Two Iterative Methods for Sizing Pipe Diameters in Gas Distribution Networks with Loops

Abstract

1. Introduction

- Classical problem: The flows need to be adjusted in an already existing network;

- Optimisation problem (subject of this article): The flows through the pipes are fixed, while the diameters of the pipes need to be adjusted (this refers to the design phase, when the network is still in a blueprint format).

- Efficiency: The correct pipe diameter ensures efficient gas flow within a network, minimising pressure drops and energy losses. This efficiency is essential in delivering gas to consumers without unnecessary waste.

- Cost-Effectiveness: Properly sized pipes help to reduce construction and operational costs. Oversized pipes require more materials and increase the initial expenses, while undersized pipes can lead to higher operating costs due to increased compression requirements.

- Pressure Control: Selecting the correct pipe diameter helps to maintain adequate pressure levels throughout the network. This is vital in ensuring a consistent and reliable gas supply to consumers, particularly in high-demand scenarios.

- Safety: An optimal pipe diameter helps to maintain safe operating conditions. If the pipes are too small, they may lead to over-pressurisation, potentially causing leaks or other safety hazards. Conversely, oversized pipes can lead to low pressure, which might result in inadequate gas delivery.

- System Reliability: Proper sizing reduces the risk of network failures, ensuring a more reliable gas distribution system. This is especially critical for industries, households, and businesses that depend on a continuous gas supply.

- Future Expansion: Selecting the optimal pipe diameters allows for the easier expansion of the gas distribution network when needed, accommodating growth and changes in demand.

2. Methods

- (A)

- Classical flow distribution problem in already existing networks of pipe with loops: A network for gas distribution is typically assumed to be predefined with an established topology (route [81]), including the pipe dimensions (length and diameter) and their characteristics (mostly the roughness of the inner pipe surface, which is a function of the material and age [82]), as well as the predetermined maximum gas consumption at network nodes (with gas income in the network treated as negative consumption). For such a network, assuming that pressure drops cannot compress the gas significantly, the flow distribution through the pipes of the network can be calculated for the steady state and usually for the working condition designed for the maximal load, i.e., for the largest possible consumption. The objective is to calculate the flow redistribution through the pipes of closed loops (a ring formed by several pipes), which can typically be achieved using numerous variations of the Hardy Cross method [3], where the two main variations are (1) loop-oriented methods and (2) node-oriented methods.

- Loop-oriented methods: These types of methods were originally introduced by Hardy Cross in 1936 [3] and later developed by Epp and Fowler in 1970 [38], Wood and Charles [28] and Wood and Rayes [29]. These types of methods require an initial assumption of a gas flow through each pipe of the network (initial guess [36]), which always needs to satisfy the mass balance in each node (first Kirchhoff law) and which is further adjusted through iterative calculation to satisfy the energy balance in each loop of the network at the end of calculation as the stopping criterion (second Kirchhoff law). Two main approaches are commonly used.

- 1.1

- Hardy Cross method: An adjustment in each iteration is made by calculating flow correction ΔQ, which needs to be algebraically added to the value from the previous iteration following specific rules [5,7] (acceleration was given by Epp and Fowler in 1970 [38], while one possible rearrangement of this method for gas distribution was given by Brkić in 2009 [5]).

- 1.2

- Node-loop method: Wood and Charles [28] and Wood and Rayes [29], to avoid the inconvenience of using ΔQ, introduced the node-loop method (belonging to the group of loop-oriented methods), which gives the new flow as Q (and not as Q = Qi−1 + ΔQ). The node-loop method for gas distribution was presented by Brkić and Praks in 2019 [6].

- Node-oriented methods: Similar reasoning as for loop-oriented methods applies to the group of loop-oriented methods, with the difference being that the energy balance for each contour in the network of pipes (second Kirchhoff law) should always be satisfied, while the mass balance for each node (first Kirchhoff law) needs to be achieved at the end of the calculation. This approach was introduced by Shamir and Howard in 1968 [34].

- B

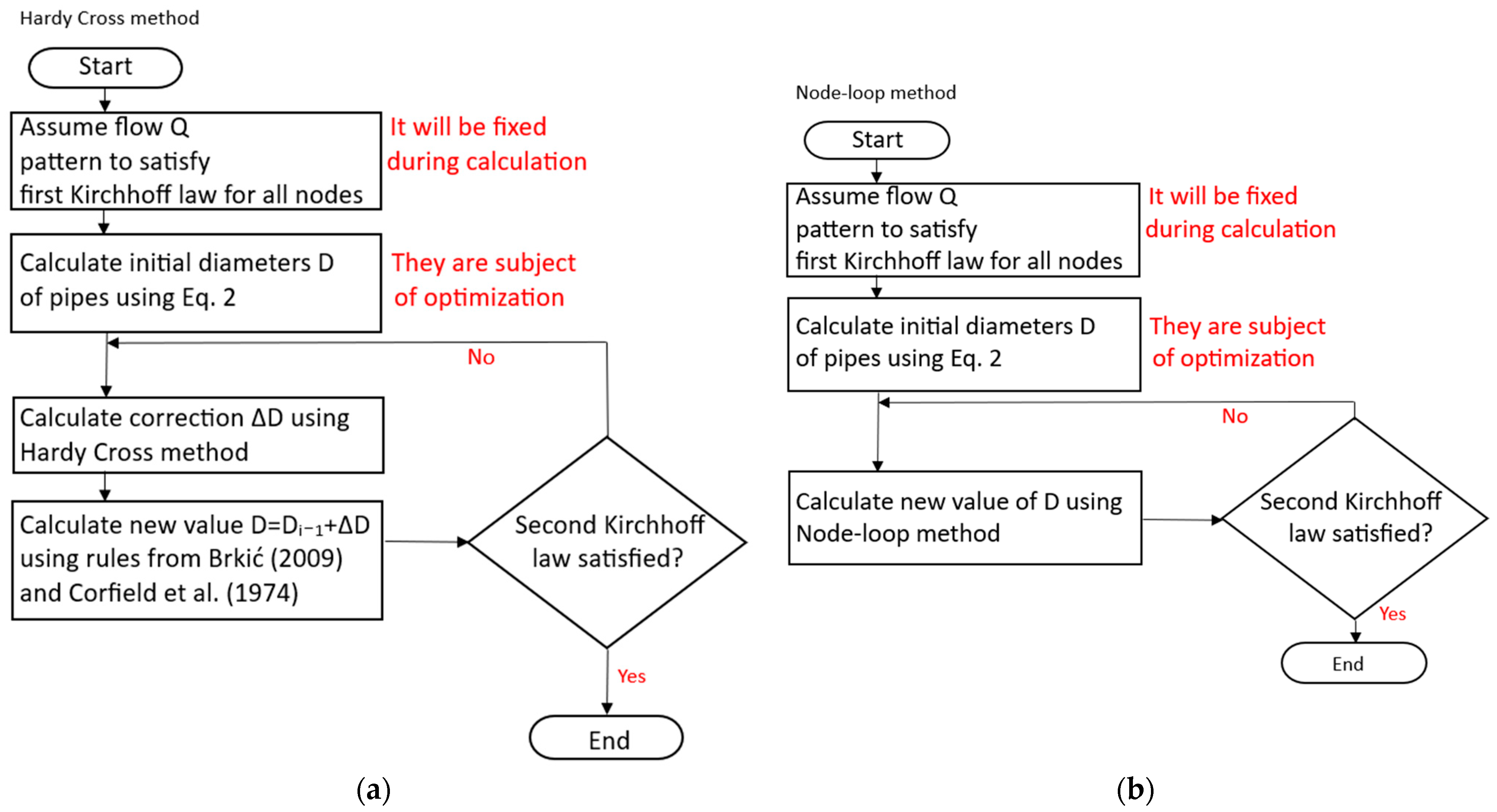

- Optimisation problem (subject of this article): In gas distribution network design and operation, it is essential to determine the optimal pipe diameters to minimise energy losses and ensure efficient gas flow. Pipe diameter calculations are often intertwined with flow and pressure calculations, requiring an iterative approach to find the best compromise between the pipe size and price. By adjusting parameters like the pipe diameter and pressure settings, network operators can aim for an ideal balance between the satisfaction of consumers and operational expenses. In the optimisation problem, the distribution of flow through the branches of a network of pipes (flow pattern) is known in advance and is not subject to changes during calculation (it is decided to keep the velocity of gas below certain prescribed technical limits, to allow the further expansion of the network or to satisfy a future increase in consumption and demand). Following the diagrams from Figure 1, this article provides two iterative methods for the optimisation of the pipe diameters for a fixed flow rate.

- Hardy Cross method with the correction of the diameter ΔD in each iteration: D = Di−1 + ΔD; see Figure 1a and Section 2.3.1 of this article.

- Node-loop method with the direct calculation of the diameter in each iteration: direct calculation of D; see Figure 1b and Section 2.3.2 of this article.

2.1. Literature Overview

- Detailed explanation of the correction of flow ΔQ in the Hardy Cross method [7] (with application to the correction of diameters ΔD during optimisation);

- Explanations of the first and second Kirchhoff laws for nodes and loops [12];

- Hydraulic models and equations for gas flow and its connection to the pressure drop [18];

- Classical versus optimisation approach applied to water distribution networks [22];

- A book with explanations of various methods for flow networks with loops applied to water distribution [25];

- Flow pattern in already existing pipe network with loops [36];

- Very illustrative but simple example of application of Hardy Cross and node-loop methods for water distribution [37];

- Approach involving virtual loop that connects two nodes with the same pressure in order to ensure a linear independent matrix needed for calculation (also application of the methods to ventilation systems of underground mines) [39];

- Safety [101].

2.2. Relation among Gas Flow, Pressure and Pipe Diameter

2.3. Iterative Methods for Optimisation of Pipe Diameters

2.3.1. Improved Hardy Cross Method

2.3.2. Node-Loop Method

3. Results and Discussion—Selection of Standardised Diameters

4. Conclusions

- Estimate consumption (maximal amount of gas consumed by households or industry);

- Assign the consumption to the nodes of the future network and choose locations for the nodes (it is fixed during calculation);

- Connect nodes with pipes, forming closed paths, i.e., loops (assign length of pipes, but not diameter);

- Redistribute the desired flow through the network considering the first Kirchhoff law for every node (it is fixed during calculation);

- Calculate the initial diameters using Equation (2) and optimise them using the methods shown;

- Select the diameters from the standardised values using the recommendations from Table 3;

Funding

Data Availability Statement

Conflicts of Interest

References

- Manojlović, V.; Arsenović, M.; Pajović, V. Optimized design of a gas-distribution pipeline network. Appl. Energy 1994, 48, 217–224. [Google Scholar] [CrossRef]

- Brkić, D. A gas distribution network hydraulic problem from practice. Petr. Sci. Technol. 2011, 29, 366–377. [Google Scholar] [CrossRef]

- Cross, H. Analysis of Flow in Networks of Conduits or Conductors; University of Illinois at Urbana Champaign, College of Engineering Experiment Station: College Station, TX, USA, 1936; Available online: http://hdl.handle.net/2142/4433 (accessed on 3 October 2023).

- Brkić, D.; Praks, P. Short overview of early developments of the Hardy Cross type methods for computation of flow distribution in pipe networks. Appl. Sci. 2019, 9, 2019. [Google Scholar] [CrossRef]

- Brkić, D. An improvement of Hardy Cross method applied on looped spatial natural gas distribution networks. Appl. Energy 2009, 86, 1290–1300. [Google Scholar] [CrossRef]

- Brkić, D.; Praks, P. An efficient iterative method for looped pipe network hydraulics free of flow-corrections. Fluids 2019, 4, 73. [Google Scholar] [CrossRef]

- Corfield, G.; Hunt, B.E.; Ott, R.J.; Binder, G.P.; Vandaveer, F.E. Distribution design for increased demand. In Gas Engineers Handbook; Segeler, C.G., Ed.; Chapter 9; Industrial Press: New York, NY, USA, 1974; pp. 63–83. [Google Scholar]

- Cross, H. Analysis of continuous frames by distributing fixed-end moments. Trans. Am. Soc. Civ. Eng. 1932, 96, 1–10. [Google Scholar] [CrossRef]

- Volokh, K.Y. On foundations of the Hardy Cross method. Int. J. Solids Struct. 2002, 39, 4197–4200. [Google Scholar] [CrossRef]

- Baugh, J.; Liu, S. A general characterization of the Hardy Cross method as sequential and multiprocess algorithms. Structures 2016, 6, 170–181. [Google Scholar] [CrossRef]

- Reza, F. Some topological considerations in network theory. IRE Trans. Circuit Theory 1958, 5, 30–42. [Google Scholar] [CrossRef]

- Kirby, E.C.; Mallion, R.B.; Pollak, P.; Skrzyński, P.J. What Kirchhoff actually did concerning spanning trees in electrical networks and its relationship to modern graph-theoretical work. Croatica Chemica Acta 2016, 89, 403–417. [Google Scholar] [CrossRef]

- Ekhtiari, A.; Dassios, I.; Liu, M.; Syron, E. A novel approach to model a gas network. Appl. Sci. 2019, 9, 1047. [Google Scholar] [CrossRef]

- Farzaneh-Gord, M.; Rahbari, H.R. Unsteady natural gas flow within pipeline network, an analytical approach. J. Nat. Gas Sci. Eng. 2016, 28, 397–409. [Google Scholar] [CrossRef]

- Amani, H.; Kariminezhad, H.; Kazemzadeh, H. Development of natural gas flow rate in pipeline networks based on unsteady state Weymouth equation. J. Nat. Gas Sci. Eng. 2016, 33, 427–437. [Google Scholar] [CrossRef]

- Walters, G.; Swan, D.; Smith, D. Pipe system pressure probabilities with fluctuating demands. Civ. Eng. Syst. 1993, 10, 259–274. [Google Scholar] [CrossRef]

- Sircar, A.; Yadav, K. Optimization of city gas network: A case study from Gujarat, India. SN Appl. Sci. 2019, 1, 769. [Google Scholar] [CrossRef]

- Coelho, P.M.; Pinho, C. Considerations about equations for steady state flow in natural gas pipelines. J. Braz. Soc. Mech. Sci. Eng. 2007, 29, 262–273. [Google Scholar] [CrossRef]

- Niazkar, M.; Afzali, S.H. Analysis of water distribution networks using MATLAB and Excel spreadsheet: Q-based methods. Comput. Appl. Eng. Educ. 2017, 25, 277–289. [Google Scholar] [CrossRef]

- Niazkar, M.; Afzali, S.H. Analysis of water distribution networks using MATLAB and Excel spreadsheet: H-based methods. Comput. Appl. Eng. Educ. 2017, 25, 129–141. [Google Scholar] [CrossRef]

- Niazkar, M.; Eryılmaz Türkkan, G. Application of third-order schemes to improve the convergence of the Hardy Cross method in pipe network analysis. Adv. Math. Phys. 2021, 2021, 6692067. [Google Scholar] [CrossRef]

- Brkić, D. Spreadsheet-based pipe networks analysis for teaching and learning purpose. Spreadsheets Educ. 2016, 9, 4646. Available online: https://sie.scholasticahq.com/article/4646.pdf (accessed on 3 October 2023).

- Spiliotis, M.; Tsakiris, G. Water distribution system analysis: Newton-Raphson method revisited. J. Hydraul. Eng. 2011, 137, 852–855. [Google Scholar] [CrossRef]

- Simpson, A.; Elhay, S. Jacobian matrix for solving water distribution system equations with the Darcy-Weisbach head-loss model. J. Hydraul. Eng. 2011, 137, 696–700. [Google Scholar] [CrossRef]

- Boulos, P.F.; Lansey, K.E.; Karney, B.W. Comprehensive Water Distribution Systems Analysis Handbook for Engineers and Planners, 2nd ed.; MWH: Broomfield, CO, USA, 2006. [Google Scholar]

- Lopes, A.M.G. Implementation of the Hardy-Cross method for the solution of piping networks. Comput. Appl. Eng. Educ. 2004, 12, 117–125. [Google Scholar] [CrossRef]

- Huddleston, D.H.; Alarcon, V.J.; Chen, W. Water Distribution network analysis using Excel. J. Hydraul. Eng. 2004, 130, 1033–1035. [Google Scholar] [CrossRef]

- Wood, D.J.; Charles, C.O.A. Hydraulic network analysis using linear theory. J. Hydraul. Div. Am. Soc. Civ. Eng. 1972, 98, 1157–1170. [Google Scholar] [CrossRef]

- Wood, D.J.; Rayes, A.G. Reliability of algorithms for pipe network analysis. J. Hydraul. Div. Am. Soc. Civ. Eng. 1981, 107, 1145–1161. [Google Scholar] [CrossRef]

- Mah, R.S.H.; Lin, T.D. Comparison of Modified Newton’s methods. Comput. Chem. Eng. 1980, 4, 75–78. [Google Scholar] [CrossRef]

- Mah, R.S.H.; Shacham, M. Pipeline network design and synthesis. Adv. Chem. Eng. 1978, 10, 125–209. [Google Scholar] [CrossRef]

- Mah, R.S.H. Pipeline network calculations using sparse computation techniques. Chem. Eng. Sci. 1974, 29, 1629–1638. [Google Scholar] [CrossRef]

- Hamam, Y.M.; Brameller, A. Hybrid method for the solution of piping networks. Proc. Inst. Electr. Eng. 1971, 118, 1607–1612. [Google Scholar] [CrossRef]

- Shamir, U.; Howard, C.D.D. Water distribution systems analysis. J. Hydraul. Div. Am. Soc. Civ. Eng. 1968, 94, 219–234. [Google Scholar] [CrossRef]

- Ateş, S. Hydraulic modelling of closed pipes in loop equations of water distribution networks. Appl. Math. Model. 2016, 40, 966–983. [Google Scholar] [CrossRef]

- Gay, B.; Middleton, P. The solution of pipe network problems. Chem. Eng. Sci. 1971, 26, 109–123. [Google Scholar] [CrossRef]

- Brkić, D. Discussion of “Economics and statistical evaluations of using Microsoft Excel Solver in pipe network analysis” by Oke, I.A.; Ismail, A.; Lukman, S.; Ojo, S.O.; Adeosun, O.O.; Nwude, M.O. J. Pipeline Syst. Eng. Pract. 2018, 9, 7018002. [Google Scholar] [CrossRef]

- Epp, R.; Fowler, A.G. Efficient code for steady-state flows in networks. J. Hydraul. Div. Am. Soc. Civ. Eng. 1970, 96, 43–56. [Google Scholar] [CrossRef]

- Mathews, E.H.; Köhler, P.A.J. A numerical optimization procedure for complex pipe and duct network design. Int. J. Numer. Methods Heat Fluid Flow 1995, 5, 445–457. [Google Scholar] [CrossRef]

- Jha, K.; Mishra, M.K. Object-oriented integrated algorithms for efficient water pipe network by modified Hardy Cross technique. J. Comput. Des. Eng. 2020, 7, 56–64. [Google Scholar] [CrossRef]

- da Silva Teixeira, G.; Alonso, G.V.; Mendes, L.J. Evaluation of Nonlinear Iterative Methods on Pipe Network//Evaluación de Métodos Iterativos no Lineales en Redes de Tuberías. Ingeniería Mecánica 2021, 24, e656. Available online: https://ingenieriamecanica.cujae.edu.cu/index.php/revistaim/article/view/656 (accessed on 27 November 2023).

- Pons Poblet, J.M. The Hardy Cross method and its implementation in Spain. Revista Digital Lampsakos 2020, 1, 56–69. [Google Scholar] [CrossRef]

- Gokyay, O. An easy MS Excel software to use for water distribution system design: A real case distribution network design solution. J. Appl. Water Eng. Res. 2020, 8, 290–297. [Google Scholar] [CrossRef]

- Demir, S.; Karadeniz, A.; Yörüklü, H.C.; Demir, N.M. An MS Excel tool for parameter estimation by multivariate nonlinear regression in environmental engineering education. Sigma J. Eng. Nat. Sci. 2017, 35, 265–273. [Google Scholar] [CrossRef]

- Jaramillo, A.; Saldarriaga, J. Fractal analysis of the optimal hydraulic gradient surface in water distribution networks. J. Water Resour. Plan. Manag. 2023, 149, 4022074. [Google Scholar] [CrossRef]

- Martin-Candilejo, A.; Santillán, D.; Garrote, L. Pump Efficiency analysis for proper energy assessment in optimization of water supply systems. Water 2020, 12, 132. [Google Scholar] [CrossRef]

- Raoni, R.; Secchi, A.R.; Biscaia, E.C., Jr. Novel method for looped pipeline network resolution. Comput. Chem. Eng. 2017, 96, 169–182. [Google Scholar] [CrossRef]

- Sugishita, K.; Abdel-Mottaleb, N.; Zhang, Q.; Masuda, N. A growth model for water distribution networks with loops. Proc. R. Soc. A Math. Phys. Eng. Sci. 2021, 477, 20210528. [Google Scholar] [CrossRef]

- Zhong, D.; Wang, L.; Wang, J.; Jia, M. An efficient mine ventilation solution method based on minimum independent closed loops. Energies 2020, 13, 5862. [Google Scholar] [CrossRef]

- Dziurzyński, W.; Krach, A.; Pałka, T. Airflow sensitivity assessment based on underground mine ventilation systems modeling. Energies 2017, 10, 1451. [Google Scholar] [CrossRef]

- Pach, G.; Różański, Z.; Wrona, P.; Niewiadomski, A.; Zapletal, P.; Zubíček, V. Reversal ventilation as a method of fire hazard mitigation in the mines. Energies 2020, 13, 1755. [Google Scholar] [CrossRef]

- McPherson, M.J. Ventilation network analysis. Subsurf. Vent. Environ. Eng. 1993, 209–240. [Google Scholar] [CrossRef]

- Zhou, L.; Bahrami, D. A derivative method to calculate resistance sensitivity for mine ventilation networks. Min. Metall. Explor. 2022, 39, 1833–1839. [Google Scholar] [CrossRef]

- Jokić, A.; Zavargó, Z. Optimization of pipeline network for oil transport. Hung. J. Ind. Chem. 2001, 29, 113–117. [Google Scholar] [CrossRef]

- Kazemzadeh, H.; Amani, H.; Kariminezhad, H. Evaluation of pipeline networks to predict an increase in crude oil flow rate. Int. J. Press. Vessel. Pip. 2021, 191, 104374. [Google Scholar] [CrossRef]

- Shestakov, R.A. Research of distribution of oil flow in the pipeline with looping. J. Phys. Conf. Ser. 2020, 1679, 052035. [Google Scholar] [CrossRef]

- Talebi, B.; Mirzaei, P.A.; Bastani, A.; Haghighat, F. A review of district heating systems: Modeling and optimization. Front. Built Environ. 2016, 2, 22. [Google Scholar] [CrossRef]

- Guelpa, E. Impact of network modelling in the analysis of district heating systems. Energy 2020, 213, 118393. [Google Scholar] [CrossRef]

- Murat, J.; Smyk, A.; Laskowski, R.M. Selecting optimal pipeline diameters for a district heating network comprising branches and rings, using graph theory and cost minimization. J. Power Technol. 2018, 98, 30–44. Available online: https://papers.itc.pw.edu.pl/index.php/JPT/article/view/1287 (accessed on 11 October 2023).

- Eames, I.; Austin, M.; Wojcik, A. Injection of gaseous hydrogen into a natural gas pipeline. Int. J. Hydrog. Energy 2022, 47, 25745–25754. [Google Scholar] [CrossRef]

- Chandrasekar, A.; Syron, E. Evaluation of heat decarbonization strategies and their impact on the Irish gas network. Gases 2021, 1, 180–198. [Google Scholar] [CrossRef]

- Elaoud, S.; Hafsi, Z.; Hadj-Taieb, L. Numerical modelling of hydrogen-natural gas mixtures flows in looped networks. J. Pet. Sci. Eng. 2017, 159, 532–541. [Google Scholar] [CrossRef]

- Praks, P.; Lampart, M.; Praksová, R.; Brkić, D.; Kozubek, T.; Najser, J. Selection of appropriate symbolic regression models using statistical and dynamic system criteria: Example of waste gasification. Axioms 2022, 11, 463. [Google Scholar] [CrossRef]

- Praks, P.; Brkić, D.; Najser, J.; Najser, T.; Praksová, R.; Stajić, Z. Methods of Artificial Intelligence for Simulation of Gasification of Biomass and Communal Waste. In Proceedings of the 22nd International Carpathian Control Conference (ICCC), Velké Karlovice, Czech Republic, 31 May–1 June 2021. [Google Scholar] [CrossRef]

- Cheli, L.; Guzzo, G.; Adolfo, D.; Carcasci, C. Steady-state analysis of a natural gas distribution network with hydrogen injection to absorb excess renewable electricity. Int. J. Hydrog. Energy 2021, 46, 25562–25577. [Google Scholar] [CrossRef]

- Abbas, A.J.; Hassani, H.; Burby, M.; John, I.J. An investigation into the volumetric flow rate requirement of hydrogen transportation in existing natural gas pipelines and its safety implications. Gases 2021, 1, 156–179. [Google Scholar] [CrossRef]

- Vysocký, J.; Foltyn, L.; Brkić, D.; Praksová, R.; Praks, P. Steady-State Analysis of Electrical Networks in Pandapower Software: Computational Performances of Newton–Raphson, Newton–Raphson with Iwamoto Multiplier, and Gauss–Seidel Methods. Sustainability 2022, 14, 2002. [Google Scholar] [CrossRef]

- Renouard, M.P. Nouvelles règles à calcul pour la détermination des pertes de charge dans les conduites de gaz. J. Usines À Gaz 1952, 10, 337–339. (In French) [Google Scholar]

- Renouard, P. Méthode de calcul concernant l’écoulement du gaz en conduits. Travaux 1962, 329, 179. (In French) [Google Scholar]

- Piotrowski, R.; Ujazdowski, T. Designing control strategies of aeration system in biological WWTP. Energies 2020, 13, 3619. [Google Scholar] [CrossRef]

- Bagajewicz, M.; Valtinson, G. Computation of natural gas pipeline hydraulics. Ind. Eng. Chem. Res. 2014, 53, 10707–10720. [Google Scholar] [CrossRef]

- Ouyang, L.B.; Aziz, K. Steady-state gas flow in pipes. J. Pet. Sci. Eng. 1996, 14, 137–158. [Google Scholar] [CrossRef]

- Schroeder, D.W., Jr. A Tutorial on Pipe Flow Equations. In Proceedings of the PSIG Annual Meeting, Bonita Springs, FL, USA, 11–14 May 2010; Paper Number: PSIG-1008a. Available online: https://onepetro.org/PSIGAM/proceedings-abstract/PSIG10/All-PSIG10/2431 (accessed on 3 October 2023).

- Colebrook, C.F. Turbulent flow in pipes, with particular reference to the transition region between the smooth and rough pipe laws. J. Inst. Civ. Eng. 1939, 11, 133–156. [Google Scholar] [CrossRef]

- Brkić, D.; Stajić, Z. Excel VBA-based user defined functions for highly precise Colebrook’s pipe flow friction approximations: A comparative overview. Facta Univ. Ser. Mech. Eng. 2021, 19, 253–269. [Google Scholar] [CrossRef]

- Praks, P.; Brkić, D. Review of new flow friction equations: Constructing Colebrook’s explicit correlations accurately. Rev. Int. Metodos Numer. Calc. Diseño Ing. 2020, 36, 41. [Google Scholar] [CrossRef]

- Carvajal, J.; Zambrano, W.; Gómez, N.; Saldarriaga, J. Turbulent flow in PVC pipes in water distribution systems. Urban Water J. 2020, 17, 503–511. [Google Scholar] [CrossRef]

- Aynsley, R.M. A Resistance approach to analysis of natural ventilation airflow networks. J. Wind Eng. Ind. Aerodyn. 1997, 67–68, 711–719. [Google Scholar] [CrossRef]

- Anonymous. Pipeline-network analyzer. J. Frankl. Inst. 1952, 254, 195. [Google Scholar] [CrossRef]

- Taherinejad, M.; Hosseinalipour, S.M.; Madoliat, R. Dynamic simulation of gas pipeline networks with electrical analogy. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 4431–4441. [Google Scholar] [CrossRef]

- Toktoshov, G.Y. The routes choosing methodology for laying networks in three-dimensional space. In Proceedings of the 17th International Asian School-Seminar “Optimization Problems of Complex Systems (OPCS)”, Novosibirsk, Russian, 13–17 September 2021; pp. 139–143. [Google Scholar] [CrossRef]

- Zhao, Q.; Wu, W.; Simpson, A.R.; Willis, A. Simpler is better—Calibration of pipe roughness in water distribution systems. Water 2022, 14, 3276. [Google Scholar] [CrossRef]

- Chaubey, S.K.; Gupta, K.; Madić, M. An investigation on mean roughness depth and material erosion speed during manufacturing of stainless-steel miniature ratchet gears by wire-EDM. Facta Univ. Ser. Mech. Eng. 2023, 21, 239–258. [Google Scholar] [CrossRef]

- Chaubey, S.K.; Gupta, K. A review on Wire-EDM of bio titanium. Rep. Mech. Eng. 2023, 4, 141–152. [Google Scholar] [CrossRef]

- Odell, W.W. Facts Relating to the Production and Substitution of Manufactured Gas for Natural Gas (No. 301). Department of Commerce, Bureau of Mines. 1929. Available online: https://books.google.com/books?hl=en&lr=&id=st4RRgrGA3sC&oi=fnd&pg=PA1&ots=A0gdw9fRsE&sig=0jy_T3hokBlDwzEA9BtdO_ye5AY (accessed on 1 December 2023).

- Anonymous. Substitution of manufactured gas for natural gas. J. Frankl. Inst. 1930, 209, 121–125. [Google Scholar] [CrossRef]

- Rimos, S.; Hoadley, A.F.; Brennan, D.J. Determining the economic consequences of natural gas substitution. Energy Convers. Manag. 2014, 85, 709–717. [Google Scholar] [CrossRef]

- Featherstone, R.E.; El-Jumaily, K.K. Optimal diameter selection for pipe networks. J. Hydraul. Eng. 1983, 109, 221–234. [Google Scholar] [CrossRef]

- Arumugam, A.; Subramani, S.; Kibrom, H.; Gebreamlak, M.; Mengstu, M.; Teame, M. Comparison and validation of models for the design of optimal economic pipe diameters: A case study in the Anseba region, Eritrea. TecnoLógicas 2021, 24, e1992. [Google Scholar] [CrossRef]

- ElZahar, M.M.H.; Amin, M.M.M. Optimization of water pipe network and formulation of pumping rate. KSCE J. Civ. Eng. 2023, 27, 2882–2890. [Google Scholar] [CrossRef]

- Brkić, D.; Praks, P.; Praksová, R.; Kozubek, T. Symbolic regression approaches for the direct calculation of pipe diameter. Axioms 2023, 12, 850. [Google Scholar] [CrossRef]

- Lamri, A.A.; Easa, S.M. Explicit solution for pipe diameter problem using Lambert W-function. J. Irrig. Drain. Eng. 2022, 148, 04022030. [Google Scholar] [CrossRef]

- Brkić, D.; Stajić, Z.; Živković, M. Sizing pipes without iterative calculus: Solutions for head loss, flow discharge and diameter. In Proceedings of the 24th International Carpathian Control Conference, Szilvásvárad, Hungary, 12–14 June 2023. [Google Scholar] [CrossRef]

- ISO 6708:1995; Pipework Components—Definition and Selection of DN (Nominal Size). International Organization for Standardization,: Geneva, Switzerland. Available online: https://www.iso.org/standard/21274.html (accessed on 3 October 2023).

- Debnath, L. A brief historical introduction to Euler’s formula for polyhedra, topology, graph theory and networks. Int. J. Math. Educ. Sci. Technol. 2010, 41, 769–785. [Google Scholar] [CrossRef]

- Hu, G.; Qiu, W.Y.; Ceulemans, A. A new Euler’s formula for DNA polyhedra. PLoS ONE 2011, 6, e26308. [Google Scholar] [CrossRef]

- Pîrvan-Moldovan, A.; Diudea, M.V. Euler characteristic of polyhedral graphs. Croat. Chem. Acta 2016, 89, 471–479. [Google Scholar] [CrossRef]

- Alrumaih, T.N.; Alenazi, M.J. GENIND: An industrial network topology generator. Alex. Eng. J. 2023, 79, 56–71. [Google Scholar] [CrossRef]

- Filo, G. Artificial intelligence methods in hydraulic system design. Energies 2023, 16, 3320. [Google Scholar] [CrossRef]

- Tawfik, A.M. Hydraulic solutions of pipeline systems using artificial neural networks. Ain Shams Eng. J. 2023, 14, 101896. [Google Scholar] [CrossRef]

- Brkić, D.; Praks, P. Probability analysis and prevention of offshore oil and gas accidents: Fire as a cause and a consequence. Fire 2021, 4, 71. [Google Scholar] [CrossRef]

- Règle a Calcul Pertes de Charge Dans les Canalisations de gaz a Basse Pression (in French). Available online: https://photocalcul.com/Calcul/Regles/Notices-regles/notice_GraphoplexGDF_908445.pdf (accessed on 14 December 2023).

- Brkić, D.; Praks, P. Discussion of “Explicit solution for pipe diameter problem using Lambert W-function” by Lamri, A.A.; Easa, S.M. J. Irrig. Drain. Eng. 2023, 149, 07023016. [Google Scholar] [CrossRef]

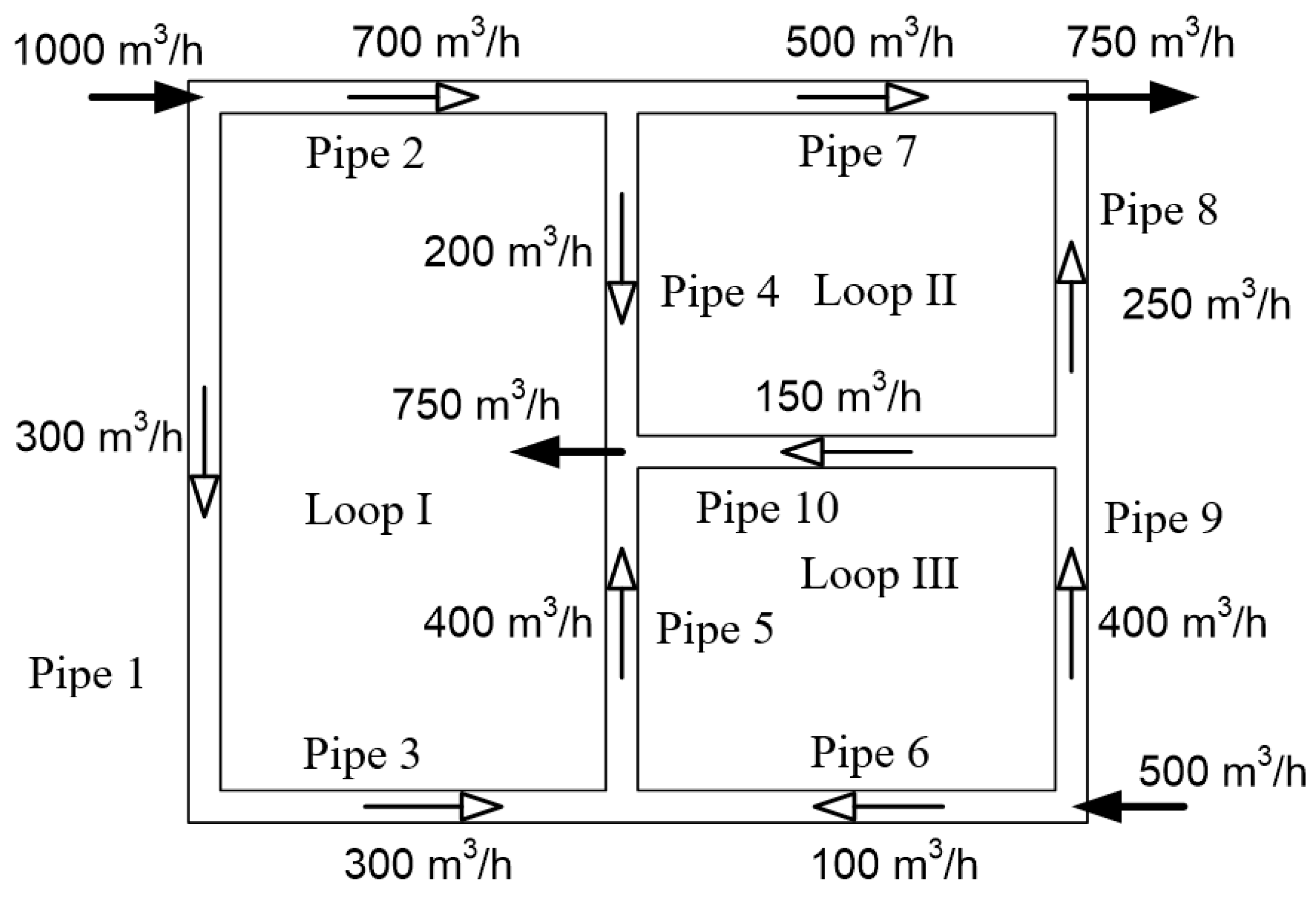

| Nodes between/among Pipes | Inflow/Outflow 1 | Flow Qst | |

|---|---|---|---|

| m3/h | m3/s | ||

| 1 and 2 | Inflow | +1000 | +0.27778 |

| 6 and 9 | Inflow | +500 | +0.13889 |

| 4, 5 and 10 | Outflow | −750 | −0.20833 |

| 7 and 8 | Outflow | −750 | −0.20833 |

| Σ | 0 | 0 | |

| Pipe | Length L | Fixed flow Qst | 1 Initial Diameter D | |

|---|---|---|---|---|

| m | m3/h | m3/s | m | |

| 1 | 200 | 300 | 0.083333333 | 0.042052209 |

| 2 | 100 | 700 | 0.194444444 | 0.064235810 |

| 3 | 100 | 300 | 0.083333333 | 0.042052209 |

| 4 | 100 | 200 | 0.055555556 | 0.034335485 |

| 5 | 100 | 400 | 0.111111111 | 0.048557708 |

| 6 | 100 | 100 | 0.027777778 | 0.024278854 |

| 7 | 100 | 500 | 0.138888889 | 0.054289168 |

| 8 | 100 | 250 | 0.069444444 | 0.038388239 |

| 9 | 100 | 400 | 0.111111111 | 0.048557708 |

| 10 | 100 | 150 | 0.041666667 | 0.029735402 |

| Initial | Improved Hardy Cross | Node Loop | ||||||

|---|---|---|---|---|---|---|---|---|

| Final | Standard Diameter Dn | Final | Standard Diameter Dn | |||||

| Pipe | 1 Diameter D | Velocity u | Diameter D | 2 Velocity u | Diameter D | 2 Velocity u | ||

| m | m/s | M | m/s | mm | m | m/s | mm | |

| 1 | 0.042052209 | 15 | 0.045862467 | 12.61 | 40 | 0.045306252 | 12.92 | 40 |

| 2 | 0.06423581 | 15 | 0.060425552 | 16.95 | 65 | 0.108246703 | 5.28 | 90 or 100 |

| 3 | 0.042052209 | 15 | 0.045862467 | 12.61 | 40 | 0.049136481 | 10.99 | 40 |

| 4 | 0.034335485 | 15 | 0.032068353 | 17.20 | 40 | 0.03146551 | 17.86 | 40 |

| 5 | 0.048557708 | 15 | 0.052026572 | 13.07 | 50 | 0.073402904 | 6.56 | 50 or 65 |

| 6 | 0.024278854 | 15 | 0.023937460 | 15.43 | 25 | 0.024266423 | 15.02 | 32 |

| 7 | 0.054289168 | 15 | 0.052746042 | 15.89 | 65 | 0.076781193 | 7.50 | 50 or 65 |

| 8 | 0.038388239 | 15 | 0.039931365 | 13.86 | 32 | 0.056199567 | 7.00 | 32 or 40 |

| 9 | 0.048557708 | 15 | 0.048899102 | 14.79 | 40 | 0.084311913 | 4.98 | 90 or 100 |

| 10 | 0.029735402 | 15 | 0.028533670 | 16.29 | 32 | 0.028112346 | 16.78 | 32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brkić, D. Two Iterative Methods for Sizing Pipe Diameters in Gas Distribution Networks with Loops. Computation 2024, 12, 25. https://doi.org/10.3390/computation12020025

Brkić D. Two Iterative Methods for Sizing Pipe Diameters in Gas Distribution Networks with Loops. Computation. 2024; 12(2):25. https://doi.org/10.3390/computation12020025

Chicago/Turabian StyleBrkić, Dejan. 2024. "Two Iterative Methods for Sizing Pipe Diameters in Gas Distribution Networks with Loops" Computation 12, no. 2: 25. https://doi.org/10.3390/computation12020025

APA StyleBrkić, D. (2024). Two Iterative Methods for Sizing Pipe Diameters in Gas Distribution Networks with Loops. Computation, 12(2), 25. https://doi.org/10.3390/computation12020025