Yb:MoO3/Ag/MoO3 Multilayer Transparent Top Cathode for Top-Emitting Green Quantum Dot Light-Emitting Diodes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of the Dielectric/Ultra-Thin Metal/Dielectric (DMD) Cathode

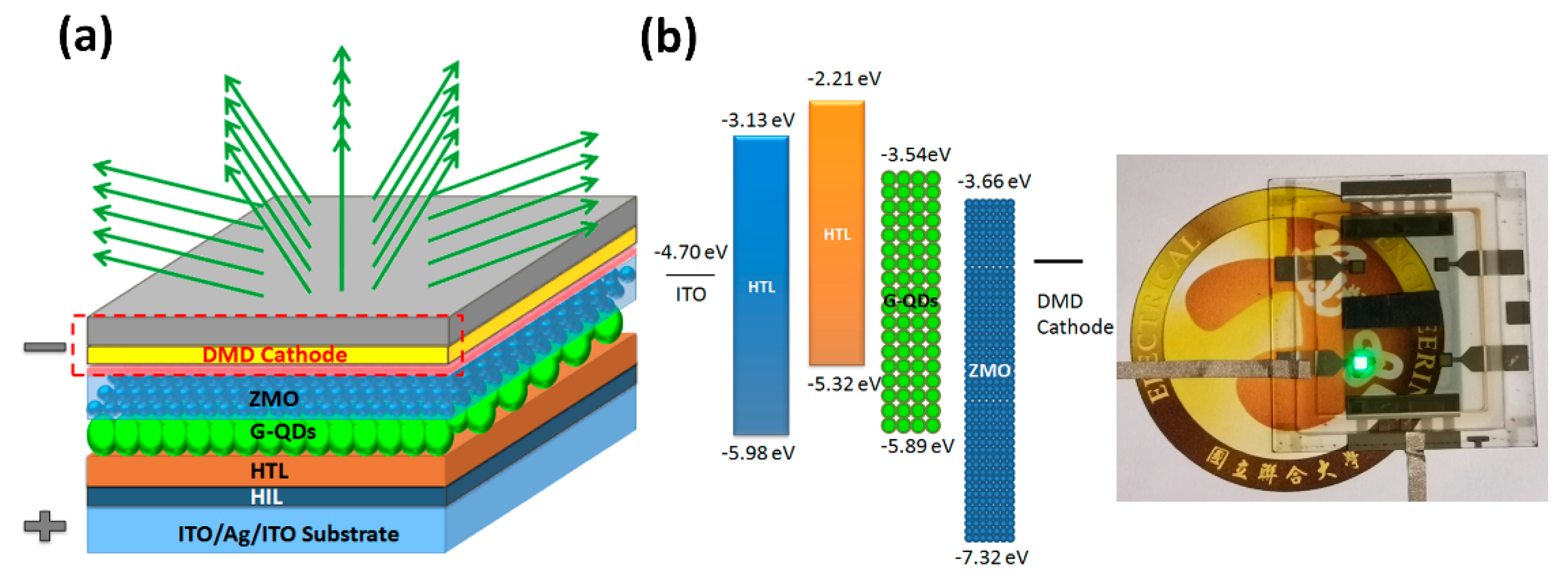

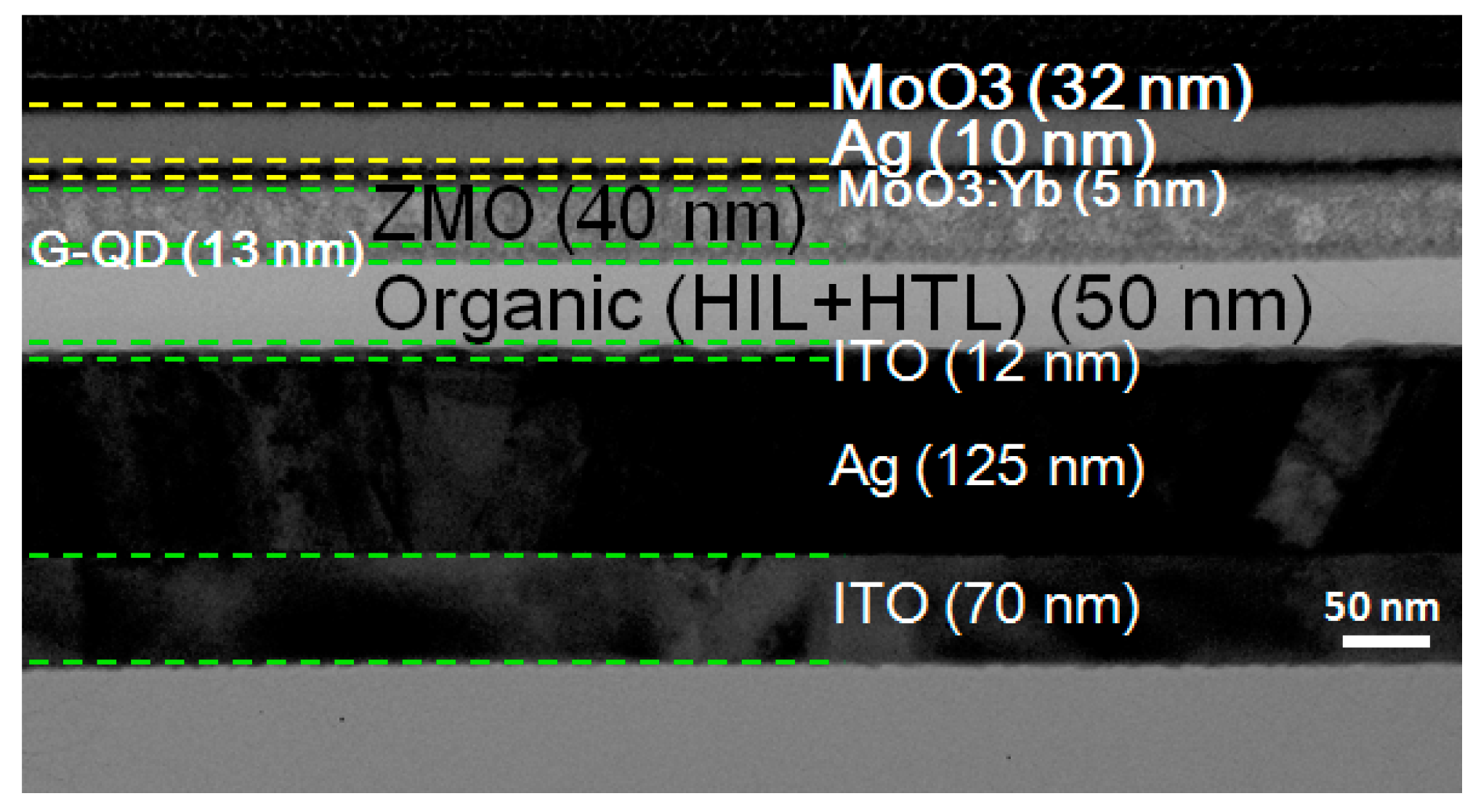

2.2. Fabrication of Top-Emitting Green QLEDs

2.3. Fabrication of Electron-Only Devices (EODs)

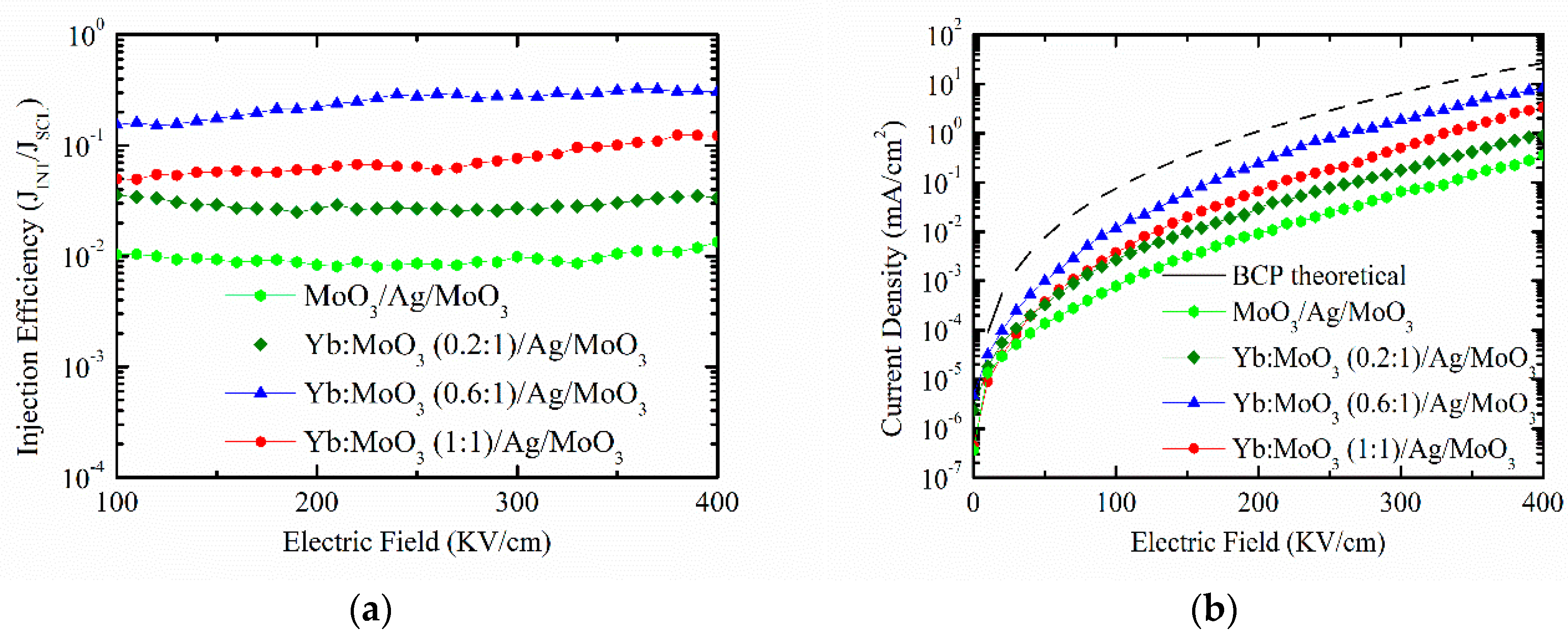

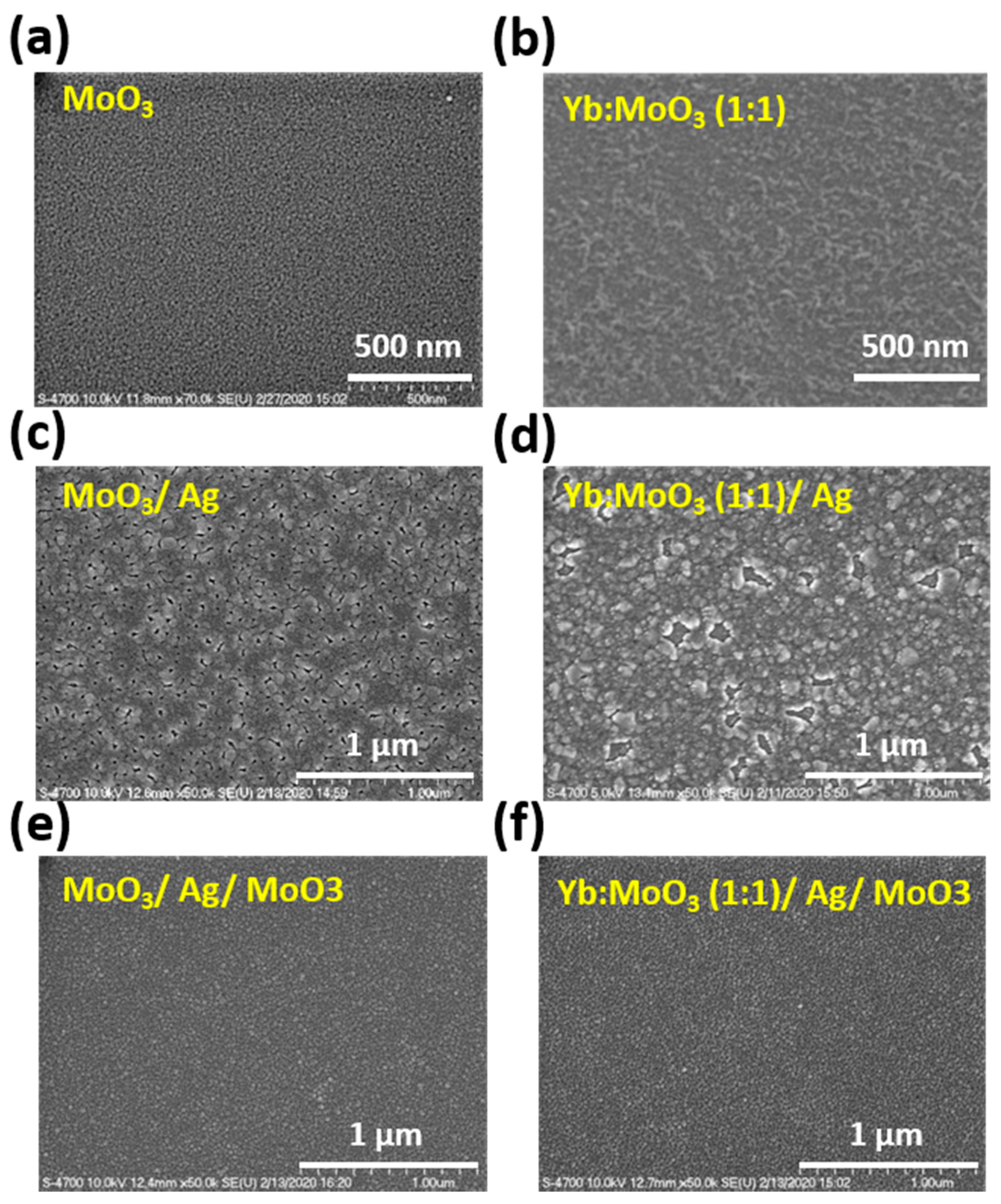

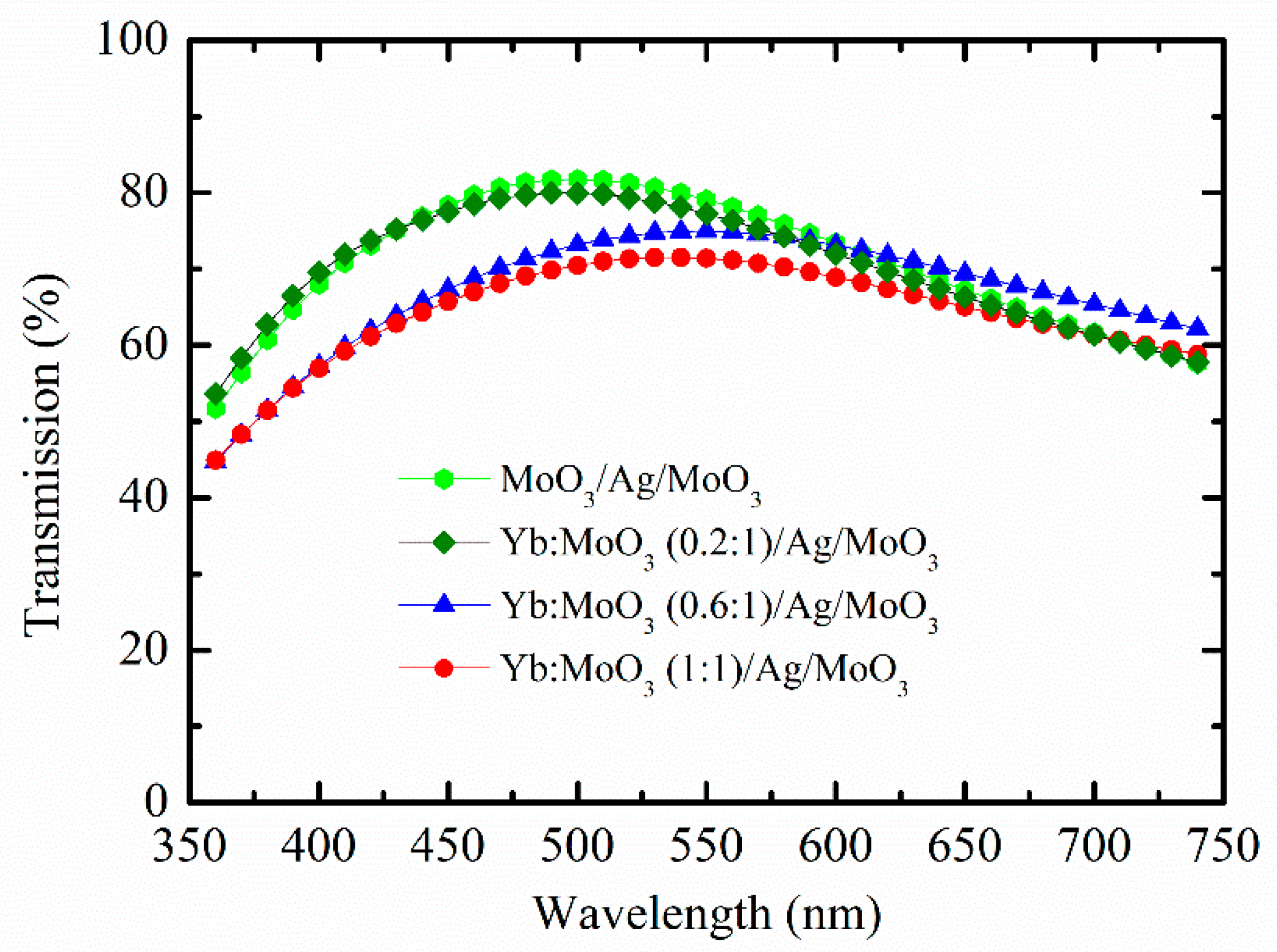

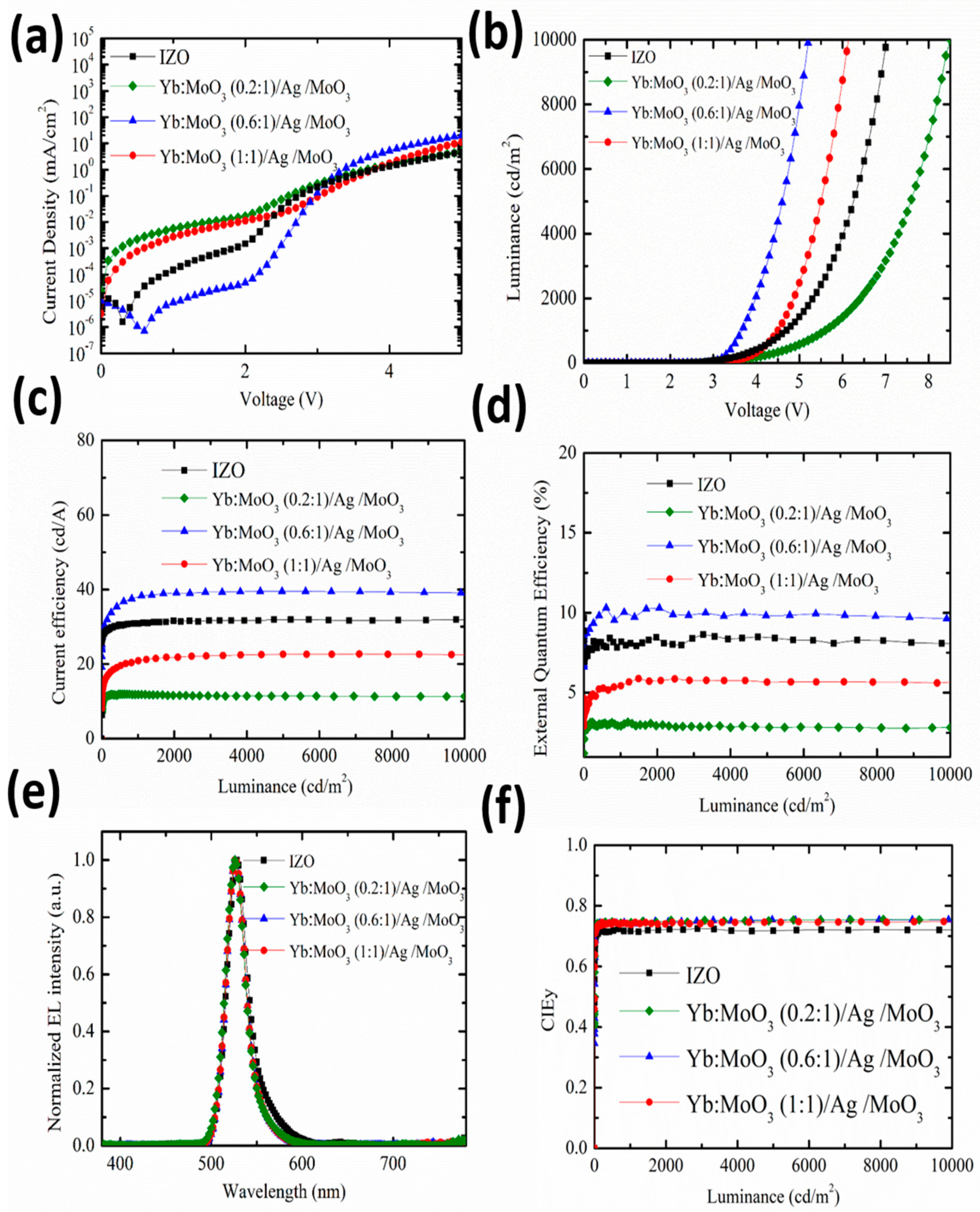

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Giovanella, U.; Pasini, M.; Lorenzon, M.; Galeotti, F.; Lucchi, C.; Meinardi, F.; Luzzati, S.; Dubertret, B.; Brovelli, S. Efficient Solution-Processed Nanoplatelet-Based Light-Emitting Diodes with High Operational Stability in Air. Nano Lett. 2018, 18, 3441–3448. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhao, Y.; Fan, F.; Levina, L.; Liu, M.; Quintero-Bermudez, R.; Gong, X.; Na Quan, L.; Fan, J.; Yang, Z.; et al. Bright colloidal quantum dot light-emitting diodes enabled by efficient chlorination. Nat. Photonics 2018, 12, 159–164. [Google Scholar] [CrossRef]

- Chen, S.; Cao, W.; Liu, T.; Tsang, S.-W.; Yang, Y.; Yan, X.; Qian, L. On the degradation mechanisms of quantum-dot light-emitting diodes. Nat. Commun. 2019, 10, 765. [Google Scholar] [CrossRef]

- Li, N.; Kristal, B.; Wang, Y.; Feng, J.; Lu, Z.; Yu, G.; Chen, Z.; Li, Y.; Li, X.; Xu, X. Enhanced Efficiency of InP-Based Red Quantum Dot Light-Emitting Diodes. ACS Appl. Mater. Interfaces 2019, 11, 34067–34075. [Google Scholar] [CrossRef] [PubMed]

- Ippen, C.; Guo, W.; Zehnder, D.; Kim, D.; Manders, J.; Barrera, D.; Newmeyer, B.; Hamilton, D.; Wang, C.; Hotz, C.; et al. High efficiency heavy metal free QD-LEDs for next generation displays. J. Soc. Inf. Disp. 2019, 27, 338–346. [Google Scholar] [CrossRef]

- Su, Q.; Sun, Y.; Zhang, H.; Chen, S. Origin of Positive Aging in Quantum-Dot Light-Emitting Diodes. Adv. Sci. 2018, 5, 1800549. [Google Scholar] [CrossRef] [Green Version]

- Colvin, V.L.; Schlamp, M.C.; Alivisatos, A.P. Light-emitting diodes made from cadmium selenide nanocrystals and a semiconducting polymer. Nature 1994, 370, 354–357. [Google Scholar] [CrossRef]

- Wang, F.; Sun, W.; Liu, P.; Wang, Z.; Zhang, J.; Wei, J.; Li, Y.; Hayat, T.; Alsaedi, A.; Tan, Z. Achieving Balanced Charge Injection of Blue Quantum Dot Light-Emitting Diodes through Transport Layer Doping Strategies. J. Phys. Chem. Lett. 2019, 10, 960–965. [Google Scholar] [CrossRef]

- Liu, S.; Liu, W.; Ji, W.; Yu, J.; Zhang, W.; Zhang, L.; Xie, W. Top-emitting quantum dots light-emitting devices employing microcontact printing with electricfield-independent emission. Sci. Rep. 2016, 6, 22530. [Google Scholar] [CrossRef] [Green Version]

- Bai, J.; Chang, C.; Wei, J.; Dong, C.; Peng, H.; Jin, X.; Zhang, Q.; Li, F.; Li, Q. High efficient light-emitting diodes with improved the balance of electron and hole transfer via optimizing quantum dot structure. Opt. Mater. Express 2019, 9, 3089–3097. [Google Scholar] [CrossRef]

- Pan, J.; Wei, C.; Wang, L.; Zhuang, J.; Huang, Q.; Su, W.; Cui, Z.; Nathan, A.; Lei, W.; Chen, J. Boosting the efficiency of inverted quantum dot light-emitting diodes by balancing charge densities and suppressing exciton quenching through band alignment. Nanoscale 2018, 10, 592–602. [Google Scholar] [CrossRef] [PubMed]

- Vivo, P.; Jukola, J.; Ojala, M.; Chukharev, V.; Lemmetyinen, H. Influence of Alq3/Au cathode on stability and efficiency of a layered organic solar cell in air. Solar Energy Mater. Sol. Cells 2008, 92, 1416–1420. [Google Scholar] [CrossRef]

- Lee, I.; Kim, S.; Park, J.Y.; Kim, S.; Cho, H.W.; Ham, J.; Gim, S.; Kim, K.; Hong, K.; Lee, J.-L. Symmetrical Emission Transparent Organic Light-Emitting Diodes with Ultrathin Ag Electrodes. IEEE Photonics J. 2018, 10, 1–10. [Google Scholar] [CrossRef]

- Han, S.; Feng, X.; Lu, Z.H.; Johnson, D.; Wood, R. Transparent-cathode for top-emission organic light-emitting diodes. Appl. Phys. Lett. 2003, 82, 2715–2717. [Google Scholar] [CrossRef]

- Burrows, P.E.; Gu, G.; Forrest, S.R.; Vicenzi, E.P.; Zhou, T.X. Semitransparent cathodes for organic light emitting devices. J. Appl. Phys. 2000, 87, 3080–3085. [Google Scholar] [CrossRef]

- Chen, B.J.; Sun, C.Q.; Tan, S.C. Transparent organic light-emitting devices with LiF/Mg:Ag cathode. Opt. Express 2005, 13, 937–941. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, X.; Yan, H.; Jiao, Z.; Yang, J.; Yuan, G. P-191: Dielectric-Metal-Dielectric Structure and Its Application as Top Cathode in Highly Efficient Top-Emitting WOLEDs. SID Symp. Dig. Tech. Pap. 2019, 50, 1946–1949. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Kuo, Y.-P.; Chen, P.-Y.; Lu, H.-H.; Lin, M.-Y. Influence of Annealing Temperature on Weak-Cavity Top-Emission Red Quantum Dot Light Emitting Diode. Nanomaterials 2019, 9, 1639. [Google Scholar] [CrossRef] [Green Version]

- Yu, S.; Li, L.; Lyu, X.; Zhang, W. Preparation and investigation of nano-thick FTO/Ag/FTO multilayer transparent electrodes with high figure of merit. Sci. Rep. 2016, 6, 20399. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Peng, H.; Chen, S. Highly transparent quantum-dot light-emitting diodes with sputtered indium-tin-oxide electrodes. J. Mater. Chem. C 2016, 4, 1838–1841. [Google Scholar] [CrossRef]

- Bi, Y.; Feng, J.; Liu, Y.-S.; Li, Y.-F.; Chen, Y.; Zhang, X.-L.; Han, X.-C.; Sun, H.-B. Surface Plasmon-Polariton Mediated Red Emission from Organic Light-Emitting Devices Based on Metallic Electrodes Integrated with Dual-Periodic Corrugation. Sci. Rep. 2014, 4, 7108. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oh, J.-H.; Park, J.-W. Highly Transparent and Colorless Organic Light-Emitting Diodes. Phys. Status Solidi (RRL) Rapid Res. Lett. 2020. [Google Scholar] [CrossRef]

- Kim, H.-K.; Lee, K.-S.; Kwon, J.H. Transparent indium zinc oxide top cathode prepared by plasma damage-free sputtering for top-emitting organic light-emitting diodes. Appl. Phys. Lett. 2006, 88, 12103. [Google Scholar] [CrossRef]

- Meyer, J.; Winkler, T.; Hamwi, S.; Schmale, S.; Johannes, H.-H.; Weimann, T.; Hinze, P.; Kowalsky, W.; Riedl, T. Transparent Inverted Organic Light-Emitting Diodes with a Tungsten Oxide Buffer Layer. Adv. Mater. 2008, 20, 3839–3843. [Google Scholar] [CrossRef]

- Lee, J.-H.; Lee, S.; Kim, J.-B.; Jang, J.; Kim, J.-J. A high performance transparent inverted organic light emitting diode with 1,4,5,8,9,11-hexaazatriphenylenehexacarbonitrile as an organic buffer layer. J. Mater. Chem. 2012, 22, 15262–15266. [Google Scholar] [CrossRef]

- Park, C.H.; Lee, H.J.; Hwang, J.H.; Kim, K.N.; Shim, Y.S.; Jung, S.-G.; Park, C.H.; Park, Y.W.; Ju, B.-K. High-Performance Hybrid Buffer Layer Using 1,4,5,8,9,11-Hexaazatriphenylenehexacarbonitrile/Molybdenum Oxide in Inverted Top-Emitting Organic Light-Emitting Diodes. ACS Appl. Mater. Interfaces 2015, 7, 6047–6053. [Google Scholar] [CrossRef]

- Ryu, S.Y.; Choi, S.H.; Kim, J.T.; Kim, C.S.; Baik, H.K.; Jeong, H.S. Highly efficient transparent organic light-emitting diodes by ion beam assisted deposition-prepared indium tin oxide cathode. Appl. Phys. Lett. 2007, 90, 033513. [Google Scholar] [CrossRef]

- Song, M.-G.; Kim, K.-S.; Yang, H.I.; Kim, S.K.; Kim, J.-H.; Han, C.-W.; Choi, H.-C.; Pode, R.; Kwon, J.H. Highly reliable and transparent Al doped Ag cathode fabricated using thermal evaporation for transparent OLED applications. Org. Electron. 2020, 76, 105418. [Google Scholar] [CrossRef]

- Kim, H.-J.; Seo, K.-W.; Noh, Y.-J.; Na, S.-I.; Sohn, A.; Kim, D.-W.; Kim, H.-K. Work function and interface control of amorphous IZO electrodes by MoO3 layer grading for organic solar cells. Sol. Energy Mater. Sol. Cells 2015, 141, 194–202. [Google Scholar] [CrossRef]

- Banzai, K.; Naka, S.; Okada, H. MoO3/Ag/MoO3 anode for organic light-emitting diodes and its carrier injection property. Jpn. J. Appl. Phys. 2015, 54, 054101. [Google Scholar] [CrossRef]

- Yeh, T.H.; Lee, C.C.; Shih, C.J.; Kumar, G.; Biring, S.; Liu, S.W. Vacuum-deposited MoO3/Ag/WO3 multilayered electrode for highly efficient transparent and inverted organic light-emitting diodes. Org. Electron. 2018, 59, 266–271. [Google Scholar] [CrossRef]

- Han, Y.C.; Lim, M.S.; Park, J.H.; Choi, K.C. ITO-free flexible organic light-emitting diode using ZnS/Ag/MoO3 anode incorporating a quasi-perfect Ag thin film. Org. Electron. 2013, 14, 3437–3443. [Google Scholar] [CrossRef]

- Yasuda, T.; Yamaguchi, Y.; Zou, D.; Tsutsui, T. Carrier Mobilities in Organic Electron Transport Materials Determined from Space Charge Limited Current. Jpn. J. Appl. Phys. 2002, 41, 5626. [Google Scholar] [CrossRef]

- Bozano, L.; Carter, S.; Scott, J.C.; Malliaras, G.G.; Brock, P.J. Temperature- and field-dependent electron and hole mobilities in polymer light-emitting diodes. Appl. Phys. Lett. 1999, 74, 1132–1134. [Google Scholar] [CrossRef] [Green Version]

| Sheet Resistance (Ω/sq) (5 Point Average) | T% (400–700 nm) | T% (Peak) | |

|---|---|---|---|

| MoO3/Ag/MoO3 | 8.3 | 74.1 | 81.7 |

| Yb:MoO3 (0.2:1)/Ag/MoO3 | 8.4 | 73.1 | 80.0 |

| Yb:MoO3 (0.6:1)/Ag/MoO3 | 12.2 | 70.5 | 75.0 |

| Yb:MoO3 (1:1)/Ag/MoO3 | 13.1 | 66.7 | 71.5 |

| Top-Emitting G-QLED | x | y | l | FWHM | VT | cd/A | EQE |

|---|---|---|---|---|---|---|---|

| -- | -- | nm | nm | V [1 cd/m2] | 1000 nits | ||

| Yb:MoO3 (0.2:1)/Ag/MoO3 | 0.233 | 0.718 | 528 | 25 | 2.2 | 11.8 | 2.9 |

| Yb:MoO3 (0.6:1)/Ag/MoO3 | 0.199 | 0.742 | 528 | 25 | 2.2 | 38.0 | 9.8 |

| Yb:MoO3 (1:1)/Ag/MoO3 | 0.197 | 0.744 | 528 | 25 | 2.3 | 28.0 | 7.4 |

| IZO | 0.196 | 0.739 | 529 | 26 | 2.2 | 30.9 | 8.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.-Y.; Chen, Y.-M.; Deng, Y.-Z.; Kuo, Y.-P.; Chen, P.-Y.; Tsai, L.; Lin, M.-Y. Yb:MoO3/Ag/MoO3 Multilayer Transparent Top Cathode for Top-Emitting Green Quantum Dot Light-Emitting Diodes. Nanomaterials 2020, 10, 663. https://doi.org/10.3390/nano10040663

Lee C-Y, Chen Y-M, Deng Y-Z, Kuo Y-P, Chen P-Y, Tsai L, Lin M-Y. Yb:MoO3/Ag/MoO3 Multilayer Transparent Top Cathode for Top-Emitting Green Quantum Dot Light-Emitting Diodes. Nanomaterials. 2020; 10(4):663. https://doi.org/10.3390/nano10040663

Chicago/Turabian StyleLee, Chun-Yu, Yi-Min Chen, Yao-Zong Deng, Ya-Pei Kuo, Peng-Yu Chen, Leo Tsai, and Ming-Yi Lin. 2020. "Yb:MoO3/Ag/MoO3 Multilayer Transparent Top Cathode for Top-Emitting Green Quantum Dot Light-Emitting Diodes" Nanomaterials 10, no. 4: 663. https://doi.org/10.3390/nano10040663

APA StyleLee, C.-Y., Chen, Y.-M., Deng, Y.-Z., Kuo, Y.-P., Chen, P.-Y., Tsai, L., & Lin, M.-Y. (2020). Yb:MoO3/Ag/MoO3 Multilayer Transparent Top Cathode for Top-Emitting Green Quantum Dot Light-Emitting Diodes. Nanomaterials, 10(4), 663. https://doi.org/10.3390/nano10040663