Ablation in Externally Applied Electric and Magnetic Fields

Abstract

1. Introduction

2. Experimental: Samples, Fabrication, Characterization

3. Results

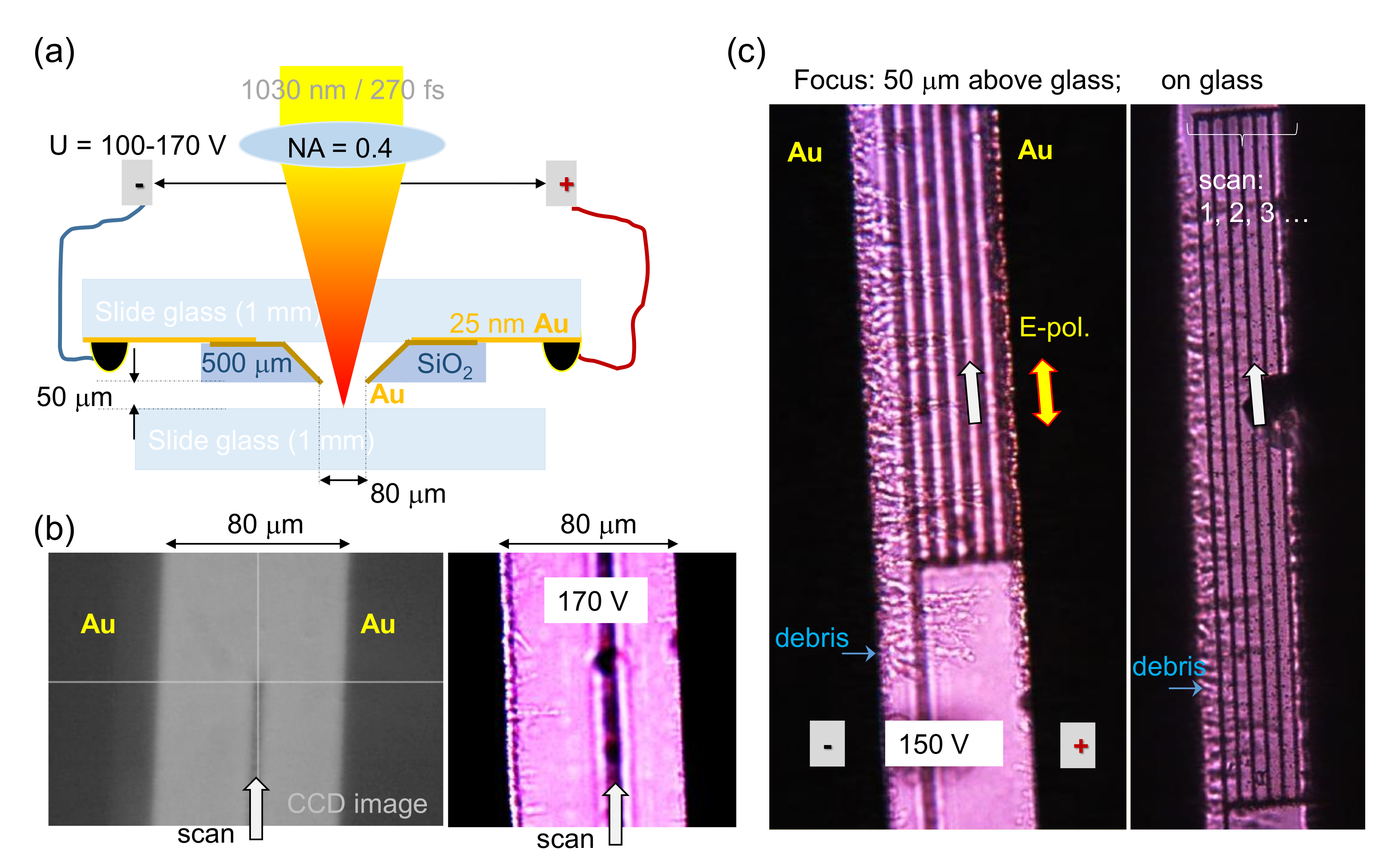

3.1. Ablation of Glass in External E-Field

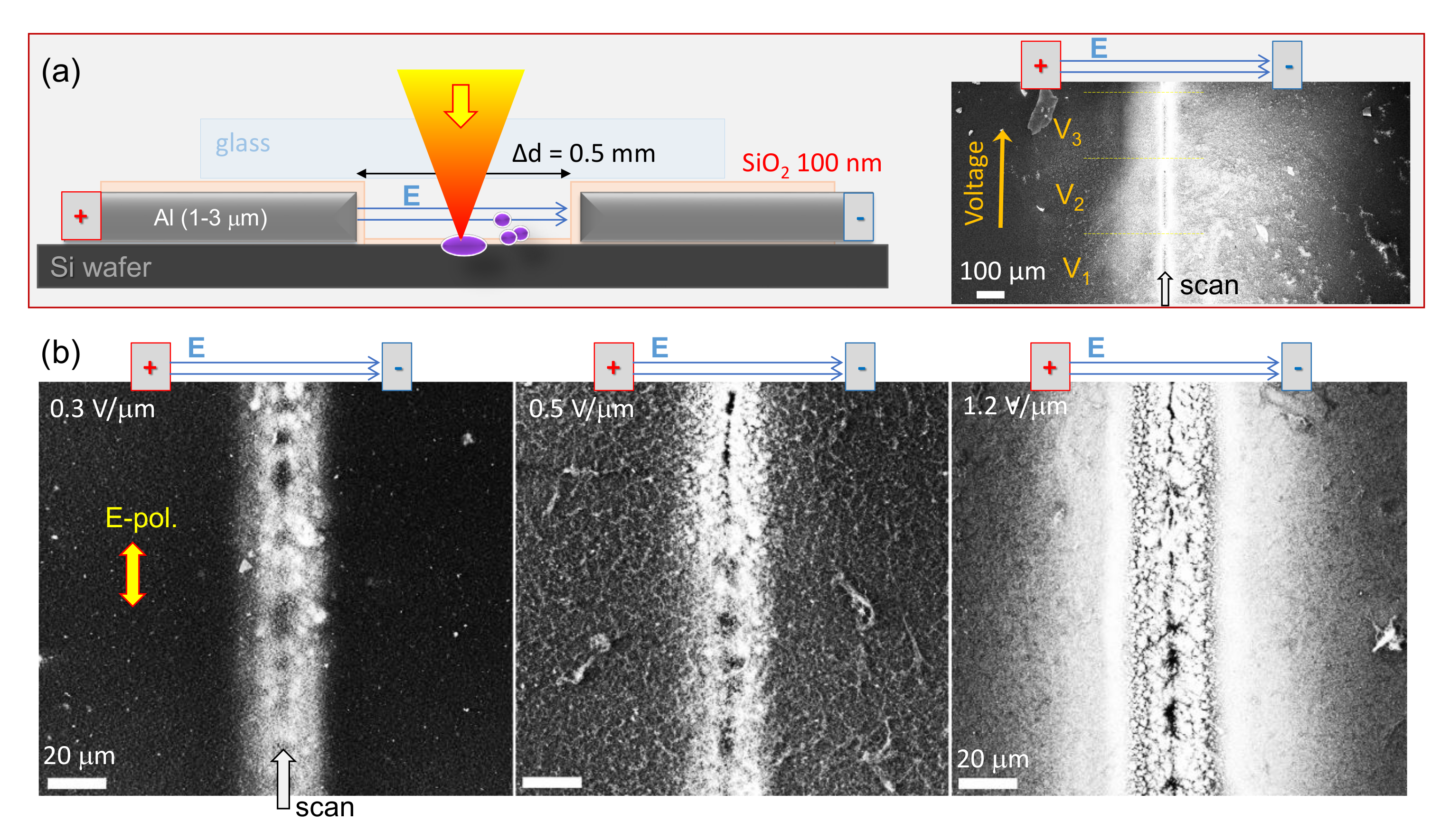

3.2. Ablation of Si in External E-Field

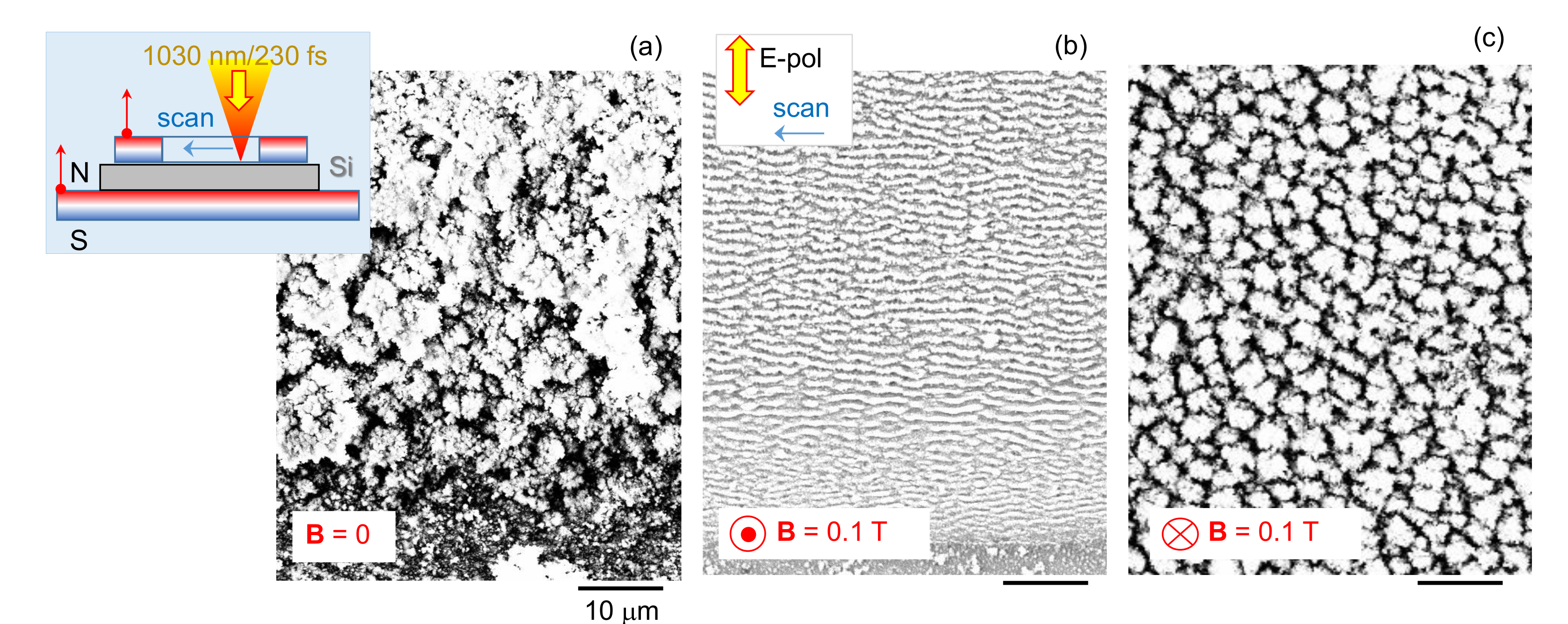

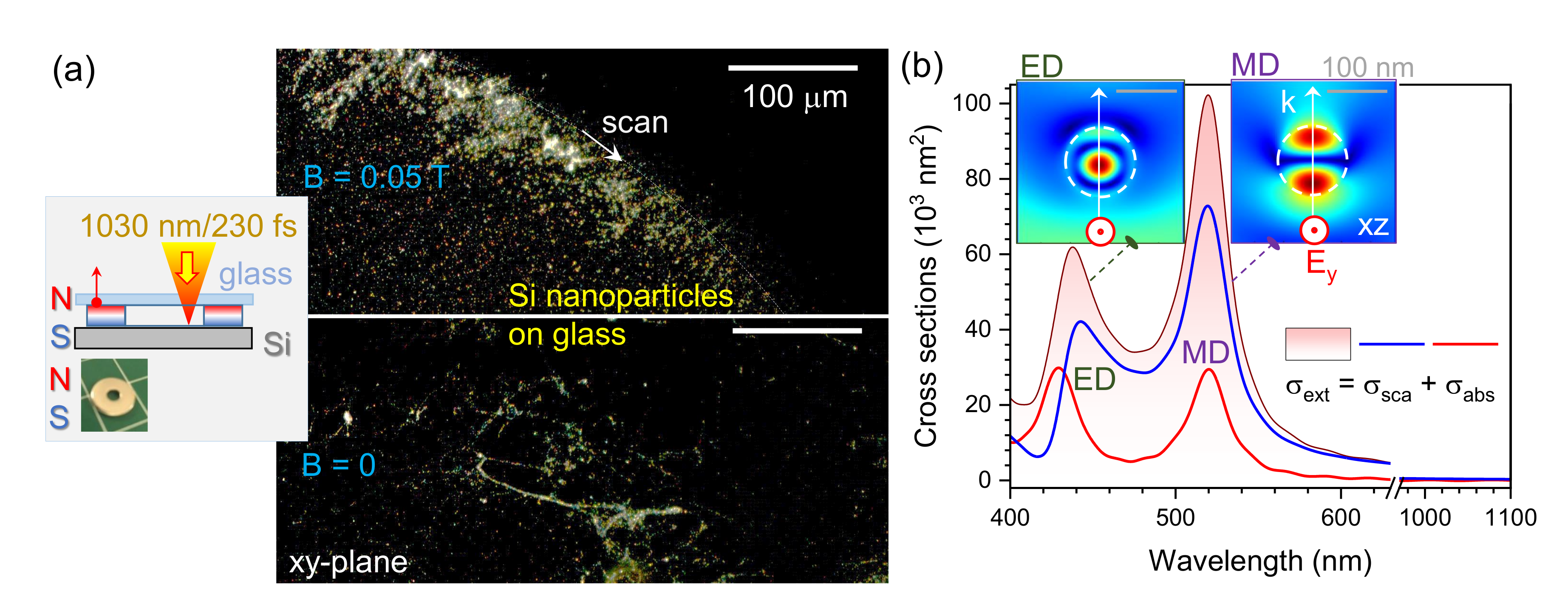

3.3. Ablation of Si in External B-Field

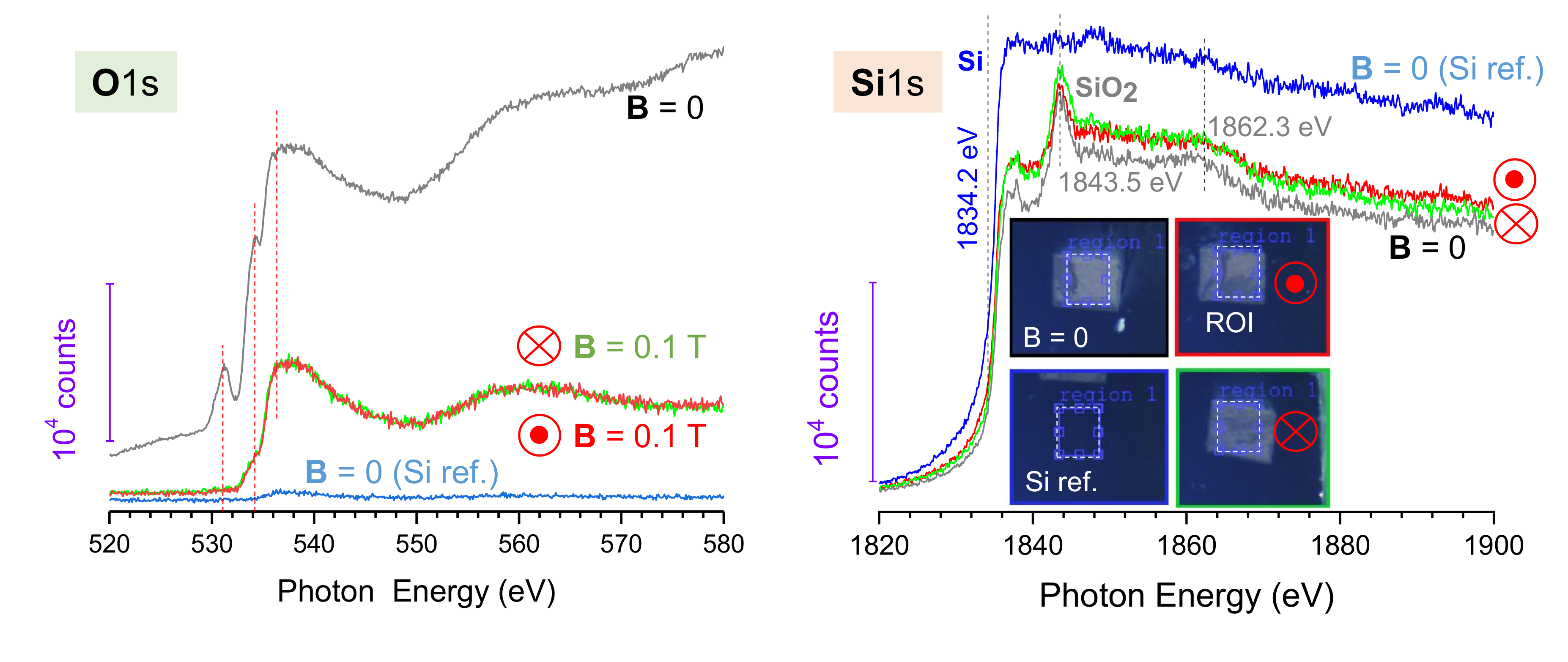

3.4. NEXAFS of Si Ablated in External B-Field

3.5. Debris Harvesting from Si Ablated in External B-Field

4. Discussion

5. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shimotsuma, Y.; Kazansky, P.; Qiu, J.; Hirao, K. Self-organized nanogratings in glass irradiated by ultrashort light pulses. Phys. Rev. Lett. 2003, 91, 247405. [Google Scholar] [CrossRef]

- Umran, F.A.; Liao, Y.; Elias, M.M.; Sugioka, K.; Stoian, R.; Cheng, G.; Cheng, Y. Formation of nanogratings in a transparent material with tunable ionization property by femtosecond laser irradiation. Opt. Express 2013, 21, 15259–15267. [Google Scholar] [CrossRef] [PubMed]

- Ozkan, A.; Malshe, A.; Railkar, T.; Brown, W.; Shirk, M.; Molian, P. Femtosecond laser-induced periodic structure writing on diamond crystals and microclusters. Appl. Phys. Lett. 1999, 75, 3716. [Google Scholar] [CrossRef]

- Das, S.K.; Messaoudi, H.; Debroy, A.; McGlynn, E.; Grunwald, R. Multiphoton excitation of surface plasmon-polaritons and scaling of nanoripple formation in large bandgap materials. Opt. Mater. Express 2013, 3, 1705–1715. [Google Scholar] [CrossRef]

- Davis, K.M.; Miura, K.; Sugimoto, N.; Hirao, K. Writing waveguides in glass with a femtosecond laser. Opt. Lett. 1996, 21, 1729–1731. [Google Scholar] [CrossRef] [PubMed]

- Ròdenas, A.; Gu, M.; Corrielli, G.; Paié, P.; John, S.; Kar, A.; Osellame, R. Three-dimensional femtosecond laser nanolithography of crystals. Nat. Photonics 2019, 13, 105–109. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Ueno, S.; Kumai, R.; Kinoshita, K.; Murai, T.; Tomita, T.; Matsuo, S.; Hashimoto, S. Raman spectroscopic study of femtosecond laser-induced phase transformation associated with ripple formation on single-crystal SiC. Appl. Phys. A Mater. Sci. 2010, 99, 23–27. [Google Scholar] [CrossRef]

- Drs, J.; Kishi, T.; Bellouard, Y. Laser-assisted morphing of complex three dimensional objects. Opt. Express 2015, 23, 17355–17366. [Google Scholar] [CrossRef]

- Marcinkevicius, A.; Juodkazis, S.; Watanabe, M.; Miwa, M.; Matsuo, S.; Misawa, H.; Nishii, J. Femtosecond Laser-Assisted Three-Dimensional Microfabrication in Silica. Opt. Lett. 2001, 26, 277–279. [Google Scholar] [CrossRef]

- Hua, J.G.; Ren, H.; Jia, A.; Tian, Z.N.; Wang, L.; Juodkazis, S.; Chen, Q.D.; Sun, H.B. Convex silica microlens arrays via femtosecond laser writing. Opt. Lett. 2020, 45. [Google Scholar] [CrossRef]

- Zhang, D.; Göcke, B.; Barcikowski, S. Laser synthesis and processing of colloids: Fundamentals and applications. Chem. Rev. 2017, 117, 3990–4103. [Google Scholar] [CrossRef] [PubMed]

- Oktem, B.; Pavlov, I.; Ilday, S.; Kalaycioglu, H.; Rybak, A.; Yavas, S.; Erdogan, M.; Ilday, F.O. Nonlinear laser lithography for indefinitely large-area nanostructuring with femtosecond pulses. Nat. Photonics 2013, 7, 897–901. [Google Scholar] [CrossRef]

- Bhuyan, M.K.; Courvoisier, F.; Lacourt, P.A.; Jacquot, M.; Salut, R.; Furfaro, L.; Dudley, J.M. High aspect ratio nanochannel machining using single shot femtosecond Bessel beams. Appl. Phys. Lett. 2010, 97, 081102. [Google Scholar] [CrossRef]

- Wang, G.; Yu, Y.; Jiang, L.; Li, X.; Xie, Q.; Lu, Y. Cylindrical shockwave-induced compression mechanism in femtosecond laser Bessel pulse micro-drilling of PMMA. Appl. Phys. Lett. 2017, 110, 161907. [Google Scholar] [CrossRef]

- Osellame, R.; Hoekstra, H.; Cerullo, G.; Pollnau, M. Femtosecond laser microstructuring: An enabling tool for optofluidic lab-on-chip. Laser Photonics Rev. 2011, 5, 442–463. [Google Scholar] [CrossRef]

- Gamaly, E.G.; Rode, A.V. Physics of ultra-short laser interaction with matter: From phonon excitation to ultimate transformations. J. Progr. Quant. Electron. 2013, 37, 215–323. [Google Scholar] [CrossRef]

- Kuznetsov, A.I.; Miroshnichenko, A.E.; Fu, Y.H.; Zhang, J.; Lukyanchuk, B. Magnetic light. Sci. Rep. 2012, 2, 492. [Google Scholar] [CrossRef]

- Maksimovic, J.; Ng, S.H.; Katkus, T.; Cowie, B.C.; Juodkazis, S. External Field-Controlled Ablation: Magnetic Field. Nanomaterials 2019, 9, 1662. [Google Scholar] [CrossRef]

- Chen, J.G. NEXAFS investigation of transition metal oxides, nitrides, carbides, sulfides and other interstitial compounds. Surf. Sci. Rep. 1997, 30, 1–152. [Google Scholar] [CrossRef]

- Yang, T.; Bellouard, Y. Monolithic transparent 3D dielectrophoretic micro-actuator fabricated by femtosecond laser. J. Micromech. Microeng. 2015, 25, 105009. [Google Scholar] [CrossRef]

- Hashimoto, T.; Juodkazis, S.; Misawa, H. Void formation in glass. New J. Phys. 2007, 9, 253. [Google Scholar] [CrossRef]

- Farrokhi, H.; Gruzdev, V.; Zheng, H.; Zhou, W. Fundamental mechanisms of nanosecond-laser-ablation enhancement by an axial magnetic field. J. Opt. Soc. Am. B 2019, 36, 1091–1100. [Google Scholar] [CrossRef]

- Buividas, R.; Gervinskas, G.; Tadich, A.; Cowie, B.C.C.; Mizeikis, V.; Vailionis, A.; de Ligny, D.; Gamaly, E.G.; Rode, A.V.; Juodkazis, S. Phase Transformation in Laser-Induced Micro-Explosion in Olivine (Fe,Mg)2SiO4. Adv. Eng. Mater. 2014, 16, 767–773. [Google Scholar] [CrossRef]

- Thompson, S.P. Structural signatures of medium-range order in annealed laboratory silicates. Astron. Astrophys. 2008, 484, 251–265. [Google Scholar] [CrossRef]

- Wong, J.; George, G.N.; Pickering, I.J.; Rek, Z.U.; Rowen, M.; Tanaka, T.; Via, G.H.; DeVries, B.; Vaughan, D.E.W.; Brown, G.E. New opportunities in XAFS investigation in the 1–2 keV region. Solid State Commun. 1994, 92, 559–562. [Google Scholar] [CrossRef]

- Nath, K.; Shimoyama, I.; Sekiguchi, T.; Baba, Y. Synchrotron radiation photoabsorption and photoemission spectroscopy for thermal-induced reoriented Si polymer. J. Electron Spectrosc. Relat. Phenom. 2005, 144–147, 323–326. [Google Scholar] [CrossRef]

- Li, D.; Bancroft, G.; Kasrai, M.; Fleet, M.; Sncco, R.; Feng, X.; Tan, K.; Yang, B. X-ray absorption spectroscopy of silicon dioxide (SiO2) polymorphs: The structural characterization of opal. Am. Mineral. 1994, 79, 622–632. [Google Scholar]

- Vailionis, A.; Gamaly, E.G.; Mizeikis, V.; Yang, W.; Rode, A.; Juodkazis, S. Evidence of super-dense Aluminum synthesized by ultra-fast micro-explosion. Nat. Commun. 2011, 2, 445. [Google Scholar] [CrossRef]

- Tsukada, C.; Tsuji, T.; Matsuo, K.; Nomoto, T.; Kutluk, G.; Sawada, M.; Ogawa, S.; Yoshida, T.; Yagi, S. Spectroscopic and morphological studies on interaction between gold nanoparticle and liposome constructed with phosphatidylcholine. In IOP Conference Series: Materials Science and Engineering; IOP: Bristol, UK, 2015; p. 012001. [Google Scholar]

- Gann, E.; McNeill, C.R.; Tadich, A.; Cowie, B.C.C.; Thomsen, L. Quick AS NEXAFS Tool (QANT): A program for NEXAFS loading and analysis developed at the Australian Synchrotron. J. Synchrotron Rad. 2016, 32, 374–380. [Google Scholar] [CrossRef]

- Rode, A.V.; Gamaly, E.G.; Christy, A.G.; Fitz Gerald, J.G.; Hyde, S.T.; Elliman, R.G.; Luther-Davies, B.; Veinger, A.I.; Androulakis, J.; Giapintzakis, J. Unconventional magnetism in all-carbon nanofoam. Phys. Rev. B 2004, 70, 054407. [Google Scholar] [CrossRef]

- Rekštytė, S.; Jonavicius, T.; Gailevičius, D.; Malinauskas, M.; Mizeikis, V.; Gamaly, E.G.; Juodkazis, S. Nanoscale precision of 3D polymerisation via polarisation control. Adv. Opt. Mater. 2016, 4, 1209–1214. [Google Scholar] [CrossRef]

- Yamasaki, K.; Juodkazis, S.; Matsuo, S.; Misawa, H. Three-dimensional microchannels in polymers: One step fabrication. Appl. Phys. A 2003, 77, 371–373. [Google Scholar] [CrossRef]

- Juodkazis, S.; Yamasaki, K.; Mizeikis, V.; Matsuo, S.; Misawa, H. Formation of Embedded Patterns in Glasses Using Femtosecond Irradiation. Appl. Phys. A 2004, 79, 1549–1553. [Google Scholar] [CrossRef]

- Juodkazis, S.; Matsuo, S.; Misawa, H.; Mizeikis, V.; Marcinkevicius, A.; Sun, H.B.; Tokuda, Y.; Takahashi, M.; Yoko, T.; Nishii, J. Application of femtosecond laser pulses for microfabrication of transparent media. Appl. Surf. Sci. 2002, 197–198, 705–709. [Google Scholar] [CrossRef]

- Mikutis, M.; Kudrius, T.; Šlekys, G.; Paipulas, D.; Juodkazis, S. High 90% efficiency Bragg gratings formed in fused silica by femtosecond Gauss-Bessel laser beams. Opt. Mater. Express 2013, 3, 1862–1871. [Google Scholar] [CrossRef]

- Gamaly, E.G.; Rode, A.V. Ultrafast re-structuring of the electronic landscape of transparent dielectrics: New material states (Die-Met). Appl. Phys. A 2018, 124, 278. [Google Scholar] [CrossRef]

- Marcinkevicius, A.; Juodkazis, S.; Matsuo, S.; Mizeikis, V.; Misawa, H. Application of Bessel Beams for Microfabrication of Dielectrics by Femtosecond Laser. Jpn. J. Appl. Phys. 2001, 40, L1197–L1199. [Google Scholar] [CrossRef]

- Gaižauskas, E.; Vanagas, E.; Jarutis, V.; Juodkazis, S.; Mizeikis, V.; Misawa, H. Discrete Damage Traces from Filamentation of Bessel-Gauss Pulses. Opt. Lett. 2006, 31, 80–82. [Google Scholar] [CrossRef]

- Kudrius, T.; Šlekys, G.; Juodkazis, S. Surface-texturing of sapphire by femtosecond laser pulses for photonic applications. J. Phys. D Appl. Phys. 2010, 43, 145501. [Google Scholar] [CrossRef]

- Juodkazis, S.; Gaižauskas, E.; Jarutis, V.; Misawa, H.; Matsuo, S.; Reif, J. Optical Third Harmonic Generation During Femtosecond Pulse Diffraction in Bragg Grating. J. Phys. D Appl. Phys. 2006, 39, 50–53. [Google Scholar] [CrossRef]

- Juodkazis, S.; Mizeikis, V.; Sudžius, M.; Misawa, H.; Kitamura, K.; Takekawa, S.; Gamaly, E.G.; Krolikowski, W.Z.; Rode, A.V. Laser induced memory bits in photorefractive LiNbO3 and LiTaO3. Appl. Phys. A 2008, 93, 129–133. [Google Scholar] [CrossRef]

- Özdemir, Ş.; Rotter, S.; Nori, F.; Yang, L. Parity-time symmetry and exceptional points in photonics. Nat. Mater. 2019, 18, 783–798. [Google Scholar] [CrossRef] [PubMed]

- El-Ganainy, R.; Makris, K.; Christodoulides, D.; Musslimani, Z.H. Theory of coupled optical PT-symmetric structures. Opt. Lett. 2007, 32, 2632–2634. [Google Scholar] [CrossRef] [PubMed]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maksimovic, J.; Ng, S.-H.; Katkus, T.; An Le, N.H.; Chon, J.W.M.; Cowie, B.C.C.; Yang, T.; Bellouard, Y.; Juodkazis, S. Ablation in Externally Applied Electric and Magnetic Fields. Nanomaterials 2020, 10, 182. https://doi.org/10.3390/nano10020182

Maksimovic J, Ng S-H, Katkus T, An Le NH, Chon JWM, Cowie BCC, Yang T, Bellouard Y, Juodkazis S. Ablation in Externally Applied Electric and Magnetic Fields. Nanomaterials. 2020; 10(2):182. https://doi.org/10.3390/nano10020182

Chicago/Turabian StyleMaksimovic, Jovan, Soon-Hock Ng, Tomas Katkus, Nguyen Hoai An Le, James W.M. Chon, Bruce C.C. Cowie, Tao Yang, Yves Bellouard, and Saulius Juodkazis. 2020. "Ablation in Externally Applied Electric and Magnetic Fields" Nanomaterials 10, no. 2: 182. https://doi.org/10.3390/nano10020182

APA StyleMaksimovic, J., Ng, S.-H., Katkus, T., An Le, N. H., Chon, J. W. M., Cowie, B. C. C., Yang, T., Bellouard, Y., & Juodkazis, S. (2020). Ablation in Externally Applied Electric and Magnetic Fields. Nanomaterials, 10(2), 182. https://doi.org/10.3390/nano10020182