Low-Threshold Nanolaser Based on Hybrid Plasmonic Waveguide Mode Supported by Metallic Grating Waveguide Structure

Abstract

:1. Introduction

2. Materials and Methods

3. Results

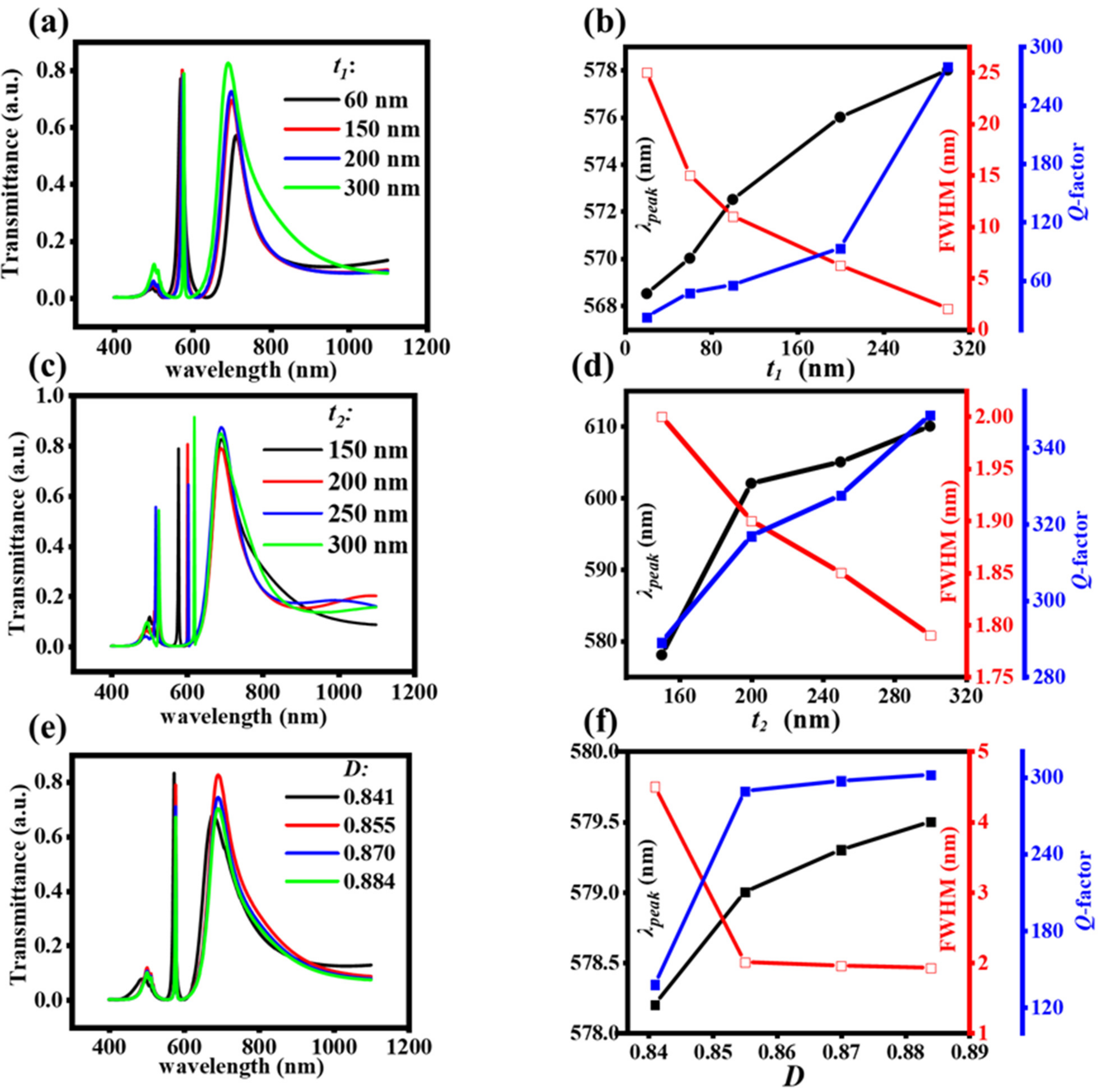

3.1. Effects of Structural Parameters on Transmission Spectrum

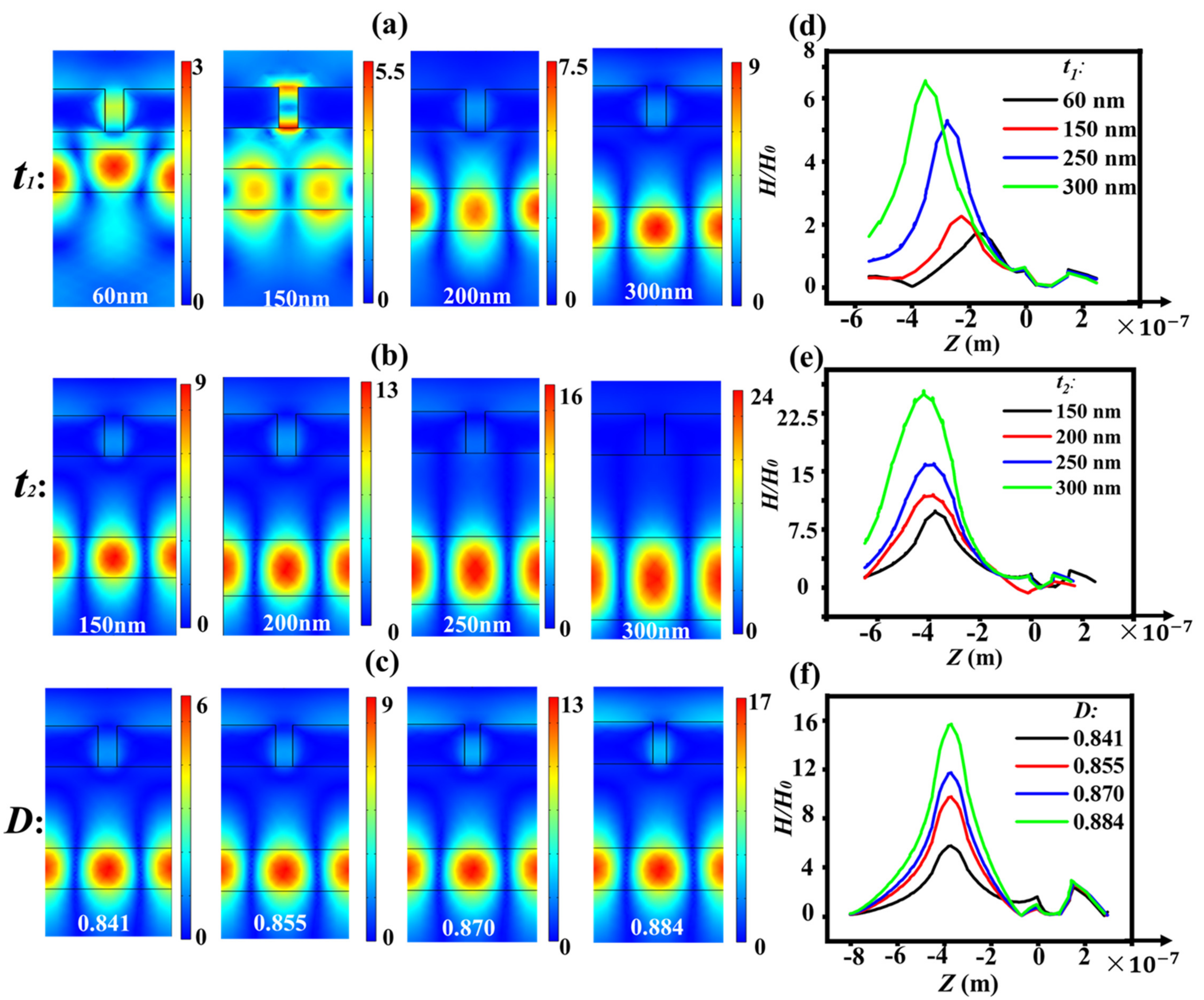

3.2. The Reasons of the Change of the Narrow Transmission Peak

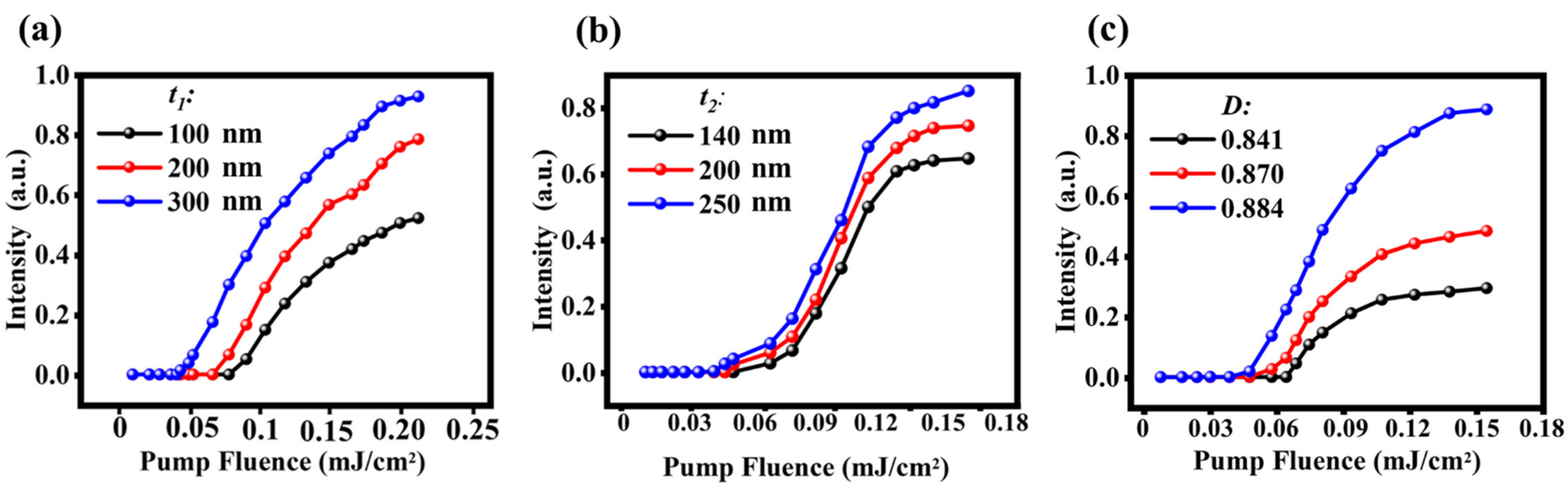

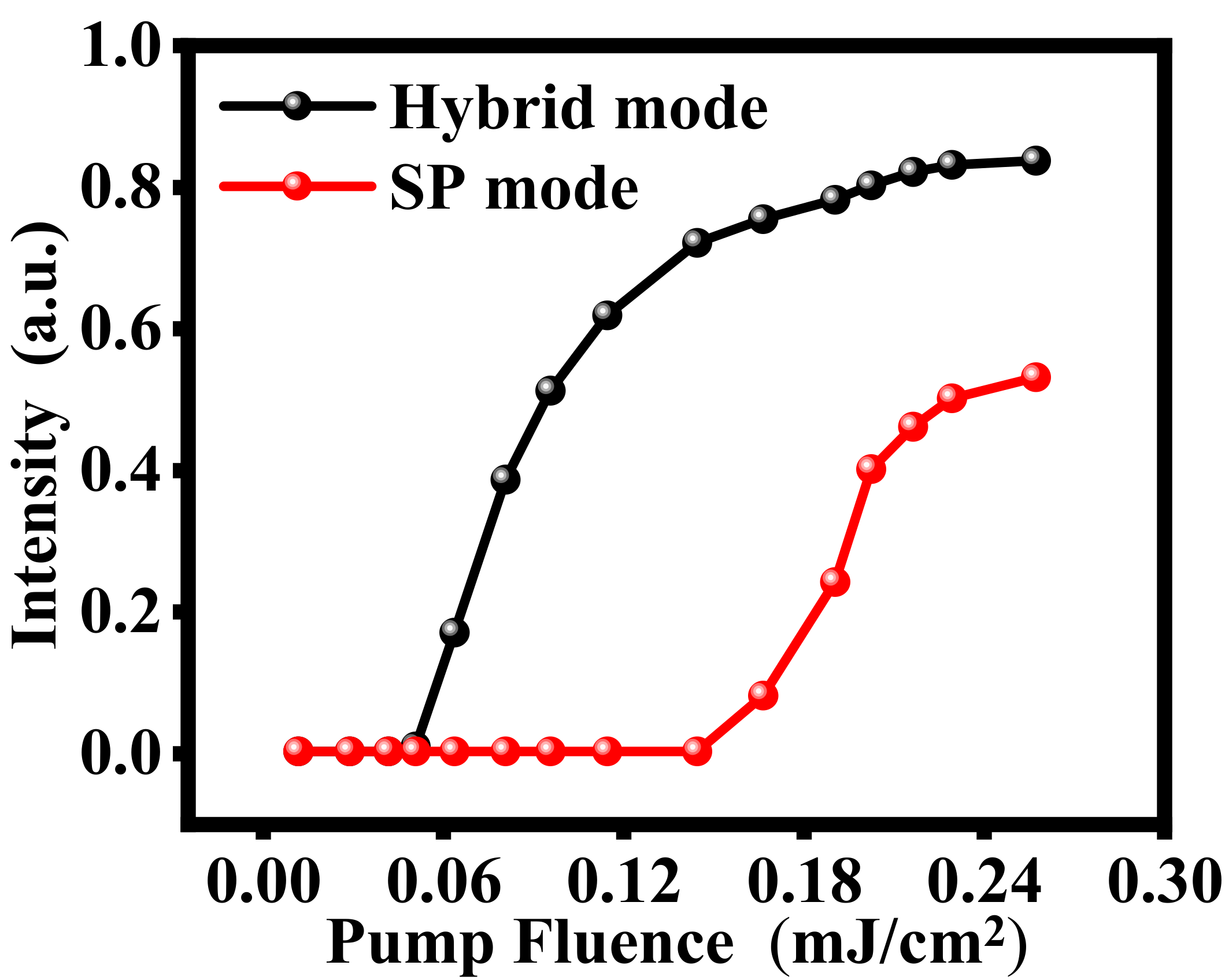

3.3. Lasing Action

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bergman, D.J.; Stockman, M.I. Surface Plasmon Amplification by Stimulated Emission of Radiation: Quantum Generation of Coherent Surface Plasmons in Nanosystems. Phys. Rev. Lett. 2003, 90, 027402. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Wang, X.-Y.; Li, B.; Chen, H.-Z.; Wang, Y.-L.; Dai, L.; Oulton, R.F.; Ma, R.-M. Unusual scaling laws for plasmonic nanolasers beyond the diffraction limit. Nat. Commun. 2017, 8, 1–8. [Google Scholar] [CrossRef]

- Galanzha, E.I.; Weingold, R.; Nedosekin, D.A.; Sarimollaoglu, M.; Nolan, J.; Harrington, W.; Kuchyanov, A.S.; Parkhomenko, R.; Watanabe, F.; Nima, Z.; et al. Spaser as a biological probe. Nat. Commun. 2017, 8, 15528. [Google Scholar] [CrossRef] [Green Version]

- Gao, Z.S.; Wang, J.H.; Song, P.; Kang, B.; Xu, J.J.; Chen, H.Y. Spaser Nanoparticles for Ultranarrow Bandwidth STED Super-Resolution Imaging. Adv. Mater. 2020, 32, 1907233. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Li, C.; Huang, Y.-Z.; Zhang, Q. Plasmonic Nanolasers in On-Chip Light Sources: Prospects and Challenges. ACS Nano 2020, 14, 14375–14390. [Google Scholar] [CrossRef] [PubMed]

- Ma, R.-M.; Oulton, R.F. Applications of nanolasers. Nat. Nanotechnol. 2019, 14, 12–22. [Google Scholar] [CrossRef] [PubMed]

- Gerislioglu, B.; Dong, L.; Ahmadivand, A.; Hu, H.; Nordlander, P.; Halas, N.J. Monolithic Metal Dimer-on-Film Structure: New Plasmonic Properties Introduced by the Underlying Metal. Nano Lett. 2020, 20, 2087–2093. [Google Scholar] [CrossRef]

- Ahmadivand, A.; Gerislioglu, B. Deep- and vacuum-ultraviolet metaphotonic light sources. Mater. Today 2021. [Google Scholar] [CrossRef]

- Wang, X.-Y.; Wang, Y.-L.; Wang, S.; Li, B.; Zhang, X.-W.; Dai, L.; Ma, R.-M. Lasing Enhanced Surface Plasmon Resonance Sensing. Nanophotonics 2016, 6, 472–478. [Google Scholar] [CrossRef]

- Azzam, S.I.; Kildishev, A.V.; Ma, R.-M.; Ning, C.-Z.; Oulton, R.; Shalaev, V.M.; Stockman, M.I.; Xu, J.-L.; Zhang, X. Ten years of spasers and plasmonic nanolasers. Light. Sci. Appl. 2020, 9, 1–21. [Google Scholar] [CrossRef]

- Hakala, T.K.; Rekola, H.; Väkeväinen, A.I.; Martikainen, J.-P.; Nečada, M.; Moilanen, A.; Törmä, P. Lasing in dark and bright modes of a finite-sized plasmonic lattice. Nat. Commun. 2017, 8, 13687. [Google Scholar] [CrossRef] [Green Version]

- Wan, M.; Gu, P.; Liu, W.Y.; Chen, Z.; Wang, Z.L. Low threshold spaser based on deep-subwavelength spherical hyperbolic metamaterial cavities. Appl. Phys. Lett. 2017, 110, 031103. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, J.; Mao, Y.-F.; Chen, J.; Wang, S.; Chen, H.-Z.; Zhang, Y.; Wang, S.-Y.; Chen, X.; Li, T.; et al. Stable, high-performance sodium-based plasmonic devices in the near infrared. Nat. Cell Biol. 2020, 581, 401–405. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Y.; Liu, W.; Yang, J.; Ma, Y.; Lu, H.; Sun, Y.; Jiang, H.; Chen, H. Controllable lasing behavior enabled by compound dielectric waveguide grating structures. Opt. Express 2016, 24, 19458. [Google Scholar] [CrossRef] [PubMed]

- Oulton, R.F.; Sorger, V.J.; Genov, D.A.; Pile, D.F.P.; Zhang, X. A hybrid plasmonic waveguide for subwavelength confinement and long-range propagation. Nat. Photonics 2008, 2, 496–500. [Google Scholar] [CrossRef] [Green Version]

- Butt, M.A.; Kazanskiy, N.L.; Khonina, S.N. Modal Characteristics of Refractive Index Engineered Hybrid Plasmonic Waveguide. IEEE Sens. J. 2020, 20, 9779–9786. [Google Scholar] [CrossRef]

- Yang, H.; Li, Z.; Liu, K.; Mao, H.; Song, C.; Wang, J. Systematic Evolution of Resonant Coupling Behavior Between Surface Plasmon Polaritons and Multi-waveguide Modes in Metal-Dielectric Multi-layers. Plasmonics 2020, 15, 1967–1975. [Google Scholar] [CrossRef]

- Guo, L.; Guo, M.; Yang, H.; Ma, J.; Chen, S. Ultra-Narrow-Band Filter Based on High Q Factor in Metallic Nanoslit Arrays. Sensors 2020, 20, 5205. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Liu, Z.; Tang, Q.; Shi, L.; Chen, Q.; Du, G.; Wu, B.; Liu, G.; Li, L. Grating-assisted ultra-narrow multispectral plasmonic resonances for sensing application. Appl. Phys. Express 2019, 12, 072002. [Google Scholar] [CrossRef]

- Liu, B.; Chen, S.; Zhang, J.; Yao, X.; Zhong, J.; Lin, H.; Huang, T.; Yang, Z.; Zhu, J.; Liu, S.; et al. A Plasmonic Sensor Array with Ultrahigh Figures of Merit and Resonance Linewidths down to 3 nm. Adv. Mater. 2018, 30, e1706031. [Google Scholar] [CrossRef]

- Lee, K.-L.; Lee, C.-W.; Wei, P.-K. Sensitive detection of nanoparticles using metallic nanoslit arrays. Appl. Phys. Lett. 2007, 90, 233119. [Google Scholar] [CrossRef]

- Eryilmaz, S.B.; Tidin, O.; Okyay, A.K. Plasmonic Nanoslit Array Enhanced Metal–Semiconductor–Metal Optical Detectors. IEEE Photonics Technol. Lett. 2012, 24, 548–550. [Google Scholar] [CrossRef] [Green Version]

- Oulton, R.F.; Sorger, V.J.; Zentgraf, T.; Ma, R.-M.; Gladden, C.; Dai, L.; Bartal, G.; Zhang, X.J. Plasmon lasers at deep subwavelength scale. Nature 2009, 461, 629–632. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Degl’Innocenti, R.; Shah, Y.D.; Wallis, R.; Klimont, A.; Ren, Y.; Jessop, D.S.; Beere, H.E.; Ritchie, D.A. A hybrid plasmonic waveguide terahertz quantum cascade laser. Appl. Phys. Lett. 2015, 106, 082101. [Google Scholar] [CrossRef]

- Wang, D.; Bourgeois, M.R.; Lee, W.-K.; Li, R.; Trivedi, D.; Knudson, M.P.; Wang, W.; Schatz, G.C.; Odom, T.W. Stretchable Nanolasing from Hybrid Quadrupole Plasmons. Nano Lett. 2018, 18, 4549–4555. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, F.; Xu, C.; He, Z.; Gao, J.; Zhou, Y.; Xu, L. The Design and Research of a New Hybrid Surface Plasmonic Waveguide Nanolaser. Materials 2021, 14, 2230. [Google Scholar] [CrossRef] [PubMed]

- Ho, Y.-L.; Clark, J.K.; Kamal, A.S.A.; Delaunay, J.-J. On-Chip Monolithically Fabricated Plasmonic-Waveguide Nanolaser. Nano Lett. 2018, 18, 7769–7776. [Google Scholar] [CrossRef] [PubMed]

- Bermúdez-Ureña, E.; Tutuncuoglu, G.; Cuerda, J.; Smith, C.L.C.; Bravo-Abad, J.; Bozhevolnyi, S.I.; I Morral, A.F.; García-Vidal, F.J.; Quidant, R. Plasmonic Waveguide-Integrated Nanowire Laser. Nano Lett. 2017, 17, 747–754. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Cui, T.; Qian, L.Y.; Gao, K.; Kangni, W. Enhanced lasing behavior enabled by guided-mode resonance structure embedded with double waveguide layers. Appl. Opt. 2020, 59, 6113–6118. [Google Scholar] [CrossRef]

- Sun, Z.; Yang, Y.; Zuo, X. Narrow-band optical transmission of metallic nanoslit arrays. Appl. Phys. Lett. 2012, 101, 171106. [Google Scholar] [CrossRef]

- Lu, H.; Gan, X.; Mao, D.; Jia, B.; Zhao, J. Flexibly tunable high-quality-factor induced transparency in plasmonic systems. Sci. Rep. 2018, 8, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, R.; Tiwari, A.K.; Ramakrishna, S.A. Surface plasmon coupling for selectively enhanced random lasing in periodically patterned silver columnar thin film metamaterials. Appl. Phys. Lett. 2020, 116, 241902. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, L.; Lyu, M.; Sun, Z. Resonances of hybridized bound plasmon modes in optically-thin metallic nanoslit arrays for narrow-band transmissive filtering. Optics 2016, 127, 2784–2788. [Google Scholar] [CrossRef]

- Han, Z.; Bozhevolnyi, S. Plasmon-induced transparency with detuned ultracompact Fabry-Perot resonators in integrated plasmonic devices. Opt. Express 2011, 19, 3251–3257. [Google Scholar] [CrossRef] [PubMed]

- Gu, P.; Chen, J.; Yang, C.; Yan, Z.; Tang, C.; Cai, P.; Gao, F.; Yan, B.; Liu, Z.; Huang, Z. Narrowband Light Reflection Resonances from Waveguide Modes for High-Quality Sensors. Nanomaterials 2020, 10, 1966. [Google Scholar] [CrossRef] [PubMed]

- Balanis, S.C.A. Advanced Engineering Electromagnetics; John Wiley & Sons: Hoboken, NJ, USA, 1989. [Google Scholar]

- Wang, K.; Gu, Z.; Liu, S.; Sun, W.; Zhang, N.; Xiao, S.; Song, Q. High-Density and Uniform Lead Halide Perovskite Nanolaser Array on Silicon. J. Phys. Chem. Lett. 2016, 7, 2549–2555. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.-H.; Taflove, A. Finite-difference time-domain model of lasing action in a four-level two-electron atomic system. Opt. Express 2004, 12, 3827–3833. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.; Zhang, C.; Wang, K.; Wang, S.; Xiao, S.; Song, Q. Lead Halide Perovskite Nanoribbon Based Uniform Nanolaser Array on Plasmonic Grating. ACS Photonics 2017, 4, 649–656. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Yan, M.; Ning, T.; Zhao, L.; Jiang, S.; Huo, Y. Low-Threshold Nanolaser Based on Hybrid Plasmonic Waveguide Mode Supported by Metallic Grating Waveguide Structure. Nanomaterials 2021, 11, 2555. https://doi.org/10.3390/nano11102555

Zhang X, Yan M, Ning T, Zhao L, Jiang S, Huo Y. Low-Threshold Nanolaser Based on Hybrid Plasmonic Waveguide Mode Supported by Metallic Grating Waveguide Structure. Nanomaterials. 2021; 11(10):2555. https://doi.org/10.3390/nano11102555

Chicago/Turabian StyleZhang, Xin, Meng Yan, Tingyin Ning, Lina Zhao, Shouzhen Jiang, and Yanyan Huo. 2021. "Low-Threshold Nanolaser Based on Hybrid Plasmonic Waveguide Mode Supported by Metallic Grating Waveguide Structure" Nanomaterials 11, no. 10: 2555. https://doi.org/10.3390/nano11102555

APA StyleZhang, X., Yan, M., Ning, T., Zhao, L., Jiang, S., & Huo, Y. (2021). Low-Threshold Nanolaser Based on Hybrid Plasmonic Waveguide Mode Supported by Metallic Grating Waveguide Structure. Nanomaterials, 11(10), 2555. https://doi.org/10.3390/nano11102555