1. Introduction

In the construction industry, especially in constructing reinforced concrete multi-story buildings, the cast-in-situ concrete is the most commonly used material as it offers a lot of advantages when compared to other materials [

1], such as flexibility, ease of handling, and cost-effective solutions.

The aforementioned is no different in Croatia, where concrete and reinforced concrete (RC) are considered as “the material” [

2,

3,

4,

5]. As RC construction consists of three main elements, formwork, rebar, and cast-in-situ concrete [

6], it is important to consider both material and processes in pre-construction (initiation, planning, design, and procurement) and construction stages as the key drivers to sustainable usage of the building and post-construction stages. Herein, the focus is on formwork selection, as the formwork is a temporary support for the construction of a concrete structure, which is mainly used to shape and maintain fresh concrete until it reaches adequate strength. Whether it is a traditional or modern system, the final geometry and surface quality of the completed concrete structure are highly dependent on the formwork system (FWS) employed in the construction [

7,

8]. Thus, the selection criteria and the basic requirements of the formwork system should be thoroughly considered before the commencement of construction [

7]. In public investment projects, designers usually highlight the formwork system according to the general design of an RC building, yet shifting the decision to the selected contractor to use the best of his abilities often translates to “what he has.” In such cases, building designs often have a number of details that cannot be constructed by a standard, out-of-the-catalog formwork system, which ultimately slows down the constructor in their work and causes delays.

Therefore, focusing on the future RC building and making informed choices during pre-construction stages is of utmost importance and can significantly influence the later stages, resulting in being within the planned time and budget. Unfortunately, many construction projects result in time and cost overruns [

9,

10,

11,

12]. Reasons for such are many, but can be summed up to poor planning, design, and/or execution [

13]. As there are many decisions that need to be made in avoiding those overruns, the selection of an appropriate formwork system represents a critical decision in the planning of reinforced concrete multi-story buildings.

While this decision has traditionally been deferred to the construction phase, increasing evidence of time and cost overruns in construction projects has highlighted the necessity of addressing it during earlier stages, particularly in design and planning. Early identification and selection of the optimal FWS enhances the likelihood of achieving significant improvements in both time efficiency and cost effectiveness.

To do so, one of the ways the more clarity and consistency throughout the selection process is the use of adequate multi-criteria decision-making (MCDM) methods such as AHP [

14,

15,

16], SAW [

17,

18], TOPSIS [

19,

20], PROMETHEE [

21,

22,

23], VIKOR [

24,

25], ELECTRE [

26], and COPRAS [

27]. These methods are based on an analytical approach, whether they are used in single or group decision-making surroundings [

28,

29,

30,

31,

32,

33], and have been extensively explored and applied in many real-world problems. However, comprehending the decision-making process and selecting a satisfactory choice from a large set of alternatives characterized by multiple conflicting attributes imposes a significant cognitive burden on decision-makers.

At first, the optimal FWS selection may be seen as a non-complex problem with meaningless or low impact to construction projects, but knowing that formwork values around 40% to 60% of the whole RC construction project, and in some cases even more [

1,

4,

7], this decision should not be taken lightly. As the choice should be made by an informed decision-maker, in such a demanding multi-criteria and multi-stakeholder environment that is a construction project, making an informed choice of optimal FWS selection is of utmost importance. As the optimal FWS selection problem can be seen as a single or group decision-making problem, the important is to have a such decision-support framework that offers not just a predefined set of criteria to use in making decision, or predefined method to use, but to offer the decision-maker the possibility of building up a set of criteria that will give the best possible result for their RC building problem.

Predominantly, the various authors focus their efforts either to define a finite number of criteria for particular selection or make tremendous efforts in developing new methods to make an appropriate decision. Yet, some focus their efforts on aligning construction processes and the decision process. Antoniou and Tsisoulpa [

13] indirectly refer to poor FWS design as one of the identified design errors related to the causes of claims during the construction phase. Their insights show that the driving factors should be made prior to the construction phase. Therefore, to make an optimal FWS selection, the informed choice should be made during the planning and design stage. Such should give advantages in having fewer overruns as the driving decision of FWS selection will have enough checking points to pass, i.e., after each phase, well before construction.

To cope with such a problem, a lot of researchers approach the problem in different ways. Some focused on the parts of the problem, such as the decisive criteria in formwork selection problem [

34], or on more broader criteria for FWS, focusing the use of different analytical approaches [

35,

36,

37], while others focused on the particularities of formwork material [

38,

39], general construction topics and processes [

40,

41,

42,

43,

44,

45,

46,

47,

48], or MCDM methods [

40,

43,

47,

48,

49,

50,

51,

52,

53,

54,

55,

56,

57,

58,

59] that can be used to solve different decision-making problems, such as selecting, sorting, and choosing, that are present in construction project management.

In an FWS selection problem, AHP and SAW methods and their derivatives are predominantly used. The AHP is one of the most world-wide-known outranking methods, with strict mathematical rules seeking consistency [

14,

15,

16], even proved its usability outside consistency [

55]. The SAW method lacks stability in such [

53], offering more variety in its application. Within similar research, the focus is on setting numerous criteria [

35,

36,

37], which often does more harm than good. Nonetheless, such insights are valuable and well-developed for academic purposes but often lack practical utilization in the professional sector.

Most of the data in a MCDM problem are unstable and changeable, and thus, sensitivity analysis can effectively contribute to making proper decisions. Therefore, Alinezhad et al. [

52] offered a new method for sensitivity analysis within SAW so that by changing one element of the decision-making matrix, the changes in the results of a decision-making problem can be determined. On the other hand, Hopfe et al. [

51] offer different approaches to normalizing the results of SAW. Both approaches provide more precision to SAW than is usually defined (see

Section 2.3). To support the previous statement, Zavadskas et al. [

53] concluded that only significant attributes relative to the other attributes have an impact on the results.

Despite the aforementioned, AHP still remained the most used method in such industries [

28]. Additionally, Sun et al. [

57] even developed a visual analytics approach that integrates visual representations of alternatives with the decision-making analysis process. Such tends to assist decision-makers in gaining a better understanding of the decision-making process and helping them visually identify the best choice. Overall, developing a stable decision-support framework that is transparent and open to adopting changes is proven to be a more efficient and effective way of making informed decisions [

41,

42,

43,

48,

60].

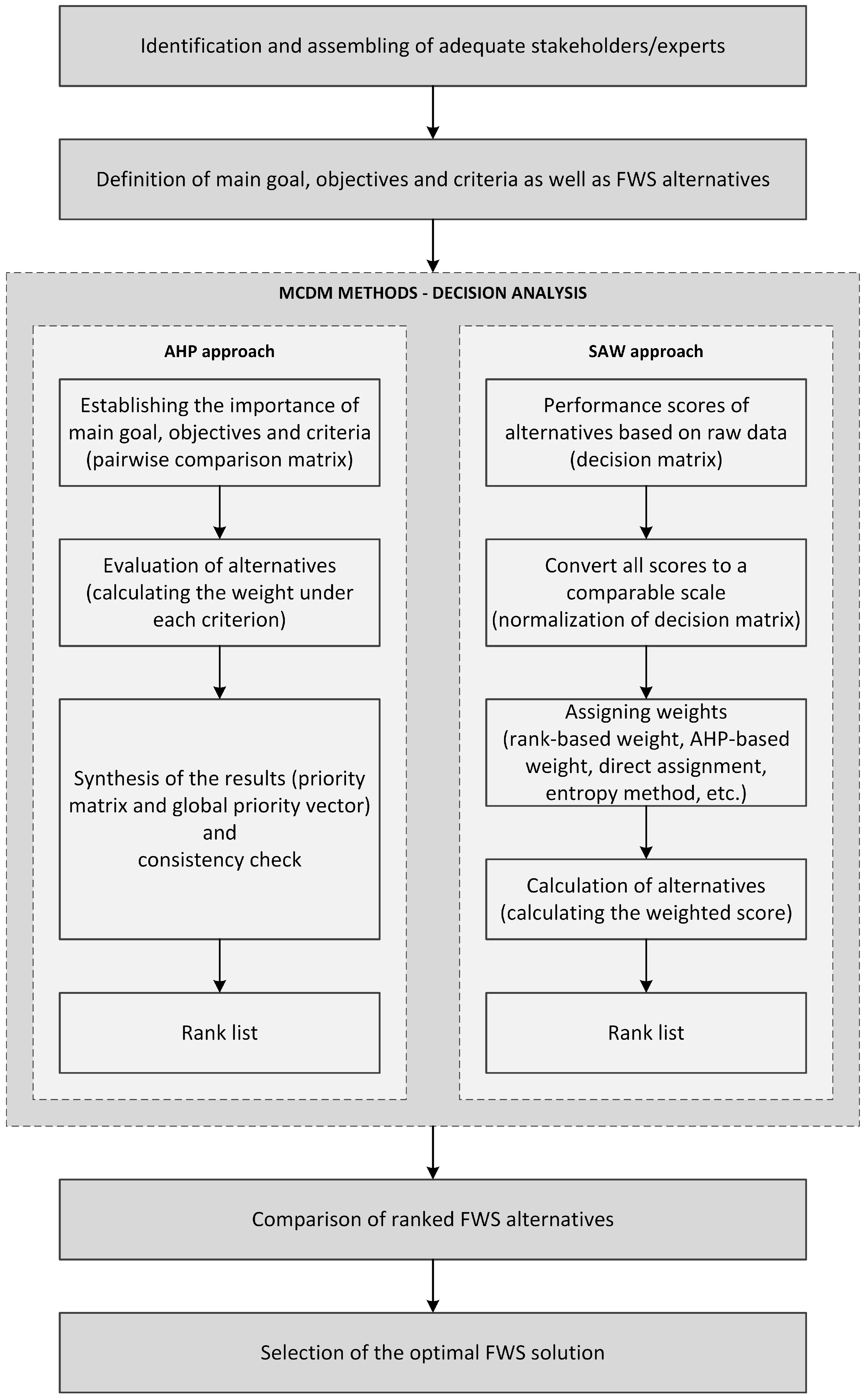

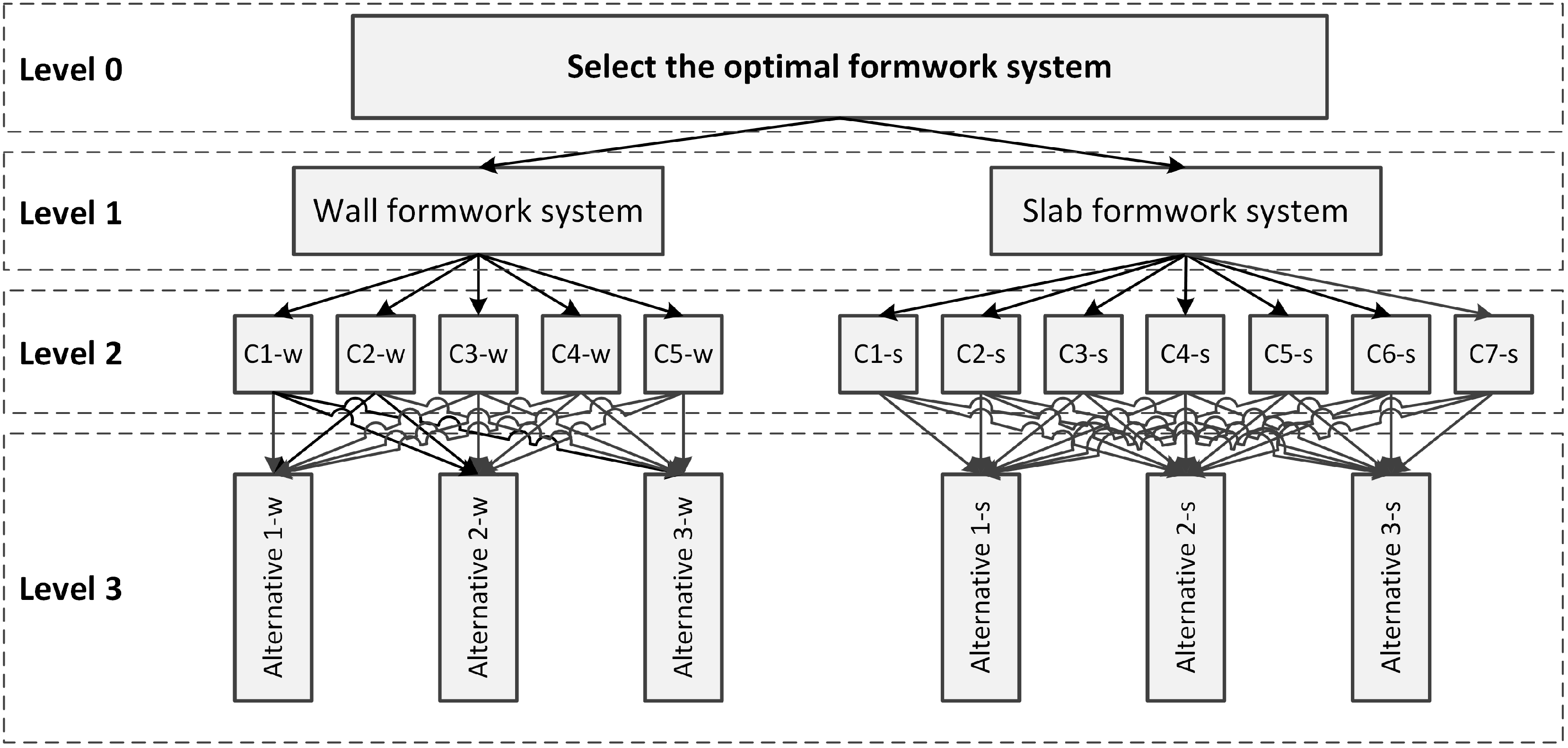

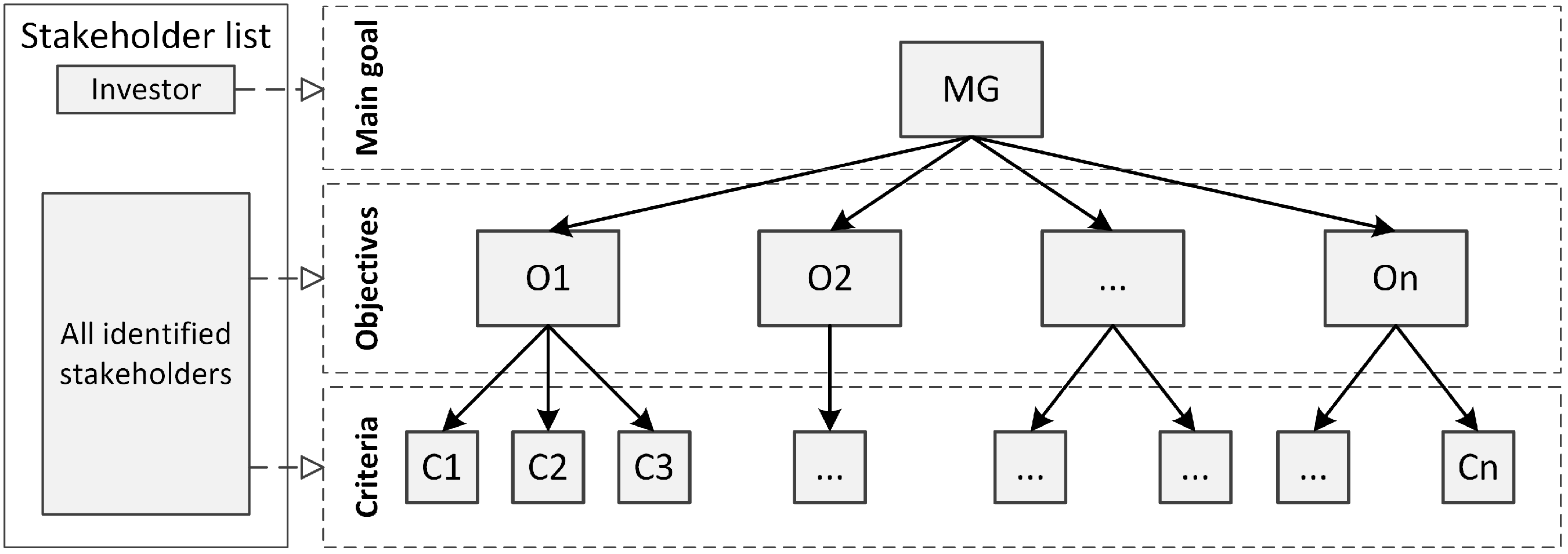

Therefore, the main goal is to develop a decision-support framework based on the Analytic Hierarchy Process (AHP) and Simple Additive Weighting (SAW) methods that will provide decision-makers with a structured and systematic approach for evaluating alternatives and selecting the most suitable formwork system for a given project. The focus is on the following: (1) creating an appropriate framework to build up a hierarchical goal structure that can be applied to any construction project, and (2) showing an analytical approach to decision-making by AHP and SAW methods that will result in a more appropriate approach to use by experts.

By offering an analytical foundation for the decision-making process, ensuring both clarity and consistency in decision-making outcomes, the framework tends to assist designers and engineers during early stages in mitigating risks associated with delays and potential standstills during construction. As such, it is expected that the developed framework will contribute to robust planning and execution of construction projects.