112942