Fabrication and Characterization of Waste Wood Cellulose Fiber/Graphene Nanoplatelet Carbon Papers for Application as Electromagnetic Interference Shielding Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of WWCF/GnP Papers and Their Carbon Papers

2.3. Analysis of WWCF/GnP Carbon Papers

3. Results and Discussion

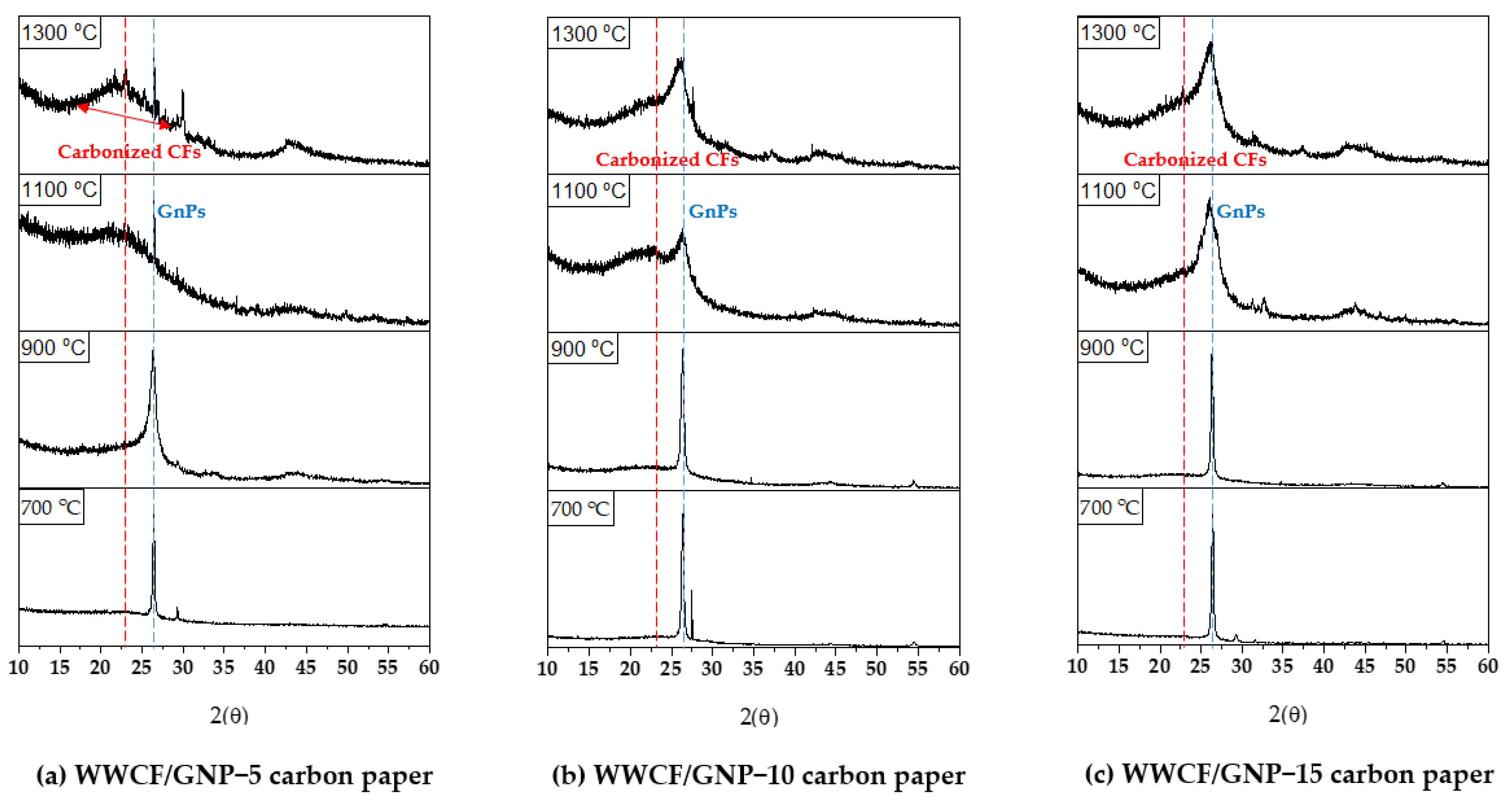

3.1. X-ray Diffraction Profiles and Raman Analysis

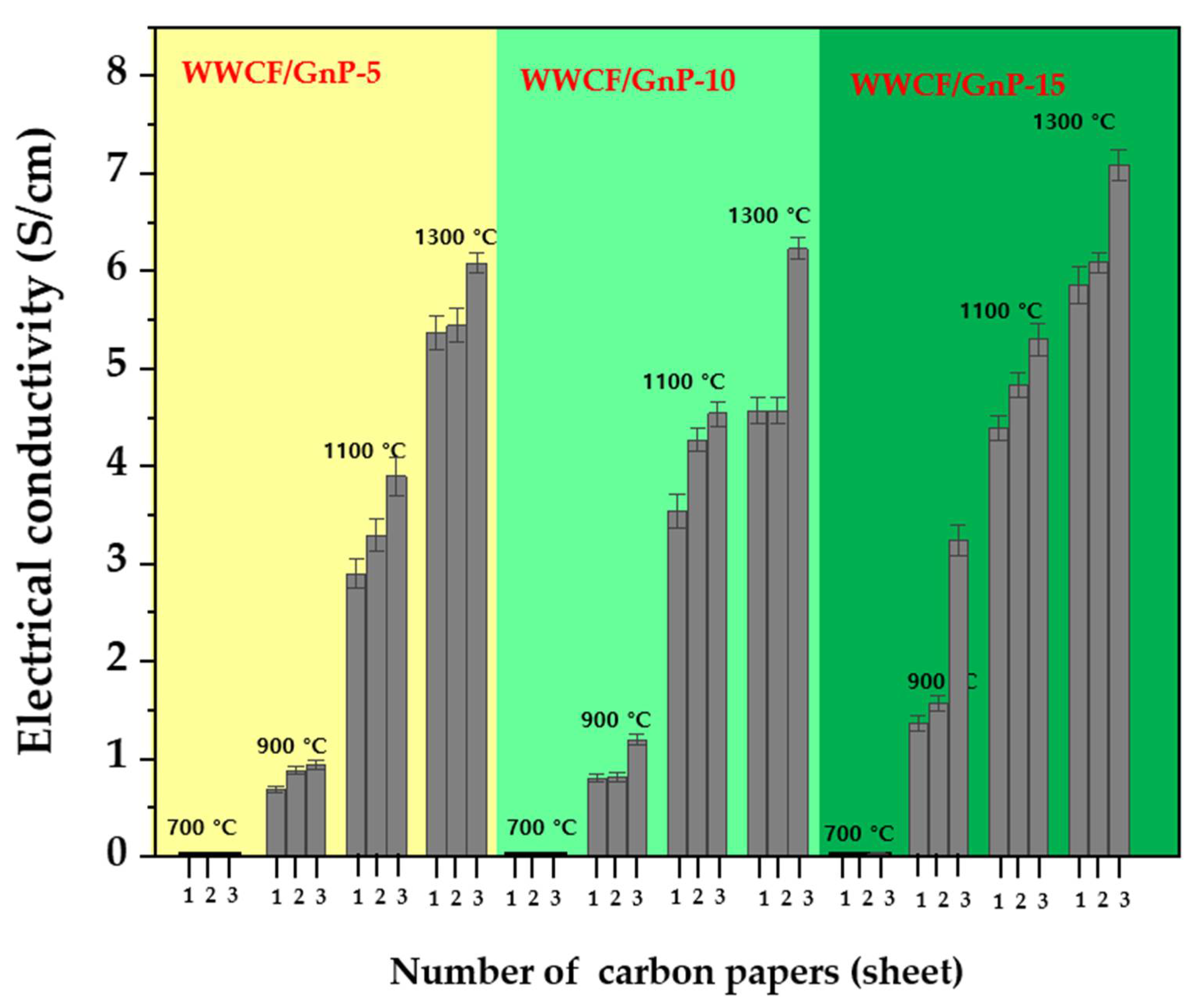

3.2. Electrical Conductivity

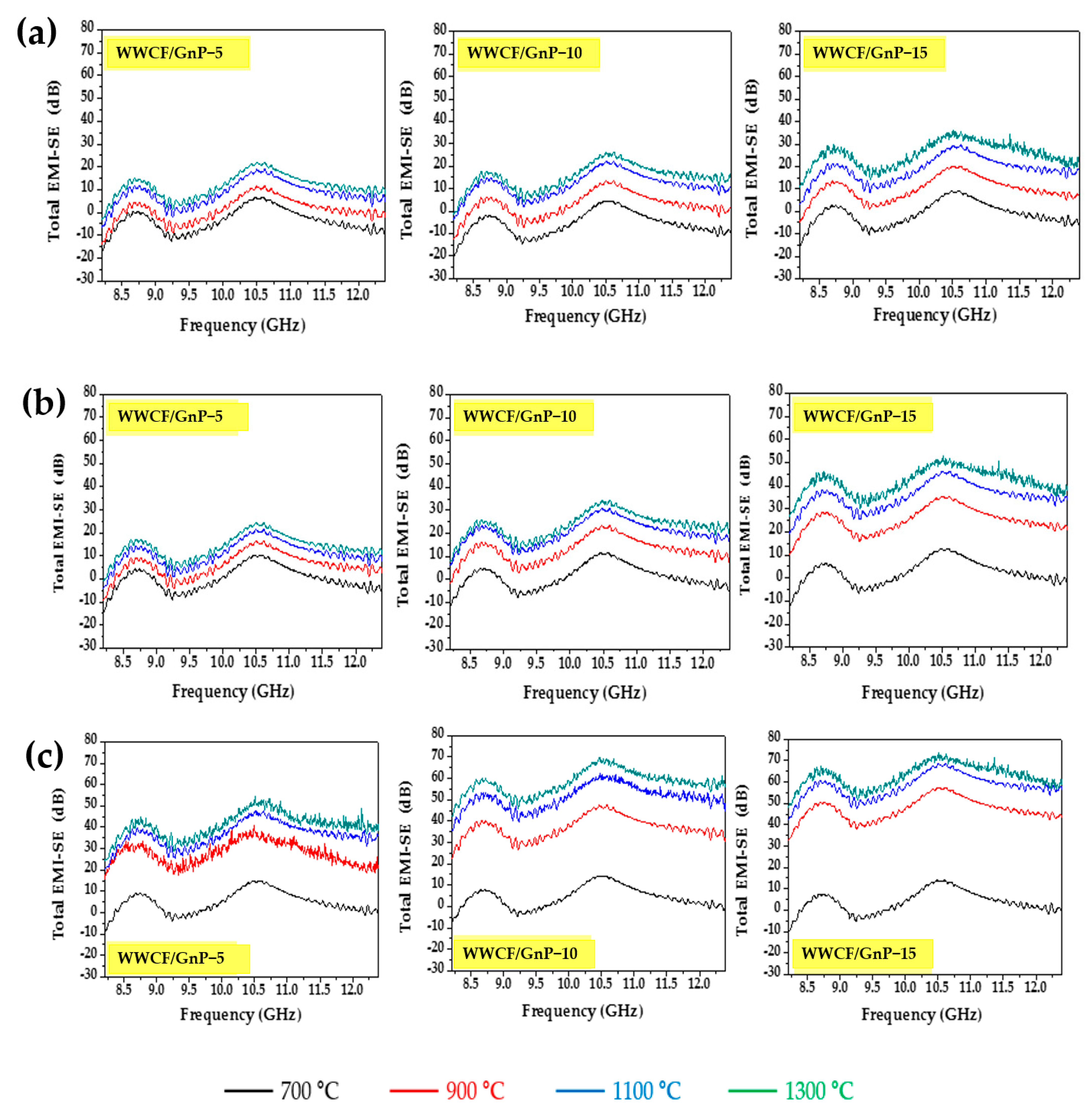

3.3. Electromagnetic Interference Shielding Effectiveness

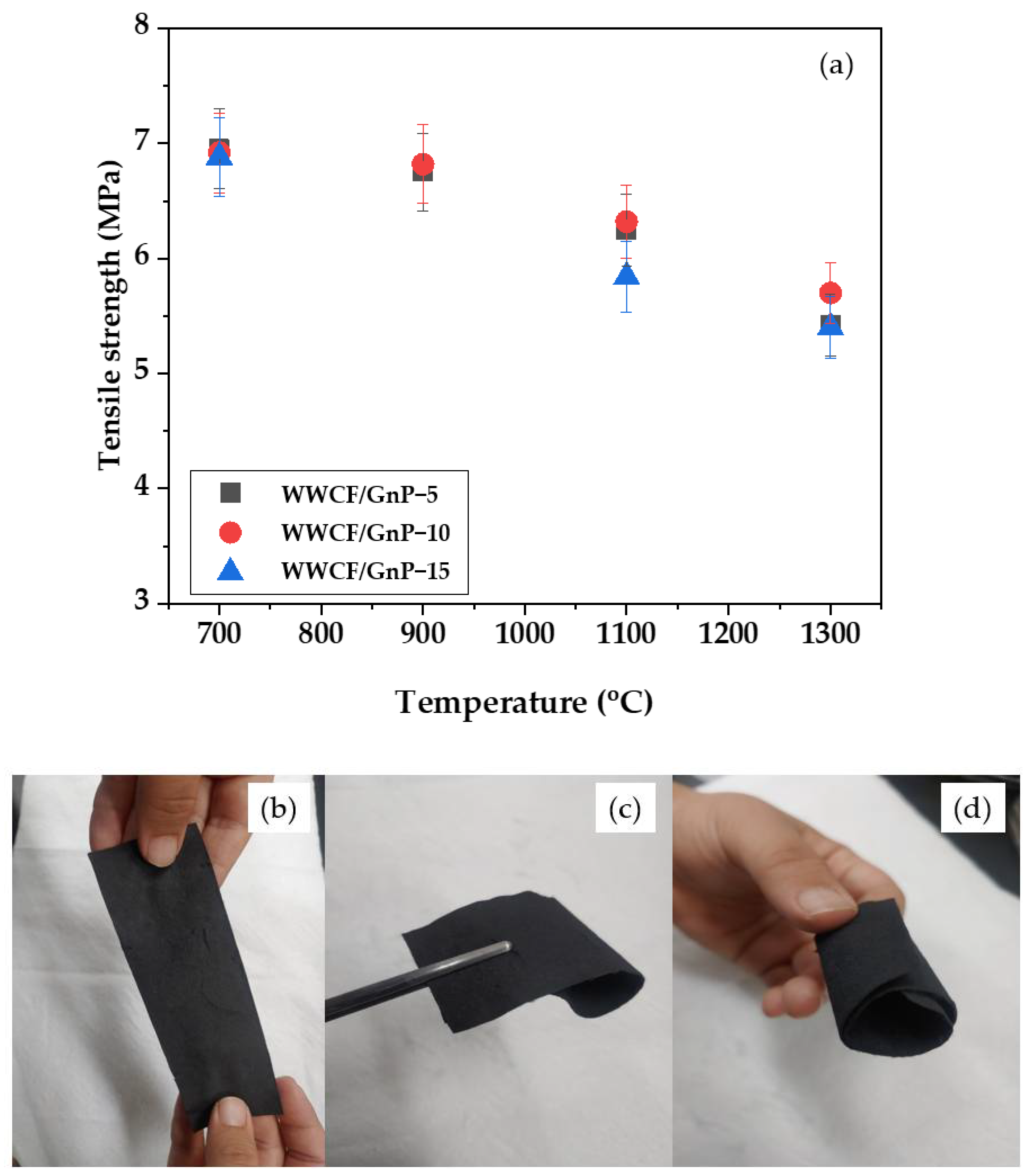

3.4. Mechanical Performance of WWCF/GnP Carbon Papers

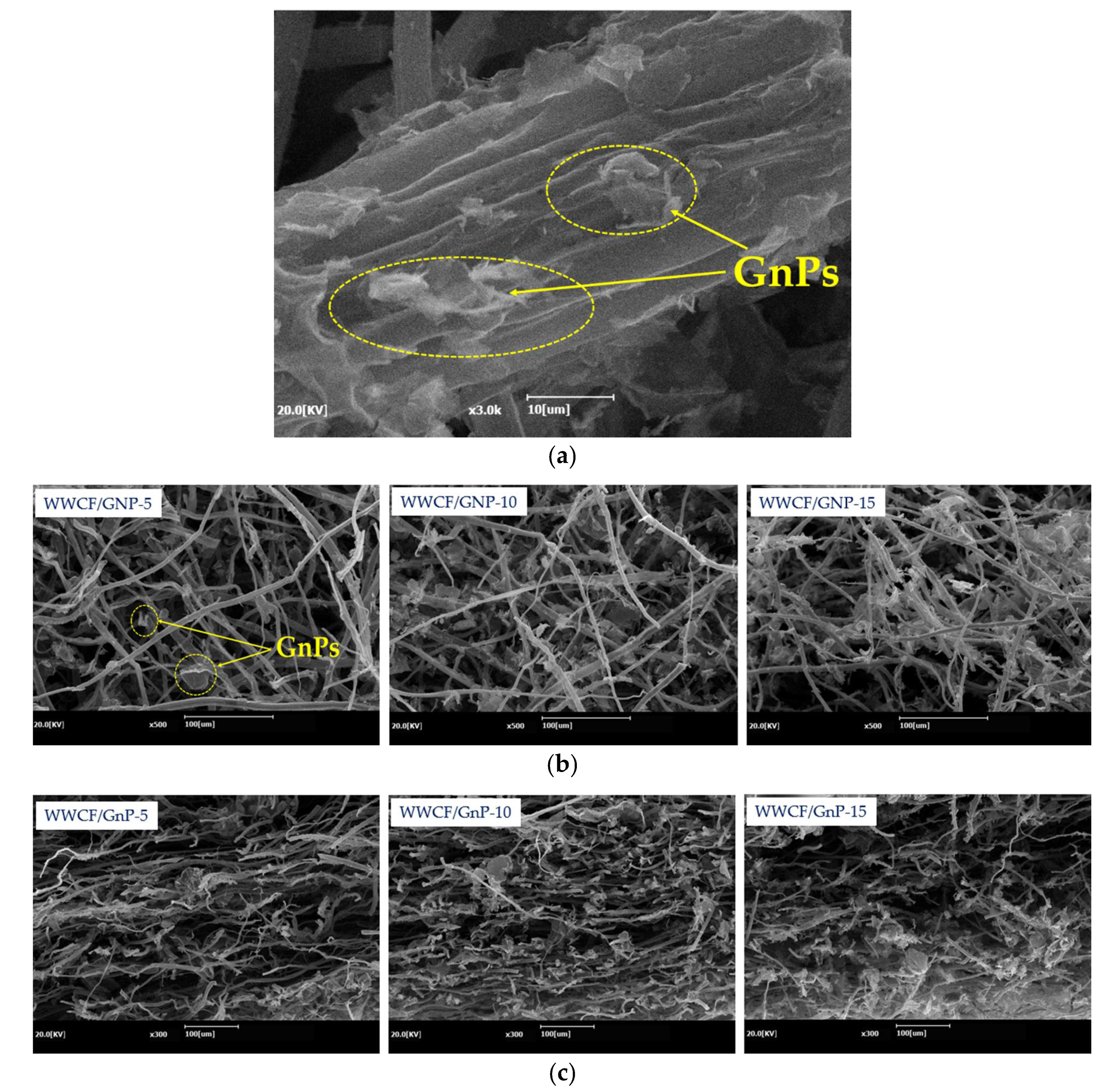

3.5. Morphology of WWCF/GnP Carbon Papers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Yu, I.K.M.; Tsang, D.C.W.; Li, S.; Poon, C.S. Mixture design and reaction sequence for recycling construction wood waste into rapid-shaping magnesia-phosphate cement particleboard. Ind. Eng. Chem. Res. 2017, 56, 6645–6654. [Google Scholar] [CrossRef]

- Hossain, M.U.; Wang, I.; Iris, K.M.; Tsang, D.S.; Poon, C.S. Environmental and technical feasibility study of upcycling wood waste into cement-bonded particle board. Constr. Build. Master. 2018, 173, 474–480. [Google Scholar] [CrossRef]

- Tsai, W.-T.; Wu, P.-H. Environmental concerns about carcinogenic air toxics produced from waste woods as alternative energy sources. Energy Sources A Recover. Util. Environ. Eff. 2013, 35, 725–732. [Google Scholar] [CrossRef]

- Mancini, M.; Rinnan, Å. Near infrared technique as a tool for the rapid assessment of waste wood quality for energy applications. Renew. Energy 2021, 177, 113–123. [Google Scholar] [CrossRef]

- Felton, C.C.; Groot, R.C. The recycling potential of preservative-treated wood. For. Prod. J. 1996, 46, 37–46. [Google Scholar]

- Humar, M.; Jermer, J.; Peek, R. Regulations in the European Union with emphasis on Germany, Sweden and Slovenia. Environ. Impacts Treat. Wood 2006, 6495, 37–57. [Google Scholar]

- Berger, F.; Gauvin, F.; Brouwers, H.J.H. The recycling potential of wood waste into wood-wool/cement composite. Constr. Build. Mater. 2020, 260, 119786. [Google Scholar] [CrossRef]

- Ince, C.; Tayançlı, S. Recycling waste wood in cement mortars towards the regeneration of sustainable environment. Constr. Build. Mater. 2021, 299, 123891. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fiber. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Kim, H.G.; Lee, U.S.; Kwac, L.K.; Lee, S.O.; Kim, Y.S.; Shin, H.K. Electron beam irradiation isolates cellulose nanofiber from Korea “Tall Goldenrod” invasive alien plant. Nanomaterials 2019, 9, 1358. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.G.; Kim, Y.S.; Kwac, L.K.; Shin, H.K. Characterization of activated carbon paper electrodes prepared by rice husk-isolated cellulose fibers for supercapacitor applications. Molecules 2020, 25, 3591. [Google Scholar] [CrossRef]

- Greetha, S.; Satheesh Kumar, K.K.; Rao, C.R.K.; Vijayan, M.; Trivedi, D.C. EMI shielding: Methods and materials-a review. J. Appl. Polym. Sci. 2009, 112, 2073–2086. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. Electromagnetic interference shielding mechanisms of CNT/polymer composites. Carbon 2009, 47, 1738–1746. [Google Scholar] [CrossRef]

- Maruthi, N.; Faisal, M.; Raghavendra, N. Conducting polymer based composites as efficient EMI shielding materials: A compressive review and future prospects. Synth. Met. 2021, 272, 116664. [Google Scholar] [CrossRef]

- Bhaskaran, K.; Bheema, R.K.; Etika, K.C. The influence of Fe3O4@GNP hybrids on enhancing the EMI shielding effectiveness of epoxy composites in the X-band. Synth. Met. 2020, 265, 116374. [Google Scholar] [CrossRef]

- Shui, X.; Chung, D.D.L. Magnetic properties of nickel filament polymer-matrix composites. J. Electron. Mater. 1996, 25, 930–934. [Google Scholar] [CrossRef]

- Chang, H.; Yeh, Y.-M.; Huang, K.-D. Electromagnetic shielding by composite films prepared with carbon fiber, Ni nanoparticles, and multi-walled carbon nanotubes in polyurethane. Mater. Trans. 2010, 51, 1145–1149. [Google Scholar] [CrossRef] [Green Version]

- Liu, P.; Ng, V.M.H.; Yao, Z.; Zhou, J.; Lei, Y.; Yang, Z.; Lv, H.; Kong, L.B. Facile synthesis and hierarchical assembly of flowerlike NiO structures with enhanced dielectric and microwave absorption properties. ACS Appl. Mater. Interfaces 2017, 9, 16404–16416. [Google Scholar] [CrossRef]

- Liu, P.; Yao, Z.; Ng, V.M.H.; Zhou, J.; Kong, L.B.; Yue, K. Facile synthesis of ultrasmall Fe3O4 nanoparticles on MXenes for high microwave absorption performance. Compos. Part A Appl. Sci. Manuf. 2018, 115, 371–382. [Google Scholar] [CrossRef]

- Yim, Y.J.; Lee, J.J.; Tugirumubano, A.; Go, S.H.; Kim, H.G.; Kwac, L.K. Electromagnetic interference shielding behavior of magnetic carbon fibers prepared by electroless FeCoNi-plating. Materials 2021, 14, 3774. [Google Scholar] [CrossRef]

- Madhusudhan, C.K.; Mahendra, K.; Madhukar, B.S.; Somesh, T.E.; Faisal, M. Incorporation of graphite into iron decorated polypyrrole for dielectric and EMI shielding applications. Synth. Met. 2020, 267, 116450. [Google Scholar] [CrossRef]

- Lee, S.H.; Yu, S.; Shahzad, F.; Hong, J.; Noh, S.J.; Kim, W.N.; Hong, S.M.; Koo, C.M. Low percolation 3D Cu and Ag shell network composites for EMI shielding and thermal conduction. Compos. Sci. Technol. 2019, 182, 107778. [Google Scholar] [CrossRef]

- Mei, H.; Zhao, X.; Gui, X.; Lu, D.; Han, D.; Xiao, S.; Cheng, L. SiC encapsulated Fe@CNT ultra-high absorptive shielding material for high temperature resistant EMI shielding. Ceram. Int. 2019, 45, 17144–17151. [Google Scholar] [CrossRef]

- Yazdi, M.K.; Noorbakhsh, B.; Nazari, B.; Ranjbar, Z. Preparation and EMI shielding performance of epoxy/non-metallic conductive fillers nano-composites. Prog. Org. Coat. 2020, 145, 105674. [Google Scholar] [CrossRef]

- Liao, S.Y.; Wang, X.Y.; Li, X.M.; Wan, Y.J.; Zhao, T.; Hu, Y.G.; Zhu, P.L.; Sun, R.; Wong, W.P. Flexible liquid metal/cellulose nanofiber composites film with excellent thermal reliability for highly efficient and broadband EMI shielding. Chem. Eng. J. 2021, 422, 129962. [Google Scholar] [CrossRef]

- Wang, A.; Zhang, X.; Chen, F.; Fu, Q. Aramid nanofiber framework supporting graphene nanoplate via wet-spinning for a high-performance filament. Carbon 2021, 179, 655–665. [Google Scholar] [CrossRef]

- Li, S.; Li, W.; Nie, J.; Liu, D.; Sui, G. Synergistic effect of graphene nanoplate and carbonized loofah fiber on the electromagnetic shielding effectiveness of PEEK-based composites. Carbon 2019, 143, 154–161. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Tang, M.; Zhou, L.; Li, J.; Fan, X.; Shi, X.; Qin, J. Synergistic effect of carbon nanotube and graphene nanoplates on the mechanical, electrical and electromagnetic interference shielding properties of polymer composites and polymer composite foams. Chem. Eng. J. 2018, 353, 381–393. [Google Scholar] [CrossRef]

- Shao, G.; Liu, P.; Zhang, K.; Li, W.; Chen, X.; Ma, F. Mechanical properties of graphene nanoplates reinforced copper matrix composites prepared by electrostatic self-assembly and spark plasma sintering. Mater. Sci. Eng. A 2019, 739, 329–334. [Google Scholar] [CrossRef]

- Rafiee, Z.; Mosahebfard, A.; Sheikhi, M.H. High-performance ZnO nanowires-based glucose biosensor modified by graphene nanoplates. Mater. Sci. Semicond. Process. 2020, 115, 105116. [Google Scholar] [CrossRef]

- Kashi, S.; Gupta, R.K.; Baum, T.; Kao, N.; Bhattacharya, S.N. Morphology, electromagnetic properties and electromagnetic interference shielding performance of poly lactide/graphene nanoplatelet nanocomposites. Mater. Des. 2016, 95, 119–126. [Google Scholar] [CrossRef]

- Bhosale, S.D.; Gaikwad, S.D.; Gadve, R.D.; Goyal, R.K. Synergistic effects of graphene nanoplatelets on X-band electromagnetic interference shielding, thermal expansion and thermal stability of poly (ether-ketone) based nanocomposites. Mater. Sci. Eng. B 2021, 265, 115038. [Google Scholar] [CrossRef]

- Aïssa, B.; Sinopoli, A.; Ali, A.; Zakaria, Y.; Zekri, A.; Helal, M.; Nedil, M.; Rosie, F.; Mansour, S.; Mahmoud, K.A. Nanoelectromagnetic of a highly conductive 2D transition metal carbide (MXene)/Graphene nanoplatelets composite in the EHF M-band frequency. Carbon 2021, 173, 528–539. [Google Scholar] [CrossRef]

- Liu, P.; Yao, Z.; Zhou, J.; Yang, Z.; Kong, L.B. Small magnetic Co-doped NiZn ferrite/graphene nanocomposites and their dual-region microwave absorption performance. J. Mater. Chem. 2016, 4, 9738–9749. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.; Kwac, L.K.; Kim, H.G.; Shin, H.K. Fabrication and Characterization of Waste Wood Cellulose Fiber/Graphene Nanoplatelet Carbon Papers for Application as Electromagnetic Interference Shielding Materials. Nanomaterials 2021, 11, 2878. https://doi.org/10.3390/nano11112878

Park J, Kwac LK, Kim HG, Shin HK. Fabrication and Characterization of Waste Wood Cellulose Fiber/Graphene Nanoplatelet Carbon Papers for Application as Electromagnetic Interference Shielding Materials. Nanomaterials. 2021; 11(11):2878. https://doi.org/10.3390/nano11112878

Chicago/Turabian StylePark, Jihyun, Lee Ku Kwac, Hong Gun Kim, and Hye Kyoung Shin. 2021. "Fabrication and Characterization of Waste Wood Cellulose Fiber/Graphene Nanoplatelet Carbon Papers for Application as Electromagnetic Interference Shielding Materials" Nanomaterials 11, no. 11: 2878. https://doi.org/10.3390/nano11112878