Self-Catalyzed InSb/InAs Quantum Dot Nanowires

Abstract

1. Introduction

2. Methods

3. Results and Discussion

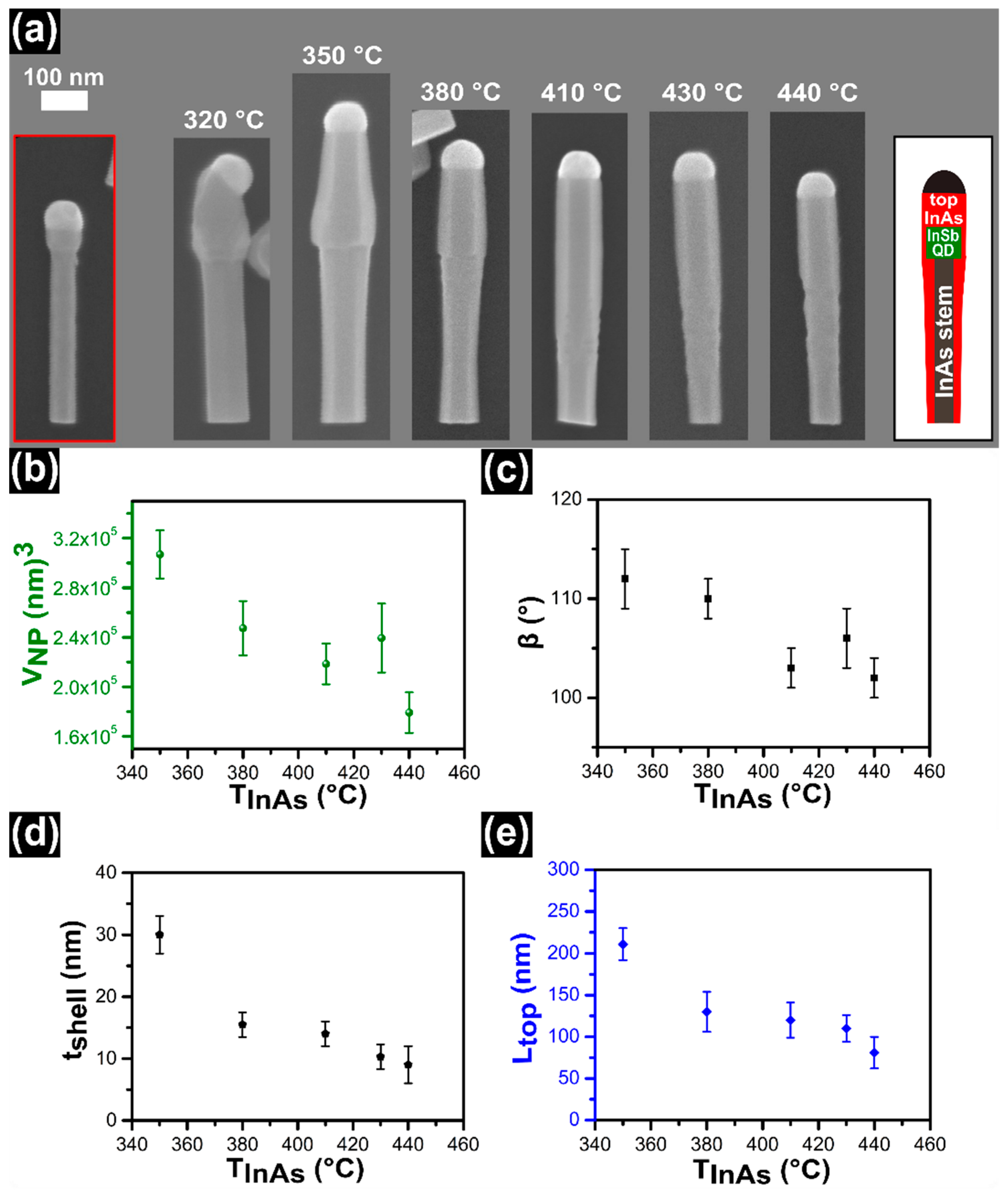

3.1. InAs Growth Temperature Series

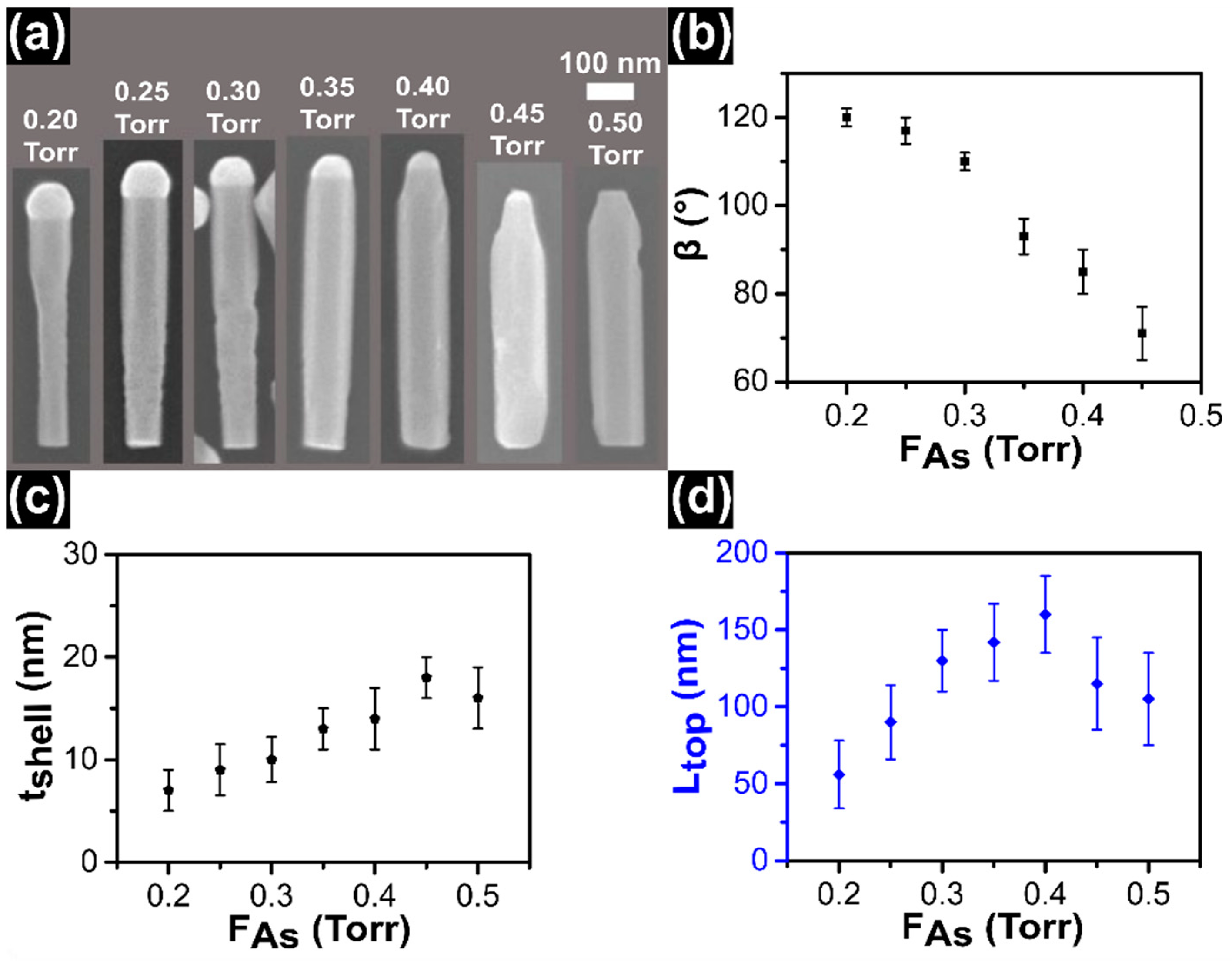

3.2. As Line Pressure Series

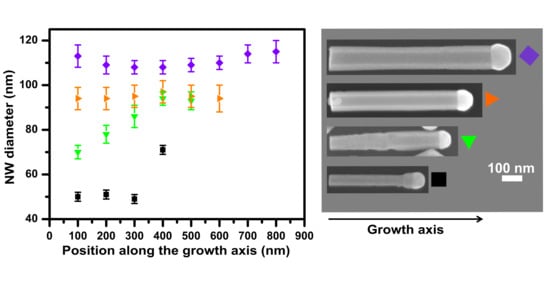

3.3. Time Series

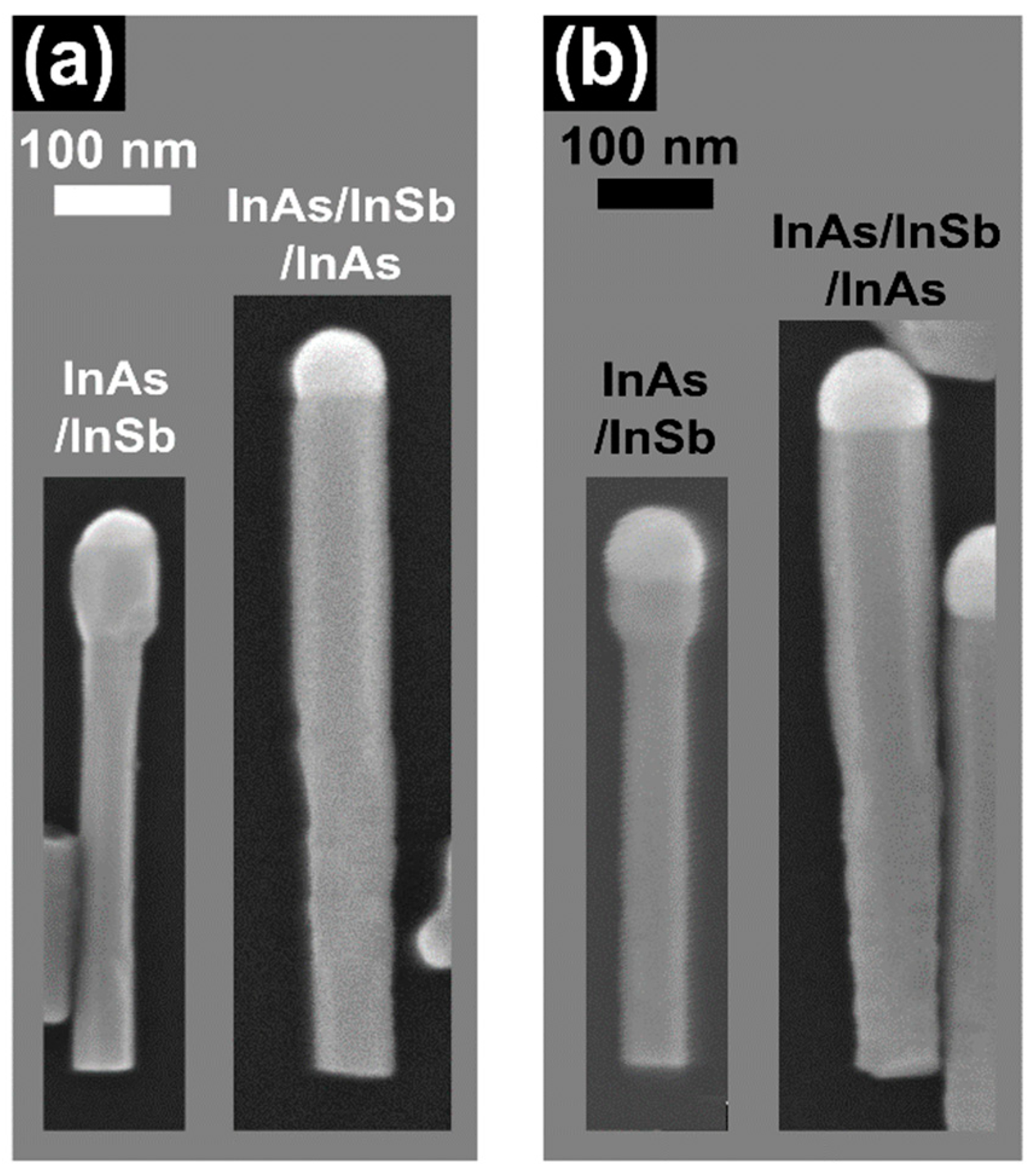

3.4. Nanoparticle Consumption

3.5. Discussion

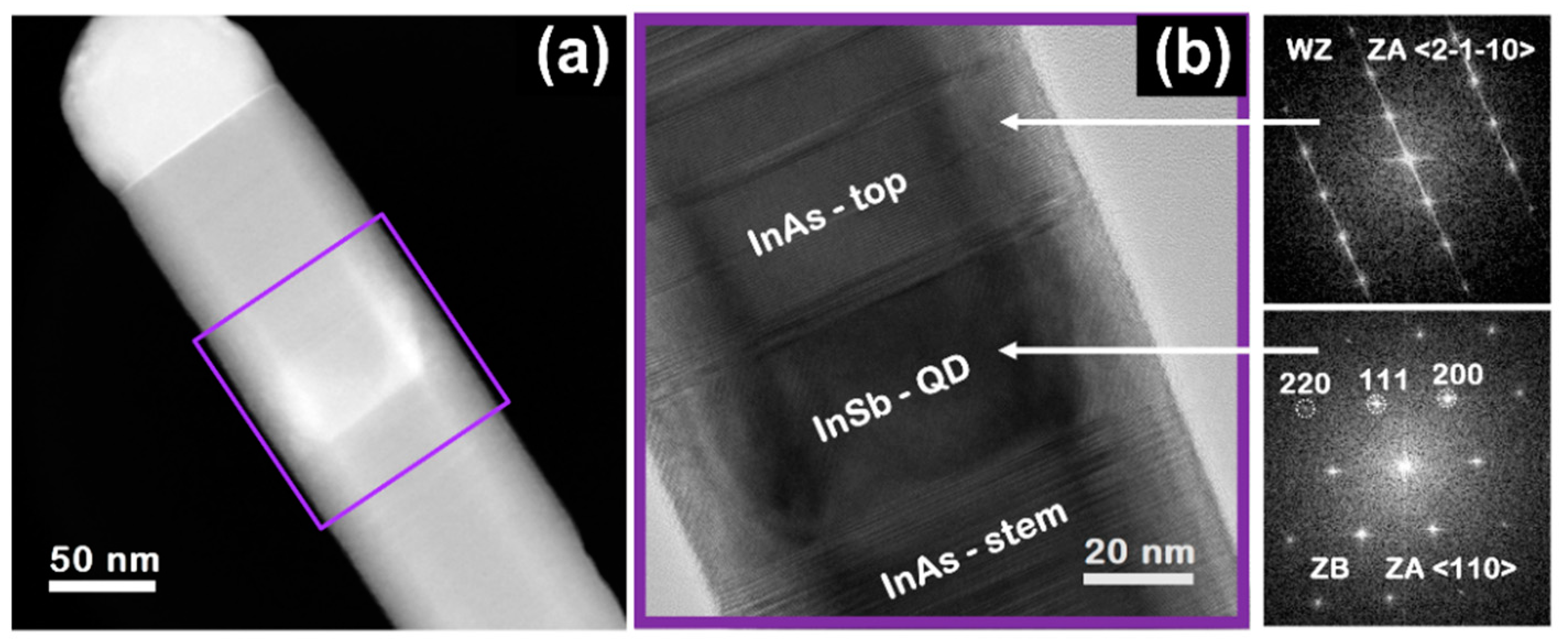

3.6. Study of Crystal Structure

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, J.; Ramsay, A.; Sanchez, A.; Zhang, Y.; Kim, D.; Brossard, F.; Hu, X.; Benamara, M.; Ware, M.E.; Mazur, Y.I.; et al. Defect-Free Self-Catalyzed GaAs/GaAsP Nanowire Quantum Dots Grown on Silicon Substrate. Nano Lett. 2016, 16, 504–511. [Google Scholar] [CrossRef]

- Dalacu, D.; Mnaymneh, K.; Lapointe, J.; Wu, X.; Poole, P.J.; Bulgarini, G.; Zwiller, V.; Reimer, M.E. Ultraclean Emission from InAsP Quantum Dots in Defect-Free Wurtzite InP Nanowires. Nano Lett. 2012, 12, 5919–5923. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; Zhang, X.; Ren, X.; Huang, H.; Guo, J.; Guo, X.; Liu, M.; Wang, Q.; Cai, S.; Huang, Y. Growth of InAs Quantum Dots on GaAs Nanowires by Metal Organic Chemical Vapor Deposition. Nano Lett. 2011, 11, 3941–3945. [Google Scholar] [CrossRef] [PubMed]

- Uccelli, E.; Arbiol, J.; Morante, J.R.; Fontcuberta, I.; Morral, A. InAs Quantum Dot Arrays Decorating the Facets of GaAs Nanowires. ACS Nano 2010, 4, 5985–5993. [Google Scholar] [CrossRef] [PubMed]

- Loitsch, B.; Winnerl, J.; Grimaldi, G.; Wierzbowski, J.; Rudolph, D.; Morkötter, S.; Döblinger, M.; Abstreiter, G.; Koblmüller, G.; Finley, J.J. Crystal Phase Quantum Dots in the Ultrathin Core of GaAs-AlGaAs Core-Shell Nanowires. Nano Lett. 2015, 15, 7544–7551. [Google Scholar] [CrossRef] [PubMed]

- Zannier, V.; Rossi, F.; Ercolani, D.; Sorba, L. Growth Dynamics of InAs/InP Nanowire Heterostructures by Au-Assisted Chemical Beam Epitaxy. Nanotechnology 2019, 30, 094003–094008. [Google Scholar] [CrossRef]

- Glas, F. Stress Relaxation in Nanowires with Heterostructures. In Wide Band Gap Semiconductor Nanowires 1; Consonni, V., Feuillet, G., Eds.; ISTE Ltd.; John Wiley & Sons, Inc.: London, UK; Hoboken, NJ, USA, 2014. [Google Scholar] [CrossRef]

- Arif, O.; Zannier, V.; Li, A.; Roosi, F.; Ercolani, D.; Beltram, F.; Sorba, L. Growth and Strain Relaxation Mechanisms of InAs/InP/GaAsSb Core-Dual-Shell Nanowires. Cryst. Growth Des. 2020, 20, 1088–1096. [Google Scholar] [CrossRef]

- Rieger, T.; Grützmacher, D.; Lepsa, M.I. Misfit Dislocation Free InAs/GaSb Core-Shell Nanowires Grown by Molecular Beam Epitaxy. Nanoscale 2015, 7, 356–364. [Google Scholar] [CrossRef]

- Ercolani, D.; Rossi, F.; Li, A.; Roddaro, S.; Grillo, V.; Salviati, G.; Beltram, F.; Sorba, L. InAs/InSb Nanowire Heterostructures Grown by Chemical Beam Epitaxy. Nanotechnology 2009, 20, 505605–505610. [Google Scholar] [CrossRef]

- Kats, V.N.; Kochereshko, V.P.; Platonov, A.V.; Chizhova, T.V.; Cirlin, G.E.; Bouravleuv, A.D.; Samsonenko, Y.B.; Soshnikov, I.P.; Ubyivovk, E.V.; Bleuse, J.; et al. Optical Study of GaAs Quantum Dots Embedded into AlGaAs Nanowires. Semicond. Sci. Technol. 2012, 27, 015009–015013. [Google Scholar] [CrossRef]

- Borgström, M.T.; Zwiller, V.; Müller, E.; Imamoglu, A. Optically Bright Quantum Dots in Single Nanowires. Nano Lett. 2005, 5, 1439–1443. [Google Scholar] [CrossRef] [PubMed]

- Van Weert, M.H.M.; Akopian, N.; Perinetti, U.; Van Kouwen, M.P.; Algra, R.E.; Verheijen, M.A.; Erik, P.A.M.B.; Kouwenhoven, L.P.; Zwiller, V. Selective Excitation and Detection of Spin States in a Single Nanowire Quantum Dot. Nano Lett. 2009, 9, 1989–1993. [Google Scholar] [CrossRef] [PubMed]

- Roddaro, S.; Pescaglini, A.; Ercolani, D.; Sorba, L.; Beltram, F. Manipulation of Electron Orbitals in Hard-Wall InAs/InP Nanowire Quantum Dots. Nano Lett. 2011, 11, 1695–1699. [Google Scholar] [CrossRef] [PubMed]

- Prete, D.; Erdman, P.A.; Demontis, V.; Zannier, V.; Ercolani, D.; Sorba, L.; Beltram, F.; Rossella, F.; Taddei, F.; Roddaro, S. Thermoelectric Conversion at 30 K in InAs/InP Nanowire Quantum Dots. Nano Lett. 2019, 19, 3033–3039. [Google Scholar] [CrossRef] [PubMed]

- Sadre Momtaz, Z.; Servino, S.; Demontis, V.; Zannier, V.; Ercolani, D.; Rossi, F.; Rossella, F.; Sorba, L.; Beltram, F.; Roddaro, S. Orbital Tuning of Tunnel Coupling in InAs/InP Nanowire Quantum Dots. Nano Lett. 2020, 20, 1693–1699. [Google Scholar] [CrossRef]

- Thomas, F.S.; Baumgartner, A.; Gubser, L.; Jünger, C.; Fülöp, G.; Nilsson, M.; Rossi, F.; Zannier, V.; Sorba, L.; Schönenberger, C. Highly Symmetric and Tunable Tunnel Couplings in InAs/InP Nanowire Heterostructure Quantum Dots. Nanotechnology 2020, 31, 135003–135009. [Google Scholar] [CrossRef] [PubMed]

- Harmand, J.; Liu, L.; Patriarche, G.; Tchernycheva, M.; Photonique, L.D.; Nanostructures, D.; Nozay, D. Potential of Semiconductor Nanowires for Single Photon Sources. Proc. SPIE 2009, 7222, 722219. [Google Scholar] [CrossRef]

- Dalacu, D.; Mnaymneh, K.; Wu, X.; Lapointe, J.; Aers, G.C.; Poole, P.J.; Robin, L.; Dalacu, D.; Mnaymneh, K.; Wu, X.; et al. Selective-Area Vapor-Liquid-Solid Growth of Tunable InAsP Quantum Dots in Nanowires. Appl. Phys. Lett. 2011, 98, 251101–251103. [Google Scholar] [CrossRef]

- Lu, Q.; Zhuang, Q.; Krier, A. Gain and Threshold Current in Type II In(As)Sb Mid-Infrared Quantum Dot Lasers. Photonics 2015, 2, 414–425. [Google Scholar] [CrossRef]

- Borg, B.M.; Wernersson, L. Synthesis and Properties of Antimonide Nanowires. Nanotechnology 2013, 24, 202001–202018. [Google Scholar] [CrossRef]

- Yazji, S.; Hoffman, E.A.; Ercolani, D.; Rossella, F.; Pitanti, A.; Cavalli, A.; Roddaro, S.; Abstreiter, G.; Sorba, L.; Zardo, I. Complete Thermoelectric Benchmarking of Individual InSb Nanowires Using Combined Micro-Raman and Electric Transport Analysis. Nano Res. 2015, 8, 4048–4060. [Google Scholar] [CrossRef]

- Fan, D.; Li, S.; Kang, N.; Caroff, P.; Wang, L.B.; Huang, Y.Q.; Deng, M.T.; Yu, C.L.; Xu, H.Q. Formation of Long Single Quantum Dots in High Quality InSb Nanowires Grown by Molecular Beam Epitaxy. Nanoscale 2015, 7, 14822–14828. [Google Scholar] [CrossRef] [PubMed]

- Fang, M.; Han, N.; Wang, F.; Yang, Z.X.; Yip, S.; Dong, G.; Hou, J.J.; Chueh, Y.; Ho, J.C. III–V Nanowires: Synthesis, Property Manipulations, and Device Applications. J. Nanomater. 2014, 2014. [Google Scholar] [CrossRef]

- Yip, S.; Shen, L.; Ho, J.C. Recent Advances in III-Sb Nanowires: From Synthesis to Applications. Nanotechnology 2019, 30, 202003–202027. [Google Scholar] [CrossRef] [PubMed]

- Mingo, N. Thermoelectric Figure of Merit and Maximum Power Factor in III-V Semiconductor Nanowires. Appl. Phys. Lett. 2004, 84, 2652–2654. [Google Scholar] [CrossRef]

- Moiseev, K.D.; Parkhomenko, Y.A.; Ankudinov, A.V.; Gushchina, E.V.; Mikha, M.P.; Titkov, A.N.; Yakovlev, Y.P. InSb/InAs Quantum Dots Grown by Liquid Phase Epitaxy. Tech. Phys. Lett. 2007, 33, 295–298. [Google Scholar] [CrossRef]

- Anyebe, E.A. Recent Progress on the Gold-Free Integration of Ternary III—As Antimonide Nanowires Directly on Silicon. Nanomaterials 2020, 10, 2064. [Google Scholar] [CrossRef]

- Gao, Z.; Sun, J.; Han, M.; Yin, Y.; Gu, Y. Recent Advances in Sb-Based III–V Nanowires. Nanotechnology 2019, 30, 212002–212027. [Google Scholar] [CrossRef]

- Pea, M.; Ercolani, D.; Li, A.; Gemmi, M.; Rossi, F.; Beltram, F.; Sorba, L. Suppression of Lateral Growth in InAs/InAsSb Heterostructured Nanowires. J. Cryst. Growth 2013, 366, 8–14. [Google Scholar] [CrossRef]

- Lu, Q.; Zhuang, Q.; Marshall, A.; Kesaria, M.; Beanland, R.; Krier, A. InSb Quantum Dots for the Mid-Infrared Spectral Range Grown on GaAs Substrates Using Metamorphic InAs Buffer Layers. Semicond. Sci. Technol. 2014, 29, 075011–075018. [Google Scholar] [CrossRef]

- Sokura, L.A.; Nevedomskiy, V.N.; Bert, N.A. Structural Features of Indium Antimonide Quantum Dots on the Indium Arsenide Substrate. St. Petersbg. Polytech. Univ. J. Phys. Math. 2015, 1, 109–112. [Google Scholar] [CrossRef][Green Version]

- Carrington, P.J.; Repiso, E.; Lu, Q.; Fujita, H.; Marshall, A.R.J.; Zhuang, Q.; Krier, A.; La, L. InSb Based Quantum Dot Nanostructures for Mid-Infrared Photonic. Devices. Proc. SPIE 2016, 9919, 99190C. [Google Scholar] [CrossRef]

- Tasco, V.; Deguffroy, N.; Baranov, A.N.; Tournié, E.; Satpati, B.; Trampert, A.; Dunaevski, M.; Titkov, A. High-Density InSb-Based Quantum Dots Emitting in the Mid-Infrared. J. Cryst. Growth 2007, 301–302, 713–717. [Google Scholar] [CrossRef]

- Mazur, Y.I.; Dorogan, V.G.; Salamo, G.J.; Tarasov, G.G.; Liang, B.L.; Reyner, C.J.; Nunna, K.; Huffaker, D.L. Coexistence of Type-I and Type-II Band Alignments in Antimony-Incorporated InAsSb Quantum Dot Nanostructures. Appl. Phys. Lett. 2012, 100, 033102–033105. [Google Scholar] [CrossRef]

- Ting, D.Z.; Soibel, A.; Khoshakhlagh, A.; Keo, S.A.; Rafol, S.B.; Höglund, L.; Luong, E.M.; Fisher, A.M.; Hill, C.J.; Gunapala, S.D. Development of InAs/InAsSb Type II Strained-Layer Superlattice Unipolar Barrier Infrared Detectors. J. Electron. Mater. 2019, 48, 6145–6151. [Google Scholar] [CrossRef]

- Svensson, S.F.; Jeppesen, S.; Thelander, C.; Samuelson, L.; Linke, H.; Dick, K.A. Control and Understanding of Kink Formation in InAs-InP Heterostructure Nanowires. Nanotechnology 2013, 24, 345601–345609. [Google Scholar] [CrossRef]

- Gudiksen, M.S.; Lauhon, L.J.; Wang, J.; Smith, D.C.; Lieber, C.M. Growth of Nanowire Superlattice Structures for Nanoscale Photonics and Electronics. Nature 2002, 415, 617–620. [Google Scholar] [CrossRef]

- Zannier, V.; Ercolani, D.; Gomes, U.P.; David, J.; Gemmi, M.; Dubrovskii, V.G.; Sorba, L. Catalyst Composition Tuning: The Key for the Growth of Straight Axial Nanowire Heterostructures with Group III Interchange. Nano Lett. 2016, 16, 7183–7190. [Google Scholar] [CrossRef]

- Ercolani, D.; Gemmi, M.; Nasi, L.; Rossi, F.; Pea, M.; Li, A.; Salviati, G.; Beltram, F.; Sorba, L. Growth of InAs/InAsSb Heterostructured Nanowires. Nanotechnology 2012, 23, 115606–115614. [Google Scholar] [CrossRef]

- Gomes, U.P.; Ercolani, D.; Sibirev, N.V.; Gemmi, M.; Dubrovskii, V.G.; Beltram, F.; Sorba, L. Catalyst-Free Growth of InAs Nanowires on Si (111) by CBE. Nanotechnology 2015, 26, 415604. [Google Scholar] [CrossRef]

- Gomes, U.P.; Ercolani, D.; Zannier, V.; Battiato, S.; Ubyivovk, E.; Mikhailovskii, V.; Murata, Y.; Heun, S.; Beltram, F.; Sorba, L. Heterogeneous Nucleation of Catalyst-Free InAs Nanowires on Silicon. Nanotechnology 2017, 28, 065603–065609. [Google Scholar] [CrossRef] [PubMed]

- Arif, O.; Zannier, V.; Dubrovskii, V.G.; Shtrom, I.V.; Rossi, F.; Beltram, F.; Sorba, L. Growth of Self-Catalyzed InAs/InSb Axial Heterostructured Nanowires: Experiment and Theory. Nanomaterials 2020, 10, 494. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Lee, T.R. Contact angle and wetting properties. In Surface Science Techniques; Bracco, G., Holst, B., Eds.; Springer Series in Surface Sciences; Springer: Berlin/Heidelberg, Germany, 2013; Volume 51. [Google Scholar] [CrossRef]

- Panciera, F.; Baraissov, Z.; Patriarche, G.; Dubrovskii, V.G.; Glas, F.; Travers, L.; Mirsaidov, U.; Harmand, J.C. Phase selection in self-catalyzed GaAs nanowires. Nano Lett. 2020, 20, 1669–1675. [Google Scholar] [CrossRef] [PubMed]

- Anandan, D.; Kakkerla, R.K.; Yu, H.W.; Ko, H.L.; Nagarajan, V.; Singh, S.K.; Lee, C.T.; Chang, E.Y. Growth of Foreign-Catalyst-Free Vertical InAs/InSb Heterostructure Nanowires on Si (1 1 1) Substrate by MOCVD. J. Cryst. Growth 2019, 506, 45–54. [Google Scholar] [CrossRef]

- Li, B.; Yan, X.; Zhang, X.; Ren, X. Self-Catalyzed Growth of InAs Nanowires on InP Substrate. Nanoscale Res. Lett. 2017, 12, 3–7. [Google Scholar] [CrossRef]

- Yan, X.; Zhang, X.; Li, J.; Wu, Y.; Ren, X. Self-Catalyzed Growth of Pure Zinc Blende ⟨110⟩ InP Nanowires. Appl. Phys. Lett. 2015, 107, 023101–023105. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Horiuchi, I.; Paek, J.H.; Sawaki, N. In-Assisted Catalyst-Free MBE-VLS Growth of InAs Nanowires on Si Substrate. AIP Conf. Proc. 2011, 1399, 229–230. [Google Scholar] [CrossRef]

- Hertenberger, S.; Rudolph, D.; Becker, J.; Bichler, M.; Finley, J.J.; Abstreiter, G.; Koblmüller, G. Rate-Limiting Mechanisms in High-Temperature Growth of Catalyst-Free InAs Nanowires with Large Thermal Stability. Nanotechnology 2012, 23, 235602–235613. [Google Scholar] [CrossRef]

- Grap, T.; Rieger, T.; Blömers, C.; Schäpers, T.; Grützmacher, D.; Lepsa, M.I. Self-Catalyzed VLS Grown InAs Nanowires with Twinning Superlattices. Nanotechnology 2013, 24, 335601–335607. [Google Scholar] [CrossRef]

- Colombo, C.; Spirkoska, D.; Frimmer, M.; Abstreiter, G.; Fontcuberta, I.; Morral, A. Ga-Assisted Catalyst-Free Growth Mechanism of GaAs Nanowires by Molecular Beam Epitaxy. Phys. Rev. B. 2008, 77, 155326–155330. [Google Scholar] [CrossRef]

- Rudolph, D.; Hertenberger, S.; Bolte, S.; Paosangthong, W.; Spirkoska, D.; Döblinger, M.; Bichler, M.; Finley, J.J.; Abstreiter, G.; Koblmüller, G. Direct Observation of a Noncatalytic Growth Regime for GaAs Nanowires. Nano Lett. 2011, 11, 3848–3854. [Google Scholar] [CrossRef] [PubMed]

- Gomes, U.P.; Ercolani, D.; Zannier, V.; David, J.; Gemmi, M.; Beltram, F.; Sorba, L. Nucleation and Growth Mechanism of Self-Catalyzed InAs Nanowires on Silicon. Nanotechnology 2016, 27, 255601–255607. [Google Scholar] [CrossRef] [PubMed]

- Dubrovskii, V.G.; Sibirev, N.V.; Halder, N.N.; Ritter, D. Classification of the Morphologies and Related Crystal Phases of III–V Nanowires Based on the Surface Energy Analysis. J. Phys. Chem. C 2019, 123, 18693–18701. [Google Scholar] [CrossRef]

- Dubrovskii, V.G. Development of Growth Theory for Vapor-Liquid-Solid Nanowires: Contact Angle, Truncated Facets, and Crystal Phase. Cryst. Growth Des. 2017, 17, 2544–2548. [Google Scholar] [CrossRef]

- Tersoff, J. Stable Self-Catalyzed Growth of III–V Nanowires. Nano Lett. 2015, 15, 6609–6613. [Google Scholar] [CrossRef]

- Küpers, H.; Lewis, R.B.; Tahraoui, A.; Matalla, M.; Krüger, O.; Bastiman, F.; Riechert, H.; Geelhaar, L. Diameter Evolution of Selective Area Grown Ga-Assisted GaAs Nanowires. Nano Res. 2018, 11, 2885–2893. [Google Scholar] [CrossRef]

- Oehler, F.; Cattoni, A.; Scaccabarozzi, A.; Patriarche, G.; Glas, F.; Harmand, J.C. Measuring and Modeling the Growth Dynamics of Self-Catalyzed GaP Nanowire Arrays. Nano Lett. 2018, 18, 701–708. [Google Scholar] [CrossRef]

- Anyebe, E.A. Influence of Growth Parameters on In-Droplet-Assisted Growth of InAs Nanowires on Silicon. Appl. Nanosci. 2017, 7, 365–370. [Google Scholar] [CrossRef][Green Version]

| Type of Growth | Growth Conditions | R (nm) | H (nm) | β (°) | DInsb (nm) | Dbottom (nm) | LNWs (nm) |

|---|---|---|---|---|---|---|---|

| InAs/InSb | Without In NP consumption | 33 ± 2 | 54 ± 4 | 118 ± 3 | 70 ± 4 | 50 ± 4 | 400 ± 21 |

| InAs/InSb | With In NP consumption | 32 ± 2 | 31 ± 3 | 88 ± 5 | 75 ± 3 | 51 ± 3 | 460 ± 35 |

| InAs/InSb/InAs | Without In NP consumption | 44 ± 2 | 67 ± 5 | 113 ± 3 | 90 ± 4 | 68 ± 5 | 535 ± 33 |

| InAs/InSb/InAs | With In NP consumption | 36 ± 4 | 50 ± 7 | 109 ± 3 | 79 ± 6 | 66 ± 6 | 555 ± 40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arif, O.; Zannier, V.; Rossi, F.; Ercolani, D.; Beltram, F.; Sorba, L. Self-Catalyzed InSb/InAs Quantum Dot Nanowires. Nanomaterials 2021, 11, 179. https://doi.org/10.3390/nano11010179

Arif O, Zannier V, Rossi F, Ercolani D, Beltram F, Sorba L. Self-Catalyzed InSb/InAs Quantum Dot Nanowires. Nanomaterials. 2021; 11(1):179. https://doi.org/10.3390/nano11010179

Chicago/Turabian StyleArif, Omer, Valentina Zannier, Francesca Rossi, Daniele Ercolani, Fabio Beltram, and Lucia Sorba. 2021. "Self-Catalyzed InSb/InAs Quantum Dot Nanowires" Nanomaterials 11, no. 1: 179. https://doi.org/10.3390/nano11010179

APA StyleArif, O., Zannier, V., Rossi, F., Ercolani, D., Beltram, F., & Sorba, L. (2021). Self-Catalyzed InSb/InAs Quantum Dot Nanowires. Nanomaterials, 11(1), 179. https://doi.org/10.3390/nano11010179