3.2. Phase Analysis

Figure 6 presents the X-ray diffraction (XRD) patterns of 316L stainless steel powder and the top and side surfaces of samples fabricated using LPBF. The diffraction peaks corresponding to γ-Fe planes (111), (200), (220), and (311) are labeled. The powder exhibited characteristic peaks consistent with the γ-Fe austenitic phase. The top surface of the LPBF-fabricated sample showed a preferential orientation along the (111) plane, indicated by the increased intensity of that peak, while the side surface exhibited a stronger (220) orientation. These differences reflected anisotropic microstructural development, likely influenced by directional heat dissipation and rapid cooling during fabrication.

Saeidi et al. [

39] also observed preferential orientation along the (111) plane in LPBF samples and attributed it to high undercooling and directional solidification that promoted uniform grain growth. AlMangour et al. [

43] identified austenite as the dominant phase, with trace ferrite (α-Fe) resulting from high cooling rates. Yakout et al. [

44] reported similar austenitic structures with minor martensitic peaks, suggesting the formation of needle-like martensite with a body-centered tetragonal (BCT) structure. In contrast, Wang et al. [

45] detected only a single austenitic phase with no evidence of martensitic transformation.

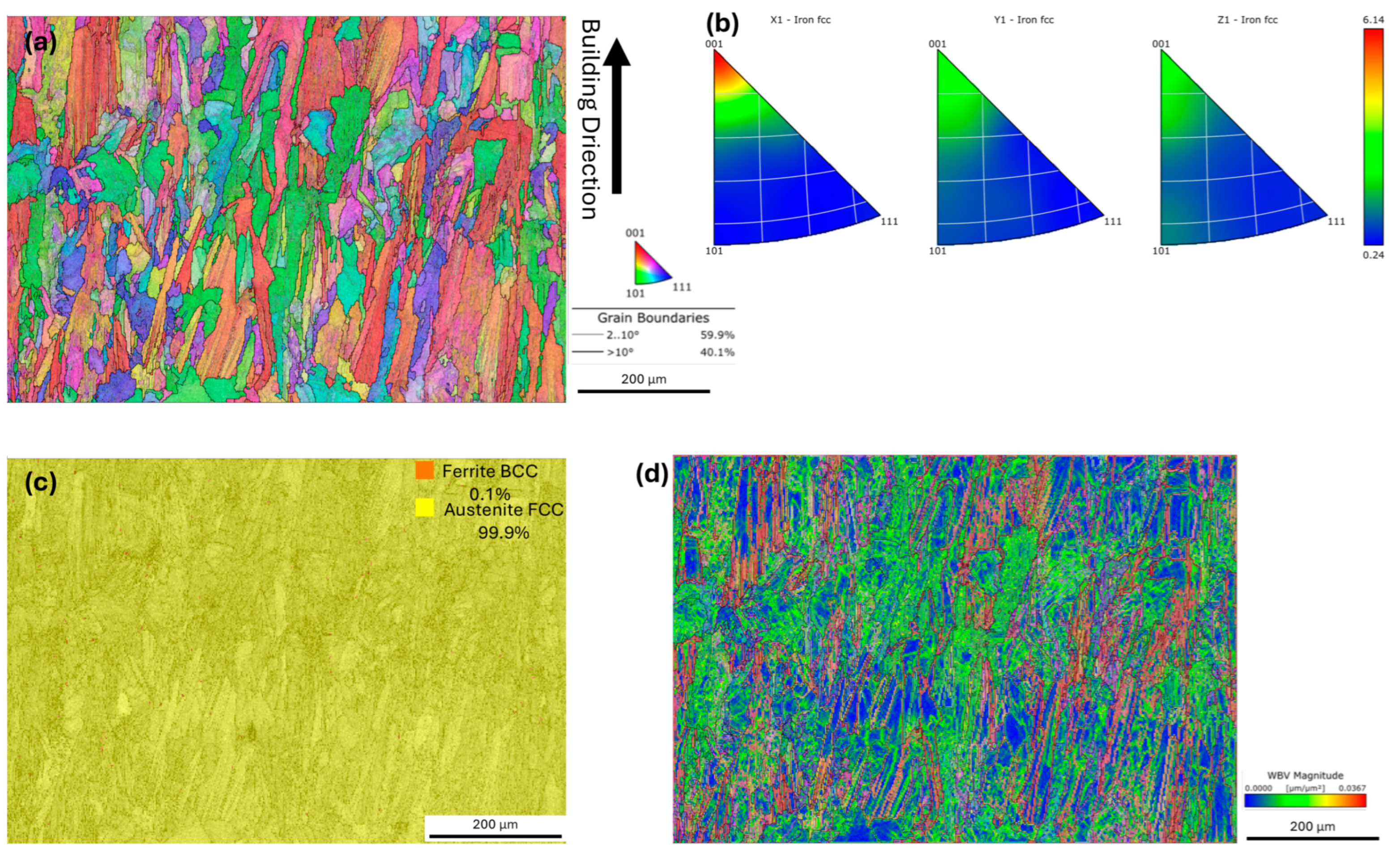

Electron backscatter diffraction (EBSD) analysis provided detailed insight into the microstructure of 316L stainless steel fabricated by laser powder bed fusion (LPBF), as shown in

Figure 7. The grain size analysis, based on an equivalent circle diameter approach (threshold angle 10°), revealed a mean grain size of 23.4 μm. The inverse pole figure (IPF) map in

Figure 7a reveals a strong crystallographic texture along the building direction, with elongated grains that are typical for additively manufactured austenitic stainless steels. The grain boundary analysis shown in

Figure 7a indicates that low-angle grain boundaries (LAGBs, with misorientation angles between 2 and 10 degrees) accounted for 59.9% of the total grain boundary length, while high-angle grain boundaries (HAGBs, above 10 degrees) constituted the remaining 40.1%. The dominance of LAGBs reflected the prevalence of subgrain and cellular structures generated by the rapid solidification conditions during LPBF processing. These LAGBs are effective in impeding dislocation motion and promoting work hardening, thereby contributing to the material’s strength and ductility. The pole figures shown in

Figure 7b reveal a strong crystallographic texture along the building direction, with the majority of austenite grains preferentially oriented along the <001> direction. This texture developed as a result of the steep thermal gradients and unidirectional heat flow during the laser powder bed fusion process, which promoted epitaxial growth of columnar grains parallel to the building direction. Such a strong <001> texture is known to induce mechanical anisotropy, typically resulting in improved ductility and work-hardening capacity along the build direction, as the <001> axis in FCC austenite facilitates slip and coordinated plastic deformation. The phase map

Figure 7c demonstrates that the microstructure consisted of 99.9% austenite (FCC) and only 0.1% ferrite (BCC), confirming the near-complete stabilization of the austenite phase by the combined effects of high cooling rates and nickel enrichment. The weighted Burgers vector (WBV) misorientation density map in

Figure 7d illustrates the spatial distribution of local lattice misorientation, which is closely related to dislocation density. Regions with high WBV values indicated higher stored strain and dislocation content, often resulting from the rapid cooling and repeated thermal cycling during layer-by-layer fabrication. A higher density of dislocations, as reflected by elevated WBV values, can significantly enhance the work hardening rate of the material, contributing to increased tensile strength and ductility. The dense network of dislocations impedes the movement of new dislocations during plastic deformation, resulting in more uniform strain distribution and delayed necking under tensile loading.

3.4. Metallography of 0° Interlayer Rotation

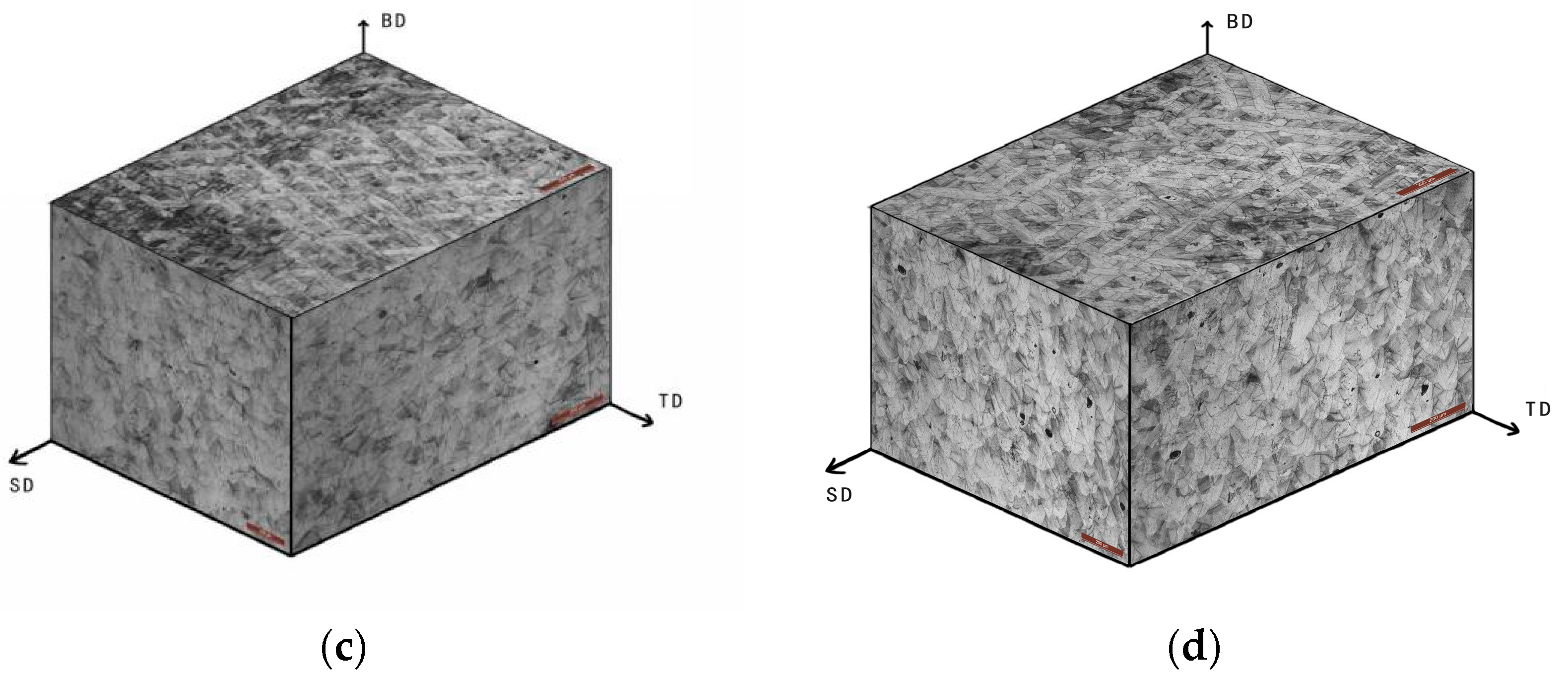

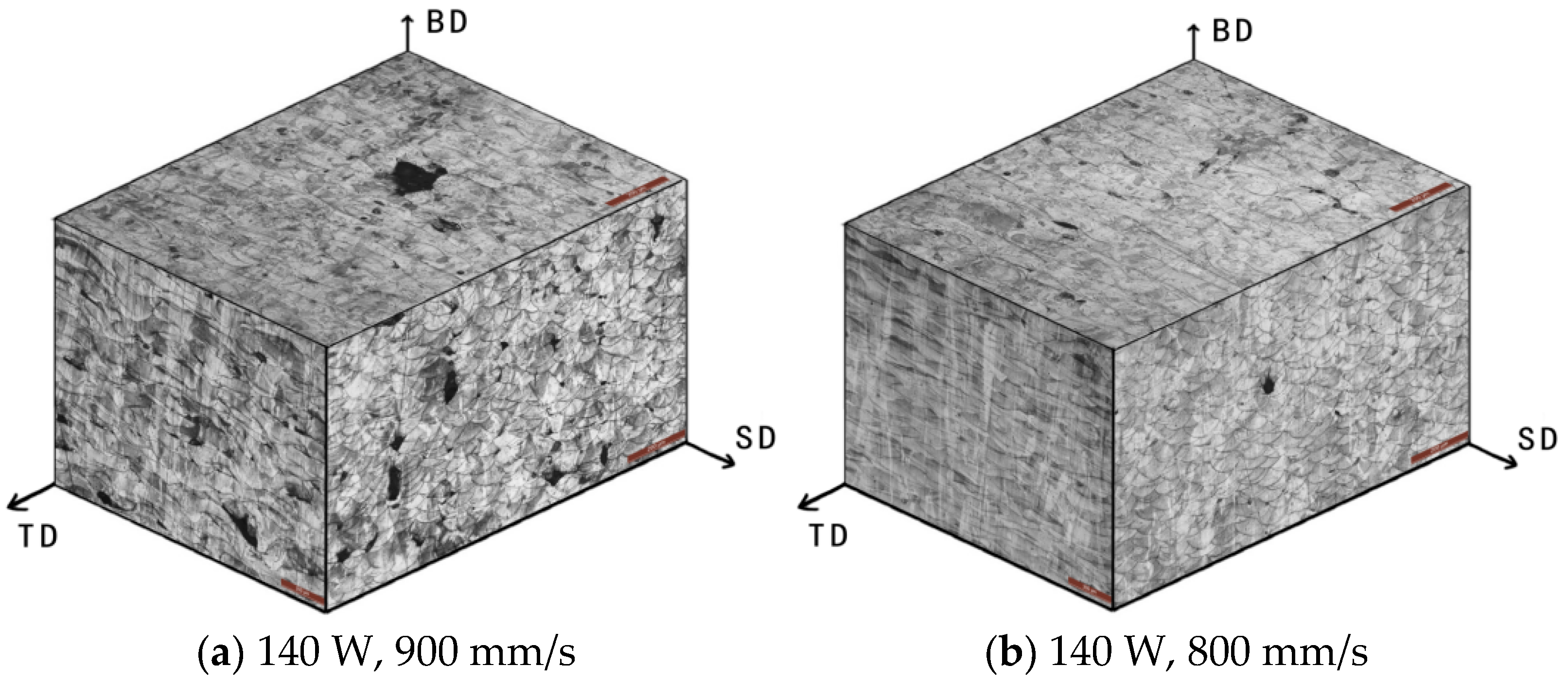

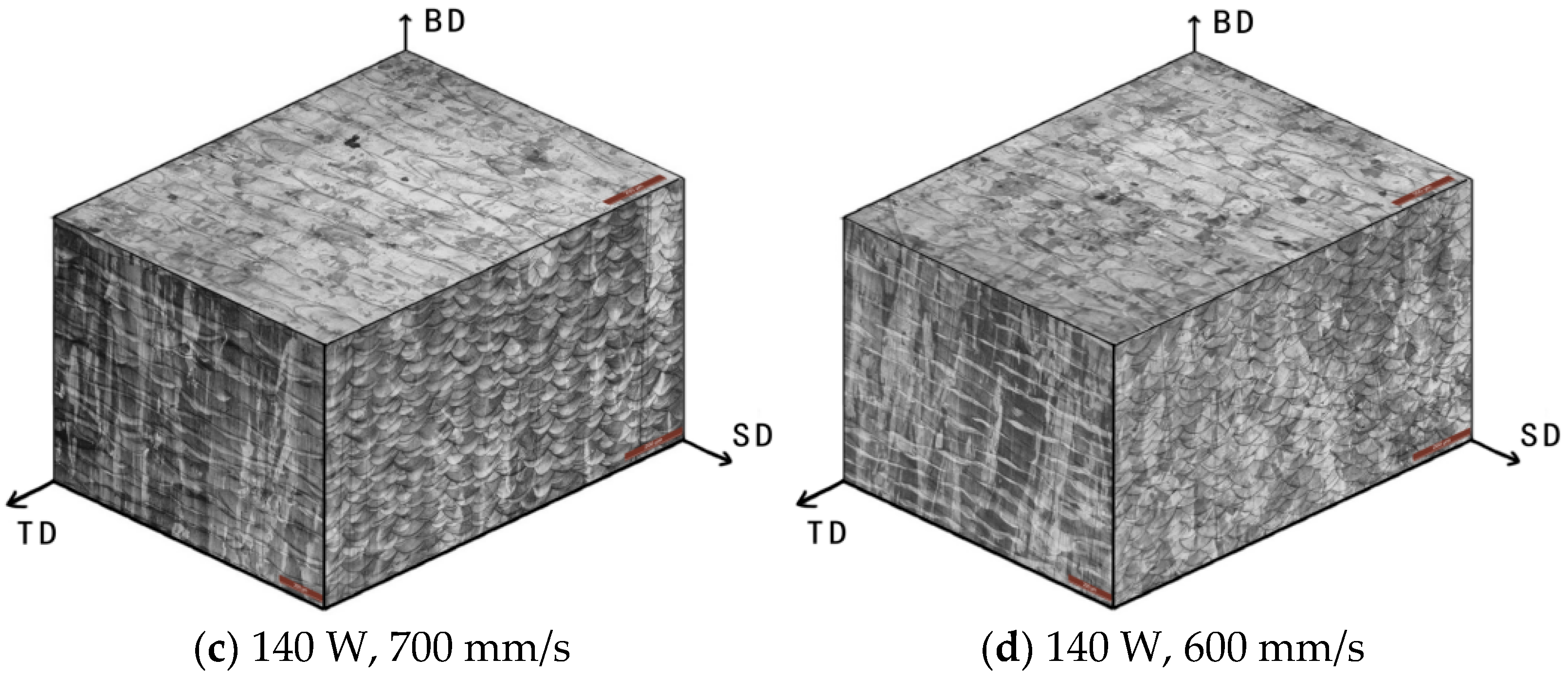

As shown in

Figure 10, the specimens were fabricated under conditions of 0° interlayer rotation, 140 W laser power, and scanning speeds ranging from 600 mm/s to 900 mm/s. The transverse direction (TD), scanning direction (SD), and building direction (BD) defined the spatial orientation of the sample. The BD-SD plane, which was parallel to the scanning track, was referred to as the parallel plane; the BD-TD plane, perpendicular to the scanning direction, was defined as the vertical plane; and the TD-SD plane represented the top plane. When scanning was performed in a single direction, the molten pool appeared strip-shaped on the parallel plane and fish scale-shaped on the vertical plane. Under the condition of 140 W and 900 mm/s, the porosity was highest. This was attributed to the presence of unmelted particles and spheroidization, which obstructed flow and disrupted the formation of continuous scanning tracks, resulting in distorted and discontinuous melt paths.

As shown in

Figure 11, the images depict the top surface (SD-TD plane) of metallographic specimens fabricated with an interlayer rotation angle of 0°. The average scanning track widths in

Figure 11a through

Figure 11d were approximately 88 μm, 79 μm, 77 μm, and 68 μm, respectively. The results indicated that, under constant laser power, the scanning track width decreased as scanning speed increased. In

Figure 11d, the specimen shows a large lack of fusion (LoF) pores, suggesting insufficient energy input at higher scanning speeds. In general, the top surface track widths under 0° interlayer rotation were larger than those observed at 67°. This was because the tracks produced by unidirectional scanning at 0° remained in the same plane and were well aligned, leaving no visible gaps. In contrast, under 67° rotation, the scanning tracks from successive layers did not lie in the same plane due to the angular offset. As a result, when the surface was ground in a single direction for imaging, only a partial cross-section of the top of each melt pool was revealed, making the measured track widths appear smaller than their actual dimensions due to partial coverage from overlapping layers.

Figures S8–S10 are metallographic images of the vertical surface, and the molten pool is “fish scale-like”. As shown in

Figure S6, the metallographic image of the parallel surface, the molten pool is strip-like. Five images are counted for each working condition, five molten pools are counted in each image, and the average value is taken.

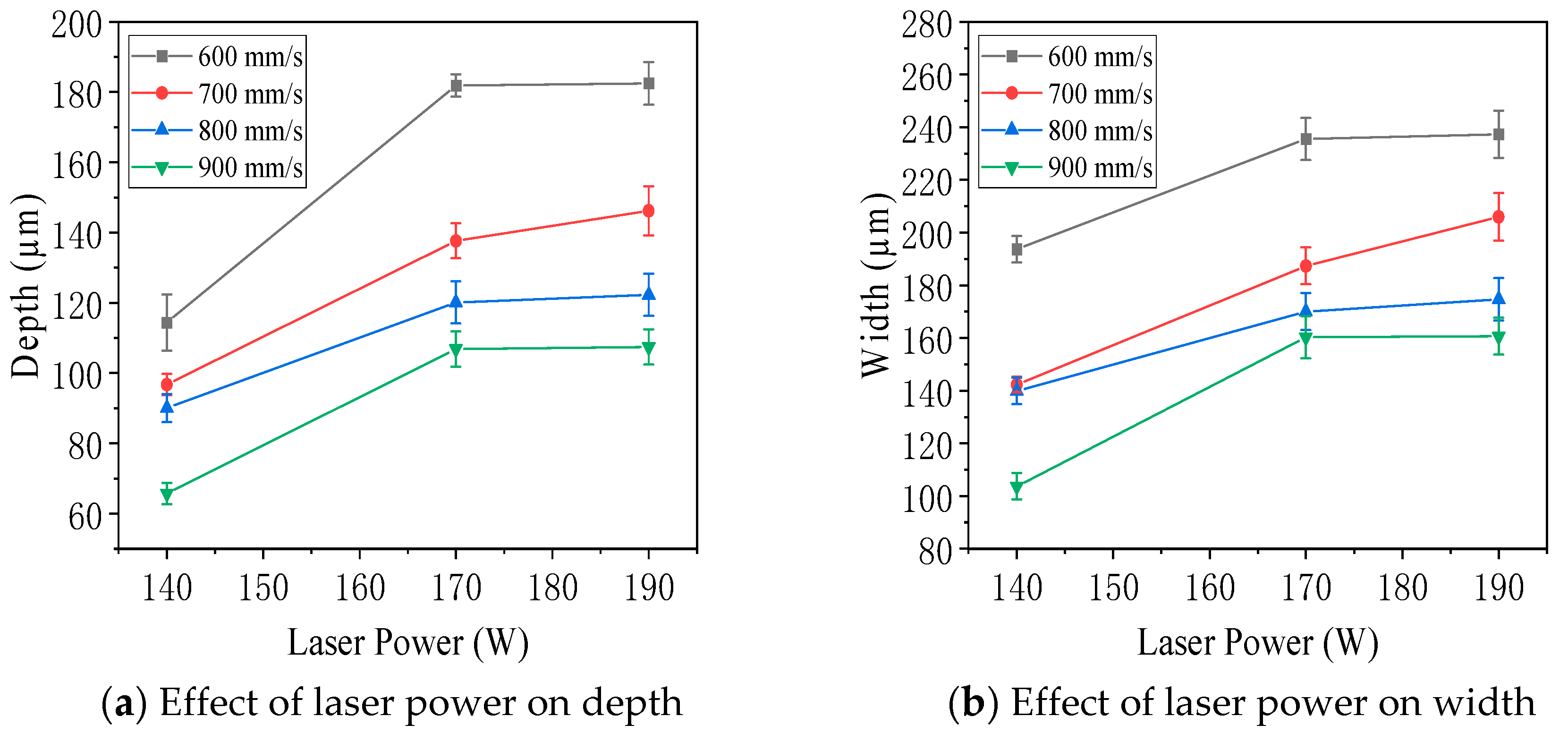

Figure 12 presents the measured depth and width of molten pools on the vertical plane of specimens fabricated with an interlayer rotation angle of 0° under varying laser power and scanning speed. As shown in

Figure 12a,b, both the depth and width of the molten pools increased with increasing laser power and gradually stabilized.

Figure 12c,d showed that, with constant laser power, increasing the scanning speed led to a decrease in both the depth and width of the molten pools. These trends indicated that higher energy input, achieved through increased laser power or reduced scanning speed, promoted deeper and wider melt pools, enhancing material fusion and process stability.

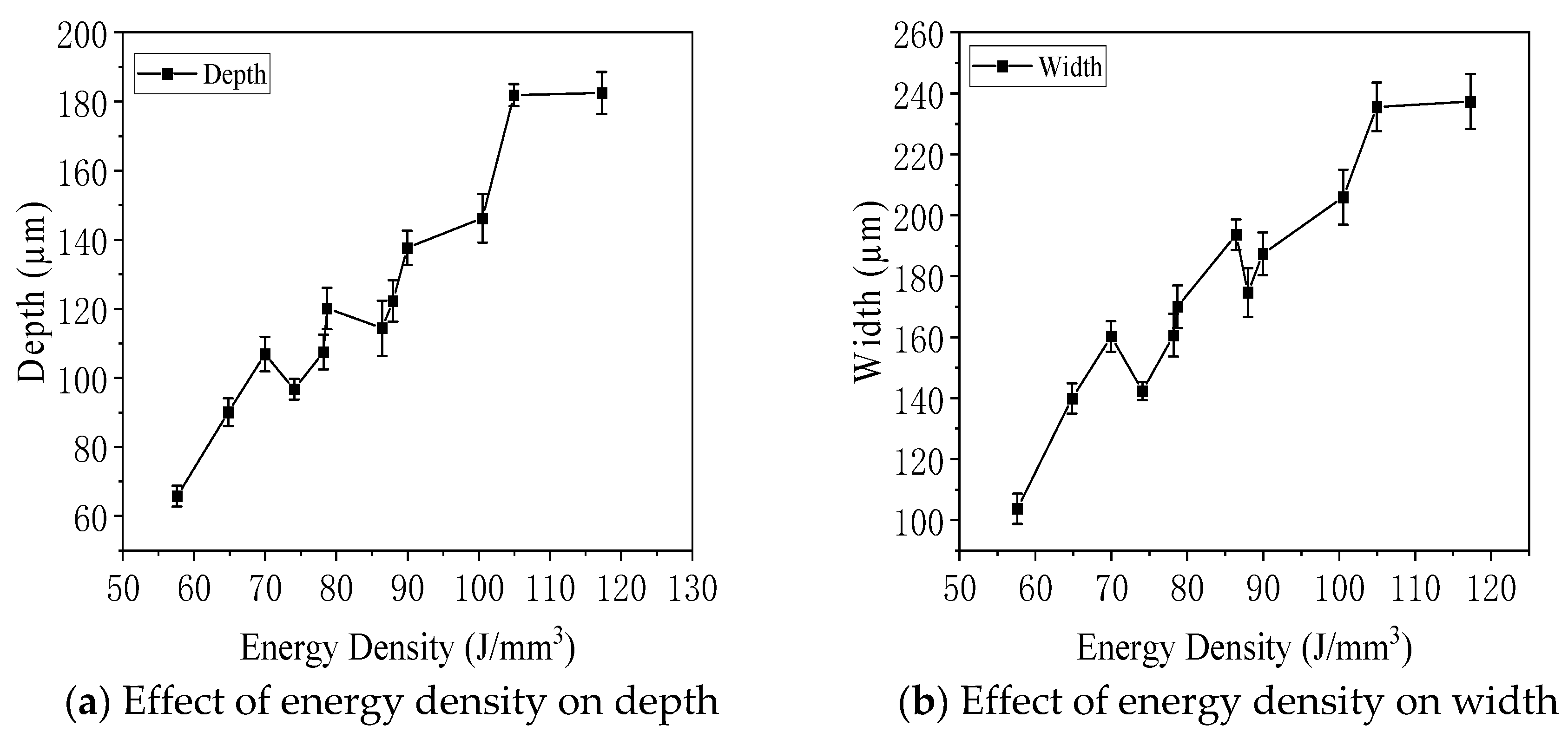

Figure 13 illustrates the influence of energy density on the depth and width of molten pools observed on the vertical plane of specimens fabricated with an interlayer rotation angle of 0°. As shown in

Figure 13a,b, both the depth and width of the molten pools increased with increasing energy density and then gradually stabilized. Contour plots in

Figure 13c,d further confirmed this trend. Under the condition of 190 W laser power and 600 mm/s scanning speed, corresponding to an energy density of 117.28 J/mm

3, the molten pool exhibited the largest average width of 237 μm and depth of 183 μm. In contrast, at 140 W and 900 mm/s, with an energy density of 57.61 J/mm

3, the smallest average width and depth were observed—104 μm and 66 μm, respectively. These results demonstrated that higher energy density promoted deeper and wider molten pools, improving material melting and bonding.

Figure 14 illustrates the effect of laser power, scanning speed, and energy density on the thickness of molten pools observed on the parallel surface of specimens with an interlayer rotation angle of 0°. As shown in

Figure 14a, when the scanning speed was held constant, the molten pool thickness increased with higher laser power.

Figure 14b showed that, under constant laser power, the thickness decreased as the scanning speed increased.

Figure 14c demonstrated a positive correlation between energy density and molten pool thickness. The contour plot in

Figure 14d summarizes these trends. The maximum thickness was 92 µm at 190 W and 600 mm/s, corresponding to an energy density of 117.28 J/mm

3, while the minimum thickness was 46 µm at 140 W and 900 mm/s, with an energy density of 57.61 J/mm

3. The thickness of the molten pool on the parallel surface was generally smaller than the depth observed on the vertical surface. This was because the parallel surface did not intersect the central axis of the molten pool in the vertical plane, resulting in lower measured values. Therefore, the parallel surface thickness was not used as the standard metric for molten pool geometry.

3.5. Defects

As shown in

Figure 15, four types of defects were observed in the molten pool region.

Figure 15a shows a defect caused by excessive scanning speed and low energy density. Under these conditions, the molten pool boundary was not properly bonded, and residual stress led to crack initiation at the boundary, eventually forming large-area voids. These regions were often accompanied by partially unmelted powder particles, further weakening the material.

Figure 15b depicts pore defects formed under low scanning speed and high energy density. In this case, the molten pool was deep, and nitrogen from the protective atmosphere dissolved into the melt due to intense convection. As the laser moved on and rapid solidification occurred, the gas was trapped before it could escape, forming spherical pores near the bottom of the molten pool. These defects were typically small and remained confined within the melt zone.

Figure 15c revealed that unmelted powder particles embedded within the solidified material acted as crack initiation points, leading to the formation of larger pores. These unmelted particles disrupted the metallurgical continuity and significantly reduced mechanical integrity.

Figure 15d showed a spheroidization phenomenon at the top of the uppermost molten pool layer. This defect originated from two primary causes: poor wettability between the molten metal and the solid substrate, which depended on surface tension, and droplet splashing during the melting process. The spheroidized particles failed to coalesce and left behind internal voids. These spherical defects degraded mechanical properties, increased surface roughness, and posed risks to the powder spreading mechanism. Specifically, they elevated friction against the recoater blade, potentially causing mechanical wear or damage to the equipment.

Defects in additively manufactured 316L stainless steel, such as pores, unmelted powder particles, lack-of-fusion regions, and balling, have important implications not only for mechanical integrity but also for the biological performance of implantable devices. High porosity and surface-connected voids may serve as initiation sites for crack propagation under cyclic physiological loads, potentially compromising implant longevity and increasing the risk of failure in vivo [

46]. Moreover, interconnected pores and rough defect surfaces can accelerate corrosion processes in the physiological environment, which may lead to the release of metallic ions that can trigger adverse tissue reactions or inflammatory responses [

19].

From a biomaterials standpoint, the presence and morphology of defects can significantly affect the tissue response at the implant–tissue interface. For example, surface-connected pores may alter protein adsorption and cellular adhesion, which are critical for successful osseointegration and long-term implant stability [

47]. While controlled surface porosity can sometimes promote bone ingrowth and mechanical interlocking, excessive or irregular defects may instead lead to fibrous encapsulation or local inflammation, undermining the desired biointegration [

48].

Thus, minimizing the size, number, and connectivity of process-induced defects is crucial for optimizing both the mechanical and biological outcomes of LPBF-fabricated 316L implants. A comprehensive understanding of the relationships among processing parameters, defect formation, and subsequent biological interactions is necessary to ensure safe and reliable performance of metallic biomaterials in clinical applications [

49].

3.6. Grain Morphology

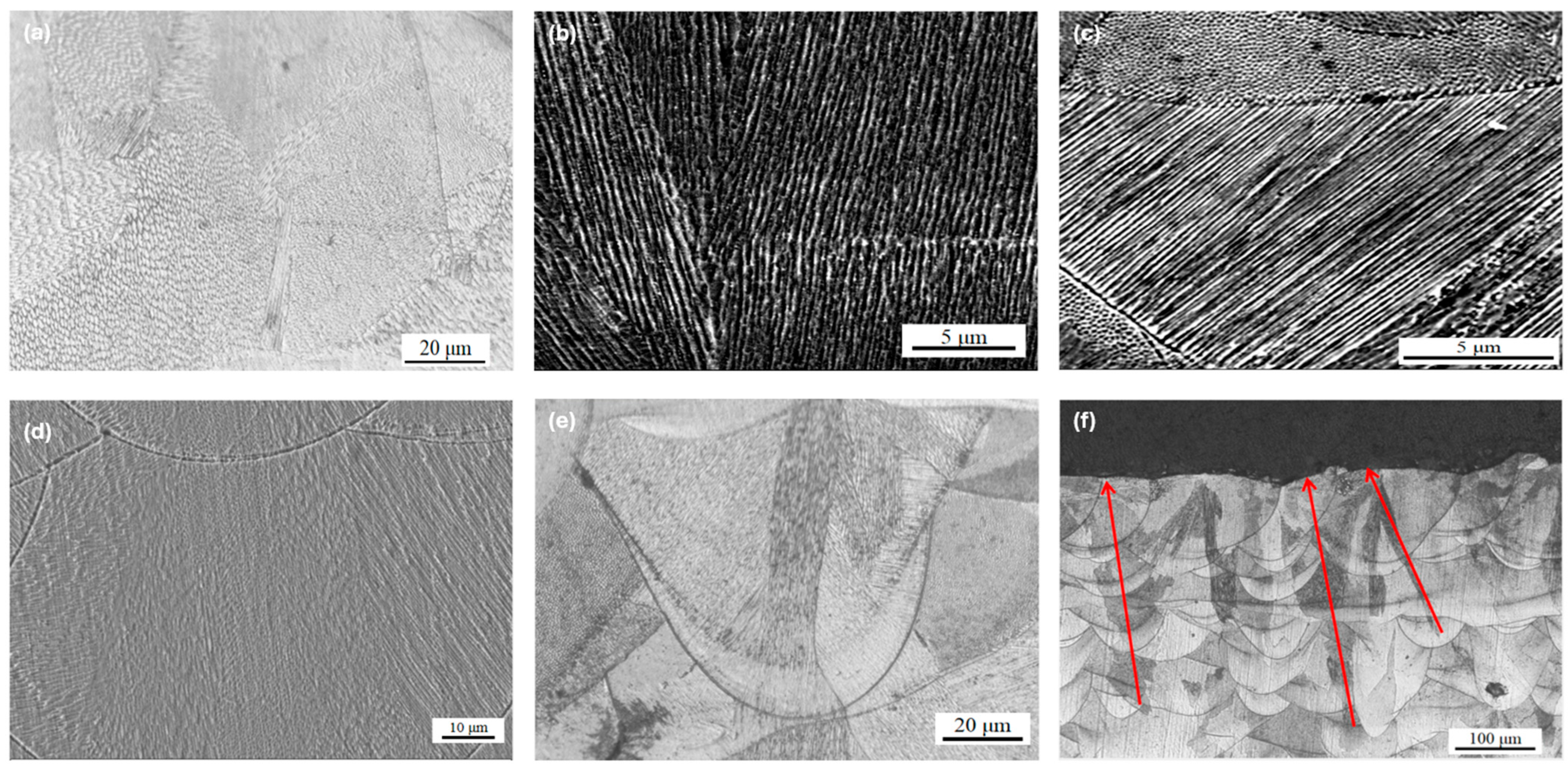

In

Figure 16a, the honeycomb cellular structure represents the cross-sectional view of columnar crystals, while

Figure 16b displays the longitudinal morphology of the columnar crystals.

Figure 16c,d show that the columnar crystals grew either perpendicular to or at an angle to the molten pool boundary. This growth followed a non-uniform nucleation and crystallization mechanism, driven by thermal gradients. Heat within the molten pool primarily diffused from the melt zone toward the previously solidified material and the substrate, promoting directional solidification along the path of the steepest temperature gradient.

Figure 16e,f illustrate that the columnar crystals extended across multiple molten pool layers. During the LPBF process, melting of the upper layer caused heat to conduct downward into the solidified austenite below, triggering recrystallization along the thermal path. Due to the high thermal conductivity and substantial supercooling, the resulting recrystallized grains were fine. The direction opposite to heat conduction marked the epitaxial growth path of the columnar grains, which became visible after etching. This observation was consistent with the findings of Qiu et al. [

50], who reported that epitaxial grain growth could span more than ten layers. Ma et al. [

51] similarly visualized epitaxial columnar grains using three-dimensional imaging and discussed the influence of processing conditions on their length and width. Zhong et al. [

52] concluded, based on high-magnification electron microscopy, that the grain morphology consisted of vertically oriented columnar crystals and horizontally oriented cellular crystals in the cross-section.

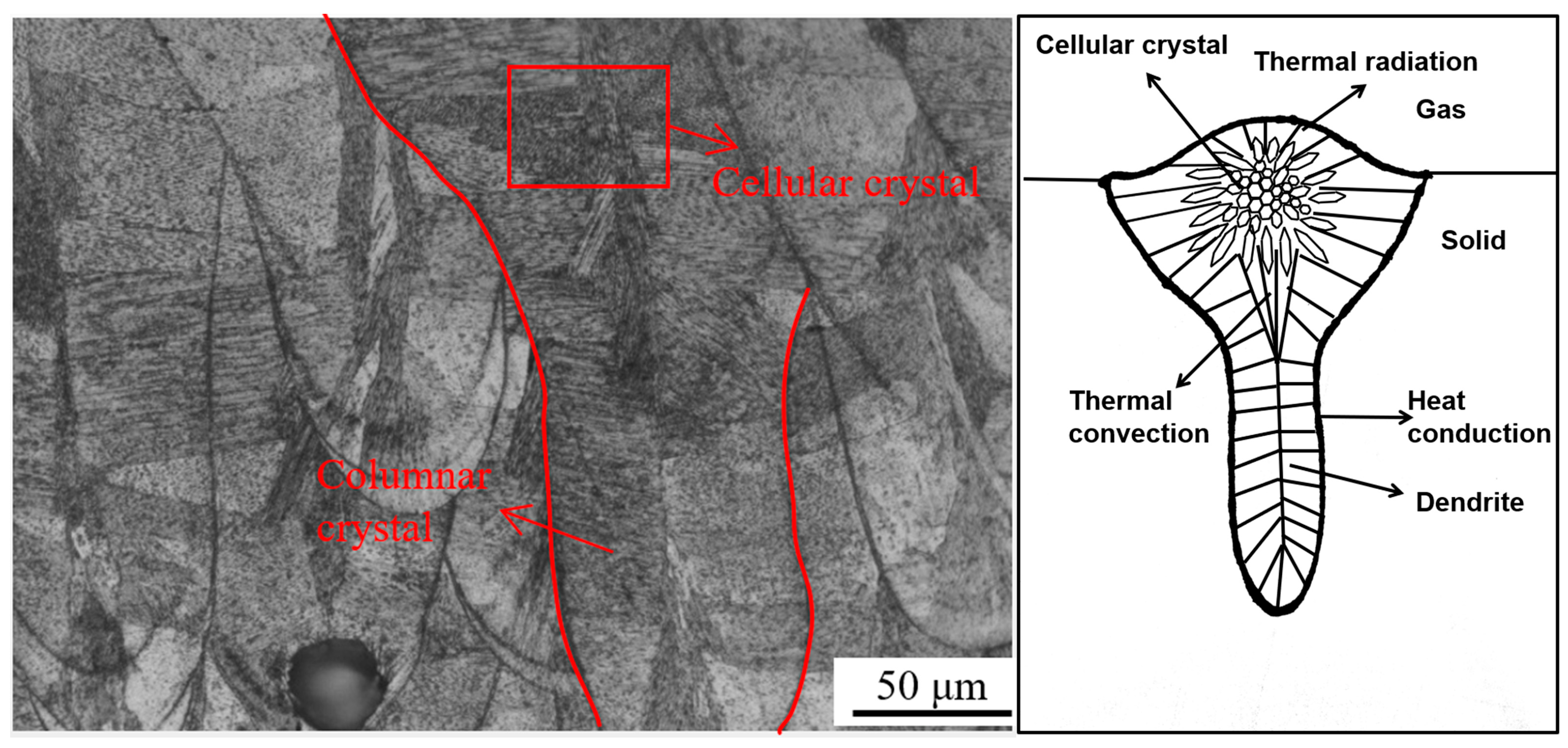

Figure 17 shows a typical morphology of the molten pool formed during the LPBF process. Heat conduction was the primary mode of heat dissipation, resulting in a high cooling rate at the molten pool boundary. Consequently, the growth direction of the columnar crystals near the boundary was either perpendicular to the boundary or aligned along the steepest temperature gradient. Within the molten pool, heat convection occurred, and due to the influence of gravity, the convective flow was predominantly vertical. This internal convection altered the growth direction of columnar crystals, causing variation across the melt pool region.

Cellular crystals were observed in the central region of the molten pool. The gradual increase in the length of their axes from the center outward indicated that heat dissipated from the core toward the surrounding material. Liu et al. [

53] reported that columnar crystal morphology varied with height due to repeated thermal cycling. Heat conducted downward from the upper layers caused the lower layers to experience grain coarsening and lamellar structure formation, with the grain axis oriented along the build direction. Brytan [

54] also observed a honeycomb columnar structure, where the overlapping of molten pools caused submicron grains to shift their growth direction, exhibiting epitaxial columnar growth across multiple layers.

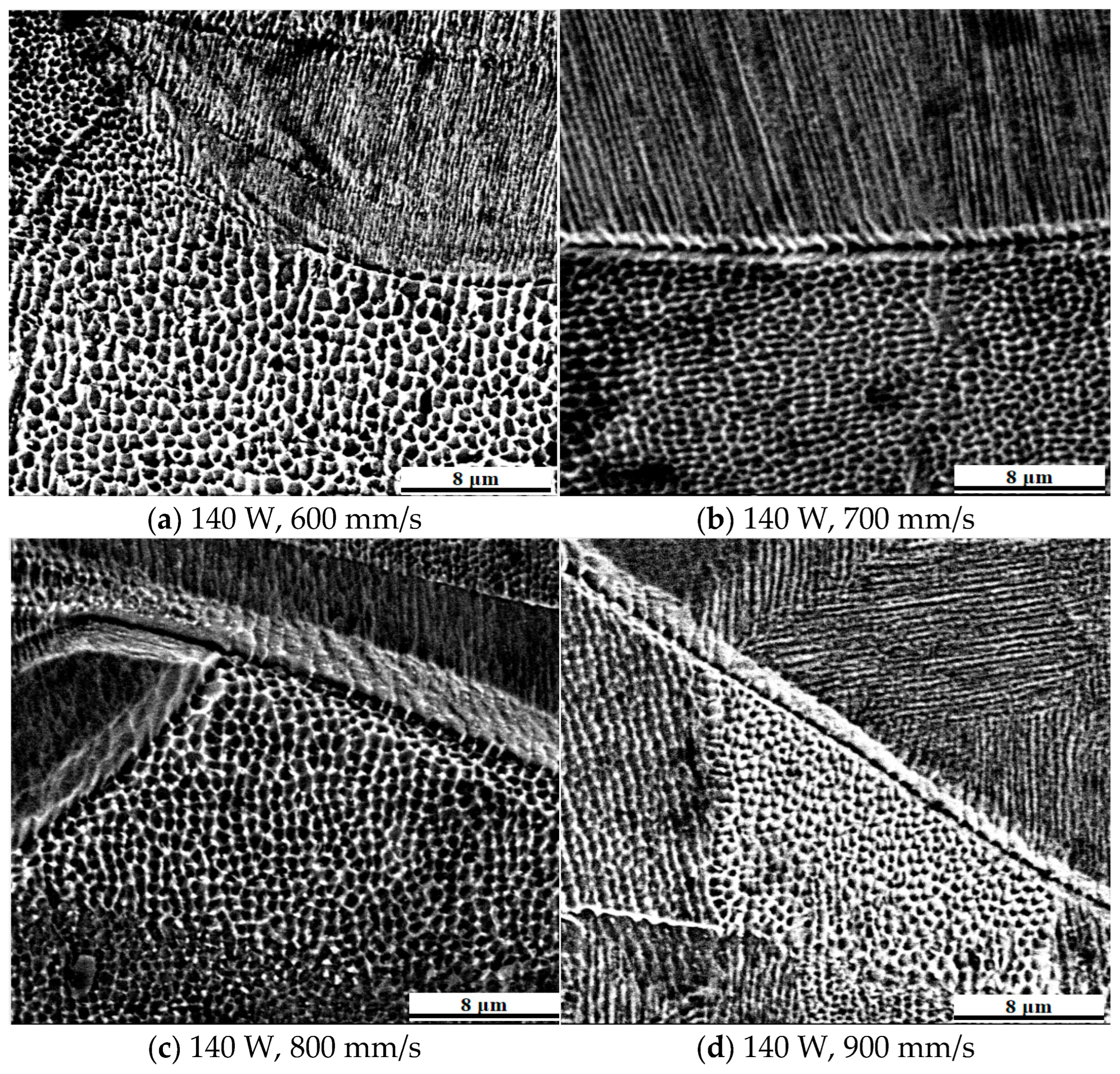

Figure 18 shows the cellular austenitic structure of 316L stainless steel specimens fabricated at different scanning speeds. The average diameters of the cellular grains in

Figure 18a–d were 0.93 µm, 0.89 µm, 0.66 µm, and 0.55 µm, respectively. As scanning speed increased, the diameters decreased due to a reduction in energy input and an increase in cooling rate. Lower scanning speeds provided more thermal energy and longer solidification times, allowing grains to grow larger. In contrast, rapid solidification at higher scanning speeds led to the formation of finer grains. Both cellular and columnar grains were observed in the specimens, and they belonged to the same austenitic phase (γ-Fe). These two morphologies formed under different thermal conditions during solidification. Columnar grains developed along steep and directional thermal gradients, typically growing epitaxially in the build direction. Cellular grains formed under conditions of moderate thermal gradient and higher undercooling, often within the center of the molten pool. While they appear distinct, cellular and columnar structures can transition within a single grain as local thermal gradients vary. In some cases, the cellular appearance may simply reflect a transverse view of a columnar grain. The grain boundaries were enriched with chromium and molybdenum, elements that resist corrosion and are less susceptible to etching, thus outlining the microstructure. These observations aligned with previous findings that prolonged thermal cycles promoted element diffusion, grain boundary refinement, and transitions between grain morphologies. The current study confirmed that the observed needle-like structures corresponded to differently oriented austenitic grains, as demonstrated by EBSD mapping. The EBSD results showed that over 99.9% of the matrix was composed of austenitic iron, providing direct microstructural evidence in support of the XRD findings, which indicated a predominantly single austenitic phase.

In addition, due to the grain characteristics, the more equiaxed crystals there are in the sample structure, the higher the tensile strength and the lower the elongation. Conversely, the more columnar crystals there are, the higher the elongation and the lower the tensile strength. Shang et al. [

55] found that as the scanning speed decreases, the average diameter of the cellular crystals and the distance between the columnar crystals will increase.

According to the Johnson–Mehl formula [

56]:

In the formula, k represents a constant, ∆T represents the material undercooling which is proportional to the cooling rate, P(t) represents the number of nuclei, N represents the nucleation rate which is proportional to exp(−1/(∆T2)), and v represents the grain growth rate which is proportional to ∆T. Both N and v are proportional to ∆T. The growth rate of the former is much greater than that of the latter. In the case of a large undercooling of the laser-melted powder, many nuclei are formed in the molten pool. On the other hand, the rapid cooling process inhibits the growth of the grains, resulting in fine grains.

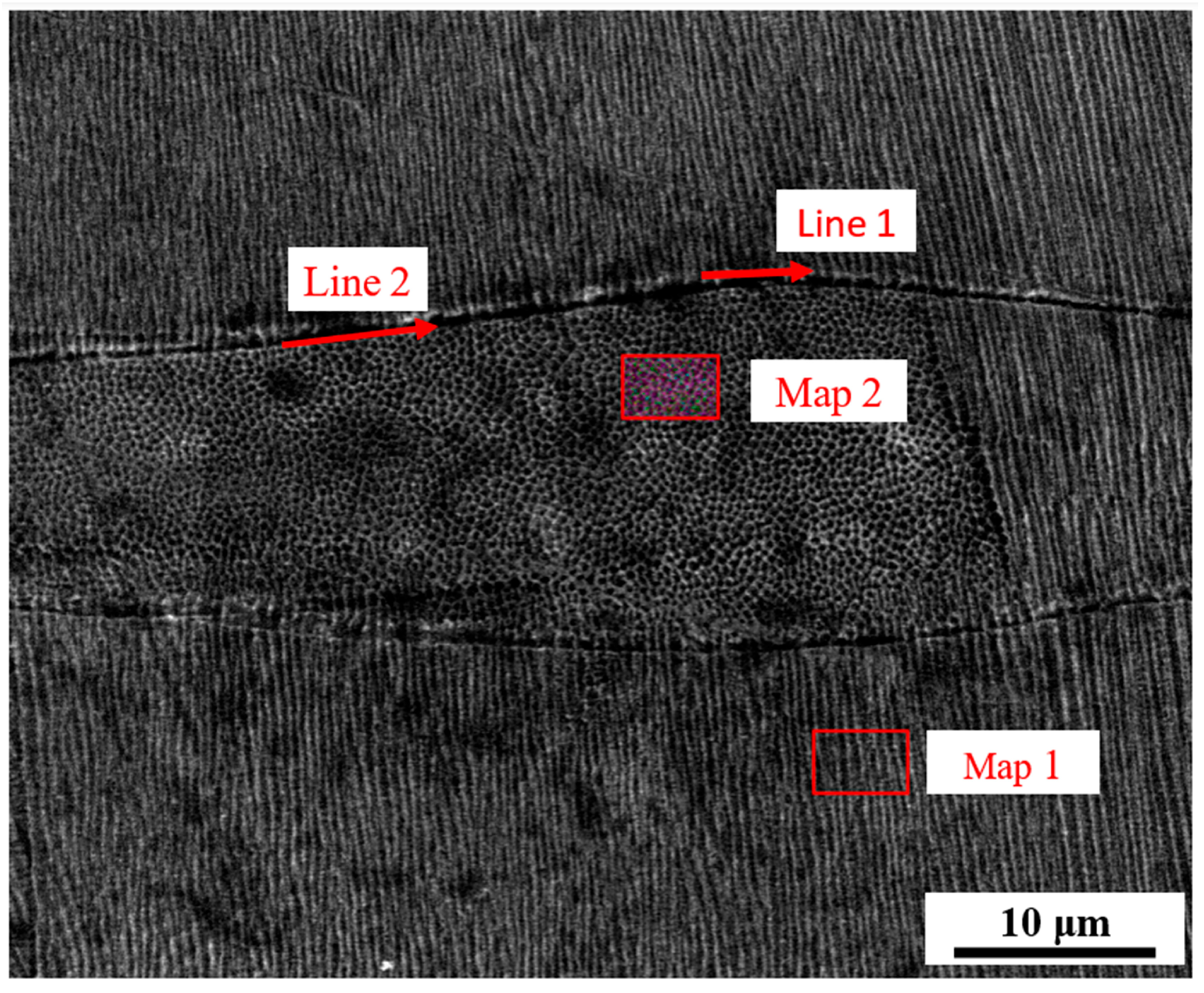

Figure 19 and

Table 3 present the elemental distribution and microstructural characteristics of 316L stainless steel specimens fabricated by laser powder bed fusion. Elemental mapping and line scans were performed on both cellular and columnar grain regions. As shown in Map 1 and Map 2 of

Figure 19, the chemical compositions of the columnar and cellular crystals were broadly similar. However, the grain boundaries of the cellular regions exhibited pronounced enrichment of chromium and nickel, consistent with solute segregation during rapid solidification. These elements are known to stabilize the austenitic phase and resist corrosion, which also makes the boundaries less responsive to chemical etching. This phenomenon explained the distinct white outlines observed around the cellular grains.

Table 3 provides quantitative results from energy dispersive spectroscopy (EDS). The grain boundaries in Map 1 and Map 2 showed elevated concentrations of chromium (13.73 wt% and 11.96 wt%) and nickel (26.64 wt% and 31.98 wt%), confirming microsegregation. Line 1 and Line 2 data show that the molten pool boundaries were enriched in carbon (5.67 wt% and 3.21 wt%), suggesting the formation of carbides at these locations. Carbides are typically hard and brittle, which can serve as crack initiation sites, especially under residual stress conditions during solidification and cooling. These carbide-rich regions were more susceptible to corrosion and fracture, reducing mechanical performance. This aligned with observations at higher scanning speeds, where many pores were located along molten pool boundaries. The SEM and EDS elemental maps in the larger area in

Figure S4 demonstrated a uniform distribution of Fe, Ni, Mo, and Cr throughout the microstructure of the LPBF-fabricated 316L stainless steel.

Microsegregation and repeated thermal cycling in LPBF can enhance diffusion, refine grain boundaries, and contribute to complex microstructural evolution. In this study, the distinction between grain interiors and boundaries, in terms of both chemistry and morphology, emphasized the significant role of solidification dynamics in determining final material properties. Qiu et al. [

50] found that there was no obvious difference in the elemental composition between the top and bottom of the molten pool. The columnar crystal structure at the bottom of the molten pool was not due to chemical factors but to different cooling rates.

The grain morphology observed in the LPBF-fabricated 316L stainless steel samples had a significant positive impact for implant applications. The microstructural analysis revealed predominantly fine, cellular, and columnar austenitic grains, which are characteristic of rapid solidification and high thermal gradients in the LPBF process. This refined grain structure was found to enhance both mechanical strength and ductility compared to conventionally processed 316L stainless steel. Such improvements are crucial for load-bearing implants, as they contribute to greater resistance to fatigue and fracture during physiological loading. Additionally, the presence of fine grains increases grain boundary area, which can hinder crack propagation and improve overall toughness—properties essential for the long-term reliability of biomedical implants. Recent studies [

22,

57] have also suggested that the unique columnar and cellular grain morphology produced by LPBF can promote favorable cellular responses at the tissue–implant interface, further supporting osseointegration and implant stability. Therefore, the grain morphology obtained in this study not only provided mechanical benefits but also reinforced the biological performance required for successful implant integration.

3.7. Mechanical Properties

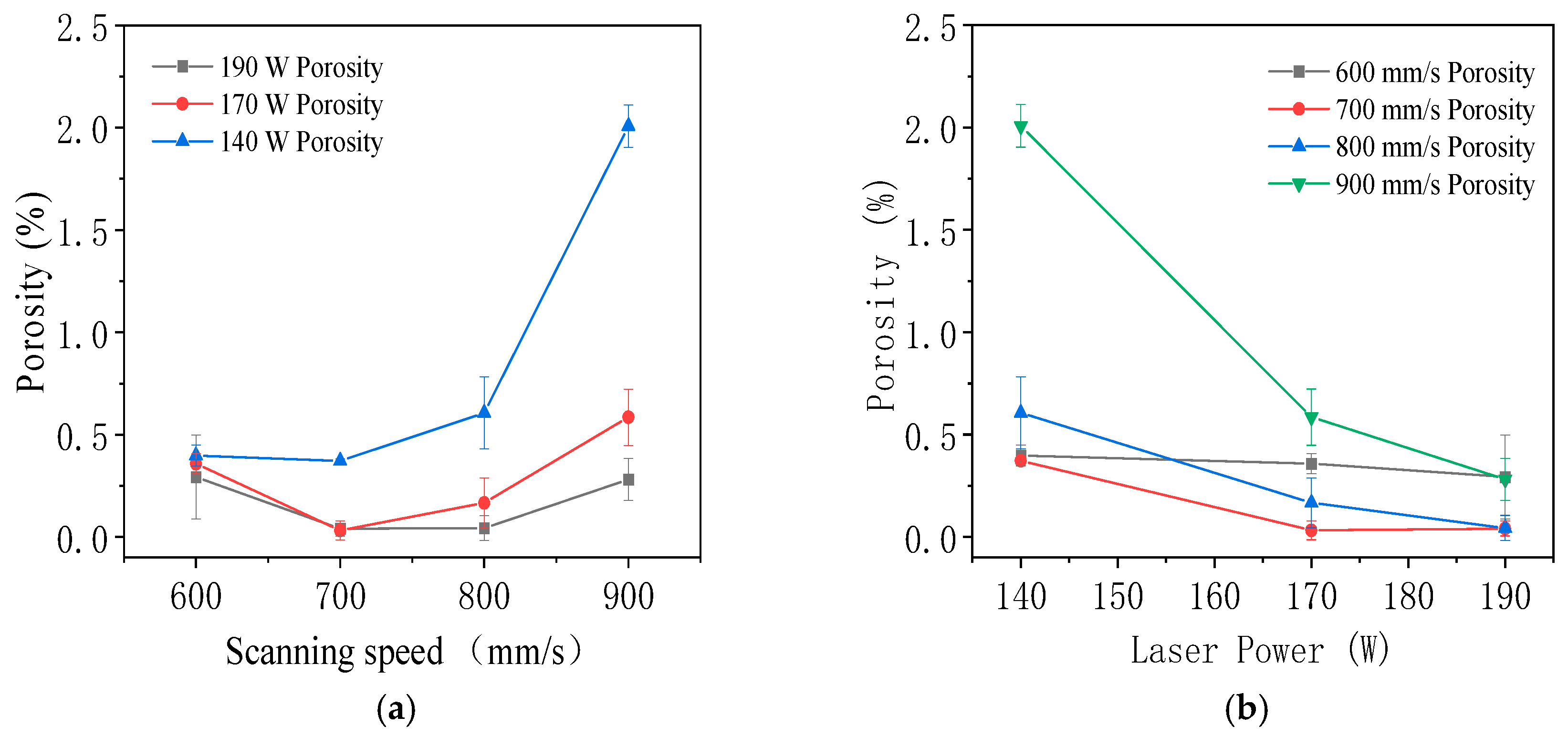

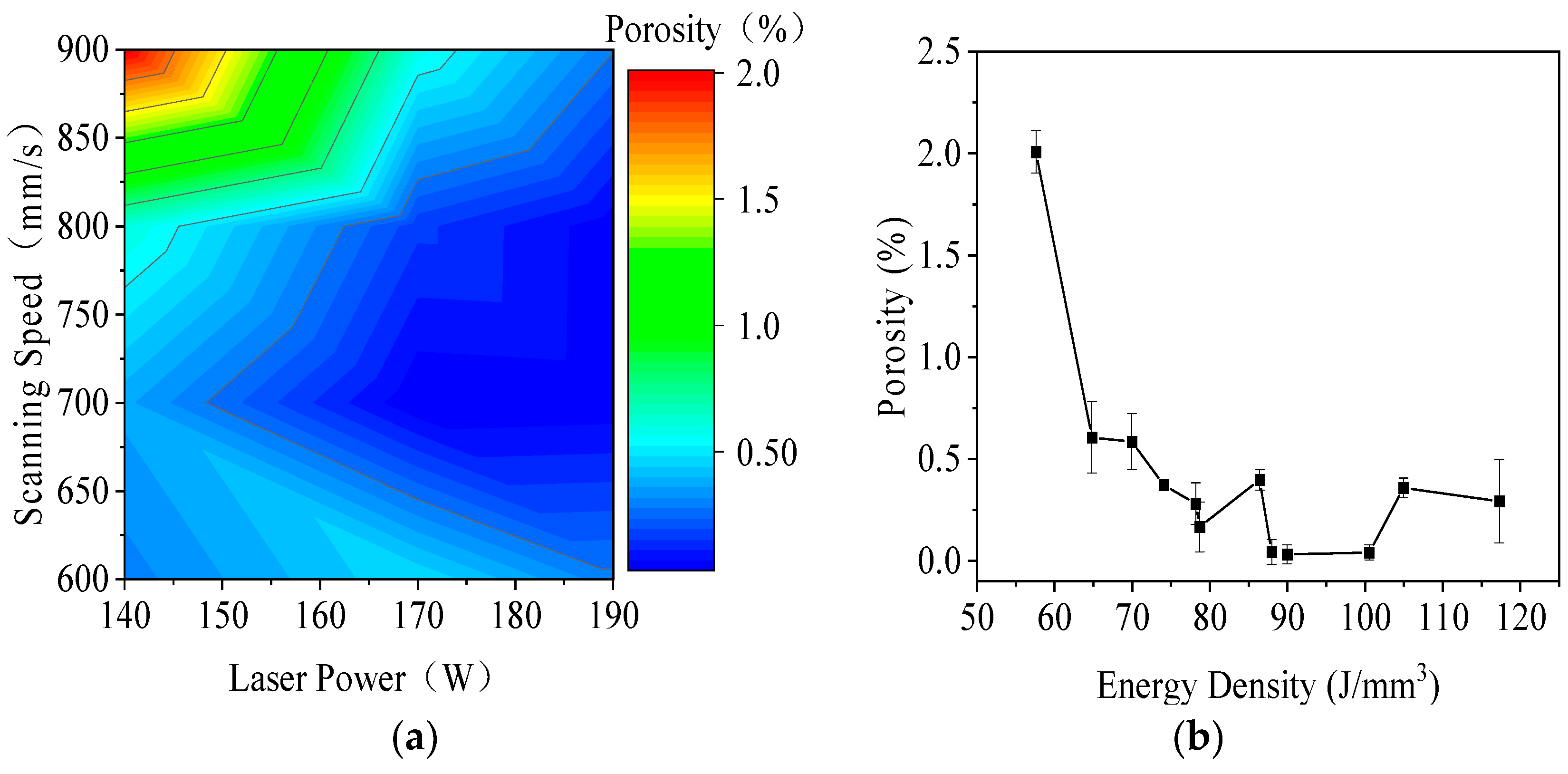

Figure 20 presents the engineering stress–strain curves of 316L stainless steel specimens fabricated by laser powder bed fusion under varying laser powers and scanning speeds. All specimens showed continuous plastic deformation without a distinct yield point, a behavior characteristic of austenitic stainless steels processed by rapid solidification. The overall trend indicated that higher energy input—achieved by lower scanning speeds or higher laser powers—resulted in greater tensile strength and elongation.

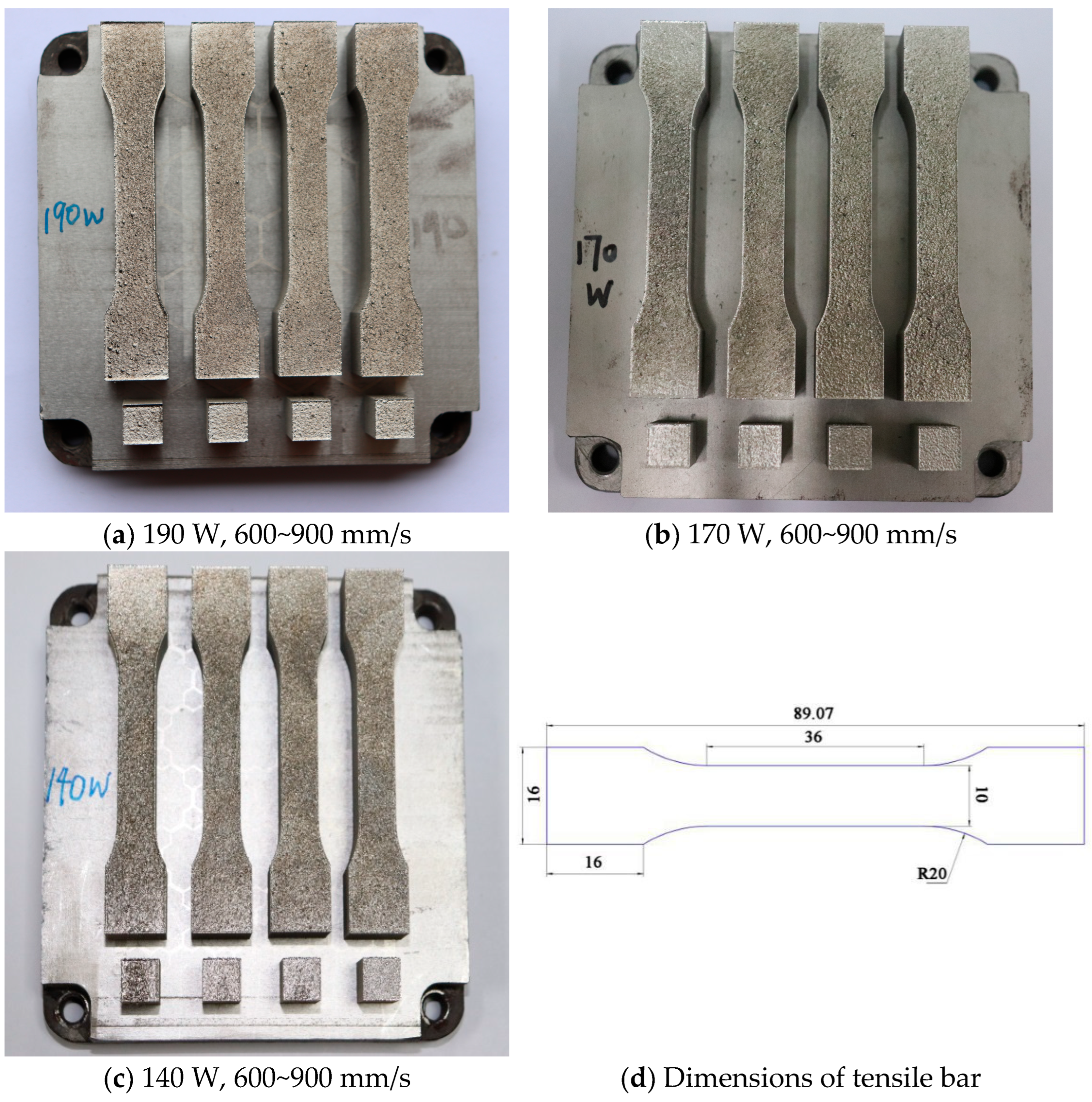

Figure S5 shows the tensile parts and metallographic specimens after cutting the 3D printed specimens on the substrate.

Figure S6 shows the fractured tensile part.

Figure 20a displays the curves for specimens fabricated at a scanning speed of 600 mm/s. These samples showed the highest tensile strengths and the longest strain ranges before fracture, reflecting dense microstructures and strong interlayer bonding. The elastic region in the stress–strain curves appears as a very short, steep initial segment due to the inherently small elastic strain range of 316L stainless steel compared to its extensive plastic deformation.

Figure 20b shows the results for specimens produced at 700 mm/s. Although slightly reduced compared to 600 mm/s, the mechanical response remained strong, with moderate strain hardening and ductility. In

Figure 20c, the specimens fabricated at 800 mm/s exhibit a further decrease in tensile strength and elongation. The curves began to steepen, indicating more brittle behavior due to reduced energy input and the onset of microstructural defects.

Figure 20d represents specimens printed at 900 mm/s, which showed the lowest mechanical performance across all conditions. These curves ended abruptly, corresponding to early failure likely caused by a lack of fusion, higher porosity, and unmelted powder particles.

The differences among the curves highlighted the strong dependence of mechanical properties on process parameters, with energy input directly influencing grain morphology, defect formation, and fracture resistance. These observations were consistent with fracture surface analyses and porosity trends discussed in related sections of the study.

As shown in

Table 4, the tensile strength and Vickers hardness of the 316L specimens formed by laser melting in the selected area under different process parameters in this experiment are shown, and the error is the standard deviation.

Table 4 summarizes the mechanical properties of 316L stainless steel specimens fabricated by laser powder bed fusion under twelve different combinations of laser power and scanning speed. The table includes values for energy density, ultimate tensile strength, and Vickers hardness, with each entry representing the average of three specimens and the accompanying standard deviation.

At 190 W, the specimen fabricated at 600 mm/s achieved a tensile strength of 736.72 MPa and a Vickers hardness of 242.06 HV0.2, corresponding to an energy density of 117.28 J/mm3. As the scanning speed increased to 700 mm/s, the energy density decreased to 100.53 J/mm3, but the hardness improved to 250.10 HV0.2, and the tensile strength remained high at 734.10 MPa, indicating a favorable balance of energy input and solidification dynamics. At 800 mm/s and 900 mm/s, the tensile strengths decreased to 724.01 MPa and 722.10 MPa, respectively, while hardness values also declined slightly, reflecting less stable molten pool formation and higher porosity at reduced energy input.

At 170 W, similar trends were observed. The specimen at 600 mm/s showed a tensile strength of 727.70 MPa and a hardness of 248.17 HV0.2, with an energy density of 104.94 J/mm3. With increasing scanning speed, tensile strength gradually declined from 723.81 MPa at 700 mm/s to 718.80 MPa at 900 mm/s. Hardness also dropped from 243.74 HV0.2 to 222.03 HV0.2, suggesting insufficient energy delivery at higher scanning speeds.

For 140 W, the lowest energy input conditions were applied. The specimen at 600 mm/s achieved a tensile strength of 707.10 MPa and a hardness of 224.87 HV0.2. As scanning speed increased to 700 mm/s, 800 mm/s, and 900 mm/s, tensile strength declined progressively from 699.88 MPa to 688.88 MPa, while hardness fluctuated modestly, with a minimum of 218.73 HV0.2 at 700 mm/s. These results indicated that low power combined with high scanning speed resulted in insufficient melting, reduced bonding between layers, and decreased mechanical performance.

Overall,

Table 4 demonstrated that both tensile strength and hardness were positively correlated with energy density up to an optimal range. Excessively high or low energy inputs led to degraded performance, either due to overheating and spatter or insufficient fusion. The data highlighted the importance of tuning process parameters to achieve a stable melt pool, low porosity, and refined grain structure, all of which are critical for enhancing the mechanical integrity of LPBF-fabricated components.

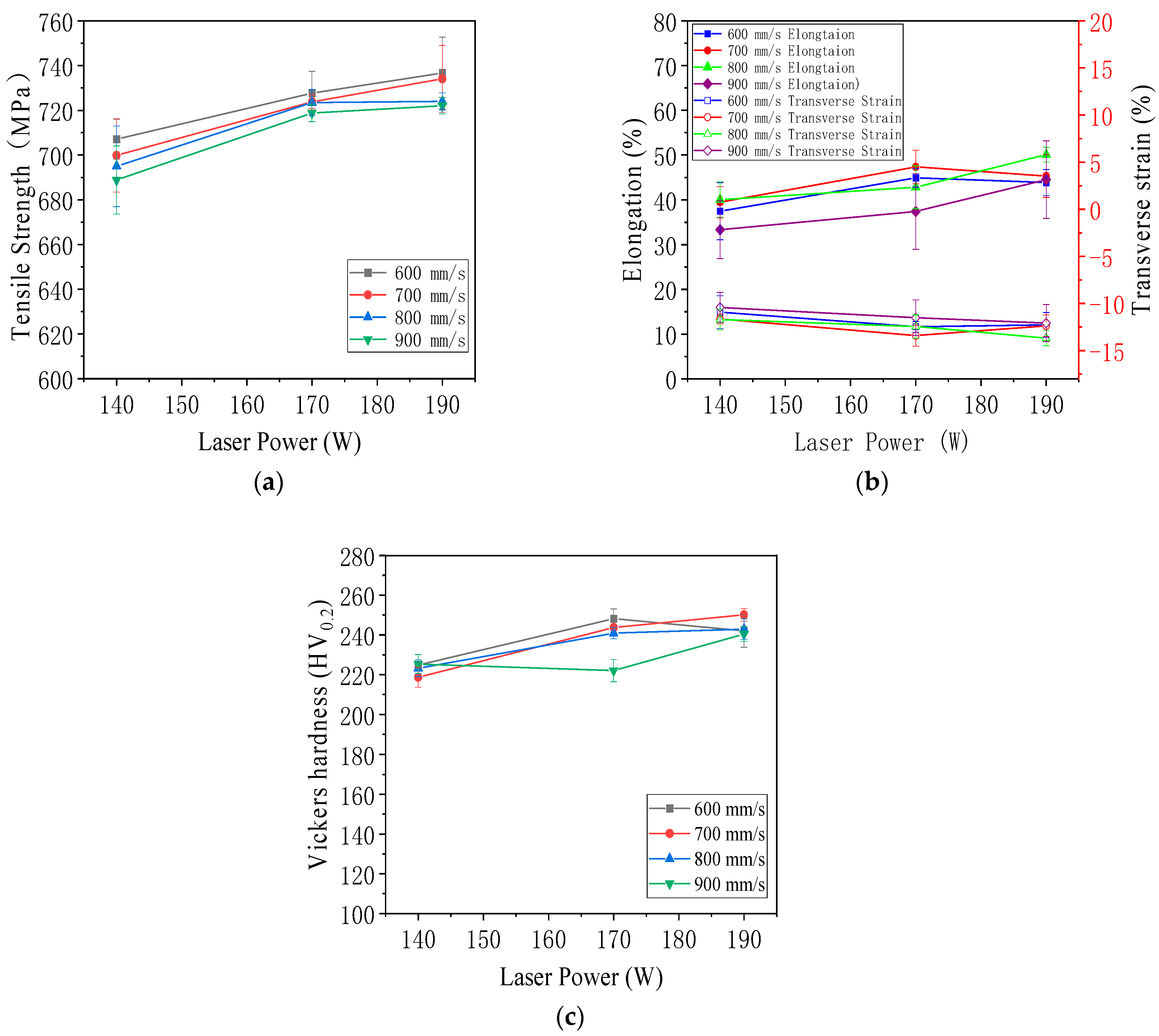

Figure 21a shows the effect of laser power on the ultimate tensile strength of LPBF-formed tensile specimens. The median value is the average of three groups of specimens, and the error is the standard deviation. The data and images show that at a certain scanning speed, the tensile strength of LPBF-formed tensile specimens increases with the increase in laser power. The standard deviation of the tensile strength at 140 W is large. The laser power is insufficient, and many holes are formed inside the tensile part. The size, number, and position of these pores are random and uncontrollable, resulting in a large standard deviation at low power. Under the process of laser power of 140 W and scanning speed of 900 mm/s, the lowest tensile strength of this experiment can be obtained, which is 660 MPa, and the energy density of this process is also the lowest in this experiment. Under the process of laser power of 190 W and scanning speed of 700 mm/s, the maximum tensile strength of this experiment can be obtained, which is 763 MPa, and the Vickers hardness obtained under this process parameter is also the largest. The maximum tensile strength obtained in this experiment is much higher than the 596 MPa of cast 316L stainless steel [

59] and the 625 MPa of 316L stainless steel [

60]. This result provides strong data support for using laser 3D printed 316L stainless steel to manufacture load-bearing parts.

Figure 21b shows the effect of laser power on the elongation and transverse strain of LPBF-formed tensile specimens. The median value is the average of three groups of specimens, and the error is the standard deviation. Under the process of 140 W and 900 mm/s, the minimum elongation of this test is 33.3%, and the minimum transverse strain is −10.4%. Under the process of 190 W and 800 mm/s, the maximum elongation of this test is 50.1%, and the maximum transverse strain is −13.7%. When the scanning speed is constant, the elongation of the tensile specimen formed by LPBF has a slight downward trend with the decrease in laser power, but this trend is not obvious. When the scanning speed is constant, as the laser power decreases, the absolute value of the transverse strain of the tensile specimen formed by LPBF also tends to decrease slightly. Therefore, the elongation and the absolute value of the transverse strain are positively correlated.

As shown in

Figure 21c, the effect of laser power on the Vickers hardness of LPBF-formed tensile specimens, the median value is the average of three groups of specimens, and the error is the standard deviation. The scanning speed is 900 mm/s, and the Vickers hardness of 140 W is slightly higher than that of 170 W. This is because the high scanning rate molten pool is shallow, which is prone to interlayer shedding, resulting in the non-randomness of the pores and measurement errors. The process parameters are laser power 190 W, scanning speed 700 mm/s, and the maximum average Vickers hardness value is 250.10 HV

0.2. Under this process, the maximum Vickers hardness value of this test is 253.07 HV

0.2. The process parameters are laser power 140 W, scanning speed 700 mm/s, and the minimum average Vickers hardness value is 218.73 HV

0.2. In addition, the minimum Vickers hardness value of this test is 217.83 HV

0.2 under this process. When the scanning speed is constant, with the increase in laser power, the Vickers hardness has a significant upward trend. The Vickers hardness and tensile strength are positively correlated.

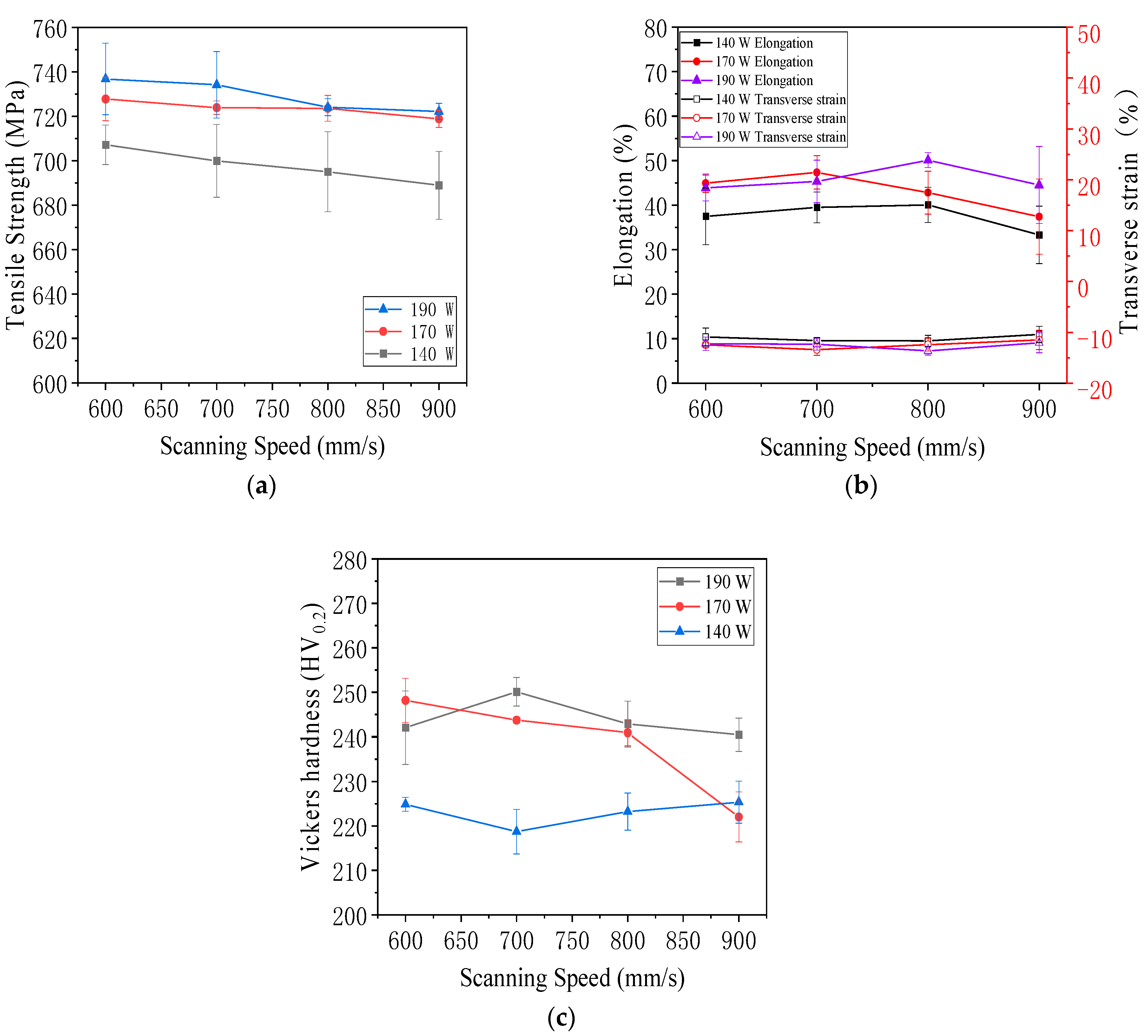

As shown in

Figure 22a, the scanning speed affects the ultimate tensile strength of the LPBF-built tensile specimen. The median value is the average of three groups of specimens, and the error is the standard deviation. It is easy to see from the data and images that when the laser power is constant, the ultimate tensile strength of the LPBF-built tensile specimen decreases with the scanning speed’s increase. Therefore, it can be concluded that the scanning speed is negatively correlated with the ultimate tensile strength of the LPBF-built tensile specimen.

As shown in

Figure 22b, the effect of scanning speed on the elongation and transverse strain of LPBF tensile specimens was presented. The median value represented the average of three groups of specimens, and the error was the standard deviation. The elongation fluctuated between 50.11% and 33.33%, and the elongation of the experimental group with a laser power of 140 W was the lowest. The transverse strain showed no obvious change and remained stable at −10.42% to −13.67%, with minimal variation.

As shown in

Figure 22c, the Vickers hardness of the experimental group with a laser power of 140 W is significantly the lowest, and the average hardness of the experimental groups with laser powers of 140 W and 190 W does not change significantly with the increase in scanning speed. When the laser power is 170 W, the Vickers hardness decreases significantly with the increase in scanning speed.

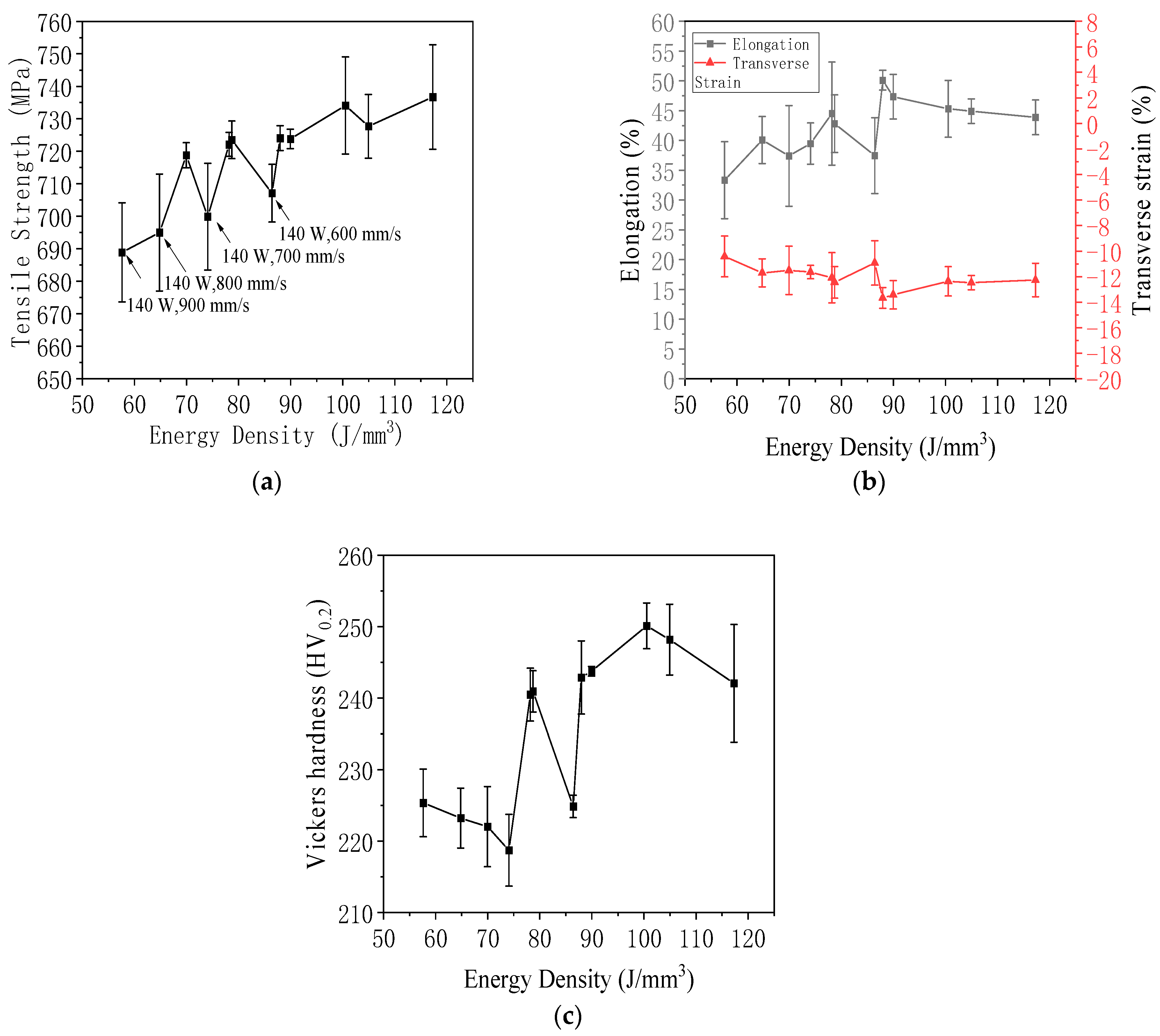

As shown in

Figure 23a, as the energy density increases, the overall trend of tensile strength is to increase. The tensile strength increases with the increase in energy density, and energy density is used as an indicator to measure selective laser melting [

61]. Compared with the experimental group with similar energy density, the tensile strength of the 140 W group is significantly lower. Therefore, this experiment found that energy density is not the only indicator determining tensile strength. When the energy density of two specimens is similar, the laser power plays a decisive role in their tensile strength.

Figure 23b illustrates the effect of energy density on the elongation and transverse strain of 316L stainless steel specimens fabricated by laser powder bed fusion. As energy density increased, elongation showed a general upward trend, indicating improved ductility. This enhancement was attributed to reduced porosity and stronger interlayer bonding at moderate to high energy inputs. At lower energy densities, elongation values were significantly lower, reflecting premature failure due to lack of fusion and the presence of internal defects. The transverse strain exhibited a corresponding pattern, with its absolute value increasing alongside elongation. This relationship reflected the Poisson effect typical of ductile metals, where materials with higher elongation also experienced greater lateral contraction. The inverse correlation between elongation and transverse strain was consistent with the behavior of 316L stainless steel, a material known to exhibit a positive Poisson’s ratio. These findings suggested that energy density played a critical role not only in determining strength but also in influencing the material’s plastic deformation characteristics. Optimizing energy input was therefore essential to balance strength and ductility for structural applications.

Figure 23c shows the relationship between energy density and Vickers hardness in 316L stainless steel specimens fabricated by laser powder bed fusion. As energy density increased, Vickers hardness exhibited a general upward trend. This was attributed to improved metallurgical bonding, reduced porosity, and more uniform microstructures achieved at higher energy input levels. The minimum average hardness of 218.37 HV

0.2 was observed at 74.07 J/mm

3 (140 W, 700 mm/s), while the maximum average value reached 250.10 HV

0.2 at 100.53 J/mm

3 (190 W, 700 mm/s). Although the energy density at 86.42 J/mm

3 (140 W, 600 mm/s) was close to the optimal range, the hardness remained lower than expected (224.87 HV

0.2), likely due to inconsistent melting or pore formation. The standard deviation in hardness was larger at both low and high extremes of energy density, suggesting increased variability due to defect concentration, such as a lack of fusion at low energy input and keyhole porosity or spatter at excessively high levels. This variability underscored the sensitivity of hardness to local structural inhomogeneities. The observed trend indicated that an energy density window between 90 J/mm

3 and 100 J/mm

3 was optimal for achieving high and stable hardness in LPBF-fabricated 316L stainless steel.

In summary, the mechanical properties of LPBF-fabricated 316L stainless steel were strongly influenced by laser power, scanning speed, and resulting energy density. Optimal mechanical performance, including high tensile strength, elongation, and Vickers hardness, was achieved at moderate to high energy densities, particularly around 100 J/mm3. Insufficient energy input led to poor interlayer bonding and increased porosity, while excessively high input introduced variability through keyhole defects and spatter. The results demonstrated that the fine-tuning of process parameters is essential to balance strength, ductility, and hardness, ensuring reliable structural performance in additively manufactured components.

3.8. Fracture Analysis

Figure 24 presents the fracture morphologies of two 316L stainless steel specimens fabricated by laser powder bed fusion, one with the highest tensile strength and one with the lowest. As shown in

Figure 24a, the low-strength specimen exhibited large pores with a measured porosity of 5.76%. In contrast,

Figure 24b showed that the high-strength specimen contained only a few small pores, with a porosity of about 0.44%. Both fracture surfaces displayed numerous micro-pits known as dimples, which are indicative of ductile fracture. The average diameter of these dimples was 7 µm. These features were not pre-existing voids but were generated during plastic deformation, confirming a ductile fracture mechanism.

Figure 24c showed an enlarged view of a pore from the low-strength sample, revealing numerous unmelted powder particles with diameters up to 109 µm. These particles acted as crack initiation sites during tensile loading.

Figure 24d illustrates the region surrounding the pore, where short, dense tearing ridges and curved river-like patterns are visible. These features are characteristic of quasi-cleavage fracture, a transitional mode combining brittle cleavage and ductile tearing.

Figure 24e further emphasizes this mixed fracture mode, showing both micropores and tearing edges. In contrast,

Figure 24f reveals a fully dimpled fracture surface, representative of a ductile failure. Some dimples enclosed fine unmelted particles around 3.22 µm in diameter, indicating that even under high-energy input conditions, complete powder melting was not always achieved. These residual particles may reduce mechanical performance by serving as localized stress concentrators.

From a biomaterials perspective, the fracture behavior of LPBF-fabricated 316L stainless steel is of critical importance for the safe and effective function of load-bearing implants. Ductile fracture characterized by the presence of equiaxed dimples, as observed in low-porosity specimens, is generally desirable for biomedical applications because it indicates substantial energy absorption before failure and enhances the structural reliability of implants under physiological loading conditions [

62]. This ductile mode of failure reduces the likelihood of sudden, catastrophic implant fracture, which is a key concern in orthopedic and dental applications. In contrast, the quasi-cleavage fracture surfaces found in specimens with higher porosity or unmelted particles may serve as early indicators of mechanical vulnerability. These features are often associated with brittle failure and lower energy absorption and may be linked to premature implant failure when subjected to cyclic loading in vivo [

63].

The presence and distribution of defects not only lower the fatigue resistance of the material but can also affect the biological response, as crack initiation sites may create pathways for fluid ingress, promote localized corrosion, and facilitate the release of metal ions or particles into the surrounding tissue [

64,

65]. Such events have been associated with inflammation, impaired osseointegration, and ultimately reduced implant longevity [

66]. Therefore, understanding and controlling fracture mechanisms through process parameter optimization are essential for developing LPBF 316L stainless steel implants that combine high mechanical performance with excellent biocompatibility and clinical safety.