Characterization and Design of Photovoltaic Solar Cells That Absorb Ultraviolet, Visible and Infrared Light

Abstract

1. Introduction

2. Fields of Application of III-V Solar Cells

2.1. Space Applications

2.2. Terrestrial Concentrator Systems

3. III-V Solar Cell Design

3.1. Bandgap versus Efficiency

3.2. Bandgap versus Lattice Constant

4. The GaInP/GaInAs/Ge Solar Cell

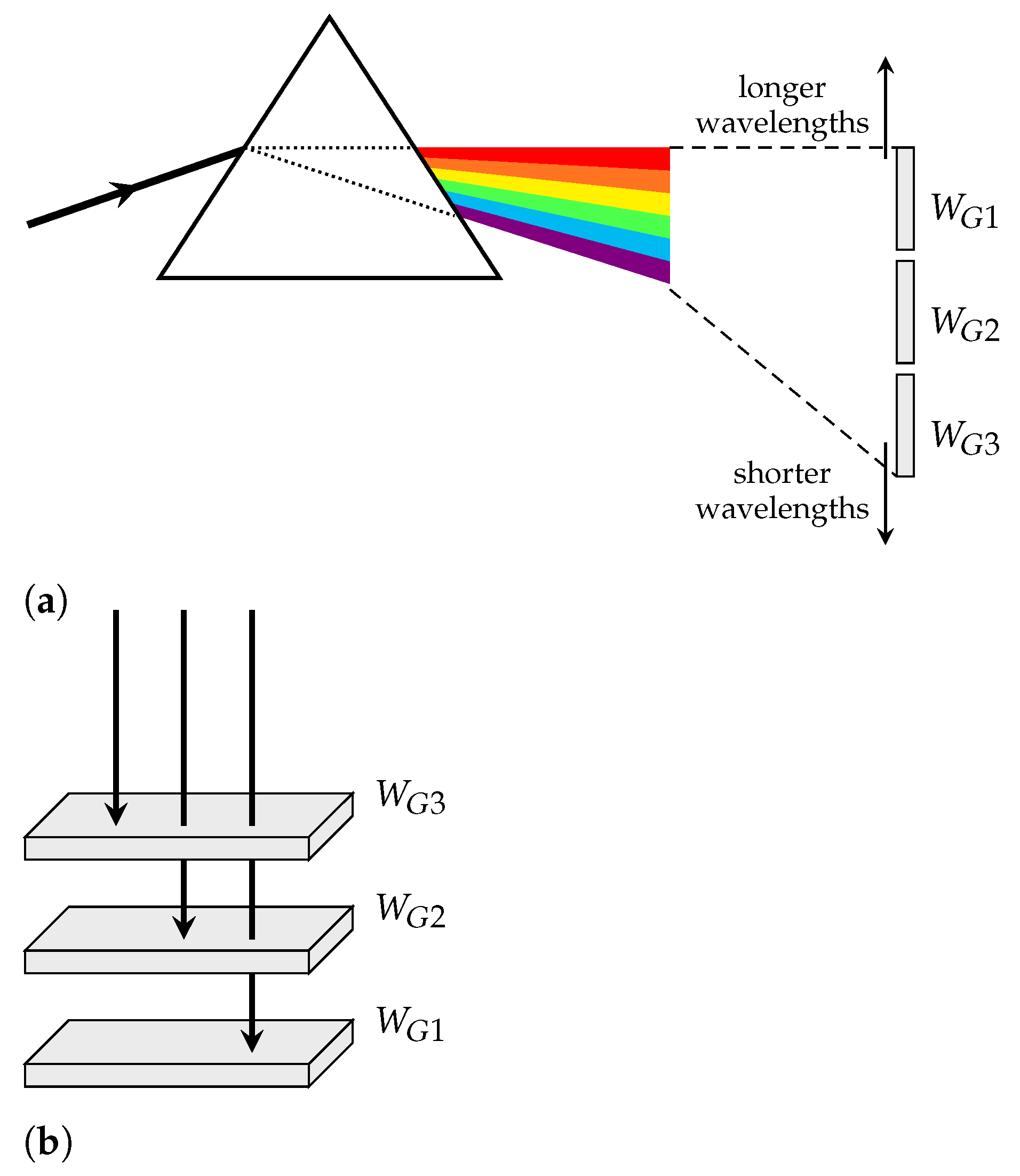

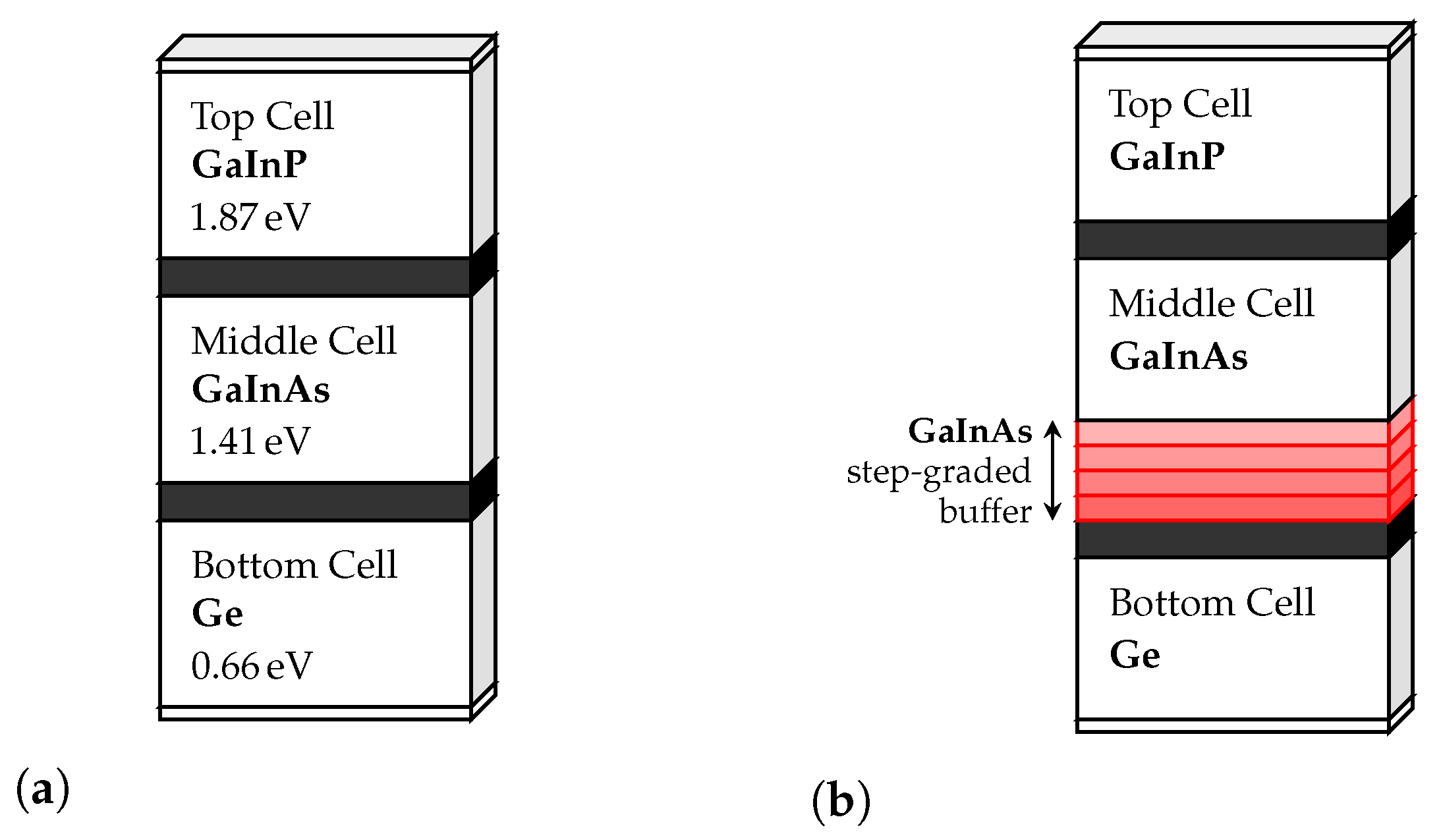

4.1. III-V Solar Cell Designs

4.2. Simulating the LM State-Of-The-Art Cell

4.2.1. The GaInP Top Subcell

4.2.2. The GaInAs Middle Subcell

4.2.3. The Ge Bottom Subcell

4.2.4. I–V Characteristic of the Stacked Cell

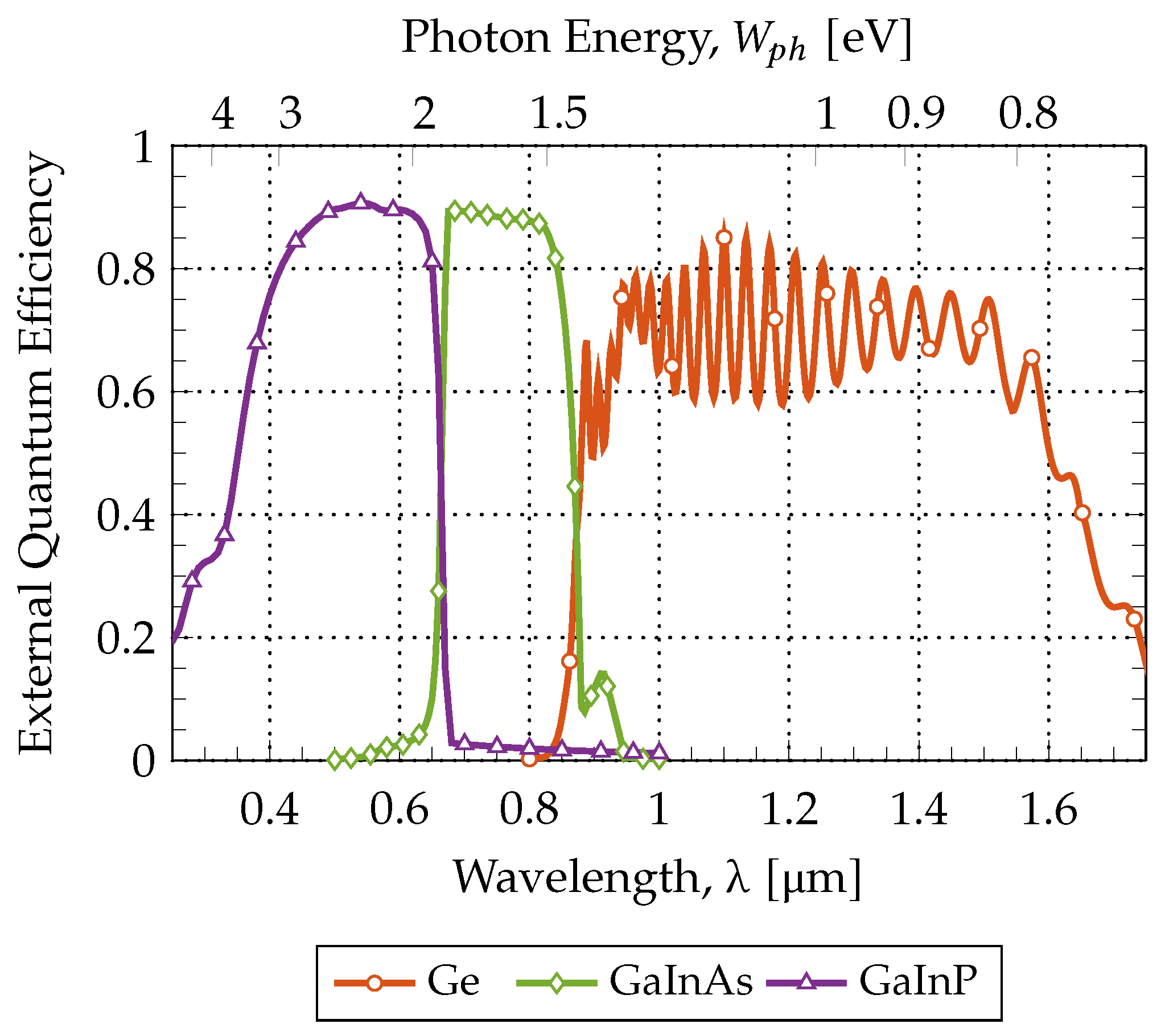

4.2.5. External Quantum Efficiencies

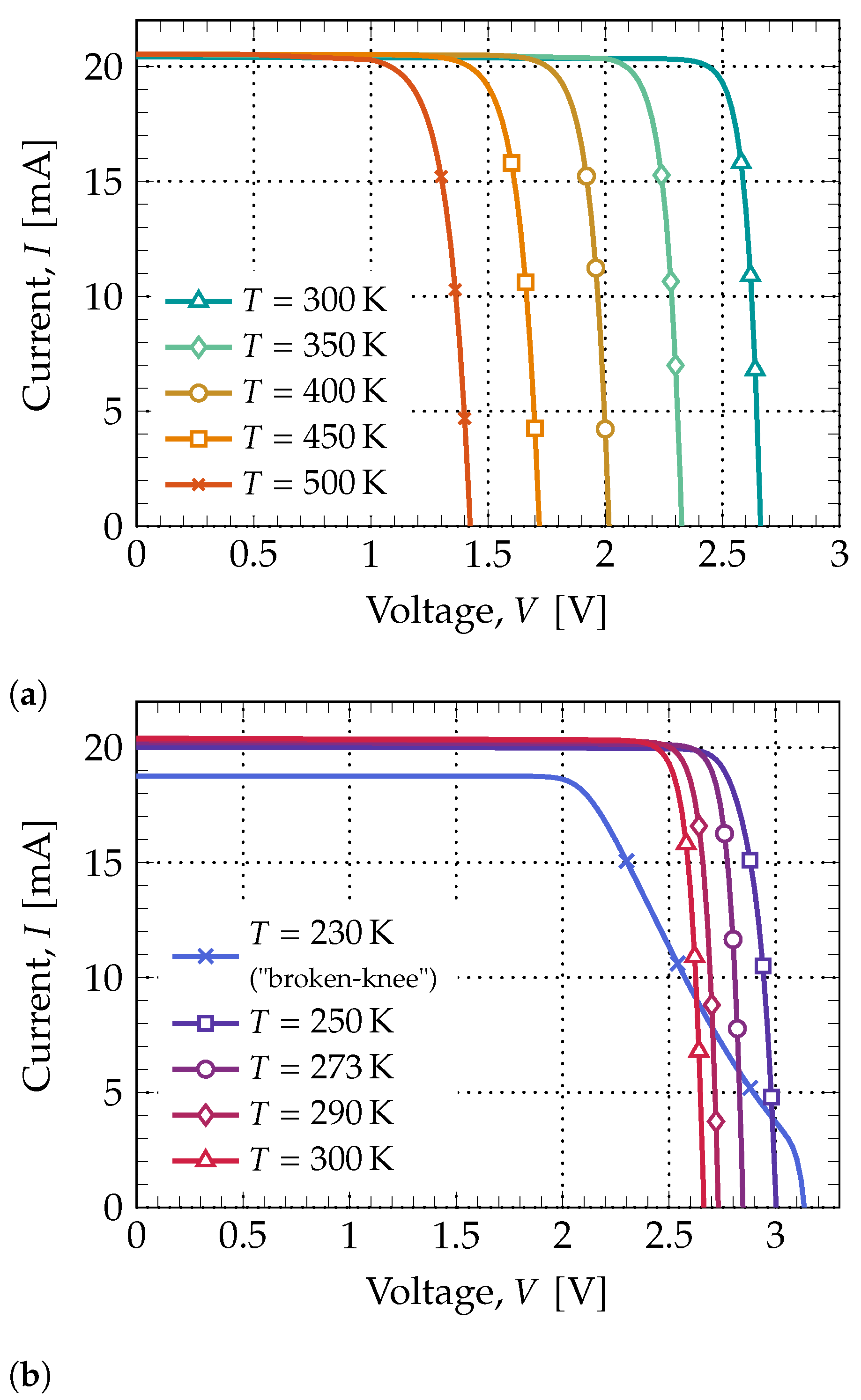

4.3. Temperature Effects

High and Low Temperatures

5. Cell Optimization

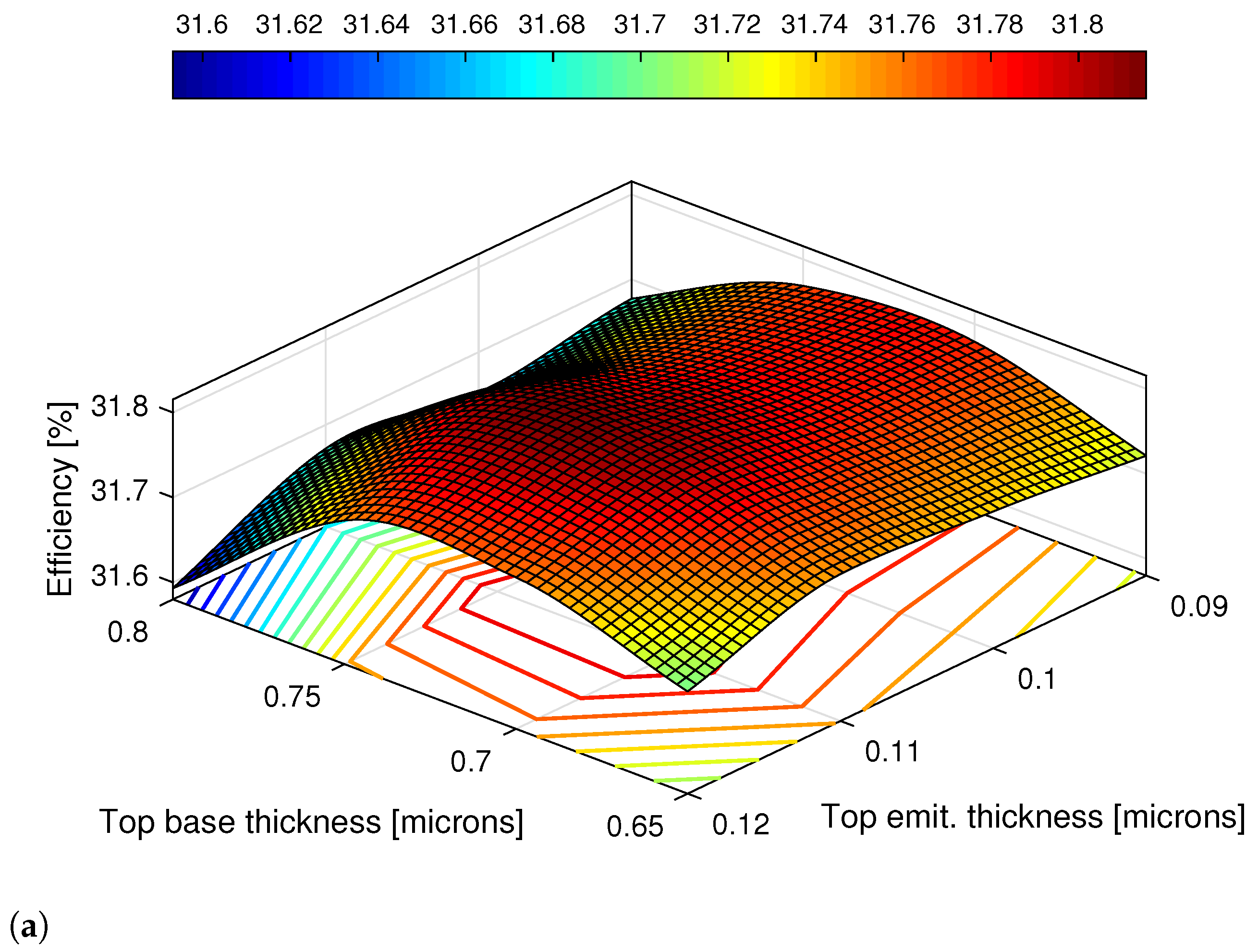

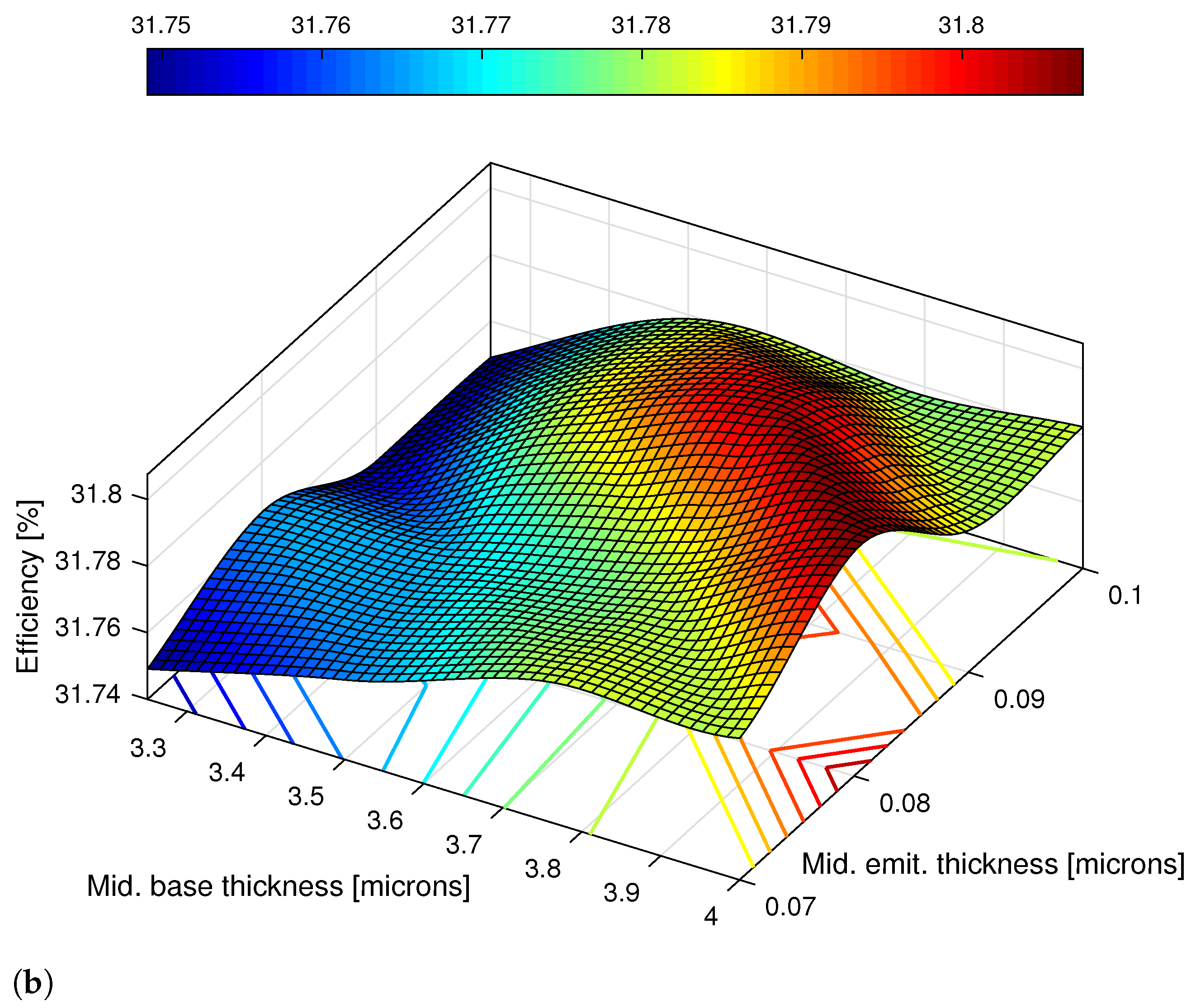

5.1. Thickness Variation

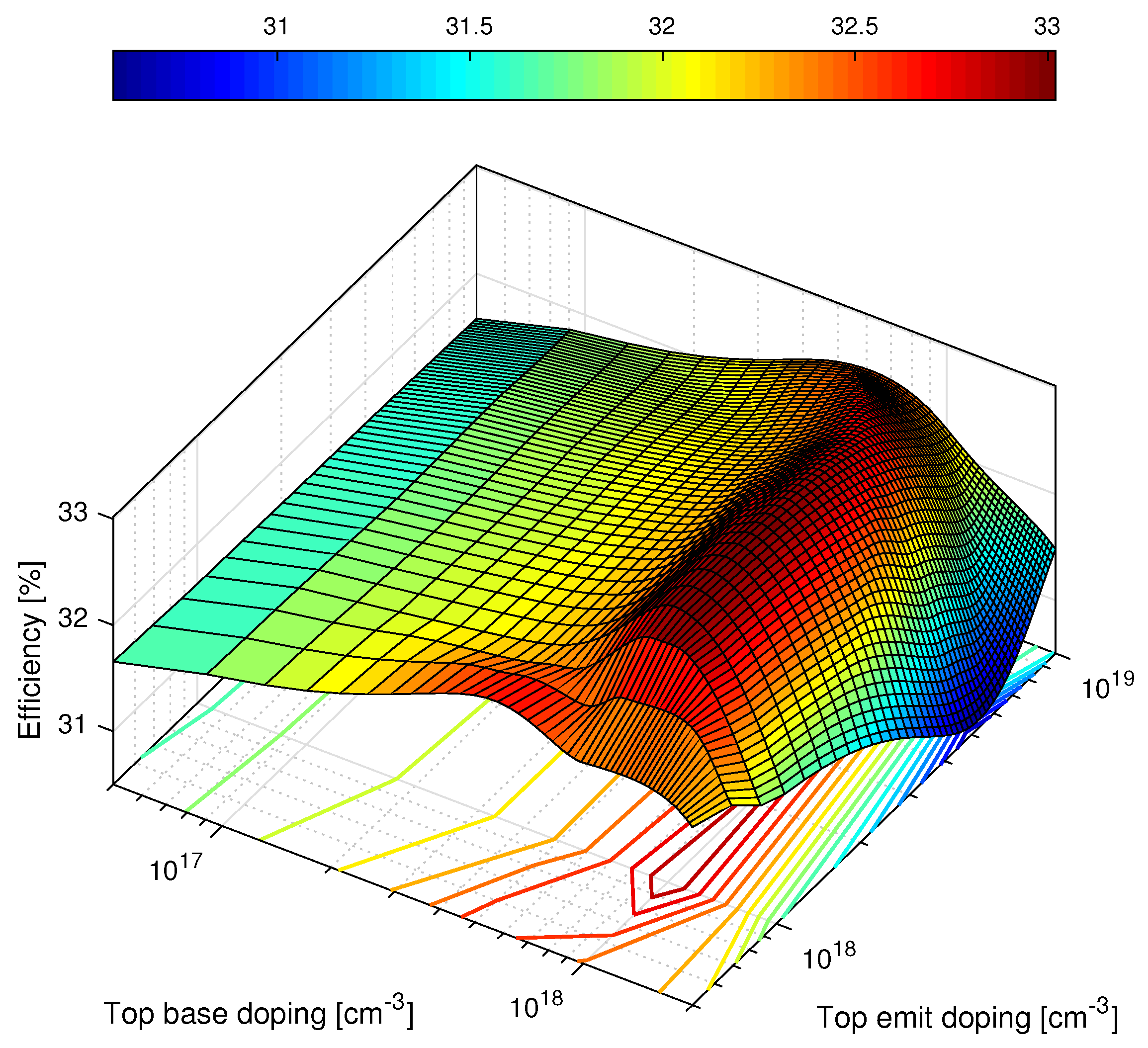

5.2. Doping Variation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IRENA. Renewable Capacity Highlights 2019; IRENA: Abu Dhabi, UAE, 2019. [Google Scholar]

- Durão, B.; Torres, J.P.N.; Fernandes, C.A.F.; Lameirinhas, R.A.M. Socio-economic Study to Improve the Electrical Sustainability of the North Tower of Instituto Superior Técnico. Sustainability 2020, 12, 1923. [Google Scholar] [CrossRef]

- Melo, I.; Torres, J.P.N.; Fernandes, C.A.F.; Lameirinhas, R.A.M. Sustainability economic study of the islands of the Azores archipelago using photovoltaic panels, wind energy and storage system. Renewables 2020, 7, 1–21. [Google Scholar] [CrossRef]

- Bhattacharya, I.; Foo, S.Y. Indium phosphide, indium-gallium-arsenide and indium-gallium-antimonide based high efficiency multijunction photovoltaics for solar energy harvesting. In Proceedings of the 2009 1st Asia Symposium on Quality Electronic Design, Kuala Lumpur, Malaysia, 15–16 July 2009; pp. 237–241. [Google Scholar]

- Bhattacharya, I.; Foo, S.Y. Effects of Gallium-Phosphide and Indium-Gallium-Antimonide semiconductor materials on photon absorption of multijunction solar cells. In Proceedings of the IEEE SoutheastCon 2010 (SoutheastCon), Concord, NC, USA, 18–21 March 2010; pp. 316–319. [Google Scholar]

- Alves, P.; Fernandes, J.; Torres, J.; Branco, P.; Fernandes, C.; Gomes, J. Energy Efficiency of a PV/T Collector for Domestic Water Heating Installed in Sweden or in Portugal: Impact of Heat Pipe Cross-Section Geometry and Water Flowing Speed. In Proceedings of the Sdewes 2017, Dubrovnik, Croatia, 4–8 October 2017. [Google Scholar]

- Gomes, J.; Luc, B.; Carine, G.; Fernandes, C.A.; Torres, J.P.N.; Olsson, O.; Nashih, S.K. Analysis of different C-PVT reflector geometries. In Proceedings of the 2016 IEEE International Power Electronics and Motion Control Conference (PEMC), Varna, Bulgaria, 25–30 September 2016. [Google Scholar]

- Mota, F.; Torres, J.P.N.; Fernandes, C.A.F.; Lameirinhas, R.A.M. Influence of an aluminium concentrator corrosion on the output characteristic of a photovoltaic system. Sci. Rep. 2020, 10, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Marques, L.; Torres, J.; Branco, P. Triangular shape geometry in a Solarus AB concentrating photovoltaic-thermal collector. Int. J. Interact. Des. Manuf. (IJIDeM) 2018, 12, 1455–1468. [Google Scholar] [CrossRef]

- Torres, J.P.N.; Fernandes, C.A.; Gomes, J.; Luc, B.; Carine, G.; Olsson, O.; Branco, P.J. Effect of reflector geometry in the annual received radiation of low concentration photovoltaic systems. Energies 2018, 11, 1878. [Google Scholar] [CrossRef]

- Fernandes, C.A.; Torres, J.P.N.; Morgado, M.; Morgado, J.A. Aging of solar PV plants and mitigation of their consequences. In Proceedings of the 2016 IEEE International Power Electronics and Motion Control Conference (PEMC), Varna, Bulgaria, 25–30 September 2016. [Google Scholar]

- Torres, J.P.N.; Nashih, S.K.; Fernandes, C.A.; Leite, J.C. The effect of shading on photovoltaic solar panels. Energy Syst. 2018, 9, 195–208. [Google Scholar] [CrossRef]

- Fernandes, C.A.F.; Torres, J.P.N.; Branco, P.C.; Fernandes, J.; Gomes, J.R. Cell string layout in solar photovoltaic collectors. Energy Convers. Manag. 2017, 149, 997–1009. [Google Scholar] [CrossRef]

- Fernandes, C.A.; Torres, J.P.N.; Gomes, J.; Branco, P.C.; Nashih, S.K. Stationary solar concentrating photovoltaic-thermal collector—Cell string layout. In Proceedings of the 2016 IEEE International Power Electronics and Motion Control Conference (PEMC), Varna, Bulgaria, 25–30 September 2016. [Google Scholar]

- Campos, C.; Torres, J.; Fernandes, J. Effects of the heat transfer fluid selection on the efficiency of a hybrid concentrated photovoltaic and thermal collector. Energies 2019, 12, 1814. [Google Scholar] [CrossRef]

- Torres, J.P.N.; Fernandes, J.F.; Fernandes, C.; Costa, B.P.J.; Barata, C.; Gomes, J. Effect of the collector geometry in the concentrating photovoltaic thermal solar cell performance. Therm. Sci. 2018, 22, 2243–2256. [Google Scholar] [CrossRef]

- Torres, J.; Seram, V.; Fernandes, C. Influence of the Solarus AB reflector geometry and position of receiver on the output of the concentrating photovoltaic thermal collector. Int. J. Interact. Des. Manuf. (IJIDeM) 2019, 14, 153–172. [Google Scholar] [CrossRef]

- Alves, P.; Fernandes, J.F.; Torres, J.P.N.; Branco, P.C.; Fernandes, C.; Gomes, J. From Sweden to Portugal: The effect of very distinct climate zones on energy efficiency of a concentrating photovoltaic/thermal system (CPV/T). Sol. Energy 2019, 188, 96–110. [Google Scholar] [CrossRef]

- Nashih, S.K.; Fernandes, C.A.F.; Torres, J.P.N.; Gomes, J.; Costa Branco, P.J. Validation of a simulation model for analysis of shading effects on photovoltaic panels. ASME J. Sol. Energy Eng. 2016, 138, 044503. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2017; IRENA: Abu Dhabi, UAE, 2018. [Google Scholar]

- NREL. NREL Scientists Spurred the Success of Multijunction Solar Cells; NREL: Golden, CO, USA, 2012. [Google Scholar]

- Green, M.A.; Hishikawa, Y.; Dunlop, E.D.; Levi, D.H.; Hohl-Ebinger, J.; Yoshita, M.; Ho-Baillie, A.W. Solar cell efficiency tables (Version 52). Prog. Photovoltaics Res. Appl. 2019, 27, 3–12. [Google Scholar] [CrossRef]

- Chiu, P.T.; Law, D.; Woo, R.; Singer, S.; Bhusari, D.; Hong, W.; Zakaria, A.; Boisvert, J.; Mesropian, S.; King, R.; et al. 35.8% space and 38.8% terrestrial 5J direct bonded cells. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 35–37. [Google Scholar]

- Landis, G.A. Review of solar cell temperature coefficients for space. In Proceedings of the 13th Space Photovoltaic Research and Technology Conference, Cleveland, OH, USA, 14–16 June 1994; pp. 385–399. [Google Scholar]

- Landis, G.A.; Merritt, D.; Raffaelle, R.P.; Scheiman, D. High-Temperature Solar Cell Development; NASA John Glenn Research Center: Cleveland, OH, USA, 2005; pp. 241–247. [Google Scholar]

- King, R.R.; Bhusari, D.; Larrabee, D.; Liu, X.; Rehder, E.; Edmondson, K.; Cotal, H.; Jones, R.K.; Ermer, J.H.; Fetzer, C.M.; et al. Solar cell generations over 40% efficiency. Prog. Photovolt. Res. Appl. 2012, 20, 801–815. [Google Scholar] [CrossRef]

- Cotal, H.; Fetzer, C.; Boisvert, J.; Kinsey, G.; King, R.; Hebert, P.; Yoon, H. III-V multijunction solar cells for concentrating photovoltaics. Energy Environ. Sci. 2009, 2, 174–192. [Google Scholar] [CrossRef]

- Steiner, M.; Philipps, S.P.; Hermle, M.; Bett, A.W.; Dimroth, F. Validated front contact grid simulation for GaAs solar cells under concentrated sunlight. Prog. Photovolt. Res. Appl. 2011, 19, 73–83. [Google Scholar] [CrossRef]

- Philipps, S.P.; Dimroth, F.; Bett, A.W. High-Efficiency III-V Multijunction Solar Cells. In McEvoy’s Handbook of Photovoltaics: Fundamentals and Applications, 3rd ed.; Kalogirou, S.A., Ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 439–463. [Google Scholar]

- King, R.R.; Fetzer, C.M.; Law, D.C.; Edmondson, K.M.; Yoon, H.; Kinsey, G.S.; Krut, D.D.; Ermer, J.H.; Hebert, P.; Cavicchi, B.T.; et al. Advanced III-V multijunction cells for space. In Proceedings of the 2006 IEEE 4th World Conference on Photovoltaic Energy Conversion, Waikoloa, HI, USA, 7–12 May 2006; Volume 2, pp. 1757–1762. [Google Scholar]

- Sharma, P. Modeling, Optimization, and Characterization of High Concentration Photovoltaic Systems Using Multijunction Solar Cells. Ph.D. Thesis, School of Electrical Engineering and Computer Science, University of Ottawa, Ottawa, ON, USA, 2017. [Google Scholar]

- Dugas, J.; Oualid, J. Modelling of base doping concentration influence in polycrystalline silicon solar cells. Sol. Cells 1987, 20, 145–154. [Google Scholar] [CrossRef]

- King, R.; Law, D.; Edmondson, K.; Fetzer, C.; Kinsey, G.; Hojun, Y.; Krut, D.; Ermer, J.; Sherif, R.; Karam, N. Advances in High-Efficiency III-V Multijunction Solar Cells. Adv. Optoelectron. 2007. [Google Scholar] [CrossRef]

| Experimental | Simulation | ||

|---|---|---|---|

| (Spectrolab) | without MG * | with MG * | |

| 14.37 | 15.8771 | 14.4693 | |

| 2.622 | 2.6296 | 2.6248 | |

| 2.301 | 2.39 | 2.38 | |

| FF | 0.85 | 0.89 | 0.88 |

| 32.0 | 36.9 | 33.65 | |

| Figure 7a | Figure 7b | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 18.7692 | 19.9959 | 20.2036 | 20.3397 | 20.4106 | 20.5206 | 20.5199 | 20.5445 | 20.5342 | |

| 3.1344 | 3.0021 | 2.8466 | 2.7307 | 2.6627 | 2.3263 | 2.0162 | 1.7189 | 1.4237 | |

| 0.64 | 0.88 | 0.91 | 0.90 | 0.89 | 0.87 | 0.85 | 0.81 | 0.77 | |

| 27.77 | 38.79 | 38.25 | 36.72 | 35.73 | 30.59 | 25.74 | 21.05 | 16.46 | |

| Base | Emit. | |||||

|---|---|---|---|---|---|---|

| 0.75 | 0.10 | 18.6750 | 2.6251 | 0.8847 | 31.7687 | 0.0000 |

| 0.70 | 0.11 | 18.5956 | 2.6254 | 0.8893 | 31.8039 | +0.1107 |

| Base | Emit. | |||||

|---|---|---|---|---|---|---|

| 3.50 | 0.08 | 18.6750 | 2.6251 | 0.8847 | 31.7687 | 0.0000 |

| 4.00 | 0.08 | 18.6744 | 2.6272 | 0.8851 | 31.8074 | +0.1220 |

| 3.75 | 0.09 | 18.6861 | 2.6262 | 0.8847 | 31.8036 | +0.1098 |

| Base | Emit. | |||||

|---|---|---|---|---|---|---|

| 18.6371 | 2.6805 | 0.90 | 33.02 | +3.9368 | ||

| 18.5943 | 2.6276 | 0.89 | 31.84 | +0.2343 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bernardes, S.; Lameirinhas, R.A.M.; Torres, J.P.N.; Fernandes, C.A.F. Characterization and Design of Photovoltaic Solar Cells That Absorb Ultraviolet, Visible and Infrared Light. Nanomaterials 2021, 11, 78. https://doi.org/10.3390/nano11010078

Bernardes S, Lameirinhas RAM, Torres JPN, Fernandes CAF. Characterization and Design of Photovoltaic Solar Cells That Absorb Ultraviolet, Visible and Infrared Light. Nanomaterials. 2021; 11(1):78. https://doi.org/10.3390/nano11010078

Chicago/Turabian StyleBernardes, Sara, Ricardo A. Marques Lameirinhas, João Paulo N. Torres, and Carlos A. F. Fernandes. 2021. "Characterization and Design of Photovoltaic Solar Cells That Absorb Ultraviolet, Visible and Infrared Light" Nanomaterials 11, no. 1: 78. https://doi.org/10.3390/nano11010078

APA StyleBernardes, S., Lameirinhas, R. A. M., Torres, J. P. N., & Fernandes, C. A. F. (2021). Characterization and Design of Photovoltaic Solar Cells That Absorb Ultraviolet, Visible and Infrared Light. Nanomaterials, 11(1), 78. https://doi.org/10.3390/nano11010078