Monolayer-Scale GaN/AlN Multiple Quantum Wells for High Power e-Beam Pumped UV-Emitters in the 240–270 nm Spectral Range

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

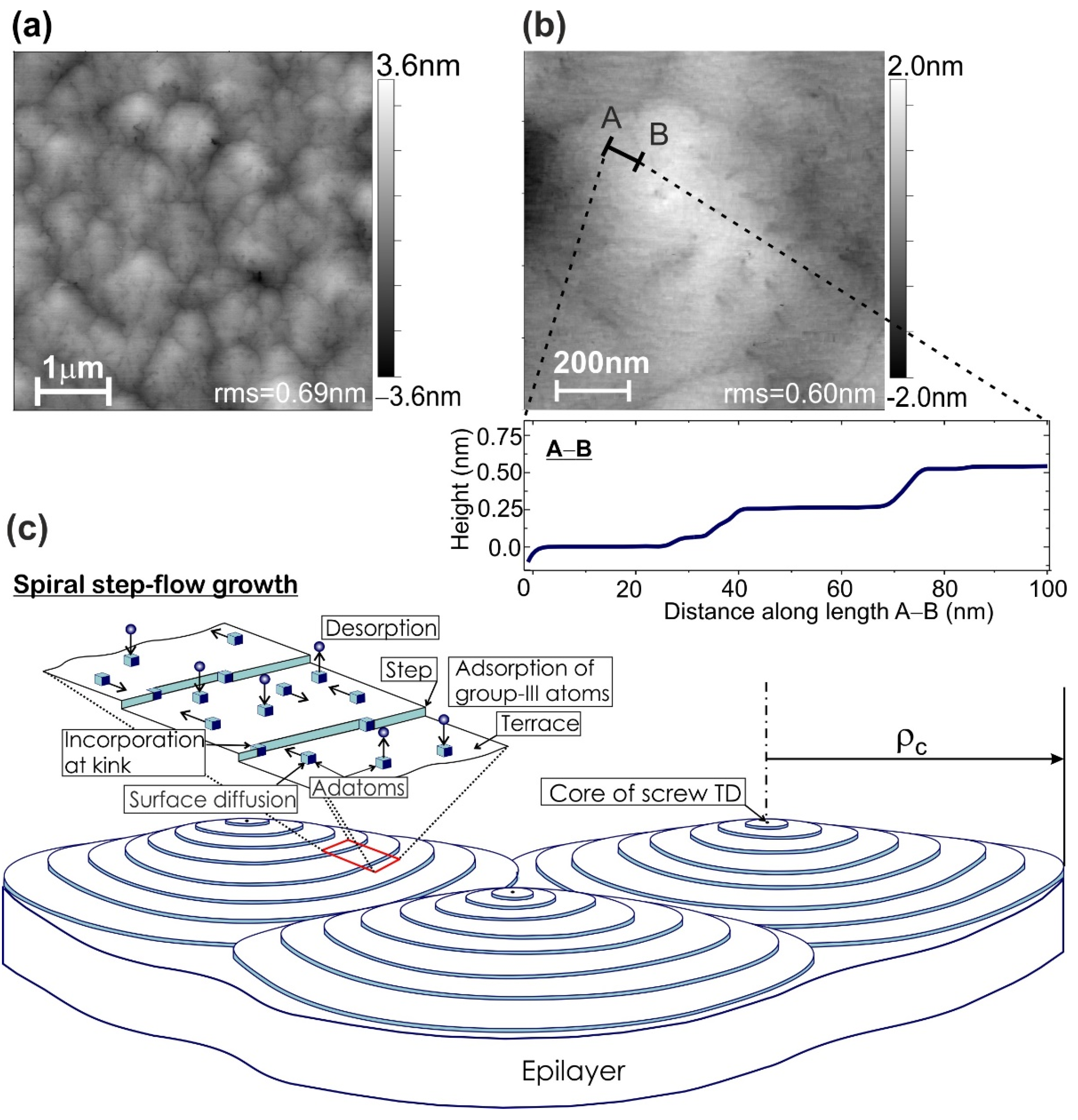

3.1. Surface Topology of AlN Templates

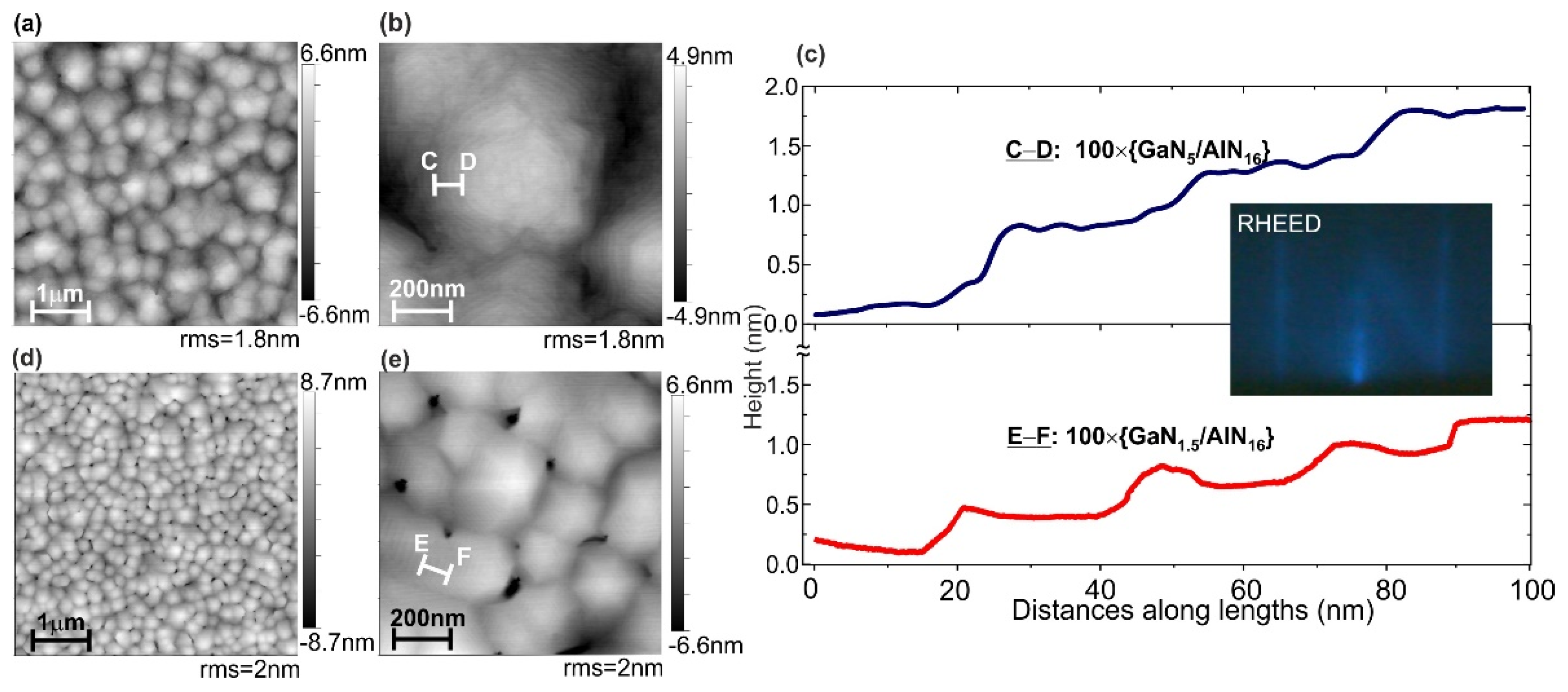

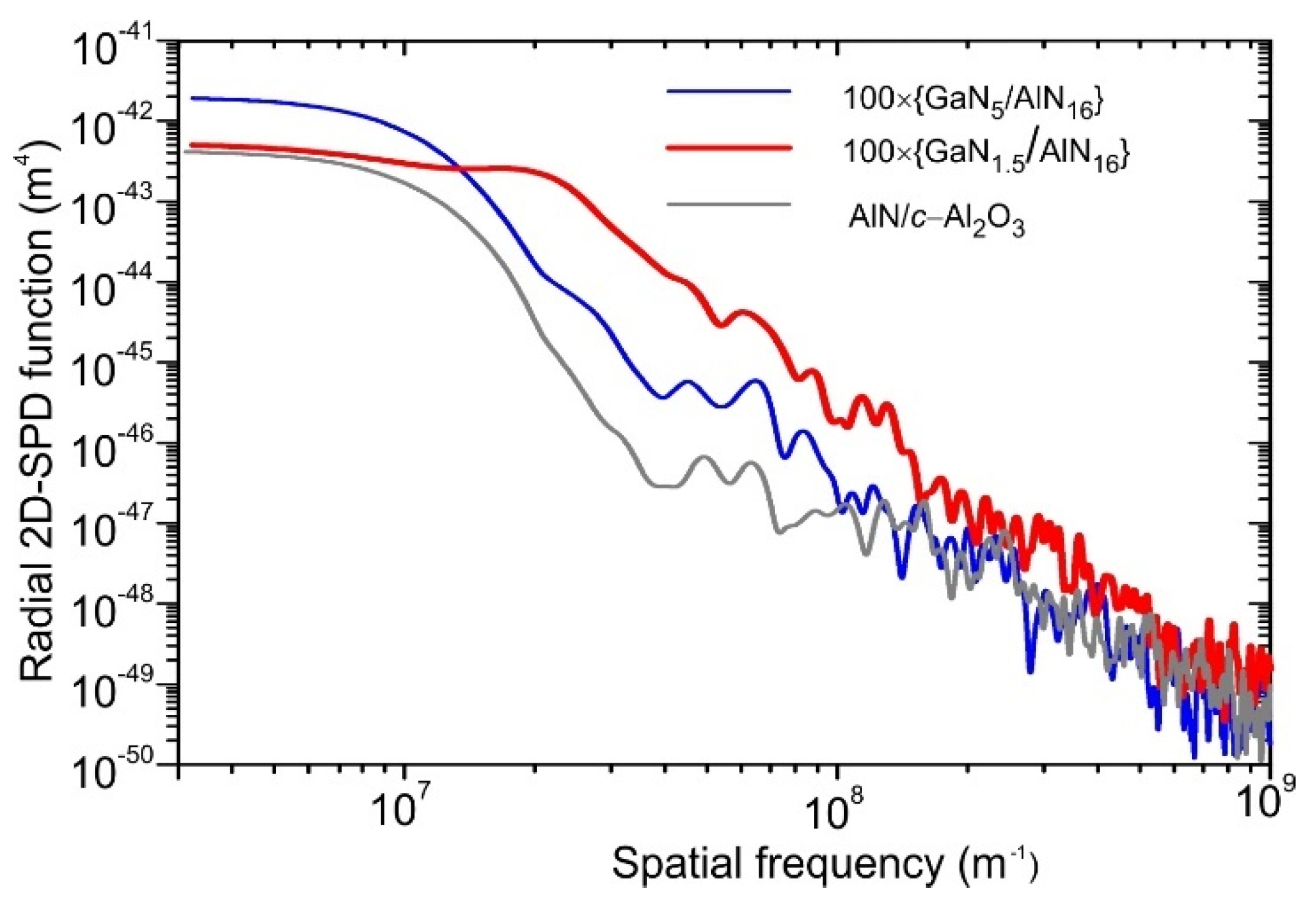

3.2. Surface Topology of GaN/AlN Heterostructures

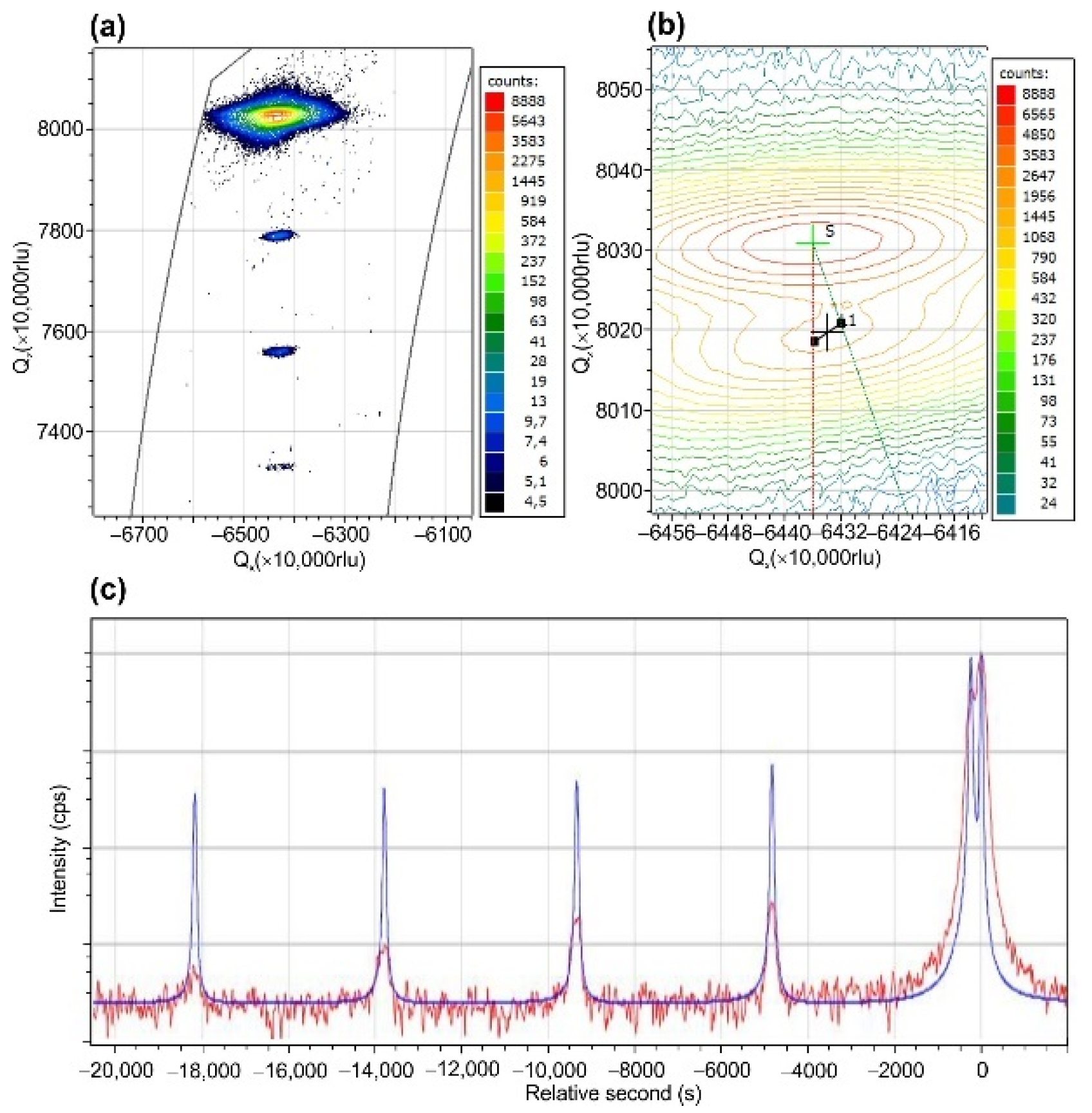

3.3. Stress Measurements

3.4. XRD Analysis

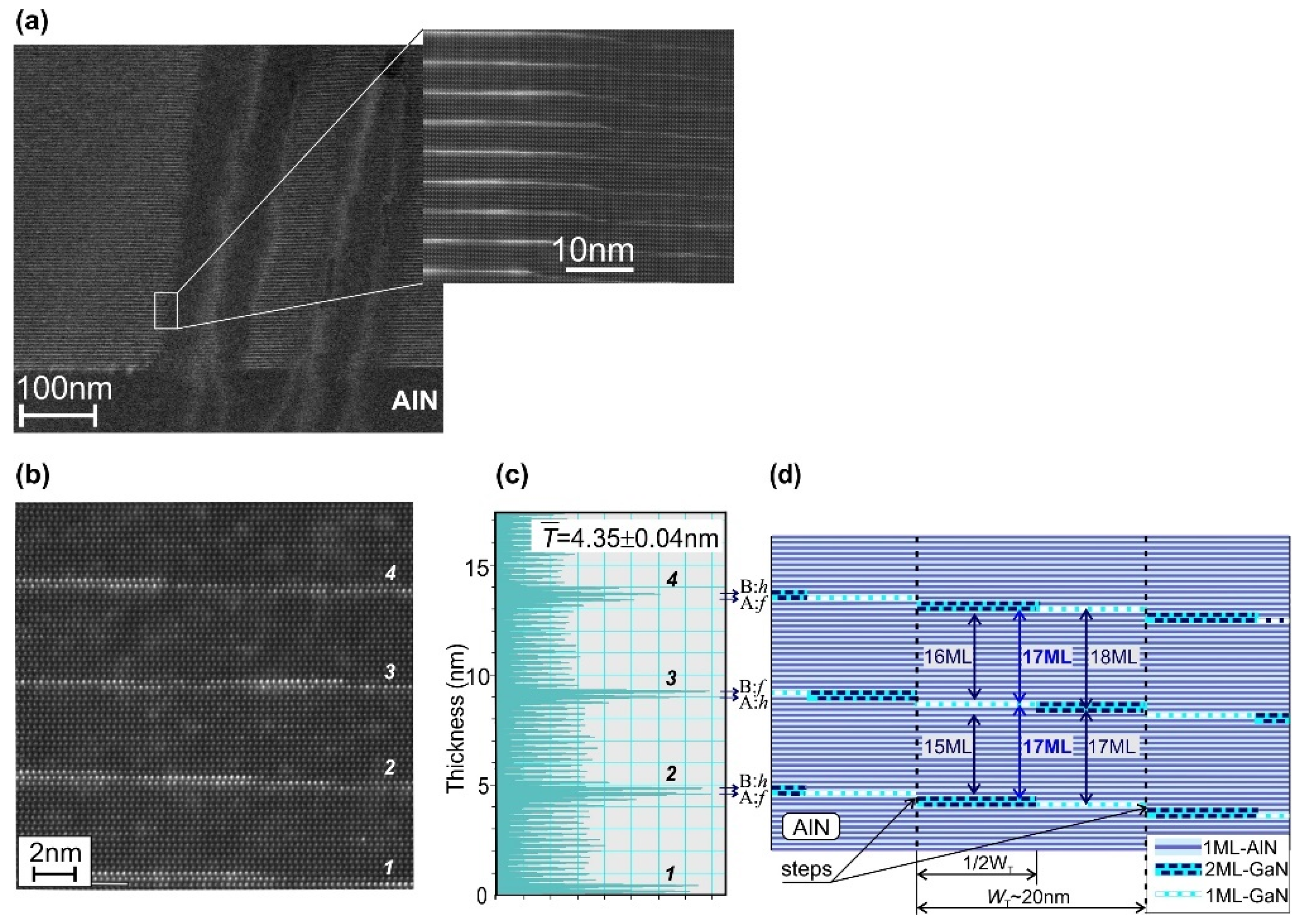

3.5. Study of GaN/AlN MQW Structures by HAADF STEM

3.6. Study of Cathodoluminescence of 2D-GaN/AlN MQW Structures

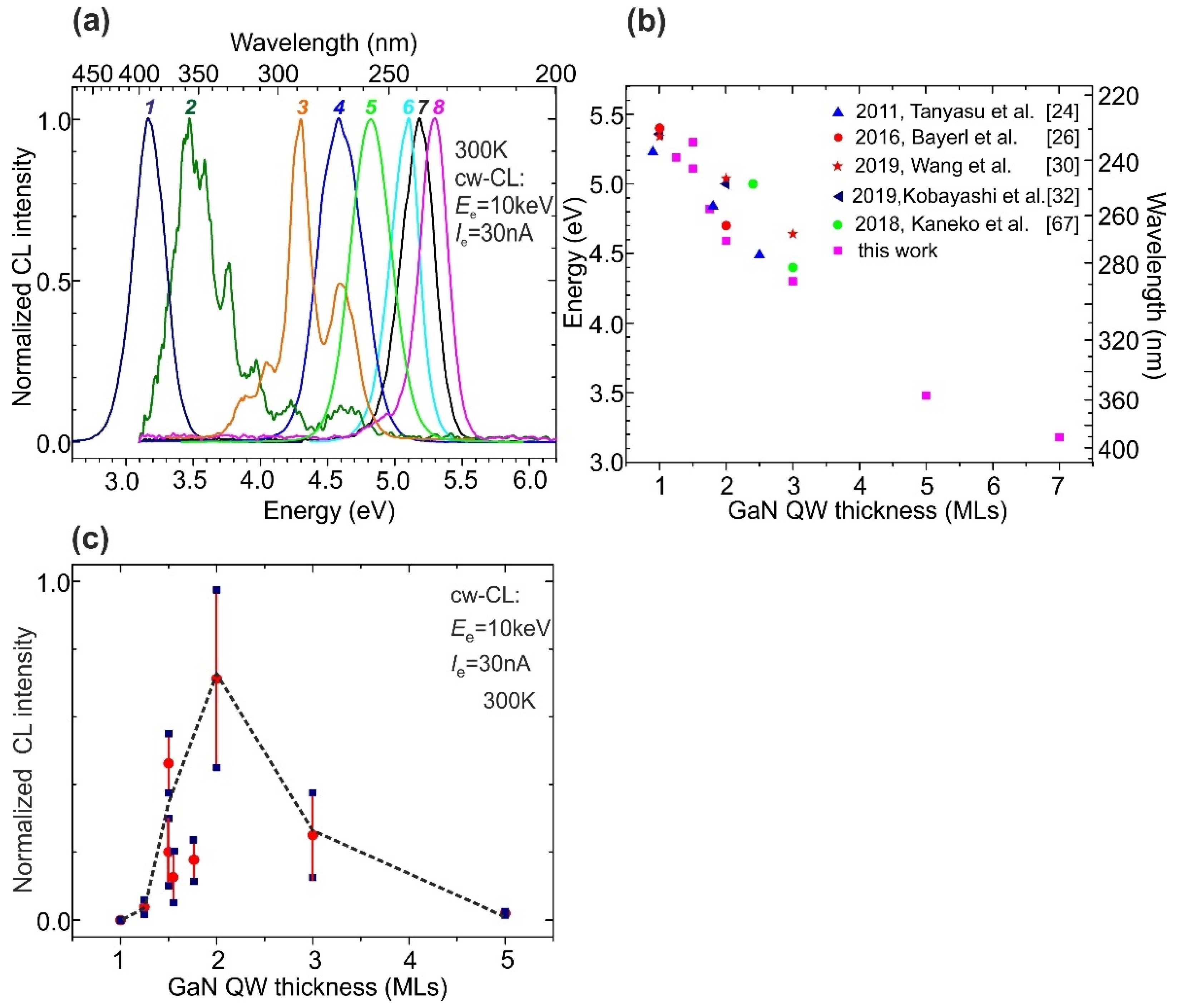

3.6.1. Cathodoluminescence Excited by Continuous-Wave Low-Current e-Beam

3.6.2. Cathodoluminescence Excited by Pulsed High-Current e-Beams

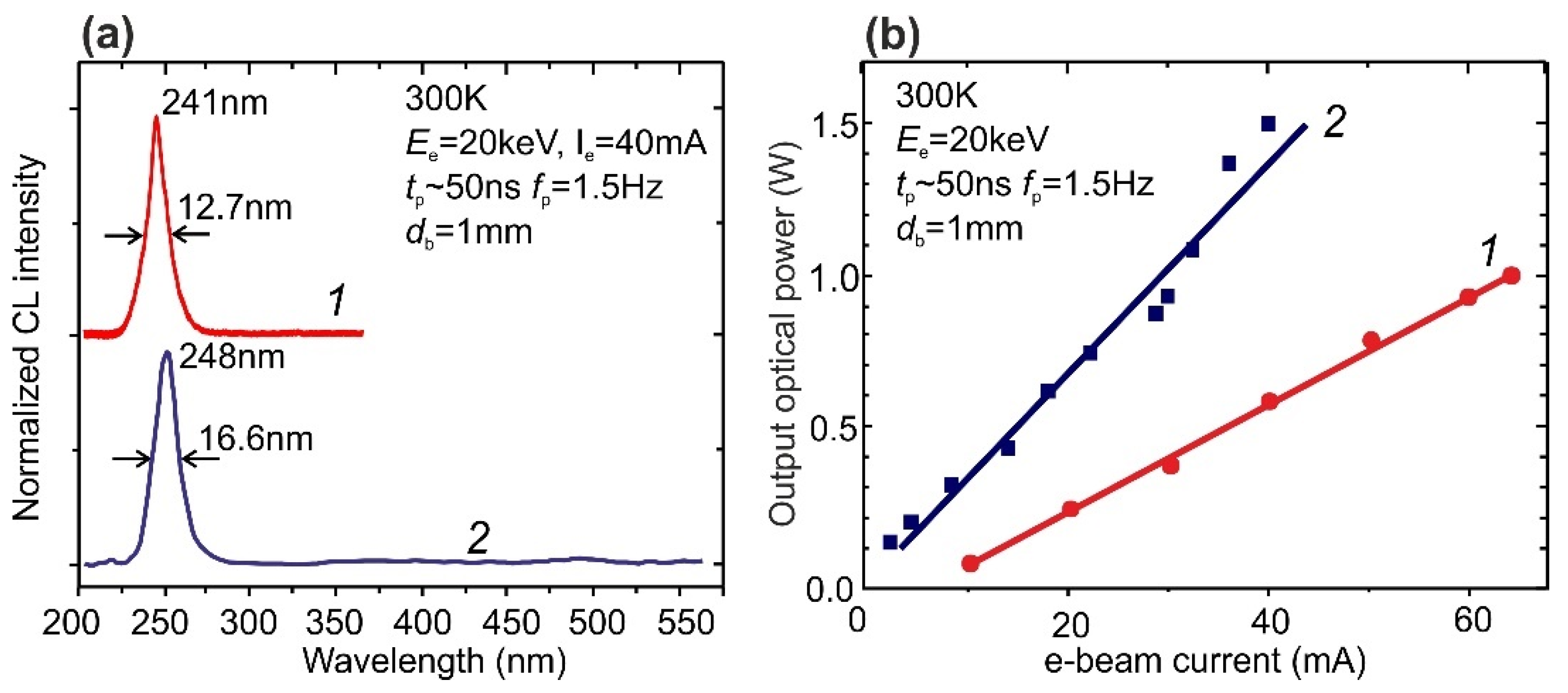

Thermoionic e-Gun with a LaB6 Cathode

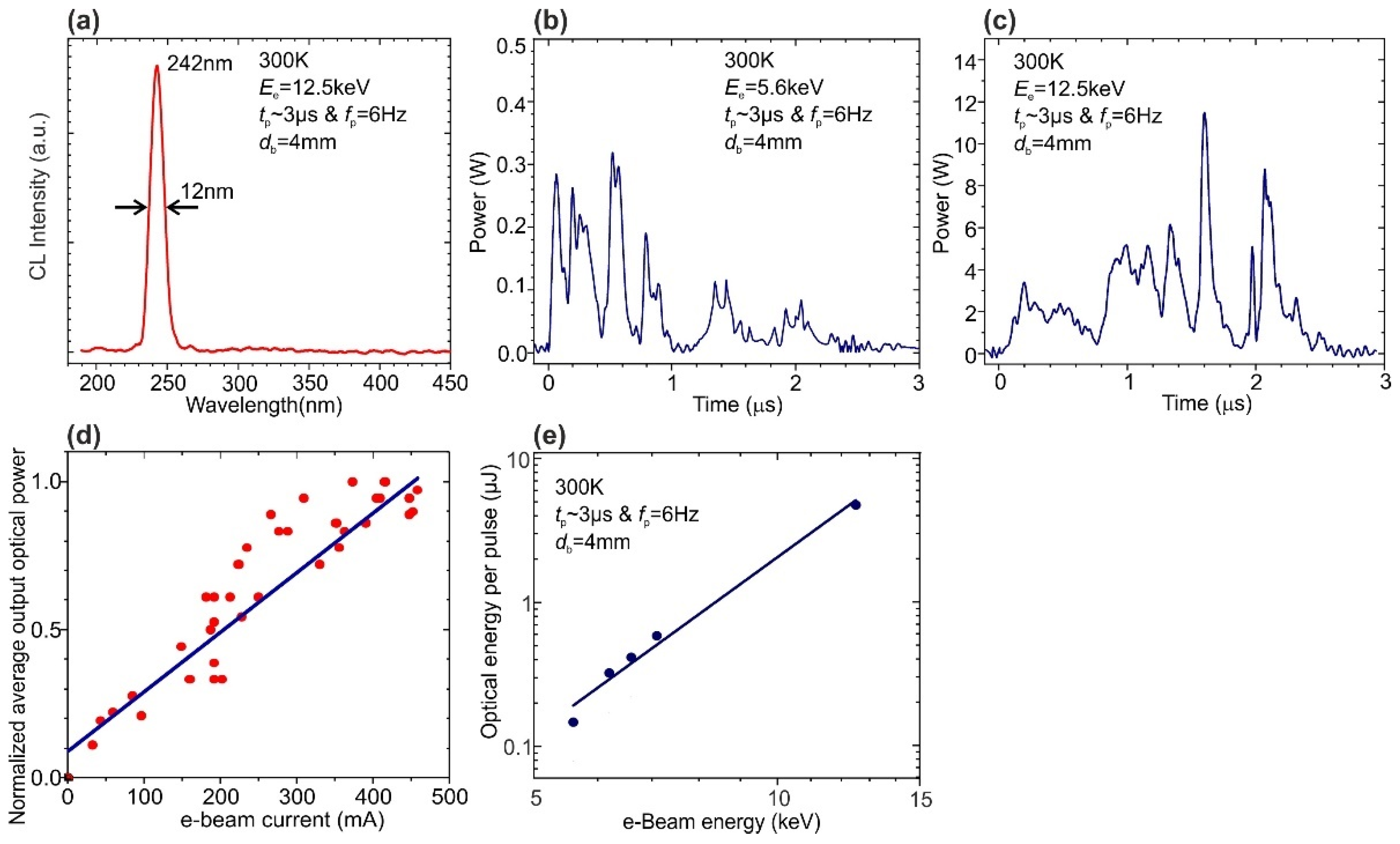

Cold e-Gun with a Ferroelectric Plasma Cathode

4. Conclusions

5. Patent

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Raeiszadeh, M.; Adeli, B. A Critical Review on Ultraviolet Disinfection Systems against COVID-19 Outbreak: Applicability, Validation, and Safety Considerations. ACS Photonics 2020, 7, 2941–2951. [Google Scholar] [CrossRef]

- Won, W.-S.; Tran, L.G.; Park, W.-T.; Kim, K.-K.; Shin, C.S.; Kim, N.; Kim, Y.-J.; Yoon, Y.-J. UV-LEDs for the Disinfection and Bio-Sensing Applications. Int. J. Precis. Eng. Manuf. 2018, 19, 1901–1915. [Google Scholar] [CrossRef]

- Welch, D.; Buonanno, M.; Grilj, V.; Shuryak, I.; Crickmore, C.; Bigelow, A.W.; Randers-Pehrson, G.; Johnson, G.W.; Brenner, D.J. Far-UVC light: A new tool to control the spread of airborne-mediated microbial diseases. Sci. Rep. 2018, 8, 2752. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Nesterenko, P.N.; Paull, B.; Stanley, R.; Macka, M. Performance of a new 235 nm UV-LED based on-capillary photometric detector. Anal. Chem. 2016, 88, 12116–12121. [Google Scholar] [CrossRef]

- Inoue, S.-I.; Tamari, N.; Taniguchi, M. 150 mW deep-ultraviolet light-emitting diodes with large-area AlN nanophotonic light extraction structure emitting at 265 nm. Appl. Phys. Lett. 2017, 110, 141106. [Google Scholar] [CrossRef] [Green Version]

- Lobo-Ploch, N.; Mehnke, F.; Sulmoni, L.; Cho, H.K.; Guttmann, M.; Glaab, J.; Hilbrich, K.; Wernicke, T.; Einfeldt, S.; Kneissl, M. Milliwatt power 233 nm AlGaN-based deep UV-LEDs on sapphire substrates. Appl. Phys. Lett. 2020, 117, 111102. [Google Scholar] [CrossRef]

- Bernardini, F.; Fiorentini, V.; Vanderbilt, D. Spontaneous polarization and piezoelectric constants of III-V nitrides. Phys. Rev. B 1997, 56, R10024. [Google Scholar] [CrossRef] [Green Version]

- Guo, Q.; Kirste, R.; Mita, S.; Tweedie, J.; Reddy, P.; Washiyama, S.; Breckenridge, M.H.; Collazo, R.; Sitar, Z. The polarization field in Al-rich AlGaN multiple quantum wells. Jpn. J. Appl. Phys. 2019, 58, SCCC10. [Google Scholar] [CrossRef]

- Nam, K.B.; Li, J.; Nakarmi, M.L.; Lin, J.Y.; Jiang, H.X. Unique optical properties of AlGaN alloys and related ultraviolet emitters. Appl. Phys. Lett. 2004, 84, 5264–5266. [Google Scholar] [CrossRef] [Green Version]

- Wierer, J.J., Jr.; Montaño, I.; Crawford, M.H.; Allerman, A.A. Effect of thickness and carrier density on the optical polarization of Al0.44Ga0.56N/Al0.55Ga0.45N quantum well layers. J. Appl. Phys. 2014, 115, 174501. [Google Scholar] [CrossRef]

- Rudinsky, M.E.; Karpov, S.Y. Radiative and Auger Recombination Constants and Internal Quantum Efficiency of (0001) AlGaN Deep-UV Light-Emitting Diode Structures. Phys. Status Solidi A 2020, 217, 1900878. [Google Scholar] [CrossRef]

- Liu, D.; Cho, S.J.; Zhang, H.; Carlos, C.R.; Kalapala, A.R.K.; Park, J.; Kim, J.; Dalmau, R.; Gong, J.; Moody, B.; et al. Influences of screw dislocations on electroluminescence of AlGaN/AlN-based UVC LEDs. AIP Adv. 2019, 9, 085128. [Google Scholar] [CrossRef] [Green Version]

- Liang, Y.-H.; Towe, E. Progress in efficient doping of high aluminum-containing group III-nitrides. Appl. Phys. Rev. 2018, 5, 011107. [Google Scholar] [CrossRef]

- Hirayama, H.; Noguchi, N.; Yatabe, T.; Kamata, N. 227 nm AlGaN Light-Emitting Diode with 0.15 mW Output Power Realized using a Thin Quantum Well and AlN Buffer with Reduced Threading Dislocation Density. Appl. Phys. Express 2008, 1, 051101. [Google Scholar] [CrossRef]

- Sharma, T.K.; Naveh, D.; Towe, E. Strain-driven light-polarization switching in deep ultraviolet nitride emitters. Phys. Rev. B 2011, 84, 035305. [Google Scholar] [CrossRef] [Green Version]

- Northrup, J.E.; Chua, C.L.; Yang, Z.; Wunderer, T.; Kneissl, M.; Johnson, N.M.; Kolbe, T. Effect of strain and barrier composition on the polarization of light emission from AlGaN/AlN quantum wells. Appl. Phys. Lett. 2012, 100, 021101. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, H.P.; Tansu, N. Large optical gain AlGaN-delta-GaN quantum wells laser active regions in mid- and deep-ultraviolet spectral regimes. Appl. Phys. Lett. 2011, 98, 171111. [Google Scholar] [CrossRef]

- Haughn, C.R.; Rupper, G.; Wunderer, T.; Yang, Z.; Johnson, N.M.; Wraback, M.; Garrett, G.A. Highly radiative nature of ultra-thin c-plane Al-rich AlGaN/AlN quantum wells for deep ultraviolet emitters. Appl. Phys. Lett. 2019, 114, 102101. [Google Scholar] [CrossRef]

- Jmerik, V.N.; Shubina, T.V.; Mizerov, A.M.; Belyaev, K.G.; Sakharov, A.V.; Zamoryanskaya, M.V.; Sitnikova, A.A.; Davydov, V.Y.; Kop’ev, P.S.; Lutsenko, E.V.; et al. AlGaN quantum well structures for deep-UV LEDs grown by plasma-assisted MBE using sub-monolayer digital-alloying technique. J. Cryst. Growth 2009, 311, 2080–2083. [Google Scholar] [CrossRef]

- Jmerik, V.N.; Mizerov, A.M.; Sitnikova, A.A.; Kop’ev, P.S.; Ivanov, S.V.; Lutsenko, E.V.; Tarasuk, N.P.; Rzheutskii, N.V.; Yablonskii, G.P. Low-threshold 303 nm lasing in AlGaN-based multiple-quantum well structures with an asymmetric waveguide grown by plasma-assisted molecular beam epitaxy on c-sapphire. Appl. Phys. Lett. 2010, 96, 141112. [Google Scholar] [CrossRef]

- Ivanov, S.V.; Nechaev, D.V.; Sitnikova, A.A.; Ratnikov, V.V.; Yagovkina, M.A.; Rzheutskii, N.V.; Lutsenko, E.V.; Jmerik, V.N. Plasma-assisted molecular beam epitaxy of Al(Ga)N layers and quantum well structures for optically pumped mid-UV lasers on c-Al2O3. Semicond. Sci. Technol. 2014, 29, 084008. [Google Scholar] [CrossRef]

- Rong, X.; Wang, X.; Ivanov, S.V.; Jiang, X.; Chen, G.; Wang, P.; Wang, W.; He, C.; Wang, T.; Schulz, T.; et al. High-Output-Power Ultraviolet Light Source from Quasi-2D GaN Quantum Structure. Adv. Mater. 2016, 28, 7978–7983. [Google Scholar] [CrossRef]

- Kamiya, K.; Ebihara, Y.; Shiraishi, K.; Kasu, M. Structural design of AlN/GaN superlattices for deep-ultraviolet lightemitting diodes with high emission efficiency. Appl. Phys. Lett. 2011, 99, 151108. [Google Scholar] [CrossRef]

- Taniyasu, Y.; Kasu, M. Polarization property of deep-ultraviolet light emission from C-plane AlN/GaN short-period superlattices. Appl. Phys. Lett. 2011, 99, 251112. [Google Scholar] [CrossRef]

- Verma, J.; Islam, S.M.; Protasenko, V.; Kandaswamy, P.K.; Xing, H.; Jena, D. Tunnel-injection quantum dot deep-ultraviolet light-emitting diodes with polarization-induced doping in III-nitride heterostructures. Appl. Phys. Lett. 2014, 104, 021105. [Google Scholar] [CrossRef] [Green Version]

- Bayerl, D.; Islam, S.M.; Jones, C.M.; Protasenko, V.; Jena, D.; Kioupakis, E. Deep ultraviolet emission from ultra-thin GaN/AlN heterostructures. Appl. Phys. Lett. 2016, 109, 241102. [Google Scholar] [CrossRef]

- Islam, S.M.; Lee, K.; Verma, J.; Protasenko, V.; Rouvimov, S.; Bharadwaj, S.; Xing, H.; Jena, D. MBE-grown 232–270 nm deep-UV LEDs using monolayer thin binary GaN/AlN quantum heterostructures. Appl. Phys. Lett. 2017, 110, 041108. [Google Scholar] [CrossRef]

- Islam, S.M.; Protasenko, V.; Lee, K.; Rouvimov, S.; Verma, J.; Xing, H.; Jena, D. Deep-UV emission at 219 nm from ultrathin MBE GaN/AlN quantum heterostructures. Appl. Phys. Lett. 2017, 111, 091104. [Google Scholar] [CrossRef]

- Jmerik, V.N.; Nechaev, D.V.; Toropov, A.A.; Evropeitsev, E.A.; Kozlovsky, V.I.; Martovitsky, V.P.; Rouvimov, S.; Ivanov, S.V. High-efficiency electron-beam-pumped sub-240-nm ultraviolet emitters based on ultra-thin GaN/AlN multiple quantum wells grown by plasma-assisted molecular-beam epitaxy on c-Al2O3. Appl. Phys. Express 2018, 11, 091003. [Google Scholar] [CrossRef]

- Wang, Y.; Rong, X.; Ivanov, S.; Jmerik, V.; Chen, Z.; Wang, H.; Wang, T.; Wang, P.; Jin, P.; Chen, Y.; et al. Deep Ultraviolet Light Source from Ultrathin GaN/AlN MQW Structures with Output Power Over 2 Watt. Adv. Optical Mater. 2019, 1801763. [Google Scholar] [CrossRef]

- Toropov, A.A.; Evropeitsev, E.A.; Nestoklon, M.O.; Smirnov, D.S.; Shubina, T.V.; Kaibyshev, V.K.; Budkin, G.V.; Jmerik, V.N.; Nechaev, D.V.; Rouvimov, S.; et al. Strongly confined excitons in GaN/AlN Nanostructures with atomically thin GaN Layers for efficient light emission in deep-ultraviolet. Nano Lett. 2020, 20, 158–165. [Google Scholar] [CrossRef]

- Kobayashi, H.; Ichikawa, S.; Funato, M.; Kawakami, Y. Self-Limiting Growth of Ultrathin GaN/AlN Quantum Wells for Highly Efficient Deep Ultraviolet Emitters. Adv. Opt. Mater. 2019, 1900860. [Google Scholar] [CrossRef]

- Jmerik, V.; Toropov, A.; Davydov, V.; Ivanov, S. Monolayer-Thick GaN/AlN Multilayer Heterostructures for Deep-Ultraviolet Optoelectronics. Phys. Status Solidi RRL 2021, 2100242. [Google Scholar] [CrossRef]

- Jmerik, V.N.; Nechaev, D.V.; Ivanov, S.V. Kinetics of metal-rich PA molecular beam epitaxy of AlGaN heterostructures for mid-UV photonics. In Molecular Beam Epitaxy: From Research to Mass Production, 2nd ed.; Henini, M., Ed.; Elsevier Inc.: Amsterdam, The Netherlands; Oxford, UK; Cambridge, MA, USA, 2018; pp. 135–179. [Google Scholar] [CrossRef]

- Nechaev, D.V.; Koshelev, O.A.; Ratnikov, V.V.; Brunkov, P.N.; Myasoedov, A.V.; Sitnikova, A.A.; Ivanov, S.V.; Jmerik, V.N. Effect of stoichiometric conditions and growth mode on threading dislocations filtering in AlN/c-Al2O3 templates grown by PA MBE. Superlattices Microstruct. 2020, 138, 106368. [Google Scholar] [CrossRef]

- Koshelev, O.A.; Nechaev, D.V.; Brunkov, P.N.; Ivanov, S.V.; Jmerik, V.N. Stress control in thick AlN/c-Al2O3 templates grown by plasma-assisted molecular beam epitaxy. Semicond. Sci. Technol. 2021, 36, 035007. [Google Scholar] [CrossRef]

- Ferreyra, R.A.; Zhu, C.; Teke, A.; Morcoc, H. Group III Nitrides. In Springer Handbook of Electronic and Photonic Materials, Kasap, S., Capper, P., Eds.; Springer Int. Publishing: Berlin/Heidelberg, Germany, 2017; pp. 743–827. [Google Scholar] [CrossRef]

- Zolotukhin, D.S.; Nechaev, D.V.; Ivanov, S.V.; Zhmerik, V.N. Monitoring of Elastic Stresses with Optical System for Measuring the Substrate Curvature in Growth of III-N Heterostructures by Molecular-Beam Epitaxy. Tech. Phys. Lett. 2017, 43, 262–266. [Google Scholar] [CrossRef]

- Zamoryanskaya, M.V.; Konnikov, S.G.; Zamoryanskii, A.N. A High-Sensitivity System for Cathodoluminescent Studies with the Camebax Electron Probe Microanalyzer. Instrum. Exp. Tech. 2004, 47, 477–483. [Google Scholar] [CrossRef]

- Xie, M.H.; Seutter, S.M.; Zhu, W.K.; Zheng, L.X.; Wu, H.; Tong, S.Y. Anisotropic Step-Flow Growth and Island Growth of GaN(0001) by Molecular Beam Epitaxy. Phys. Rev. Lett. 1999, 82, 2749–2752. [Google Scholar] [CrossRef] [Green Version]

- Heying, B.; Tarsa, E.J.; Elsass, C.R.; Fini, P.; DenBaars, S.P.; Speck, J.S. Dislocation mediated surface morphology of GaN. J. Appl. Phys. 1999, 85, 6470–6476. [Google Scholar] [CrossRef]

- Skierbiszewski, C.; Siekacz, M.; Perlin, P.; Feduniewicz-Zmuda, A.; Cywin´ski, G.; Grzegory, I.; Leszczyn´ski, M.; Wasilewski, Z.R.; Porowski, S. Role of dislocation-free GaN substrates in the growth of indium containing optoelectronic structures by plasma-assisted MBE. J. Cryst. Growth 2007, 305, 346–354. [Google Scholar] [CrossRef]

- Bryan, I.; Bryan, Z.; Mita, S.; Rice, A.; Tweedie, J.; Collazo, R.; Sitar, Z. Surface kinetics in AlN growth: A universal model for the control of surface morphology in III-nitrides. J. Cryst. Growth 2016, 438, 81–89. [Google Scholar] [CrossRef] [Green Version]

- Burton, W.K.; Cabrera, N.; Frank, F.C. The Growth of Crystals and the Equilibrium Structure of their Surfaces. Phil. Trans. R. Soc. Lond. A 1951, 243, 299–358. [Google Scholar] [CrossRef]

- Laurent, M.A.; Keller, S.; Mishra, U.K. Comprehensive Analysis of Surface Morphology and Growth Mode of AlInGaN Films. Phys. Status Solidi A 2018, 1800523. [Google Scholar] [CrossRef] [Green Version]

- McSkimming, B.M.; Chaix, C.; Speck, J.S. High active nitrogen flux growth of GaN by plasma assisted molecular beam epitaxy. J. Vac. Sci. Technol. A 2015, 33, 05E128. [Google Scholar] [CrossRef]

- Available online: http://gwyddion.net (accessed on 29 September 2021).

- Tersoff, J.; Phang, Y.H.; Zhang, Z.; Lagally, M.G. Step-Bunching Instability of Vicinal Surfaces under Stress. Phys. Rev. Lett. 1995, 75, 2730. [Google Scholar] [CrossRef] [PubMed]

- Schwoebel, R.L.; Shipsey, E.J. Step Motion on Crystal Surfaces. J. Appl. Phys. 1966, 37, 3682. [Google Scholar] [CrossRef]

- Ehrlich, G. Direct observation of individual atoms on metals. Surf. Sci. 1977, 63, 422–447. [Google Scholar] [CrossRef]

- Duport, C.; Nozières, P.; Villain, J. New Instability in Molecular Beam Epitaxy. Phys. Rev. Lett. 1995, 74, 134–137. [Google Scholar] [CrossRef] [PubMed]

- Zheng, H.; Xie, M.H.; Wu, H.S.; Xue, Q.K. Kinetic energy barriers on the GaN(0001) surface: A nucleation study by scanning tunneling microscopy. Phys. Rev. B 2008, 77, 045303. [Google Scholar] [CrossRef]

- Kaufmann, N.A.K.; Lahourcade, L.; Hourahine, B.; Martin, D.; Grandjean, N. Critical impact of Ehrlich-Schwöbel barrier on GaN surface morphology during homoepitaxial growth. J. Cryst. Growth 2016, 433, 36–42. [Google Scholar] [CrossRef] [Green Version]

- Stoney, G.G. The tensions of metallic films deposited by electrolysis. Proc. R. Soc. Land. 1909, A82, 172–175. [Google Scholar] [CrossRef] [Green Version]

- Floro, J.A.; Chason, E.; Lee, S.R.; Twesten, R.D.; Hwang, R.Q.; Freund, L.B. Real-Time Stress Evolution During Sil-xGex heteroepitaxy: Dislocations, Islanding, and Segregation. J. Electron. Mater. 1997, 26, 969–979. [Google Scholar] [CrossRef]

- Brandt, O.; Ploog, K.; Bierwolf, R.; Hohenstein, M. Breakdown of Continuum Elasticity Theory in the Limit of Monatomic Films. Phys. Rev. Lett. 1992, 68, 1339–1342. [Google Scholar] [CrossRef] [PubMed]

- Massies, J.; Grandjean, N. Oscillation of the Lattice Relaxation in Layer-by-Layer Epitaxial Growth of Highly Strained Materials. Phys. Rev. Lett. 1993, 71, 1411–1414. [Google Scholar] [CrossRef] [PubMed]

- Deelman, P.W.; Schowalter, L.J.; Thundat, T. In situ measurements of temperature-dependent strain relaxation of Ge/Si(111). J. Vac. Sci. Technol. A 1997, 15, 930–935. [Google Scholar] [CrossRef]

- Muller, P.; Kern, R. Some elastic effects in crystal growth. In Stress and Strain in Epitaxy: Theoretical Concepts, Measurements and Applications; Hanbucken, M., Deville, J.P., Eds.; Elsevier: Amsterdam, The Netherlands; Oxford, UK; Cambridge, MA, USA, 2001; pp. 3–61. [Google Scholar] [CrossRef] [Green Version]

- Bourret, A.; Adelmann, C.; Daudin, B.; Rouviere, J.-L.; Feuillet, G.; Mula, G. Strain relaxation in (0001)AlN/GaN heterostructures. Phys. Rev. B 2001, 63, 245307. [Google Scholar] [CrossRef]

- Chandolu, A.; Nikishin, S.; Holtz, M.; Temkin, H. X-ray diffraction study of AlN/AlGaN short period superlattices. J. Appl. Phys. 2007, 102, 114909. [Google Scholar] [CrossRef] [Green Version]

- Gao, N.; Feng, X.; Lu, S.; Lin, W.; Zhuang, Q.; Chen, H.; Huang, K.; Li, S.; Kang, J. Integral Monolayer-Scale Featured Digital-Alloyed AlN/GaN Superlattices Using Hierarchical Growth Units. Cryst. Growth Des. 2019, 19, 1720–1727. [Google Scholar] [CrossRef]

- Enslin, J.; Mehnke, F.; Mogilatenko, A.; Bellmann, K.; Guttmann, M.; Kuhn, C.; Rass, J.; Lobo-Ploch, N.; Wernicke, T.; Weyers, M.; et al. Metamorphic Al0.5Ga0.5N:Si on AlN/sapphire for the growth of UVB LEDs. J. Cryst. Growth 2017, 464, 185–189. [Google Scholar] [CrossRef]

- Tabataba-Vakili, F.; Wunderer, T.; Kneissl, M.; Yang, Z.; Teepe, M.; Batres, M.; Feneberg, M.; Vancil, B.; Johnson, N.M. Dominance of radiative recombination from electron-beam-pumped deep-UV AlGaN multi-quantum-well heterostructures. Appl. Phys. Lett. 2016, 109, 181105. [Google Scholar] [CrossRef]

- Sun, W.; Tan, C.-K.; Tansu, N. AlN/GaN Digital Alloy for Mid- and Deep-Ultraviolet Optoelectronics. Sci. Rep. 2017, 7, 11826. [Google Scholar] [CrossRef] [Green Version]

- Gorczyca, I.; Suski, T.; Christensen, N.E.; Svane, A. Theoretical study of nitride short period superlattices. J. Phys. Condens. Matter. 2018, 30, 063001. [Google Scholar] [CrossRef] [Green Version]

- Kaneko, M.; Ueta, S.; Horita, M.; Kimoto, T.; Suda, J. Deep-ultraviolet light emission from 4H-AlN/4H-GaN short-period superlattice grown on 4H-SiC(11-20). Appl. Phys. Lett. 2018, 112, 012106. [Google Scholar] [CrossRef]

- Jiang, B.; Kirkman, G.; Reinhardt, N. High brightness electron beam produced by a ferroelectric cathode. Appl. Phys. Lett. 1995, 66, 1196–1198. [Google Scholar] [CrossRef]

- Mesyats, G.A. Electron emission from ferroelectric plasma cathodes. Phys. Uspekhi 2008, 51, 79–100. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jmerik, V.; Nechaev, D.; Orekhova, K.; Prasolov, N.; Kozlovsky, V.; Sviridov, D.; Zverev, M.; Gamov, N.; Grieger, L.; Wang, Y.; et al. Monolayer-Scale GaN/AlN Multiple Quantum Wells for High Power e-Beam Pumped UV-Emitters in the 240–270 nm Spectral Range. Nanomaterials 2021, 11, 2553. https://doi.org/10.3390/nano11102553

Jmerik V, Nechaev D, Orekhova K, Prasolov N, Kozlovsky V, Sviridov D, Zverev M, Gamov N, Grieger L, Wang Y, et al. Monolayer-Scale GaN/AlN Multiple Quantum Wells for High Power e-Beam Pumped UV-Emitters in the 240–270 nm Spectral Range. Nanomaterials. 2021; 11(10):2553. https://doi.org/10.3390/nano11102553

Chicago/Turabian StyleJmerik, Valentin, Dmitrii Nechaev, Kseniya Orekhova, Nikita Prasolov, Vladimir Kozlovsky, Dmitry Sviridov, Mikhail Zverev, Nikita Gamov, Lars Grieger, Yixin Wang, and et al. 2021. "Monolayer-Scale GaN/AlN Multiple Quantum Wells for High Power e-Beam Pumped UV-Emitters in the 240–270 nm Spectral Range" Nanomaterials 11, no. 10: 2553. https://doi.org/10.3390/nano11102553

APA StyleJmerik, V., Nechaev, D., Orekhova, K., Prasolov, N., Kozlovsky, V., Sviridov, D., Zverev, M., Gamov, N., Grieger, L., Wang, Y., Wang, T., Wang, X., & Ivanov, S. (2021). Monolayer-Scale GaN/AlN Multiple Quantum Wells for High Power e-Beam Pumped UV-Emitters in the 240–270 nm Spectral Range. Nanomaterials, 11(10), 2553. https://doi.org/10.3390/nano11102553