A Review of Microwave Synthesis of Zinc Oxide Nanomaterials: Reactants, Process Parameters and Morphologies

Abstract

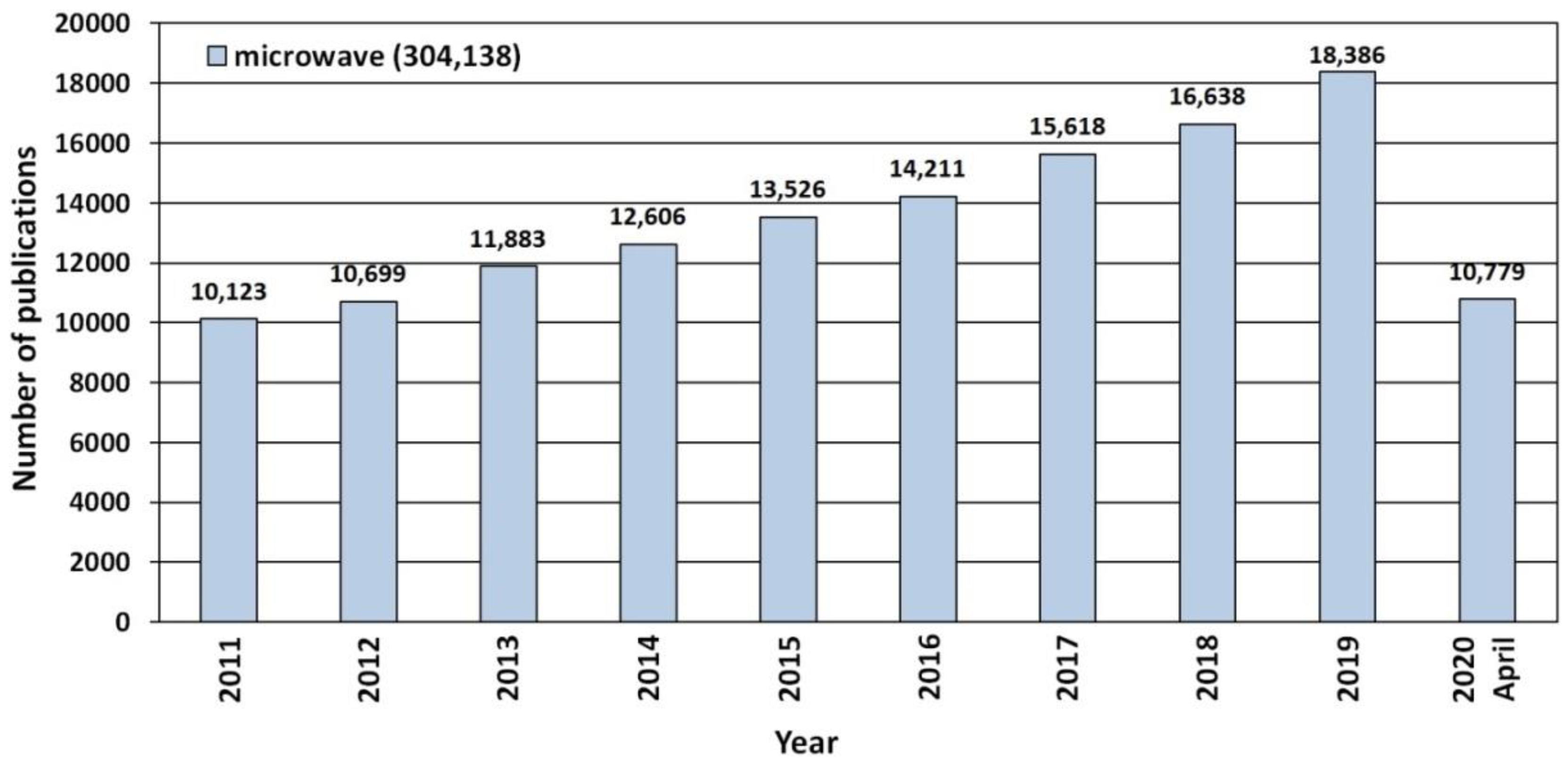

1. Introduction

1.1. Nanotechnology

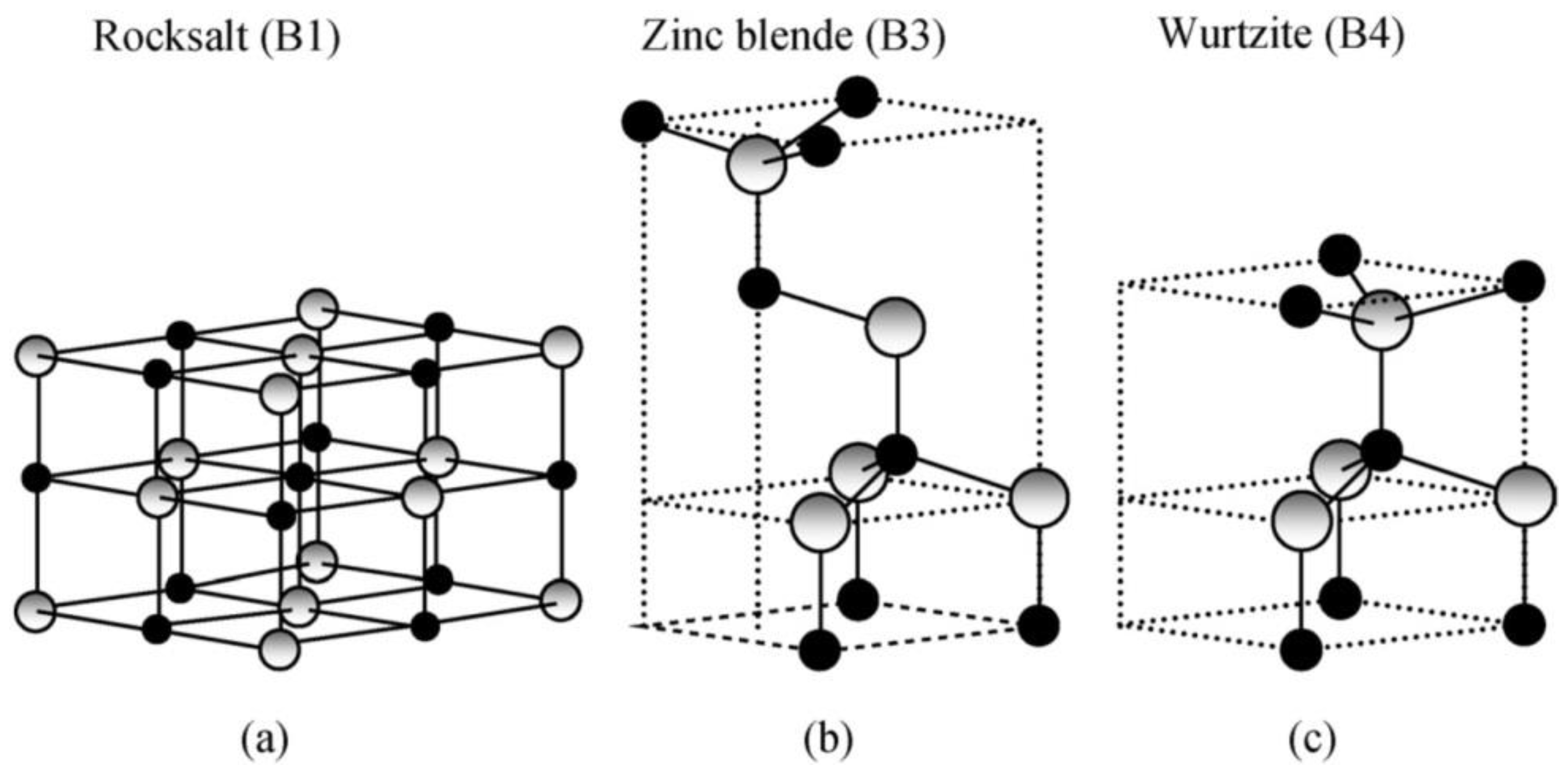

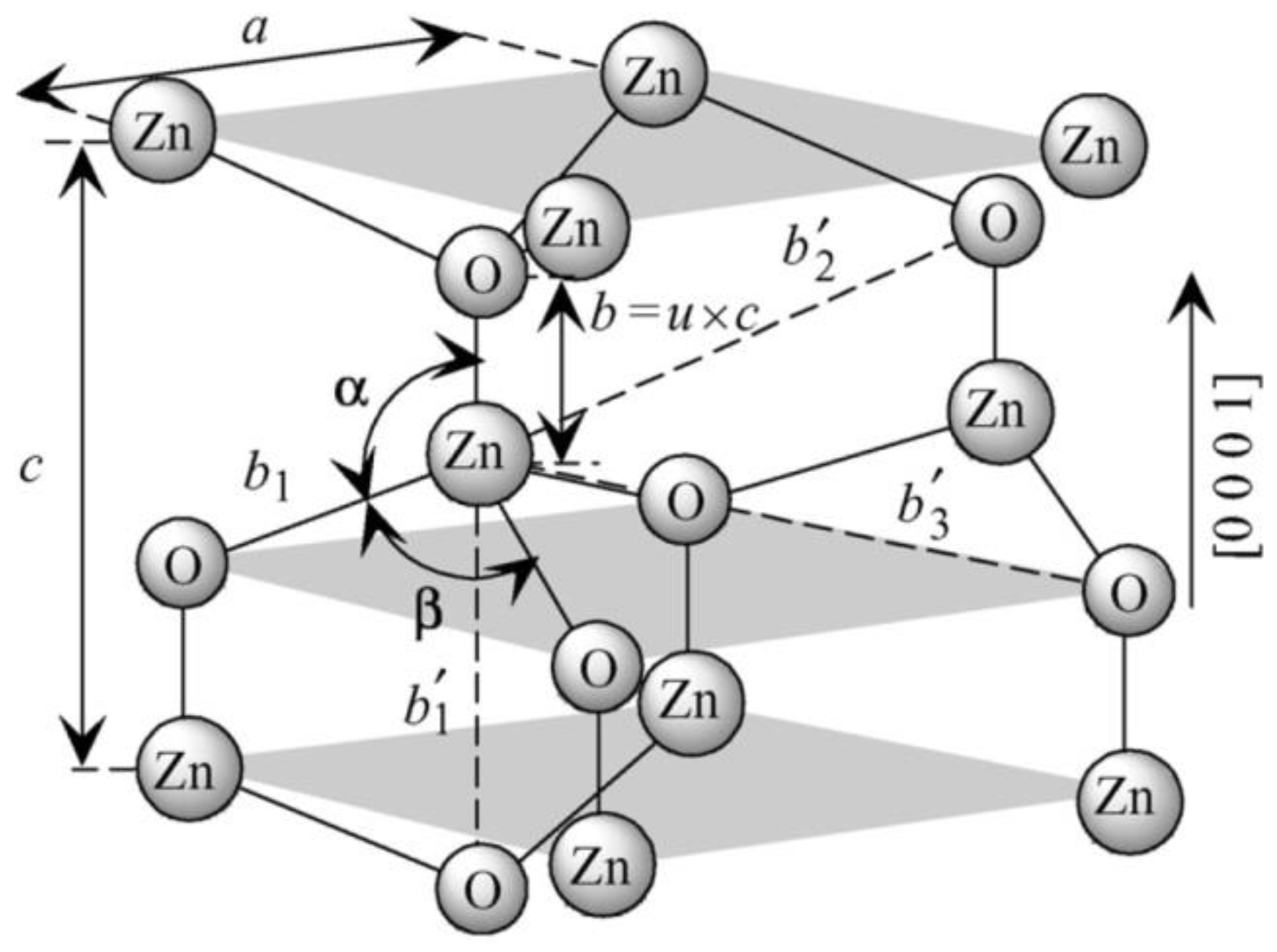

1.2. Bulk ZnO: Properties and Application

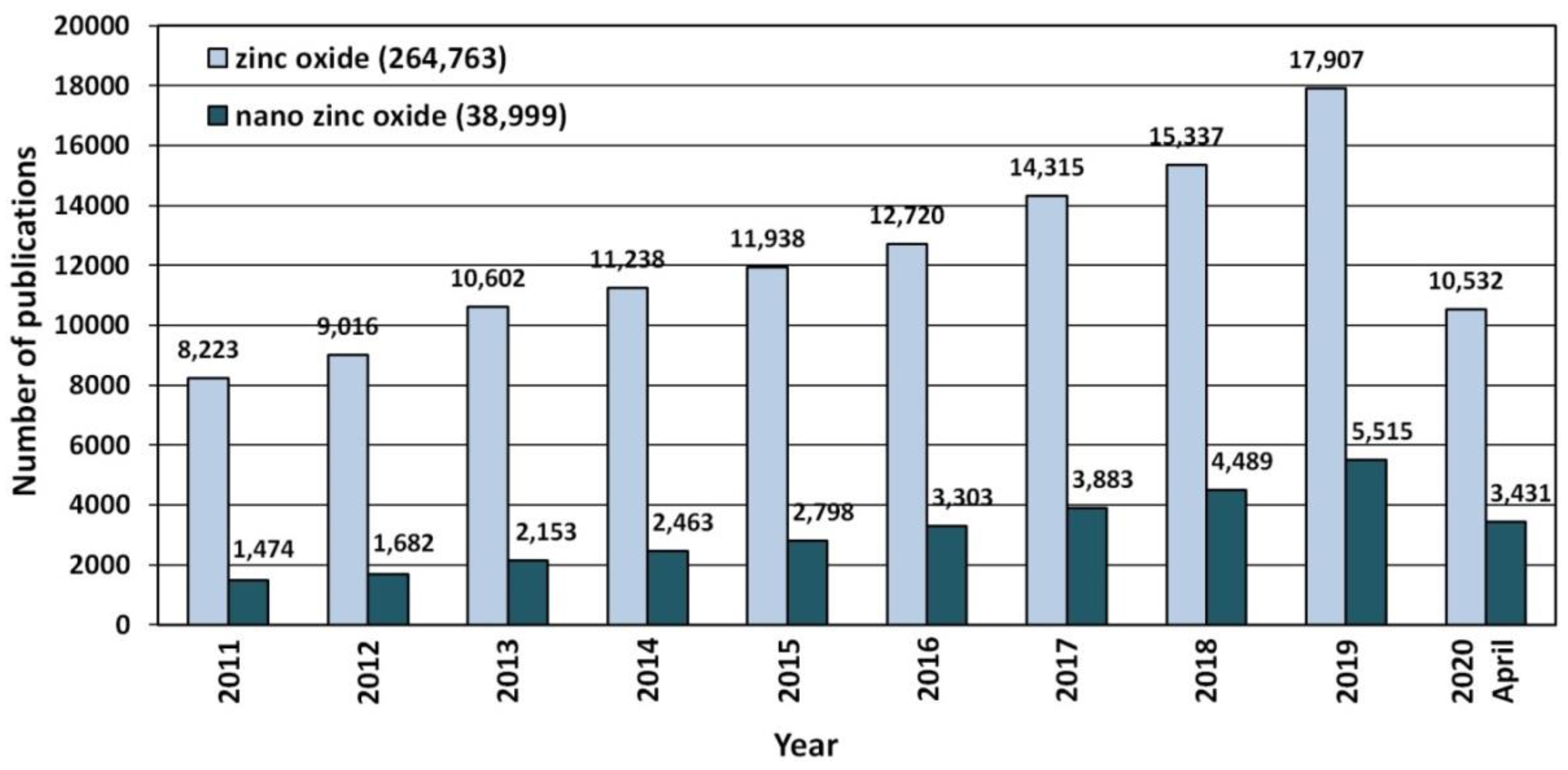

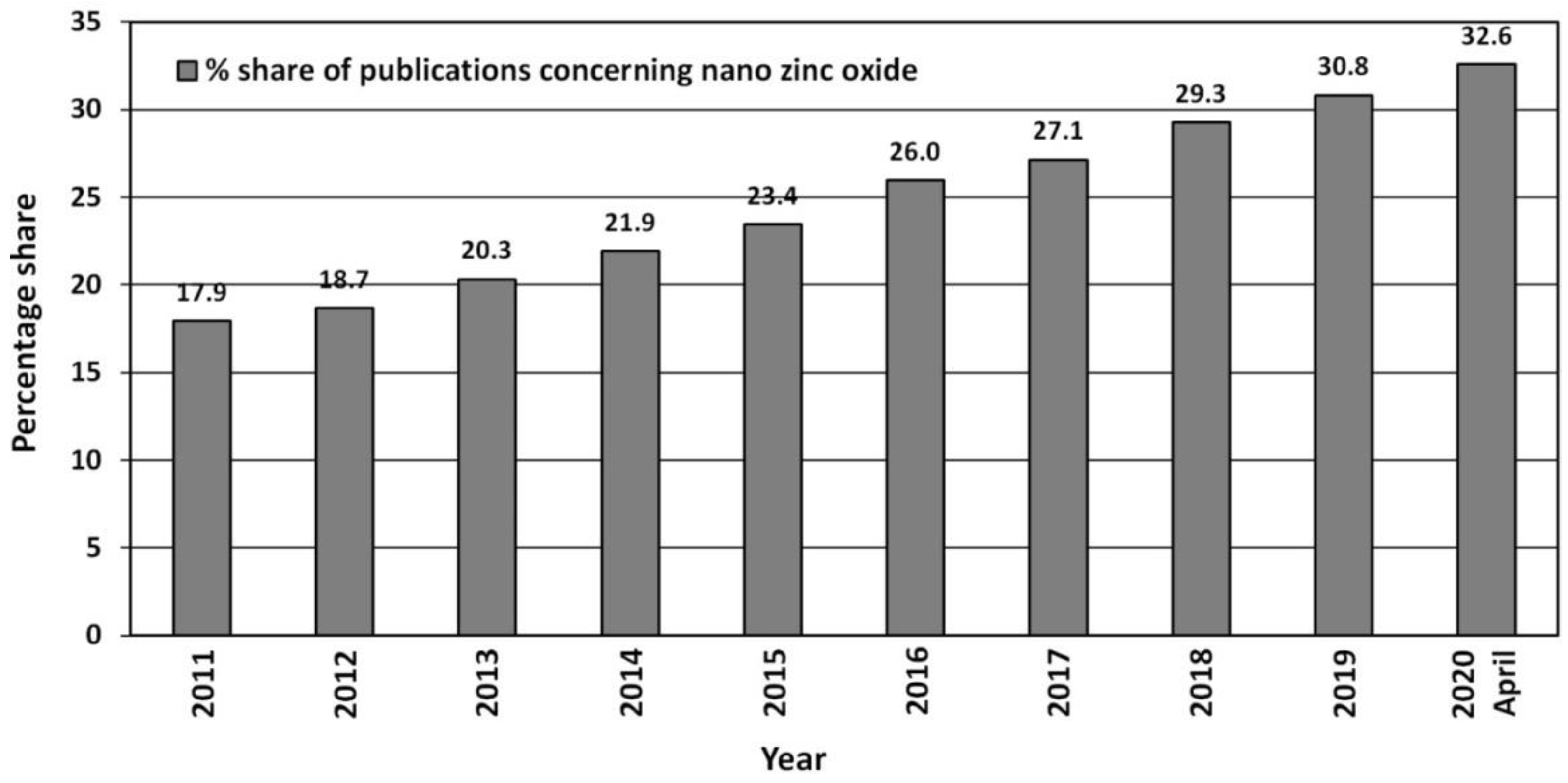

1.3. Nano ZnO: Properties and Application

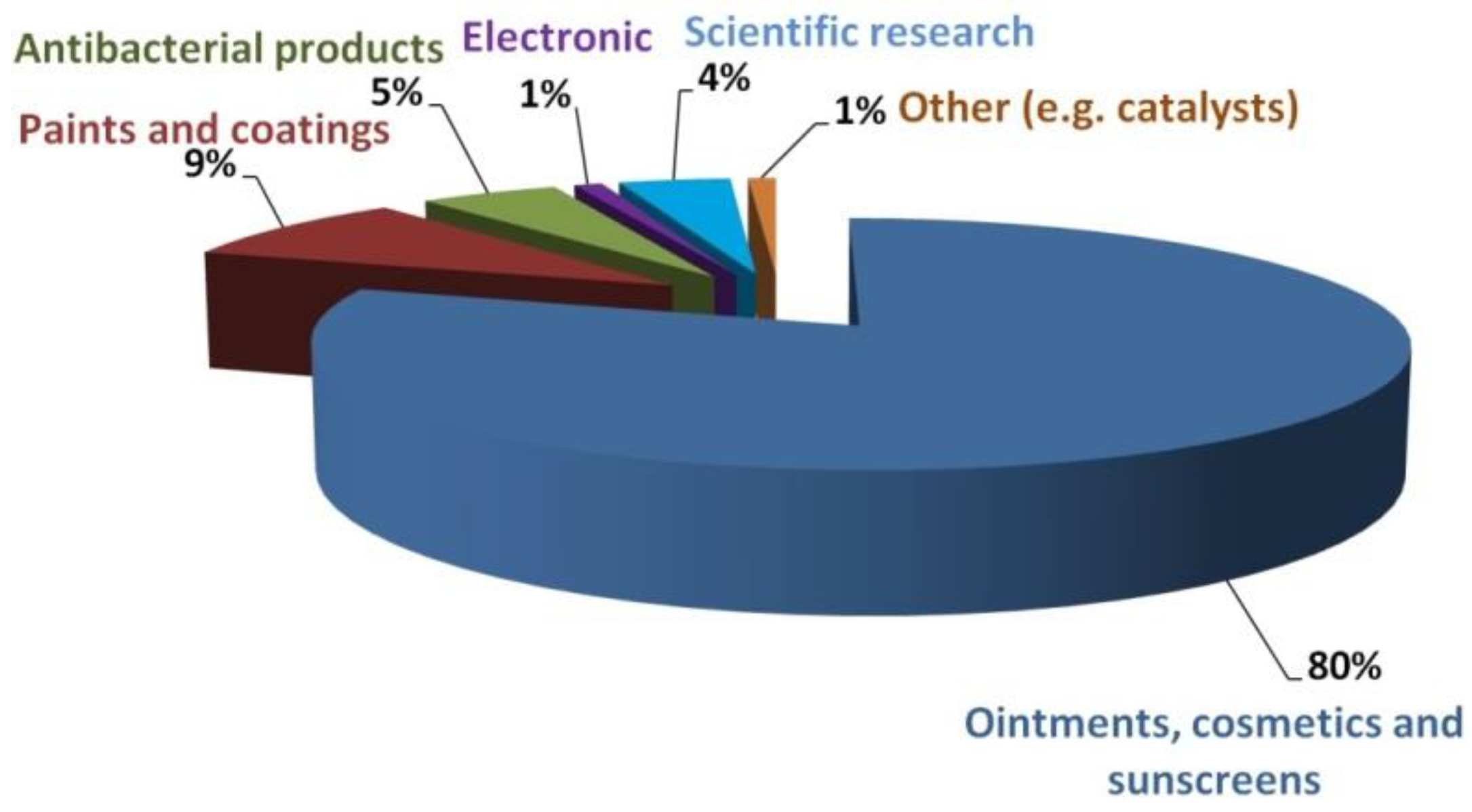

1.4. ZnO Market

- -

- pharmaceuticals,

- -

- cosmetics,

- -

- paints,

- -

- various coatings,

- -

- antibacterial products,

- -

- electronics,

- -

- and in scientific research.

1.5. Obtaining ZnO Nanomaterials

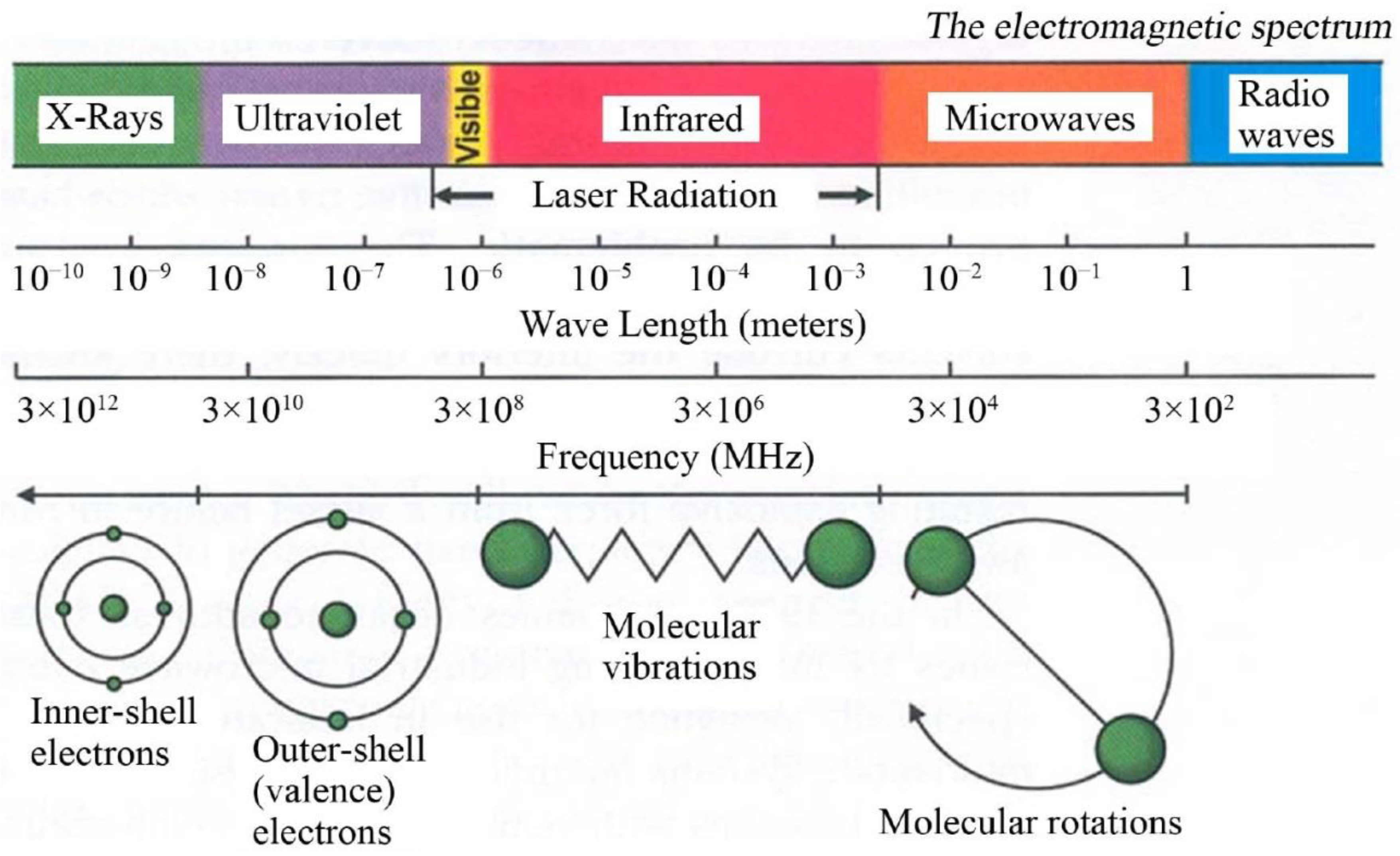

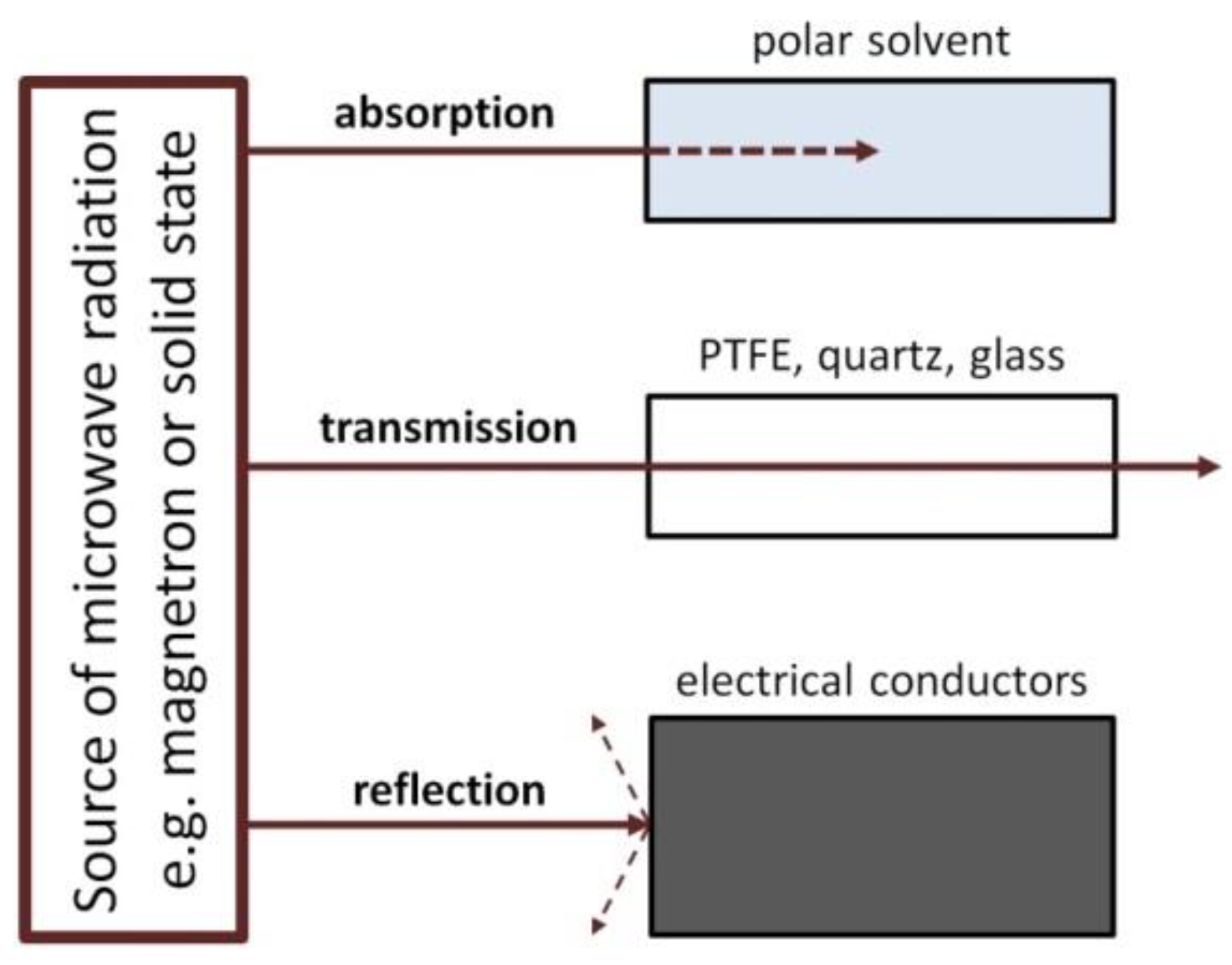

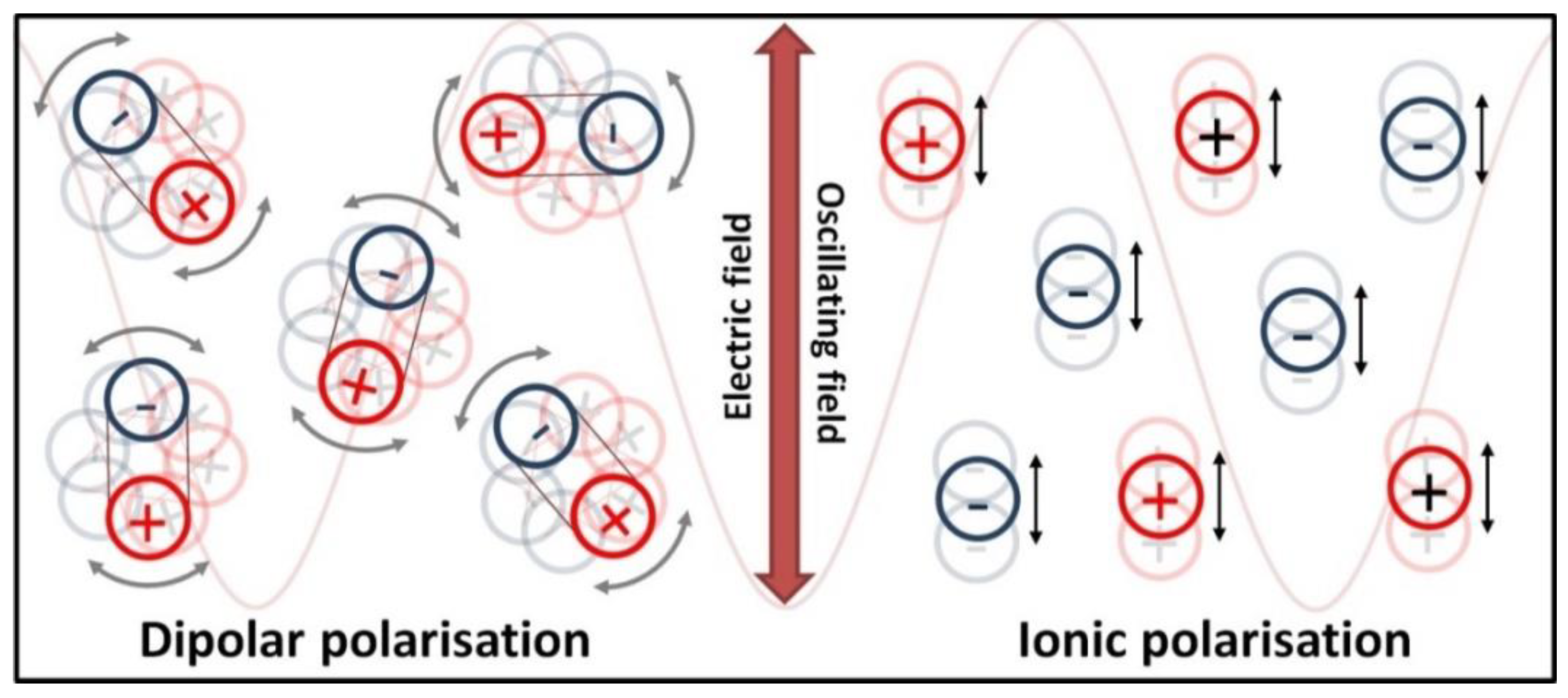

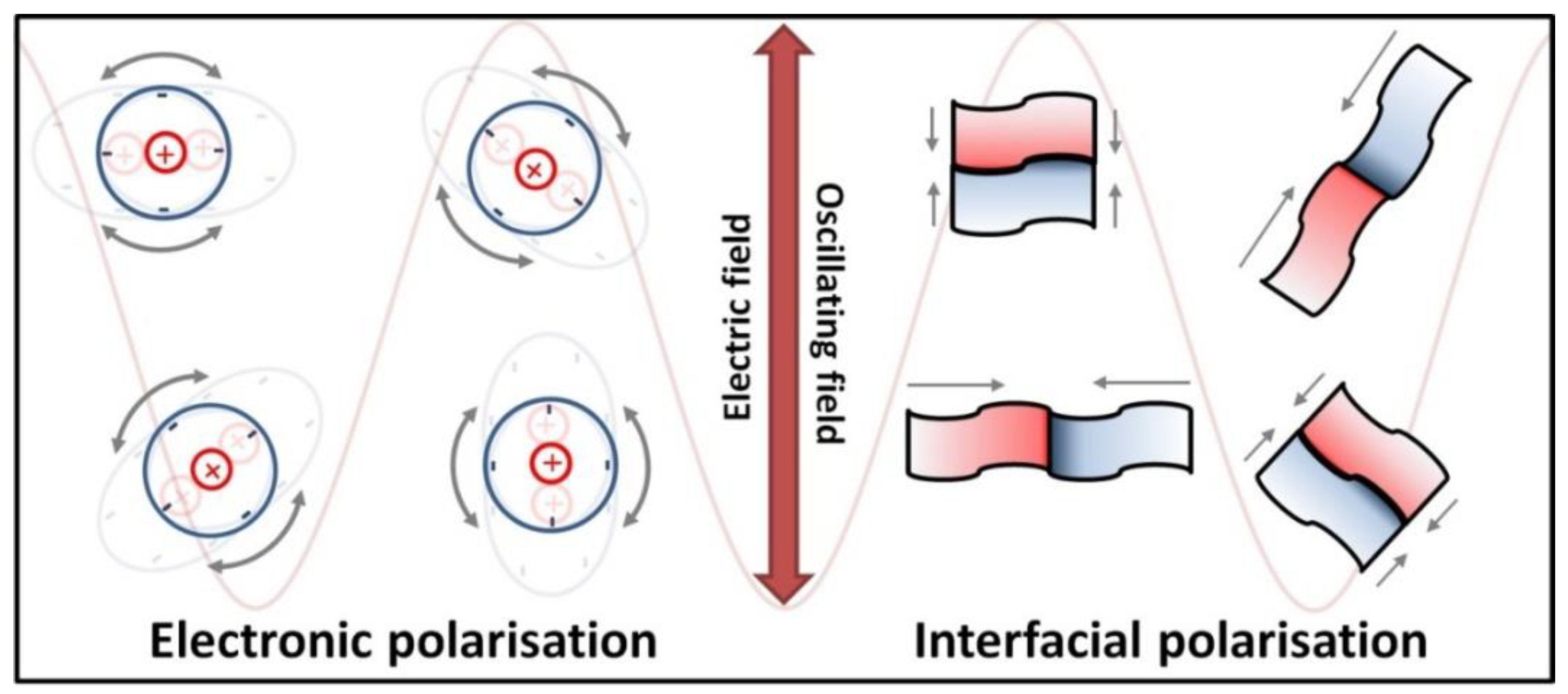

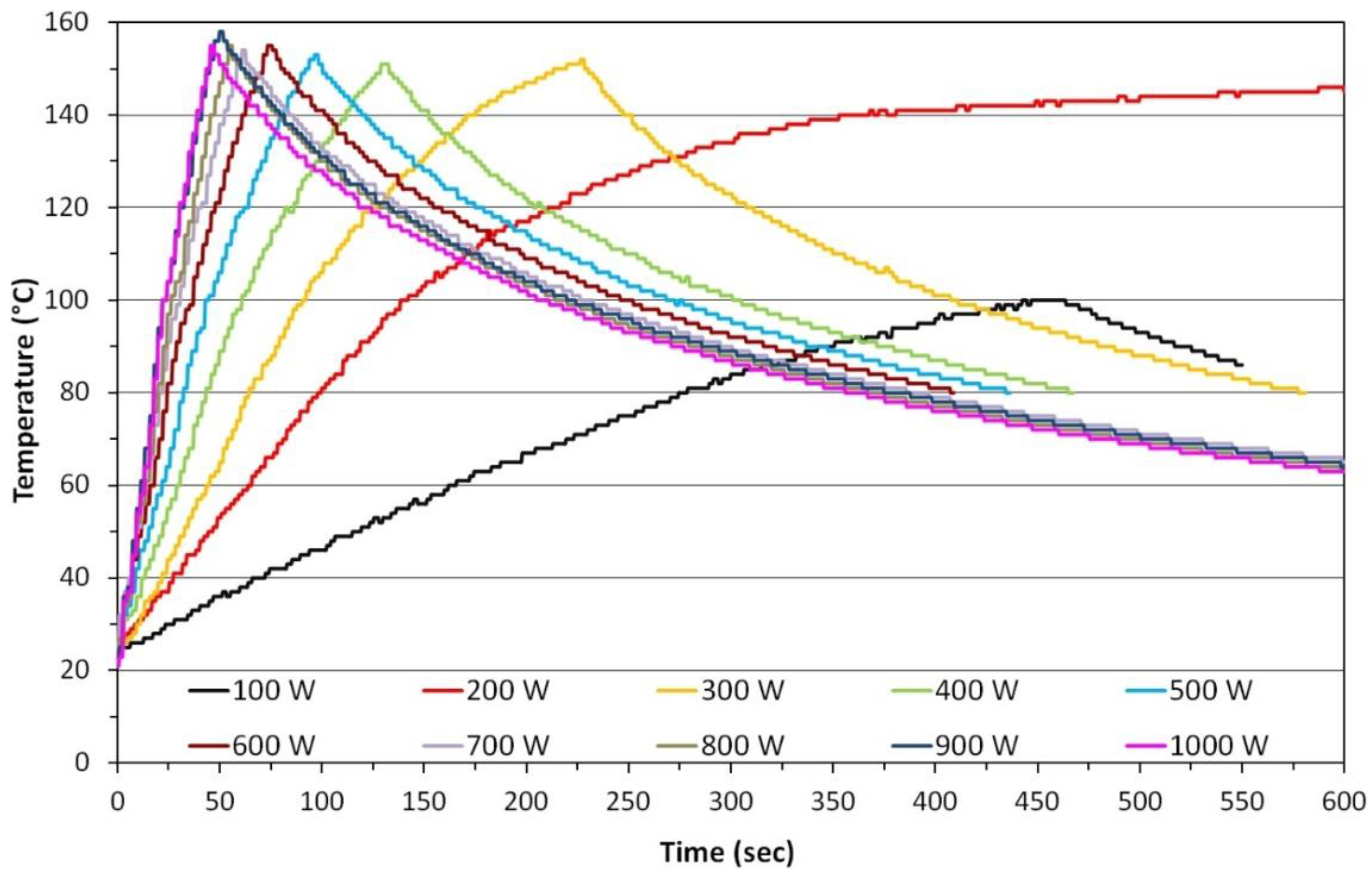

2. Microwave Heating

- -

- low microwave absorbing, where tanδ value <0.1

- -

- medium microwave absorbing, where tanδ value ranges from 0.1 to 0.5

- -

- high microwave absorbing, where tanδ value is higher than 0.5.

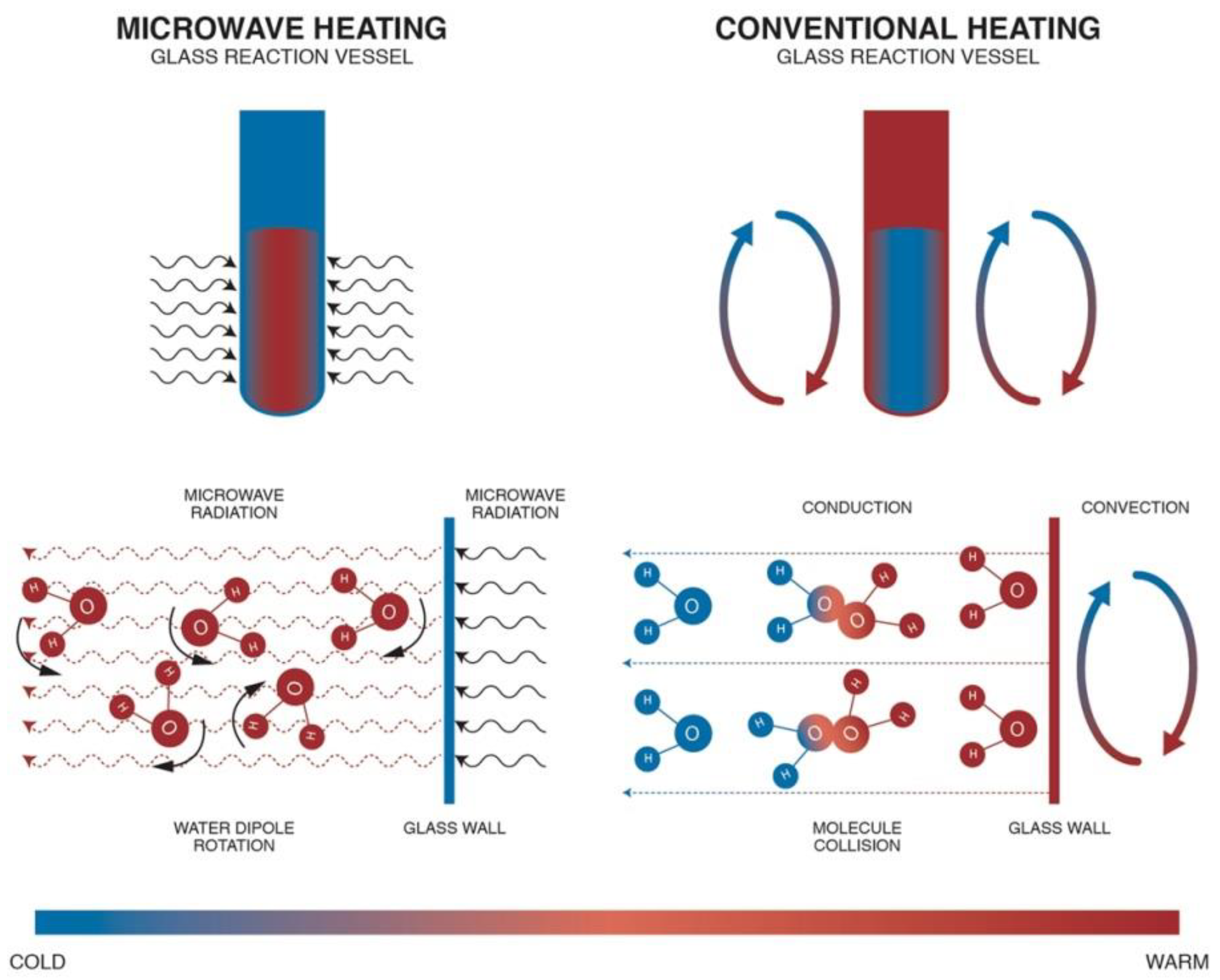

2.1. Comparison of Conventional Heating with Microwave Heating

- (a)

- long heating time, which depends on the thermal conduction of the material of which the reaction chamber walls are made;

- (b)

- temperature maximums occur on the reaction vessel/chamber wall surface, which is one of the direct causes of the heterogeneity of the obtained products (so-called wall effect);

- (c)

- limited reaction control caused by a high thermal inertia of the system, which results from the heating of the heating jacket and the reaction chamber walls;

- (d)

- difficulties involved in the speed of the feedstock cooling process;

- (e)

- high heat losses.

- (a)

- No direct contact of heat source with heated material (contactless method).

- (b)

- Minimisation of the “wall effect” because the wall of the vessel (reaction chamber) is not heated directly.

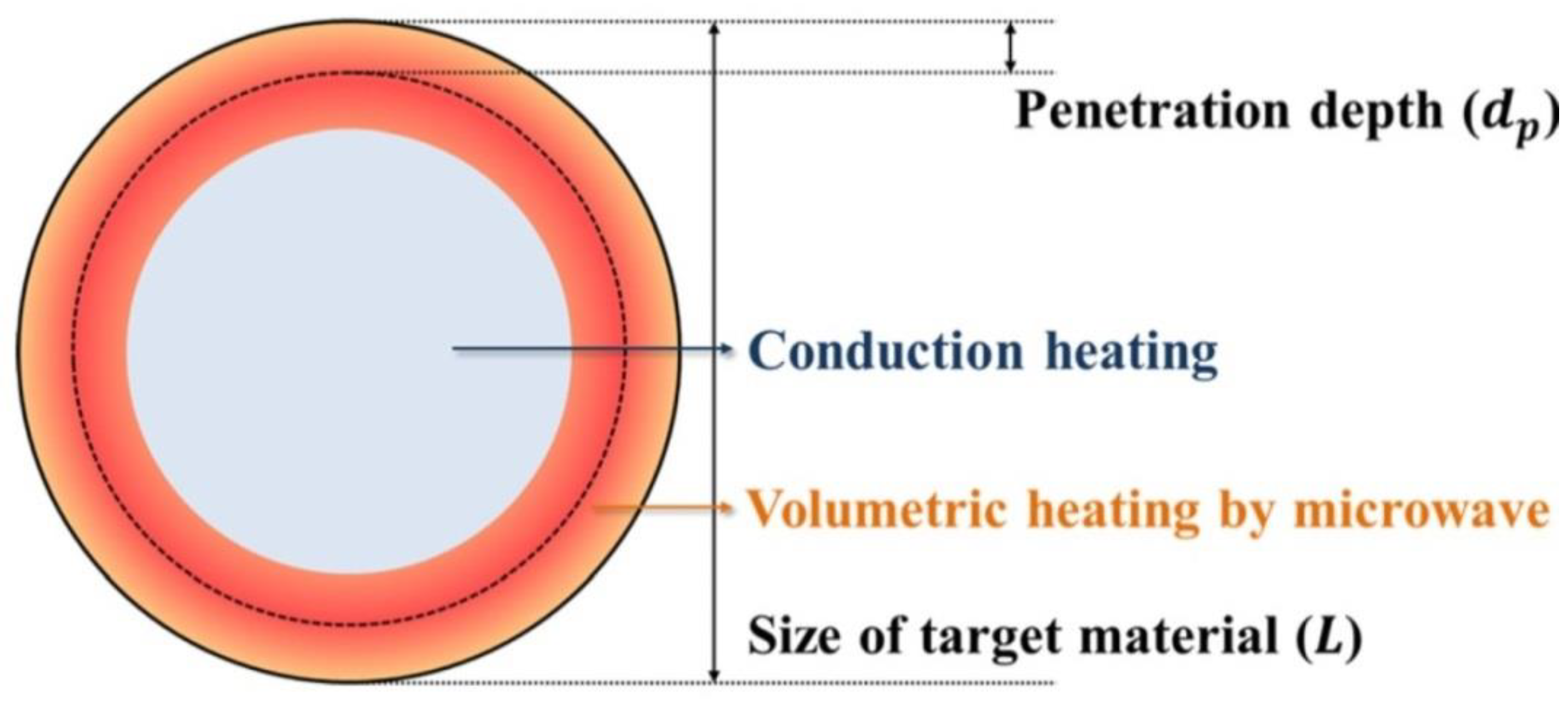

- (c)

- Volumetric heating of the feedstock.

- (d)

- Instantaneous and precise electronic control. Quick heating switching on and off, e.g., heating process can be controlled with the accuracy of 1 s, namely after switching off the magnetron power unit, the heat source supply is interrupted immediately.

- (e)

- Rapid heating with preservation of low thermal gradients (rapid energy transfer) [468].

- (f)

- (g)

- (h)

- (i)

- (j)

- Easy to conduct under solvent-free conditions [451].

- (k)

- Very high power densities developed in the processing zone [452].

- (l)

- Superior moisture levelling [452].

- (m)

- Energy saving [467].

- (n)

- Higher production efficiency (faster throughputs) [452].

- (o)

- Lower apparatus size (compact equipment) [452].

- (p)

- Shorter time of apparatus start-up.

- (q)

2.2. Application of Microwave Heating, Chemical Microwave Apparatus

- (a)

- (b)

- industrial application (np. drying, wood curing, rubber curing and vulcanisation, disinfection, coal pre-treatment and processing, ceramic processing, polymer processing, polymeric composites, ceramic composites, melting of glasses, melting of metallic materials, roasting of tea/coffee beans, plant extraction processes) [442,447,448,449,450,451,481,482,483],

- (c)

- waste treatment (np. medical waste, garbage, sludge) [447];

- (d)

- (e)

- (f)

- -

- random setting of the reaction vessel,

- -

- random geometry of the reaction vessel (shape and size),

- -

- impossibility to monitor the course of the process (temperature (T), pressure (P)).

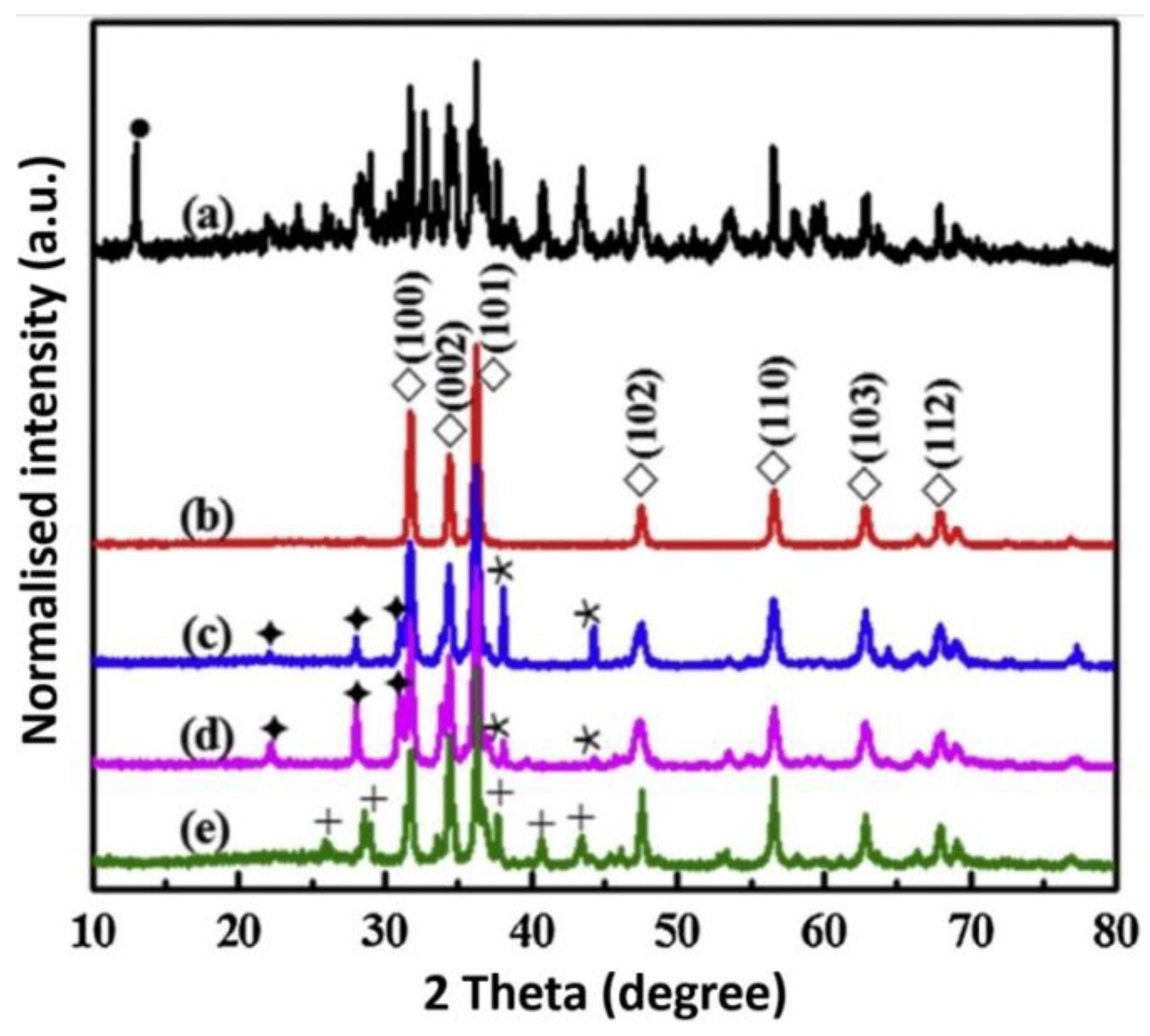

3. Microwave Hydrothermal Synthesis of ZnO

- (1)

- Microwave hydrothermal synthesis of ZnO nanostructures without any additional heat treatment, where the literature review results [506,507,508,509,510,511,512,513,514,515,516,517,518,519,520,521,522,523,524,525,526,527,528,529,530,531,532,533,534,535,536,537,538,539,540,541,542,543,544,545,546,547,548,549,550,551,552,553,554,555,556,557,558,559,560,561,562,563,564,565,566,567,568,569,570,571,572,573,574,575,576,577,578,579,580,581,582,583,584,585,586,587,588,589,590,591,592,593,594,595,596,597,598,599,600,601,602,603,604,605,606,607,608,609,610,611,612,613,614,615,616,617,618,619,620,621,622,623,624,625,626,627,628,629,630,631,632,633,634,635,636,637,638,639] are summarised in Table 5.

- (2)

- (3)

- Microwave hydrothermal synthesis of ZnO nanocomposites or ZnO hybrid nanostructures without any additional heat treatment, where the literature review results [674,675,676,677,678,679,680,681,682,683,684,685,686,687,688,689,690,691,692,693,694,695,696,697,698,699,700,701,702,703,704,705,706,707,708,709,710,711,712,713,714,715,716,717,718,719,720,721,722,723] are summarised in Table 7.

- (4)

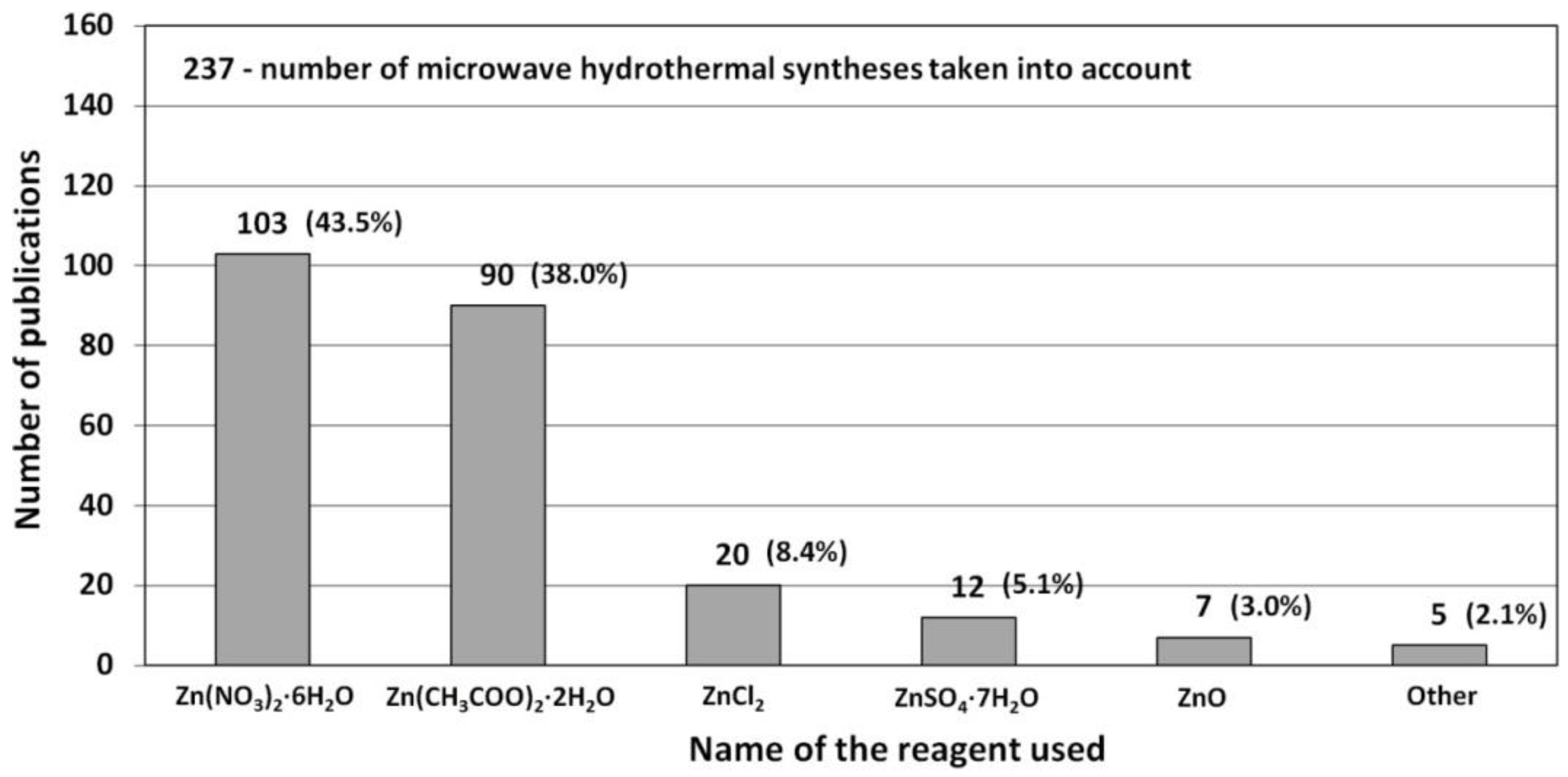

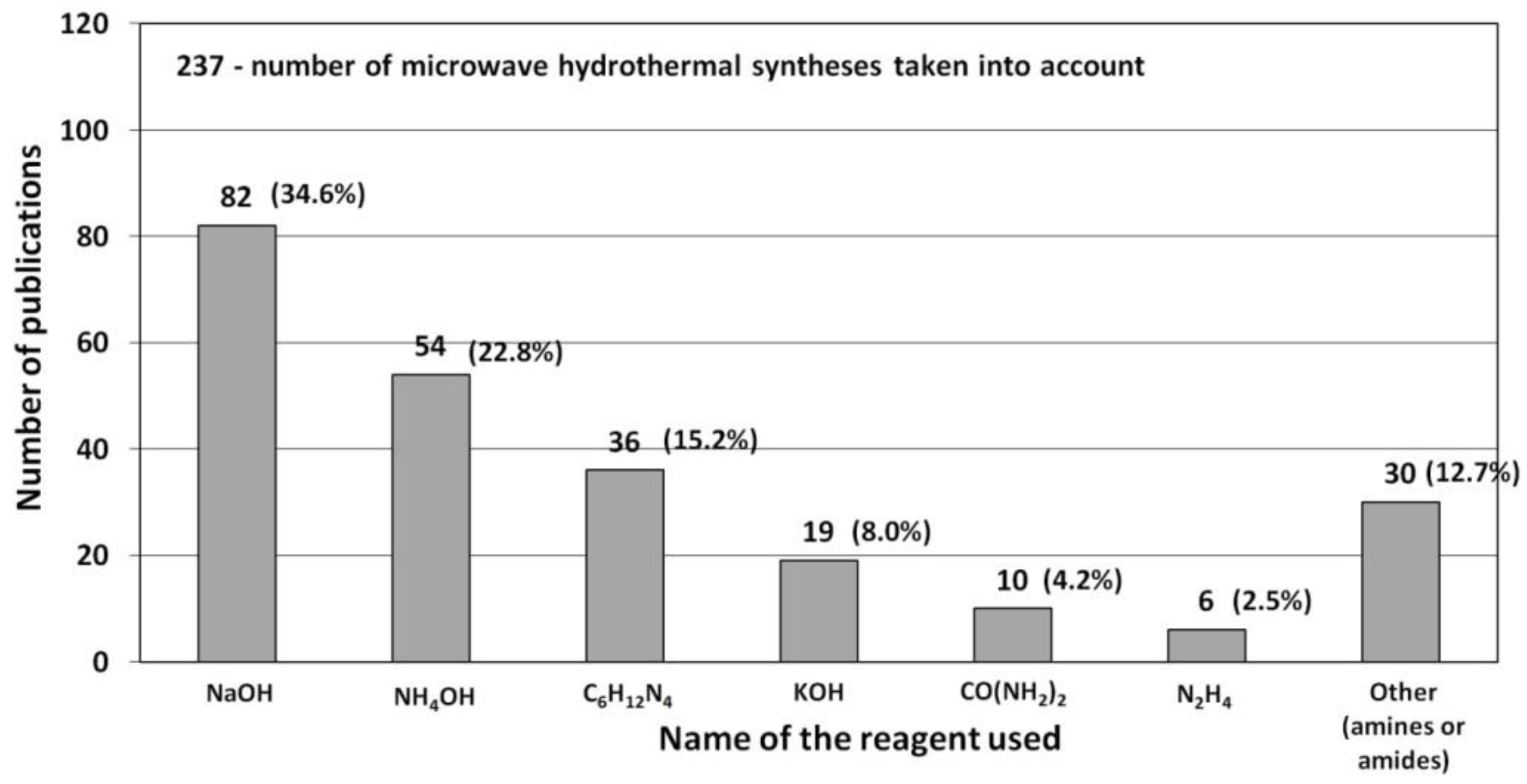

3.1. Reactants

3.2. Surfactants

- -

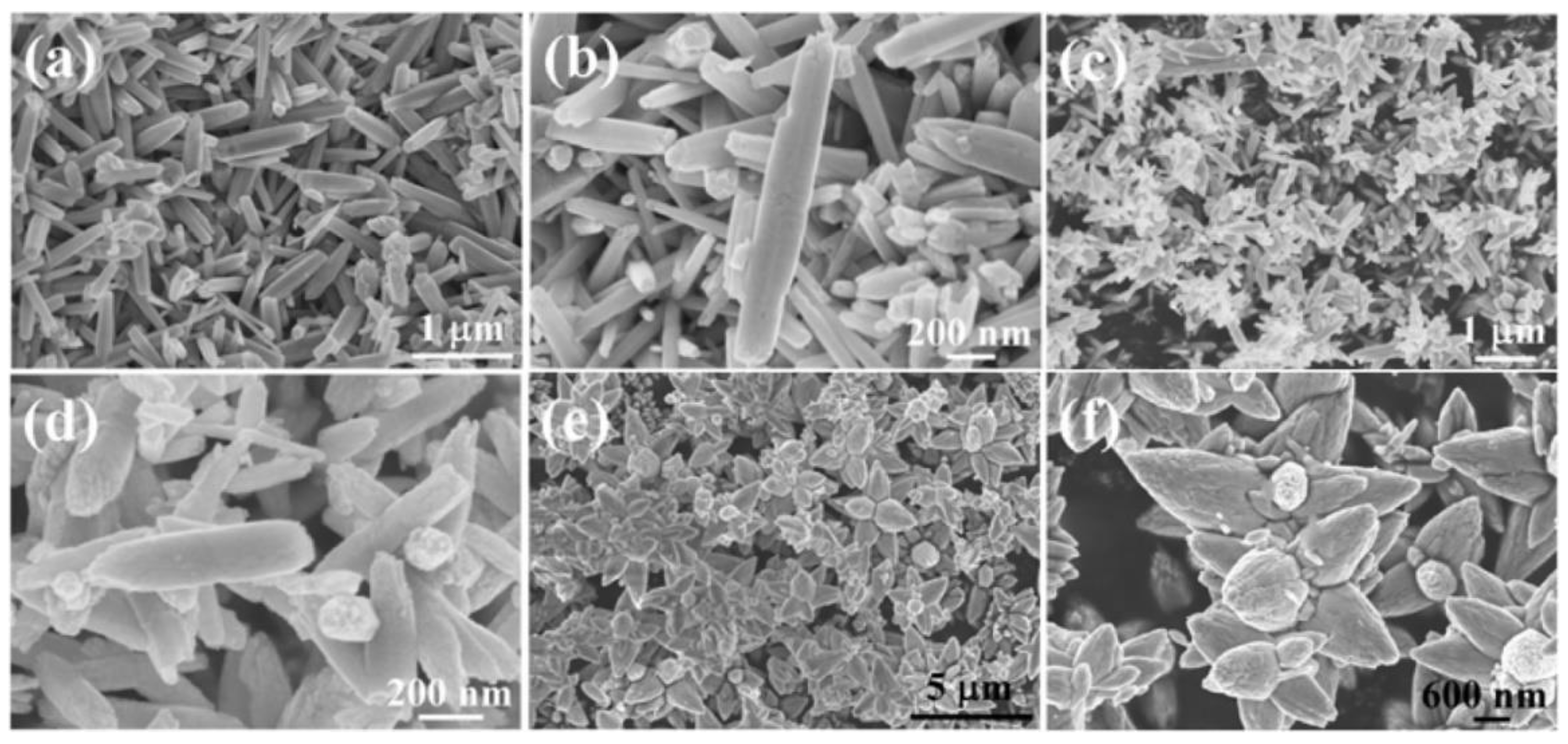

- Ethylenediamine (EDA, C2H8N2) for obtaining nanoneedles [525].

- -

- Hexamethylenetetramine (HMT, (C6H12N4)) for obtaining nanorods [525].

- -

- Triethyl citrate (C12H20O7) for obtaining hexagonal disks [525].

- -

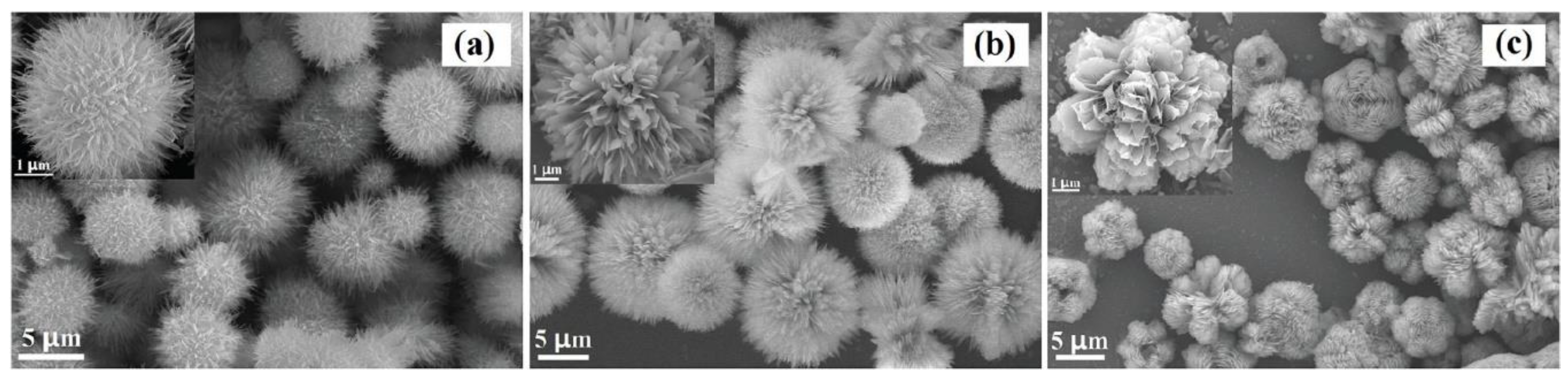

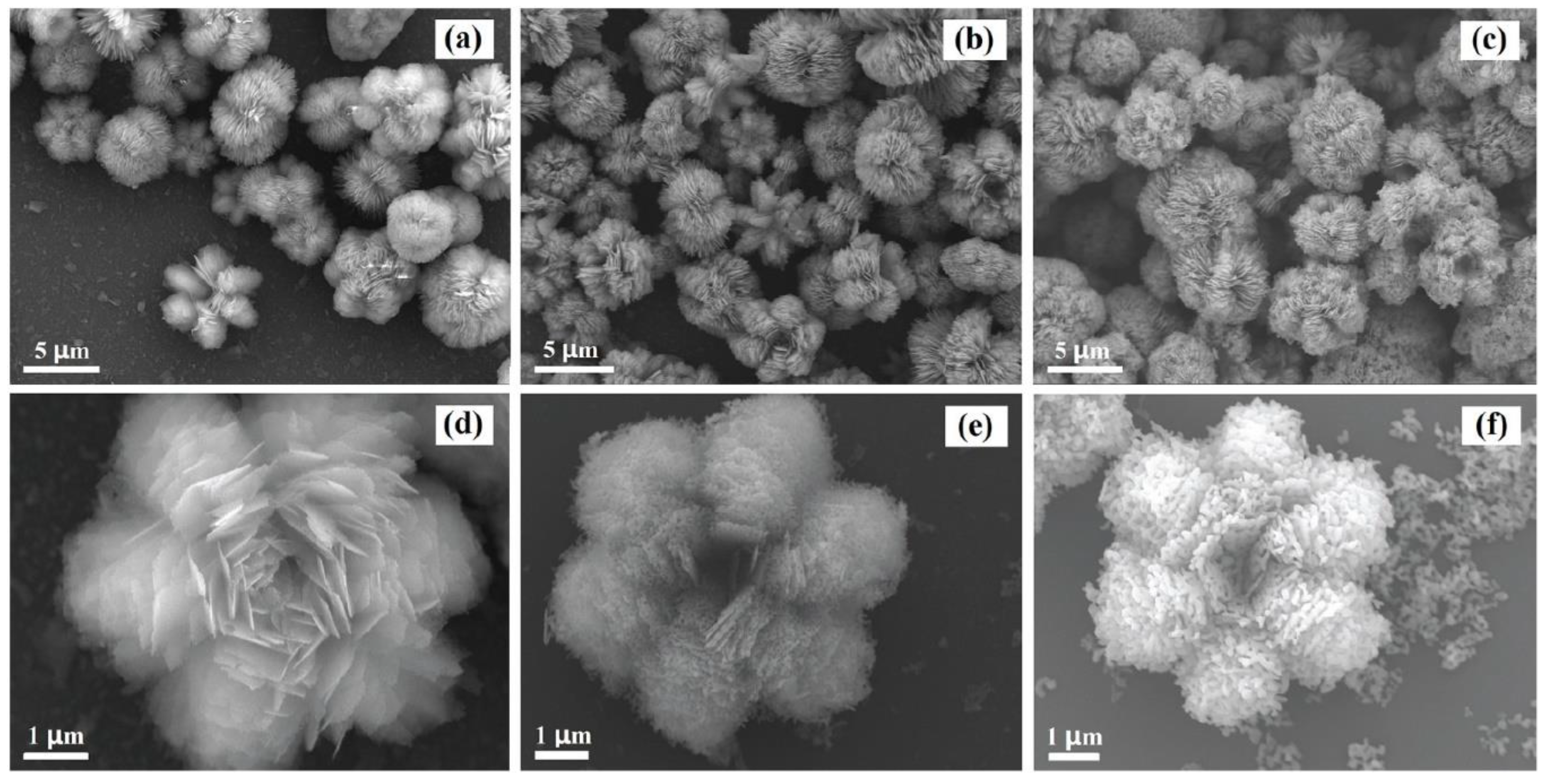

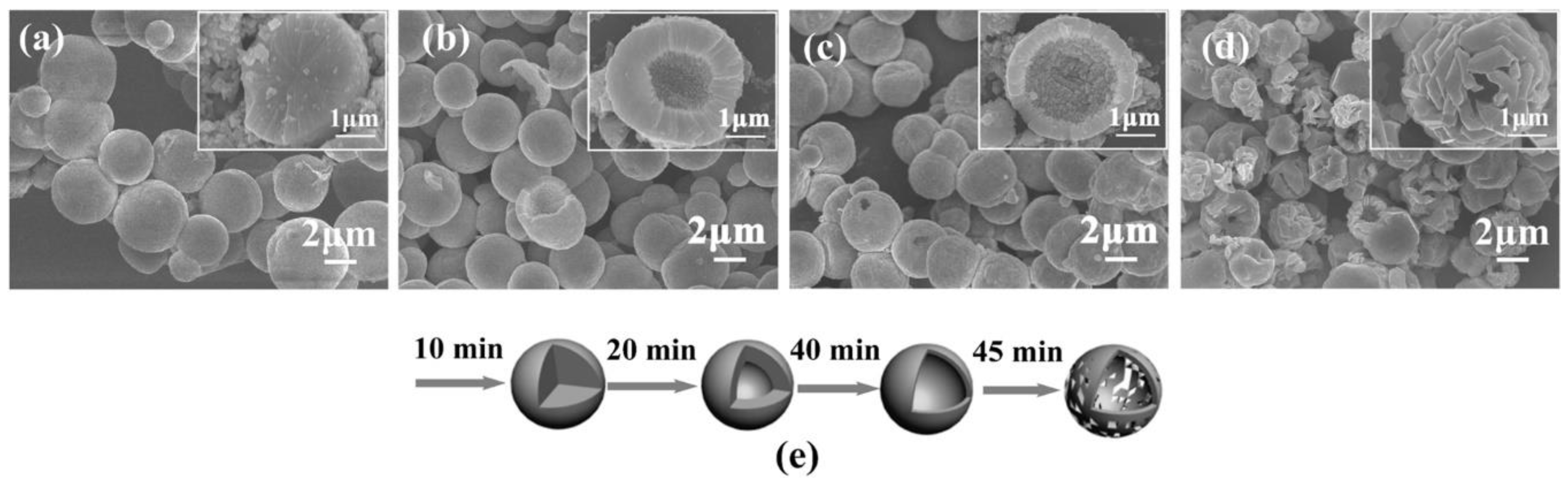

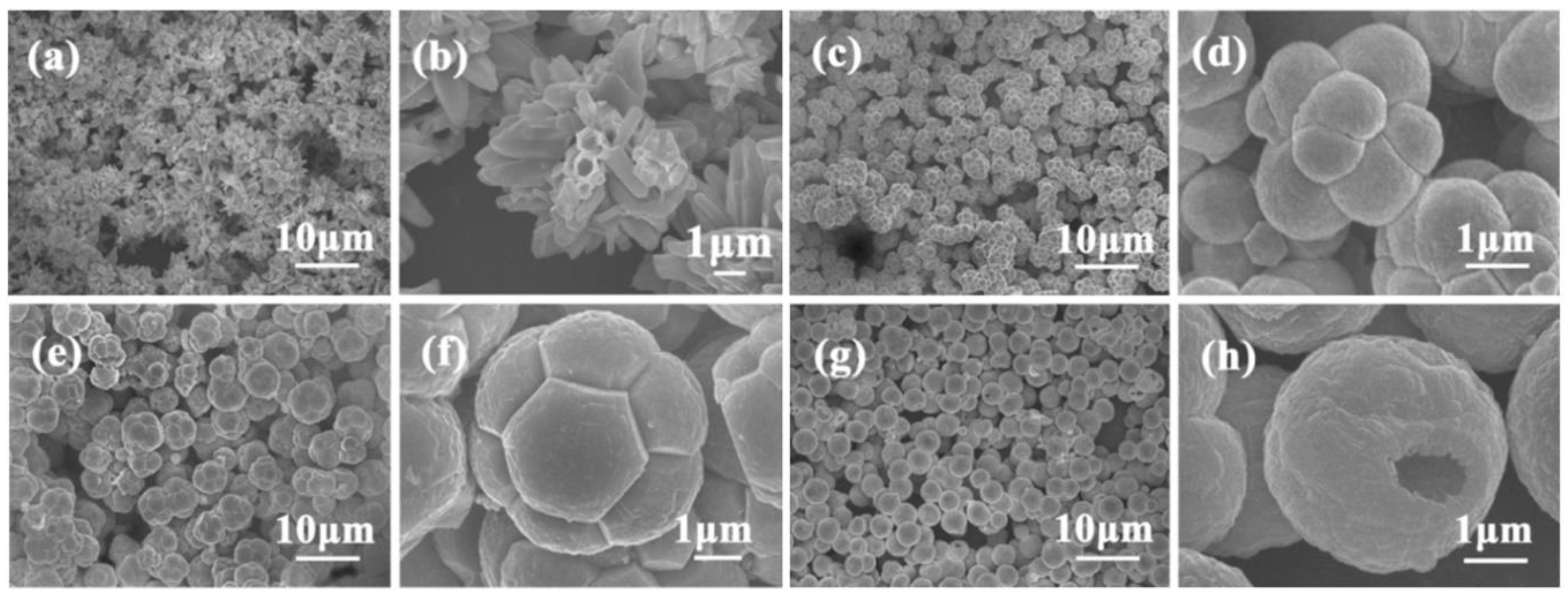

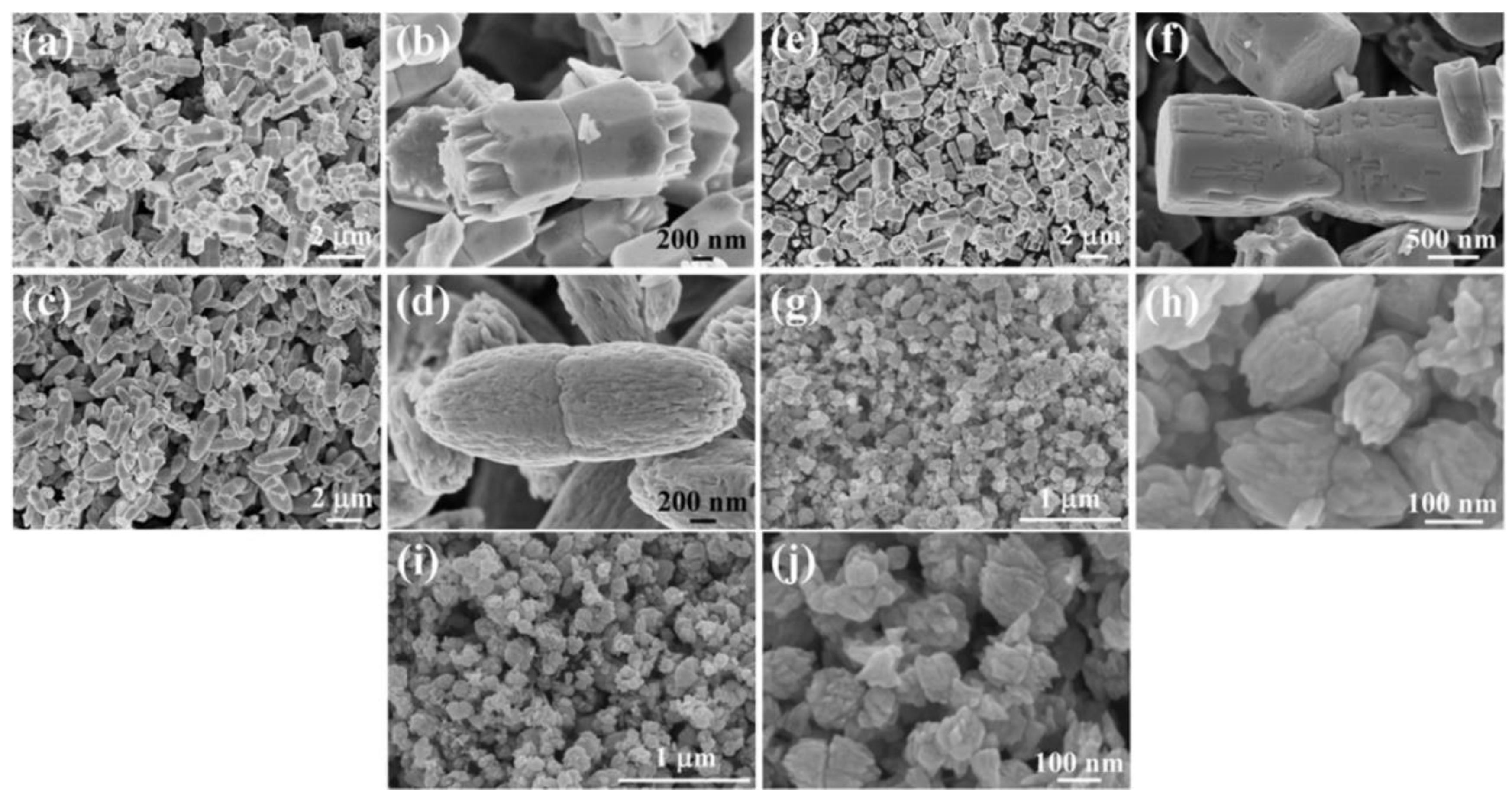

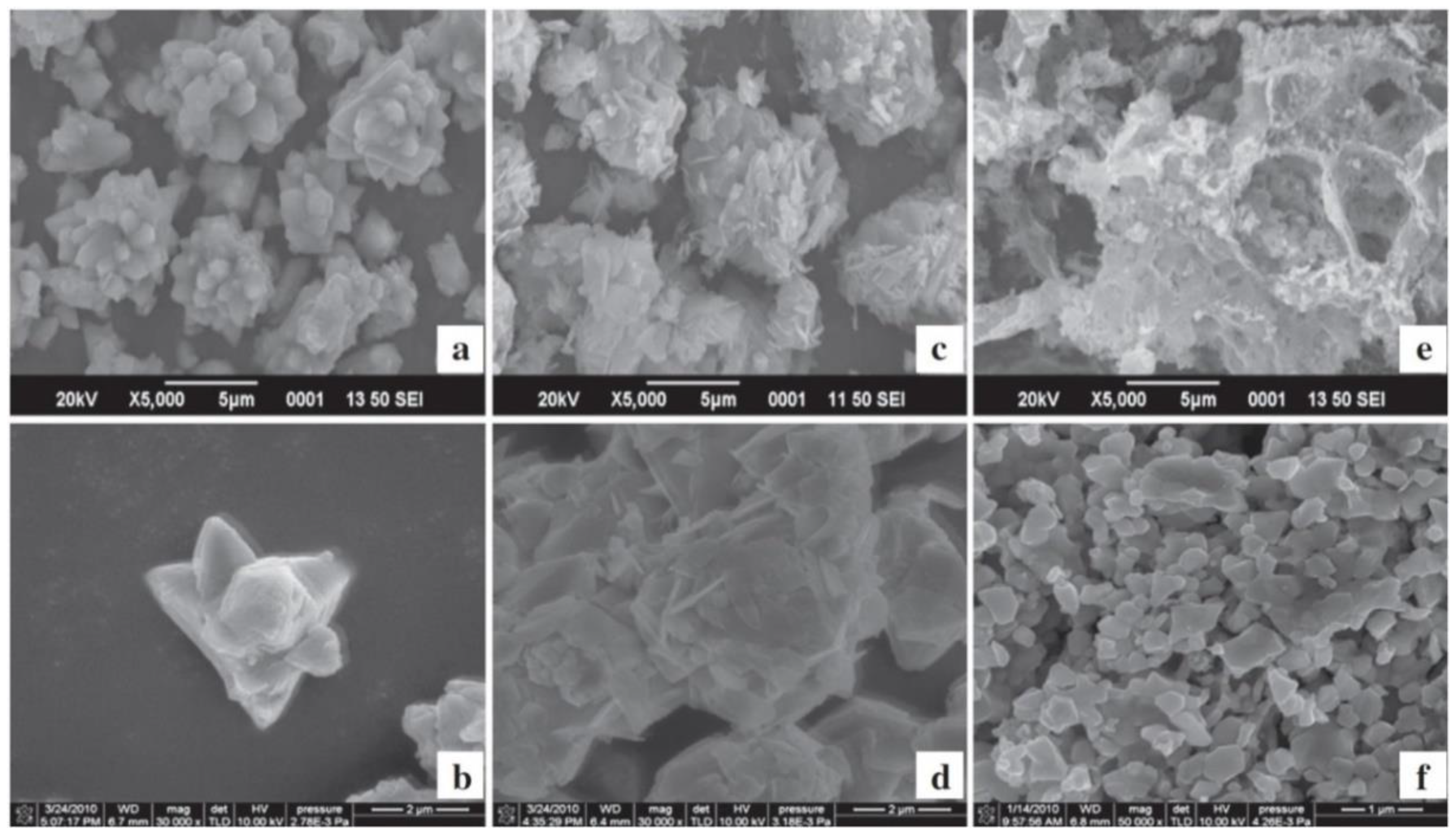

- Triethanolamine (TEA, C6H15NO3) for obtaining nanosheets [521], pompon-like spheres [554], peach nut-like spheres [554], misshapen spheres [554], rugby-like nanostructures [565], raspberry-like nanostructures [566], hollow nanospheres [566], dumbbell-like [626], football-like shape [626], and spherical nanoparticles [565,566,625,645].

- -

- -

- -

- -

- Pluronic F127 (polyoxypropylene polyoxyethylene block copolymer) for obtaining heterogeneous shapes [531].

- -

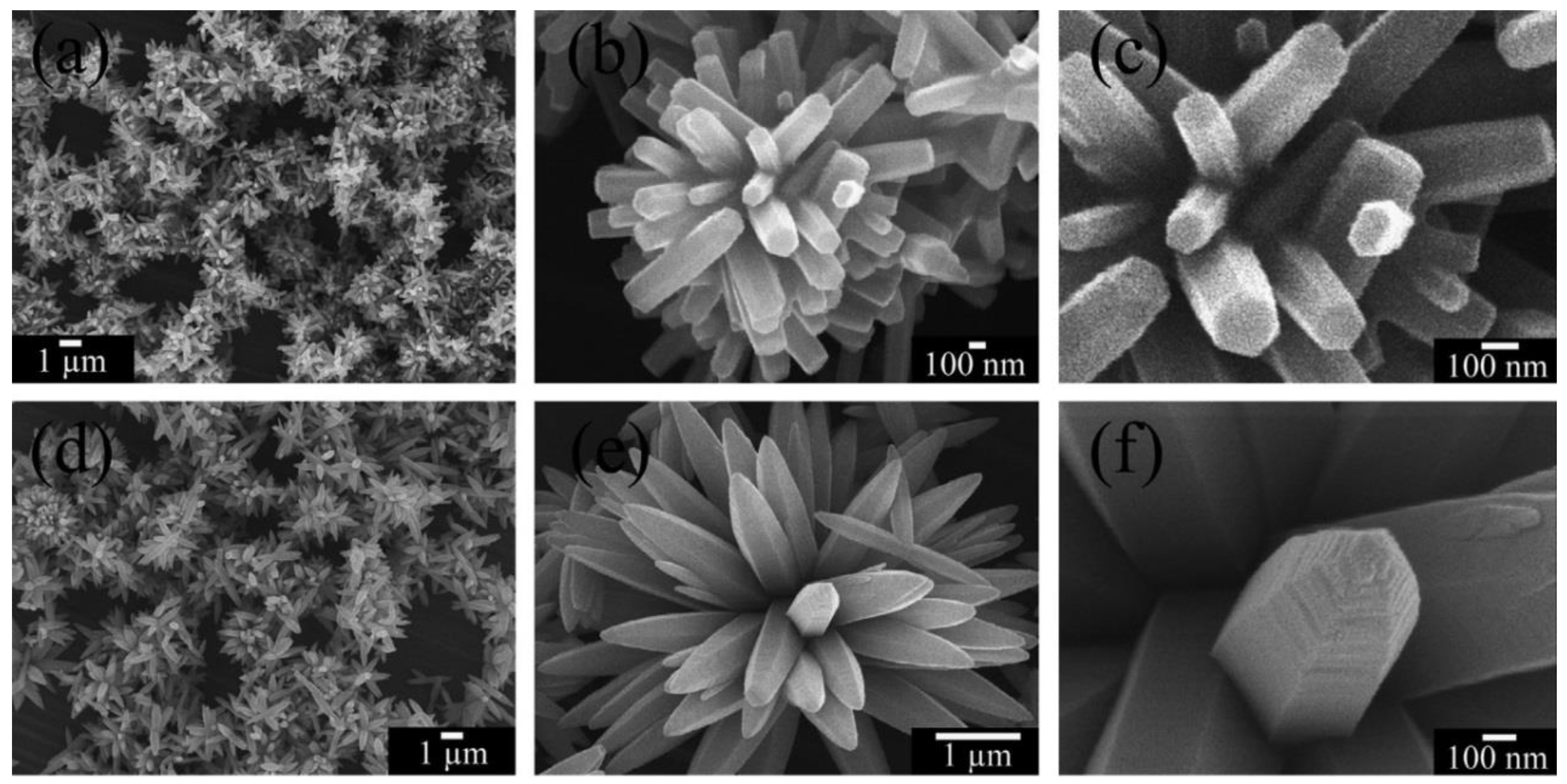

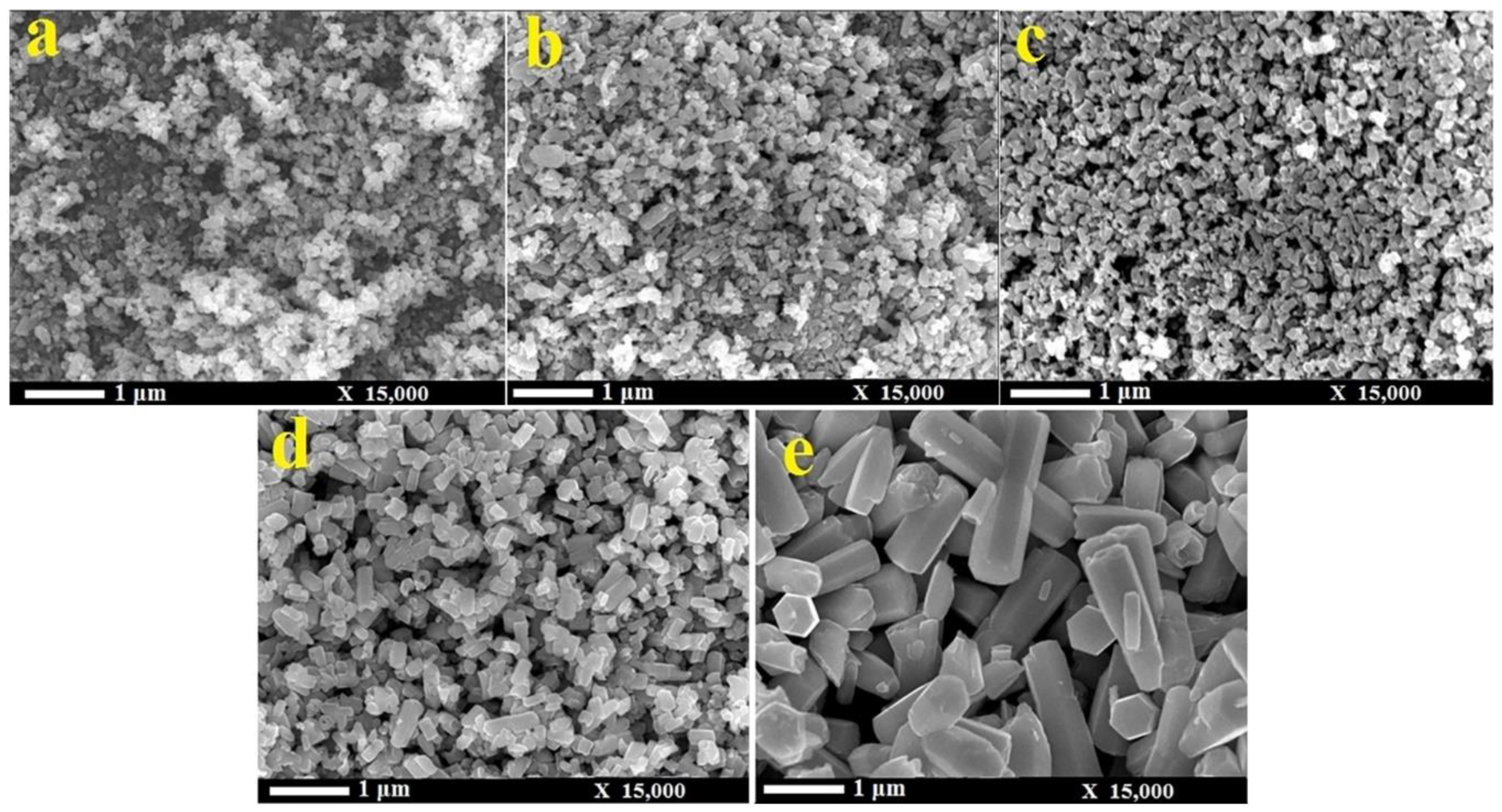

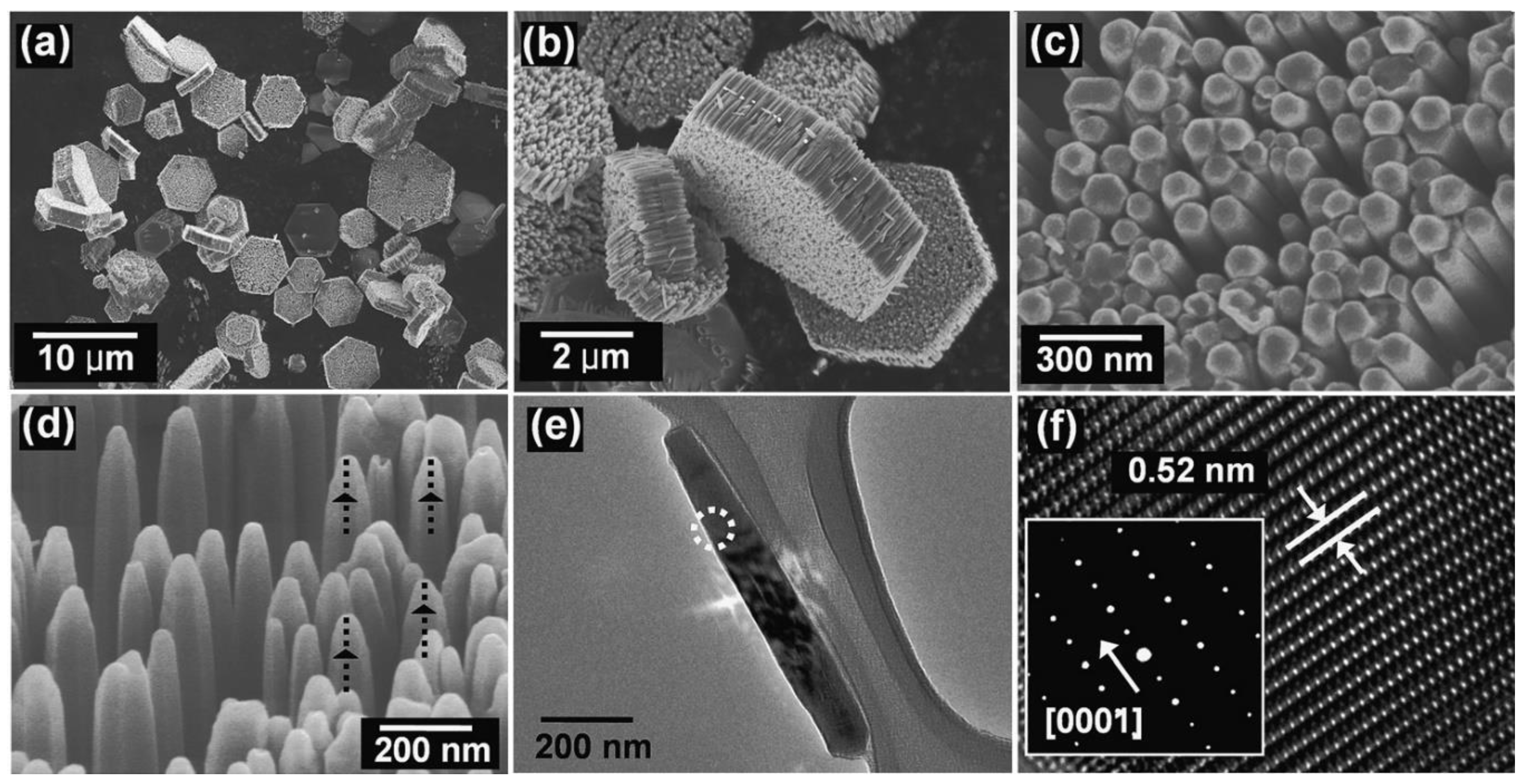

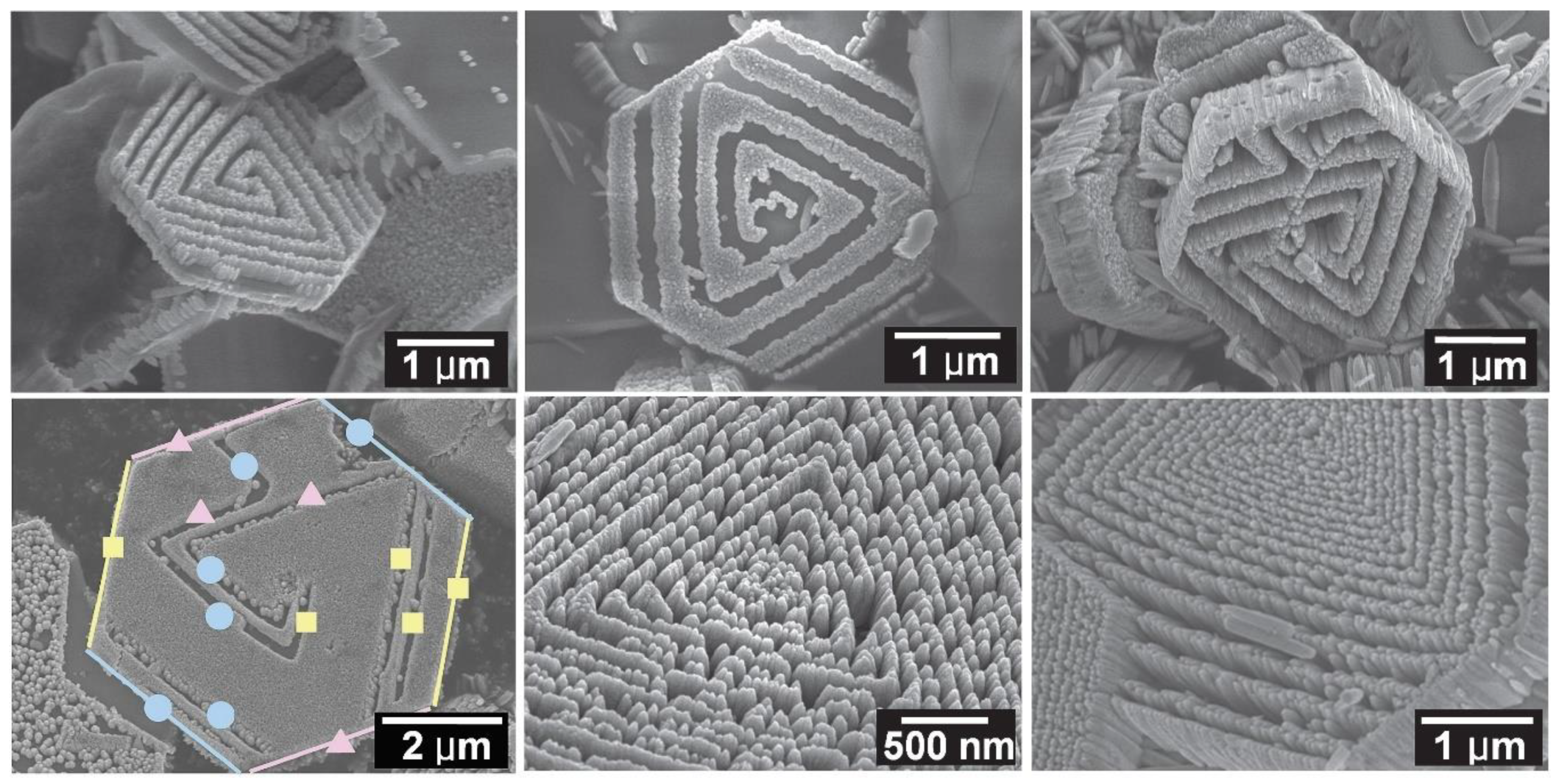

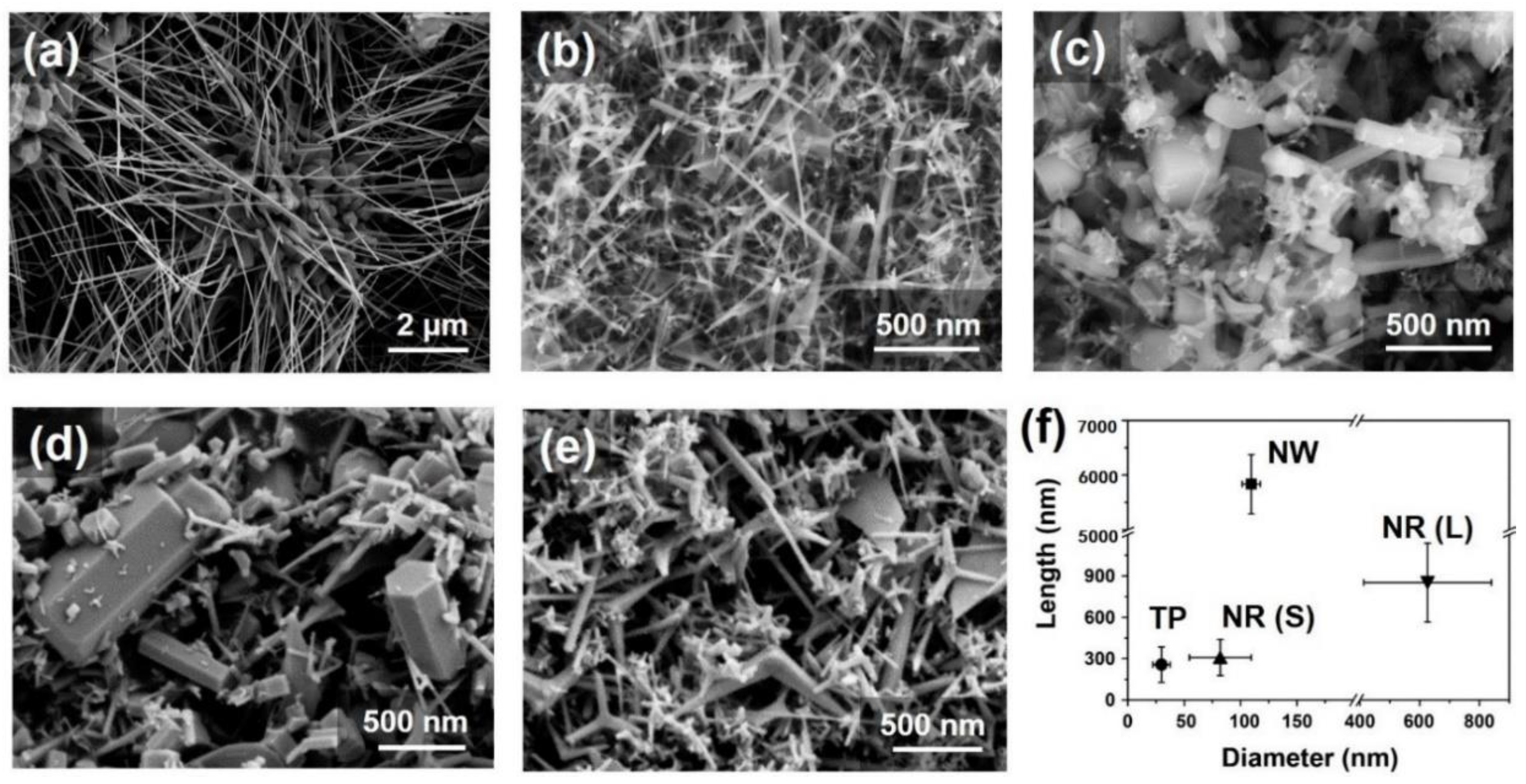

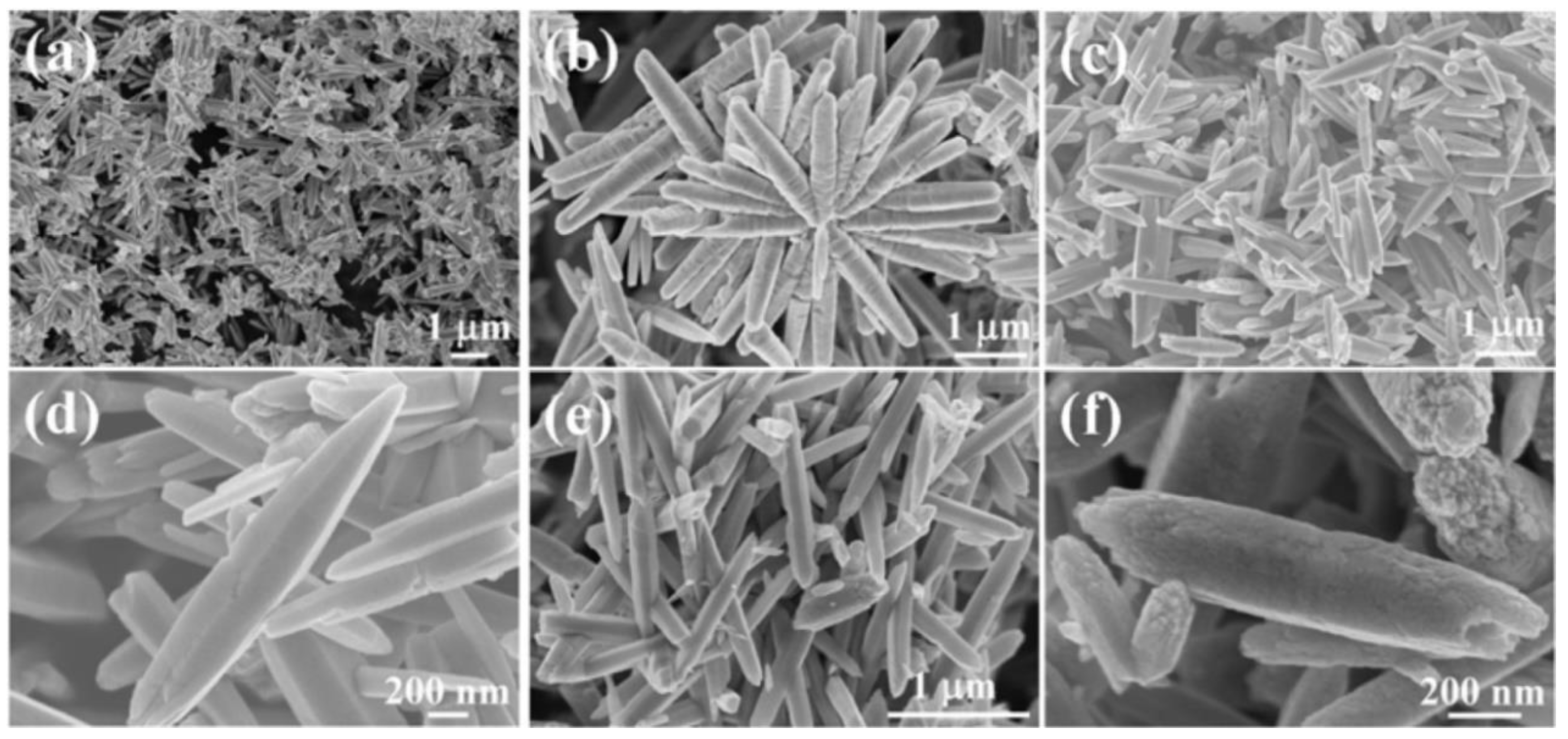

- Polyethylene glycol 400 (PEG400, C2nH4n+2On+1) for obtaining nanorods [533], flowers [533], rod-like nanostructures [574], star-like nanostructures [574], particles with an irregular shape (plate and rod-like particles) [596], quasi-spherical shapes [620], flower-like structures [620], flower-like hierarchical structures [655], rod-like structures [673], and needle-like structures [673].

- -

- Acetyl acetate (ACAC, (CH3CO)2O) for obtaining rod-like structures [644].

- -

- -

- Polyvinyl alcohol 2000 (PVA2000, (C2H4O)n) for obtaining spherical nanoparticles [578].

- -

- -

- Triethyl citrate (C12H20O7) for obtaining disk- and nut-like structures [525].

- -

- Tripotassium citrate for obtaining UFOs and balls-like structures [525].

- -

- Arginine (C6H14N4O2) for obtaining rods and flowers [543].

- -

- Albumen for obtaining whisker-like and rod-like nanostructures [585].

- -

- Triton X-100 (C14H22O(C2H4O)n (n = 9–10)) for obtaining rods (400–800 nm) and flower structures [594].

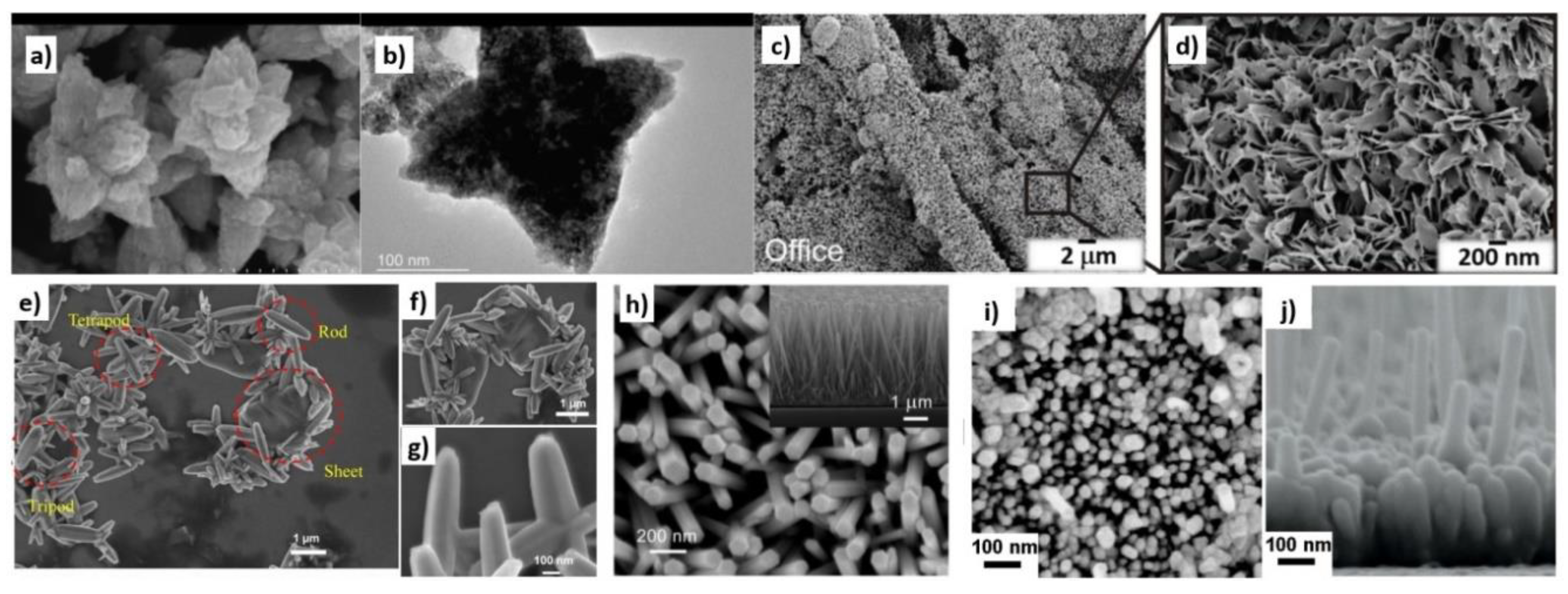

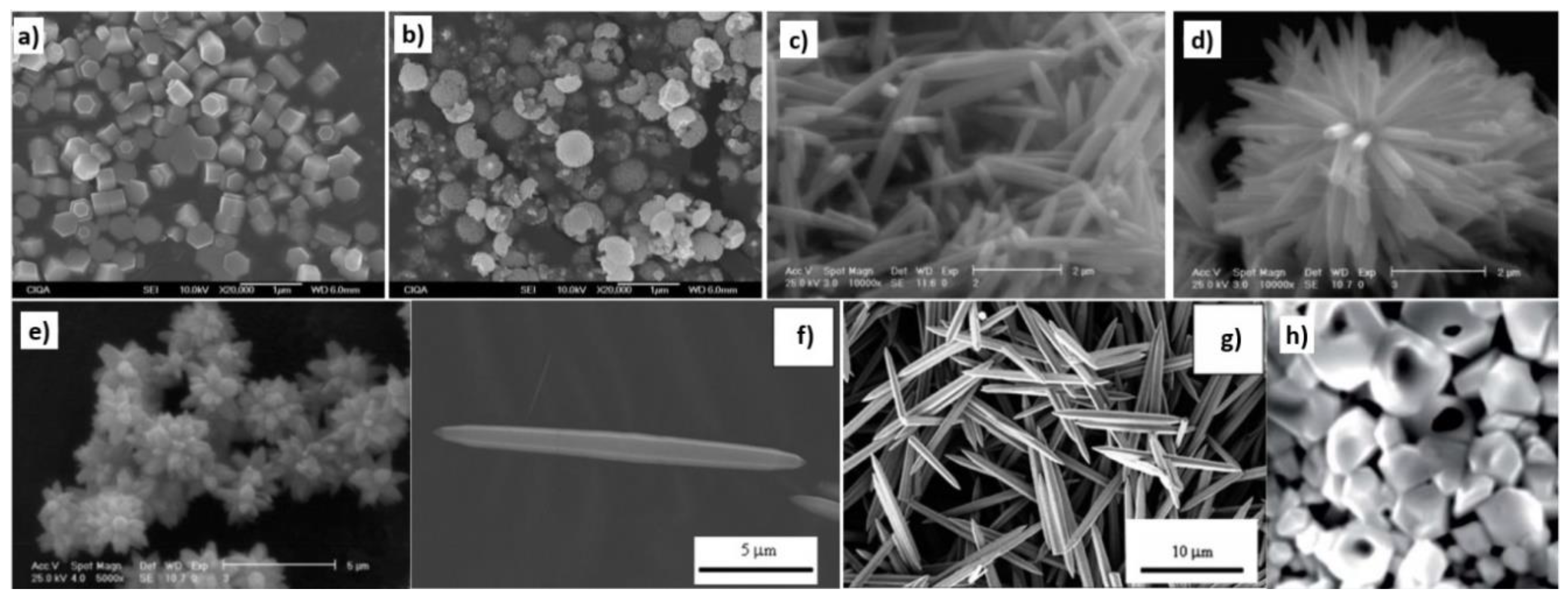

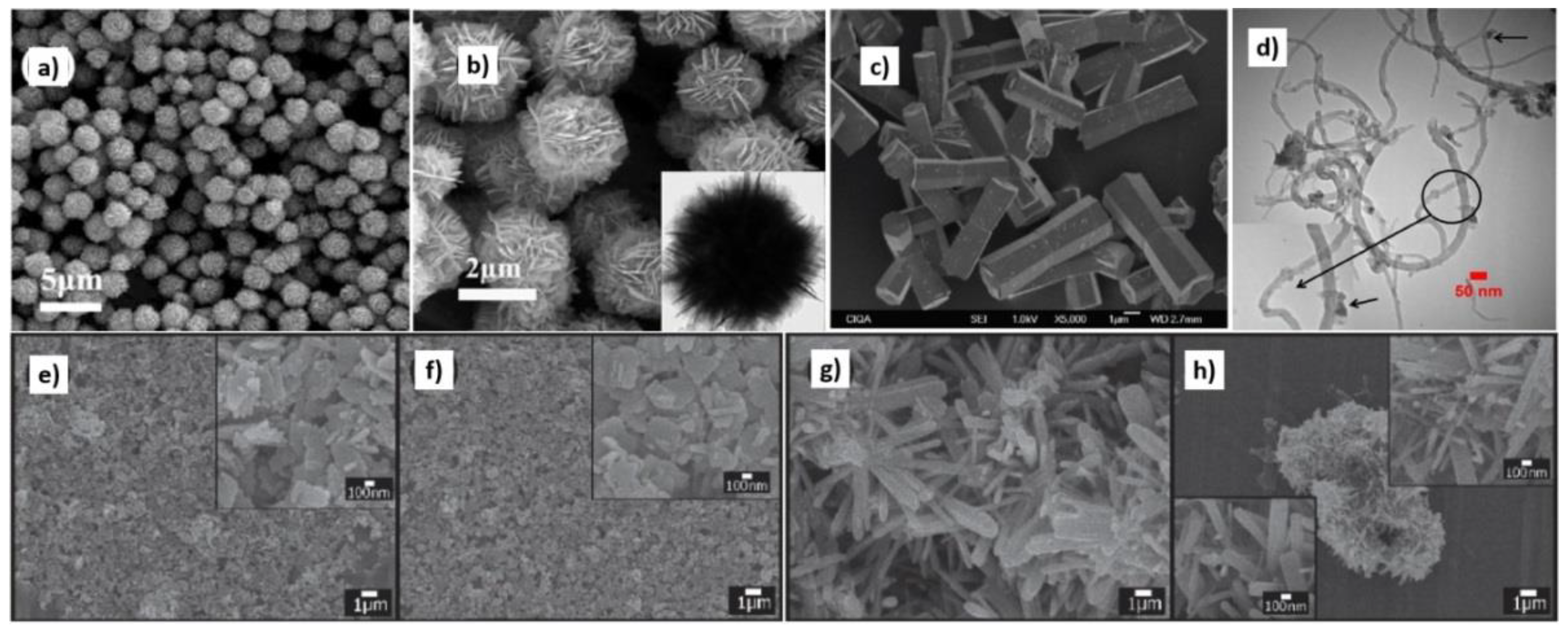

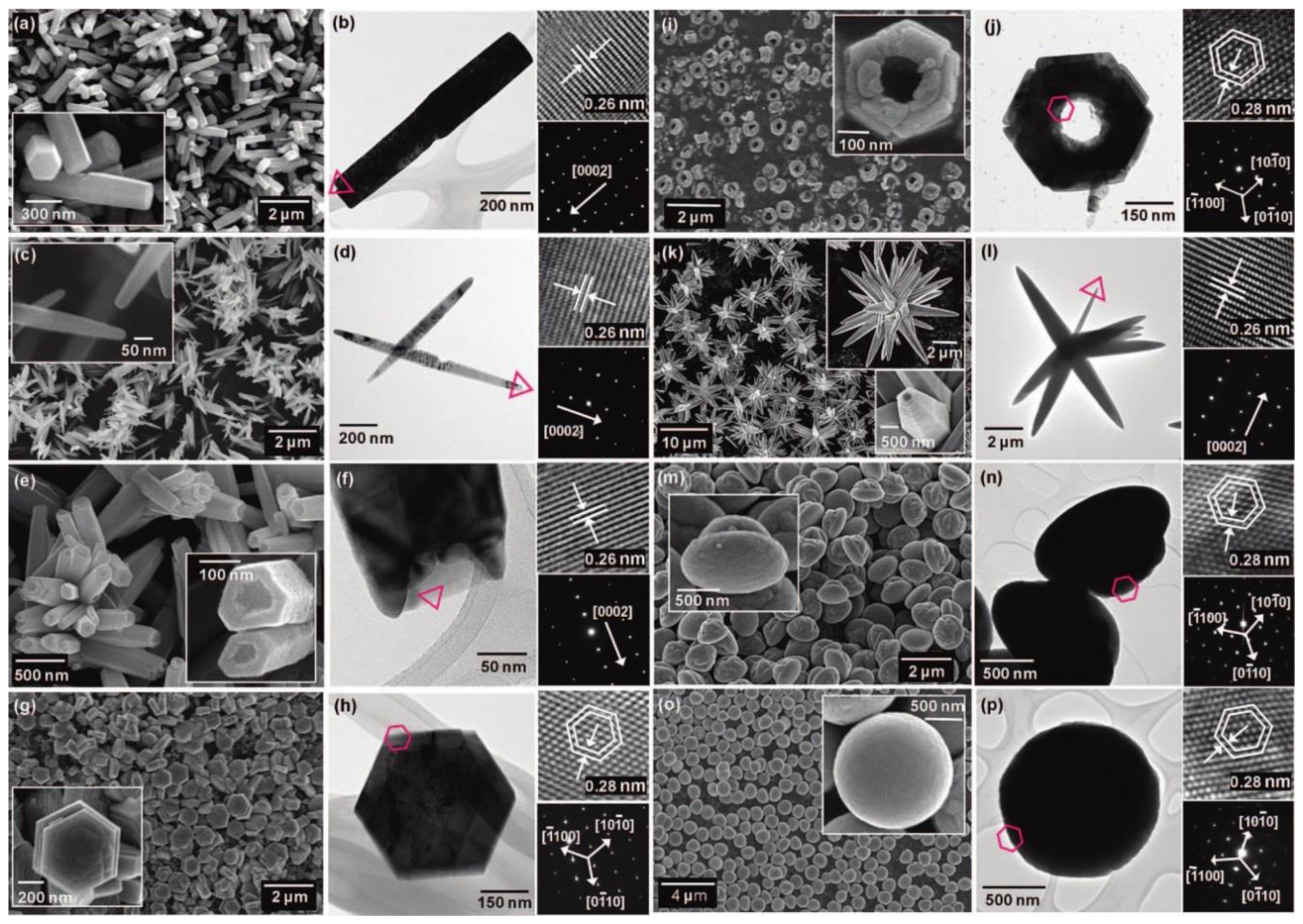

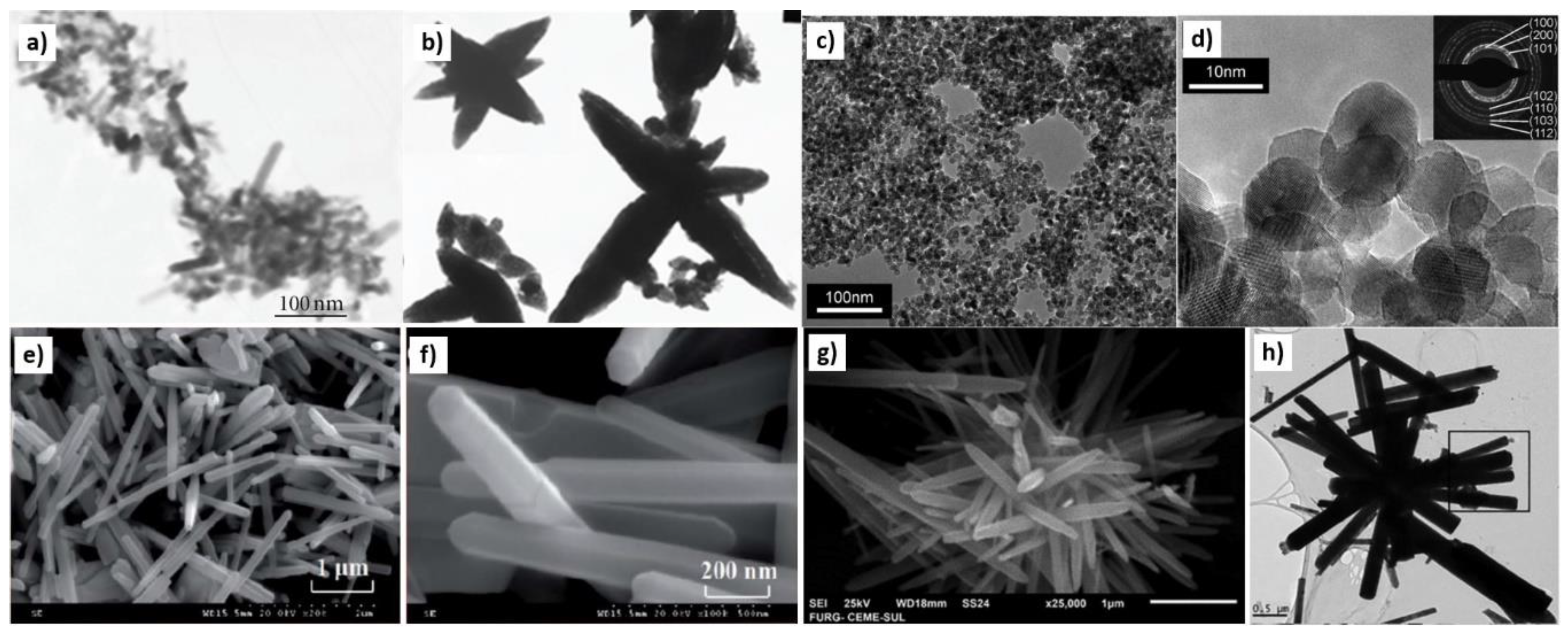

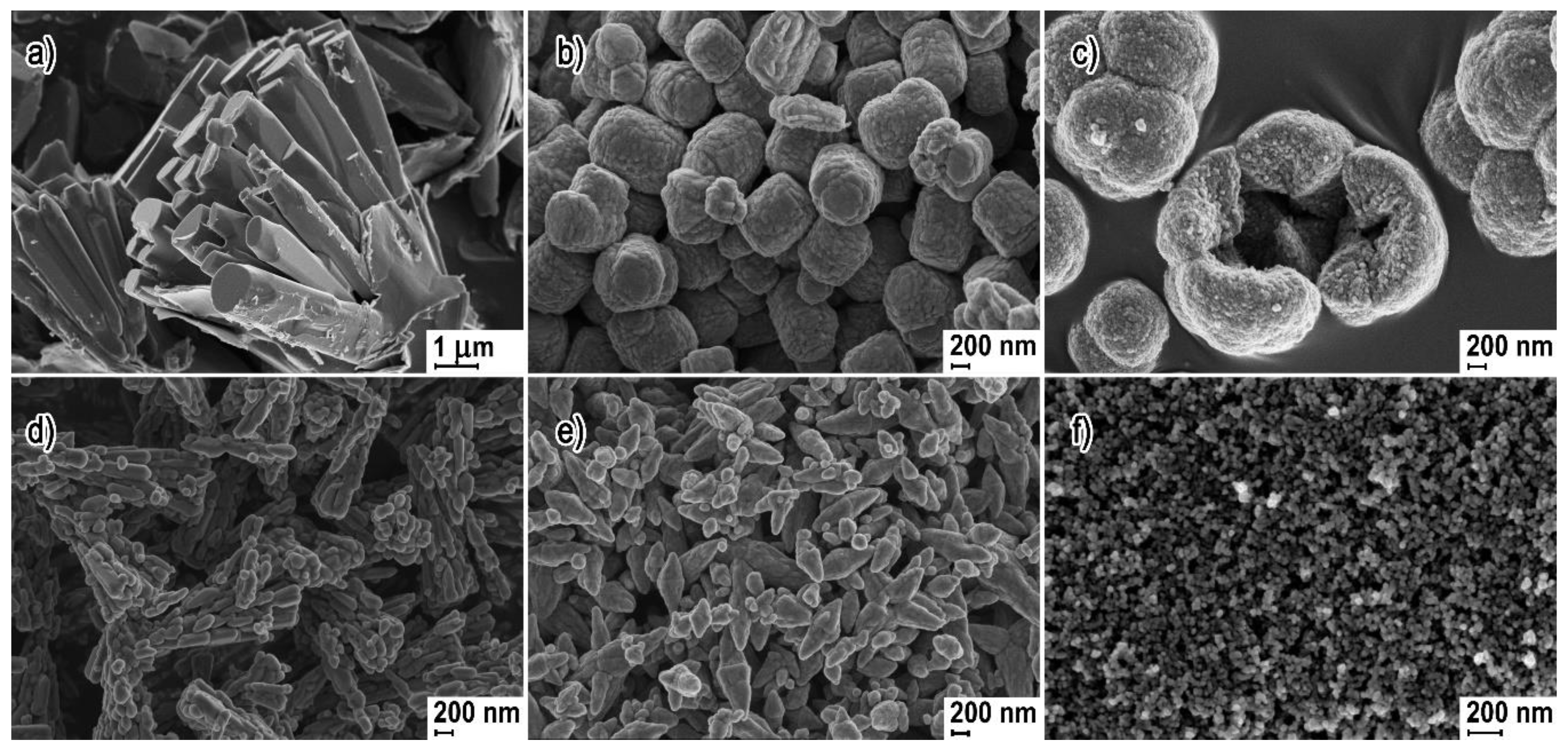

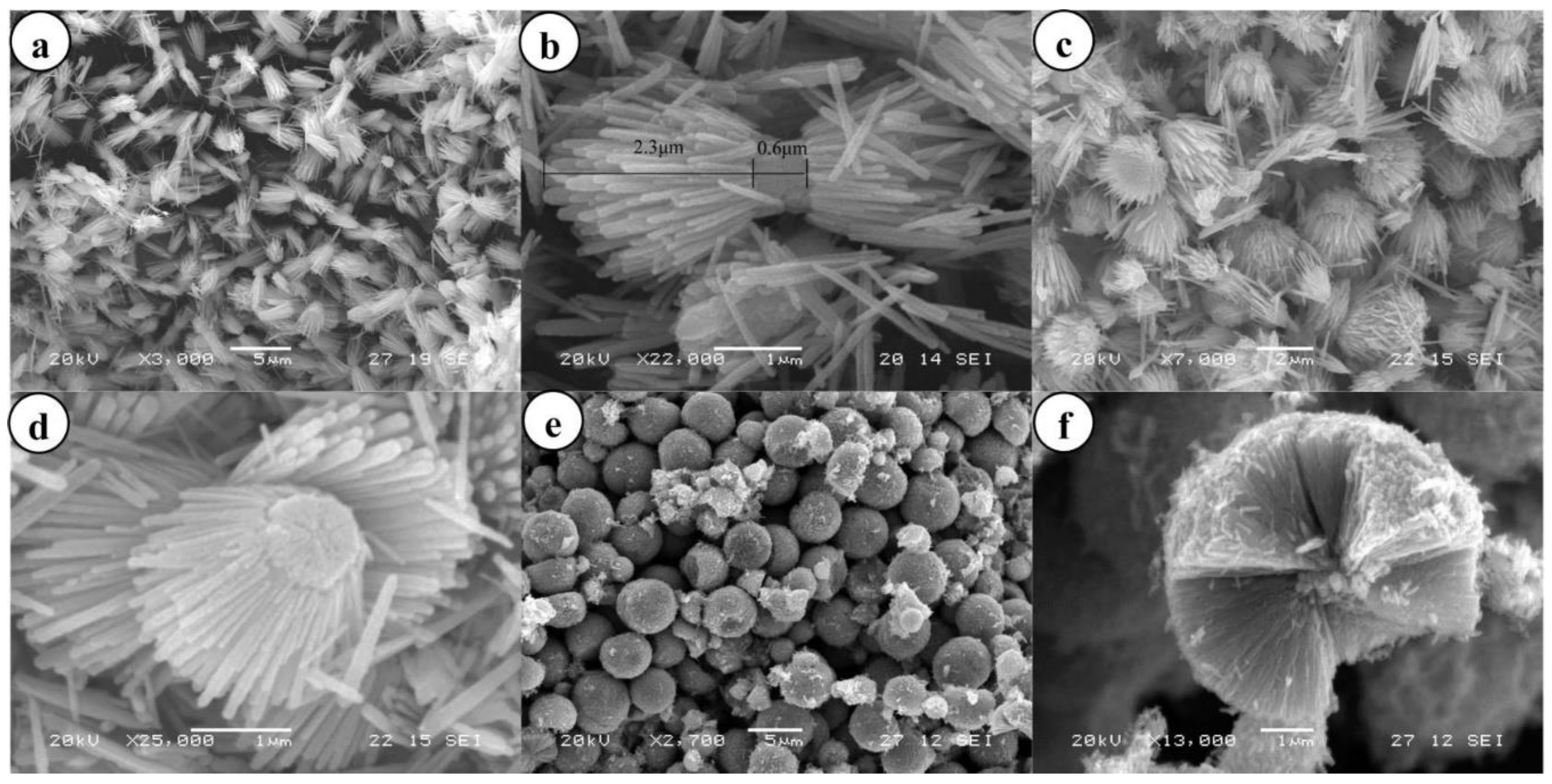

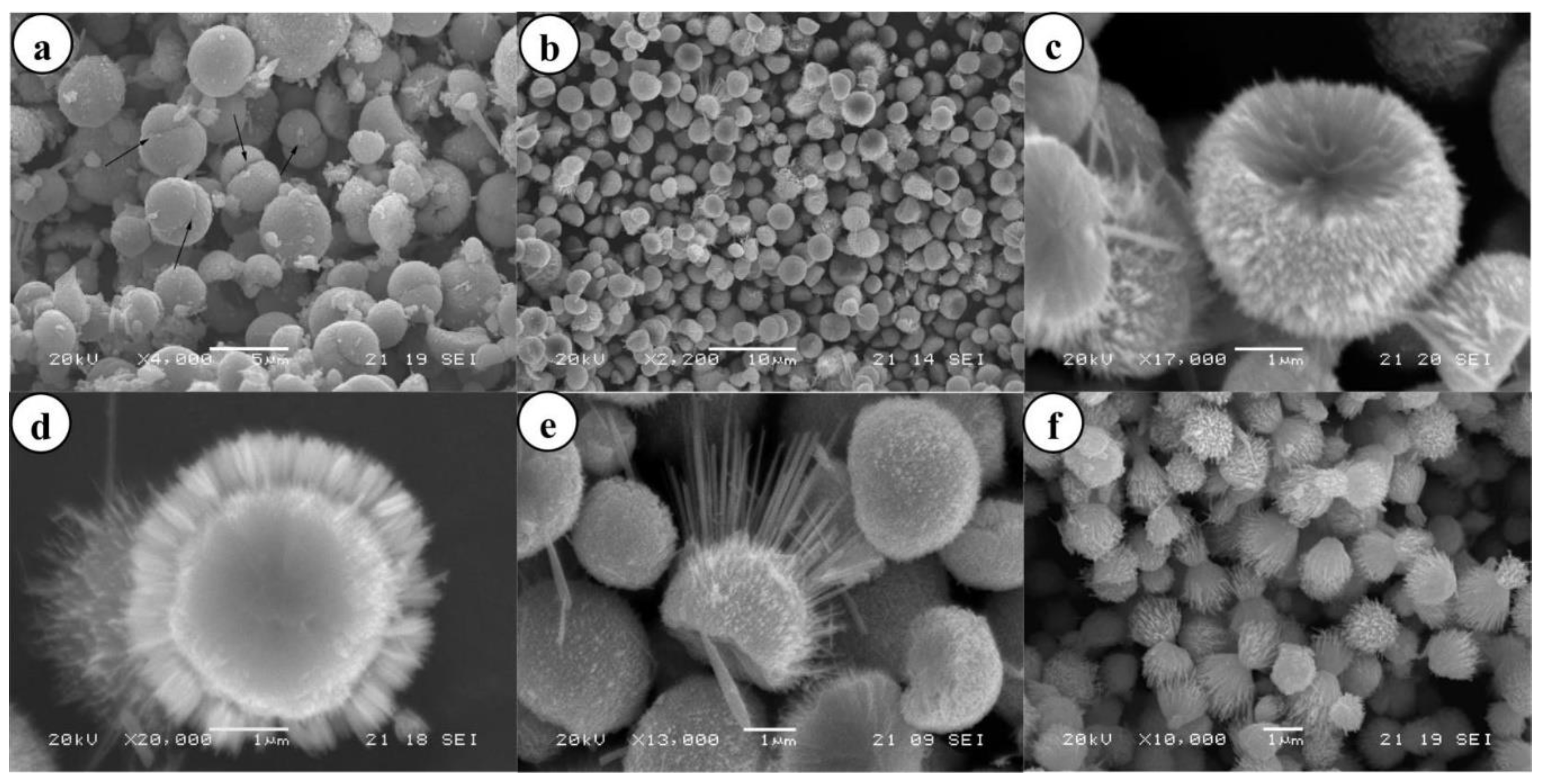

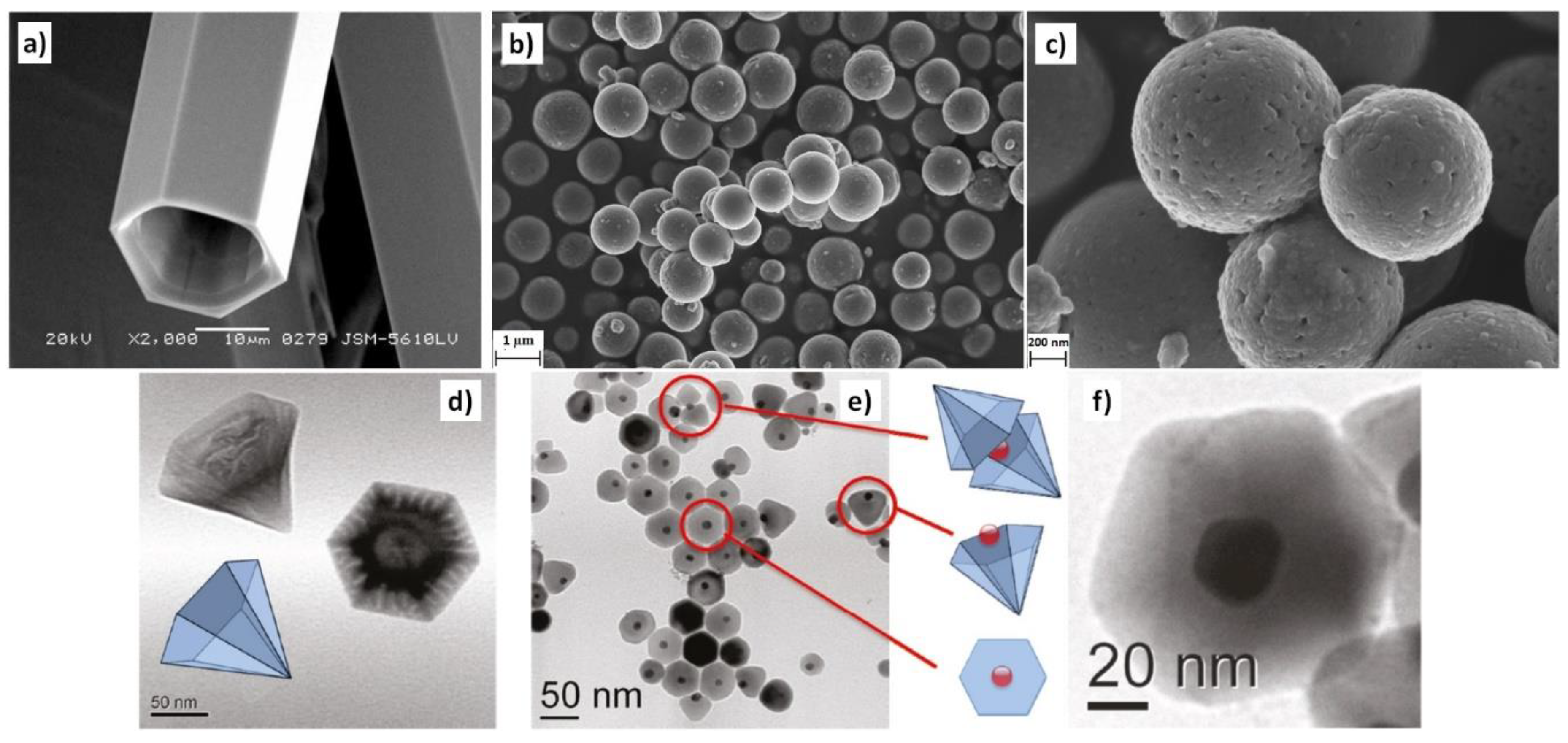

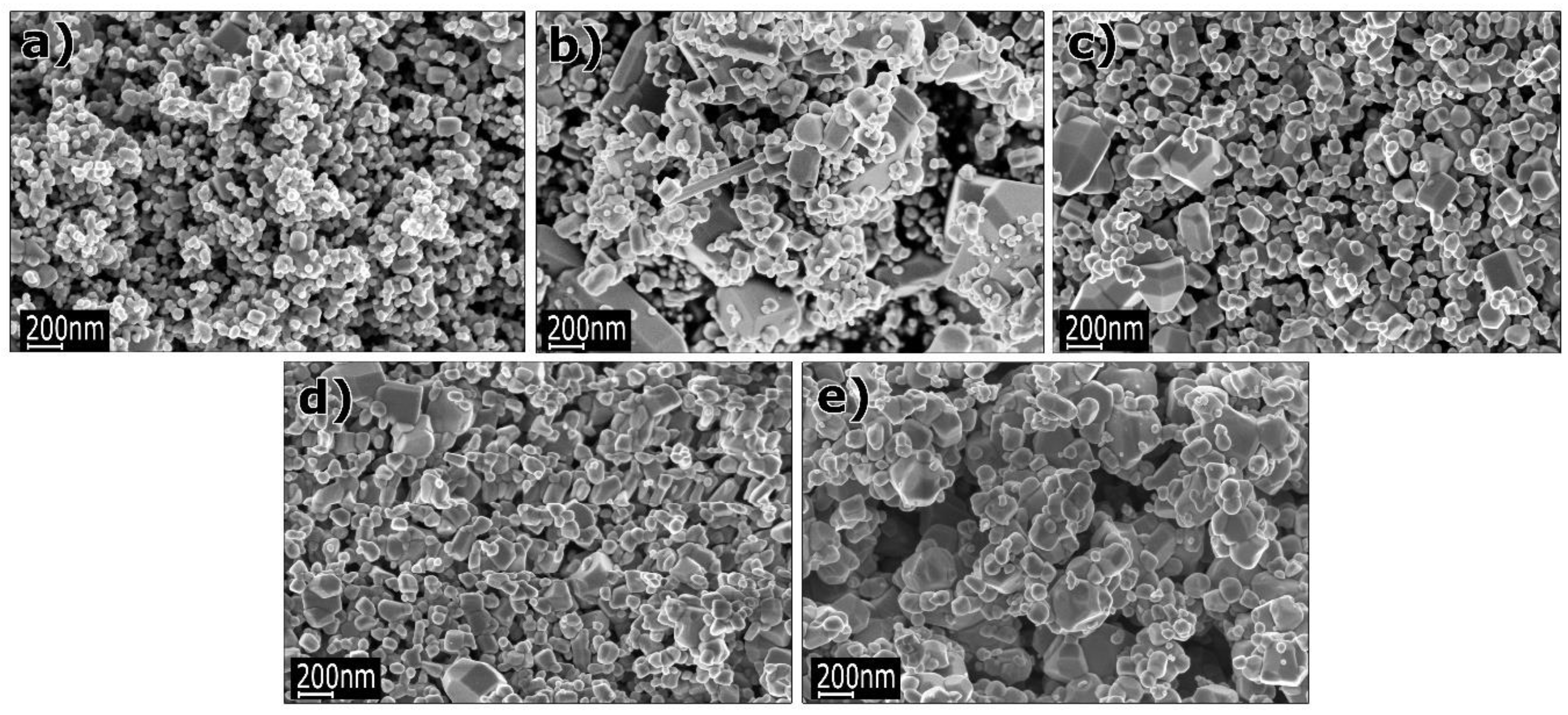

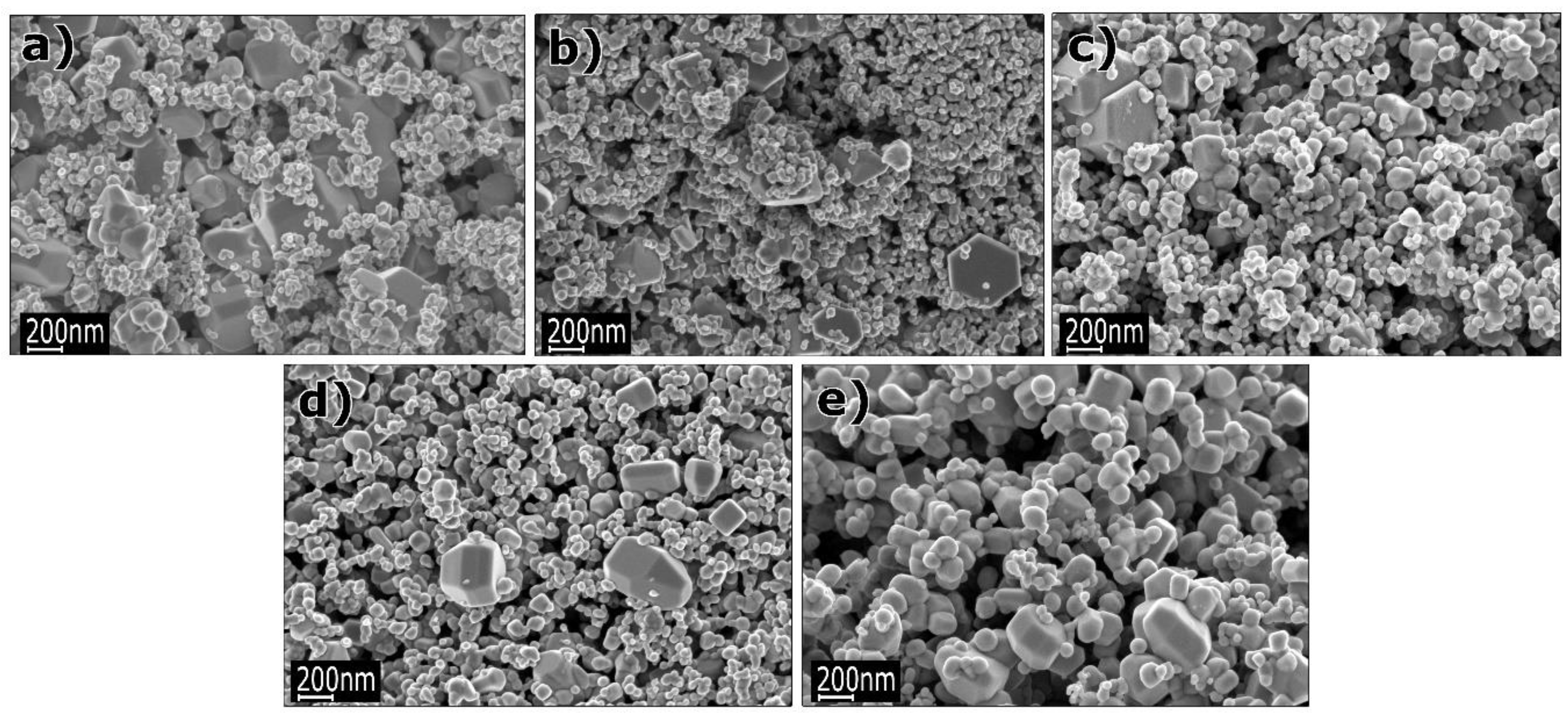

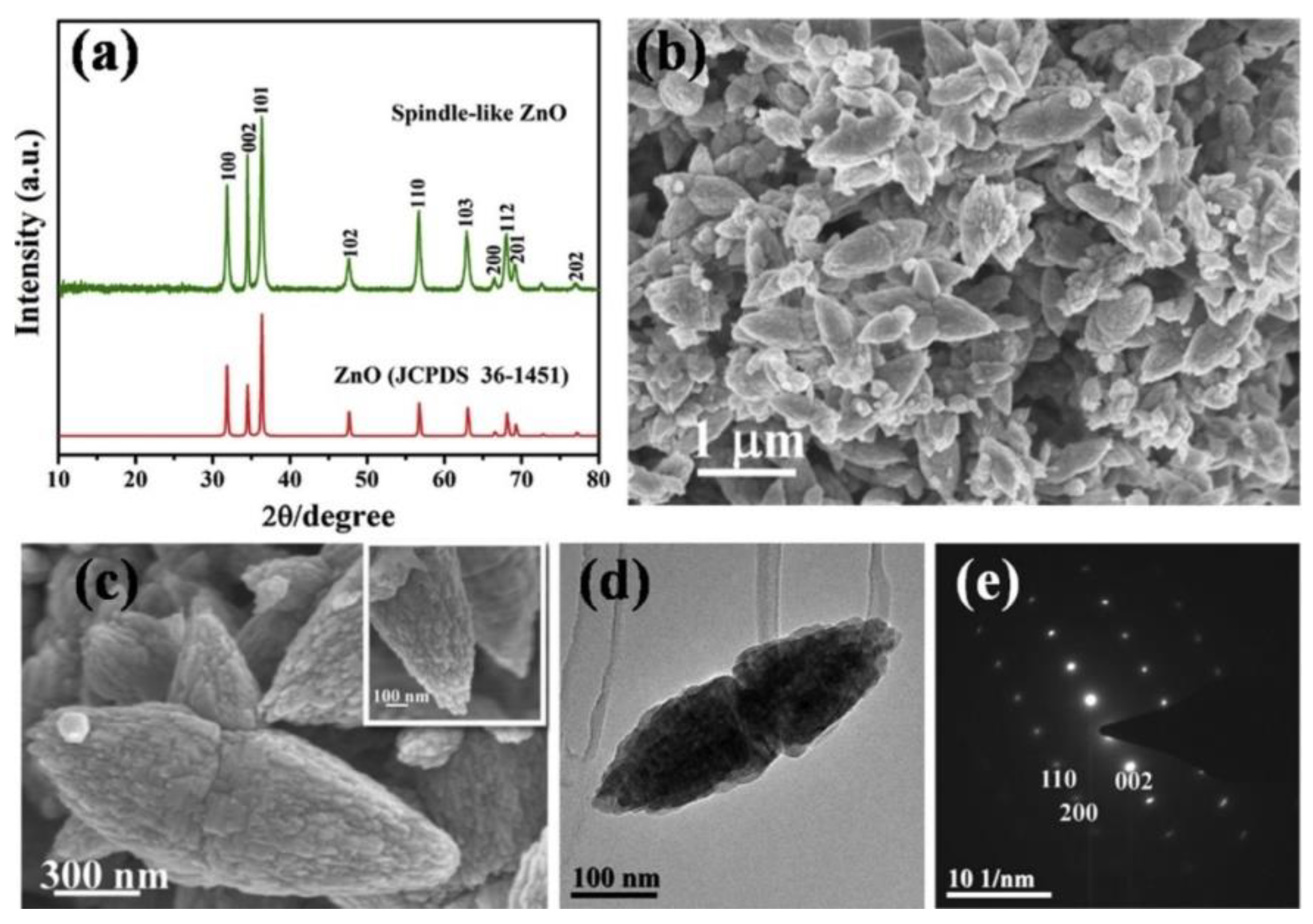

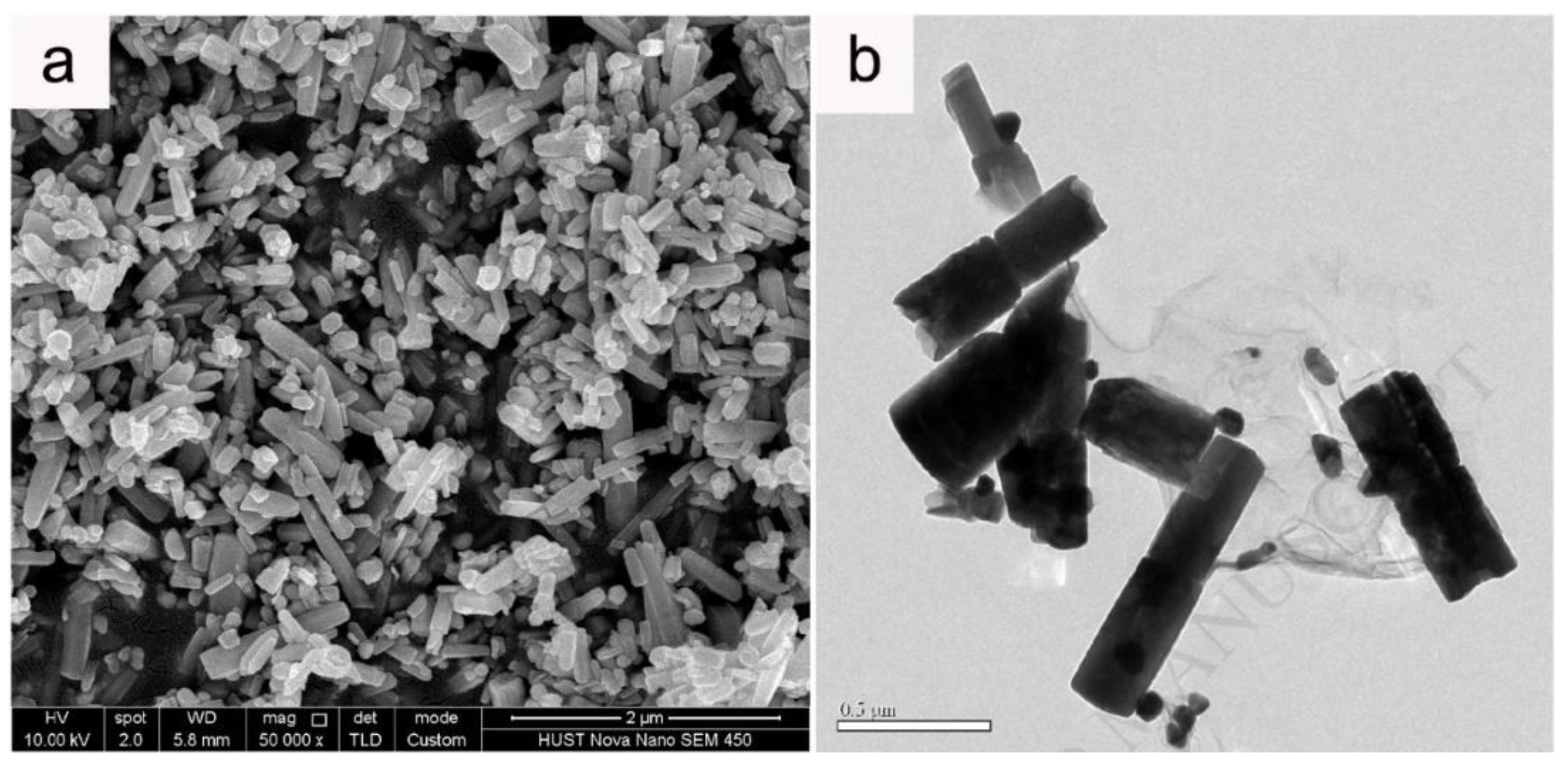

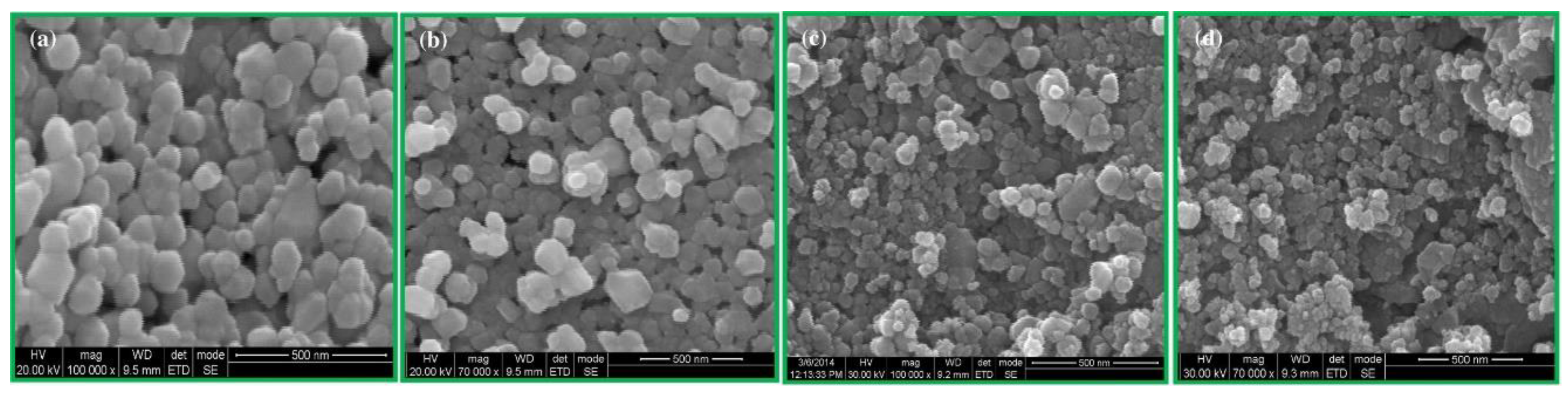

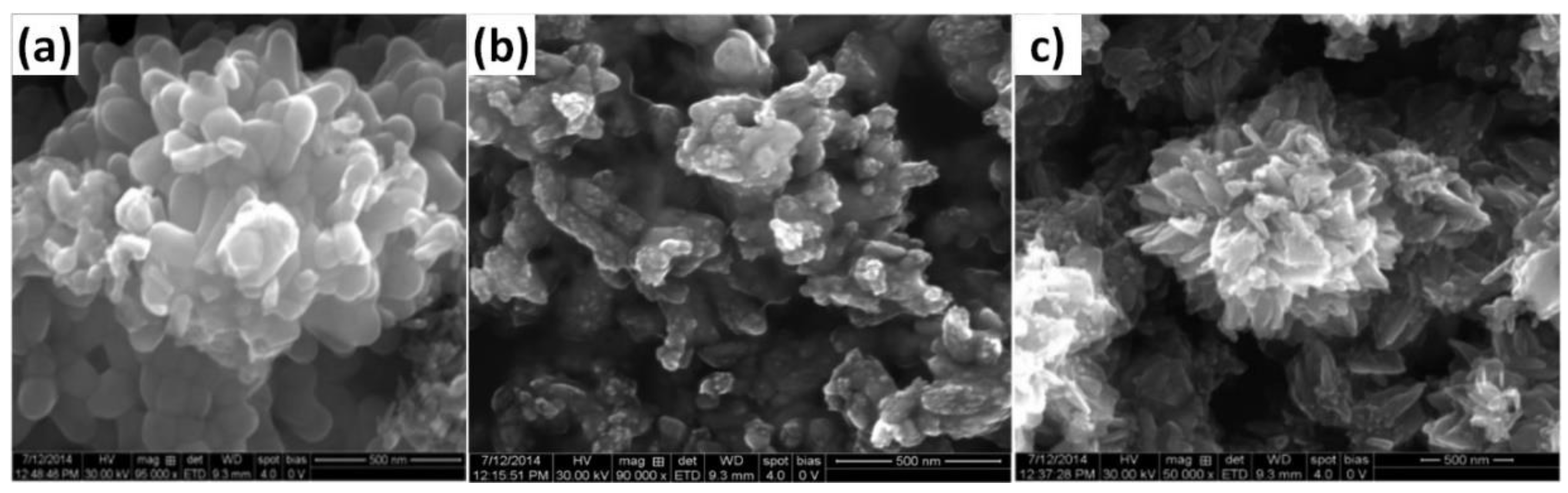

3.3. Morphology

3.4. Microwave Hydrothermal Synthesis of ZnO without Any Additional Heat Treatment

3.5. Microwave Hydrothermal Synthesis of ZnO Nanostructures with Additional Heat Treatment

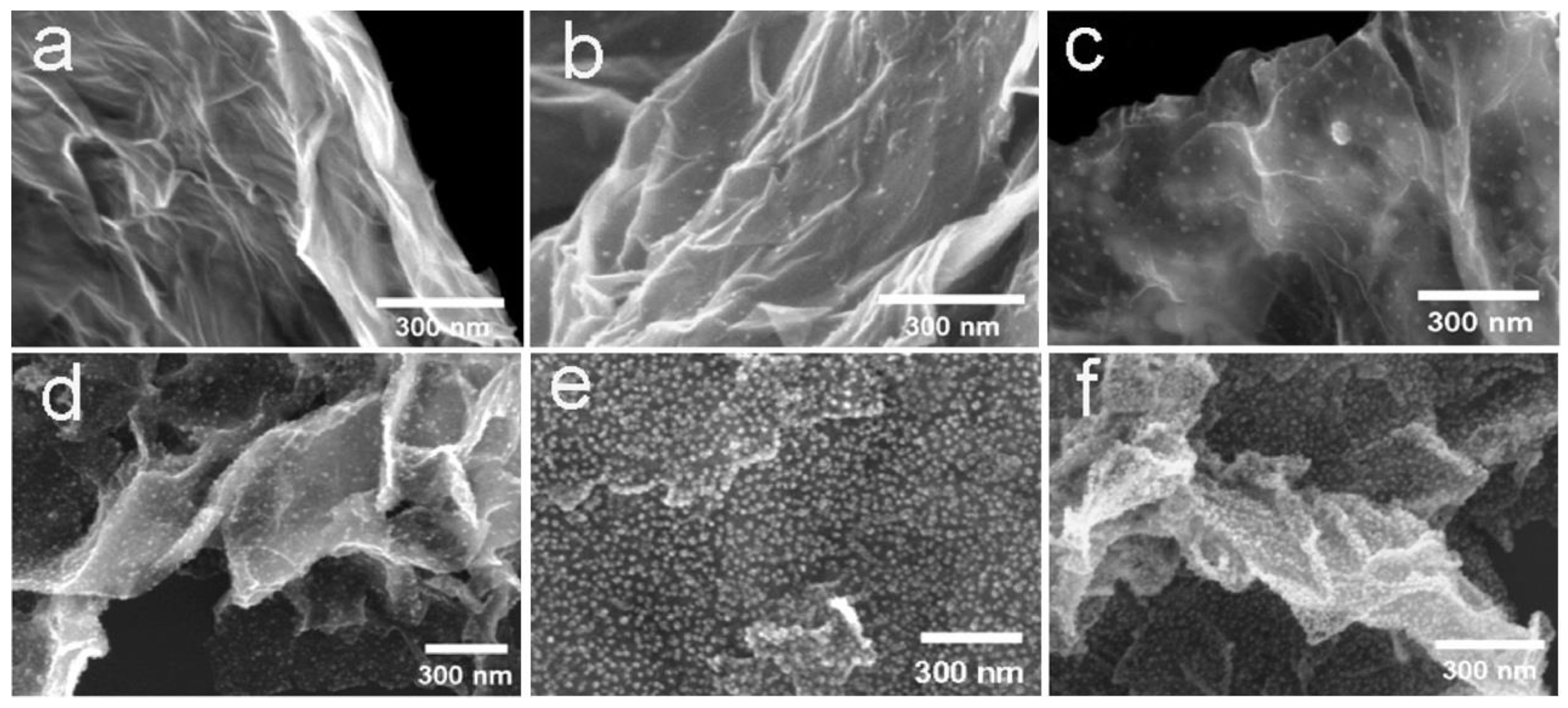

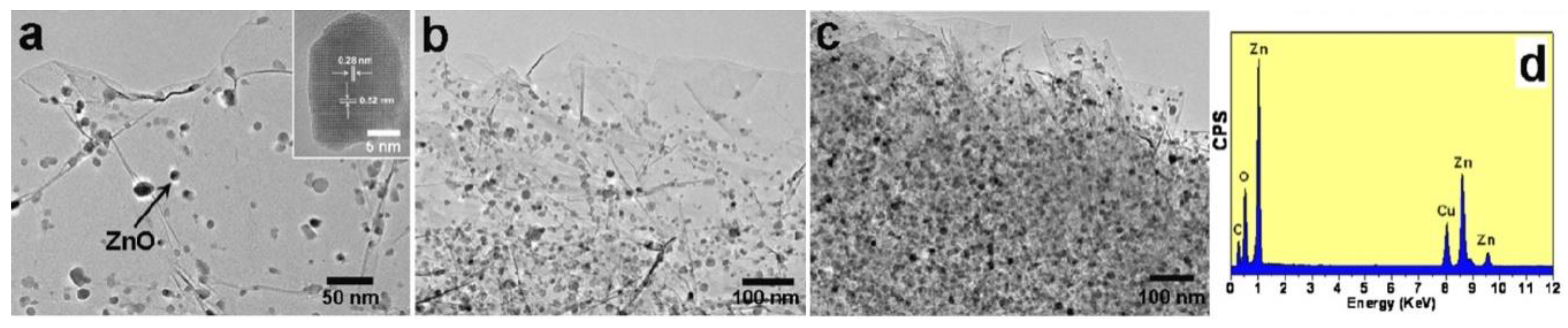

3.6. Types of ZnO Nanocomposites or ZnO Hybrid Nanostructures Obtained by the Microwave Hydrothermal Synthesis

3.7. ZnO Nanocomposites or ZnO Hybrid Nanostructures Obtained by the Microwave Hydrothermal Synthesis without Any Additional Heat Treatment

3.8. ZnO Nanocomposites or ZnO Hybrid Nanostructures Obtained by the Microwave Hydrothermal Synthesis with Additional Heat Treatment

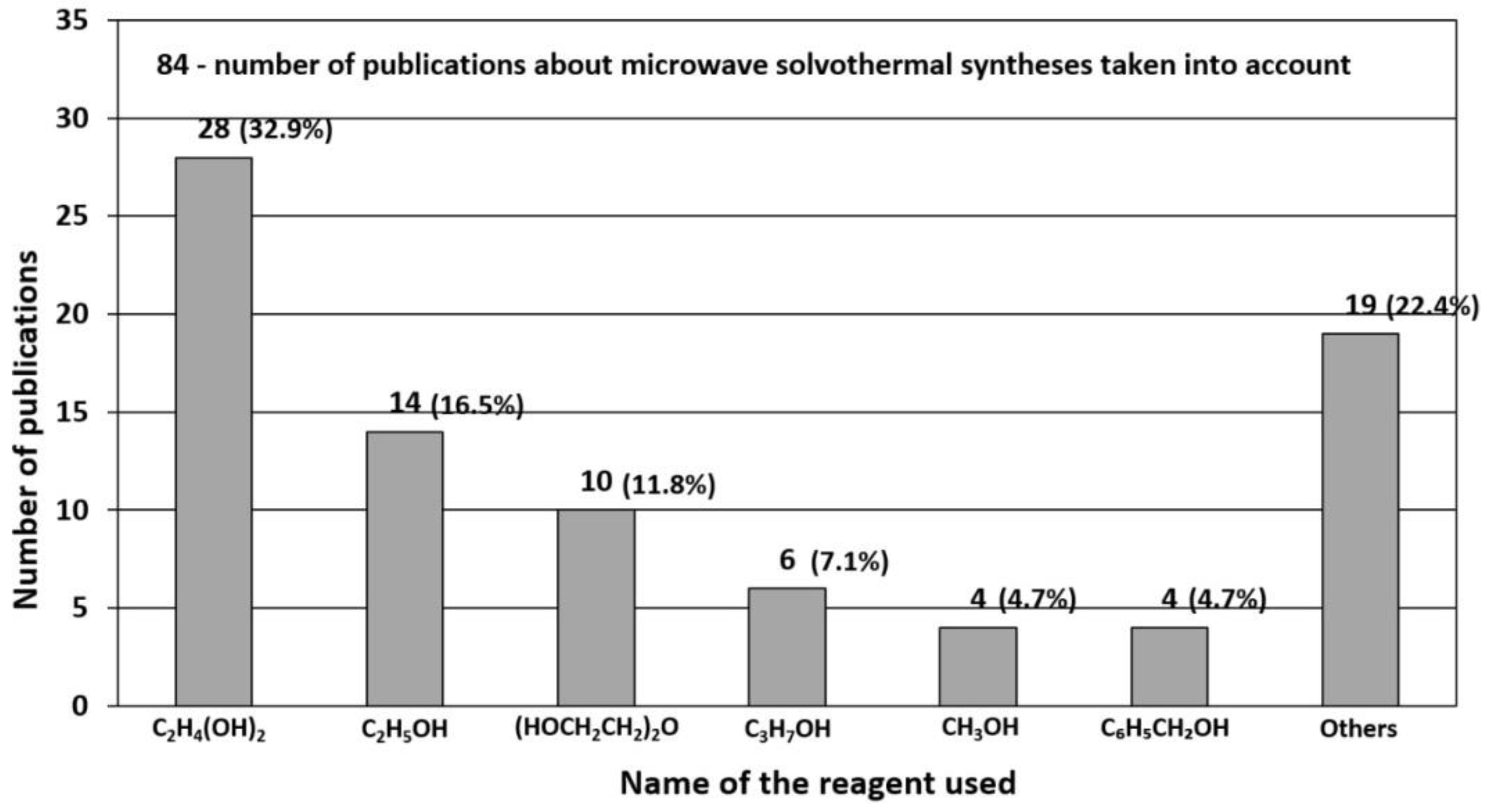

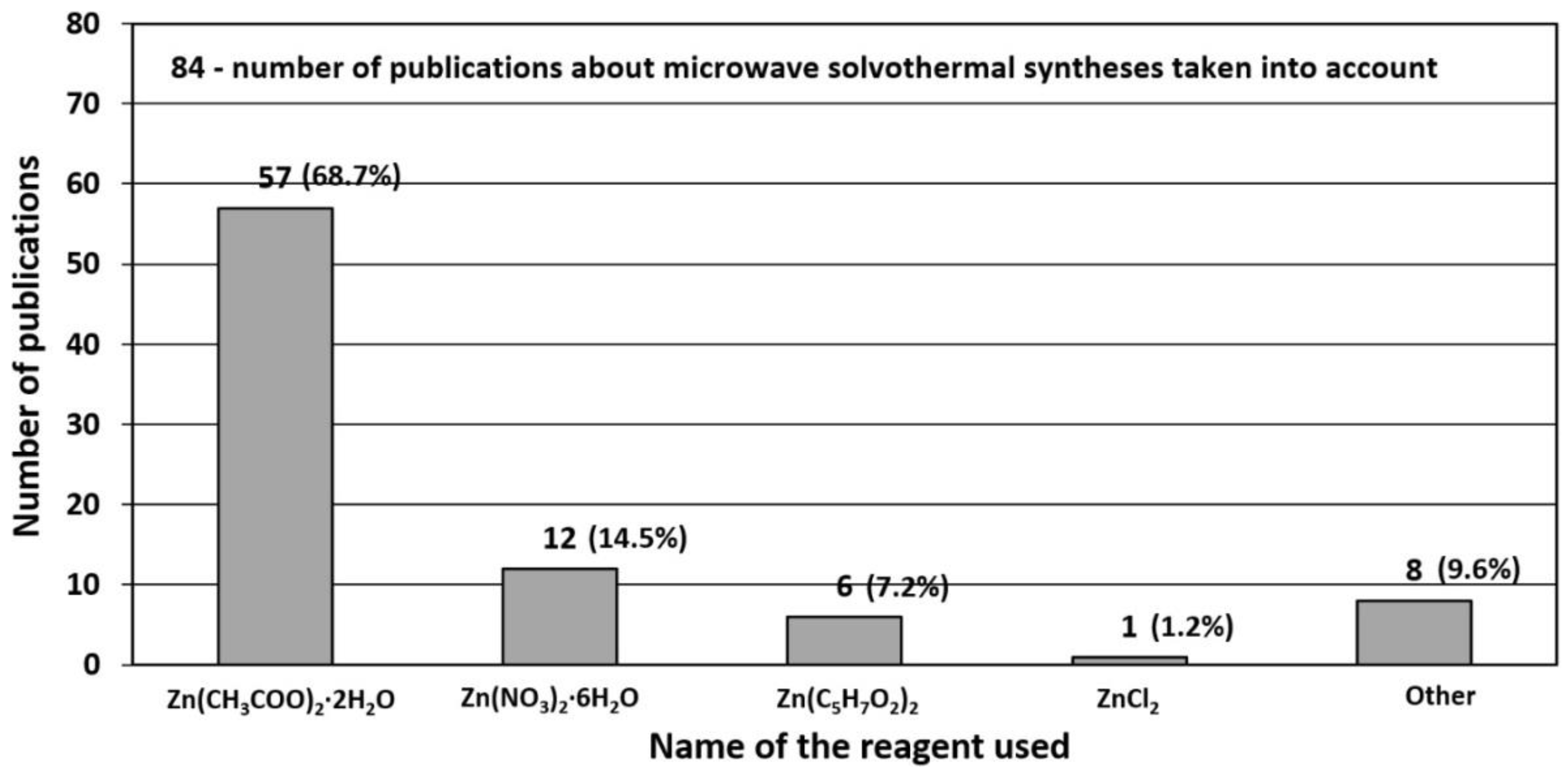

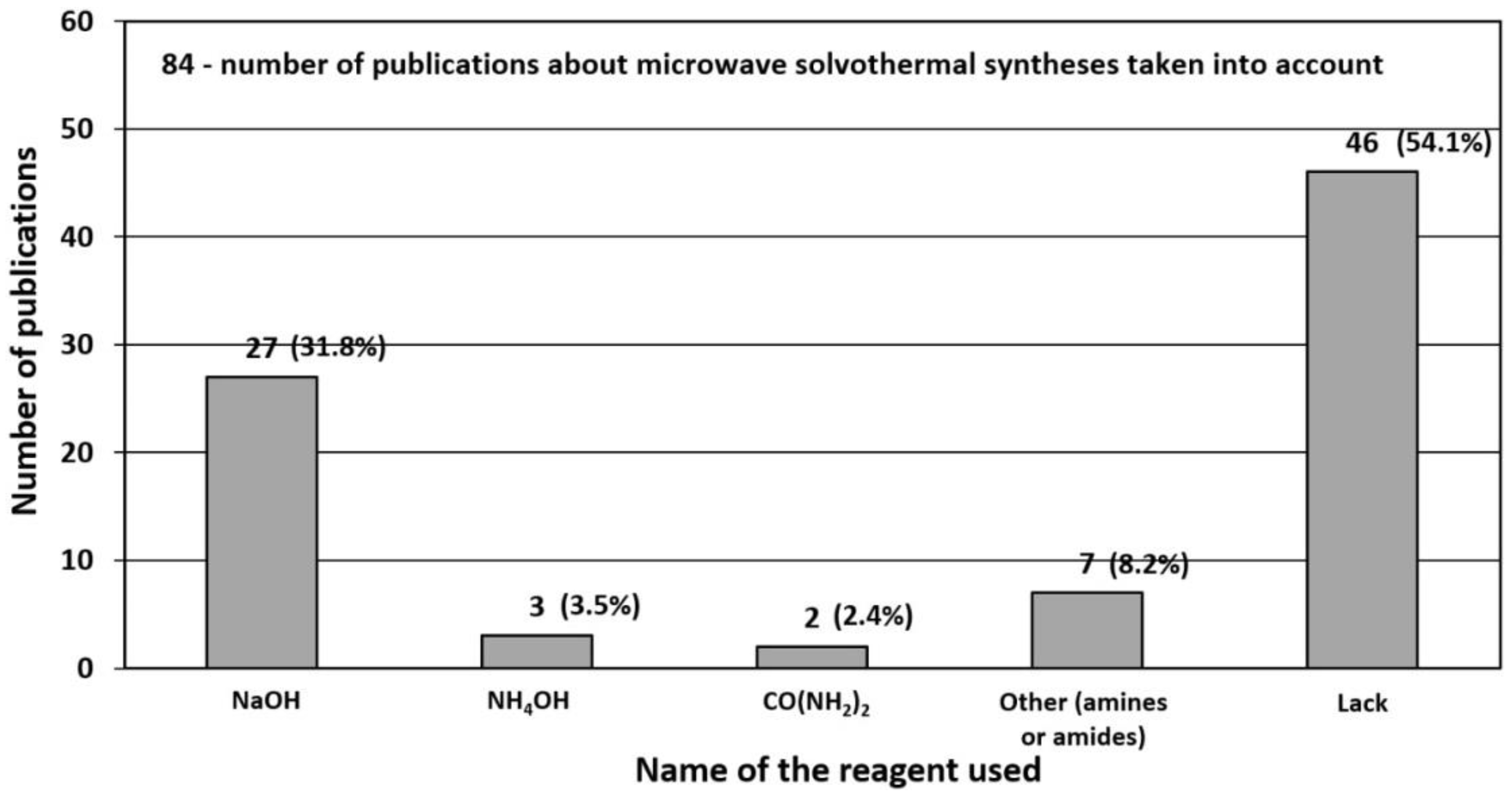

4. Microwave Solvothermal Synthesis of ZnO

- (1)

- Microwave solvothermal synthesis of ZnO nanostructures without any additional heat treatment, where the literature review results [402,573,758,759,760,761,762,763,764,765,766,767,768,769,770,771,772,773,774,775,776,777,778,779,780,781,782,783,784,785,786,787,788,789,790,791,792,793,794,795,796,797] are summarised in Table 10.

- (2)

- (3)

4.1. Reactants

4.2. Surfactants

4.3. Morphology

4.4. Microwave Solvothermal Synthesis of ZnO without Any Additional Heat Treatment

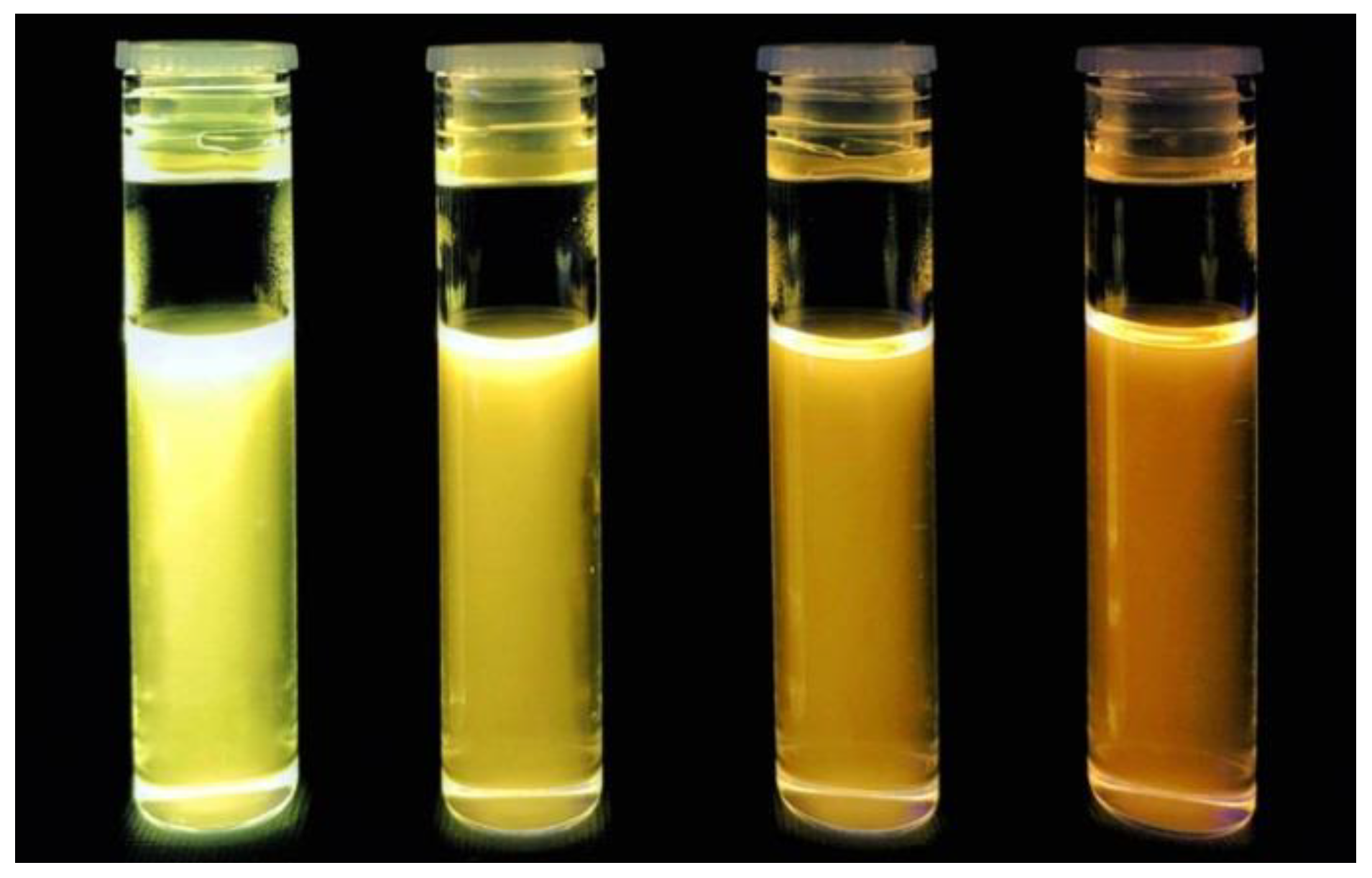

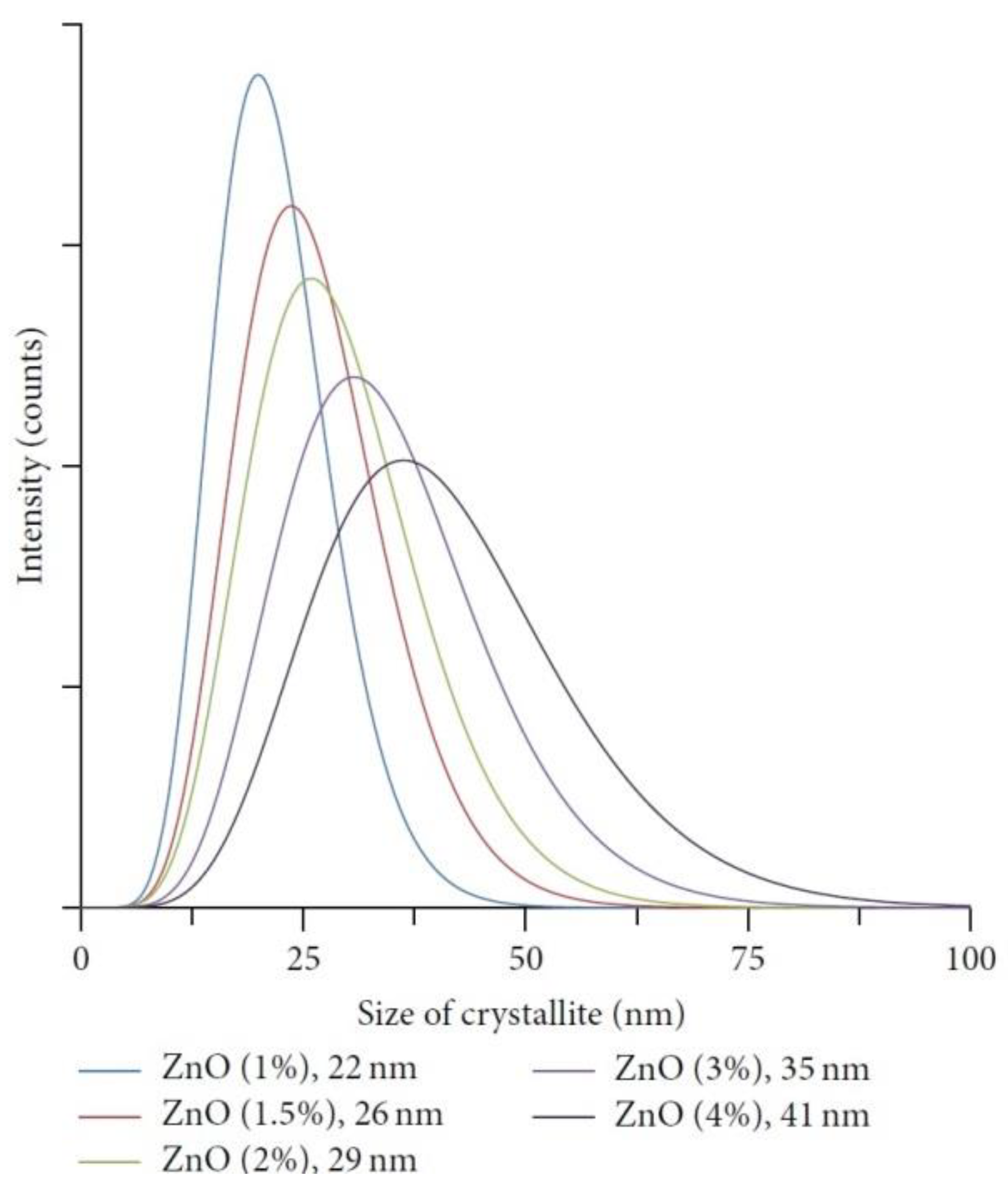

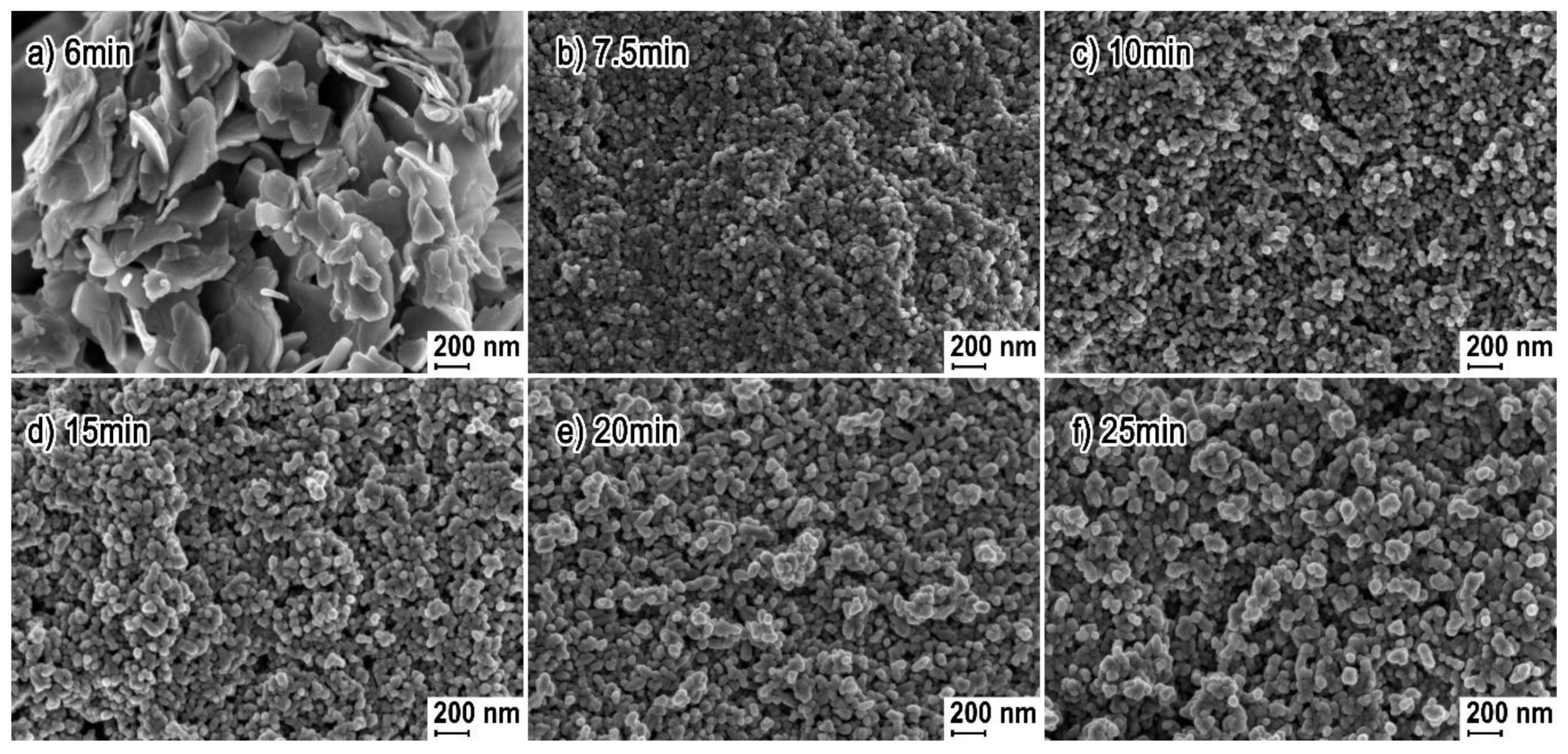

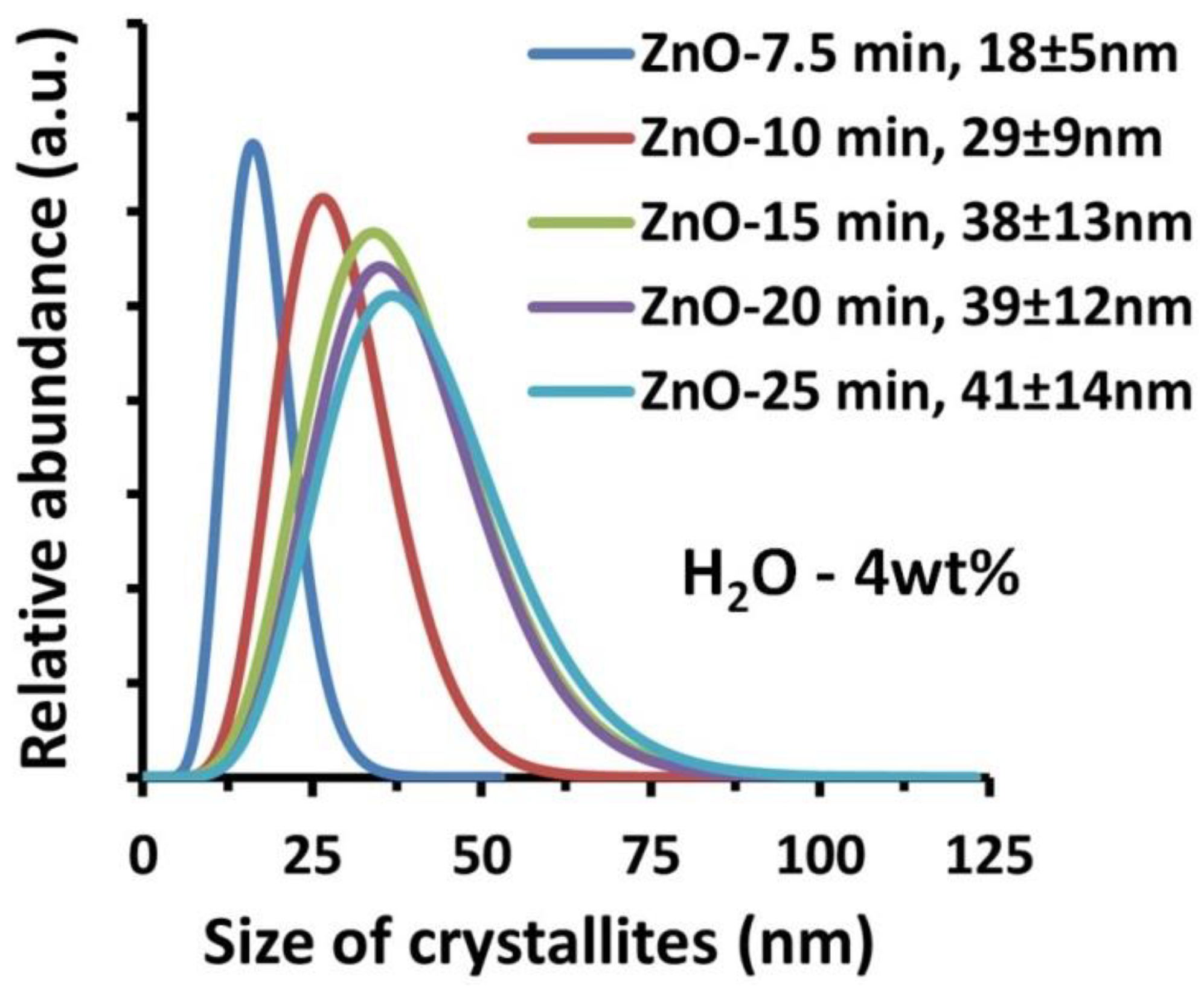

4.5. Microwave Solvothermal Synthesis of ZnO from a Solution

- (1)

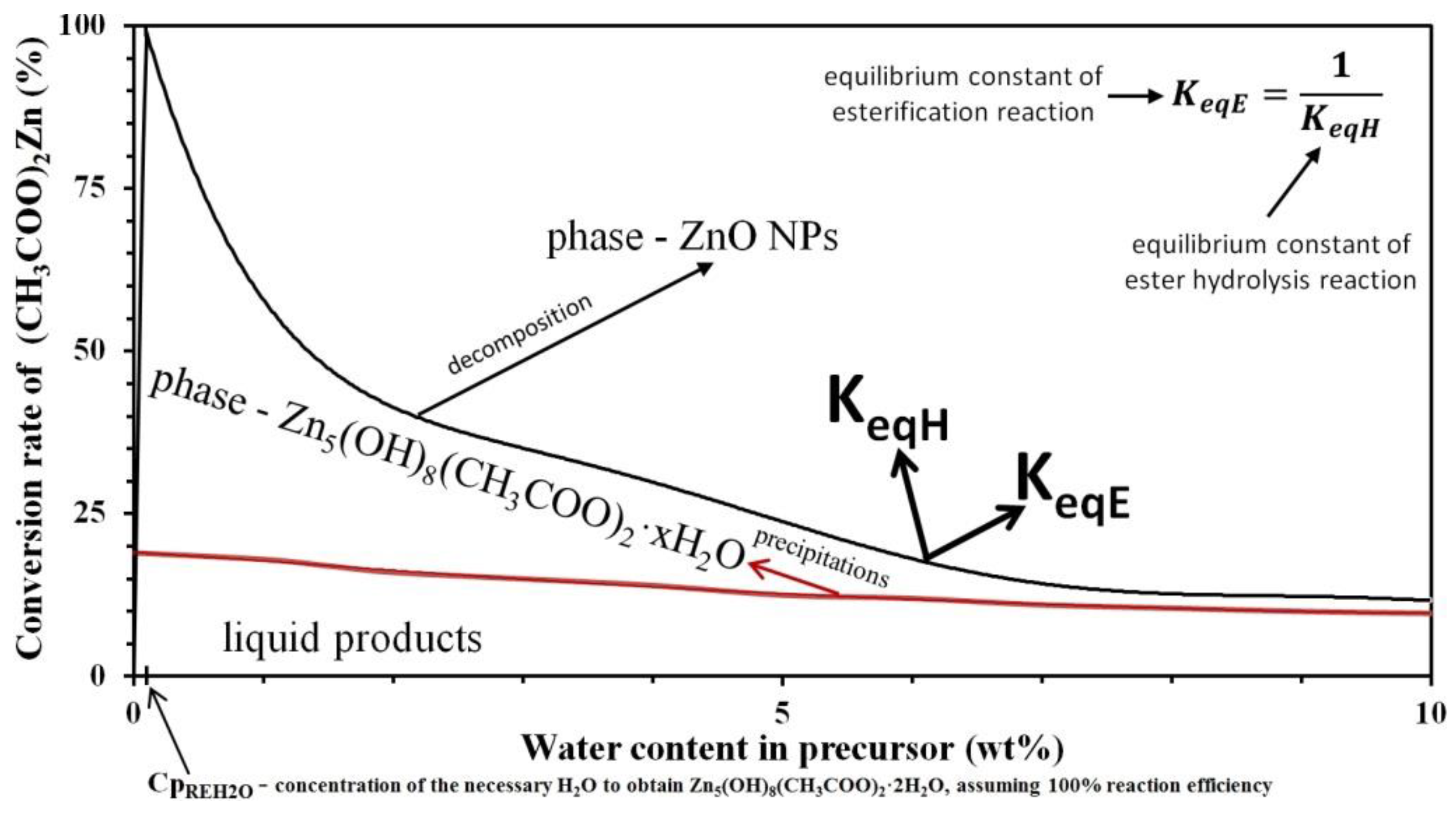

- Dissolution of zinc acetate in ethylene glycol (37,38), preparation of the precursor with a specified H2O content (39)–(41):

- (2)

- Formation (42)–(45) and growth of the intermediate (46):or possibly e.g.,nH2O comes from the simultaneous esterification reaction (47) or (48)

- (3)

- Achievement of equilibrium constant of the ester hydrolysis reaction for Equation (49) and at the same time of equilibrium constant of the esterification reaction (47) and decomposition of the intermediate caused by temperature (50):

- (4)

- As a result of hydrolysis of zinc acetate, water leads to the formation of acetic acid, which participates in an esterification reaction with ethylene glycol during the microwave solvothermal synthesis.

- The products of the esterification reaction are esters and water. However, the course of the reaction of obtaining and growth of the intermediate, Zn5(OH)8(CH3COO)2·xH2O, is possible only through the co-existence of the esterification reaction. Only water forming in the esterification reaction participates in reactions of obtaining/growth of the intermediate, Zn5(OH)8(CH3COO)2·xH2O. Once the equilibrium constant of the esterification reaction is reached, the intermediate rapidly decomposes into ZnO NPs, H2O and esters.

- The control of particle size arising from a change in the water content in the precursor is a consequence of the change in the quantity of formed crystalline nuclei of ZnO (NPs) relative to the remaining unconverted quantity of substrate (zinc acetate). After the decomposition of the intermediate into homogeneous nuclei of ZnO (NPs), no subsequent nuclei of ZnO (NPs) are formed as a result of further reactions. The only process that might occur is the growth of the existing nuclei of ZnO (NPs) until the still unreacted substrates are used up.

- Water fulfils the function of a catalyst in the described ZnO NPs solvothermal synthesis reaction. Water participates in the reaction with substrates and forms an unstable intermediate, Zn5(OH)8(CH3COO)2·xH2O, which at the same time is a catalyst of the esterification reaction.

4.6. Microwave Solvothermal Synthesis of ZnO from a Suspension

- -

- content of, ,

- -

- water being formed is collected physically or bound chemically,

- -

- other substances which may digest/dissolve ZnO are not formed.

4.7. Types of ZnO Nanocomposites or ZnO Hybrid Nanostructures Obtained by the Solvothermal Synthesis

- -

- -

- -

4.8. ZnO Nanocomposites or ZnO Hybrid Nanostructures Obtained by the Microwave Solvothermal Synthesis without Any Additional Heat Treatment

4.9. ZnO Nanocomposites or ZnO Hybrid Nanostructures Obtained by the Solvothermal Synthesis with Additional Heat Treatment

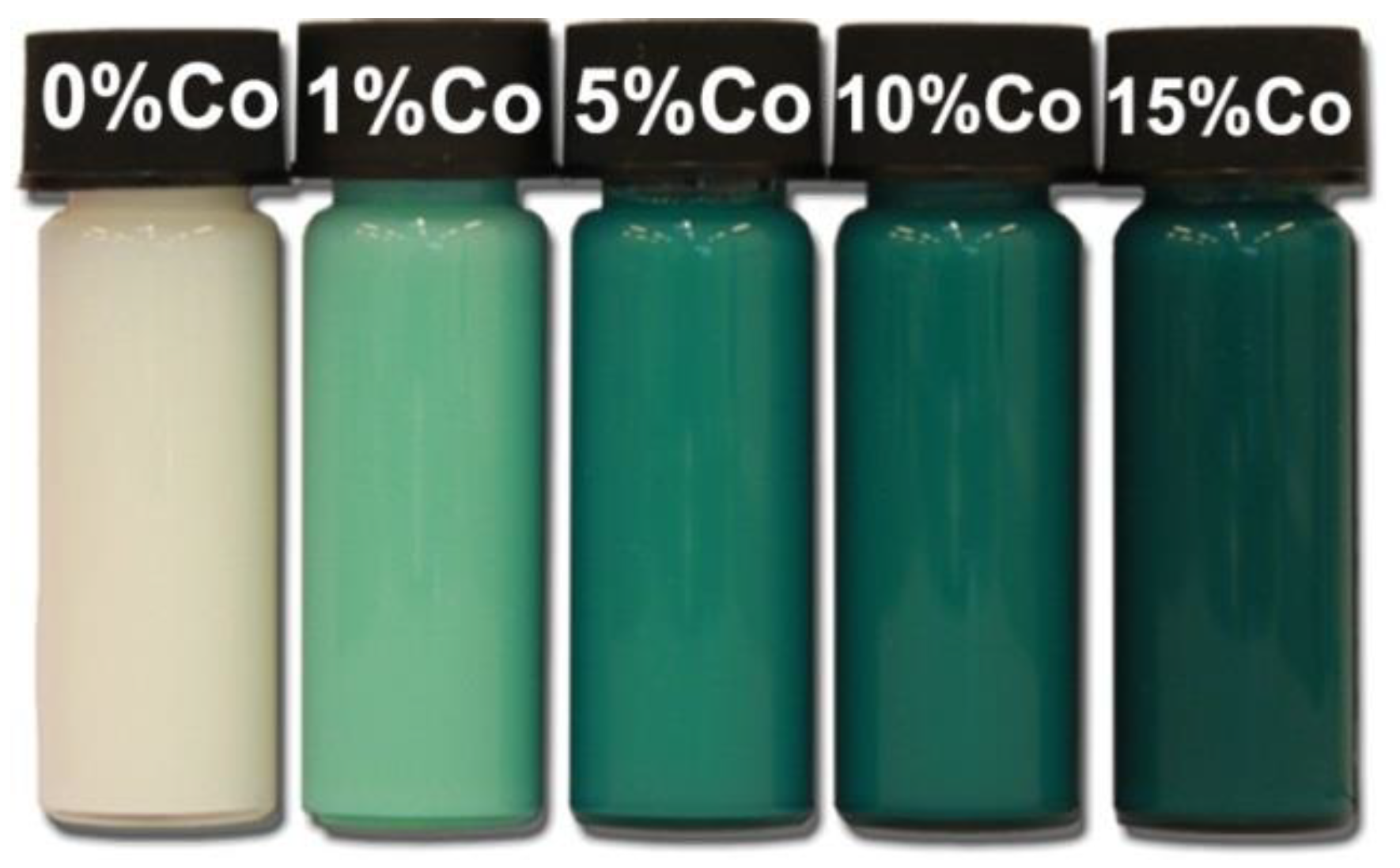

- -

- a change in their specific surface area from 37–39 m2/g to merely 3 m2/g,

- -

- an increase in the particle size from the range of 30–40 nm to the range of 50–2000 nm depending on the amount of Co,

- -

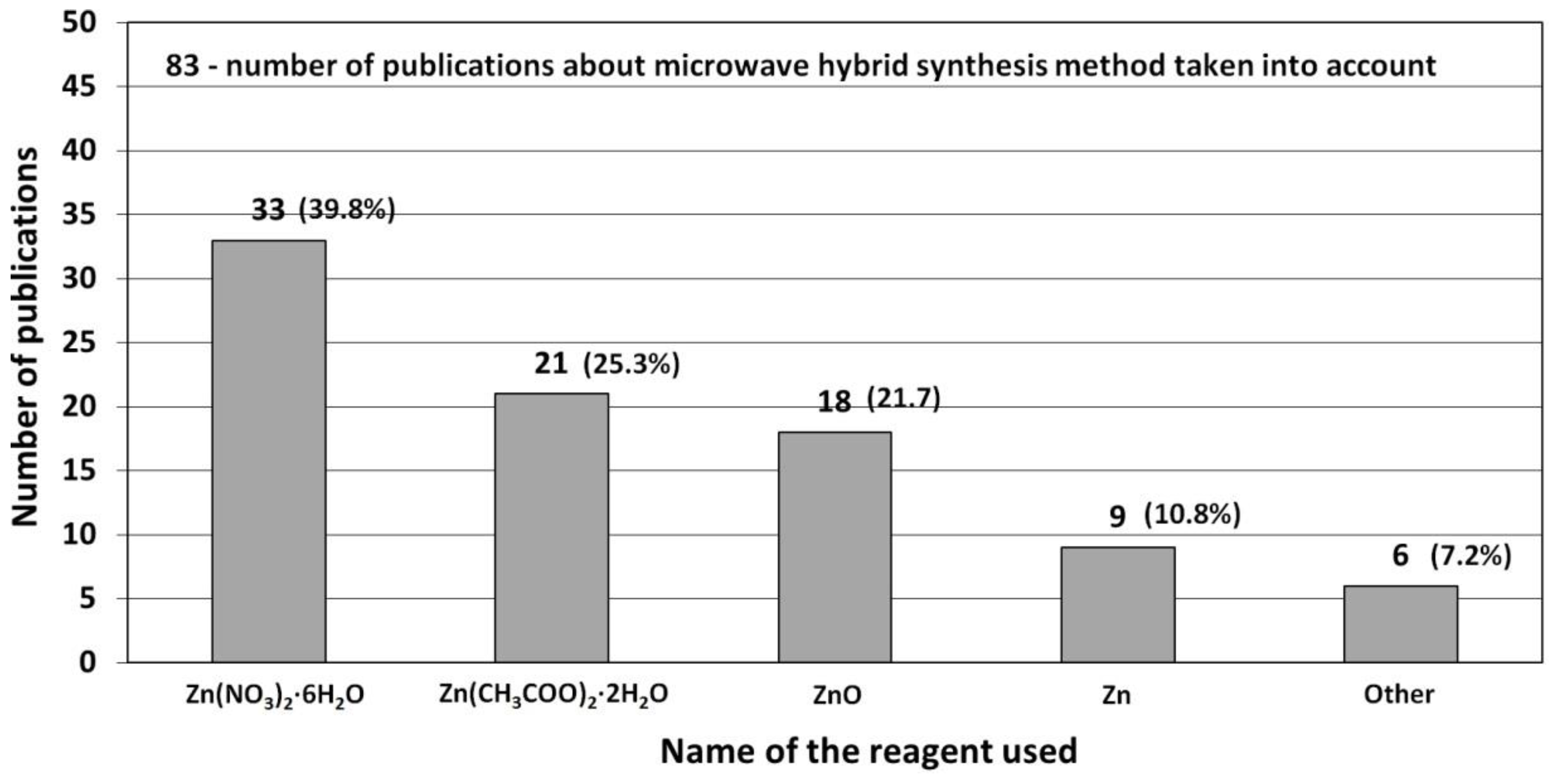

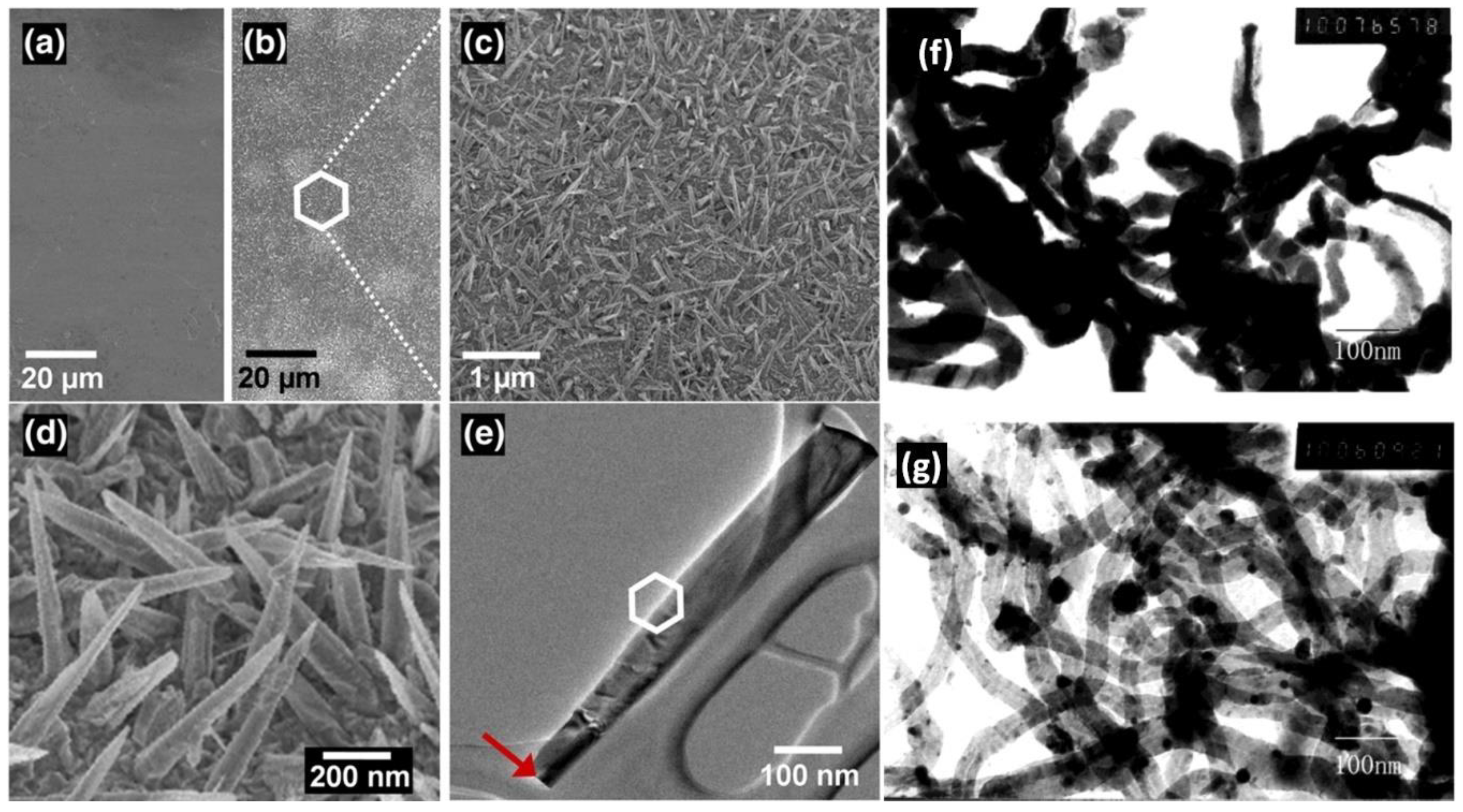

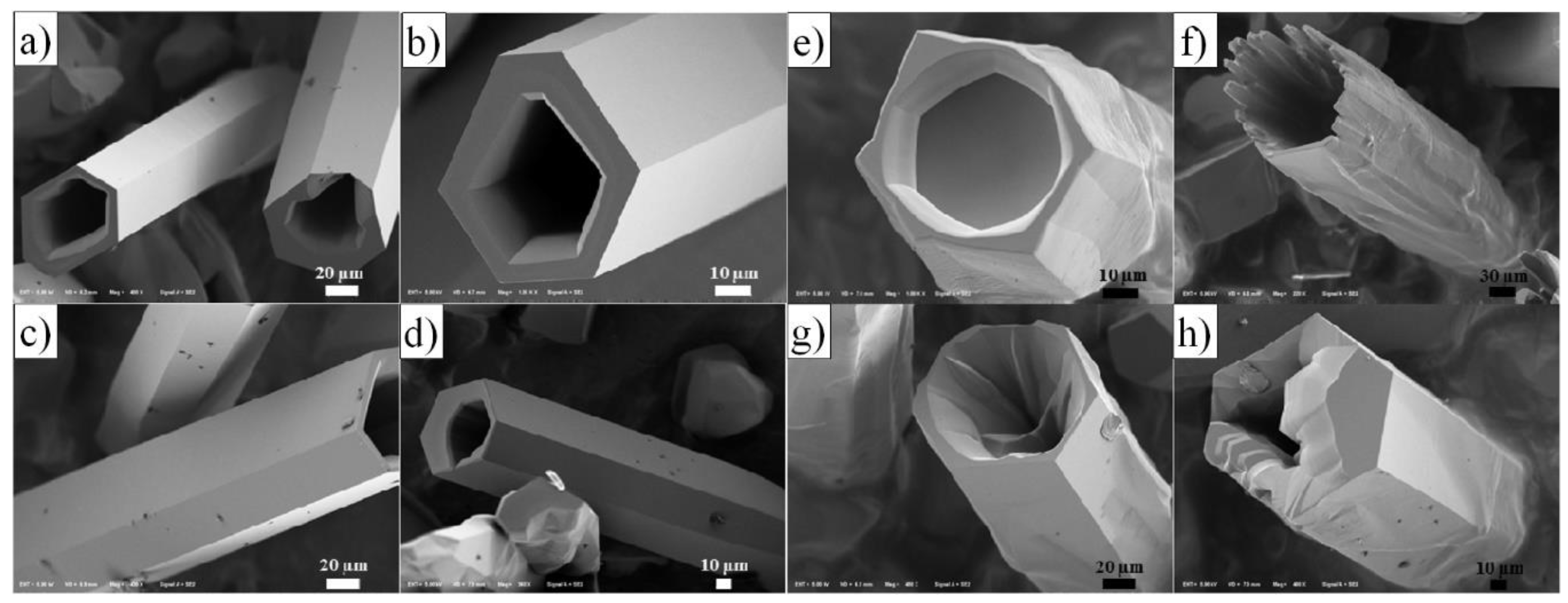

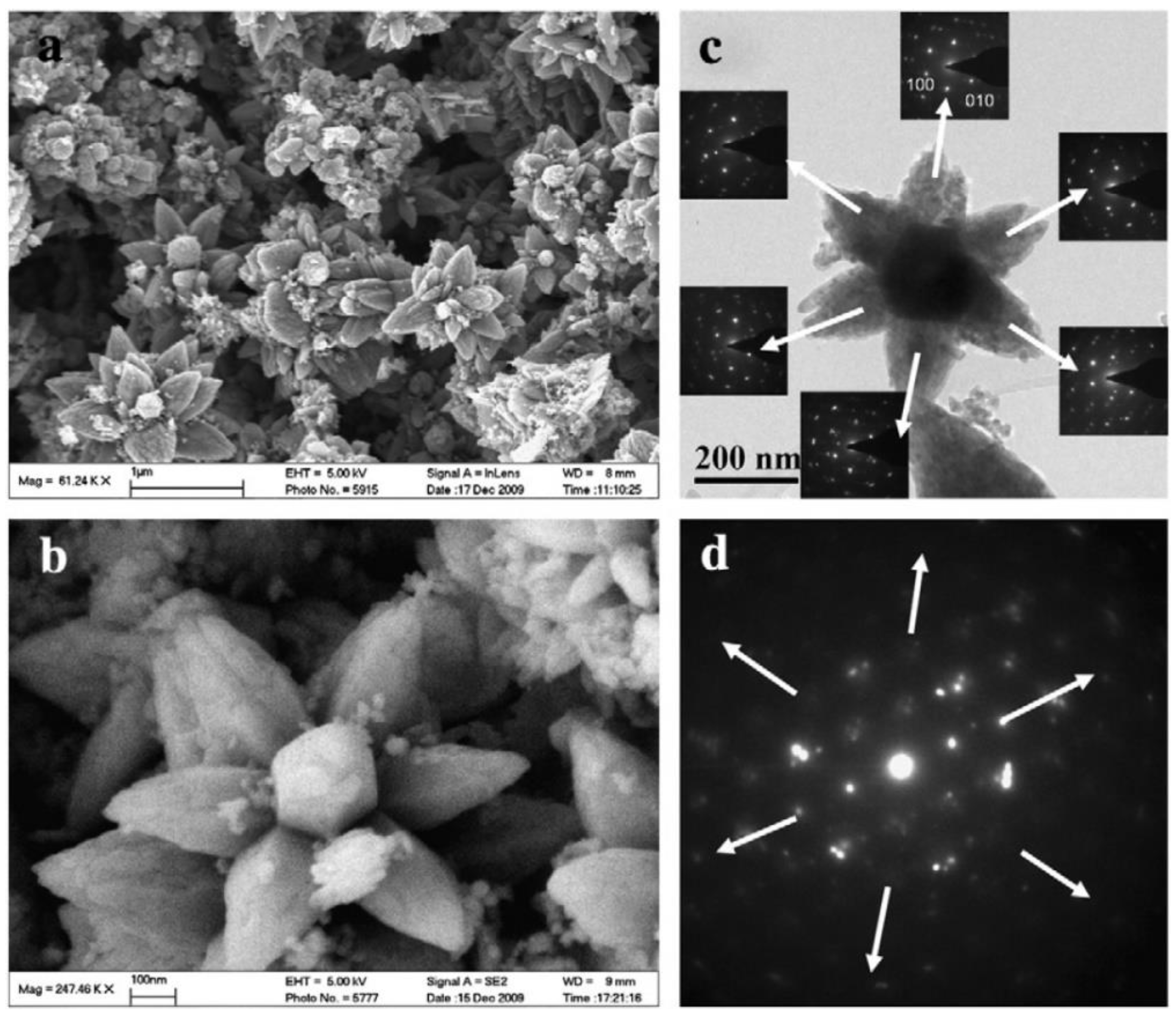

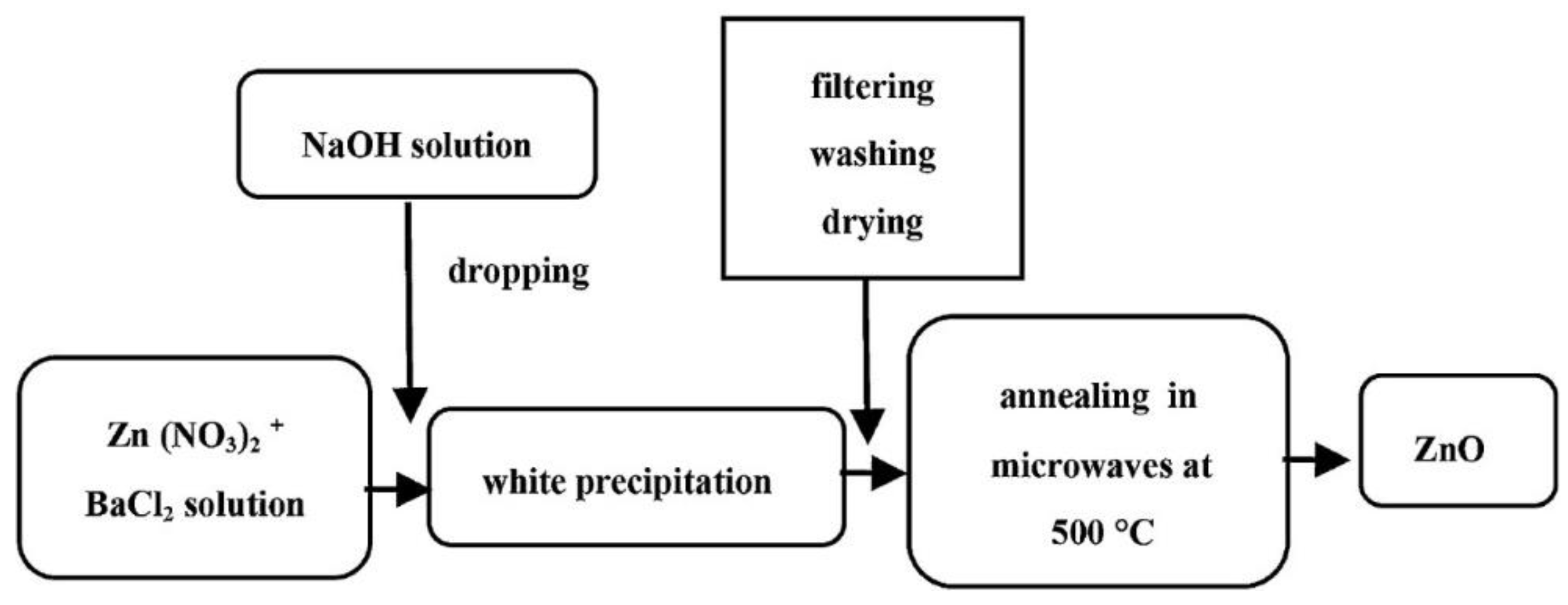

5. Microwave Hybrid Synthesis of ZnO

- (1)

- Microwave hybrid synthesis method of pure ZnO nano and microstructures, where the literature review results [844,845,846,847,848,849,850,851,852,853,854,855,856,857,858,859,860,861,862,863,864,865,866,867,868,869,870,871,872,873,874,875,876,877,878,879,880,881,882,883,884,885,886] are summarised in Table 13.

- (2)

- Microwave hybrid synthesis method of ZnO composites or ZnO hybrid structures, where the literature review results [887,888,889,890,891,892,893,894,895,896,897,898,899,900,901,902,903,904,905,906,907,908,909,910,911,912,913,914,915,916,917,918,919,920,921,922,923,924,925,926,927] are summarised in Table 14.

- (1)

- Ultrasonic microwave synthesis, which consists in the use of a new generation of microwave reactors, which permit the presence of an ultrasonic homogeniser’s sonotrode in the precursor mixture during the microwave heating. The ultrasonic homogeniser during its operation converts electrical energy into mechanical energy by moving the tip of the titanium sonotrode immersed in the fluid with a high frequency (19.5–40 kHz). Due to its inertia, the fluid no longer catches up with the rapid motion of the sonotrode, which results in cavitation, i.e., formation of gas bubbles that rapidly collapse, which is accompanied by sudden pressure changes, and as a consequence creates an impact wave.

- (2)

- Microwave assisted combustion synthesis, which consists in an exothermic reaction of combustion of one of the reactants of the reaction mixture in an oxygen atmosphere. Generally, a mixture composed among others of a Zn2+ salt and an organic component (fuel) is thoroughly mixed. There are several possibilities of the final state of the reaction mixture, among others, powder, pressed pastilles, gel, emulsion. The ready reaction mixture is introduced to a microwave reactor or oven, subjected to microwave radiation, which leads to a rapid increase in the sample temperature and ignition of the fuel, resulting in the formation of a ZnO powder.

- (3)

- Microwave assisted annealing, which consists in decomposition of the reaction mixture to ZnO only under the influence of its heating as a result of microwave radiation.

- (4)

- Microwave assisted sintering, which consists in microwave soaking of the earlier obtained ZnO.

- (5)

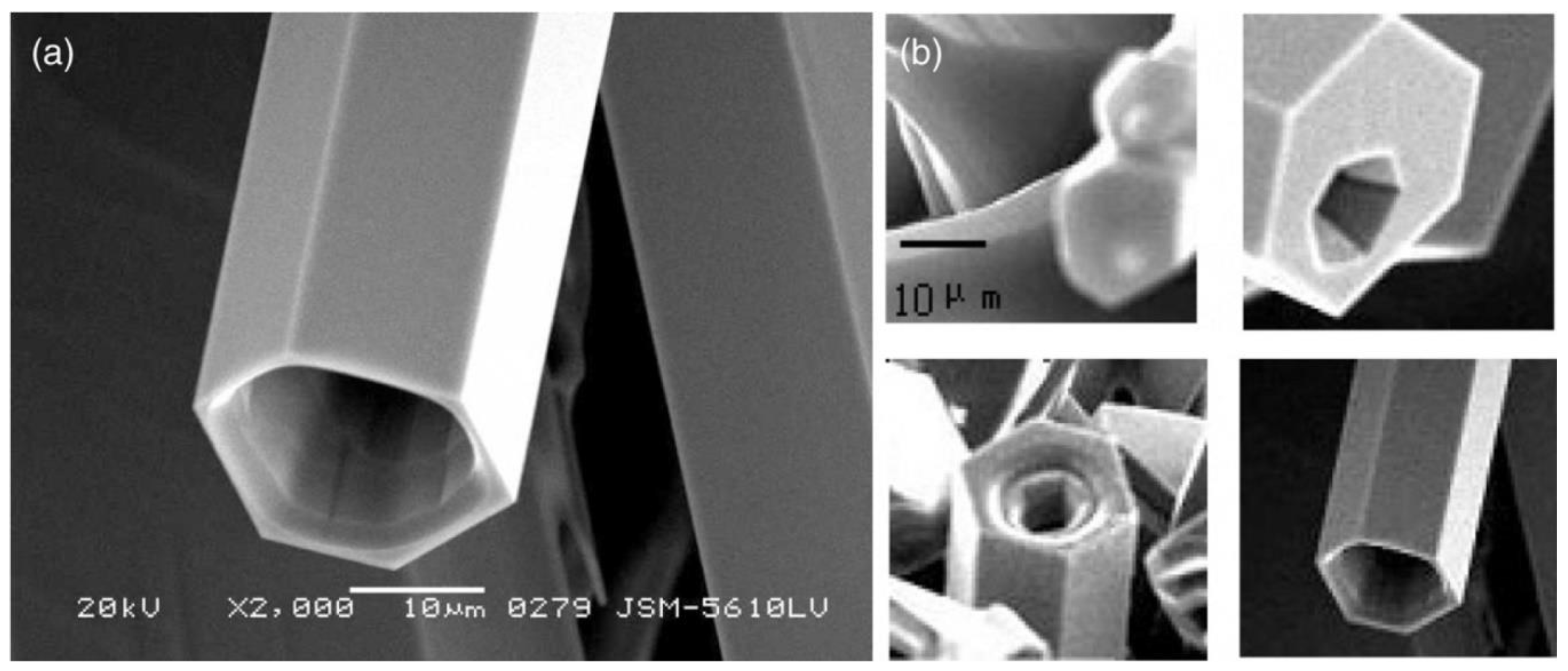

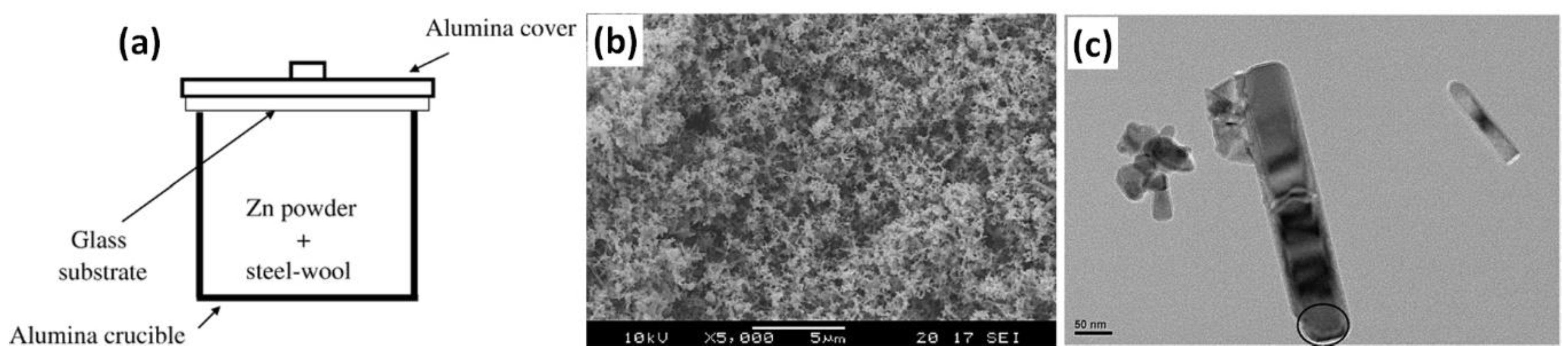

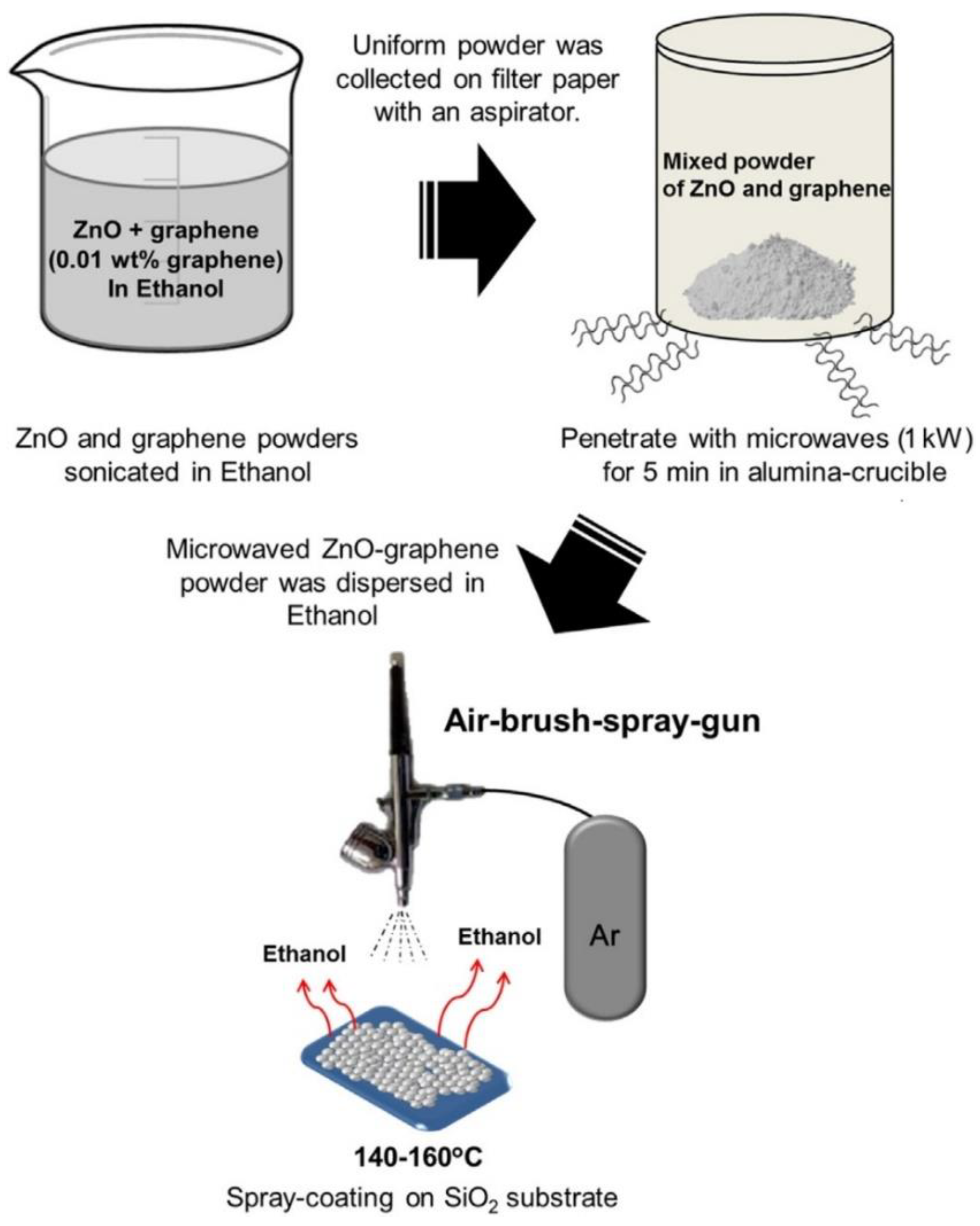

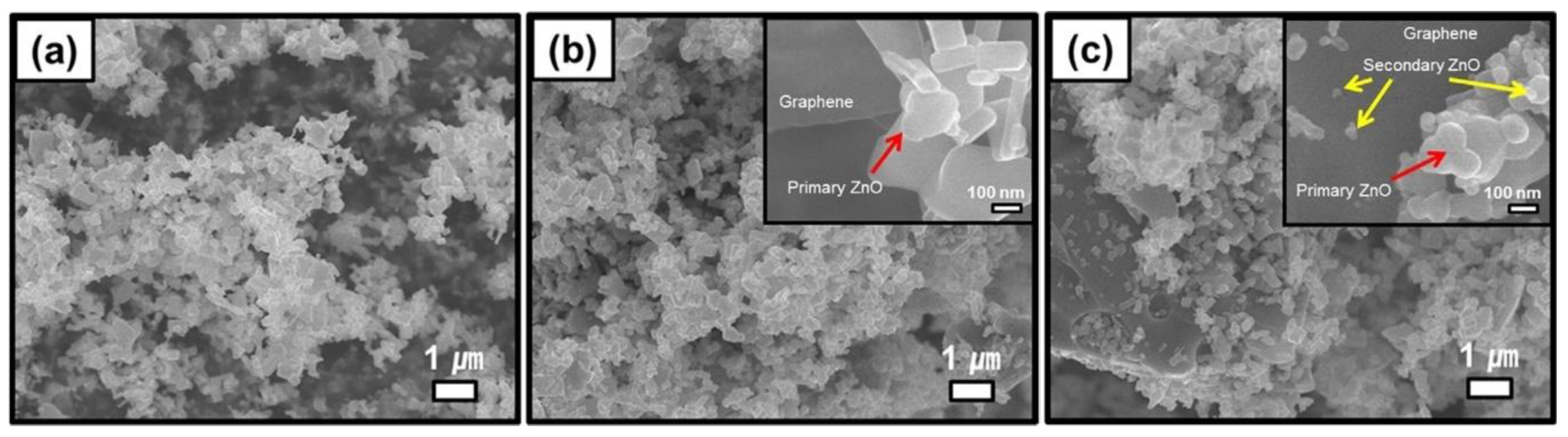

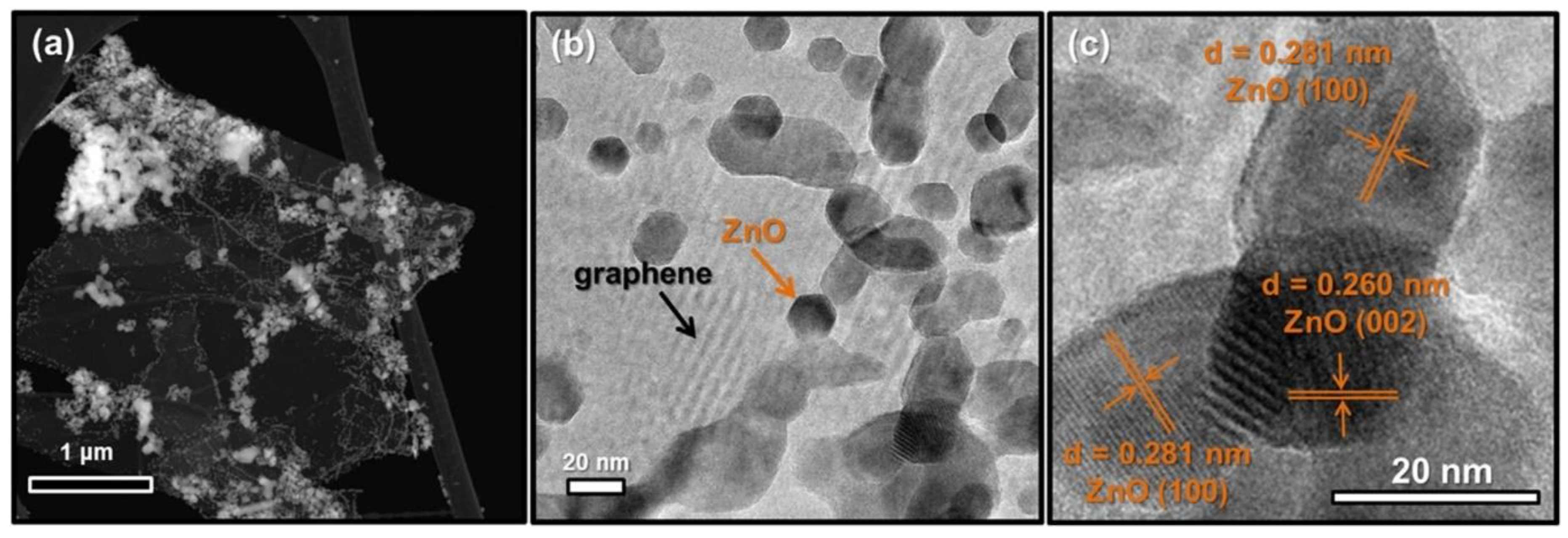

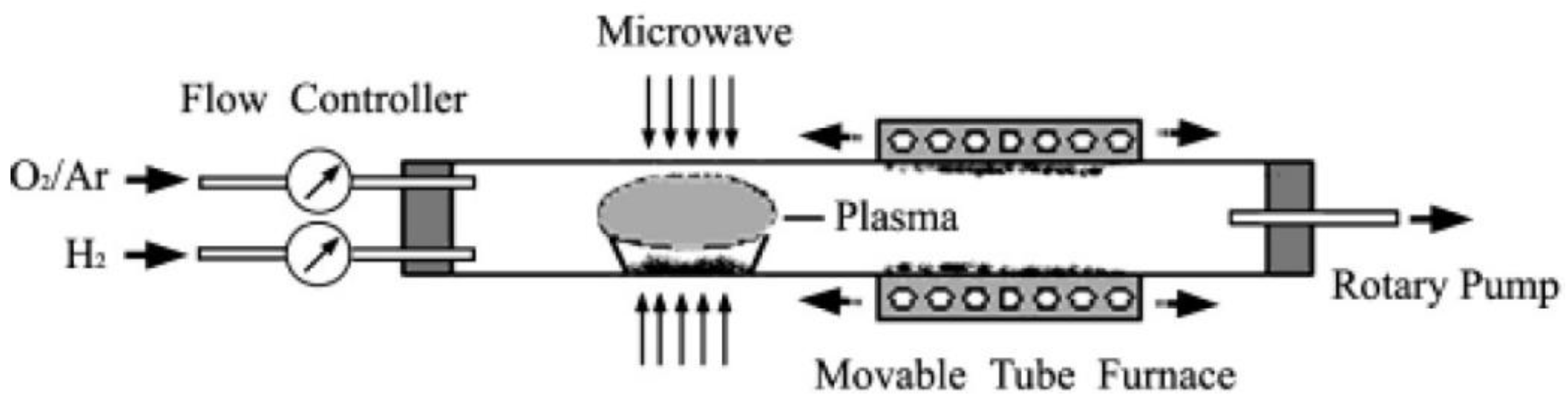

- Microwave vapour deposition, which consists in ZnO deposition from a gaseous phase, mostly at the atmospheric pressure, on the wafer (substrate) surface. For example, powdered ZnO, Zn or a Zn2+ salt is introduced to a ceramic crucible made of Al2O3, which is closed with a cover to which the substrate is attached on its inside part. Under the influence of microwave heating, a plasma arc appears in the crucible, enabling the evaporation of the Zn2+ substrate, which is deposited at the same time in the form of thin films on the whole surface of the ceramic container in the form of ZnO. Of course, there are professional microwave based plasma deposition units, which enable the application of inert carrier gases (e.g., argon, helium) or such gases (e.g., O2) that can participate in chemical reactions leading to the formation of ZnO layers.

5.1. Reactants

5.2. Morphology

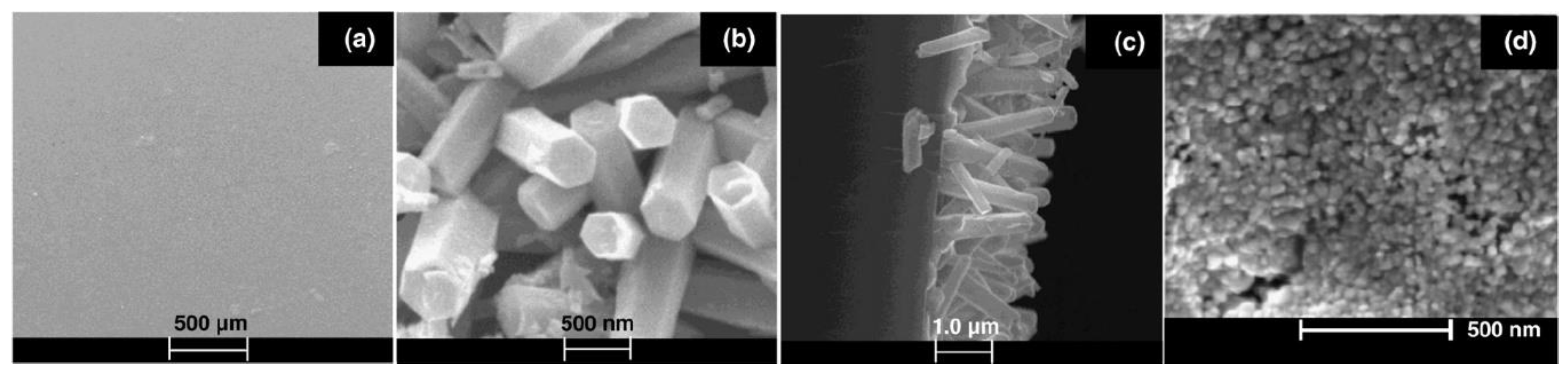

5.3. Synthesis of Pure ZnO by the Microwave Hybrid Method

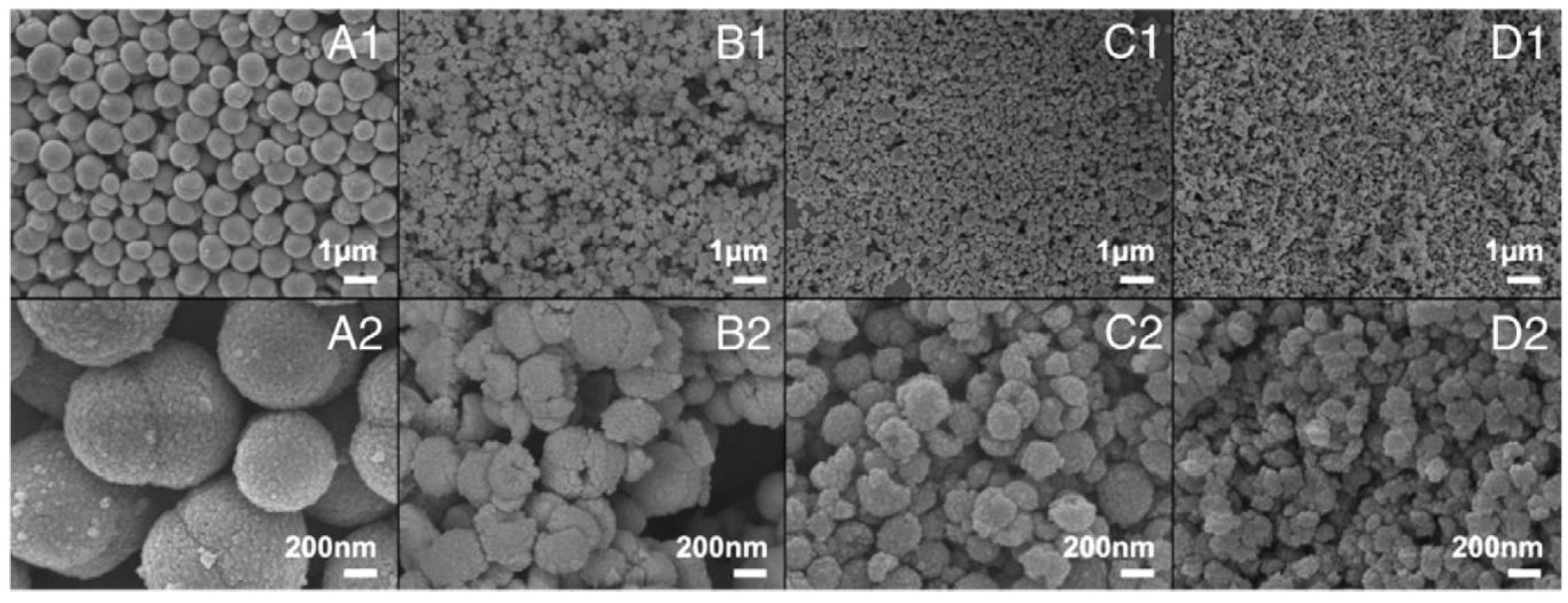

- -

- for the same duration (20 min) at various reaction temperatures (30, 40, 50 and 60 °C),

- -

- for the same reaction temperature (50 °C) with various durations (10, 20, 30 and 40 min).

5.4. Types of ZnO Nanocomposites or ZnO Hybrid Nanostructures Obtained by the Microwave Hybrid Synthesis Method

- -

- -

- -

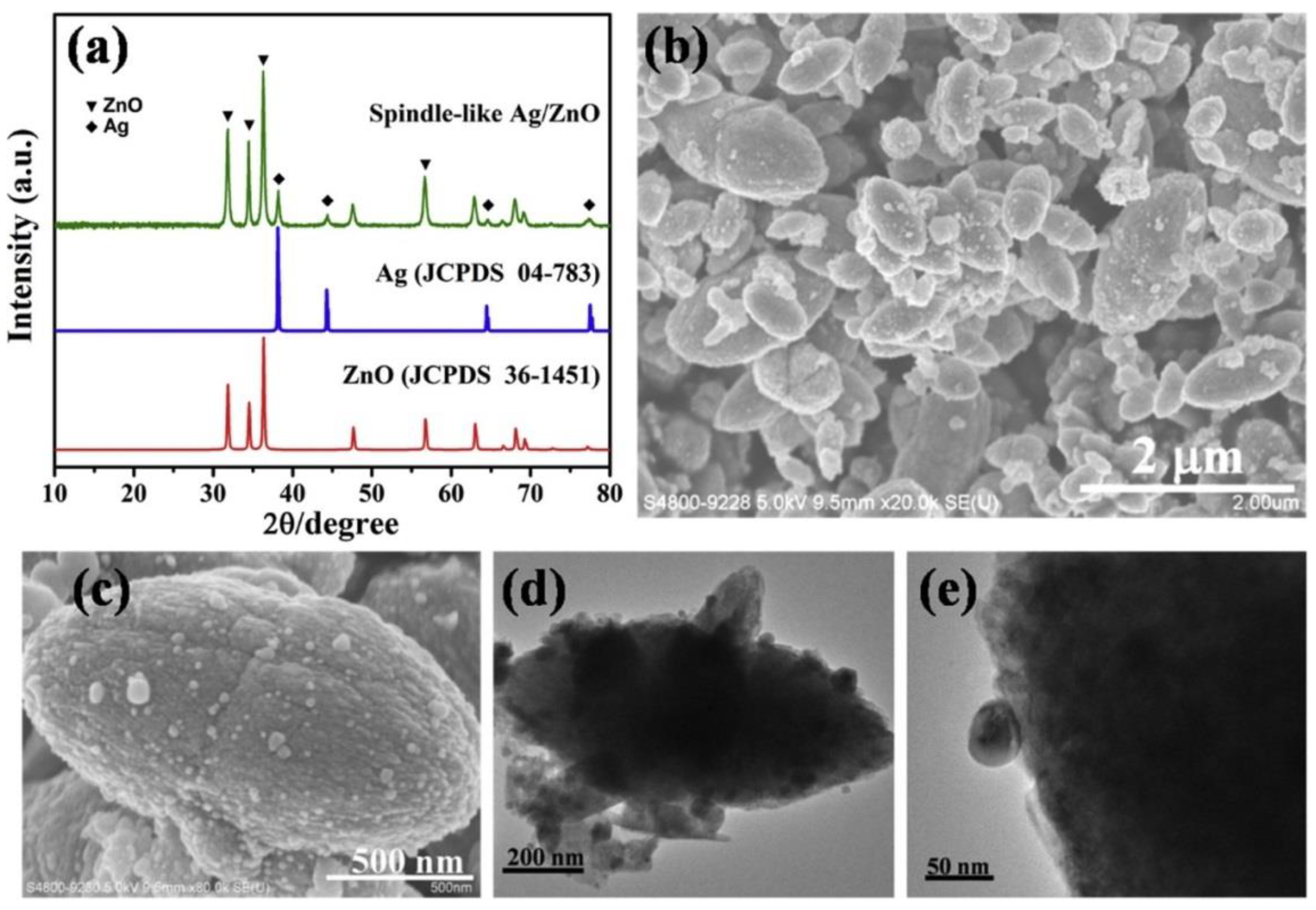

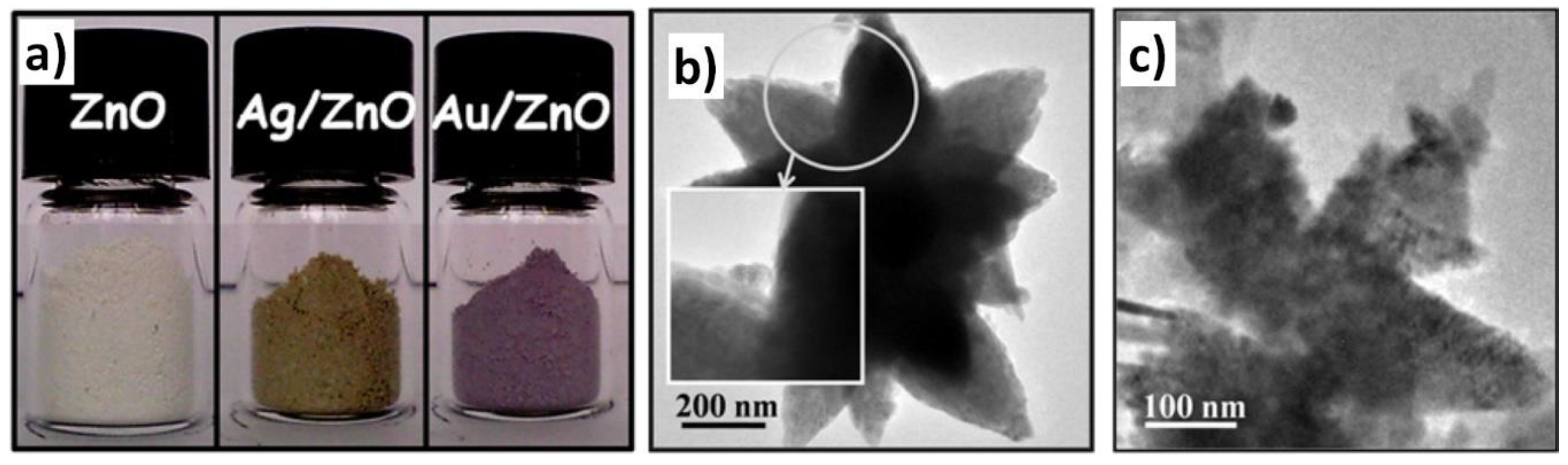

- composite and hybrid materials: Ag-ZnO [887,888,889], Au-ZnO [887], Ag–ZnO–graphene [889], Al3+ doped ZnO/Sn doped In2O3 [891], Au/Fe2O3–ZnO [892], ZnO/BiOBr [898], Zn–ZnO [899,900], ZnO–ZrO2 [901], ZnAl2O4/ZnO [902,903], Cu–ZnO–Al2O3 [905], Cu–ZnO [906], Fe2O3/ZnO [909], In2O3–Ga2O3–ZnO [912,913], MgO–ZnO [916], Sb2O3–MnO–CoO–Cr2O3–ZnO [918], TixOy–ZnO [920], ZnO/ZnFe2O4 [921], ZnO/multi-walled carbon nanotube [922], ZnO—exfoliated graphene [923], ZnO–expandable graphite [927], and ZnO–reduced graphene oxide [924,925].

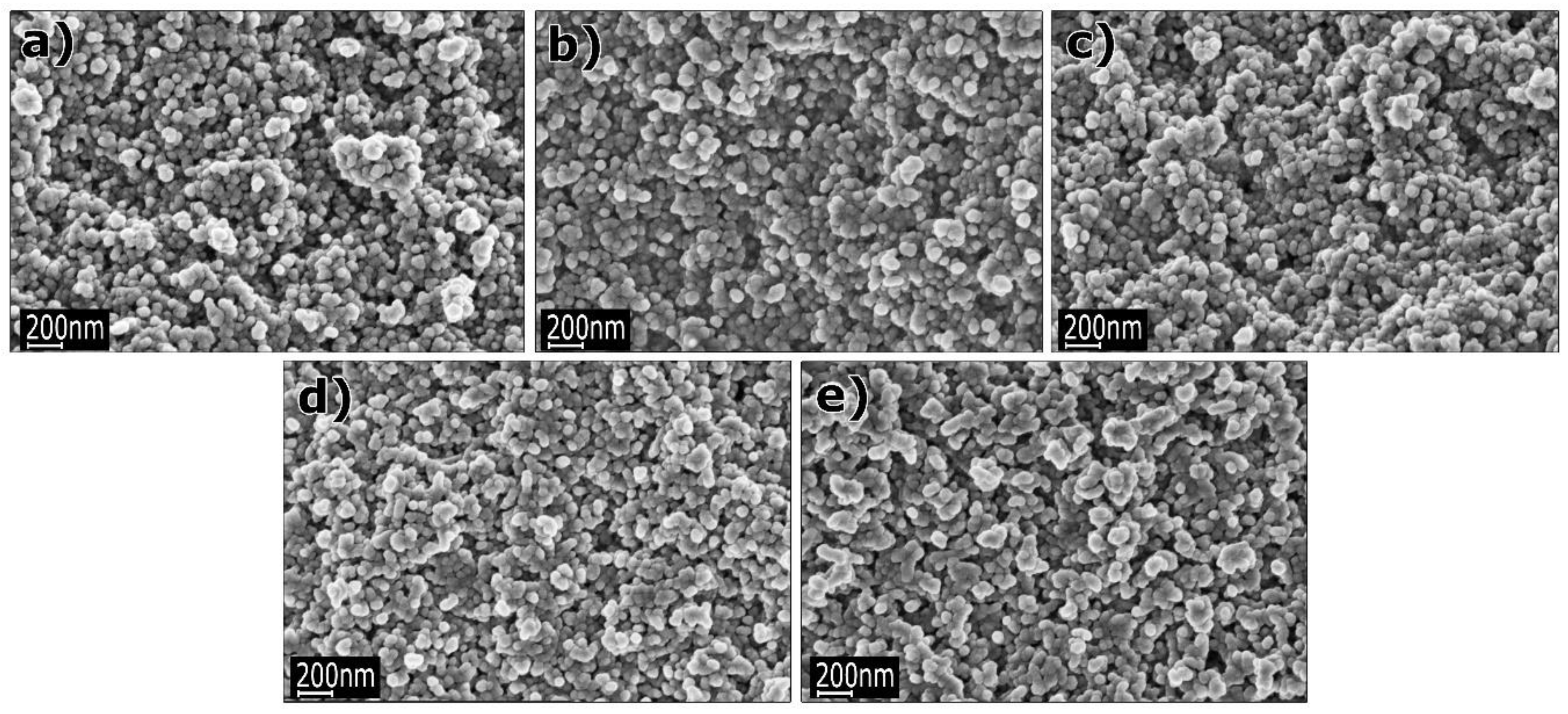

5.5. Synthesis of ZnO Nanocomposites or ZnO Hybrid Nanostructures by the Microwave Hybrid Method

- -

- zinc nitrate with hexamethylenetetramine was used to obtain ZnO NPs;

- -

- zinc nitrate, silver nitrate with hexamethylenetetramine was used to obtain Ag/ZnO nanocomposites;

- -

- zinc nitrate, silver nitrate with hexamethylenetetramine and an addition of graphene was used to obtain Ag/ZnO/graphene nanocomposites.

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Drexler, E.; Peterson, C.; Pergamit, G. Unbounding the Future: The Nanotechnology Revolution, 1st ed.; William Morrow: New York, NY, USA, 1991. [Google Scholar]

- Lloyd’s Register Foundation. Foresight Review of Nanotechnology, the Next Industrial Revolution; Lloyd’s Register Foundation: London, UK, 2014. [Google Scholar]

- Shrivastava, S.; Dash, D. Applying nanotechnology to human health: Revolution in biomedical sciences. J. Nanotechnol. 2009, 2009, 184702. [Google Scholar] [CrossRef]

- Stirling, D.A. The Nanotechnology Revolution: A Global Bibliographic Perspective, 1st ed.; Pan Stanford Publishing: Singapore, 2018; ISBN 978-981-4774-19-2. [Google Scholar]

- Lowry, G.V.; Avellan, A.; Gilbertson, L.M. Opportunities and challenges for nanotechnology in the agri-tech revolution. Nat. Nanotechnol. 2019, 14, 517–522. [Google Scholar] [CrossRef] [PubMed]

- Durkan, C. Size Really Does Matter: The Nanotechnology Revolution, 1st ed.; World Scientific Publishing: Singapore, 2019; ISBN 978-1-78634-661-2. [Google Scholar]

- McClintock, P.V.E. Size really does matter: The nanotechnology revolution. Contemp. Phys. 2019, 60, 204–205. [Google Scholar] [CrossRef]

- Wolf, E.L.; Medikonda, M. Understanding the Nanotechnology Revolution, 1st ed.; Wiley-VCH: Weinheim, Germany, 2012; ISBN 9783527411092. [Google Scholar]

- Nasrollahzadeh, M.; Sajadi, S.M.; Sajjadi, M.; Issaabadi, Z. An introduction to nanotechnology. Interface Sci. Technol. 2019, 28, 1–27. [Google Scholar] [CrossRef]

- Wennersten, R.; Fidler, J.; Spitsyna, A. Nanotechnology: A New Technological Revolution in the 21st Century. In Handbook of Performability Engineering, 1st ed.; Misra, K.B., Ed.; Springer: London, UK, 2008; pp. 943–952. [Google Scholar]

- Vance, M.E.; Kuiken, T.; Vejerano, E.P.; McGinnis, S.P.; Hochella, M.F., Jr.; Rejeski, D.; Hull, M.S. Nanotechnology in the real world: Redeveloping the nanomaterial consumer products inventory. Beilstein J. Nanotechnol. 2015, 6, 1769–1780. [Google Scholar] [CrossRef]

- Sanders, W.C. Basic Principles of Nanotechnology, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- García-Martínez, J.; Wang, Z.L. Nanotechnology for the Energy Challenge, 2nd ed.; Wiley-VCH: Weinheim, Germany, 2013. [Google Scholar] [CrossRef]

- Raj, B.; Van de Voorde, M.; Mahajan, Y. Nanotechnology for Energy Sustainability, 1st ed.; John Wiley & Sons: Weinheim, Germany, 2017. [Google Scholar]

- Fakruddin, M.; Hossain, Z.; Afroz, H. Prospects and applications of nanobiotechnology: A medical perspective. J. Nanobiotechnol. 2012, 10, 31. [Google Scholar] [CrossRef]

- Ramos, A.P.; Cruz, M.A.E.; Tovani, C.B.; Ciancaglini, P. Biomedical applications of nanotechnology. Biophys. Rev. 2017, 9, 79–89. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, K.; Dixit, S.; Mishra, K.; Srivastavaet, S. A review on positive and negative impacts of nanotechnology in agriculture. Int. J. Environ. Sci. Technol. 2019, 16, 2175–2184. [Google Scholar] [CrossRef]

- Prasad, R.; Bhattacharyya, A.; Nguyen, Q.D. Nanotechnology in sustainable agriculture: Recent developments, challenges, and perspectives. Front. Microbiol. 2017, 8, 1014. [Google Scholar] [CrossRef]

- Cheraghian, G.; Hendraningrat, L. A review on applications of nanotechnology in the enhanced oil recovery part A: Effects of nanoparticles on interfacial tension. Int. Nano Lett. 2016, 6, 129–138. [Google Scholar] [CrossRef]

- Hannah, W.; Thompson, P.B. Nanotechnology, risk and the environment: A review. J. Environ. Monit. 2008, 10, 291–300. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Nehra, M.; Kedia, D.; Dilbaghi, N.; Tankeshwar, K.; Kim, K.-H. Nanotechnology-based biomaterials for orthopaedic applications: Recent advances and future prospects. Mater. Sci. Eng. C 2020, 106, 110154. [Google Scholar] [CrossRef] [PubMed]

- King, T.; Osmond-McLeod, M.J.; Duffy, L.L. Nanotechnology in the food sector and potential applications for the poultry industry. Trends Food Sci. Technol. 2018, 72, 62–73. [Google Scholar] [CrossRef]

- He, X.; Deng, H.; Hwang, H.M. The current application of nanotechnology in food and agriculture. J. Food Drug Anal. 2019, 27, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Gothandam, K.; Ranjan, S.; Dasgupta, N.; Ramalingam, C.; Lichtfouse, E. Nanotechnology, Food Security and Water Treatment, 1st ed.; Springer: Berlin, Germany, 2018. [Google Scholar]

- AlKahtani, R.N. The implications and applications of nanotechnology in dentistry: A review. Saudi Dent. J. 2018, 30, 107–116. [Google Scholar] [CrossRef]

- Saeedi, M.; Eslamifar, M.; Khezri, K.; Dizaj, S.M. Applications of nanotechnology in drug delivery to the central nervous system. Biomed. Pharmacother. 2019, 111, 666–675. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Keskinbora, K.H.; Jameel, M.A. Nanotechnology applications and approaches in medicine: A review. J. Nanosci. Nanotechnol. Res. 2018, 2, 1–5. [Google Scholar]

- Krishna, V.D.; Wu, K.; Su, D.; Cheeran, M.C.J.; Wang, J.P.; Perez, A. Nanotechnology: Review of concepts and potential application of sensing platforms in food safety. Food Microbiol. 2018, 75, 47–54. [Google Scholar] [CrossRef]

- Bayford, R.; Rademacher, T.; Roitt, I.; Wang, S.X. Emerging applications of nanotechnology for diagnosis and therapy of disease: A review. Physiol. Meas. 2017, 38, R183. [Google Scholar] [CrossRef]

- Kaul, S.; Gulati, N.; Verma, D.; Mukherjee, S.; Nagaich, U. Role of nanotechnology in cosmeceuticals: A review of recent advances. J. Pharm. 2018, 2018, 3420204. [Google Scholar] [CrossRef] [PubMed]

- Schulte, J.; Dutta, J. Nanotechnology in environmental protection and pollution. Sci. Technol. Adv. Mater. 2005, 6, 219–220. [Google Scholar] [CrossRef]

- Matteucci, F.; Giannantonio, R.; Calabi, F.; Agostiano, A.; Gigli, G.; Rossi, M. Deployment and exploitation of nanotechnology nanomaterials and nanomedicine. AIP Conf. Proc. 2018, 1990, 020001. [Google Scholar] [CrossRef]

- Jaishree, V.; Gupta, P.D. Nanotechnology: A revolution in cancer diagnosis. Ind. J. Clin. Biochem. 2012, 27, 214–220. [Google Scholar] [CrossRef] [PubMed]

- Contera, S. Nano Comes to Life: How Nanotechnology is Transforming Medicine and the Future of Biology, 1st ed.; Princeton University Press: Oxford, UK, 2019. [Google Scholar]

- Kumar, A.; Pandey, A.N.; Jain, S.K. Nasal-nanotechnology: Revolution for efficient therapeutics delivery. Drug Deliv. 2016, 23, 671–683. [Google Scholar] [CrossRef] [PubMed]

- Silva, G.A. Nanotechnology applications and approaches for neuroregeneration and drug delivery to the central nervous system. Ann. N. Y. Acad. Sci. 2010, 1199, 221–230. [Google Scholar] [CrossRef]

- Agrawal, S.; Rathore, P. Nanotechnology pros and cons to agriculture: A review. Int. J. Curr. Microbiol. Appl. Sci. 2014, 3, 43–55. [Google Scholar]

- International Organisation for Standarization ISO/TS 80004-2:2015; International Organisation for Standarization: Geneva, Switzerland, 2015.

- Burda, C.; Chen, X.; Narayanan, R.; El-Sayed, M.A. Chemistry and properties of nanocrystals of different shapes. Chem. Ver. 2005, 105, 1025–1102. [Google Scholar] [CrossRef]

- Rao, C.N.R.; Kulkarni, G.U.; Thomas, P.J.; Edwards, P.P. Size-dependent chemistry: Properties of nanocrystals. Chemistry 2002, 8, 28–35. [Google Scholar] [CrossRef]

- Uglov, V.V.; Doroshevich, I.L.; Kvasov, N.T.; Remnev, G.E.; Shymanski, V.I. On physical properties of nanoparticles: Size effect and scale of nanoobjects. Phys. Status Solidi C 2016, 10, 903–907. [Google Scholar] [CrossRef]

- Guisbiers, G.; Mejía-Rosales, S.; Deepak, F.L. Nanomaterial properties: Size and shape dependencies. J. Nanomater. 2012, 2012, 180976. [Google Scholar] [CrossRef]

- Prabha, S.; Arya, G.; Chandra, R.; Ahmed, B.; Nimesh, S. Effect of size on biological properties of nanoparticles employed in gene delivery. Artif. Cells Nanomed. Biotechnol. 2016, 44, 83–91. [Google Scholar] [CrossRef] [PubMed]

- Mohanraj, V.J.; Chen, Y. Nanoparticles—A review. Trop. J. Pharm. Res. 2006, 5, 561–573. [Google Scholar] [CrossRef]

- Roduner, E. Size matters: Why nanomaterials are different. Chem. Soc. Rev. 2006, 35, 583–592. [Google Scholar] [CrossRef] [PubMed]

- Lundqvist, M.; Stigler, J.; Elia, G.; Lynch, I.; Cedervall, T.; Dawson, K.A. Nanoparticle size and surface properties determine the protein corona with possible implications for biological impacts. Proc. Natl. Acad. Sci. USA 2008, 105, 14265–14270. [Google Scholar] [CrossRef]

- Rodríguez-López, J.L.; Montejano-Carrizales, J.M.; Palomares-Báez, J.P.; Barrón-Escobar, H.; Velázquez-Salazar, J.J.; Cabrera-Trujillo, J.M.; José-Yacamán, M. Size effect and shape stability of nanoparticles. Key Eng. Mater. 2010, 444, 47–68. [Google Scholar] [CrossRef]

- Heera, P.; Shanmugam, S. Nanoparticle characterization and application: An overview. Int. J. Curr. Microbiol. Appl. Sci. 2015, 4, 379–386. [Google Scholar]

- Albanese, A.; Tang, P.S.; Chan, W.C.W. The effect of nanoparticle size, shape, and surface chemistry on biological systems. Annu. Rev. Biomed. Eng. 2012, 14, 1–16. [Google Scholar] [CrossRef]

- Klabunde, K.J. (Ed.) Nanoscale Materials in Chemistry, 1st ed.; Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Yaghmaee, M.S.; Shokri, B.; Rahimipour, M.R. Size dependence surface activity of metallic nanoparticles. Plasma Process. Polym. 2009, 6, S876–S882. [Google Scholar] [CrossRef]

- Ramsden, J. Nanotechnology for military applications. Nanotechnol. Percept. 2012, 8, 99–131. [Google Scholar] [CrossRef]

- Shafique, M.; Luo, X. Nanotechnology in transportation vehicles: An overview of its applications, environmental, health and safety concerns. Materials 2019, 12, 2493. [Google Scholar] [CrossRef] [PubMed]

- Foltynowicz, Z.; Czajka, B.; Maranda, A.; Wachowski, L. Aspects of nanomaterials for civil and military applications Part 1. The origin, characterization and methods of obtaining. Mater. Wysokoenergetyczne/High. Energy Mater. 2017, 9, 5–17. [Google Scholar] [CrossRef]

- Foltynowicz, Z.; Czajka, B.; Maranda, A.; Wachowski, L. Aspects of nanomaterials for civil and military applications. Part 2. The use of and concerns arising from infiltration of the natural environment. Mater. Wysokoenergetyczne/High. Energy Mater. 2017, 9, 18–39. [Google Scholar] [CrossRef]

- Abd Elkodous, M.; El-Sayyad, G.S.; Abdelrahman, I.Y.; El-Bastawisy, H.S.; Mohamed, A.E.; Mosallam, F.M.; Nassere, H.A.; Gobaraf, M.; Barakaf, A.; Elsayedf, M.A.; et al. Therapeutic and diagnostic potential of nanomaterials for enhanced biomedical applications. Colloids Surf. B 2019, 180, 411–428. [Google Scholar] [CrossRef]

- Nasrollahzadeh, M.; Sajadi, S.M.; Mohaddeseh, S.; Issaabadi, Z. Applications of nanotechnology in daily life. Interface Sci. Technol. 2019, 28, 113–143. [Google Scholar] [CrossRef]

- Zare-Zardini, H.; Ferdowsian, F.; Soltaninejad, H.; Ghorani Azam, A.; Soleymani, S.; Zare-Shehneh, M.; Mofidi, M.; Rafati, R.; Ebrahimi, L. Application of nanotechnology in biomedicine: A major focus on cancer therapy. J. Nano Res. 2016, 35, 55–66. [Google Scholar] [CrossRef]

- Jędrzak, A.; Grześkowiak, B.F.; Coy, E.; Wojnarowicz, J.; Szutkowski, K.; Jurg, S.; Jesionowski, T.; Mrówczyński, R. Dendrimer based theranostic nanostructures for combined chemo- and photothermal therapy of liver cancer cells in vitro. Colloids Surf. B 2019, 173, 698–708. [Google Scholar] [CrossRef]

- Mrówczyński, R.; Jędrzak, A.; Szutkowski, K.; Grześkowiak, B.F.; Coy, E.; Markiewicz, R.; Jesionowski, T.; Jurga, S. Cyclodextrin-based magnetic nanoparticles for cancer therapy. Nanomaterials 2018, 8, 170. [Google Scholar] [CrossRef]

- AbouAitah, K.; Hassan, H.A.; Swiderska-Sroda, A.; Gohar, L.; Shaker, O.G.; Wojnarowicz, J.; Opalinska, A.; Smalc-Koziorowska, J.; Gierlotka, S.; Lojkowski, W. Targeted nano-drug delivery of colchicine against colon cancer cells by means of mesoporous silica nanoparticles. Cancers 2020, 12, 144. [Google Scholar] [CrossRef]

- Pietrzykowska, E.; Mukhovskyi, R.; Chodara, A.A.; Wojnarowicz, J.; Koltsov, I.; Chudoba, T.; Łojkowski, W. Composites of polylactide and nano-hydroxyapatite created by cryomilling and warm isostatic pressing for bone implants applications. Mater. Lett. 2019, 236, 625–628. [Google Scholar] [CrossRef]

- Rogowska-Tylman, J.; Locs, J.; Salma, I.; Woźniak, B.; Pilmane, M.; Zalite, V.; Wojnarowicz, J.; Kędzierska-Sar, A.; Chudoba, T.; Szlązak, K.; et al. In vivo and in vitro study of a novel nanohydroxyapatite sonocoated scaffolds for enhanced bone regeneration. Mater. Sci. Eng. C 2019, 99, 669–684. [Google Scholar] [CrossRef] [PubMed]

- Pokrowiecki, R.; Zareba, T.; Mielczarek, A.; Opalińska, A.; Wojnarowicz, J.; Majkowski, M.; Lojkowski, W.; Tyski, S. Evaluation of biocidal properties of silver nanoparticles against cariogenic bacteria. Med. Dosw. Mikrobiol. 2013, 65, 197–206. [Google Scholar] [PubMed]

- Werengowska-Ciećwierz, K.; Wiśniewski, M.; Terzyk, A.P.; Furmaniak, S. The chemistry of bioconjugation in nanoparticles-based drug delivery system. Adv. Cond. Matter Phys. 2015, 2015, 98175. [Google Scholar] [CrossRef]

- Heath, J.R. Nanotechnologies for biomedical science and translational medicine. Proc. Natl. Acad. Sci. USA 2015, 112, 14436–14443. [Google Scholar] [CrossRef]

- Jeevanandam, J.; Barhoum, A.; Chan, Y.S.; Dufresne, A.; Danquah, M.K. Review on nanoparticles and nanostructured materials: History, sources, toxicity and regulations. Beilstein J. Nanotechnol. 2018, 9, 1050–1074. [Google Scholar] [CrossRef]

- Khan, I.; Saeed, K.; Khan, I. Nanoparticles: Properties, applications and toxicities. Arab. J. Chem. 2019, 12, 908–931. [Google Scholar] [CrossRef]

- Ali, A.; Phull, A.R.; Zia, M. Elemental zinc to zinc nanoparticles: Is ZnO NPs crucial for life? Synthesis, toxicological and environmental concerns. Nanotechnol. Rev. 2018, 7, 413–441. [Google Scholar] [CrossRef]

- Willander, M. Zinc Oxide Nanostructures: Advances and Applications, 1st ed.; Pan Stanford: New York, NY, USA, 2014; ISBN 9789814411332. [Google Scholar]

- Fortunato, E.; Gonçalves, A.; Pimentel, A.; Barquinha, P.; Gonçalves, G.; Pereira, L.; Ferreira, I.; Martins, R. Zinc oxide, a multifunctional material: From material to device applications. Appl. Phys. A 2009, 96, 197–205. [Google Scholar] [CrossRef]

- Xu, S.; Wang, Z.L. One-dimensional ZnO nanostructures: Solution growth and functional properties. Nano Res. 2011, 4, 1013–1098. [Google Scholar] [CrossRef]

- Morkoç, H.; Özgür, Ü. Zinc Oxide: Fundamentals, Materials and Device Technology; Wiley-VCH: Weinheim, Germany, 2009; ISBN 978-3-527-40813-9. [Google Scholar]

- Borysiewicz, M.A. ZnO as a functional material, a review. Crystals 2019, 9, 505. [Google Scholar] [CrossRef]

- Kołodziejczak-Radzimska, A.; Jesionowski, T. Zinc oxide—From synthesis to application: A review. Materials 2014, 7, 2833–2881. [Google Scholar] [CrossRef] [PubMed]

- Roberts, W.L.; Campbell, T.J.; Rapp, G.R., Jr. Encyclopedia of Minerals, 2nd ed.; Van Nostrand Reinhold: New York, NY, USA, 1990; ISBN-10 0442276818 ISBN-13. [Google Scholar]

- Ashrafi, A.; Jagadish, C. Review of zincblende ZnO: Stability of metastable ZnO phases. J. Appl. Phys. 2007, 102, 071101. [Google Scholar] [CrossRef]

- Janotti, A.; Van de Walle, C.G. Fundamentals of zinc oxide as a semiconductor. Rep. Prog. Phys. 2009, 72, 126501. [Google Scholar] [CrossRef]

- Litton, C.W.; Reynolds, D.C.; Collins, T.C. Zinc Oxide Materials for Electronic and Optoelectronic Device Applications, 1st ed.; John Wiley & Sons: Chichester, UK, 2011. [Google Scholar]

- Liu, H.; Yang, D.; Yang, H.; Zhang, H.; Zhang, W.; Fang, Y.; Liu, Z.; Tian, L.; Lin, B.; Yan, J.; et al. Comparative study of respiratory tract immune toxicity induced by three sterilization nanoparticles: Silver, zinc oxide and titanium oxide. J. Hazard. Mater. 2013, 248, 478–486. [Google Scholar] [CrossRef]

- Mirhosseini, M.; Firouzabadi, F. Antibacterial activity of zinc oxide nanoparticle suspensions on food-borne pathogens. Int. J. Dairy Technol. 2012, 65, 1–5. [Google Scholar] [CrossRef]

- Frederickson, C.J.; Koh, J.Y.; Bush, A.I. The neurobiology of zinc in health and disease. Nat. Rev. Neurosci. 2005, 6, 449–462. [Google Scholar] [CrossRef]

- Craddock, P.T.; Gurjar, L.K.; Hegde, K.T.M. Zinc production in medieval india. World Archaeol. 1983, 15, 211–217. [Google Scholar] [CrossRef]

- Halioua, B.; Ziskind, B. Medicine in the Days of the Pharaohs, 1st ed.; Belknap Press of Harvard University Press: London, UK, 2005. [Google Scholar]

- Moezzi, A.; McDonagh, A.M.; Cortie, M.B. Zinc oxide particles: Synthesis, properties and applications. Chem. Eng. J. 2012, 185, 1–22. [Google Scholar] [CrossRef]

- Schmalz, G.; Arenholt-Bindslev, D. Biocompatibility of Dental Materials, 1st ed.; Springer: Berlin, German, 2009; pp. 160–165. [Google Scholar]

- Barja-Fidalgo, F.; Moutinho-Ribeiro, M.; Oliveira, M.A.A.; Heloísa de Oliveira, B.H. A systematic review of root canal filling materials for deciduous teeth: Is there an alternative for zinc oxide-eugenol? Int. Sch. Res. Not. 2011, 2011, 367318. [Google Scholar] [CrossRef]

- Trckova, M.; Lorencova, A.; Hazova, K.; Sramkova Zajacova, Z. Prophylaxis of post-weaning diarrhoea in piglets by zinc oxide and sodium humate. Vet. Med. (Praha.) 2015, 60, 351–360. [Google Scholar] [CrossRef]

- Long, L.; Chen, J.; Zhang, Y.; Liang, X.; Ni, H.; Zhang, B.; Yin, Y. Comparison of porous and nano zinc oxide for replacing high-dose dietary regular zinc oxide in weaning piglets. PLoS ONE 2017, 12, e0182550. [Google Scholar] [CrossRef]

- Fraga, C.G. Relevance, essentiality and toxicity of trace elements in human health. Mol. Asp. Med. 2005, 26, 235–244. [Google Scholar] [CrossRef] [PubMed]

- Mońka, I.; Wiechuła, D. Importance of zinc for the human body in the aspect of zinc supplementation. Ann. Acad. Med. Siles. 2017, 71, 314–325. [Google Scholar] [CrossRef]

- Hernandezbattez, A.; Gonzalez, R.; Viesca, J.; Fernandez, J.; Diazfernandez, J.; MacHado, A.; Chou, R.; Riba, J. CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oillubricants. Wear 2008, 265, 422–428. [Google Scholar] [CrossRef]

- Sturdy, L.F.; Wright, M.S.; Yee, A.; Casadio, F.; Faber, K.T.; Kenneth, R.; Shull, K.R. Effects of zinc oxide filler on the curing and mechanical response of alkyd coatings. Polymer 2020, 191, 122222. [Google Scholar] [CrossRef]

- Heideman, G.; Datta, R.N.; Noordermeer, J.W.M.; van Baarle, B. Activators in accelerated sulfur vulcanization. Rubber Chem. Technol. 2004, 77, 512–541. [Google Scholar] [CrossRef]

- Know the True Facts and Benefits of Zinc Oxide. Available online: www.uizincoxide.com/know-true-facts-benefits-zinc-oxide (accessed on 28 September 2019).

- Morkoç, H.; Özgür, Ü. General properties of ZnO. In Zinc Oxide: Fundamentals, Materials and Device Technology, 1st ed.; Morkoç, H., Özgür, U., Eds.; Wiley-VCH: Weinheim, Germany, 2009; pp. 1–76. [Google Scholar] [CrossRef]

- Umar, A.; Hahn, Y.-B. Metal Oxide Nanostructures and Their Applications, 1st ed.; American Scientific Publishers: Los Angeles, CA, USA, 2010; ISBN 1-58883-170-1. [Google Scholar]

- Pearton, S.J.; Norton, D.P.; Ip, K.; Heo, Y.W.; Steiner, T. Recent progress in processing and properties of ZnO. Superlattice Microst. 2003, 34, 3–32. [Google Scholar] [CrossRef]

- Pearton, S.J.; Norton, D.P.; Ip, K.; Heo, Y.W.; Steiner, T. Recent progress in processing and properties of ZnO. Prog. Mater. Sci. 2005, 50, 293–340. [Google Scholar] [CrossRef]

- Heo, Y.W.; Pearton, S.J.; Norton, D.P.; Ren, F. ZnO thin-film and nanowire based sensor apllications. In Semiconductor Device-Based Sensors for Gas, Chemical, and Biomedical Applications, 1st ed.; Ren, F., Pearton, S.J., Eds.; CRC Press: Boca Raton, FL, USA, 2017; pp. 149–214. [Google Scholar]

- Birnboim, A.; Gershon, D.; Calame, J.; Birman, A.; Carmel, Y.; Rodgers, J.; Levush, B.; Bykov, Y.V.; Eremeev, A.G.; Holoptsev, V.V.; et al. Comparative study of microwave sintering of zinc oxide at 2.45, 30, and 83 GHz. J. Am. Ceram. Soc. 1998, 81, 1493–1501. [Google Scholar] [CrossRef]

- Singh, S.; Thiyagarajan, P.; Mohan Kant, K.; Anita, D.; Thirupathiah, S.; Rama, N.; Tiwari, B.; Kottaisamy, M.; Ramachandra Rao, M.S. Structure, microstructure and physical properties of ZnO based materials in various forms: Bulk, thin film and nano. J. Phys. D Appl. Phys. 2007, 40, 6312. [Google Scholar] [CrossRef]

- David, R.L. (Ed.) CRC Handbook of Chemistry and Physics; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Khan, A. Synthesis, Characterization and Luminescence Properties of Zinc Oxide Nanostructures. Available online: https://search.proquest.com/docview/305294746 (accessed on 28 September 2019).

- Jagadish, C.; Pearton, S. Zinc Oxide Bulk, Thin Films and Nanostructures, Processing, Properties and Applications, 1st ed.; Elsevier: Oxford, UK, 2006; ISBN 978-0-08-044722-3. [Google Scholar]

- Ashcroft, N.W.; Mermin, N.D. Solid State Physics; Cengage Learning: Boston, MA, USA, 1976; ISBN 0030839939. [Google Scholar]

- Klingshirn, C.F.; Waag, A.; Hoffmann, A.; Geurts, J. Zinc Oxide, 1st ed.; Springer: Berlin, Germany, 2010; ISBN 978-3-642-10576-0. [Google Scholar]

- Theerthagiri, J.; Salla, S.; Senthil, R.A.; Nithyadharseni, P.; Madankumar, A.; Arunachalam, P.; Maiyalagan, T.; Kim, H.-S. A review on ZnO nanostructured materials: Energy, environmental and biological applications. Nanotechnology 2019, 30, 392001. [Google Scholar] [CrossRef] [PubMed]

- Ealias, A.E.; Saravanakumar, M.P. A review on the classification, characterisation, synthesis of nanoparticles and their application. IOP Conf. Ser. Mater. Sci. Eng. 2017, 263, 032019. [Google Scholar] [CrossRef]

- Nikam, A.V.; Prasad, B.L.V.; Kulkarni, A.A. Wet chemical synthesis of metal oxide nanoparticles: A review. CrystEngComm 2018, 20, 5091. [Google Scholar] [CrossRef]

- Mourdikoudis, S.; Pallares, R.M.; Thanh, N.T.K. Characterization techniques for nanoparticles: Comparison and complementarity upon studying nanoparticle properties. Nanoscale 2018, 10, 12871–12934. [Google Scholar] [CrossRef]

- Mansfield, E.; Kaiser, D.L.; Fujita, D.; Van de Voorde, M. Metrology and Standardization of Nanotechnology: Protocols and Industrial Innovations, 1st ed.; Wiley-VCH: Weinheim, Germany, 2017. [Google Scholar]

- Schilling, K.; Bradford, B.; Castelli, D.; Dufour, E.; Nash, J.F.; Wolfgang Pape, W.; Schulte, S.; Tooley, I.; van den Bosch, J.; Schellauf, F. Human safety review of “nano” titanium dioxide and zinc oxide. Photochem. Photobiol. Sci. 2010, 9, 495–509. [Google Scholar] [CrossRef]

- Future Markets, Inc. The Global Market for Zinc Oxide Nanoparticles; Future Markets: Rockville, MD, USA, 2015; p. 68. [Google Scholar]

- Newman, M.D.; Stotland, M.; Ellis, J.I. The safety of nanosized particles in titanium dioxide- and zinc oxide-based sunscreens. J. Am. Acad. Dermatol. 2009, 61, 685–692. [Google Scholar] [CrossRef]

- Schneider, S.L.; Lim, H.W. A review of inorganic UV filters zinc oxide and titanium dioxide. Photodermatol. Photoimmunol. Photomed. 2019, 35, 442–446. [Google Scholar] [CrossRef]

- Ajdary, M.; Moosavi, M.A.; Rahmati, M.; Falahati, M.; Mahboubi, M.; Mandegary, A.; Jangjoo, S.; Mohammadinejad, R.; Varma, R.S. Health concerns of various nanoparticles: A review of their in vitro and in vivo toxicity. Nanomaterials 2018, 8, 634. [Google Scholar] [CrossRef]

- Smijs, T.G.; Pavel, S. Titanium dioxide and zinc oxide nanoparticles in sunscreens: Focus on their safety and effectiveness. Nanotechnol. Sci. Appl. 2011, 4, 95–112. [Google Scholar] [CrossRef]

- Lewicka, Z.A.; Benedetto, A.F.; Benoit, D.N.; Yu, W.W.; Fortner, J.D.; Colvin, V.L. The structure, composition, and dimensions of TiO2 and ZnO nanomaterials in commercial sunscreens. Nanopart. Res. 2011, 13, 3607–3617. [Google Scholar] [CrossRef]

- Mohammed, Y.H.; Holmes, A.; Haridass, I.N.; Sanchez, W.Y.; Studier, H.; Grice, J.E.; Benson, H.A.E.; Roberts, M.S. Support for the safe use of zinc oxide nanoparticle sunscreens: Lack of skin penetration or cellular toxicity after repeated application in volunteers. J. Investig. Dermatol. 2019, 139, 308–315. [Google Scholar] [CrossRef] [PubMed]

- The Global Market for Metal. Oxide Nanoparticles to 2020; Future Markets: Rockville, MD, USA, 2013; p. 322.

- Listewnik, P.; Hirsch, M.; Struk, P.; Weber, M.; Bechelany, M.; Jędrzejewska-Szczerska, M. Preparation and characterization of microsphere ZnO ALD coating dedicated for the fiber-optic refractive index sensor. Nanomaterials 2019, 9, 306. [Google Scholar] [CrossRef] [PubMed]

- Barbillon, G. Fabrication and SERS performances of metal/Si and metal/ZnO nanosensors: A review. Coatings 2019, 9, 86. [Google Scholar] [CrossRef]

- Djurišić, A.B.; Ng, A.M.C.; Chen, X.Y. ZnO nanostructures for optoelectronics: Material properties and device applications. Prog. Quantum Electron. 2010, 34, 191–259. [Google Scholar] [CrossRef]

- Boscarino, S.; Filice, S.; Sciuto, A.; Libertino, S.; Scuderi, M.; Galati, C.; Scalese, S. Investigation of ZnO-decorated CNTs for UV Light Detection Applications. Nanomaterials 2019, 9, 1099. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Zhou, P.; Wang, N.; Ma, Y.; San, H. UV-assisted photochemical synthesis of reduced graphene oxide/ZnO nanowires composite for photoresponse enhancement in UV photodetectors. Nanomaterials 2018, 8, 26. [Google Scholar] [CrossRef]

- Look, D.C. Recent advances in ZnO materials and devices. Mater. Sci. Eng. B-Adv. 2001, 80, 383–387. [Google Scholar] [CrossRef]

- Bhati, V.S.; Hojamberdiev, M.; Kumar, M. Enhanced sensing performance of ZnO nanostructures-based gas sensors: A review. Energy Rep. 2019, 6, 46–62. [Google Scholar] [CrossRef]

- Praveenkumar, S.; Manikandan, S.; Lingaraja, D.; Sugapriya, T. A review of doped and undoped ZnO nanoparticles for fabrication of gas sensor. Sens. Lett. 2018, 16, 889–900. [Google Scholar] [CrossRef]

- Zhu, L.; Zeng, W. Room-temperature gas sensing of ZnO-based gas sensor: A review. Sens. Actuators A-Phys. 2017, 267, 242–261. [Google Scholar] [CrossRef]

- Weber, M.; Kim, J.-Y.; Lee, J.-H.; Kim, J.-H.; Iatsunskyi, I.; Coy, E.; Miele, P.; Bechelany, M.; Sub Kim, S. Highly efficient hydrogen sensors based on Pd nanoparticles supported on boron nitride coated ZnO nanowires. J. Mater. Chem. A 2019, 7, 8107–8116. [Google Scholar] [CrossRef]

- Park, S.; Lee, D.; Kwak, B.; Lee, H.-S.; Lee, S.; Yoo, B. Synthesis of self-bridged ZnO nanowires and their humidity sensing properties. Sens. Actuators B-Chem. 2018, 268, 293–298. [Google Scholar] [CrossRef]

- Kumar, R.; Al-Dossary, O.; Kumar, G.; Umar, A. Zinc oxide nanostructures for NO2 gas–sensor applications: A review. Nano-Micro Lett. 2015, 7, 97–120. [Google Scholar] [CrossRef] [PubMed]

- Hjiri, M.; El Mir, L.; Leonardi, S.G.; Donato, N.; Neri, G. CO and NO2 selective monitoring by ZnO-based sensors. Nanomaterials 2013, 3, 357–369. [Google Scholar] [CrossRef] [PubMed]

- Procek, M.; Stolarczyk, A.; Pustelny, T. Impact of temperature and UV irradiation on dynamics of NO2 sensors based on ZnO nanostructures. Nanomaterials 2017, 7, 312. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.-H.; Jiang, G.-J.; Chang, K.-W.; Deng, Z.-Y.; Li, Y.-N.; Chen, K.-L.; Jeng, C.-C. Analysis of the sensing properties of a highly stable and reproducible ozone gas sensor based on amorphous In-Ga-Zn-O thin film. Sensors 2018, 18, 163. [Google Scholar] [CrossRef]

- Shewale, P.S.; Yu, Y.S.; Kim, J.H.; Bobade, C.R.; Uplane, M.D. H2S gas sensitive Sn-doped ZnO thin films: Synthesis and characterization. J. Anal. Appl. Pyrol. 2015, 112, 348–356. [Google Scholar] [CrossRef]

- Gupta, S.K.; Joshi, A.; Kaur, M. Development of gas sensors using ZnO nanostructures. J. Chem. Sci. 2010, 122, 57–62. [Google Scholar] [CrossRef]

- Kanaparthi, S.; Singh, S.G. Chemiresistive sensor based on zinc oxide nanoflakes for CO2 detection. ACS Appl. Nano Mater. 2019, 2, 700–706. [Google Scholar] [CrossRef]

- Wanga, Y.; Meng, X.; Yao, M.; Sun, G.; Zhan, Z. Enhanced CH4 sensing properties of Pd modified ZnO nanosheets. Ceram. Int. 2019, 45, 13150–13157. [Google Scholar] [CrossRef]

- Shinde, V.R.; Gujar, T.P.; Lokhande, C.D.; Mane, R.S.; Han, S.-H. Development of morphological dependent chemically deposited nanocrystalline ZnO films for liquefied petroleum gas (LPG) sensor. Sens. Actuators B-Chem. 2007, 123, 882–887. [Google Scholar] [CrossRef]

- Dighavkar, C. Characterization of nanosized zinc oxide based ammonia gas sensor. Arch. Appl. Sci. Res. 2013, 5, 6–101. [Google Scholar]

- Du, H.; Li, X.; Yao, P.; Wang, J.; Sun, Y.; Dong, L. Zinc oxide coated tin oxide nanofibers for improved selective acetone sensing. Nanomaterials 2018, 8, 509. [Google Scholar] [CrossRef] [PubMed]

- Choi, H.; Kwon, S.H.; Kang, H.; Kim, J.H.; Choi, W. Zinc-oxide-deposited carbon nanowalls for acetone sensing. Thin Solid Films 2020, 700, 137887. [Google Scholar] [CrossRef]

- Zhou, Q.; Hong, C.; Yao, Y.; Ibrahim, A.M.; Xu, L.; Kumar, R.; Talballa, S.M.; Kim, S.H.; Umar, A. Fabrication and characterization of highly sensitive acetone chemical sensor based on ZnO nanoballs. Materials 2017, 10, 799. [Google Scholar] [CrossRef]

- Sholehah, A.; Faroz, D.F.; Huda, N.; Utari, L.; Septiani, N.L.W.; Yuliarto, B. Synthesis of ZnO flakes on flexible substrate and its application on ethylene sensing at room temperature. Chemosensors 2020, 8, 2. [Google Scholar] [CrossRef]

- Pronin, I.; Yakushova, N.; Averin, I.; Karmanov, A.; Moshnikov, V.; Dimitrov, D. Investigation of gas-sensitive properties of thin-film thermovoltaic sensor elements based on zinc oxide. Coatings 2019, 9, 693. [Google Scholar] [CrossRef]

- Lu, Y.; Hsieh, C.; Su, G. The Role of ALD-ZnO seed layers in the growth of ZnO nanorods for hydrogen sensing. Micromachines 2019, 10, 491. [Google Scholar] [CrossRef]

- Calestani, D. ZnO nanostructures for gas sensing applications: From tetrapods-based chemoresistive devices to carbon fiber integration. Proceedings 2019, 14, 42. [Google Scholar] [CrossRef]

- Ocola, L.E.; Wang, Y.; Divan, R.; Chen, J. Multifunctional UV and gas sensors based on vertically nanostructured zinc oxide: Volume versus surface effect. Sensors 2019, 19, 2061. [Google Scholar] [CrossRef]

- Rai, P.; Kwak, W.-K.; Yu, Y.-T. Solvothermal synthesis of ZnO nanostructures and their morphology-dependent gas-sensing properties. ACS Appl. Mater. Interfaces 2013, 5, 3026–3032. [Google Scholar] [CrossRef] [PubMed]

- Kwoka, M.; Lyson-Sypien, B.; Kulis, A.; Maslyk, M.; Borysiewicz, M.A.; Kaminska, E.; Szuber, J. Surface properties of nanostructured, porous ZnO thin films prepared by direct current reactive magnetron sputtering. Materials 2018, 11, 131. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.H.; Mei, Z.X.; Liang, H.L.; Du, X.L. Review of flexible and transparent thin-film transistors based on zinc oxide and related materials. Chin. Phys. B 2017, 26, 047307. [Google Scholar] [CrossRef]

- Rong, P.; Ren, S.; Yu, Q. Fabrications and applications of ZnO nanomaterials in flexible functional devices—A review. Crit. Rev. Anal. Chem. 2019, 49, 336–349. [Google Scholar] [CrossRef]

- Yoshida, T.; Komatsu, D.; Shimokawa, N.; Minoura, H. Mechanism of cathodic electrodeposition of zinc oxide thin films from aqueous zinc nitrate baths. Thin Solid Films 2004, 451, 166–169. [Google Scholar] [CrossRef]

- Wang, F.; Liu, R.; Pan, A.; Cao, l.; Cheng, K.; Xue, B.; Wang, G.; Meng, Q.; Li, J.; Li, Q.; et al. The optical properties of ZnO sheets electrodeposited on ITO glass. Mater. Lett. 2007, 61, 2000–2003. [Google Scholar] [CrossRef]

- Gao, X.D.; Li, X.M.; Yu, W.D. Rapid preparation, characterization, and photoluminescence of ZnO films by a novel chemical method. Mater. Res. Bull. 2005, 40, 1104–1111. [Google Scholar] [CrossRef]

- Du, X.Y.; Fu, Y.Q.; Tan, S.C.; Luo, J.K.; Flewitt, A.J.; Milne, W.I.; Lee, D.S.; Park, N.M.; Park, J.; Choi, Y.J.; et al. ZnO film thickness effect on surface acoustic wave modes and acoustic streaming. Appl. Phys. Lett. 2008, 93, 094105. [Google Scholar] [CrossRef]

- Shinde, V.R.; Gujar, T.P.; Lokhande, C.D. Studies on growth of ZnO thin films by a novel chemical method. Sol. Energy Mater. Sol. Cells 2007, 91, 1055–1061. [Google Scholar] [CrossRef]

- Daksh, D.; Agrawal, Y.K. Rare earth-doped zinc oxide nanostructures: A review. Rev. Nanosci. Nanotechnol. 2016, 5, 1–27. [Google Scholar] [CrossRef]

- Sirelkhatim, A.; Mahmud, S.; Seeni, S.; Kaus, A.S.N.; Ann, L.C.; Bakhori, S.K.M.; Hasan, H.; Mohamad, D. Review on zinc oxide nanoparticles: Antibacterial activity and toxicity mechanism. Nano-Micro Lett. 2015, 7, 219–242. [Google Scholar] [CrossRef] [PubMed]

- Sun, Q.; Li, J.; Le, T. Zinc oxide nanoparticle as a novel class of antifungal agents: Current advances and future perspectives. J. Agric. Food Chem. 2018, 66, 43. [Google Scholar] [CrossRef] [PubMed]

- Siddiqi, K.S.; ur Rahman, A.; Tajuddin; Husen, A. Properties of zinc oxide nanoparticles and their activity against microbes. Nanoscale Res. Lett. 2018, 13, 141. [Google Scholar] [CrossRef] [PubMed]

- Oprea, O.; Andronescu, E.; Ficai, D.; Ficai, A.; Oktar, F.N.; Yetmez, M. ZnO applications and challenges. Curr. Org. Chem. 2014, 18, 192–203. [Google Scholar] [CrossRef]

- Martínez-Carmona, M.; Gun’ko, Y.; Vallet-Regí, M. ZnO nanostructures for drug delivery and theranostic applications. Nanomaterials 2018, 8, 268. [Google Scholar] [CrossRef]

- Jiang, J.; Pi, J.; Cai, J. The advancing of zinc oxide nanoparticles for biomedical applications. Bioinorg. Chem. Appl. 2018, 2018, 1062562. [Google Scholar] [CrossRef]

- Zhang, Y.; Nayak, T.R.; Hong, H.; Cai, W. Biomedical applications of zinc oxide nanomaterials. Curr. Mol. Med. 2013, 13, 1633–1645. [Google Scholar] [CrossRef]

- Jin, S.-E.; Jin, H.-E. Synthesis, characterization, and three-dimensional structure generation of zinc oxide-based nanomedicine for biomedical applications. Pharmaceutics 2019, 11, 575. [Google Scholar] [CrossRef]

- Mohd Yusof, H.; Mohamad, R.; Zaidan, U.H.; Abdul Rahman, N.A. Microbial synthesis of zinc oxide nanoparticles and their potential application as an antimicrobial agent and a feed supplement in animal industry: A review. J. Anim. Sci. Biotechnol. 2019, 10, 57. [Google Scholar] [CrossRef]

- Król, A.; Pomastowski, P.; Rafińska, K.; Railean-Plugaru, V.; Buszewski, B. Zinc oxide nanoparticles: Synthesis, antiseptic activity and toxicity mechanism. Adv. Colloid Interface Sci. 2017, 249, 37–52. [Google Scholar] [CrossRef]

- Król, A.; Railean-Plugaru, V.; Pomastowski, P.; Buszewski, B. Phytochemical investigation of Medicago sativa L. extract and its potential as a safe source for the synthesis of ZnO nanoparticles: The proposed mechanism of formation and antimicrobial activity. Phytochem. Lett. 2019, 31, 170–180. [Google Scholar] [CrossRef]

- Das, S.; Chakraborty, T. A review on green synthesis of silver nanoparticle and zinc oxide nanoparticle from different plants extract and their antibacterial activity against multi-drug resistant bacteria. J. Innov. Pharm. Biol. Sci. 2018, 5, 63–73. [Google Scholar]

- Kalpana, V.N.; Rajeswari, V.D. A review on green synthesis, biomedical applications, and toxicity studies of ZnO NPs. Bioinorg Chem. Appl. 2018, 2018, 3569758. [Google Scholar] [CrossRef] [PubMed]

- Cierech, M.; Kolenda, A.; Grudniak, A.M.; Wojnarowicz, J.; Woźniak, B.; Gołaś, M.; Swoboda-Kopeć, E.; Łojkowski, W.; Mierzwińska-Nastalska, E. Significance of polymethylmethacrylate (PMMA) modification by zinc oxide nanoparticles for fungal biofilm formation. Int. J. Pharm. 2016, 510, 323–335. [Google Scholar] [CrossRef]

- Cierech, M.; Wojnarowicz, J.; Szmigiel, D.; Bączkowski, B.; Grudniak, A.; Wolska, K.; Łojkowski, W.; Mierzwińska-Nastalska, E. Preparation and characterization of ZnO-PMMA resin nanocomposites for denture bases. Acta Bioeng. Biomech. 2016, 18, 31–41. [Google Scholar] [CrossRef]

- Cierech, M.; Osica, I.; Kolenda, A.; Wojnarowicz, J.; Szmigiel, D.; Łojkowski, W.; Kurzydłowski, K.; Ariga, K.; Mierzwińska-Nastalska, E. Mechanical and physicochemical properties of newly formed ZnO-PMMA nanocomposites for denture bases. Nanomaterials 2018, 8, 305. [Google Scholar] [CrossRef]

- Cierech, M.; Wojnarowicz, J.; Kolenda, A.; Krawczyk-Balska, A.; Prochwicz, E.; Woźniak, B.; Łojkowski, W.; Mierzwińska-Nastalska, E. Zinc oxide nanoparticles cytotoxicity and release from newly formed PMMA–ZnO nanocomposites designed for denture bases. Nanomaterials 2019, 9, 1318. [Google Scholar] [CrossRef]

- Sruthi, S.; Ashtami, J.; Mohanan, P.V. Biomedical application and hidden toxicity of zinc oxide nanoparticles. Mater. Today Chem. 2018, 10, 175–186. [Google Scholar] [CrossRef]

- Carrouel, F.; Viennot, S.; Ottolenghi, L.; Gaillard, C.; Bourgeois, D. Nanoparticles as anti-microbial, anti-inflammatory, and remineralizing agents in oral care cosmetics: A review of the current situation. Nanomaterials 2020, 10, 140. [Google Scholar] [CrossRef]

- Pokrowiecki, R.; Wojnarowicz, J.; Zareba, T.; Koltsov, I.; Lojkowski, W.; Tyski, S.; Mielczatek, A.; Zawadzki, P. Nanoparticles and human saliva: A step towards drug delivery systems for dental and craniofacial biomaterials. Int. J. Nanomed. 2019, 14, 9235–9257. [Google Scholar] [CrossRef]

- Vigneshwaran, N.; Kumar, S.; Kathe, A.A.; Varadarajan, P.V.; Prasad, V. Function finishing of cotton fabrics using zinc oxide-soluble starch nanocomposites. Nanotechnology 2006, 17, 5087–5095. [Google Scholar] [CrossRef]

- Bisht, G.; Rayamajhi, S. ZnO nanoparticles: A promising anticancer agent. Nanobiomedicine 2016, 3. [Google Scholar] [CrossRef] [PubMed]

- Ancona, A.; Dumontel, B.; Garino, N.; Demarco, B.; Chatzitheodoridou, D.; Fazzini, W.; Engelke, H.; Cauda, V. Lipid-coated zinc oxide nanoparticles as innovative ROS-generators for photodynamic therapy in cancer cells. Nanomaterials 2018, 8, 143. [Google Scholar] [CrossRef] [PubMed]

- Elsayed, E.A.; Moussa, S.A.; El-Enshasy, H.A.; Wadaan, M.A. Anticancer potentials of zinc oxide nanoparticlesagainst liver and breast cancer cell lines. J. Sci. Ind. Res. 2020, 79, 56–59. [Google Scholar]

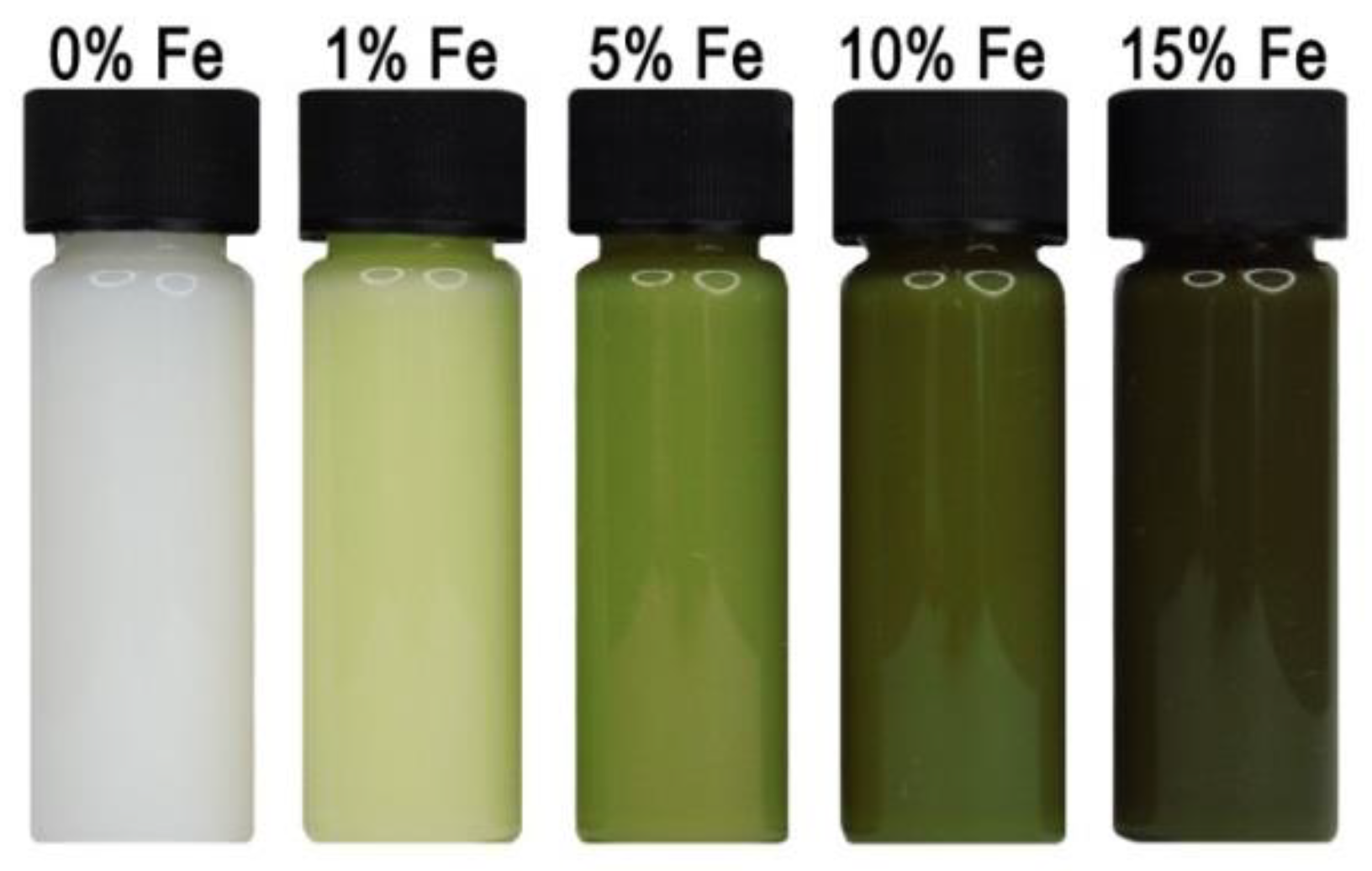

- Kielbik, P.; Kaszewski, J.; Dominiak, B.; Damentko, M.; Serafińska, I.; Rosowska, J.; Gralak, M.A.; Krajewski, M.; Witkowski, B.S.; Gajewski, Z.; et al. Preliminary studies on biodegradable zinc oxide nanoparticles doped with fe as a potential form of iron delivery to the living organism. Nanoscale Res. Lett. 2019, 14, 373. [Google Scholar] [CrossRef] [PubMed]

- Garino, N.; Limongi, T.; Dumontel, B.; Canta, M.; Racca, L.; Laurenti, M.; Castellino, M.; Casu, A.; Falqui, A.; Cauda, V. A microwave-assisted synthesis of zinc oxide nanocrystals finely tuned for biological applications. Nanomaterials 2019, 9, 212. [Google Scholar] [CrossRef]

- Napi, M.L.M.; Sultan, S.M.; Ismail, R.; How, K.W.; Ahmad, M.K. Electrochemical-based biosensors on different zinc oxide nanostructures: A review. Materials 2019, 12, 2985. [Google Scholar] [CrossRef]

- Cao, L.; Kiely, J.; Piano, M.; Luxton, R. A copper oxide/zinc oxide composite nano-surface for use in a biosensor. Materials 2019, 12, 1126. [Google Scholar] [CrossRef]

- Hahm, J. Fundamental properties of one-dimensional zinc oxide nanomaterials and implementations in various detection modes of enhanced biosensing. Annu. Rev. Phys. Chem. 2016, 67, 691–717. [Google Scholar] [CrossRef]

- Banchero, M.; Mohamed, S.S.Y.; Leone, F.; Lopez, F.; Ronchetti, S.; Manna, L.; Onida, B. Supercritical solvent impregnation of different drugs in mesoporous nanostructured ZnO. Pharmaceutics 2019, 11, 340. [Google Scholar] [CrossRef]

- Pokrowiecki, R.; Pałka, K.; Mielczarek, A. Nanomaterials in dentistry: A cornerstone or a black box? Nanomedicine 2018, 13, 639–667. [Google Scholar] [CrossRef] [PubMed]

- Leone, F.; Cataldo, R.; Mohamed, S.S.Y.; Manna, L.; Banchero, M.; Ronchetti, S.; Mandras, N.; Tullio, V.; Cavalli, R.; Onida, B. Nanostructured ZnO as multifunctional carrier for a green antibacterial drug delivery system—A feasibility study. Nanomaterials 2019, 9, 407. [Google Scholar] [CrossRef] [PubMed]

- Viter, R.; Savchuk, M.; Riekstina, U.; Poletaev, N.; Pleiko, K.; Ramanavicius, A. Photoluminescence ZnO nanorod biosensors for medical and food safety application. In Proceedings of the 2017 IEEE 7th International Conference Nanomaterials: Application & Properties (NAP), Zatoka, Ukraine, 10–15 September 2017. [Google Scholar]

- Viter, R.; Khranovskyy, V.; Starodub, N.; Ogorodniichuk, Y.; Gevelyuk, G.; Gertnere, Z.; Poletaev, N.; Yakimova, R.; Erts, D.; Smyntyna, V.; et al. Application of room temperature photoluminescence from ZnO nanorods for salmonella detection. IEEE Sens. J. 2014, 14, 2028–2034. [Google Scholar] [CrossRef]

- Sodzel, D.; Khranovskyy, V.; Beni, V.; Turner, A.P.F.; Viter, R.; Eriksson, M.O.; Holtz, P.O.; Janot, J.M.; Bechelany, M.; Balme, S.; et al. Continuous sensing of hydrogen peroxide and glucose viaquenching of the UV and visible luminescenceof ZnO nanoparticles. Microchim. Acta 2015, 182, 1819–1826. [Google Scholar] [CrossRef]

- Tereshchenkoa, A.; Bechelany, M.; Viter, R.; Khranovskyy, V.; Smyntyna, V.; Starodub, N.; Yakimovada, R. Optical biosensors based on ZnO nanostructures: Advantages and perspectives. A review. Sens. Actuators B-Chem. 2016, 229, 664–677. [Google Scholar] [CrossRef]

- Tripathy, N.; Kim, D. Metal oxide modified ZnO nanomaterials for biosensor applications. Nano Converg. 2018, 5, 27. [Google Scholar] [CrossRef]

- Nagi, J.S.; Skorenko, K.; Bernier, W.; Jones, W.E.; Doiron, A.L. Near infrared-activated dye-linked ZnO nanoparticles release reactive oxygen species for potential use in photodynamic therapy. Materials 2020, 13, 17. [Google Scholar] [CrossRef]

- Sharma, P.; Jang, N.-Y.; Lee, J.-W.; Park, B.C.; Kim, Y.K.; Cho, N.-H. Application of ZnO-based nanocomposites for vaccines and cancer immunotherapy. Pharmaceutics 2019, 11, 493. [Google Scholar] [CrossRef]

- Bogdan, J.; Pławińska-Czarnak, J.; Zarzyńska, J. Nanoparticles of titanium and zinc oxides as novel agents in tumor treatment: A review. Nanoscale Res. Lett. 2017, 12, 225. [Google Scholar] [CrossRef]

- Nguyen, H.; Tinet, E.; Chauveau, T.; Geinguenaud, F.; Lalatonne, Y.; Michel, A.; Aid-Launais, R.; Journé, C.; Lefèbvre, C.; Simon-Yarza, T.; et al. Bimodal fucoidan-coated zinc oxide/iron oxide-based nanoparticles for the imaging of atherothrombosis. Molecules 2019, 24, 962. [Google Scholar] [CrossRef]

- Malaikozhundan, B. Pharmaceutical applications of zinc oxide nanoparticles—A review. Acta Sci. Pharm. Sci. 2018, 2, 11–12. [Google Scholar]

- TelesSouza, J.M.; de Araújo, A.R.; de Carvalho, A.M.A.; das Graças Nascimento Amorim, A.; Daboit, T.C.; de Souza de Almeida Leite, J.R.; da Silva, D.A.; Eaton, P. Sustainably produced cashew gum-capped zinc oxide nanoparticles show antifungal activity against Candida parapsilosis. J. Clean. Prod. 2020, 247, 119085. [Google Scholar] [CrossRef]

- Lee, K.S.; Song, Y.; Kim, C.H.; Kim, Y.T.; Kang, T.; Lee, S.J.; Choi, B.G.; Lee, K.G. Development of zinc oxide-based sub-micro pillar arrays for on-site capture and DNA detection of foodborne pathogen. J. Colloid Interface Sci. 2020, 563, 54–61. [Google Scholar] [CrossRef] [PubMed]

- Păunica-Panea, G.; Ficai, A.; Marin, M.M.; Marin, S.; Albu, M.G.; Constantin, V.D.; Dinu-Pîrvu, C.; Vuluga, Z.; Corobea, M.C.; Ghica, M.V. New Collagen-dextran-zinc oxide composites for wound dressing. J. Nanomater. 2016, 2016, 5805034. [Google Scholar] [CrossRef]

- Rasmussen, J.W.; Martinez, E.; Louka, P.; Wingett, D.G. Zinc oxide nanoparticles for selective destruction of tumor cells and potential for drug delivery applications. Expert. Opin. Drug. Deliv. 2010, 7, 1063–1077. [Google Scholar] [CrossRef] [PubMed]

- Jin, S.-E.; Jin, J.E.; Hwang, W.; Hong, S.W. Photocatalytic antibacterial application of zinc oxide nanoparticles and self-assembled networks under dual UV irradiation for enhanced disinfection. Int. J. Nanomed. 2019, 14, 1737–1751. [Google Scholar] [CrossRef]

- Ghaffari, H.; Tavakoli, A.; Moradi, A.; Tabarraei, A.; Bokharaei-Salim, F.; Zahmatkeshan, M.; Farahmand, M.; Javanmard, D.; Kiani, S.J.; Esghaei, M.; et al. Inhibition of H1N1 influenza virus infection by zinc oxide nanoparticles: Another emerging application of nanomedicine. J. Biomed. Sci. 2019, 26, 70. [Google Scholar] [CrossRef]

- Pérez, R.; Sanchez-Salcedo, S.; Lozano, D.; Heras, C.; Esbrit, P.; Vallet-Regí, M.; Salinas, A.J. Osteogenic effect of ZnO-mesoporous glasses loaded with osteostatin. Nanomaterials 2018, 8, 592. [Google Scholar] [CrossRef]

- Beyene, Z.; Ghosha, R. Effect of zinc oxide addition on antimicrobial and antibiofilm activity of hydroxyapatite: A potential nanocomposite for biomedical applications. Mater. Today Commun. 2019, 21, 100612. [Google Scholar] [CrossRef]

- Grenho, L.; Salgado, C.L.; Fernandes, M.H.; Monteiro, F.J.; Ferraz, F.J. Antibacterial activity and biocompatibility of three-dimensional nanostructured porous granules of hydroxyapatite and zinc oxide nanoparticles—An in vitro and in vivo study. Nanotechnology 2015, 26, 315101. [Google Scholar] [CrossRef]

- Laurenti, M.; Cauda, V. ZnO nanostructures for tissue engineering applications. Nanomaterials 2017, 7, 374. [Google Scholar] [CrossRef] [PubMed]

- Subramaniam, V.D.; Prasad, S.V.; Banerjee, A.; Gopinath, M.; Murugesan, R.; Marotta, F.; Sun, X.-F.; Pathak, S. Health hazards of nanoparticles: Understanding the toxicity mechanism of nanosized ZnO in cosmetic products. Drug Chem. Toxicol. 2019, 42, 84–93. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.J.; Choy, J.H. Biokinetics of zinc oxide nanoparticles: Toxicokinetics, biological fates, and protein interaction. Int. J. Nanomed. 2014, 9, 261–269. [Google Scholar] [CrossRef]

- Hossain, F.; Perales-Perez, O.J.; Hwang, S.; Román, F. Antimicrobial nanomaterials as water disinfectant: Applications, limitations and future perspectives. Sci. Total Environ. 2014, 466, 1047–1059. [Google Scholar] [CrossRef] [PubMed]

- Lu-E Shi, L.E.; Li, Z.H.; Zheng, W.; Zhao, Y.F.; Jin, Y.F.; Tang, Z.X. Synthesis, antibacterial activity, antibacterial mechanism and food applications of ZnO nanoparticles: A review. Food Addit. Contam. Part. A 2014, 31, 173–186. [Google Scholar] [CrossRef] [PubMed]

- Długosz, O.; Szostak, K.; Staroń, A.; Pulit-Prociak, J.; Banach, M. Methods for reducing the toxicity of metal and metal oxide NPs as biomedicine. Materials 2020, 13, 279. [Google Scholar] [CrossRef]

- Singh, S. Zinc oxide nanoparticles impacts: Cytotoxicity, genotoxicity, developmental toxicity, and neurotoxicity. Toxicol. Mech. Method. 2019, 29, 300–311. [Google Scholar] [CrossRef]

- Schmidt-Mende, L.; MacManus-Driscoll, J.L. ZnO—Nanostructures, defects, and devices. Mater. Today 2007, 10, 40–48. [Google Scholar] [CrossRef]

- Willander, M.; Alnoor, H.; Savoyant, A.; Adam, R.E.; Nur, O. Optical and magneto-optical properties of zinc-oxide nanostructures grown by the low-temperature chemical route. In Oxide-Based Materials and Devices IX; SPIE: Bellingham, DC, USA, 2018; p. 105331D. [Google Scholar] [CrossRef]

- Kayani, Z.N.; Abbas, E.; Saddiqe, Z.; Riaz, S.; Naseem, S. Photocatalytic, antibacterial, optical and magnetic properties of Fe-doped ZnO nano-particles prepared by sol-gel. Mater. Sci. Semicond. Process. 2018, 88, 109–119. [Google Scholar] [CrossRef]

- Ohno, H. Making nonmagnetic semiconductors ferromagnetic. Science 1998, 281, 951–956. [Google Scholar] [CrossRef] [PubMed]

- Norris, D.J.; Efros, A.L.; Erwin, S.C. Doped nanocrystals. Science 2008, 319, 1776–1779. [Google Scholar] [CrossRef] [PubMed]

- Dietl, T.; Ohno, H.; Matsukura, M.; Cibert, J.; Ferrand, D. Zener model description of ferromagnetism in zinc-blende magnetic semiconductors. Science 2000, 287, 1019–2000. [Google Scholar] [CrossRef] [PubMed]

- Sato, K.; Katayama-Yosida, H. First principles materials design for semiconductor spintronics. Semicond. Sci. Technol. 2002, 17, 367–376. [Google Scholar] [CrossRef]

- Geetha, N.; Sivaranjani, S.; Ayeshamariam, A.; Suthan Kissinger, J.; Valan Arasu, M.; Jayachandran, M. ZnO doped oxide materials: Mini review. Fluid. Mech. Open Acc. 2016, 3, 141. [Google Scholar] [CrossRef]

- Pearton, S.J.; Norton, D.P.; Ivill, M.P.; Hebard, A.F.; Chen, W.M.; Buyanova, I.A.; Zavada, J.M. Transition metal doped ZnO for spintronics. J. Electron. Mater. 2007, 36, 462–471. [Google Scholar] [CrossRef]

- Zhang, Y.; Apostoluk, A.; Theron, C.; Cornier, T.; Canut, B.; Daniele, S.; Masenelli, B. Doping of ZnO inorganic-organic nanohybrids with metal elements. Sci. Rep. 2019, 9, 11959. [Google Scholar] [CrossRef]

- Bharat, T.C.; Shubham; Mondal, S.; Gupta, H.S.; Singh, P.K.; Das, A.K. Synthesis of doped zinc oxide nanoparticles: A review. Mater. Today Proc. 2019, 11, 767–775. [Google Scholar] [CrossRef]

- Shohany, B.G.; Zak, A.K. Doped ZnO nanostructures with selected elements - Structural, morphology and optical properties: A review. Ceram. Int. 2020, 46, 5507–5520. [Google Scholar] [CrossRef]

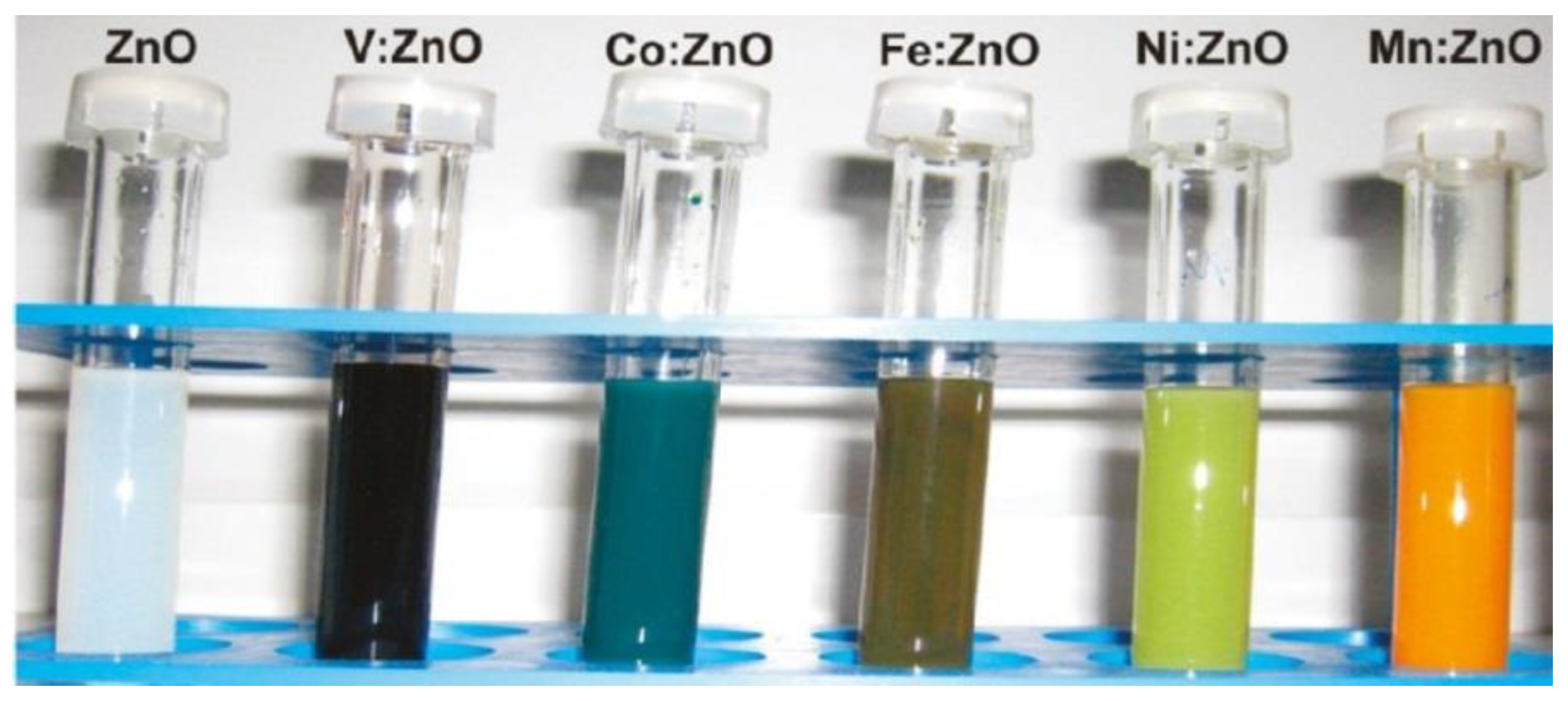

- Glaspell, G.; Dutta, P.; Manivannan, A. A room-temperature and microwave synthesis of M-doped ZnO (M = Co, Cr, Fe, Mn & Ni). J. Clust. Sci. 2005, 16, 523–536. [Google Scholar] [CrossRef]

- Rahman, F. Zinc oxide light-emitting diodes: A review. Opt. Eng. 2019, 58, 010901. [Google Scholar] [CrossRef]

- Ding, M.; Guo, Z.; Zhou, L.; Fang, X.; Zhang, L.; Zeng, L.; Xie, L.; Zhao, H. One-dimensional zinc oxide nanomaterials for application in high-performance advanced optoelectronic devices. Crystals 2018, 8, 223. [Google Scholar] [CrossRef]

- Jamadi, O.; Reveret, F.; Disseix, P.; Medard, F.; Leymarie, J.; Moreau, A.; Solnyshkov, D.; Deparis, C.; Leroux, M.; Cambril, E.; et al. Edge-emitting polariton laser and amplifier based on a ZnO waveguide. Light Sci. Appl. 2018, 7, 82. [Google Scholar] [CrossRef] [PubMed]

- Kennedy, J.; Fang, F.; Futter, J.; Leveneur, J.; Murmu, P.P.; Panin, G.N.; Kang, T.W.; Manikandan, E. Synthesis and enhanced field emission of zinc oxide incorporated carbon nanotubes. Diam. Relat. Mater. 2017, 71, 79–84. [Google Scholar] [CrossRef]

- Mao, D.S.; Wang, X.; Li, W.; Liu, X.H.; Li, Q.; Xu, J.F. Electron field emission from hydrogen-free amorphous carbon-coated ZnO tip array. J. Vac. Sci. Technol. B 2002, 20, 278–281. [Google Scholar] [CrossRef]

- Nunes Melo, A.H.; Andrade Macêdo, M. Permanent data storage in ZnO thin films by filamentary resistive switching. PLoS ONE 2016, 11, e0168515. [Google Scholar] [CrossRef]

- Laurenti, M.; Porro, S.; Pirri, C.F.; Ricciardi, C.; Chiolerio, A. Zinc oxide thin films for memristive devices: A review. Crit. Rev. Solid State Mater. Sci. 2017, 42, 153–172. [Google Scholar] [CrossRef]

- Jamalullail, N.; Salwani Mohamad, I.; Norizan, M.N.; Mahmed, N.; Taib, B.N. Recent improvements on TiO2 and ZnO nanostructure photoanode for dye sensitized solar cells: A brief review. Web Conf. 2017, 162, 01045. [Google Scholar] [CrossRef]

- Yu, L.; Li, Z. Synthesis of ZnxCd1-xSe@ZnO hollow spheres in different sizes for quantum dots sensitized solar cells application. Nanomaterials 2019, 9, 132. [Google Scholar] [CrossRef]

- Alhammadi, S.; Park, H.; Kim, W.K. Optimization of intrinsic ZnO thickness in Cu(In,Ga)Se2-based thin film solar cells. Materials 2019, 12, 1365. [Google Scholar] [CrossRef]

- Vittal, R.; Ho, K.-C. Zinc oxide based dye-sensitized solar cells: A review. Rene. Sust. Energ. Rev. 2017, 70, 920–935. [Google Scholar] [CrossRef]

- Anta, J.A.; Guillén, E.; Tena-Zaera, R. ZnO-based dye-sensitized solar cells. J. Phys. Chem. C 2012, 116, 11413–11425. [Google Scholar] [CrossRef]

- Giannouli, M.; Govatsi, Κ.; Syrrokostas, G.; Yannopoulos, S.N.; Leftheriotis, G. Factors affecting the power conversion efficiency in ZnO DSSCs: Nanowire vs. nanoparticles. Materials 2018, 11, 411. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Li, C. TiO2 coated ZnO nanorods by mist chemical vapor deposition for application as photoanodes for dye-sensitized solar cells. Nanomaterials 2019, 9, 1339. [Google Scholar] [CrossRef]

- Omelchenko, M.M.; Wojnarowicz, J.; Salamonczyk, M.; Lojkowski, W. Lyotropic liquid crystal based on zinc oxide nanoparticles obtained by microwave solvothermal synthesis. Mater. Chem. Phys. 2017, 192, 383–391. [Google Scholar] [CrossRef]

- Salzano de Luna, M.; Galizia, M.; Wojnarowicz, J.; Rosa, R.; Lojkowski, W.; Acierno, D.; Filippone, G.; Leonelli, C. Dispersing hydrophilic nanoparticles in hydrophobic polymers: HDPE/ZnO nanocomposites by a novel template-based approach. Express Polym. Lett. 2014, 8, 362–372. [Google Scholar] [CrossRef]

- Dong, Y.; Argaiz, M.; He, B.; Tomovska, R.; Sun, T.; Martín-Fabiani, I. Zinc oxide superstructures in colloidal polymer nanocomposite films: Enhanced antibacterial activity through slow drying. ACS Appl. Polym. Mater. 2020, 2, 626–635. [Google Scholar] [CrossRef]

- Prasert, A.; Sontikaew, S.; Sriprapai, D.; Chuangchote, S. Polypropylene/ZnO nanocomposites: Mechanical properties, photocatalytic dye degradation, and antibacterial property. Materials 2020, 13, 914. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, H.; Mahmood, Z.; Wang, Q.; Ma, H. Biocompatibility and biodegradability of polyacrylate/ZnO nanocomposite during the activated sludge treatment process. PLoS ONE 2018, 13, e0205990. [Google Scholar] [CrossRef]

- Abbas, M.; Buntinx, M.; Deferme, W.; Peeters, R. (Bio)polymer/ZnO nanocomposites for packaging applications: A review of gas barrier and mechanical properties. Nanomaterials 2019, 9, 1494. [Google Scholar] [CrossRef]

- Luzi, F.; Di Michele, A.; Torre, L.; Puglia, D. Active role of ZnO nanorods in thermomechanical and barrier performance of poly(vinyl alcohol-co-ethylene) formulations for flexible packaging. Polymers 2019, 11, 922. [Google Scholar] [CrossRef] [PubMed]

- Mizielińska, M.; Kowalska, U.; Jarosz, M.; Sumińska, P.; Landercy, N.; Duquesne, E. The effect of UV aging on antimicrobial and mechanical properties of PLA films with incorporated zinc oxide nanoparticles. Int. J. Environ. Res. Public Health 2018, 15, 794. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Rhim, J.-W. Carboxymethyl cellulose-based antioxidant and antimicrobial active packaging film incorporated with curcumin and zinc oxide. Int. J. Biol. Macromol. 2020, 148, 666–676. [Google Scholar] [CrossRef] [PubMed]

- Kim, I.; Viswanathan, K.; Kasi, G.; Thanakkasaranee, S.; Sadeghi, K.; Seo, J. ZnO nanostructures in active antibacterial food packaging: Preparation methods, antimicrobial mechanisms, safety issues, future prospects, and challenges. Food Rev. Int. 2020. [Google Scholar] [CrossRef]

- Mania, S.; Cieślik, M.; Konzorski, M.; Święcikowski, P.; Nelson, A.; Banach, A.; Tylingo, R. The Synergistic Microbiological Effects of Industrial Produced Packaging Polyethylene Films Incorporated with Zinc Nanoparticles. Polymers 2020, 12, 1198. [Google Scholar] [CrossRef]

- Kim, I.; Viswanathan, K.; Kasi, G.; Sadeghi, K.; Thanakkasaranee, S.; Seo, J. Poly(Lactic Acid)/ZnO bionanocomposite films with positively charged ZnO as potential antimicrobial food packaging materials. Polymers 2019, 11, 1427. [Google Scholar] [CrossRef]

- Bolognesi, C.; Castle, L.; Cravedi, J.; Engel, K.; Franz, R.; Fowler, P.; Grob, K.; Gürtler, R.; Husøy, T.; Kärenlampi, S.; et al. Safety assessment of the substance zinc oxide, nanoparticles, for use in food contact materials. EFSA J. 2016, 14, 4408. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, L.; Bao, Y.; Zhang, Y.; Wang, J.; Fu, M.; Wu, J.; Ye, D. The applications of morphology controlled ZnO in catalysis. Catalysts 2016, 6, 188. [Google Scholar] [CrossRef]

- Zhang, Z.-Y.; Xiong, H.-M. Photoluminescent ZnO nanoparticles and their biological applications. Materials 2015, 8, 3101–3127. [Google Scholar] [CrossRef]

- Lamba, N.; Gupta, R.; Modak, J.M.; Madras, G. ZnO catalyzed transesterification of Madhuca indica oil in supercritical methanol. Fuel 2019, 242, 323–333. [Google Scholar] [CrossRef]

- Ong, C.B.; Ng, L.Y.; Mohammad, A.W. A review of ZnO nanoparticles as solar photocatalysts: Synthesis, mechanisms and applications. Renew. Sustain. Energy Rev. 2018, 81, 536–551. [Google Scholar] [CrossRef]

- Chang, J.S.; Strunk, J.; Chong, M.N.; Poh, P.E.; Ocon, J.D. Multi-dimensional zinc oxide (ZnO) nanoarchitectures as efficient photocatalysts: What is the fundamental factor that determines photoactivity in ZnO? J. Hazard. Mater. 2020, 381, 120958. [Google Scholar] [CrossRef] [PubMed]

- Shen, Z.; Zhou, H.; Chen, H.; Xu, H.; Feng, C.; Zhou, X. Synthesis of nano-zinc oxide loaded on mesoporous silica by coordination effect and its photocatalytic degradation property of methyl orange. Nanomaterials 2018, 8, 317. [Google Scholar] [CrossRef] [PubMed]

- Hamid, S.B.A.; Teh, S.J.; Lai, C.W. Photocatalytic water oxidation on ZnO: A review. Catalysts 2017, 7, 93. [Google Scholar] [CrossRef]

- Tudose, I.V.; Suchea, M. ZnO for photocatalytic air purification applications. IOP Conf. Ser. Mater. Sci. Eng. 2016, 133, 012040. [Google Scholar] [CrossRef]

- Horikoshi, S.; Matsubara, A.; Takayama, S.; Sato, M.; Sakai, F.; Kajitani, M.; Abe, M.; Serpone, N. Characterization of microwave effects on metal-oxide materials: Zinc oxide and titanium dioxide. App. Catal. B 2010, 99, 490–495. [Google Scholar] [CrossRef]

- Kumari, V.; Mittal, A.; Jindal, J.; Yadav, S.; Kumar, N. S-, N- and C-doped ZnO as semiconductor photocatalysts: A review. Front. Mater. Sci. 2019, 13, 1–22. [Google Scholar] [CrossRef]

- Zhang, Y.; Ram, M.K.; Stefanakos, E.K.; Goswami, D.Y. Synthesis, characterization, and applications of ZnO nanowires. J. Nanomater. 2012, 2012, 624520. [Google Scholar] [CrossRef]

- Mirzaei, A.; Chen, Z.; Haghighat, F.; Yerushalmi, L. Removal of pharmaceuticals and endocrine disrupting compounds from water by zinc oxide-based photocatalytic degradation: A review. Sustain. Cities Soc. 2016, 27, 407–418. [Google Scholar] [CrossRef]

- Siwińska-Stefańska, K.; Kubiak, A.; Piasecki, A.; Goscianska, J.; Nowaczyk, G.; Jurga, S.; Jesionowski, T. TiO2-ZnO binary oxide systems: Comprehensive characterization and tests of photocatalytic activity. Materials 2018, 11, 841. [Google Scholar] [CrossRef]

- Kubiak, A.; Siwińska-Ciesielczyk, K.; Jesionowski, T. Titania-based hybrid materials with ZnO, ZrO2 and MoS2: A review. Materials 2018, 11, 2295. [Google Scholar] [CrossRef] [PubMed]

- Ko, H.-U.; Mun, S.; Min, S.-K.; Kim, G.-W.; Kim, J. Fabrication of cellulose ZnO hybrid nanocomposite and its strain sensing behavior. Materials 2014, 7, 7000–7009. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, A.A.; Tiwari, P.; Al-Assiri, M.S.; Al-Salami, A.E.; Umar, A.; Kumar, R.; Kim, S.H.; Ansari, Z.A.; Baskoutas, S. A highly-sensitive picric acid chemical sensor based on ZnO nanopeanuts. Materials 2017, 10, 795. [Google Scholar] [CrossRef] [PubMed]

- Chung, R.-J.; Wang, A.-N.; Liao, Q.-L.; Chuang, K.-Y. Non-enzymatic glucose sensor composed of carbon-coated nano-zinc oxide. Nanomaterials 2017, 7, 36. [Google Scholar] [CrossRef] [PubMed]

- Pavlenko, M.; Myndrul, V.; Gottardi, G.; Coy, E.; Jancelewicz, M.; Iatsunskyi, I. Porous silicon-zinc oxide nanocomposites prepared by atomic layer deposition for biophotonic applications. Materials 2020, 13, 1987. [Google Scholar] [CrossRef] [PubMed]

- Blachowicz, T.; Ehrmann, A. Recent developments in electrospun ZnO nanofibers: A short review. J. Eng. Fiber. Fabr. 2020, 15, 1–6. [Google Scholar] [CrossRef]

- Ferrone, E.; Araneo, R.; Notargiacomo, A.; Pea, M.; Rinaldi, A. ZnO nanostructures and electrospun ZnO–Polymeric hybrid nanomaterials in biomedical, health, and sustainability applications. Nanomaterials 2019, 9, 1449. [Google Scholar] [CrossRef]

- Justeau, C.; Slimani Tlemcani, T.; Poulin-Vittrant, G.; Nadaud, K.; Alquier, D. A comparative study on the effects of Au, ZnO and AZO seed layers on the performance of ZnO nanowire-based piezoelectric nanogenerators. Materials 2019, 12, 2511. [Google Scholar] [CrossRef]

- Rafique, S.; Kasi, A.K.; Kasi, J.K.; Aminullah; Bokhari, M.; Shakoor, Z. Fabrication of silver-doped zinc oxidenanorods piezoelectric nanogeneratoron cotton fabric to utilize and optimizethe charging system. Nanomater. Nanotechnol. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, J.; Wang, Z.L. Nanopiezotronics and nanogenerators. In Microsystems and Nanotechnology, 1st ed.; Zhou, Z., Wang, Z., Lin, L., Eds.; Springer: Berlin, Germany, 2012; pp. 115–147. [Google Scholar]

- Wang, S.; Gao, F.; Ma, R.; Du, A.; Tan, T.; Du, M.; Zhao, X.; Fan, Y.; Wen, M. ZnO nanoparticles anchored on a N-doped graphene-coated separator for high performance lithium/sulfur batteries. Metals 2018, 8, 755. [Google Scholar] [CrossRef]

- Fernando, J.F.S.; Zhang, C.; Firestein, K.L.; Nerkarb, J.Y.; Golberg, D.V. ZnO quantum dots anchored in multilayered and flexible amorphous carbon sheets for high performance and stable lithium ion batteries. J. Mater. Chem. A 2019, 7, 8460–8471. [Google Scholar] [CrossRef]

- Movsesyan, L.; Maijenburg, A.W.; Goethals, N.; Sigle, W.; Spende, A.; Yang, F.; Kaiser, B.; Jaegermann, W.; Park, S.-Y.; Mul, G.; et al. ZnO nanowire networks as photoanode model systems for photoelectrochemical applications. Nanomaterials 2018, 8, 693. [Google Scholar] [CrossRef] [PubMed]

- Cardoza-Contreras, M.N.; Vásquez-Gallegos, A.; Vidal-Limon, A.; Romo-Herrera, J.M.; Águila, S.; Contreras, O.E. Photocatalytic and antimicrobial properties of Ga doped and Ag doped ZnO nanorods for water treatment. Catalysts 2019, 9, 165. [Google Scholar] [CrossRef]

- Dimapilis, E.A.S.; Hsu, C.S.; Mendoza, R.M.O.; Lu, M.-C. Zinc oxide nanoparticles for water disinfection. Sustain. Environ. Res. 2018, 28, 47–56. [Google Scholar] [CrossRef]

- Butt, N.M.; Chaudhary, M.F.; Rubab, F. Antibacterial effect of zinc oxide nanoparticles against water borne bacteria. TechConnect Briefs 2015, 1, 344–348. [Google Scholar]

- Azzouz, I.; Habba, Y.; Capochichi-Gnambodoe, M.; Marty, F.; Vial, J.; Leprince-Wang, Y.; Bourouina, T. Zinc oxide nano-enabled microfluidic reactor for water purification and its applicability to volatile organic compounds. Microsyst. Nanoeng. 2018, 4, 17093. [Google Scholar] [CrossRef]

- Al-Issai, L.; Elshorbagy, W.; Maraqa, M.A.; Hamouda, M.; Soliman, A.M. Use of nanoparticles for the disinfection of desalinated water. Water 2019, 11, 559. [Google Scholar] [CrossRef]

- Lee, K.M.; Lai, C.W.; Ngai, K.S.; Juan, J.C. Recent developments of zinc oxide based photocatalyst in water treatment technology: A review. Water Res. 2016, 88, 428–448. [Google Scholar] [CrossRef]