Abstract

Reducing methane (CH4) is a key objective to address climate change quickly. Manure management and storage play a significant role. In this context, a real-scale trial was performed to measure the ability of the commercial additive SOP LAGOON to reduce carbon-based greenhouse gas (GHG) emissions from liquid manure over approximately 4 months. Gas emissions were measured at a commercial dairy farm from two slurry tanks, one treated with the abovementioned product (SL) and the other used as the untreated control (UNT). After 3 and 4 months from the first additive applications, the SL storage tank showed lower and statistically significantly different emissions concerning the UNT (up to −80% for CH4 and −75% for CO2, p < 0.001), confirming and showing improved results from those reported in the previous small-scale works. The pH of the UNT tank was lower than that of the SL on two dates, while the other chemical characteristics of the slurry were not affected. In this work, SOP LAGOON proved to be an effective additive to help the farmers mitigate the contribution of stored liquid manure to global CH4 emissions, potentially improving the overall sustainability of the dairy industry.

Keywords:

methane; CO2; climate change; manure; slurry; dairy; sustainability; mitigation; emissions 1. Introduction

The Sixth Assessment Report of the Intergovernmental Panel on Climate Change [1] urges immediate action to slow warming in the near term. The most recent projections on climate foresee a 50:50 chance of a temperature rise over the threshold of 1.5 °C above pre-industrial levels within the next 5 years [2], especially if the emissions from the food system are not addressed [3]. In this light, the scientific community and the industry alike are focusing with increasing attention on the so-called short-lived climate pollutants (SLCP), such as methane (CH4), as a key mitigation strategy [4] to limit the climate impact of human activities and avoid up to 0.6 °C of warming by 2050 [5]. The global warming potential (GWP) of CH4 on a 100-year timescale is considered 28 times greater than carbon dioxide (CO2) [6]. More recently, the new Global Warming Potential Stars (GWP*) was proposed, which recalculates the impact of CH4, taking into account the shorter lifespan, a 20-year timescale, of this gas in the atmosphere [7] before it is converted to CO2 [8] by a hydroxyl oxidation reaction. The proposed value for CH4 in the GWP* model is 84 times that of CO2, implying that these emissions have a more significant impact on the climate than previously estimated. Reducing the CH4 emissions associated with human activity by 50% over the next 30 years could mitigate a global temperature change of 0.2 °C by 2050, a significant step towards keeping the temperature increase below 2 °C [6]. In this light, the European Commission and the US government launched a climate-related initiative, the Global Methane Pledge [9], at COP26 in Glasgow, inviting the joining countries to set national goals to reduce CH4. The initiative now has 150 signatory countries after COP27, 50 more than when the initiative was launched [10].

Strategies to mitigate SLCP are therefore put in place to give a more decisive contribution to the national climate goals. For example, the California Senate Bill 1383 [11] has required the implementation of the SLCP strategy by 1 January 2018. The strategy includes a 40% CH4 emission reduction from 2013 levels by 2030. The EU aims to become carbon neutral by 2050, with a 2030 milestone of reducing at least 55% of CH4 emissions from the 1990 levels [12], with binding national emission reduction targets under the Effort Sharing Regulation (ESR). In December 2021, an amendment to this regulation was proposed [13] as part of implementing the increased emissions reductions target for 2030. The methane strategy identifies actions to accelerate the CH4 emissions reduction in line with that ambition [14].

Agricultural activities contribute to global production and are estimated to account for about 12% of the total anthropogenic GHG emissions [15], 10% to 12% of CO2 and 40% of CH4 [16], globally. The most significant sources of CH4 from agriculture are manure management (4%), rice cultivation (10%) and enteric fermentation in ruminants (29%) [17].

As reported, the dairy sector is a contributor to these emissions: while globally over 90% of CH4 emissions in the dairy sector are connected to enteric fermentations [18], in concentrated animal feed operations (CAFOs), common in most of the developed countries, liquid manure plays an important role.

Amon et al. [19] reported that more than 90% of GHG emissions from slurry originate from CH4 emissions during the storage phase. In Italy, in 2020, CH4 emissions from the manure management from dairy cows were 920 kton of CO2eq [20], representing 14.2% of CH4 emissions for the sector, while a recent study from the California Air Resources Board (CARB) indicates that 57% of CH4 emissions from the dairy sector in California are attributed to manure management and 43% to enteric fermentation [21].

An increasing number of studies have investigated the ability of feed additives to reduce enteric emissions [22,23,24,25], although the timing for their broad application remains to be determined.

Different techniques have been developed for CH4 emission abatement from liquid manure, such as solid–liquid separation, anaerobic digestion, slurry acidification, storage cover and slurry additives. Mosquera et al. [26] reported that liquid separation could reduce CH4 emissions by up to 42% while [27] reported that anaerobic digestion reduced the emissions by up to 35% compared to raw manure. Misselbrook et al. [28] found that acidification reduced CH4 emissions by 61% while Amon et al. [29], with storage cover, reported an abatement ability of up to 70%.

Besides CH4, CO2 emissions can be of interest in reducing the impact of slurry storage. Unfortunately, information about this gas and its reduction remains sparse.

In efforts to promote economic and environmental sustainability for dairy farms, slurry additives are considered with increasing interest, as they might represent a simple and economic way to address the GHG emissions from liquid manure.

The commercial additive for the liquid manure SOP LAGOON proved to be effective in reducing CH4 (and CO2) emissions from slurry in two lab-scale tests [30,31]. This work aims to investigate this product’s ability to reduce carbon-based emissions (namely CH4 and CO2) on commercial-scale farms and to investigate other potential benefits on manure management.

2. Materials and Methods

2.1. Site and Manure Management Description

The trials campaign was carried out in 2021 at a dairy farm in the Po Valley, Northern Italy, characterized by humid continental to subtropical climates (Cfa following Köppen classification).

The farm operates a total herd of about 520 heads, half of which are lactating cows, and is representative of typical housing and farming practices found in concentrated animal feeding operations (CAFOs): the animals are housed in a free stall system with straw as topping for the bedding. Animal waste is mainly handled as slurry and is conveyed through scrapers and pumping systems into two adjacent, separate, concrete storage tanks.

During the experiment, the tanks were filled on alternate days with the same type of slurry. The manure was collected for distribution on the fields uniformly from both tanks, aiming at keeping the depth of the slurry in both tanks equal for the duration of the tests.

Both tanks were mixed the day before the measurement using a propeller mixer coupled to a tractor. This was done to break up the possible crust that could form on top of the tanks, which could prevent the release of gaseous emissions. Furthermore, these activities simulate how the farmer manages the tanks before emptying them. The filling level of the tanks was also measured on the day of the gas measurements. This allowed us to confirm that the ratio of emitting surface per volume present was similar between the two storage tanks on each testing day. On the first day of measurement, the surface per volume ratio was approximately 0.35 m2/m3 in both tanks; the following measurements registered higher ratios of between 0.4 and 0.5 m2/m3, as the tanks were partially, and always uniformly, emptied for field distribution.

SOP LAGOON, SQE034 + SQE610 (www.sopfarm.com, accessed on 1 December 2022), the additive under test, is made up of 100% calcium sulfate dihydrate (gypsum) processed with proprietary technology.

The product was added to one of the two tanks (SOP LAGOON: SL), while the other tank was left as the control (untreated: UNT).

The additive was administered according to the manufacturer’s specifications provided in the technical data sheet of the product: the recommended application method consists of weekly applications of 2 g per animal contributing the slurry to the tank, with an additional dose in the first month for the activation period of 4 g/m3 of slurry already stored in the tank at the time of the first addition. In these test conditions, a total of 40 kg of the product was added over the first 4 weeks, and a total of 11 kg was added from week 5 to the end of the experiment.

The first application of SOP LAGOON was done on 27 May.

2.2. Slurry Analysis

Slurry samples from different positions in the tanks were collected during each measurement day. The chemical composition of the slurry was analyzed to characterize the matrix and to verify any effects of the treatment. Samples were stored in small air-tight containers refrigerated at 4 °C prior to laboratory analysis.

Analyses of the samples for total solids (TS), volatile solids (VS), total Kjeldahl nitrogen (TKN), total ammoniacal nitrogen (TAN), pH and total organic carbon were performed according to standard methods for the examination of water and wastewater [32].

2.3. Emission and Fluxes Determination

The emissions of CH4 and CO2 originating from the two tanks were assessed throughout four surveys to analyze the entire duration of the slurry storage. The surveys were carried out approximately one month apart (14 days in the case of the last measurement), starting after the first month of activation, from June until September.

Following the reference VERA protocol [33] (Test Protocol Covers and other Mitigation Technologies for Stored Manure—Version 3: 2018-07), and considering the surface of the tanks, five measurement points were installed for each one tank. A floating funnel was positioned at each measuring point, from which the air was sampled.

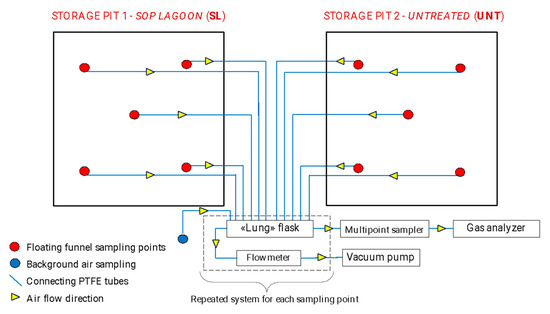

The measurement system was conceived referring to previous studies on livestock waste emissions, in particular [34,35]. The whole system, shown schematically in Figure 1, consisted of:

Figure 1.

Scheme of the system for sampling and measuring air samples from above the two slurry storage pits under study.

- Floating PVC funnels, positioned on the slurry surface. The funnels have a diameter of 42 cm. Each funnel covers a surface equal to approximately 0.14 m2, for a total covered area for each pit of approximately 0.7 m2, thus greater than the 0.5 m2 suggested by the aforementioned VERA protocol;

- PTFE tubes that connected each floating funnel with a corresponding “lung flask”, hermetically sealed with rubber stoppers. Utilizing a vacuum generated by a pump positioned downstream of the system, the air was sucked by the multi-component gas analyzer from each lung flask, passing through a multipoint gas sampler. The use of external pumps was necessary to support the emissive flow towards the lung flasks, because the vacuum generated by the small pump bundled with the multi-component gas analyzer was insufficient to overcome the hydraulic resistance of the PTFE tubes (several tens of meters long);

- A 12-way multipoint gas sampler (MGS) to which the floating funnels in the two slurry tanks (five for the UNT and five for the SL) were connected via IN channels. An additional channel was used to sample the background air (“white”) to check the atmospheric concentration of the gases under study. The multipoint gas sampler device allows the user to open one channel at a time, via solenoid valves, for a chosen time interval and to define the order of the opening and closing of the different channels. Finally, the MGS was connected via the OUT channel to the gas analyzer: a real time assessment of gases was done with a high-resolution spectrometer (ETG FTIR 9500, Chivasso, Italy) that exploits the Fourier transformed IR spectroscopy (FTIR) technique. The instrument collects a complete infrared spectrum at regular intervals, which is scanned in full, allowing the simultaneous detection and measurement of different gases present in the air at a given time. The measurement time interval, and the unit of measurement with which to express the gas concentration (mg/m3 or ppm), can be set manually. The instrument has a resolution of 0.01 ppm for CH4 and 1 ppm for CO2.

Following the VERA protocol, sampling for each point was carried out for a 30 min period. The measurement period of the gas analyzer was set as low as possible, equal to approximately 43 s, resulting in a total of approximately 40 measurements per point every 30 min. The measurements were carried out by sampling alternating points from the SL tank and the UNT tank; this was done to prevent a potential bias in the data due to the daily variability of climatic conditions. Data regarding the average hourly temperature during measurement periods were retrieved from a nearby public climate control unit and considered in the data analysis. The background air was sampled for a time interval equal to 12 min between one point and another. The expected air-flow through the funnels was about 1.5 L/min, verified via electric flow meters.

The emission flows of the gases in question were finally calculated using Equation (1):

where:

F = (Q × (Cin − Cout))/A

- F is the GHG flux (mg/m2/h);

- Q is the air flow (m3/h);

- Cin is the gas concentration in the air above the slurry surface, sampled by the funnel system (mg/m3);

- Cout is the corresponding background gas air concentration (mg/m3);

- A is the surface of the funnel (m2).

2.4. Data Analysis

The data were analyzed by the analysis of variance (ANOVA) procedure using SPSS version 28. The sampling point within a single tank was considered as a replication. The average temperature during each point sampling was used as the covariate. Each sampling data were analyzed separately.

A two-way ANOVA was carried out to obtain indications about a possible interaction between the treatment and the sampling date.

3. Results

3.1. Slurry Chemical Characteristics

The results did not show numerically relevant differences in the chemical parameters between the UNT and SL. An average of the slurry characteristics is therefore reported in Table 1.

Table 1.

Average slurry chemical characteristics.

Table 1.

Average slurry chemical characteristics.

| Variable | Value |

|---|---|

| TS (%) | 8.43 ± 0.12 |

| VS (% TS) | 74.25 ± 0.5 |

| TKN (g/kg) | 3.70 ± 0.06 |

| TAN (g/kg) | 1.69 ± 0.03 |

| TAN (% TKN) | 0.46 ± 0.01 |

| Organic Carbon (%DM) | 40.20 ± 0.20 |

± Standard error; TS: total solids; VS: volatile solids; TKN: total Kjeldahl nitrogen; TAN: total ammoniacal nitrogen; DM: dry matter.

The chemical composition of the slurry was in the range typically reported in the literature [36].

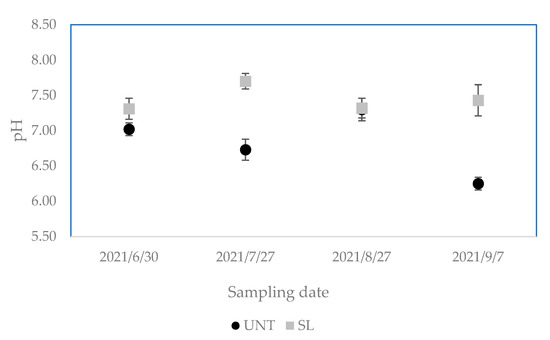

The pH analyses were statistically different on two of the four sampling dates, so the results are reported in Figure 2.

Figure 2.

pH values. Bars indicate the standard error of the measurements. Plotted values represent the average per each treatment, SL or UNT, in the sampling dates.

It is possible to observe that the pH was similar on day one and day three, but was lower and statistically significantly different (p < 0.001) in the UNT than in the SL on days two and four (−0.97 and −1.18, respectively), when the lowest values were recorded.

3.2. Gas Emissions

In this experiment, the slurry additive SOP LAGOON was tested at the tank scale level to evaluate its ability to reduce CH4 and CO2 emissions.

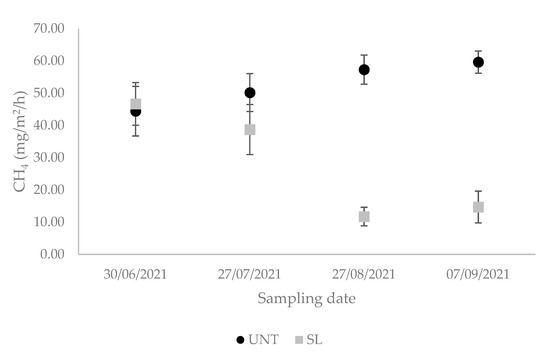

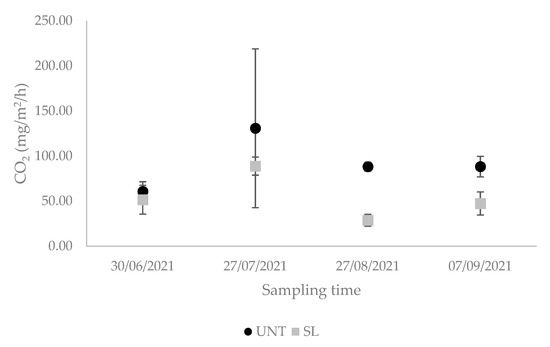

The CH4 and CO2 fluxes were determined according to Equation (1) and are reported in the following graphs.

The CH4 emissions (Figure 3) were almost at the same level for the SL and UNT on the first date, with slightly lower values registered for the UNT. The emissions for the UNT showed higher values in the subsequent dates, with a maximum of 59.64 mg/m2/h (34.2% higher than the first measurement). On the other hand, the values from the SL were lower on the second, third and fourth days than what was recorded on the first day of sampling, with the minimum value (11.73 mg/m2/h) registered on the third date. The third date measurement also showed the maximum difference between the SL and UNT −80%, (p < 0.001). At the last sampling date, the difference remained high at −75%, (p < 0.001).

Figure 3.

CH4 emissions. Bars indicate the standard error of the measurements. Plotted values represent the average flux per each treatment, SL or UNT, in the sampling dates.

The CO2 emissions are represented in Figure 4. As observed for CH4, at the first sampling date, the emissions were very similar for both treatments. In the case of this gas, both fluxes registered the peak value on the second day of measurement, of 88.75 mg/m2/h for the SL and 130.78 mg/m2/h for the UNT, when the data were most dispersed. The untreated tank showed higher emission levels at the end of the trial period for the first sampling date. In comparison, the SL showed lower levels, resulting in differences of −75% (p < 0.05) and −46% (p < 0.001), respectively, for the third and fourth sampling dates in favor of SL over UNT.

Figure 4.

CO2 emissions. Bars indicate the standard error of the measurements. Plotted values represent the average flux per each treatment, SL or UNT, in the sampling dates.

3.3. Additional Observations

As described in the Materials and Method section, a tractor-operated propeller was used to mix the manure tanks on the day before the measurements to break up the crust formed in the previous weeks and allow for easier measurement. It is worth reporting that after the slurry activation period, the agitation time for the SL was approximately a quarter of that of the UNT tank.

In addition, farm workers reported that the odors were nearly eliminated from the manure in the SL tank compared to the UNT tank at the time of spreading the manure on the fields.

4. Discussions

Slurry management and storage is a critical aspect of the livestock farming sector in generating GHG emissions, especially CH4.

The complexity, labor intensity and the equipment requested for a real-scale on-site emission measurement are limiting factors in this research. In fact, most of the studies found in the literature are based on small- (vessels or barrels) or mid- (some tens of m3 tanks) scale trials [37]. Often, when real tanks or lagoons are involved in the trial design, samples are collected from the farms for subsequent processing in a lab.

Measuring in the field in real time poses several technical challenges that must be addressed. The main one is the compatibility with the daily operations on the farm: for this work, this required coordination with the farmer in order to prevent safety issues and avoid damage to the measurement equipment, which was assembled and disassembled on each measurement day. For these reasons, the authors decided to maintain approximately one month between measurements.

The results of this work show an improved mitigation capacity of SOP LAGOON at scale than that previously measured [30,31], both for CH4 and CO2. The duration of the monitoring in this study was much longer than the previous works (5 months vs. 26 days or 1 week, respectively, for [30,31]). The experiment was performed in a commercial dairy, with pre-existing manure tanks, as opposed to the two preliminary works where the emissions were measured from manure in 220 L barrels.

The analysis of the chemical characteristics of the liquid manure in both UNT and SL does not show remarkable differences between the treatments or throughout the test dates. The values are similar to what Martínez-Suller et al. [36] found and are consistent with regular dairy farm practices, where the feed quality and composition do not vary significantly over the year.

The pH values of the liquid manure do not differ significantly when comparing one test day to the other, both for the UNT and SL. It can be noted, however, that the pH of the UNT was significantly lower than the SL at the second and fourth sampling dates. This seems to be in contrast with the emissions level, as a lower pH is generally associated with lower emissions: this is the principle of acidification. Slurry acidification (i.e., the application of strong acids to reduce the manure pH) has been investigated since 2012 [38] for its ability to curb GHG emissions, while, before that, it was mainly investigated for its ability to reduce ammonia NH3 emissions [39]. Numerous studies [40,41,42] registered lower CH4 emissions from an acidified slurry, from 49 to over 90%, obtained with the addition of different quantities of acid, from 2.4 L to 6 kg of acid (usually sulfuric acid) per m3 of manure and with different storage conditions. The addition of SOP LAGOON shows emission reduction results in line with these numbers, without a significant change in the manure pH (Figure 2). The results of the chemical analyses in the SL showed very similar pH values in all the sampling dates, slightly basic between 7.3 and 7.6. This can be an advantage over acidification when spreading manure on soils, where the soil pH does not need to be lowered [43].

Acidification can also be achieved by adding some type of gypsum [44,45,46], the base material of the additive under test. In this study, the negligible pH variations measured suggest that the mechanism of action does not follow a chemical pathway. This was expected, considering that the results were obtained with the addition of only 2 g per week of SOP LAGOON per animal, producing approximately 0.3–0.5 m3 of slurry per week, following the manufacturer’s specifications. The lower quantity used here, compared to other options previously found in the literature (from 5% up to 30% on the dry weight of the manure to be treated) [44,45,46] necessary to achieve a significant decrease of the slurry pH, represents another advantage in terms of logistics and scalability over the use of other types of gypsum.

The manufacturer recommends the application of the product for at least three months to be able to observe the results: the duration of the treatment (103 days since the first application of the additive) is consistent with this indication and is long enough to potentially allow for the biological processes within the slurry to adapt to the treatment [47].

Given the considerations above, microbial changes seem to be the only viable mechanism of action to explain the results: how this interaction takes place appears likely due to the proprietary processing technology applied to the product and requires further investigation.

The results presented in this study showed that SOP LAGOON could reduce CH4 emissions by up to approximately 80% during the storage phase.

Looking at Figure 3, it is possible to notice how UNT shows higher emission fluxes on the third and fourth date compared to the first measurement, i.e., after a storage period of 3–4 months, in accordance with the literature [48]. On the contrary, SL showed lower values than the first point of measure (approximately −70%, p < 0.001). Lowering the emissions rates of CH4 with respect to the initial condition could have remarkable benefits for the climate, including carbon sequestration [49].

Over the years, other techniques have been investigated for their ability to reduce GHG emissions.

The most commonly proposed strategy to mitigate CH4 emissions from liquid manure is the installation of biodigesters, which might not be economically viable for small-scale farms with less than 200 animals [50]. Moreover, inefficiencies in the plants, which often co-process manure together with agricultural residues, agro-industrial by-products or energy crops, cause the release of extra CH4 in the atmosphere: in Italy, that accounts for approximately 1% of the total biogas production, especially from the digestate tanks, nearly offsetting the “avoided” CH4 release from unprocessed manure [20].

Holly et al. [51] studied the different techniques to abate GHG emissions from liquid manure, including solid separation. They concluded that it could be another effective method to reduce the GHG emissions from stored manure, up to −46% compared to fresh manure. However, the direct GHG reduction can be partially offset by the carbon emissions connected to the production and use of the energy used to operate the machines.

In addition to this, the combination of the two above-mentioned techniques (digestion and separation) might even cancel the GHG mitigation potential of the two approaches taken singularly, as it can increase nitrous oxide (N2O) emissions from the solid fraction [51,52] when compared to the unseparated manure. Another disadvantage is represented by the cost of equipment, structures and maintenance, which can impose a financial burden on the farmer, if it cannot be partially recovered by selling the gas or electricity to the market.

Kupper et al. [53] published a review of studies on the emissions from stored lagoons. They reported that manure covers could be another way to curb CH4 emissions, with abatement rates between 10% to 60%, if they are impermeable. Guarino et al. [54] found that covers do not show a statistically significant efficacy when they are made of permeable materials. The natural crust that forms on top of a liquid manure tank is also considered a type of cover, with proven efficacy in reducing NH3 and CH4 emissions [55,56]. The UNT showed more significant CH4 emissions than the SL, despite presenting a crust on the top. The higher crust thickness (indirectly measured by the longer time required to break it before each measurement day) might lead to a lower oxygen diffusion in the UNT, which can be a limiting factor in the methanotrophic activity [57].

Metanotrophy in the crust does not appear to be the only mechanism of action. The previous studies [30,31] on the same additive showed emissions reduction with little or no crust forming on top of the manure. In addition, the reduction of the odors at the time of spreading (as reported by the farm operators) suggests a different evolution of the liquid manure in the SL compared to the UNT, leading again to the conclusion that a different microbial activity occurred in the SL.

Moreover, breaking the crust in preparation for the field application generates an extra cost for the farmers regarding machinery operation, fuel consumption and manpower. As the agitators are commonly powered by tractors, the CO2 released by the internal combustion engine partially offsets the GHG mitigation that the crust could offer. This topic deserves further study to better evaluate the scope of this trade-off.

This work also shows a significant great reduction (up to −75%) of the CO2 emissions from the SL compared to the UNT. Scarce information is present in the literature on CO2 fluxes, especially on the effect of additives or other containment systems. Generally, the research does not evaluate the CO2 emissions from manure because they are considered part of a cycle that sees the plants used as feed for the animals as carbon sinks [58]. Additionally, the much greater air concentration of CO2 compared to CH4 (414 ppm vs. 1.8 ppm [59]) makes it difficult to separate the baseline air concentration from the contribution of the slurry. This is why, in this work, ambient air was sampled before each point on the manure surface, and the concentration was subtracted from the measured values in order to calculate the fluxes [34,35].

By analyzing the data at different times, it is possible to notice how the SL emissions were similar to those recorded on the starting date, while those from the UNT showed greater values than the first measured point, similar to what Borgonovo et al. [30] reported.

Additional Considerations

Odors connected to farming activities can be a nuisance for the surrounding communities, especially in regions with a high population density. Presently, there is no consensus among the different regions on odor regulations [60]: restrictions on management techniques, distance from inhabited areas and seasonality for the operations are already in place, even if only locally. Several strategies can be put in place to reduce the odor emissions from livestock manure, some of which are compatible with the goal of reducing GHG, such as anaerobic digestion, solid–liquid separation or covers [61].

During this test, the dairy farm operators reported that odors from the manure treated with SOP LAGOON were strongly reduced compared to the control when the manure was spread on the fields. This is in line with the observations reported by Peterson et al. [31], who measured a significant reduction of odors from the treated lagoon water. SOP LAGOON provides similar benefits to the other techniques targeting odor issues.

5. Conclusions

Liquid manure is a critical source of GHG emissions from the dairy industry.

After three months from the first additive applications, the treated storage tank showed lower and statistically significantly different emissions compared to the untreated one, with results (up to −80% for CH4 and −75% for the CO2) that are compatible or better than other more complex strategies such as acidification or methane digesters.

The data presented in this work shows great potential for SOP LAGOON to reduce CH4 and CO2 emissions from liquid manure storage, in real field scenarios, confirming and demonstrating improved results than what was shown in the previous small-scale studies. The in-field test also allowed the operators to report a reduction in the odors at the time of spreading and a reduction of the fuel consumption for the agitation.

In this work, SOP LAGOON proves to be an effective additive to help the farmers manage their stored liquid manure, which can offer economic, social and environmental benefits for the dairy industry.

Further studies could also investigate the effects of SOP LAGOON on the emissions at the moment of the manure spreading and its influence on soil and crops.

Author Contributions

Conceptualization, M.E.C., J.B. and M.A.; methodology, M.E.C., J.B., M.C., D.A. and M.A.; software, M.E.C. and M.A.; validation, M.E.C., J.B., M.C. and M.A.; formal analysis, M.E.C., J.B., M.C. and M.A.; investigation, J.B., M.C. and M.Z.; resources, M.E.C., J.B., M.C. and M.A.; data curation, M.E.C., J.B., M.C., M.Z. and M.A.; writing—original draft preparation, M.E.C., J.B.; writing—review and editing, M.E.C., J.B., M.C., D.A., L.P. and M.A.; project administration, M.E.C. and J.B.; funding acquisition, J.B. and M.E.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded in part by LOMBARDY REGION, INNODRIVER-S3 -Edition 2019-Measure A-B, InnoADD, number 1742664 and in part by SOP Srl Società Benefit.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Climate Change 2022: Impacts, Adaptation and Vulnerability. In Contribution of Working Group II to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Pörtner, H.-O., Roberts, D.C., Tignor, M.M.B., Poloczanska, E.S., Mintenbeck, K., Alegría, A., Craig, M., Langsdorf, S., Löschke, S., Möller, V., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2022; p. 3056. [Google Scholar] [CrossRef]

- WMO Update: 50:50 Chance of Global Temperature Temporarily Reaching 1.5 °C Threshold in Next Five Years. Available online: https://public.wmo.int/en/media/press-release/wmo-update-5050-chance-of-global-temperature-temporarily-reaching-15%C2%B0c-threshold (accessed on 14 December 2022).

- Clark, M.A.; Domingo, N.G.G.; Colgan, K.; Thakrar, S.K.; Tilman, D.; Lynch, J.; Azevedo, I.L.; Hill, J.D. Global Food System Emissions Could Preclude Achieving the 1.5° and 2°C Climate Change Targets. Science 2020, 370, 705–708. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Wang, P.; Ferris, T.; Lin, H.; Dreyfus, G.; Gu, B.-H.; Zaelke, D.; Wang, Y. Fast Action on Short-Lived Climate Pollutants and Nature-Based Solutions to Help Countries Meet Carbon Neutrality Goals. Adv. Clim. Change Res. 2022, 13, 564–577. [Google Scholar] [CrossRef]

- Xu, Y.; Ramanathan, V. Well below 2 °C: Mitigation Strategies for Avoiding Dangerous to Catastrophic Climate Changes. Proc. Natl. Acad. Sci. USA 2017, 114, 10315–10323. [Google Scholar] [CrossRef] [PubMed]

- Methane Emissions. Available online: https://energy.ec.europa.eu/topics/oil-gas-and-coal/methane-emissions_en (accessed on 14 December 2022).

- Allen, M.R.; Shine, K.P.; Fuglestvedt, J.S.; Millar, R.J.; Cain, M.; Frame, D.J.; Macey, A.H. A Solution to the Misrepresentations of CO2-Equivalent Emissions of Short-Lived Climate Pollutants under Ambitious Mitigation. NPJ Clim. Atmos. Sci. 2018, 1, 16. [Google Scholar] [CrossRef]

- The Biogenic Carbon Cycle and Cattle. Available online: https://clear.ucdavis.edu/explainers/biogenic-carbon-cycle-and-cattle (accessed on 14 December 2022).

- Global Methane Pledge. Available online: https://www.globalmethanepledge.org/ (accessed on 14 December 2022).

- GMP COP27 Joint Factsheet. Available online: https://energy.ec.europa.eu/system/files/2022-11/GMP%20COP27%20Joint%20Factsheet.pdf (accessed on 14 December 2022).

- SB 1383. Available online: https://www.yubasutterrecycles.com/files/2793c2592/SB+1383.pdf (accessed on 14 December 2022).

- Brandt, A.R.; Heath, G.A.; Cooley, D. Methane Leaks from Natural Gas Systems Follow Extreme Distributions. Environ. Sci. Technol. 2016, 50, 12512–12520. [Google Scholar] [CrossRef] [PubMed]

- Regulation of the European Parliament and of the Council. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:06d0c90a-5d91-11ec-9c6c-01aa75ed71a1.0001.02/DOC_1&format=PDF (accessed on 14 December 2022).

- European Commission. An EU Methane Strategy. Available online: https://ec.europa.eu/commission/presscorner/detail/en/qanda_20_1834 (accessed on 14 December 2022).

- Climate Change and Land—IPCC. Available online: https://www.ipcc.ch/site/assets/uploads/sites/4/2020/02/SPM_Updated-Jan20.pdf (accessed on 31 December 2022).

- Emissions from Livestock and Manure Management. Available online: https://www.ipcc-nggip.iges.or.jp/public/2019rf/pdf/4_Volume4/19R_V4_Ch10_Livestock.pdf (accessed on 14 December 2022).

- Estimated Global Anthropogenic Methane Emissions by Source 2010. Available online: https://www.igsd.org/estimated-global-anthropogenic-methane-emissions-by-source-2010/ (accessed on 14 December 2022).

- The Role of the Dairy Sector in a Low-Carbon Future. Available online: https://www.fao.org/3/CA2929EN/ca2929en.pdf (accessed on 14 December 2022).

- Amon, B.; Kryvoruchko, V.; Moitzi, G.; Amon, T. Greenhouse Gas and Ammonia Emission Abatement by Slurry Treatment. Int. Congr. Ser. 2006, 1293, 295–298. [Google Scholar] [CrossRef]

- Italian Greenhouse Gas Inventory. Available online: https://www.isprambiente.gov.it/files2022/pubblicazioni/rapporti/nir2022_italy_r360.pdf (accessed on 14 December 2022).

- Current California GHG Emission Inventory Data. Available online: https://ww2.arb.ca.gov/ghg-inventory-data (accessed on 14 December 2022).

- McCauley, J.I.; Labeeuw, L.; Jaramillo-Madrid, A.C.; Nguyen, L.N.; Nghiem, L.D.; Chaves, A.V.; Ralph, P.J. Management of Enteric Methanogenesis in Ruminants by Algal-Derived Feed Additives. Curr. Pollut. Rep. 2020, 6, 188–205. [Google Scholar] [CrossRef]

- Jayanegara, A.; Sarwono, K.A.; Kondo, M.; Matsui, H.; Ridla, M.; Laconi, E.B.; Nahrowi. Use of 3-Nitrooxypropanol as Feed Additive for Mitigating Enteric Methane Emissions from Ruminants: A Meta-Analysis. Ital. J. Anim. Sci. 2018, 17, 650–656. [Google Scholar] [CrossRef]

- Honan, M.; Feng, X.; Tricarico, J.M.; Kebreab, E.; Honan, M.; Feng, X.; Tricarico, J.M.; Kebreab, E. Feed Additives as a Strategic Approach to Reduce Enteric Methane Production in Cattle: Modes of Action, Effectiveness and Safety. Anim. Prod. Sci. 2021, 62, 1303–1317. [Google Scholar] [CrossRef]

- Carrazco, A.V.; Peterson, C.B.; Zhao, Y.; Pan, Y.; McGlone, J.J.; DePeters, E.J.; Mitloehner, F.M. The Impact of Essential Oil Feed Supplementation on Enteric Gas Emissions and Production Parameters from Dairy Cattle. Sustainability 2020, 12, 10347. [Google Scholar] [CrossRef]

- Mosque, J.; Schils, R.; Groenestein, K.; Hoeksma, P.; Velthof, G.; Hummelink, E. Emissies van Lachgas, Methaan En Ammoniak Uit Mest.Pdf. Available online: https://edepot.wur.nl/161899 (accessed on 14 December 2022).

- VanderZaag, A.C.; Baldé, H.; Crolla, A.; Gordon, R.J.; Ngwabie, N.M.; Wagner-Riddle, C.; Desjardins, R.; MacDonald, J.D. Potential Methane Emission Reductions for Two Manure Treatment Technologies. Environ. Technol. 2018, 39, 851–858. [Google Scholar] [CrossRef] [PubMed]

- Misselbrook, T.; Hunt, J.; Perazzolo, F.; Provolo, G. Greenhouse Gas and Ammonia Emissions from Slurry Storage: Impacts of Temperature and Potential Mitigation through Covering (Pig Slurry) or Acidification (Cattle Slurry). J. Environ. Qual. 2016, 45, 1520–1530. [Google Scholar] [CrossRef] [PubMed]

- Amon, B.; Kryvoruchko, V.; Fröhlich, M.; Amon, T.; Pöllinger, A.; Mösenbacher, I.; Hausleitner, A. Ammonia and Greenhouse Gas Emissions from a Straw Flow System for Fattening Pigs: Housing and Manure Storage. Livest. Sci. 2007, 112, 199–207. [Google Scholar] [CrossRef]

- Borgonovo, F.; Conti, C.; Lovarelli, D.; Ferrante, V.; Guarino, M. Improving the Sustainability of Dairy Slurry by A Commercial Additive Treatment. Sustainability 2019, 11, 4998. [Google Scholar] [CrossRef]

- Peterson, C.B.; El Mashad, H.M.; Zhao, Y.; Pan, Y.; Mitloehner, F.M. Effects of SOP Lagoon Additive on Gaseous Emissions from Stored Liquid Dairy Manure. Sustainability 2020, 12, 1393. [Google Scholar] [CrossRef]

- Baird, R.B.; Eaton, A.D.; Rice, E.W. (Eds.) Standard Methods for the Examination of Water and Wastewater, 23rd ed.; American Public Health Association, American Water Works Association, Water Environment Federation: Washington, DC, USA, 2017. [Google Scholar]

- VERA Test Protocol. Available online: https://www.vera-verification.eu/app/uploads/sites/9/2019/05/VERA_Test_protocol_slurryseparation_v3_2018_final.pdf (accessed on 14 December 2022).

- Balsari, P.; Airoldi, G.; Dinuccio, E.; Gioelli, F. Ammonia Emissions from Farmyard Manure Heaps and Slurry Stores—Effect of Environmental Conditions and Measuring Methods. Biosyst. Eng. 2007, 97, 456–463. [Google Scholar] [CrossRef]

- Finzi, A.; Mattachini, G.; Lovarelli, D.; Riva, E.; Provolo, G. Technical, Economic, and Environmental Assessment of a Collective Integrated Treatment System for Energy Recovery and Nutrient Removal from Livestock Manure. Sustainability 2020, 12, 2756. [Google Scholar] [CrossRef]

- Martínez-Suller, L.; Azzellino, A.; Provolo, G. Analysis of Livestock Slurries from Farms across Northern Italy: Relationship between Indicators and Nutrient Content. Biosyst. Eng. 2008, 99, 540–552. [Google Scholar] [CrossRef]

- Regueiro, I.; Coutinho, J.; Fangueiro, D. Alternatives to Sulfuric Acid for Slurry Acidification: Impact on Slurry Composition and Ammonia Emissions during Storage. J. Clean. Prod. 2016, 131, 296–307. [Google Scholar] [CrossRef]

- Petersen, S.O.; Andersen, A.J.; Eriksen, J. Effects of Cattle Slurry Acidification on Ammonia and Methane Evolution during Storage. J. Environ. Qual. 2012, 41, 88–94. [Google Scholar] [CrossRef]

- Ndegwa, P.M.; Hristov, A.N.; Arogo, J.; Sheffield, R.E. A Review of Ammonia Emission Mitigation Techniques for Concentrated Animal Feeding Operations. Biosyst. Eng. 2008, 100, 453–469. [Google Scholar] [CrossRef]

- Habtewold, J.; Gordon, R.; Sokolov, V.; VanderZaag, A.; Wagner-Riddle, C.; Dunfield, K. Reduction in Methane Emissions From Acidified Dairy Slurry Is Related to Inhibition of Methanosarcina Species. Front. Microbiol. 2018, 9, 2806. [Google Scholar] [CrossRef]

- Sokolov, V.K.; VanderZaag, A.; Habtewold, J.; Dunfield, K.; Wagner-Riddle, C.; Venkiteswaran, J.J.; Crolla, A.; Gordon, R. Dairy Manure Acidification Reduces CH4 Emissions over Short and Long-Term. Environ. Technol. 2021, 42, 2797–2804. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Dalby, F.R.; Feilberg, A.; Jacobsen, B.H.; Petersen, S.O. Low-Dose Acidification as a Methane Mitigation Strategy for Manure Management. Agric. Sci. Technol. 2022, 2, 437–442. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, B.R.; Jung, K.H.; Kim, T.H. Acidification of Pig Slurry Effects on Ammonia and Nitrous Oxide Emissions, Nitrate Leaching, and Perennial Ryegrass Regrowth as Estimated by 15N-Urea Flux. Asian-Australas. J. Anim. Sci. 2018, 31, 457–466. [Google Scholar] [CrossRef] [PubMed]

- Febrisiantosa, A.; Ravindran, B.; Choi, H.L. The Effect of Co-Additives (Biochar and FGD Gypsum) on Ammonia Volatilization during the Composting of Livestock Waste. Sustainability 2018, 10, 795. [Google Scholar] [CrossRef]

- SangSun, L.; HyunJin, P.; XiYing, H.; SunIl, L.; ByeongJun, J.; JinHyeob, K.; WooJung, C. Nitrogen, Carbon, and Dry Matter Losses during Composting of Livestock Manure with Two Bulking Agents as Affected by Co-Amendments of Phosphogypsum and Zeolite. Ecol. Eng. 2017, 102, 280–290. [Google Scholar]

- Hao, X.; Larney, F.J.; Chang, C.; Travis, G.R.; Nichol, C.K.; Bremer, E. The Effect of Phosphogypsum on Greenhouse Gas Emissions during Cattle Manure Composting. J. Environ. Qual. 2005, 34, 774–781. [Google Scholar] [CrossRef]

- Speshock, J.L.; Brady, J.A.; Eastman, J.; Roach, T.; Hays, S.; Kattes, D. Impact of Manure Storage Time and Temperature on Microbial Composition and Stable Fly (Diptera: Muscidae) Development. Adv. Microbiol. 2019, 9, 248–265. [Google Scholar] [CrossRef]

- Sokolov, V.; VanderZaag, A.; Habtewold, J.; Dunfield, K.; Tambong, J.T.; Wagner-Riddle, C.; Venkiteswaran, J.J.; Gordon, R. Acidification of Residual Manure in Liquid Dairy Manure Storages and Its Effect on Greenhouse Gas Emissions. Front. Sustain. Food Syst. 2020, 4, 568648. [Google Scholar] [CrossRef]

- Lynch, J.; Cain, M.; Pierrehumbert, R.; Allen, M. Demonstrating GWP *: A Means of Reporting Warming-Equivalent Emissions That Captures the Contrasting Impacts of Short- and Long-Lived Climate Pollutants. Environ. Res. Lett. 2020, 15, 044023. [Google Scholar] [CrossRef]

- Agrisource. Available online: http://agrisource.org/fr/1/home.html (accessed on 15 December 2022).

- Holly, M.A.; Larson, R.A.; Powell, J.M.; Ruark, M.D.; Aguirre-Villegas, H. Greenhouse Gas and Ammonia Emissions from Digested and Separated Dairy Manure during Storage and after Land Application. Agric. Ecosyst. Environ. 2017, 239, 410–419. [Google Scholar] [CrossRef]

- Veltman, K.; Rotz, C.A.; Chase, L.; Cooper, J.; Ingraham, P.; Izaurralde, R.C.; Jones, C.D.; Gaillard, R.; Larson, R.A.; Ruark, M.; et al. A Quantitative Assessment of Beneficial Management Practices to Reduce Carbon and Reactive Nitrogen Footprints and Phosphorus Losses on Dairy Farms in the US Great Lakes Region. Agric. Syst. 2018, 166, 10–25. [Google Scholar] [CrossRef]

- Kupper, T.; Häni, C.; Neftel, A.; Kincaid, C.; Bühler, M.; Amon, B.; VanderZaag, A. Ammonia and Greenhouse Gas Emissions from Slurry Storage—A Review. Agric. Ecosyst. Environ. 2020, 300, 106963. [Google Scholar] [CrossRef]

- Guarino, M.; Fabbri, C.; Brambilla, M.; Valli, L.; Navarotto, P. Evaluation of simplified covering systems to reduce gaseous emissions from livestock manure storage. Trans. ASABE 2006, 49, 737–747. [Google Scholar] [CrossRef]

- A Review of Livestock Methane Emission Factors. Available online: https://www.epa.ie/publications/research/climate-change/Research_Report_288.pdf (accessed on 14 December 2022).

- Aguerre, M.J.; Wattiaux, M.A.; Powell, J.M. Emissions of Ammonia, Nitrous Oxide, Methane, and Carbon Dioxide during Storage of Dairy Cow Manure as Affected by Dietary Forage-to-Concentrate Ratio and Crust Formation. J. Dairy Sci. 2012, 95, 7409–7416. [Google Scholar] [CrossRef] [PubMed]

- Duan, Y.-F.; Reinsch, S.; Ambus, P.; Elsgaard, L.; Petersen, S. Methanotrophic Activity in Slurry Surface Crusts as Influenced by CH4, O2, and Inorganic N. J. Environ. Qual. 2017, in press. [Google Scholar] [CrossRef]

- Külling, D.R.; Dohme, F.; Menz, H.; Sutter, F.; Lischer, P.; Kreuzer, M. Methane Emissions of Differently Fed Dairy Cows and Corresponding Methane and Nitrogen Emissions from Their Manure during Storage. Environ. Monit. Assess. 2002, 79, 129–150. [Google Scholar] [CrossRef]

- USEPA. Climate Change Indicators: Atmospheric Concentrations of Greenhouse Gases. Available online: https://www.epa.gov/climate-indicators/climate-change-indicators-atmospheric-concentrations-greenhouse-gases (accessed on 14 December 2022).

- Bokowa, A.; Diaz, C.; Koziel, J.A.; McGinley, M.; Barclay, J.; Schauberger, G.; Guillot, J.-M.; Sneath, R.; Capelli, L.; Zorich, V.; et al. Summary and Overview of the Odour Regulations Worldwide. Atmosphere 2021, 12, 206. [Google Scholar] [CrossRef]

- Janni, K. Reflections on Odor Management for Animal Feeding Operations. Atmosphere 2020, 11, 453. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).