Numerical Investigation of Unsteady Cavitation Dynamics over a NACA66 Hydrofoil near a Free Surface

Abstract

1. Introduction

2. Numerical Methods

2.1. Governing Equations

2.2. Large-Eddy Simulation Model

2.3. Cavitation Model

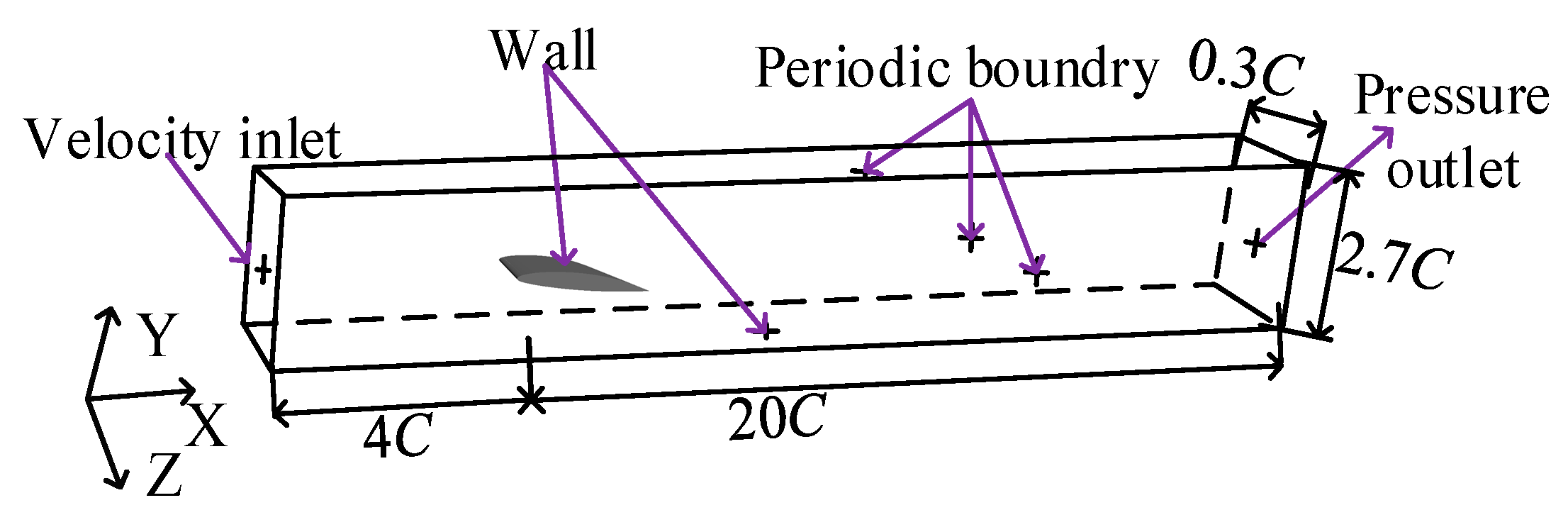

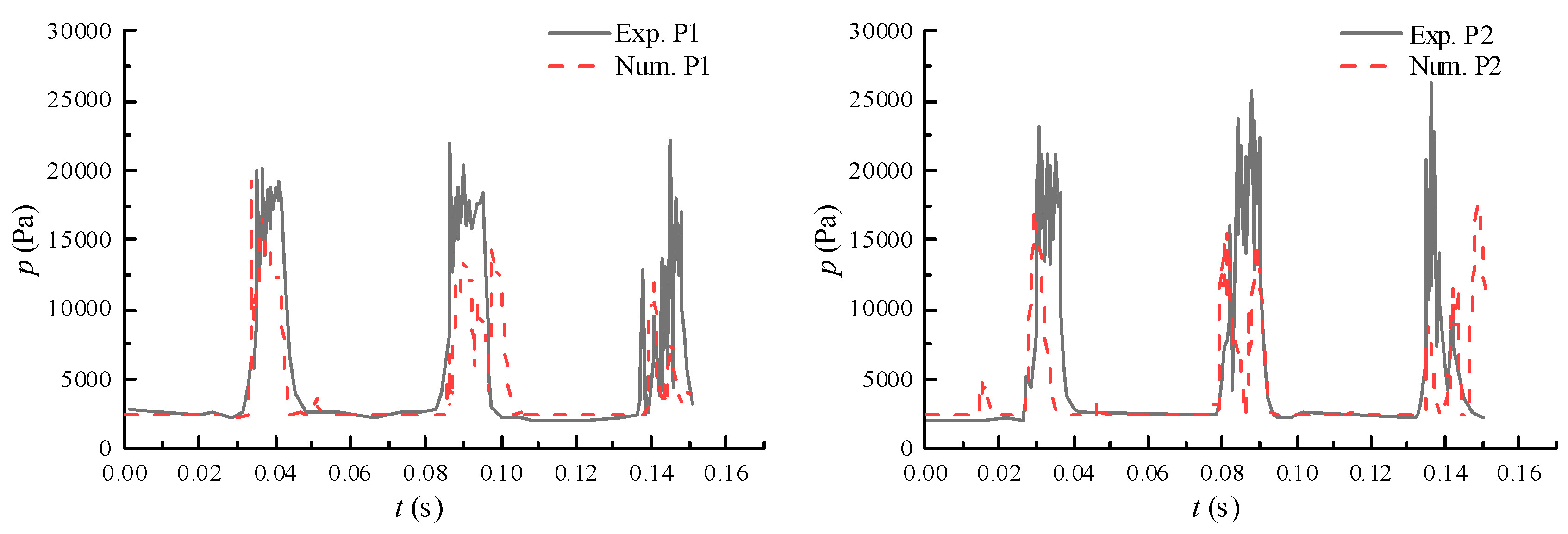

2.4. Numerical Setup and Validation

3. Results and Discussion

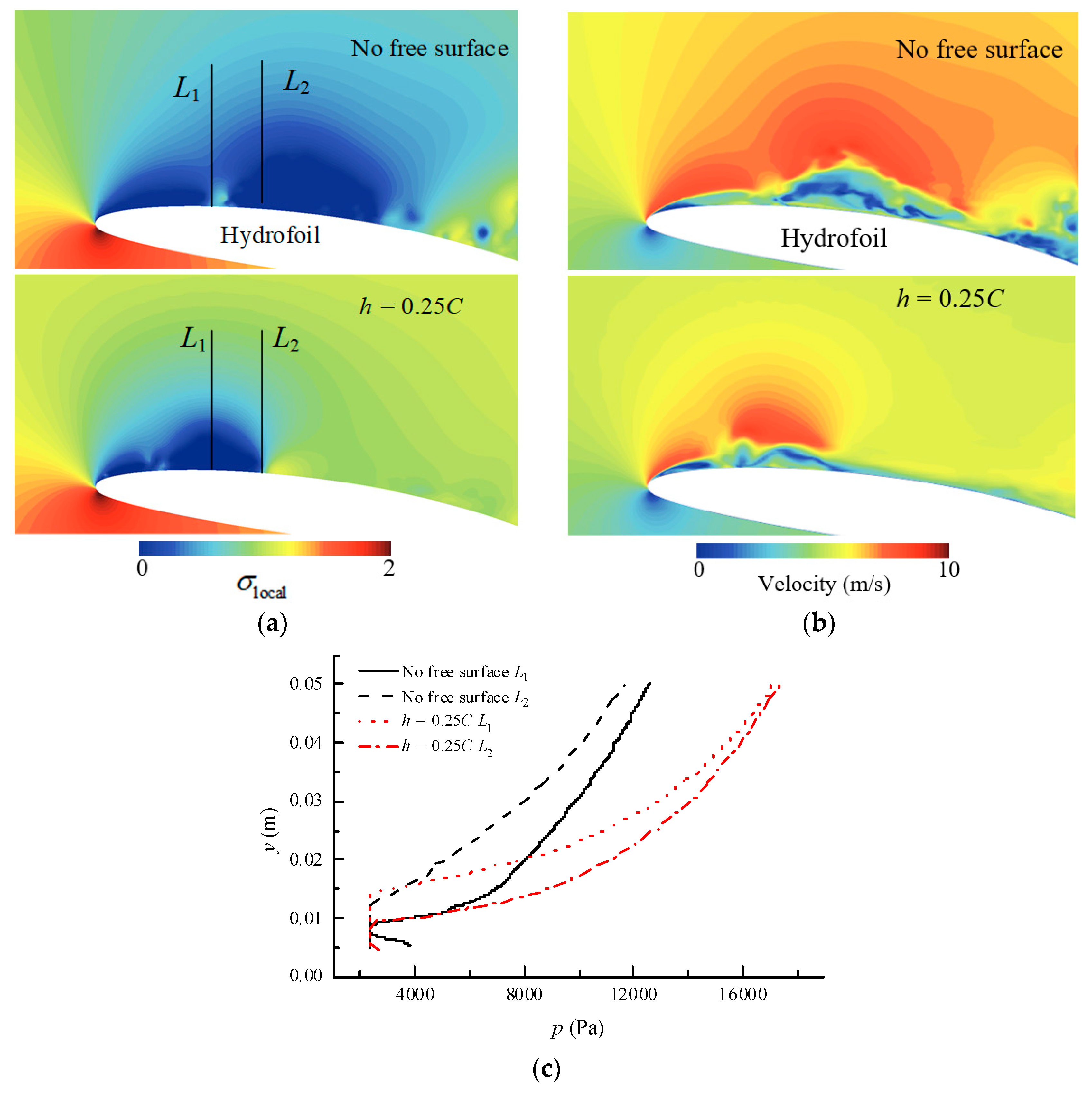

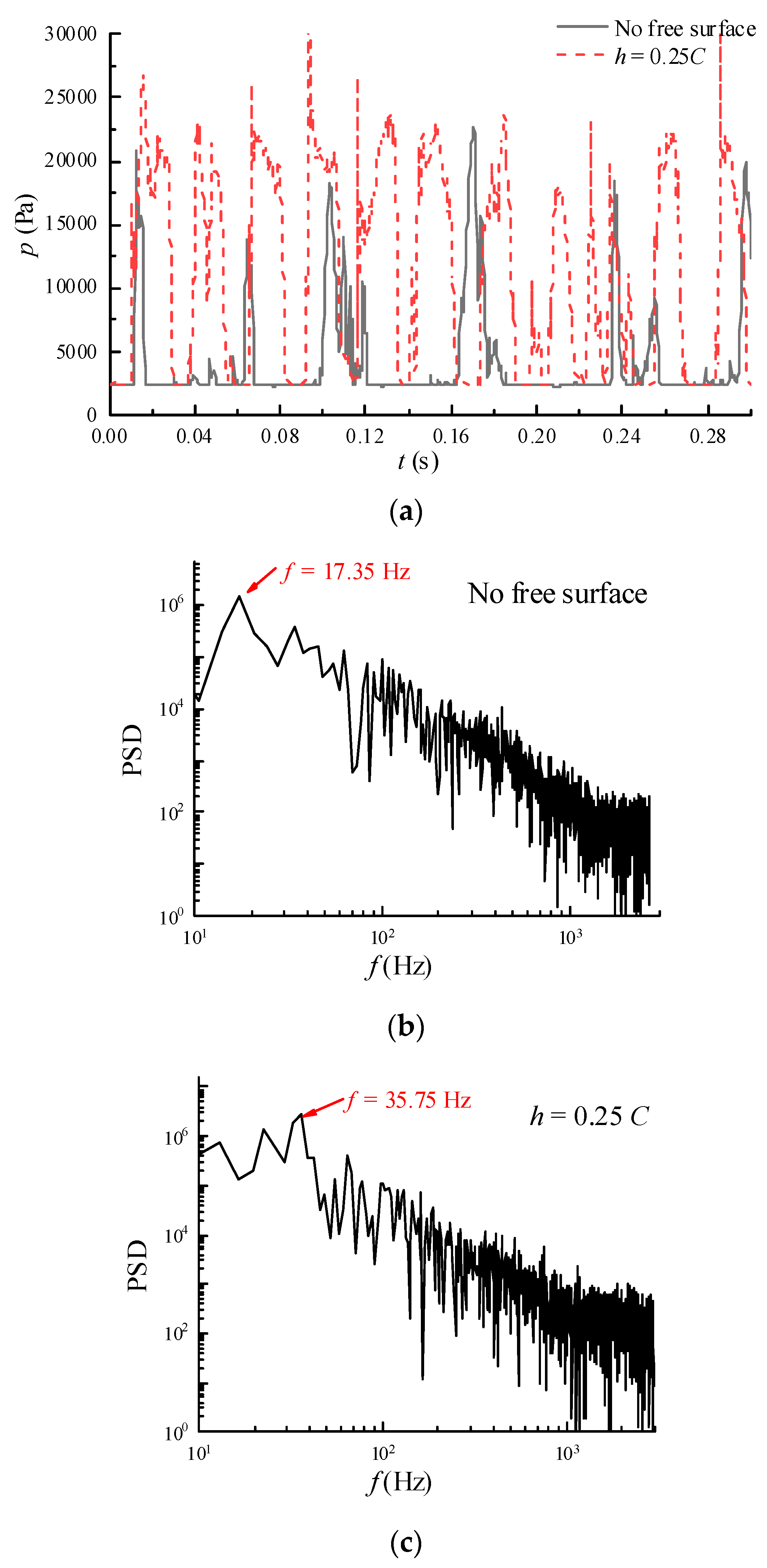

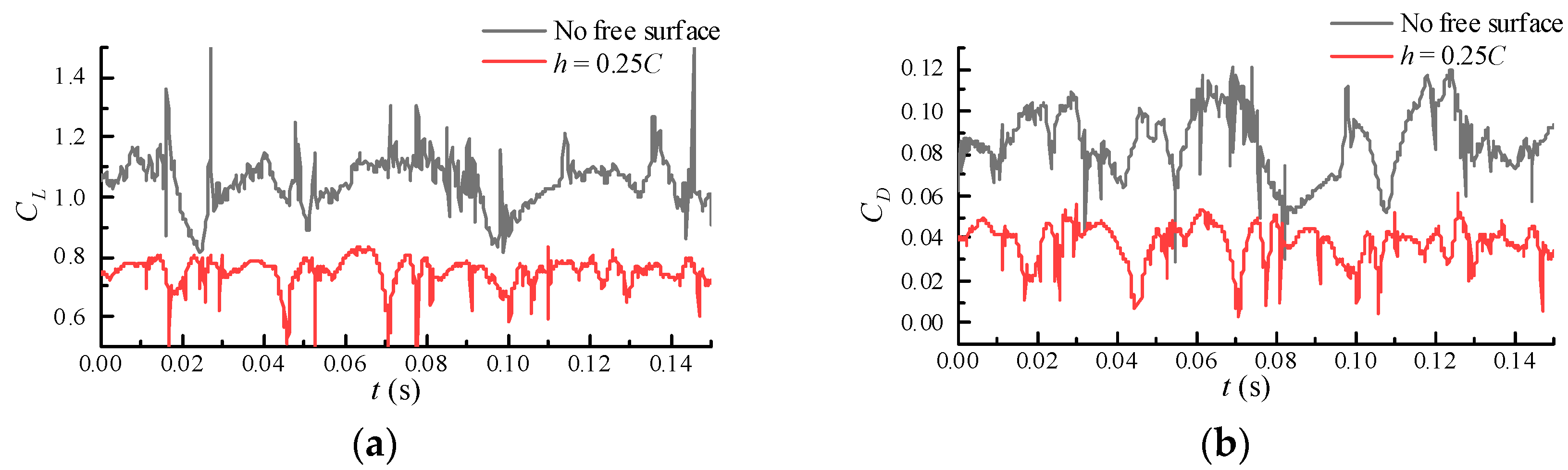

3.1. Effect of a Free Surface on the Dynamic Cavity Evolution and Hydrodynamic Load

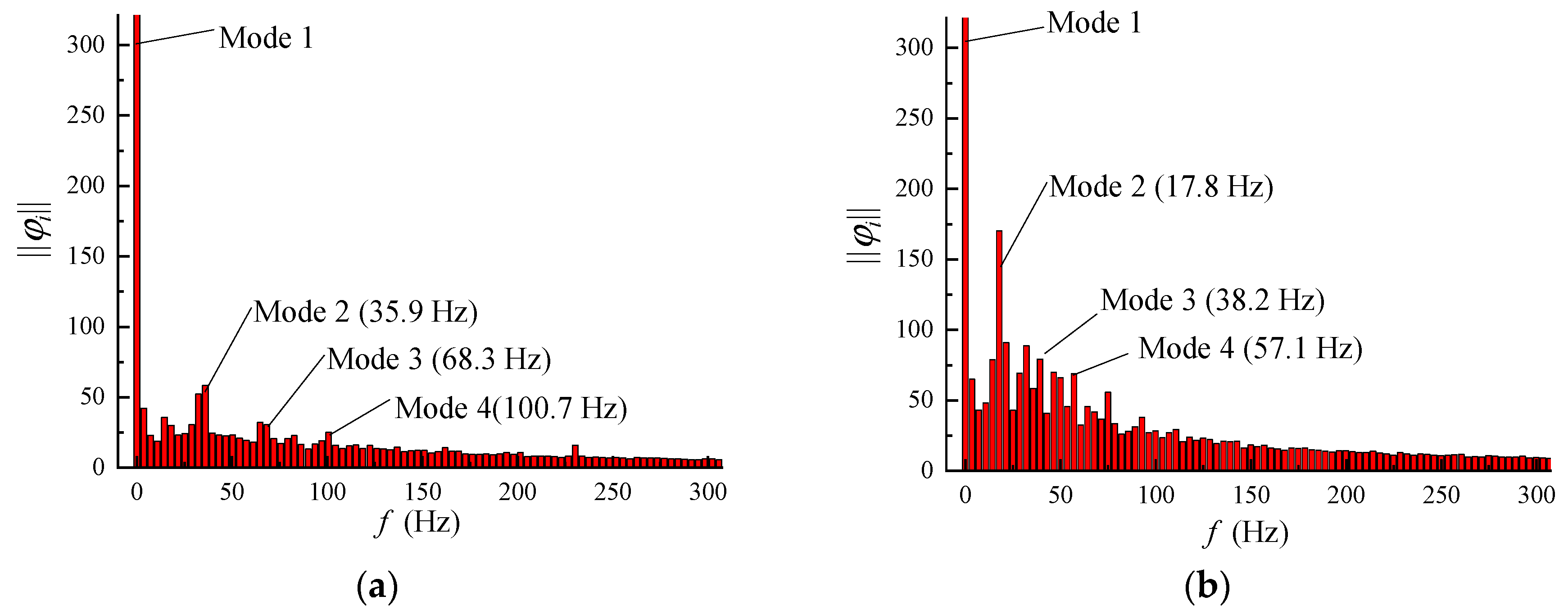

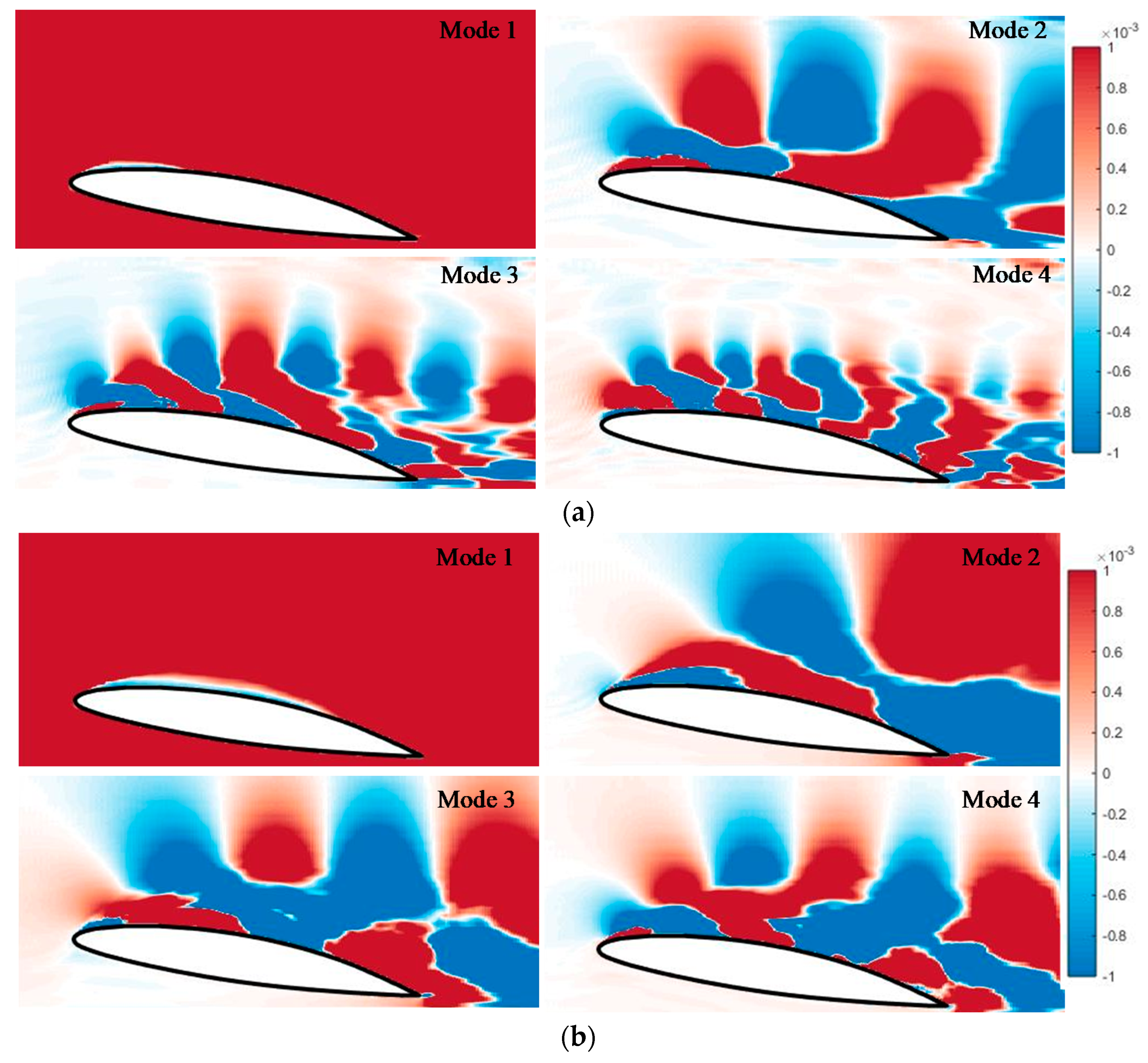

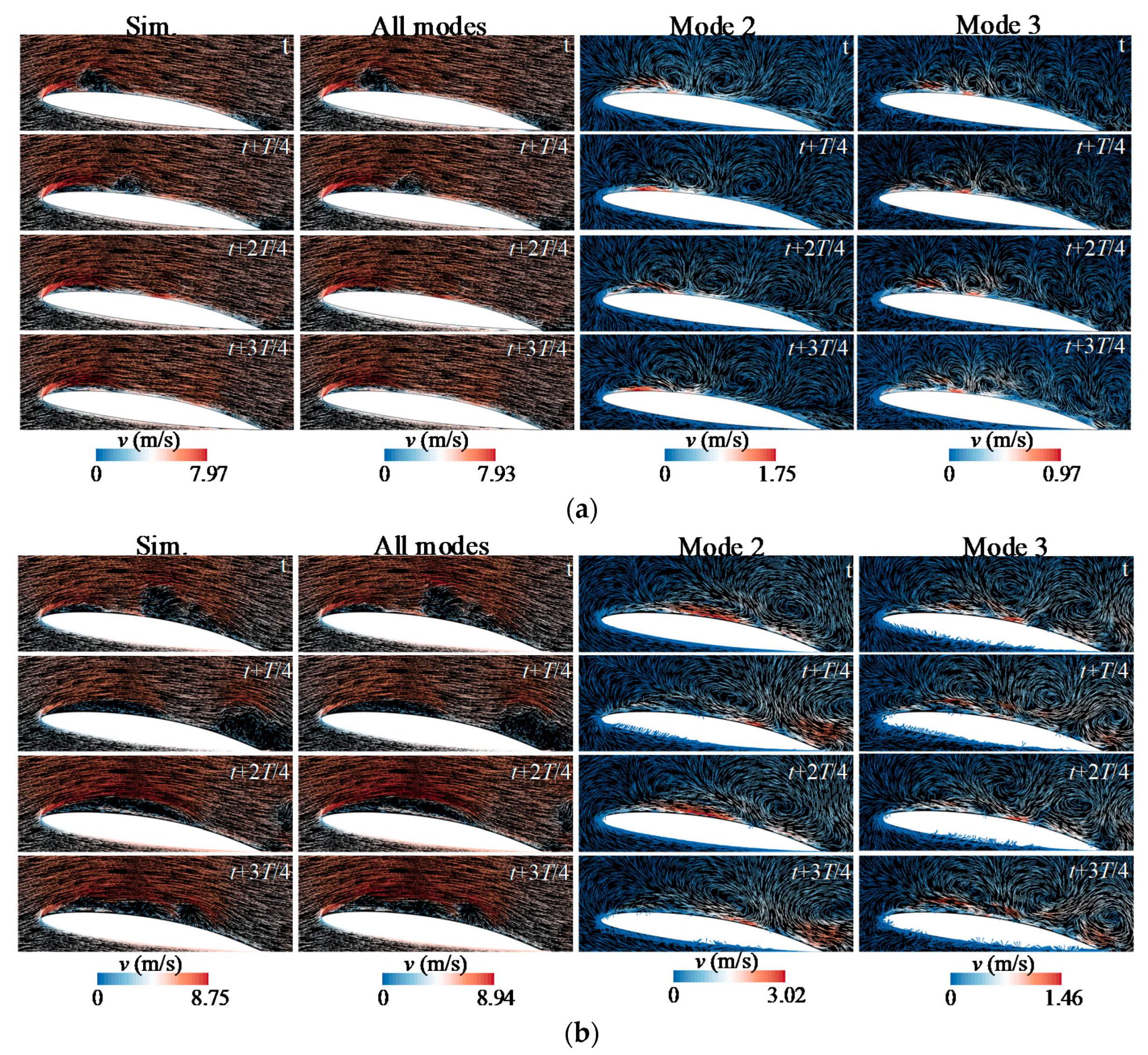

3.2. Analysis of the Flow Structure Based on the DMD Method

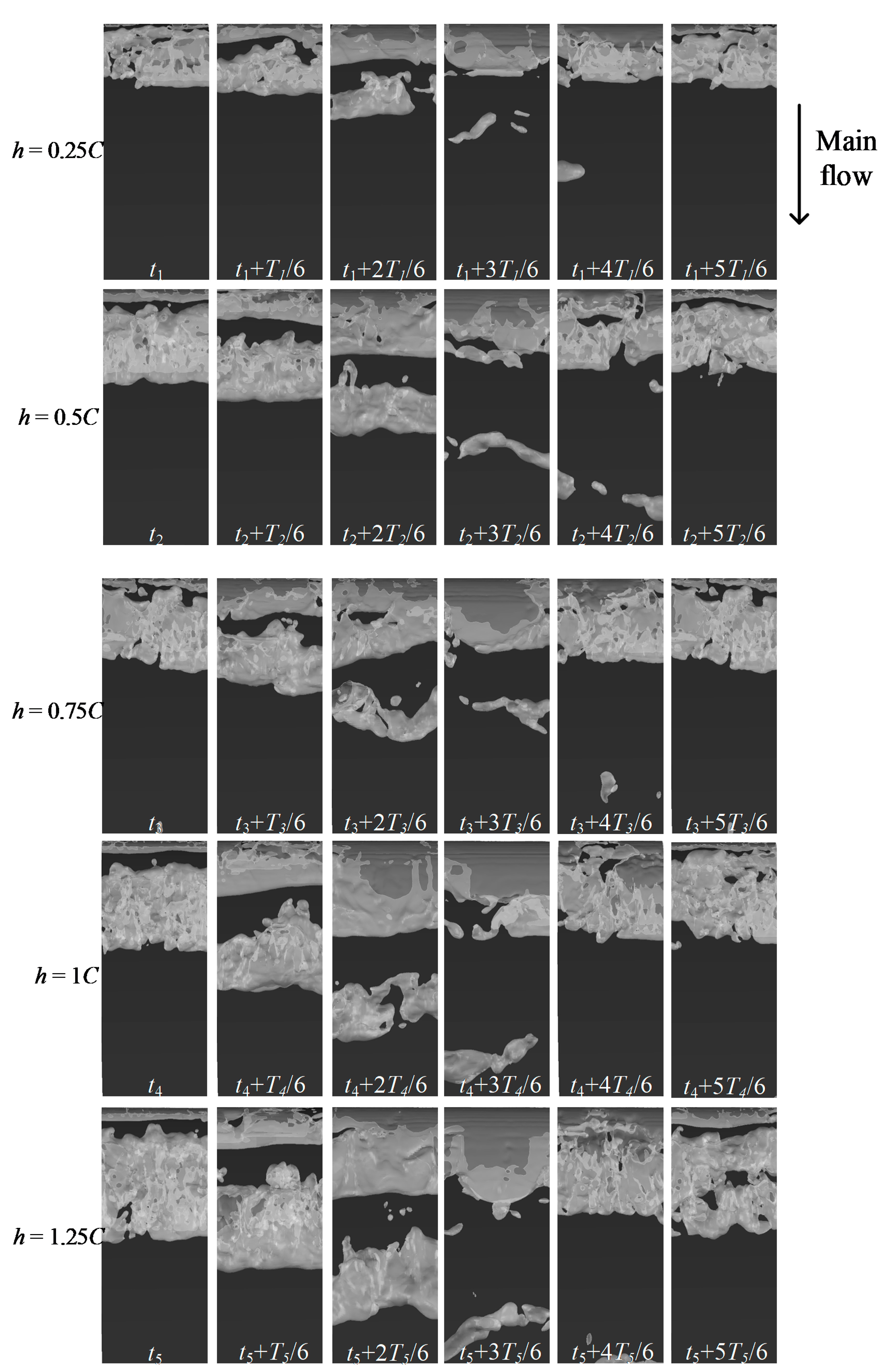

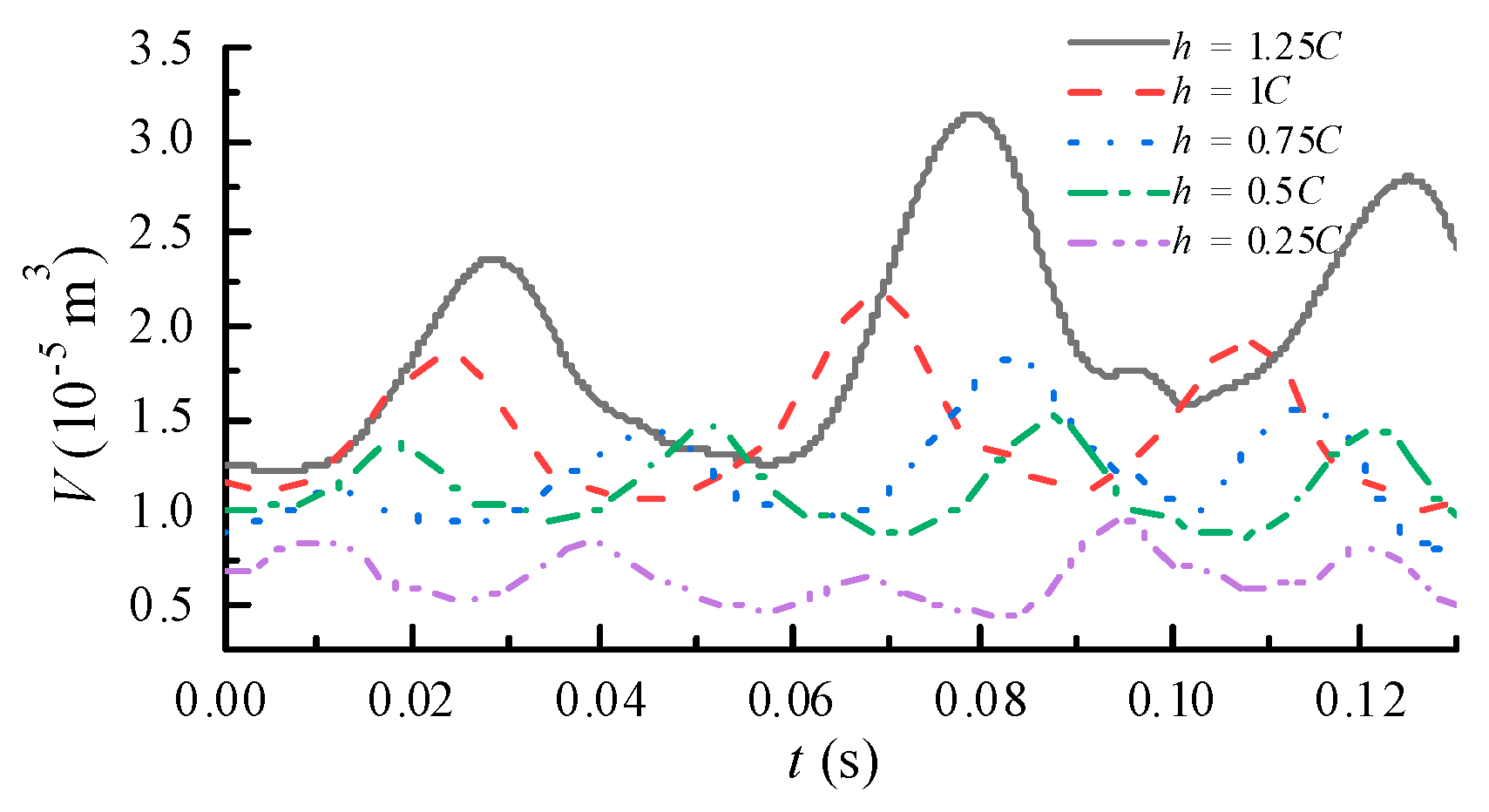

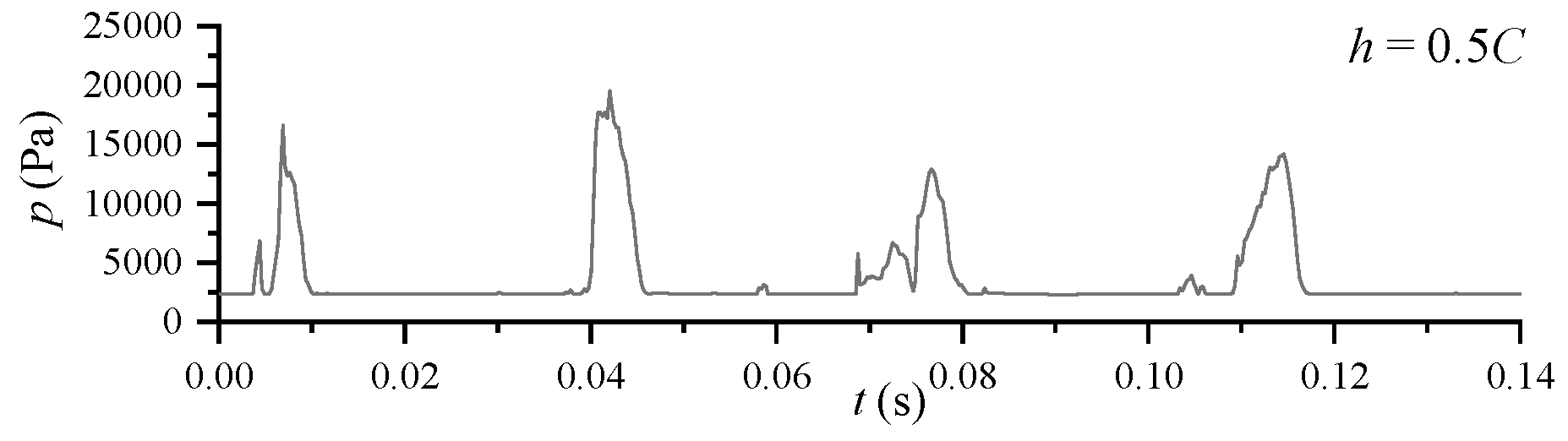

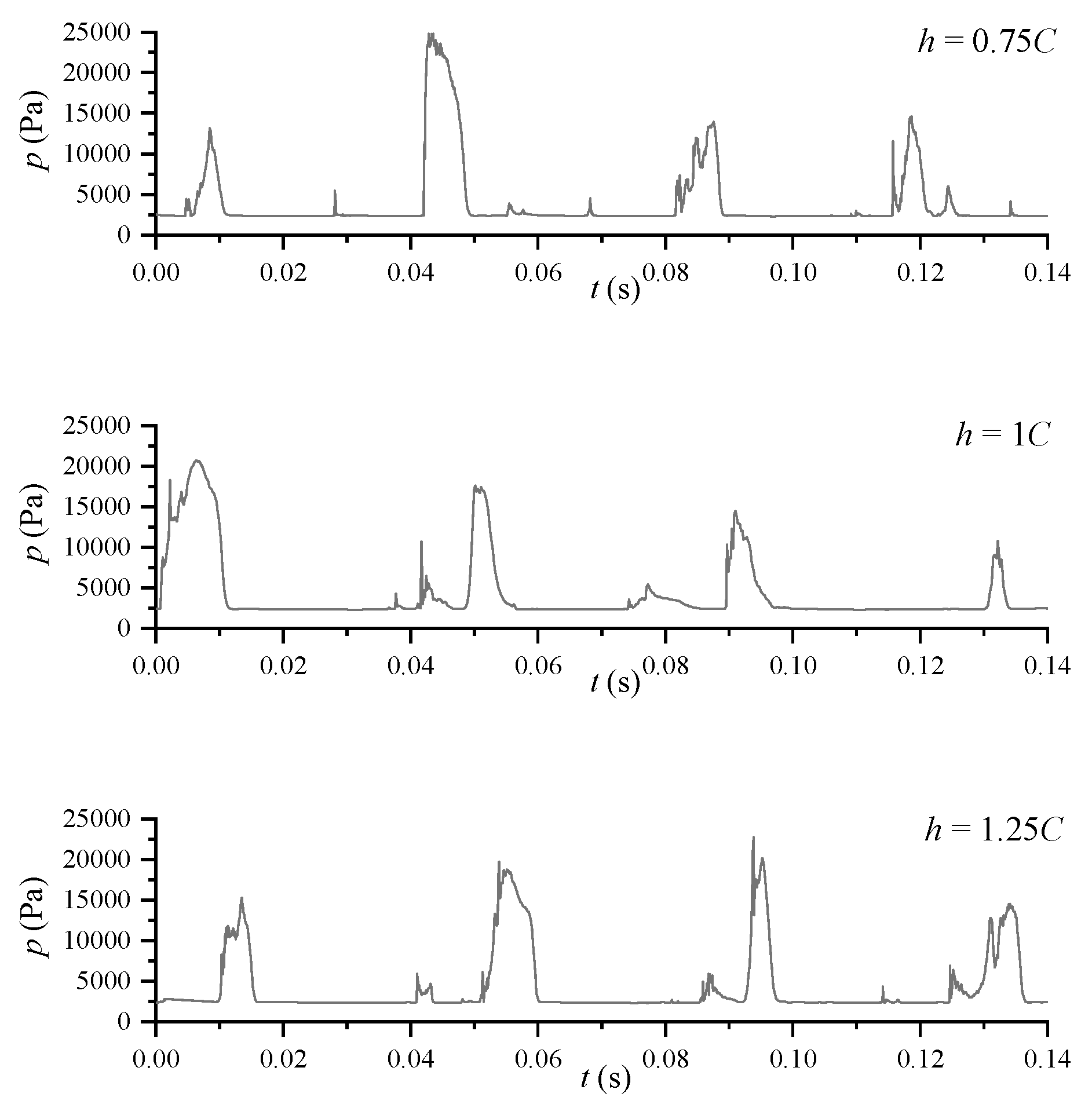

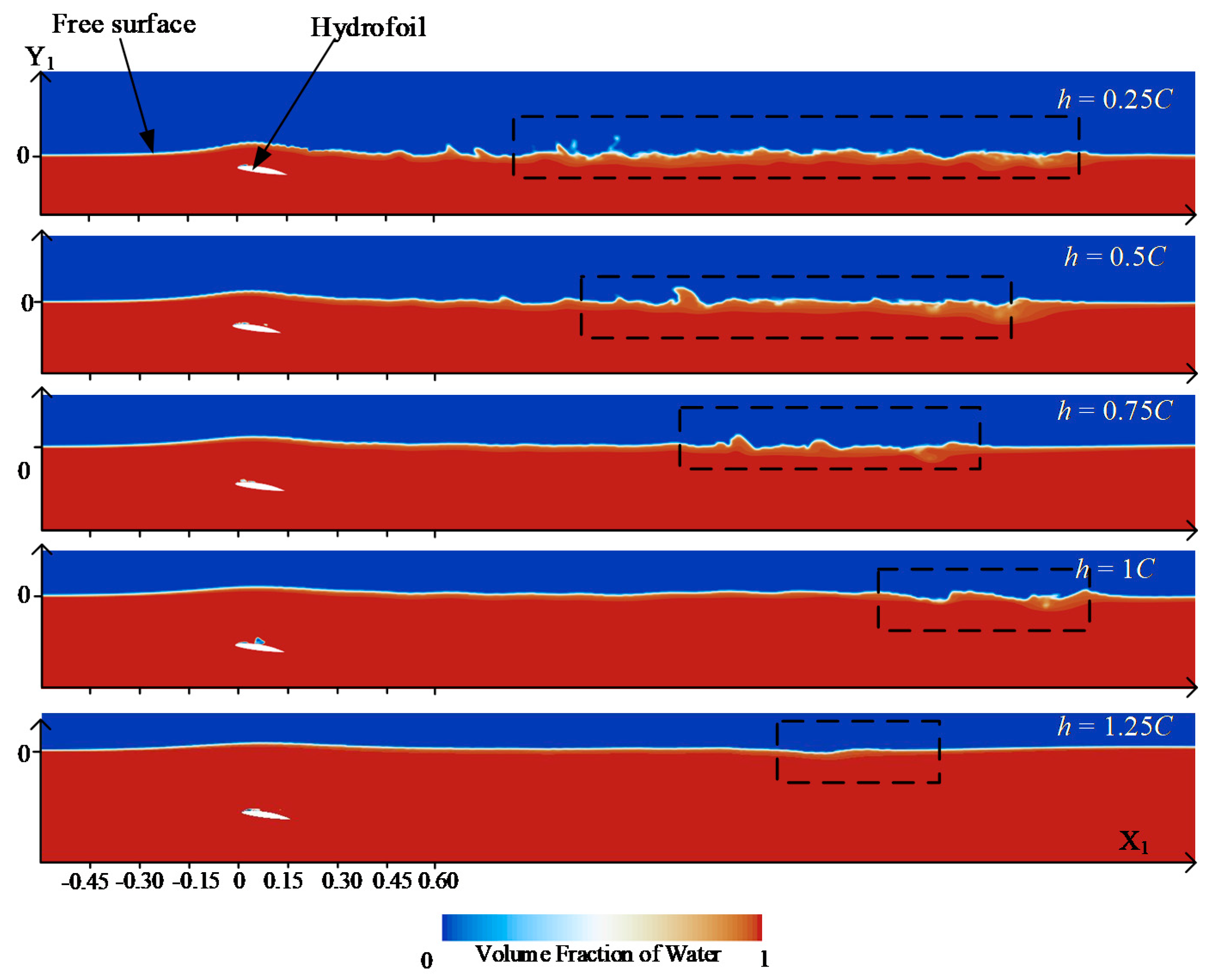

3.3. Free Surface-Cavitation Interaction at Different Water Depths

4. Conclusions

- (1)

- The existence of the free surface significantly affects the cavitation evolution and hydrodynamic load characteristics over the hydrofoil. Compared with non-free surface conditions, the free surface suppresses the cavitation intensity and accelerates the cavitation evolution. The specific feature is that the period of cavitation development, break-off, shedding and collapse becomes smaller. Meanwhile, both lift and drag are reduced due to the effects of the free surface.

- (2)

- A close relationship is found that between the characteristic mode and the flow field by an improved dynamic mode decomposition method. The existence of free surfaces reduces the energy content in each order mode and results in smaller scale of the coherent structure in higher-order modes. Moreover, compared with the free surface, the reconstructed higher-order flow field indicates that the cavitation flow field is accompanied by a smaller scale and a larger number of vortices for the free surface case.

- (3)

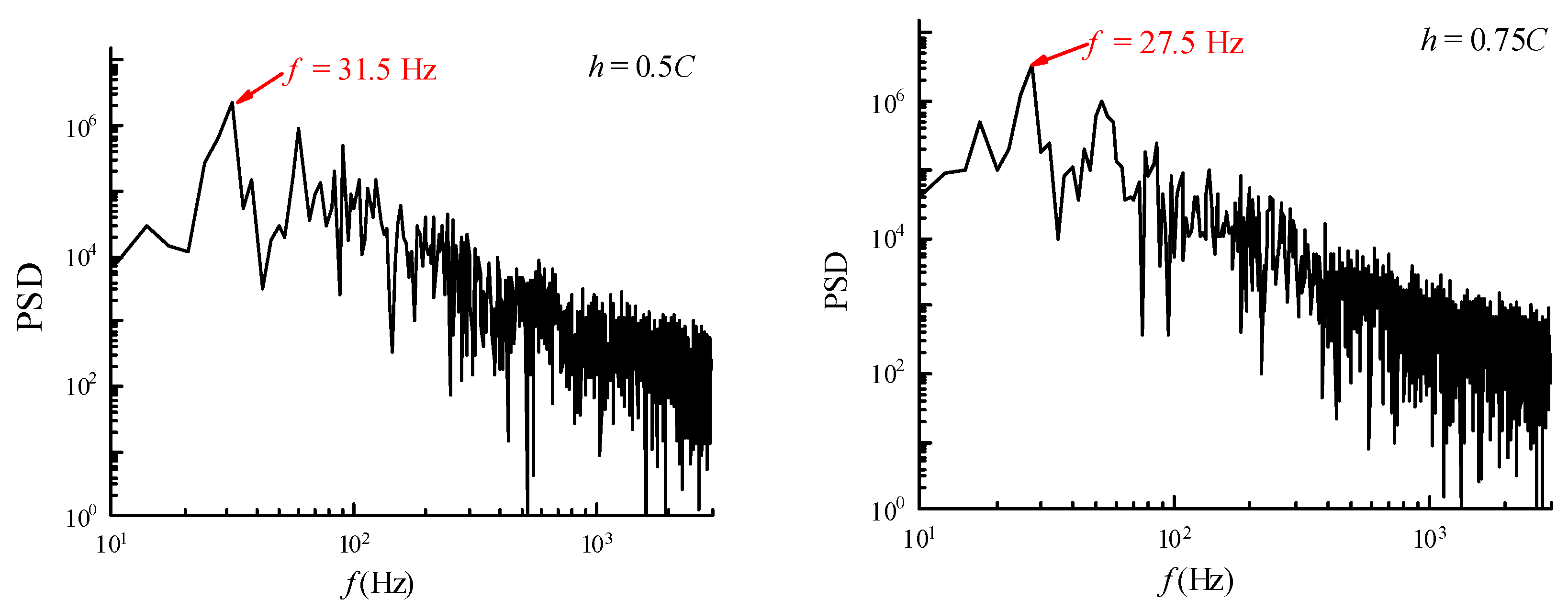

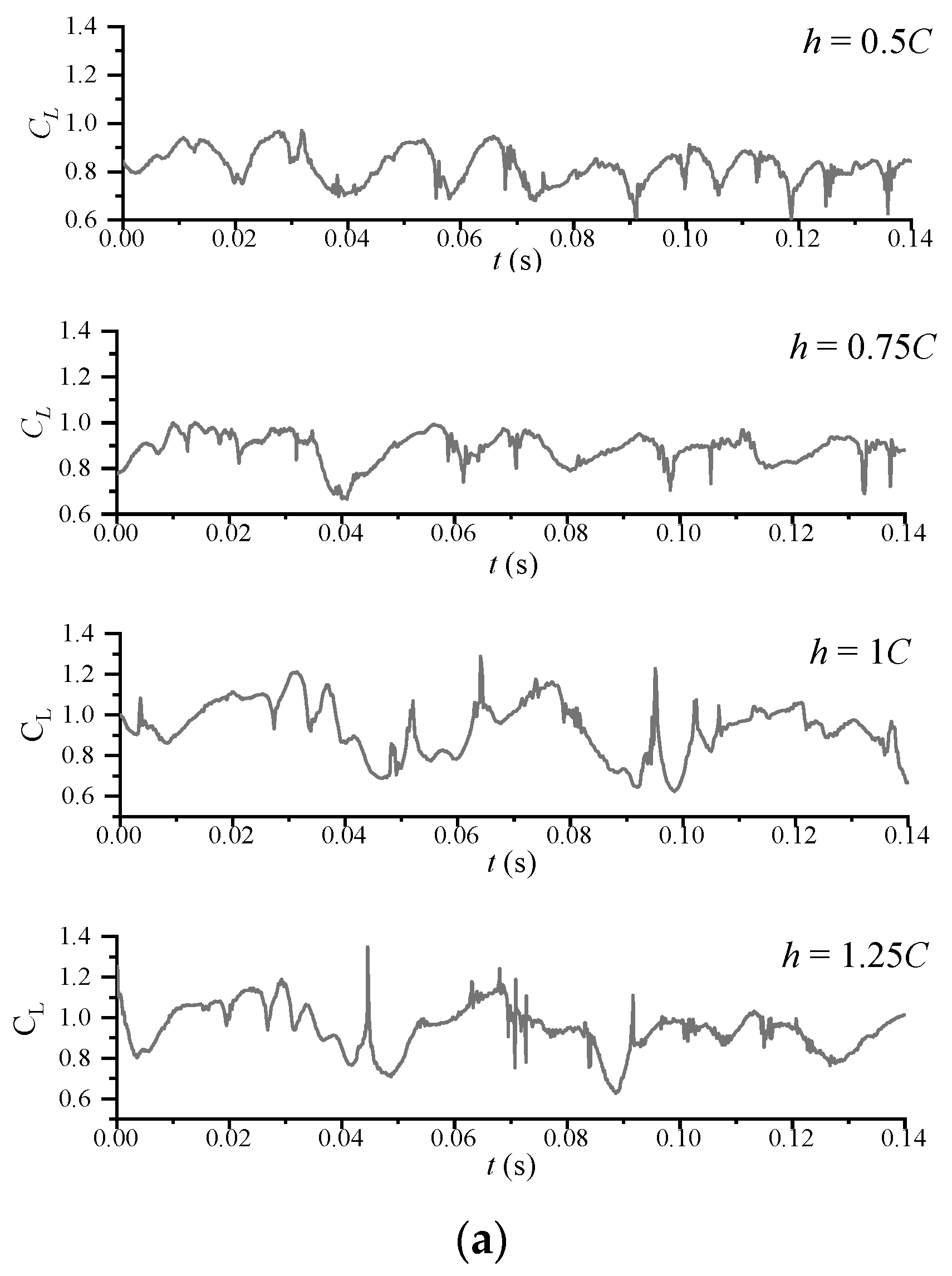

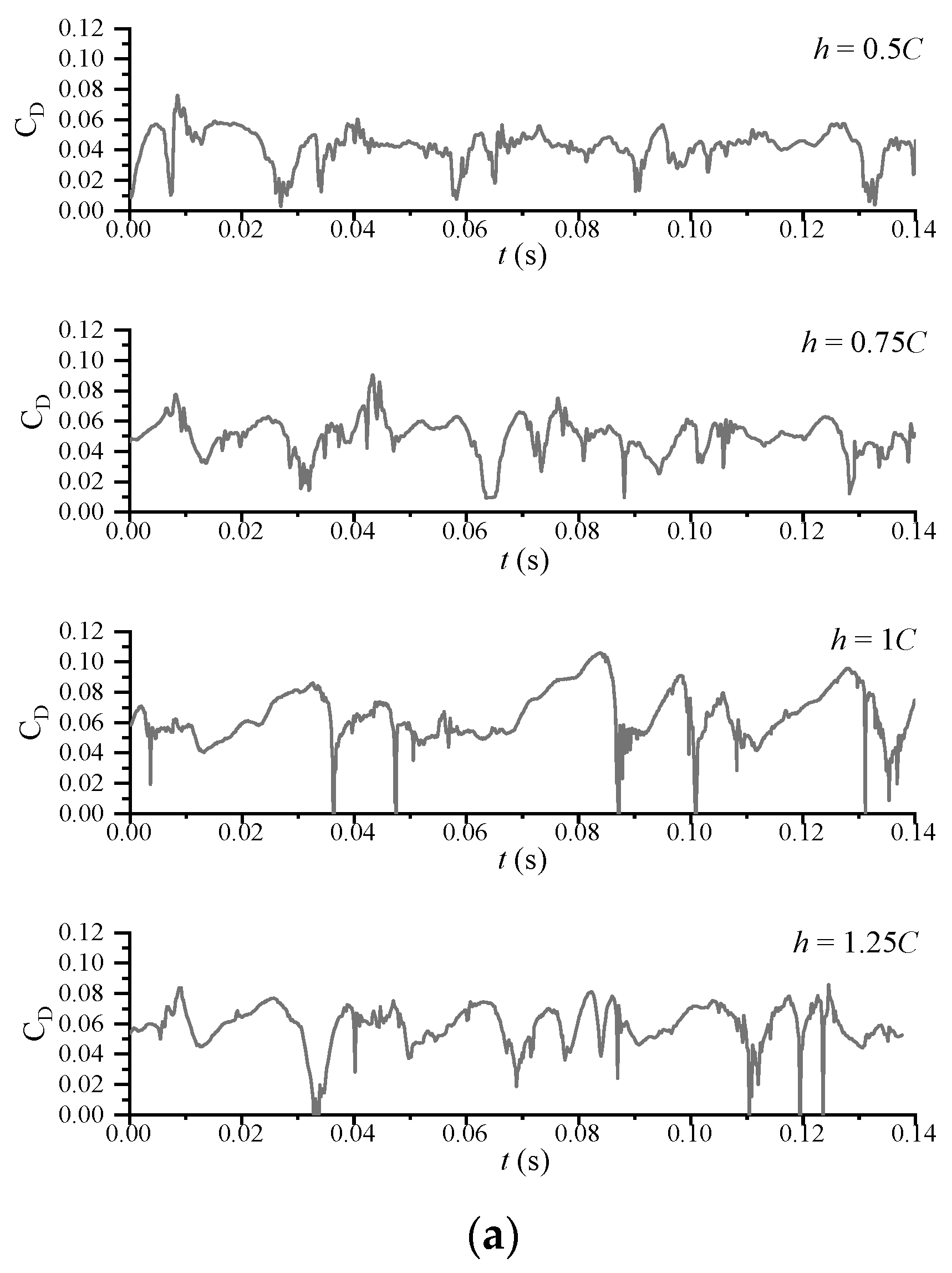

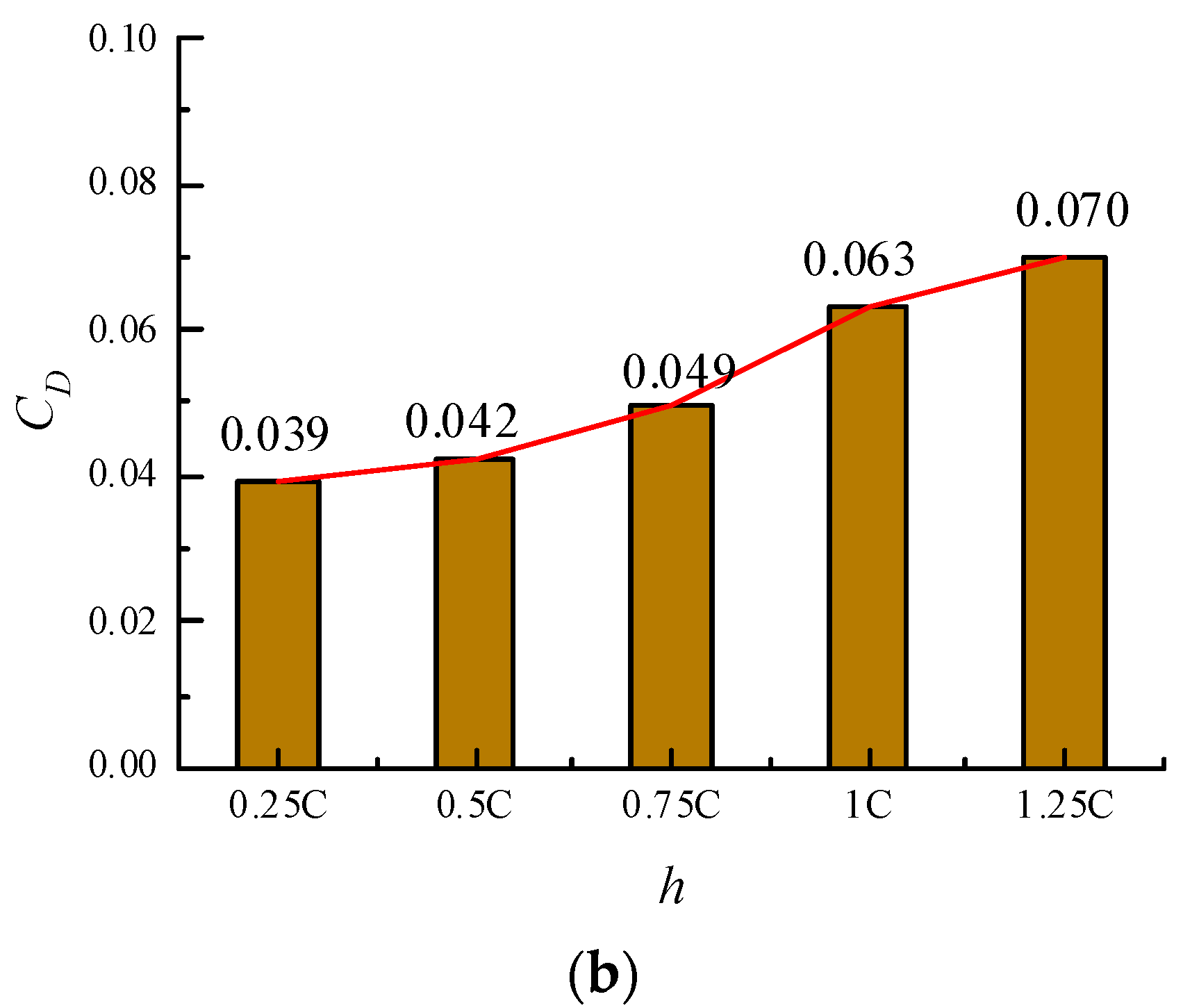

- The distance of the hydrofoil from the free surface has a significant effect on cavitation intensity, pressure pulsation, lift, drag and the wake region. For the same cavitation number, as the distance from the hydrofoil to the free surface increases, the cavitation intensity is promoted, the oscillating frequency of pulsating pressure decreases, the average lift and drag coefficients become larger. Furthermore, it is worth noting that the free surface in the wake region fluctuates more violently at small water depths cases.

Author Contributions

Funding

Conflicts of Interest

References

- Sun, T.; Zhang, X.; Xu, C.; Zhang, G.; Jiang, S.; Zong, Z. Numerical modeling and simulation of the shedding mechanism and vortex structures at the development stage of ventilated partial cavitating flows. Eur. J Mech. B Fluids 2019, 76, 223–232. [Google Scholar] [CrossRef]

- Vahaji, S.; Han, J.; Cheung, S.C.; Yeoh, G.H.; Tu, J. Numerical investigation on the bubble size distribution around NACA0015 hydrofoil. Ocean Eng. 2019, 172, 59–71. [Google Scholar] [CrossRef]

- Sun, T.Z.; Zong, Z.; Zou, L.; Wei, Y.J.; Jiang, Y.C. Numerical investigation of unsteady sheet/cloud cavitation over a hydrofoil in thermo-sensitive fluid. J. Hydrodynam. B 2017, 29, 987–999. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, Y.; Wang, G. Experimental investigation of cavitating flow-induced vibration of hydrofoils. Ocean Eng. 2017, 144, 50–60. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Cao, S. Dynamic mode decomposition of cavitating flow around ALE 15 hydrofoil. Renew. Energy 2019, 139, 214–227. [Google Scholar] [CrossRef]

- Faltinsen, O.M. Hydrodynamics of High-speed Marine Vehicles; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Furness, R.A.; Hutton, S.P. Experimental and theoretical studies of two-dimensional fixed-type cavities. J. Fluids Eng. 1975, 97, 515–521. [Google Scholar] [CrossRef]

- Arndt, R.E. Cavitation in fluid machinery and hydraulic structures. Annu. Rev. Fluid Mech. 1981, 13, 273–326. [Google Scholar] [CrossRef]

- Sun, T.; Zhang, X.; Xu, C.; Zhang, G.; Wang, C.; Zong, Z. Experimental investigation on the cavity evolution and dynamics with special emphasis on the development stage of ventilated partial cavitating flow. Ocean Eng. 2019, 187, 106140. [Google Scholar] [CrossRef]

- Knapp, R.T. Recent investigations of the mechanics of cavitation and cavitation damage. Trans. ASME 1955, 77, 1045–1054. [Google Scholar]

- Kubota, A.; Kato, H.; Yamaguchi, H.; Maeda, M. Unsteady structure measurement of cloud cavitation on a foil section using conditional sampling technique. J. Fluids Eng. 1989, 111, 204–210. [Google Scholar] [CrossRef]

- Kawanami, Y.; Kato, H.; Yamaguchi, H.; Tanimura, M.; Tagaya, Y. Mechanism and control of cloud cavitation. J. Fluids Eng. 1997, 119, 788–794. [Google Scholar] [CrossRef]

- Reisman, G.E.; Wang, Y.C.; Brennen, C.E. Observations of shock waves in cloud cavitation. J. Fluid Mech. 1998, 355, 255–283. [Google Scholar] [CrossRef]

- Arndt, R.E.; Song, C.C.S.; Kjeldsen, M.; He, J.; Keller, A. Instability of partial cavitation: A numerical/experimental approach. In Proceedings of the Twenty-Third Symposium on Naval Hydrodynamics, Val de Reuil, France, 17–22 September 2000. [Google Scholar]

- Gopalan, S.; Katz, J. Flow structure and modeling issues in the closure region of attached cavitation. Phys. Fluids 2000, 12, 895–911. [Google Scholar] [CrossRef]

- Leroux, J.B.; Astolfi, J.A.; Billard, J.Y. An experimental study of unsteady partial cavitation. J. Fluids Eng. 2004, 126, 94–101. [Google Scholar] [CrossRef]

- Leroux, J.B.; Coutier-Delgosha, O.; Astolfi, J.A. A joint experimental and numerical study of mechanisms associated to instability of partial cavitation on two-dimensional hydrofoil. Phys. Fluids 2005, 17, 052101. [Google Scholar] [CrossRef]

- Passandideh-Fard, M.; Roohi, E. Transient simulations of cavitating flows using a modified volume-of-fluid (VOF) technique. Int. J. Comput. Fluid Dyn. 2008, 22, 97–114. [Google Scholar] [CrossRef]

- Ganesh, H.; Mäkiharju, S.A.; Ceccio, S.L. Bubbly shock propagation as a mechanism for sheet-to-cloud transition of partial cavities. J. Fluid Mech. 2016, 802, 37–78. [Google Scholar] [CrossRef]

- Pendar, M.R.; Roohi, E. Cavitation characteristics around a sphere: An LES investigation. Int. J. Multiph. Flow 2018, 98, 1–23. [Google Scholar] [CrossRef]

- Capurso, T.; Lorusso, M.; Camporeale, S.M.; Fortunato, B.; Torresi, M. Implementation of a passive control system for limiting cavitation around hydrofoils. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 240, p. 032025. [Google Scholar]

- Cheng, H.; Long, X.; Ji, B.; Peng, X.; Farhat, M. LES investigation of the influence of cavitation on flow patterns in a confined tip-leakage flow. Ocean Eng. 2019, 186, 106115. [Google Scholar] [CrossRef]

- Cheng, H.Y.; Bai, X.R.; Long, X.P.; Ji, B.; Peng, X.X.; Farhat, M. Large eddy simulation of the tip-leakage cavitating flow with an insight on how cavitation influences vorticity and turbulence. Appl. Math. Model. 2020, 77, 788–809. [Google Scholar] [CrossRef]

- Dawson, T.E. An Experimental Investigation of a Fully Cavitating Two-dimensional Flat Plate Hydrofoil Near a Free Surface. Ph.D. Thesis, California Institute of Technology, Pasadena, CA, USA, 1959. [Google Scholar]

- Roohi, E.; Zahiri, A.P.; Passandideh-Fard, M. Numerical simulation of cavitation around a two-dimensional hydrofoil using VOF method and LES turbulence model. Appl. Math. Model. 2013, 37, 6469–6488. [Google Scholar] [CrossRef]

- Karim, M.M.; Prasad, B.; Rahman, N. Numerical simulation of free surface water wave for the flow around NACA 0015 hydrofoil using the volume of fluid (VOF) method. Ocean Eng. 2014, 78, 89–94. [Google Scholar] [CrossRef]

- Oguchi, K.; Enoki, M.; Hirata, N. Numerical simulation for cavitation bubble near free surface and rigid boundary. Mater. Trans. 2015, 56, 534–538. [Google Scholar] [CrossRef]

- Prasad, B.; Hino, T.; Suzuki, K. Numerical simulation of free surface flows around shallowly submerged hydrofoil by OpenFOAM. Ocean Eng. 2015, 102, 87–94. [Google Scholar] [CrossRef]

- Faltinsen, O.M.; Semenov, Y.A. The effect of gravity and cavitation on a hydrofoil near the free surface. J. Fluid Mech. 2008, 597, 371–394. [Google Scholar] [CrossRef]

- Kinzel, M.P.; Lindau, J.W.; Kunz, R.F. Free-surface proximity effects in developed and super-cavitation. In Proceedings of the 2008 DoD HPCMP Users Group Conference, Seattle, WA, USA, 14–17 July 2008; pp. 25–34. [Google Scholar]

- Wang, Y.; Wu, X.; Huang, C.; Wu, X. Unsteady characteristics of cloud cavitating flow near the free surface around an axisymmetric projectile. Int. J. Multiph. Flow 2016, 85, 48–56. [Google Scholar] [CrossRef]

- Ye, B.; Wang, Y.; Huang, C.; Huang, J. Numerical study of the pressure wave-induced shedding mechanism in the cavitating flow around an axisymmetric projectile via a compressible multiphase solver. Ocean Eng. 2019, 187, 106179. [Google Scholar] [CrossRef]

- Zhou, H.; Xiang, M.; Zhao, S.; Zhang, W. Development of a multiphase solver for cavitation flow near free surface. Ocean Eng. 2019, 188, 106236. [Google Scholar] [CrossRef]

- Sun, T.; Wei, Y.; Zou, L.; Jiang, Y.; Xu, C.; Zong, Z. Numerical investigation on the unsteady cavitation shedding dynamics over a hydrofoil in thermo-sensitive fluid. Int. J. Multiph. Flow 2019, 111, 82–100. [Google Scholar] [CrossRef]

- Capurso, T.; Lopez, M.; Lorusso, M.; Torresi, M.; Pascazio, G.; Camporeale, S.M.; Fortunato, B. Numerical investigation of cavitation on a NACA0015 hydrofoil by means of OpenFOAM. Energy Procedia 2017, 126, 794–801. [Google Scholar] [CrossRef]

- Huang, B.; Ducoin, A.; Young, Y.L. Physical and numerical investigation of cavitating flows around a pitching hydrofoil. Phys. Fluids 2013, 25, 102109. [Google Scholar] [CrossRef]

- Long, X.; Cheng, H.; Ji, B.; Arndt, R.E.; Peng, X. Large eddy simulation and Euler–Lagrangian coupling investigation of the transient cavitating turbulent flow around a twisted hydrofoil. Int. J. Multiph. Flow 2018, 100, 41–56. [Google Scholar] [CrossRef]

- Pendar, M.R.; Roohi, E. Investigation of cavitation around 3D hemispherical head-form body and conical cavitators using different turbulence and cavitation models. Ocean Eng. 2016, 112, 287–306. [Google Scholar] [CrossRef]

- Sedlar, M.; Ji, B.; Kratky, T.; Rebok, T.; Huzlik, R. Numerical and experimental investigation of three-dimensional cavitating flow around the straight NACA2412 hydrofoil. Ocean Eng. 2016, 123, 357–382. [Google Scholar] [CrossRef]

- Ji, B.; Luo, X.W.; Arndt, R.E.; Peng, X.; Wu, Y. Large eddy simulation and theoretical investigations of the transient cavitating vortical flow structure around a NACA66 hydrofoil. Int. J. Multiph. Flow 2015, 68, 121–134. [Google Scholar] [CrossRef]

- Lidtke, A.K.; Humphrey, V.F.; Turnock, S.R. Feasibility study into a computational approach for marine propeller noise and cavitation modelling. Ocean Eng. 2016, 120, 152–159. [Google Scholar] [CrossRef]

- Movahedian, A.; Pasandidehfard, M.; Roohi, E. LES investigation of sheet-cloud cavitation around a 3-D twisted wing with a NACA 16012 hydrofoil. Ocean Eng. 2019, 192, 106547. [Google Scholar] [CrossRef]

- De Giorgi, M.G.; Fontanarosa, D.; Ficarella, A. Characterization of cavitating flow regimes in an internal sharp-edged orifice by means of Proper Orthogonal Decomposition. Exp. Therm. Fluid Sci. 2018, 93, 242–256. [Google Scholar] [CrossRef]

- Prothin, S.; Djeridi, H.; Billard, J.Y. Coherent and turbulent process analysis of the effects of a longitudinal vortex on boundary layer detachment on a NACA0015 foil. J. Fluids Struct. 2014, 47, 2–20. [Google Scholar] [CrossRef]

- Schmid, P.J. Dynamic mode decomposition of numerical and experimental data. J. Fluid Mech. 2010, 656, 5–28. [Google Scholar] [CrossRef]

- Vinha, N.; Meseguer-Garrido, F.; De Vicente, J.; Valero, E. A dynamic mode decomposition of the saturation process in the open cavity flow. Aerosp. Sci. Technol. 2016, 52, 198–206. [Google Scholar] [CrossRef]

- Prothin, S.; Billard, J.Y.; Djeridi, H. Image processing using proper orthogonal and dynamic mode decompositions for the study of cavitation developing on a NACA0015 foil. Exp. Fluids 2016, 57, 157. [Google Scholar] [CrossRef]

- Nicoud, F.; Ducros, F. Subgrid-scale stress modelling based on the square of the velocity gradient tensor. Flow Turbul. Combust. 1999, 62, 183–200. [Google Scholar] [CrossRef]

- Rayleigh, L. VIII. On the pressure developed in a liquid during the collapse of a spherical cavity. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1917, 34, 94–98. [Google Scholar] [CrossRef]

- Plesset, M.S. The dynamics of cavitation bubbles. J. Appl. Mech. 1949, 16, 277–282. [Google Scholar] [CrossRef]

- Schnerr, G.H.; Sauer, J. Physical and numerical modeling of unsteady cavitation dynamics. In Proceedings of the Fourth International Conference on Multiphase Flow, New Orleans, LA, USA, 27 May–1 June 2001. [Google Scholar]

- Huang, N.E.; Wu, M.L.; Qu, W.; Long, S.R.; Shen, S.S. Applications of Hilbert–Huang transform to non-stationary financial time series analysis. Appl. Stoch. Models Bus. Ind. 2003, 19, 245–268. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, T.; Xie, Q.; Zou, L.; Wang, H.; Xu, C. Numerical Investigation of Unsteady Cavitation Dynamics over a NACA66 Hydrofoil near a Free Surface. J. Mar. Sci. Eng. 2020, 8, 341. https://doi.org/10.3390/jmse8050341

Sun T, Xie Q, Zou L, Wang H, Xu C. Numerical Investigation of Unsteady Cavitation Dynamics over a NACA66 Hydrofoil near a Free Surface. Journal of Marine Science and Engineering. 2020; 8(5):341. https://doi.org/10.3390/jmse8050341

Chicago/Turabian StyleSun, Tiezhi, Qingmo Xie, Li Zou, Hao Wang, and Chang Xu. 2020. "Numerical Investigation of Unsteady Cavitation Dynamics over a NACA66 Hydrofoil near a Free Surface" Journal of Marine Science and Engineering 8, no. 5: 341. https://doi.org/10.3390/jmse8050341

APA StyleSun, T., Xie, Q., Zou, L., Wang, H., & Xu, C. (2020). Numerical Investigation of Unsteady Cavitation Dynamics over a NACA66 Hydrofoil near a Free Surface. Journal of Marine Science and Engineering, 8(5), 341. https://doi.org/10.3390/jmse8050341