Effects of Multi-Components on the Microwave Absorption and Dielectric Properties of Plasma-Sprayed Carbon Nanotube/Y2O3/ZrB2 Ceramics

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Hong, S.M.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef] [Green Version]

- Iqbal, A.; Shahzad, F.; Hantanasirisakul, K.; Kim, M.K.; Kwon, J.; Hong, J.; Kim, H.; Kim, D.; Gogotsi, Y.; Koo, C.M. Anomalous absorption of electromagnetic waves by 2D transition metal carbonitride Ti3CNTx (MXene). Science 2020, 369, 446–450. [Google Scholar] [CrossRef]

- Lv, H.L.; Yang, Z.H.; Liu, B.; Wu, G.L.; Lou, Z.C.; Fei, B.; Wu, R.B. A flexible electromagnetic wave-electrivity harvester. Nat. Commun. 2021, 12, 834. [Google Scholar] [CrossRef]

- Li, X.; Li, M.H.; Lu, X.K.; Zhu, W.J.; Xu, H.L.; Xue, J.M.; Ye, F.; Liu, Y.S.; Fan, X.M.; Cheng, L.F. A sheath-core shaped ZrO2-SiC/SiO2 fiber felt with continuously distributed SiC for broad-band electromagnetic absorption. Chem. Eng. J. 2021, 419, 129414. [Google Scholar] [CrossRef]

- Zhang, X.; Ji, G.; Liu, W.; Zhang, X.; Gao, Q.; Li, Y. A novel Co/TiO2 nanocomposite derived from a metal–organic framework: Synthesis and efficient microwave absorption. J. Mater. Chem. C 2016, 4, 1860–1870. [Google Scholar] [CrossRef]

- Li, Y.; Qing, Y.C.; Zhou, Y.F.; Zhao, B.; Zhi, Q.; Fan, B.B.; Zhang, R. Unique nanoporous structure derived from Co3O4-C and Co/CoO-C composites towards the ultra-strong electromagnetic absorption. Compos. B Eng. 2021, 213, 108731–108734. [Google Scholar] [CrossRef]

- Zou, J.; Liu, L.; Chen, H.; Khondaker, S.I.; McCullough, R.D.; Huo, Q.; Zhai, L. Dispersion of Pristine Carbon Nanotubes Using Conjugated Block Copolymers. Adv. Mater. 2008, 20, 2055–2060. [Google Scholar] [CrossRef]

- Qing, Y.C.; Wen, Q.L.; Luo, F.; Zhou, W.C. Temperature dependence of the electromagnetic properties of graphene nanosheet reinforced alumina ceramics in the X-band. J. Mater. Chem. C 2016, 4, 4853–4862. [Google Scholar]

- Song, P.; Liu, B.; Qiu, H.; Shi, X.T.; Cao, D.P.; Gu, J.W. MXenes for polymer matrix electromagnetic interference shielding composites: A review. Compos. Commu. 2021, 24, 100653. [Google Scholar] [CrossRef]

- Zhang, C.; Yin, S.; Long, C.; Dong, B.W.; He, D.P.; Cheng, Q. Hybrid metamaterial absorber for ultra-low and dual-broadband absorption. Opt. Express 2021, 29, 14078–14086. [Google Scholar] [CrossRef]

- Zhao, B.; Li, Y.; Zeng, Q.W.; Wang, L.; Ding, J.J.; Zhang, R.; Che, R.C. Galvanic Replacement Reaction Involving Core–Shell Magnetic Chains and Orientation-Tunable Microwave Absorption Properties. Small 2020, 16, 2003502. [Google Scholar] [CrossRef]

- Huang, S.S.; Zhou, W.C.; Wei, P.; Luo, F.; Zhu, D.M. Effects of Y2O3 on mechanical, dielectric, and microwave-absorbing properties of short carbon-fiber/Al2O3 composites. Phys. Status Solidi 2014, 211, 630–635. [Google Scholar] [CrossRef]

- Faisal, M.; Khasim, S. X-band microwave absorption and dielectric properties of polyaniline-yttrium oxide composites. E-Polymers 2014, 14, 209–216. [Google Scholar] [CrossRef]

- Rangaraj, L.; Divakar, C.; Jayaram, V. Fabrication and mechanisms of densification of ZrB2-based ultra-high temperature ceramics by reactive hot pressing. J. Eur. Ceram. Soc. 2010, 30, 129–138. [Google Scholar] [CrossRef]

- Li, H.; Zhang, L.; Zeng, Q.; Wang, J.; Cheng, L.; Ren, H.; Guan, K. Crystal structure and elastic properties of ZrB compared with ZrB2: A first-principles study. Comput. Mater. Sci. 2010, 49, 814–819. [Google Scholar] [CrossRef]

- Qing, Y.C.; Su, J.; Wen, Q.; Luo, F.; Zhu, D.; Zhou, W. Enhanced dielectric and electromagnetic interference shielding properties of FeSiAl/Al2O3 ceramics by plasma spraying. J. Alloys Compd. 2015, 651, 259–265. [Google Scholar] [CrossRef]

- Zhu, S.; Fahrenholtz, W.G.; Hilmas, G.E. Enhanced densification and mechanical properties of ZrB2-SiC processed by a preceramic polymer coating route. Scripta. Mater. 2008, 59, 123–126. [Google Scholar] [CrossRef]

- Singh, H.; Sidhu, B.S.; Puri, D.; Prakash, S. Use of plasma spray technology for deposition of high temperature oxidation/corrosion resistant coatings—A review. Mater. Corros. 2007, 58, 92–102. [Google Scholar] [CrossRef]

- Wang, Y.; Darut, G.; Poirier, T.; Stellac, J.; Liaoa, H.; Planche, M.P. Ultrasonic cavitation erosion of as-sprayed and laser-remelted yttria stabilized zirconia coatings. J. Eur. Ceram. Soc. 2017, 24, 3623–3630. [Google Scholar] [CrossRef]

- Li, H.; Sun, Y.; Zhang, J. Effect of ZrO2 particle on the performance of micro-arc oxidation coatings on Ti6Al4V. Appl. Surf. Sci. 2015, 342, 183–190. [Google Scholar] [CrossRef]

- Pan, J.; Zheng, Y.; Zheng, Y.; Ye, W.; Yu, W. Solidification mechanism and microstructure evolution of Al2O3-ZrO2 ceramic coating prepared by combustion synthesis and thermal explosion spraying. Ceram. Int. 2017, 43, 4037–4041. [Google Scholar] [CrossRef]

- Zhao, B.; Li, Y.; Ji, H.Y.; Bai, P.W.; Wang, S.; Fan, B.B.; Guo, X.Q.; Zhang, R. Lightweight graphene aerogels by decoration of 1D CoNi chains and CNTs to achieve ultra-wide microwave absorption. Carbon 2021, 176, 411–420. [Google Scholar] [CrossRef]

- Che, R.C.; Peng, L.M.; Duan, X.F.; Chen, Q.; Liang, X.L. Microwave Absorption Enhancement and Complex Permittivity and Permeability of Fe Encapsulated within Carbon Nanotubes. Adv. Mater. 2004, 16, 401–405. [Google Scholar] [CrossRef]

- Gao, X.R.; Jia, Z.R.; Wang, B.B.; Wu, X.M.; Sun, T.; Liu, X.H.; Chi, Q.G.; Wu, G.L. Synthesis of NiCo-LDH/MXene hybrids with abundant heterojunction surfaces as a lightweight electromagnetic wave absorber. Chem. Eng. J. 2021, 419, 130019–130030. [Google Scholar] [CrossRef]

- Lv, H.L.; Yang, Z.H.; Ong, S.J.H.; Wei, C.; Liao, H.B.; Xi, S.B.; Du, Y.H.; Ji, G.B.; Xu, Z.C. A flexible microwave-shield with tunable frequency-transmission and electromagnetic compatiblity. Adv. Funct. Mater. 2019, 29, 1900163. [Google Scholar] [CrossRef]

- Qing, Y.C.; Zhou, W.C.; Luo, F.; Zhu, D.M. Titanium carbide (MXene) nanosheets as promising microwave absorbers. Ceram. Int. 2016, 42, 16412–16416. [Google Scholar] [CrossRef]

- Liang, X.; Man, Z.; Quan, B.; Zheng, J.; Gu, W.H.; Zhang, Z.; Ji, G.B. Environment-Stable CoxNiy Encapsulation in Stacked Porous Carbon Nanosheets for Enhanced Microwave Absorption. Nano-Micro Lett. 2020, 12, 102. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Deng, J.S.; Zhang, R.; Liang, L.Y.; Fan, B.B.; Bai, Z.Y.; Shao, G.; Park, C.B. Recent Advances on the Electromagnetic Wave Absorption Properties of Ni Based Materials. Eng. Sci. 2018, 3, 5–40. [Google Scholar] [CrossRef] [Green Version]

- Ye, X.L.; Chen, Z.F.; Ai, S.F.; Hou, B.; Zhang, J.X.; Liang, X.H.; Zhou, Q.B.; Liu, H.Z.; Cui, S. Porous SiC/melamine-derived carbon foam frameworks with excellent electromagnetic wave absorbing capacity. J. Adv. Ceram. 2019, 8, 479–488. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.J.; Zhu, J.Q.; Yin, P.G.; Guo, A.P.; Huang, A.P.; Guo, L.; Wang, G.S. Tunable high-performance microwave absorption of Co1-xS hollow spheres constructed by nanosheets within ultralow filler loading. Adv. Funct. Mater. 2018, 28, 1800761. [Google Scholar] [CrossRef]

- Yu, Z.J.; Lv, X.; Mao, K.W.; Yang, Y.J.; Liu, A.H. Role of in-situ formed free carbon on electromagnetic absorption properties of polymer-derived SiC ceramics. J. Adv. Ceram. 2020, 9, 617–628. [Google Scholar] [CrossRef]

- Li, X.; Du, D.; Wang, C.; Wang, H.; Xu, Z. In situ synthesis of hierarchical rose-like porous Fe@ C with enhanced electromagnetic wave absorption. J. Mater. Chem. C 2018, 6, 558–567. [Google Scholar] [CrossRef]

- Wang, F.; Sun, Y.; Li, D.; Zhong, B.; Wu, Z.; Zuo, S.; Yan, D.; Zhuo, R.; Feng, J.; Yan, P. Microwave absorption properties of 3D cross-linked Fe/C porous nanofibers prepared by electrospinning. Carbon 2018, 134, 264–273. [Google Scholar] [CrossRef]

- Tian, C.; Du, Y.; Xu, P.; Qiang, R.; Wang, Y.; Ding, D.; Xue, J.; Ma, J.; Zhao, H.; Han, X. Constructing uniform core–shell PPy@ PANI composites with tunable shell thickness toward enhancement in microwave absorption. ACS Appl. Mater. Interfaces 2015, 7, 20090–20099. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhao, Y.; Lu, X.; Zhu, Y.; Jiang, L. Self-healing superhydrophobic polyvinylidene fluoride/Fe3O4@polypyrrole fiber with core–sheath structures for superior microwave absorption. Nano Res. 2016, 9, 2034–2045. [Google Scholar] [CrossRef]

- Li, Y.; Qing, Y.C.; Zhao, B.; Bai, P.; Zhang, R.; Yao, H.; Luo, F. Tunable magnetic coupling and dipole polarization of core-shell Magnéli Ti4O7 ceramic/magnetic metal possessing broadband microwave absorption properties. Ceram. Int. 2021. [Google Scholar] [CrossRef]

- Gao, S.; Wang, G.S.; Guo, L.; Yu, S.H. Tunable and ultra-efficient microwave absorption properties of trace N-doped two-dimensional carbon-based nanocomposites loaded with multi-rare earth oxides. Small 2020, 16, 1906668. [Google Scholar] [CrossRef]

- Wang, G.; Hoong, S.J.; Zhao, Y.; Xu, Z.; Ji, G. Integrated multifunctional macrostructures for electromagnetic wave absorption and shielding. J. Mater. Chem. A 2020, 8, 24368–24387. [Google Scholar] [CrossRef]

- Jiao, Y.; Li, J.; Xie, A.; Wu, F.; Zhang, K.; Dong, W.; Zhu, X. Confined polymerization strategy to construct polypyrrole/zeolitic imidazolate frameworks (PPy/ZIFs) nanocomposites for tunable electrical conductivity and excellent electromagnetic absorption. Compos. Sci. Technol. 2019, 174, 232–240. [Google Scholar] [CrossRef]

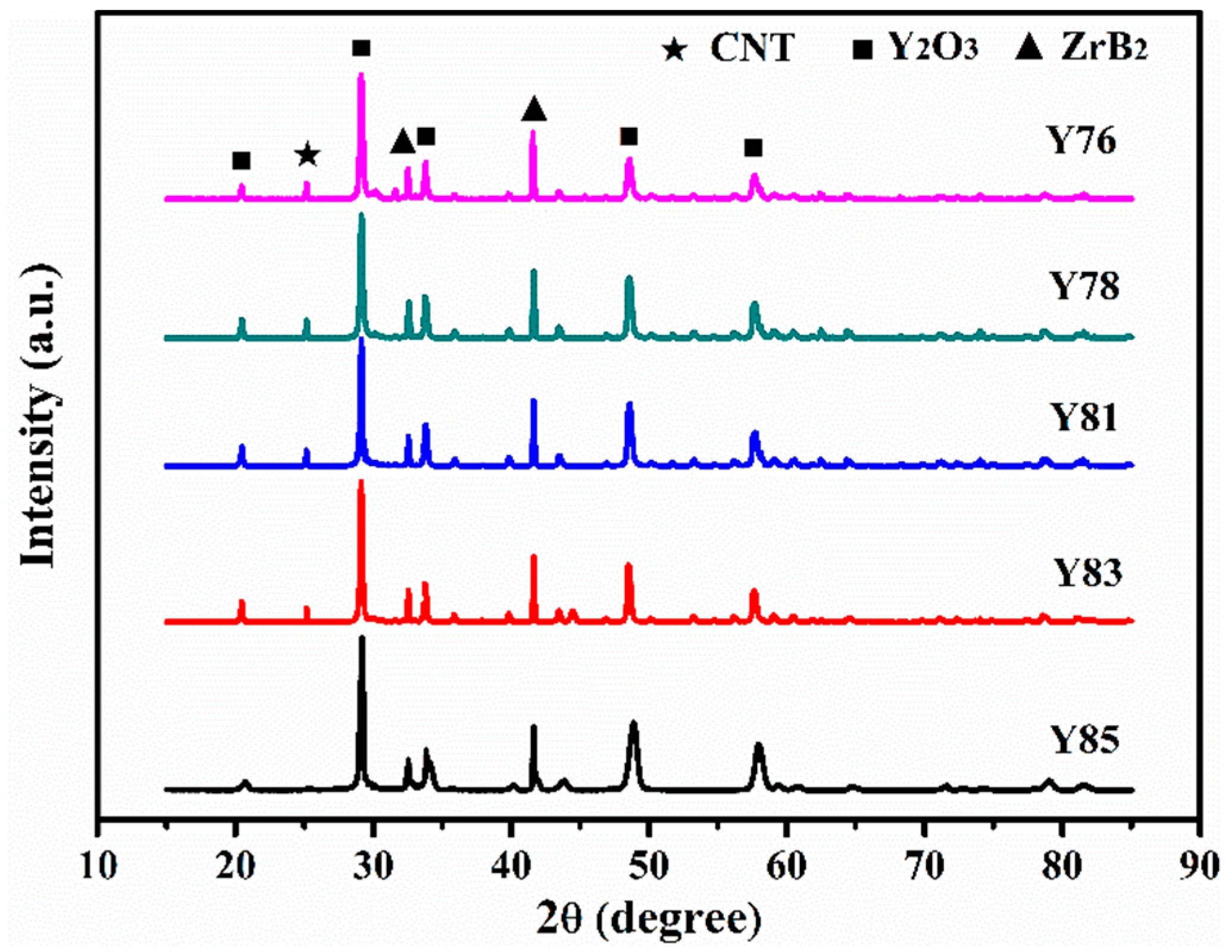

| Sample | Y2O3 (wt. %) | ZrB2 (wt. %) | CNT (wt. %) |

|---|---|---|---|

| 1 | 85 | 15 | - |

| 2 | 83 | 15 | 2 |

| 3 | 81 | 15 | 4 |

| 4 | 78 | 20 | 2 |

| 5 | 76 | 20 | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.; Qing, Y. Effects of Multi-Components on the Microwave Absorption and Dielectric Properties of Plasma-Sprayed Carbon Nanotube/Y2O3/ZrB2 Ceramics. Nanomaterials 2021, 11, 2640. https://doi.org/10.3390/nano11102640

Li R, Qing Y. Effects of Multi-Components on the Microwave Absorption and Dielectric Properties of Plasma-Sprayed Carbon Nanotube/Y2O3/ZrB2 Ceramics. Nanomaterials. 2021; 11(10):2640. https://doi.org/10.3390/nano11102640

Chicago/Turabian StyleLi, Rong, and Yuchang Qing. 2021. "Effects of Multi-Components on the Microwave Absorption and Dielectric Properties of Plasma-Sprayed Carbon Nanotube/Y2O3/ZrB2 Ceramics" Nanomaterials 11, no. 10: 2640. https://doi.org/10.3390/nano11102640

APA StyleLi, R., & Qing, Y. (2021). Effects of Multi-Components on the Microwave Absorption and Dielectric Properties of Plasma-Sprayed Carbon Nanotube/Y2O3/ZrB2 Ceramics. Nanomaterials, 11(10), 2640. https://doi.org/10.3390/nano11102640