Suppression of Tip Vortex Cavitation Noise of Propellers using PressurePoresTM Technology

Abstract

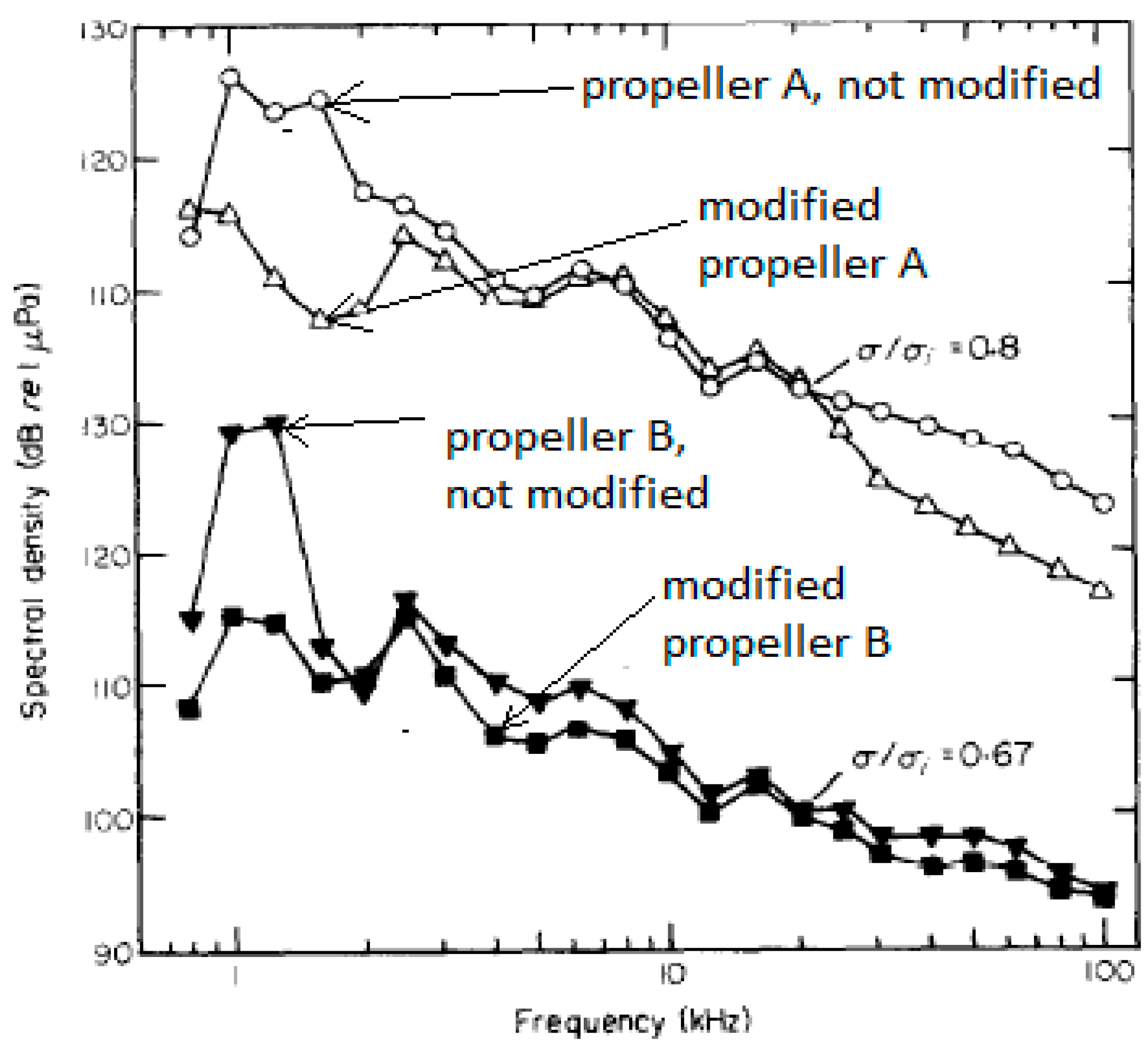

1. Introduction

2. Experimental Investigations

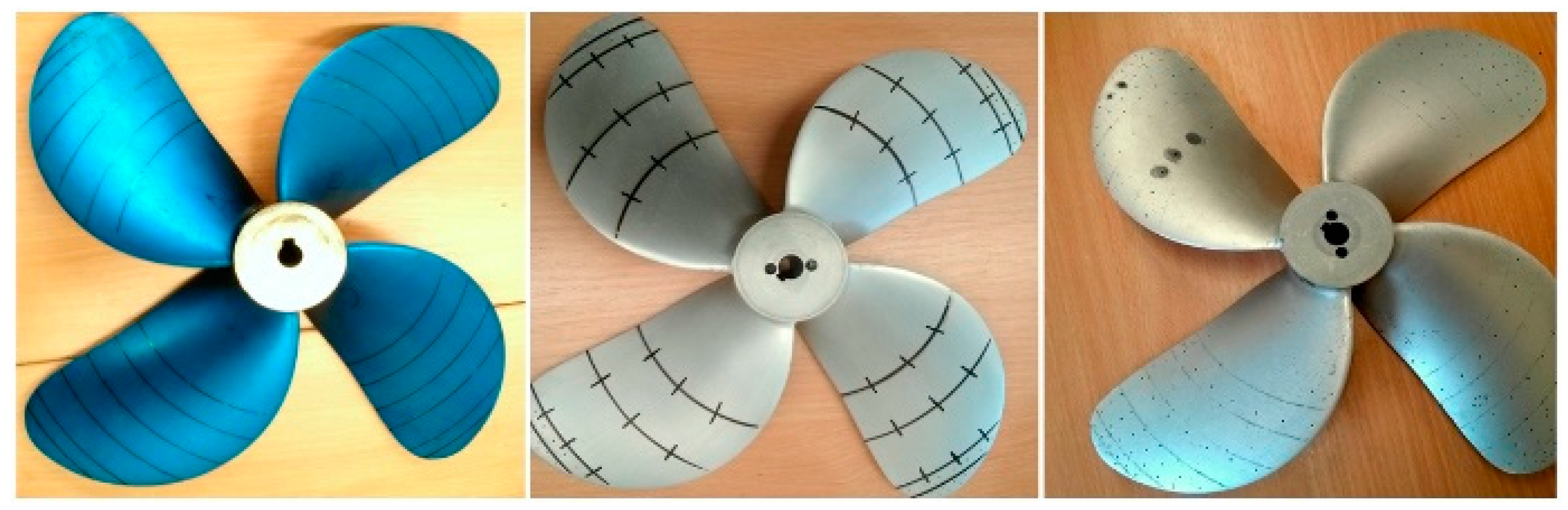

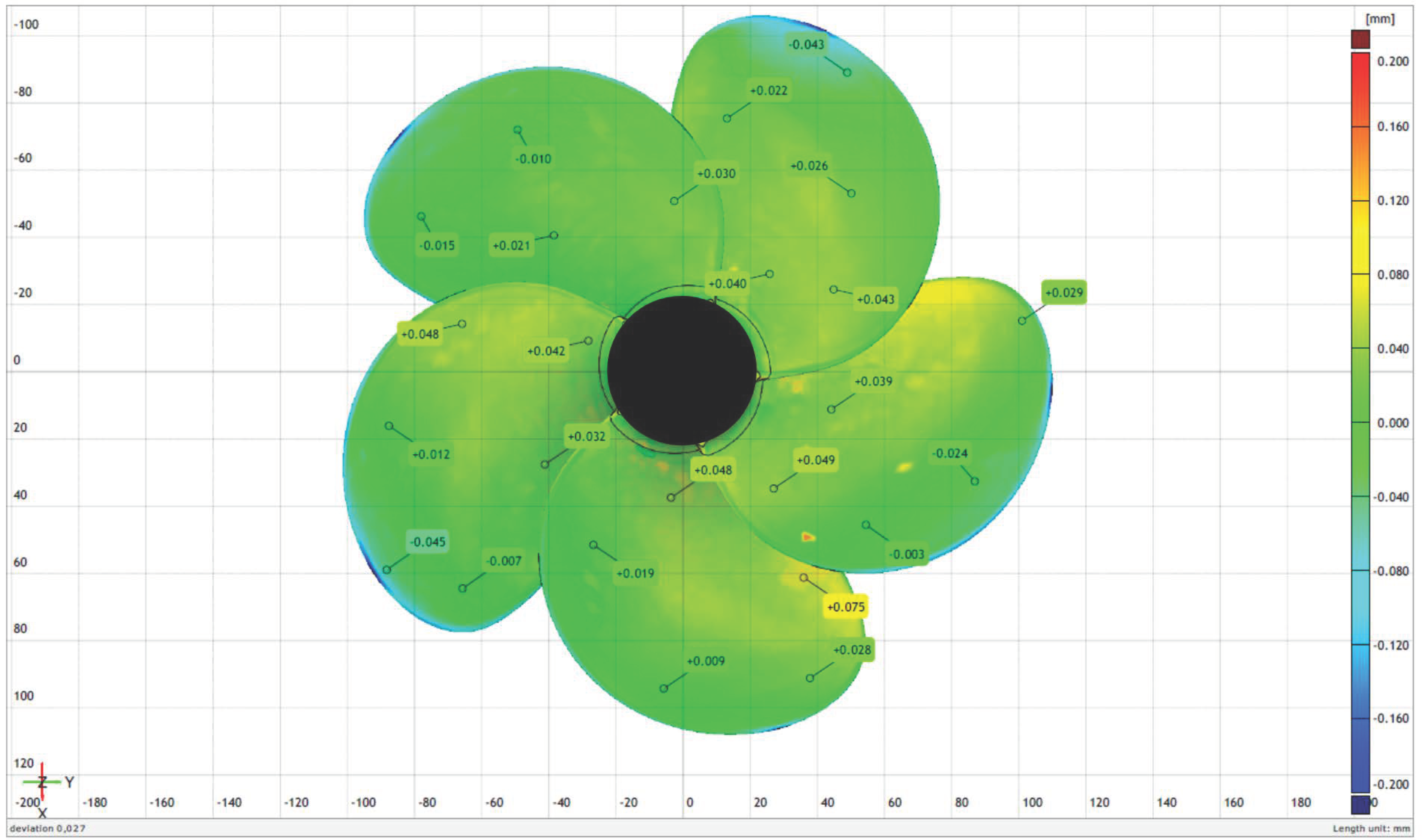

2.1. Propeller Model; The Princess Royal Propeller

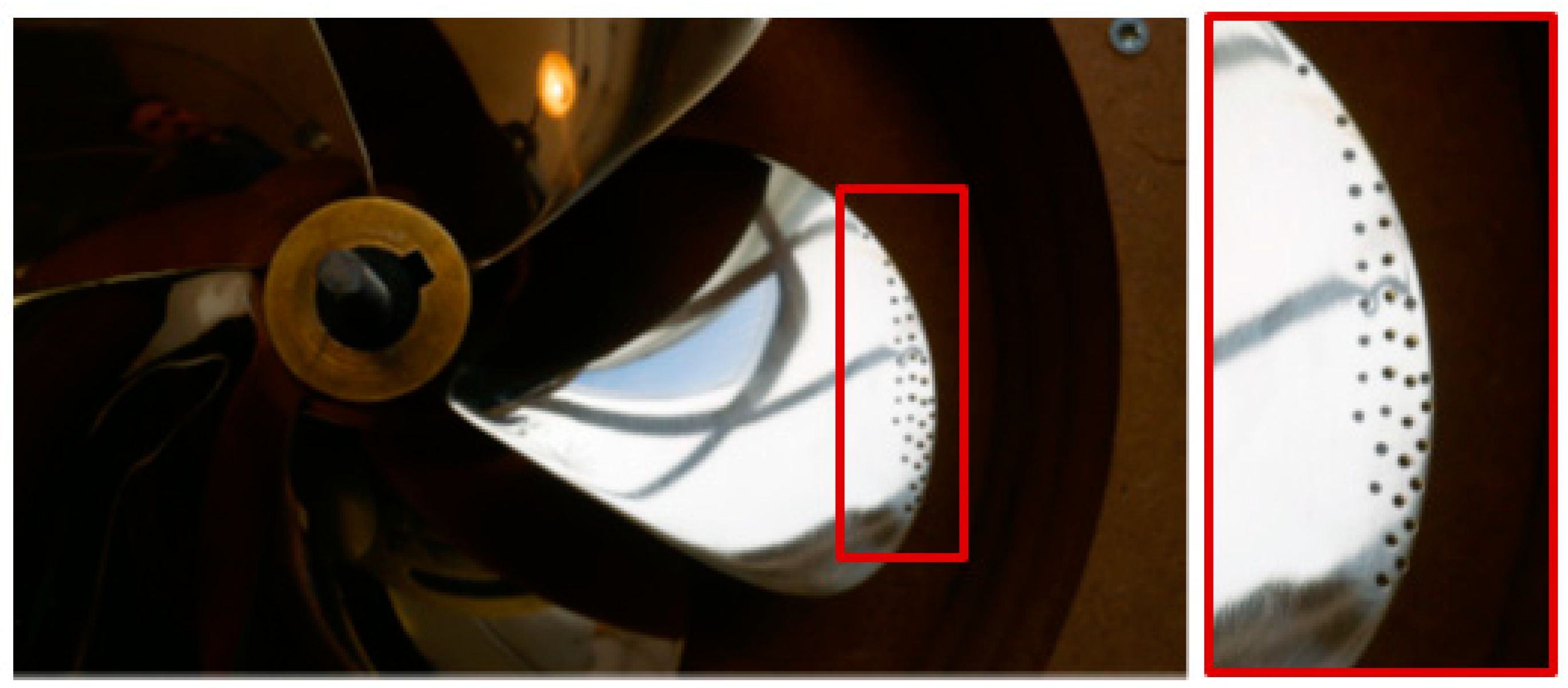

2.2. Application of the PressurePoresTM Technology

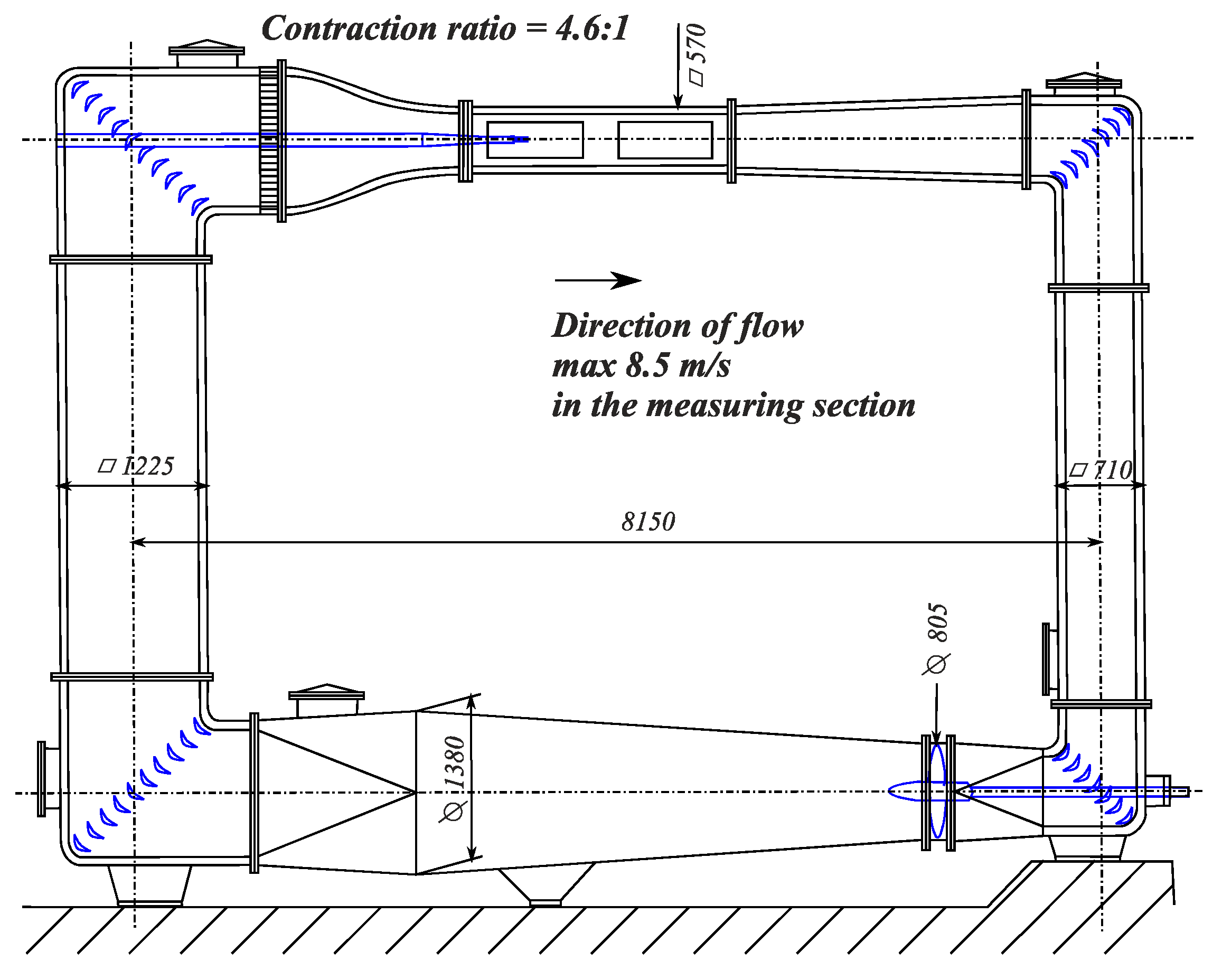

2.3. Test Facilities

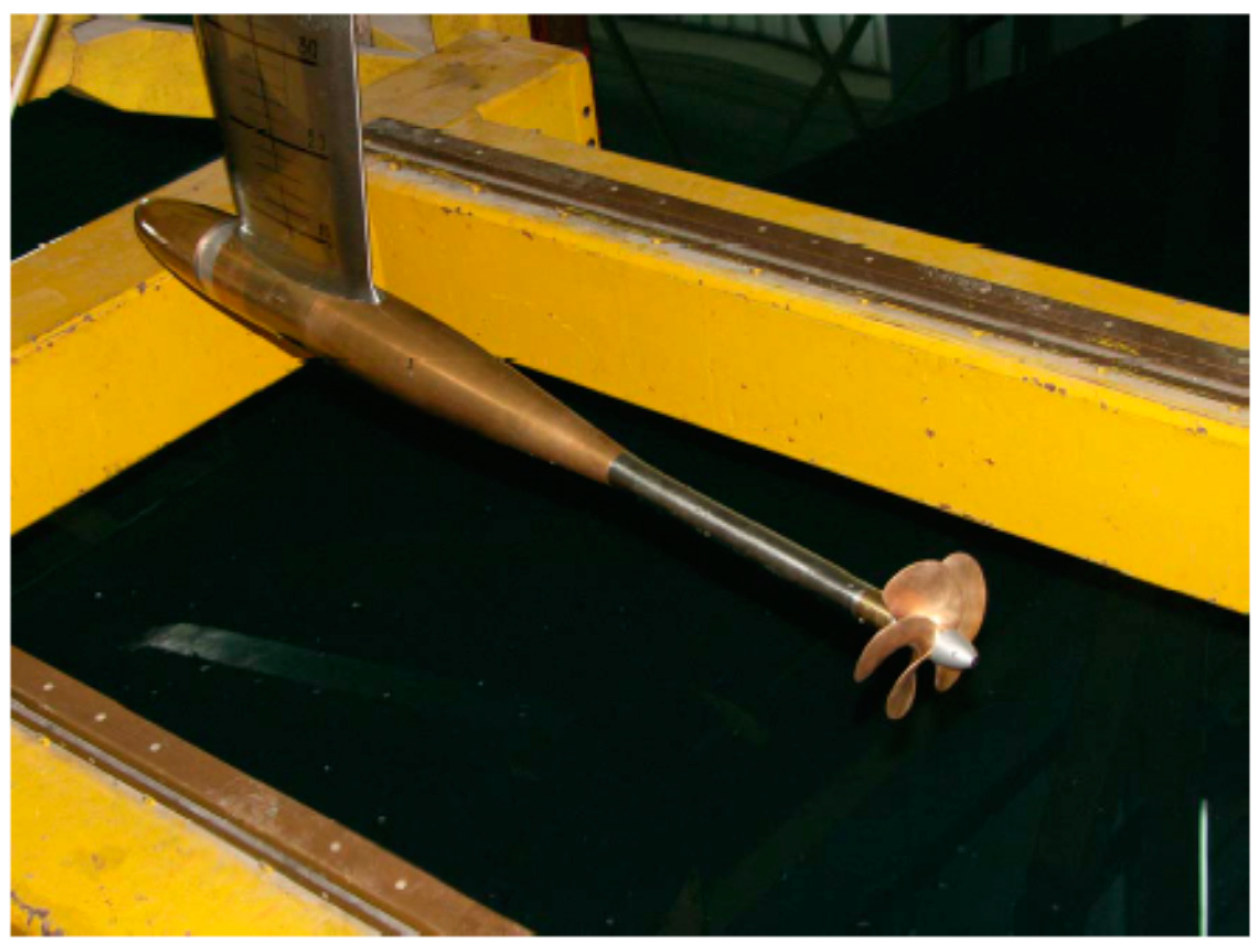

2.4. Test Setup and Test Matrix

3. Prototype Testing

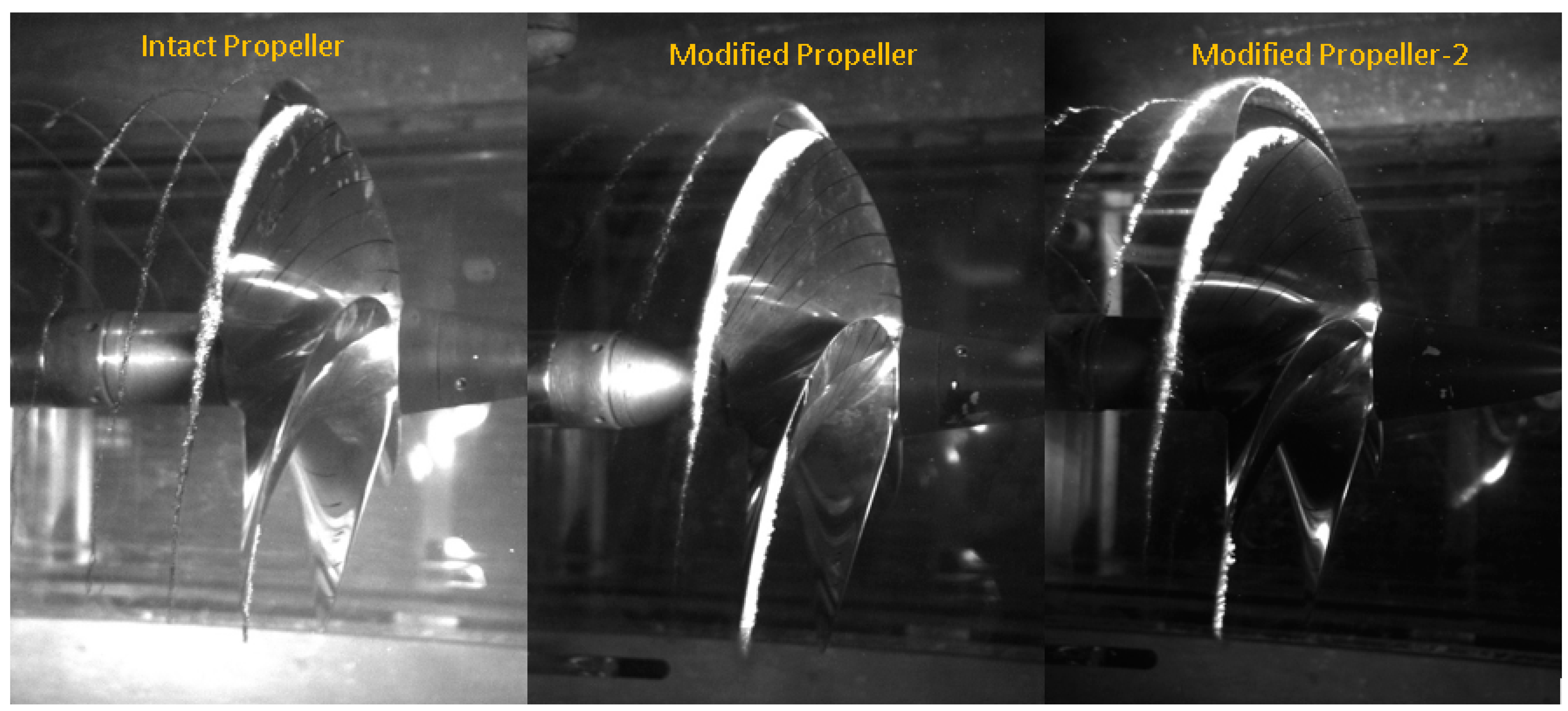

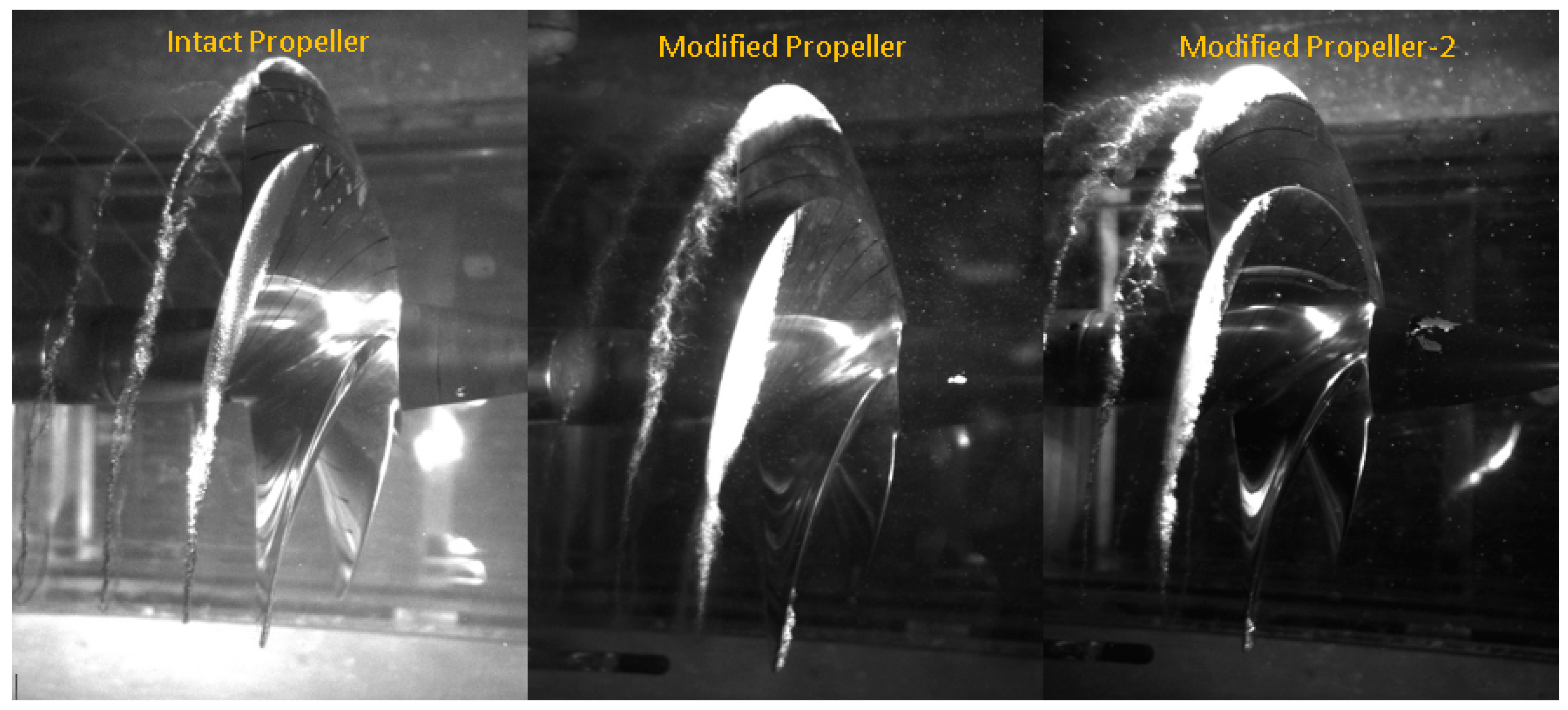

3.1. Cavitation Observations

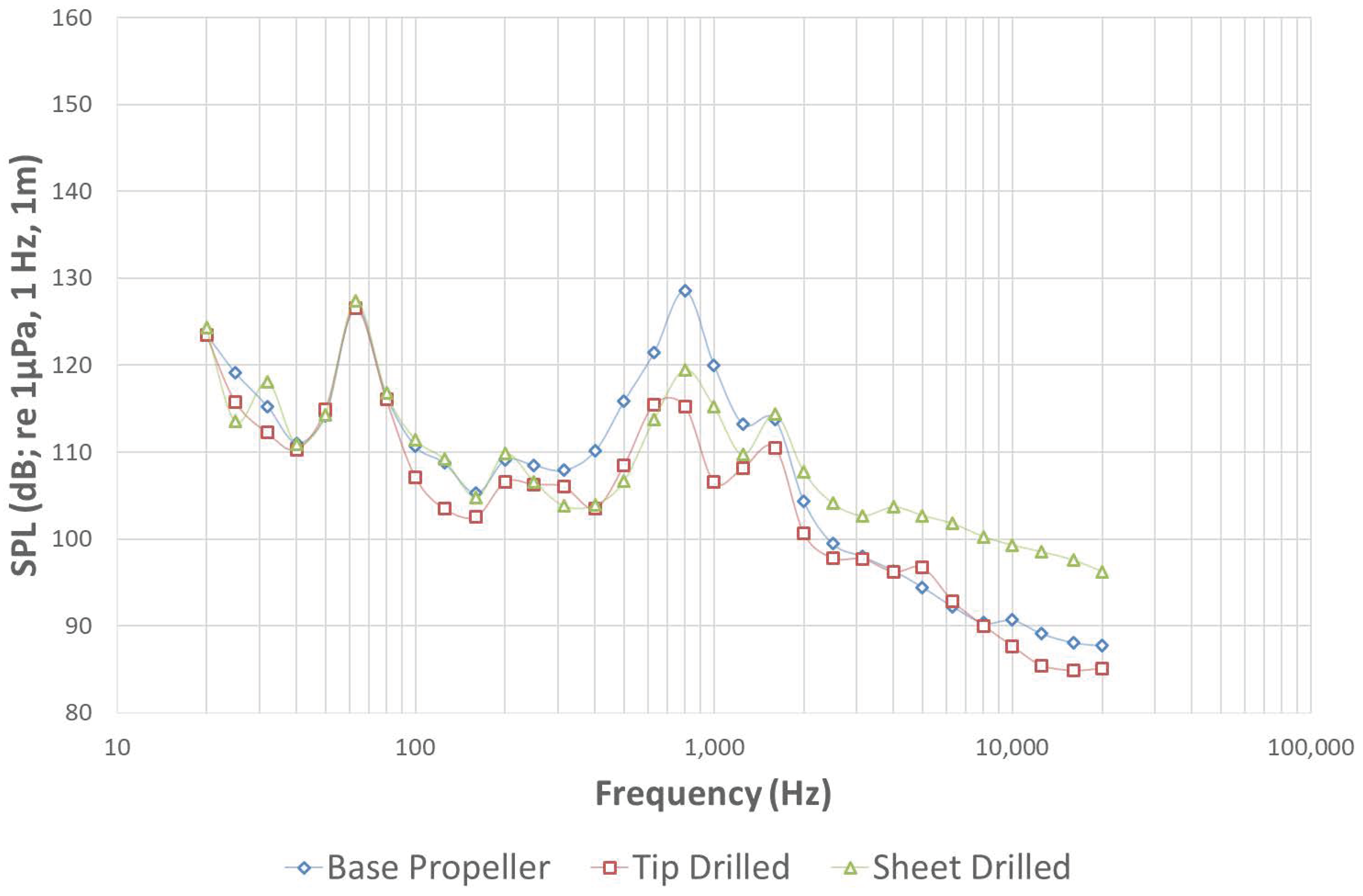

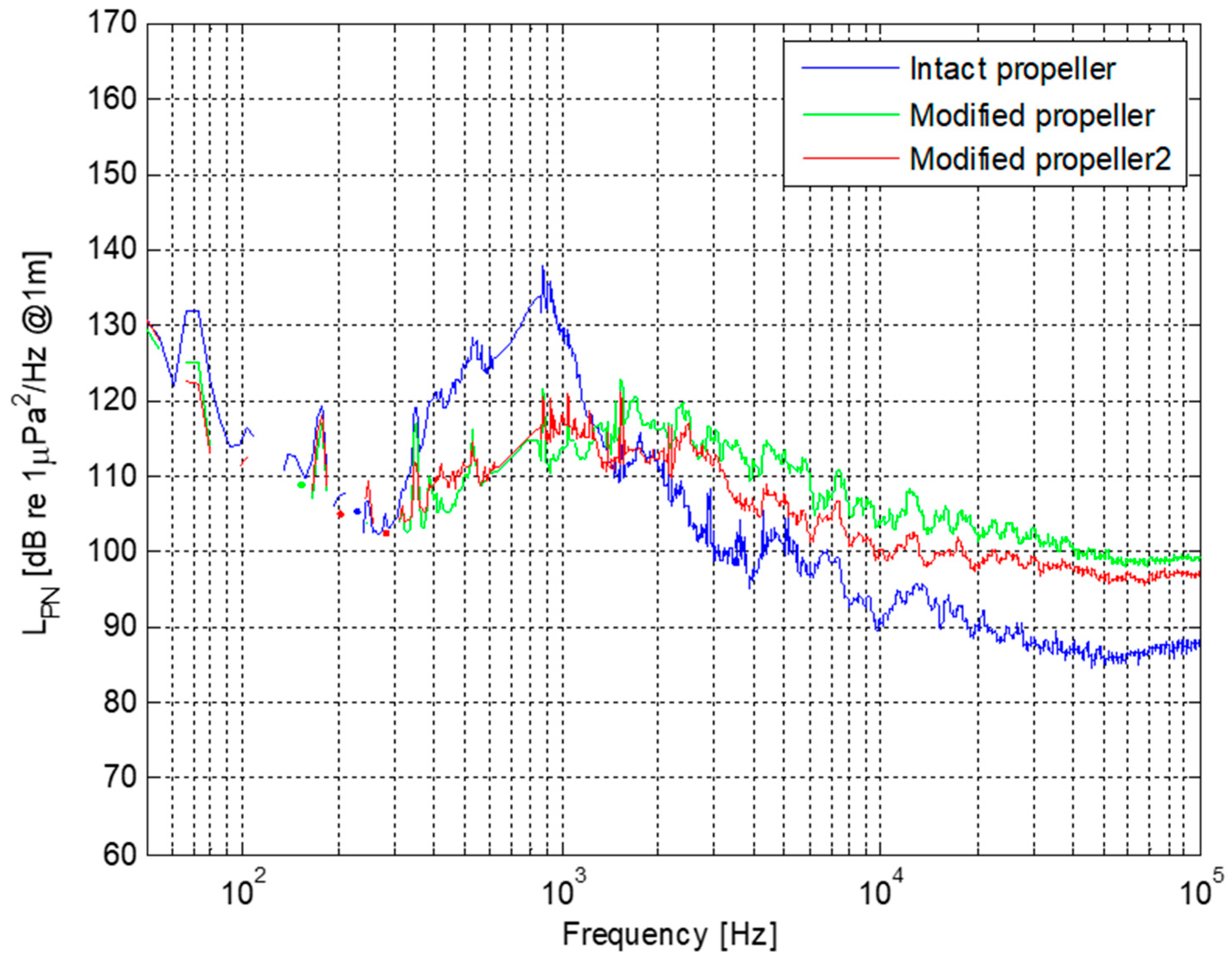

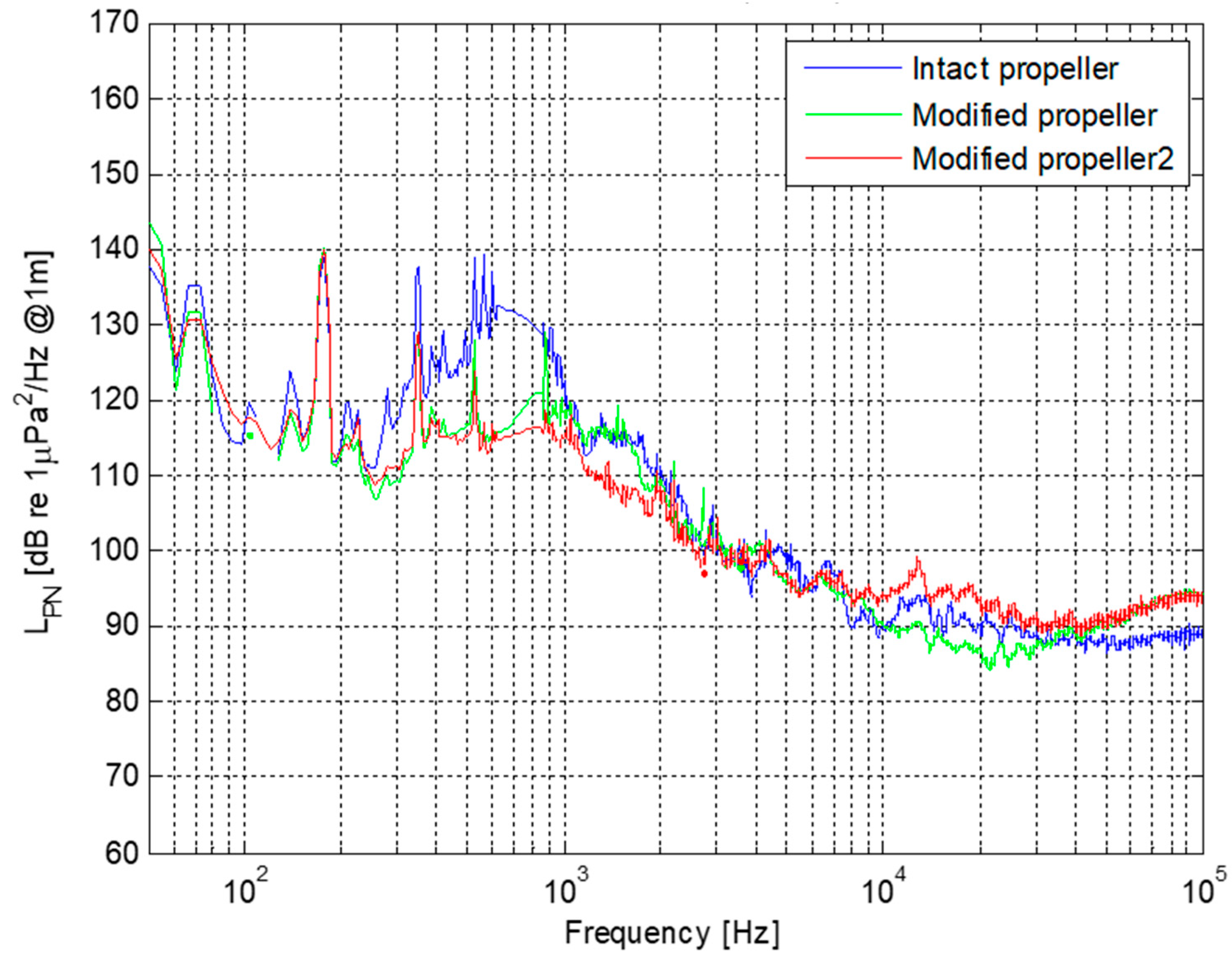

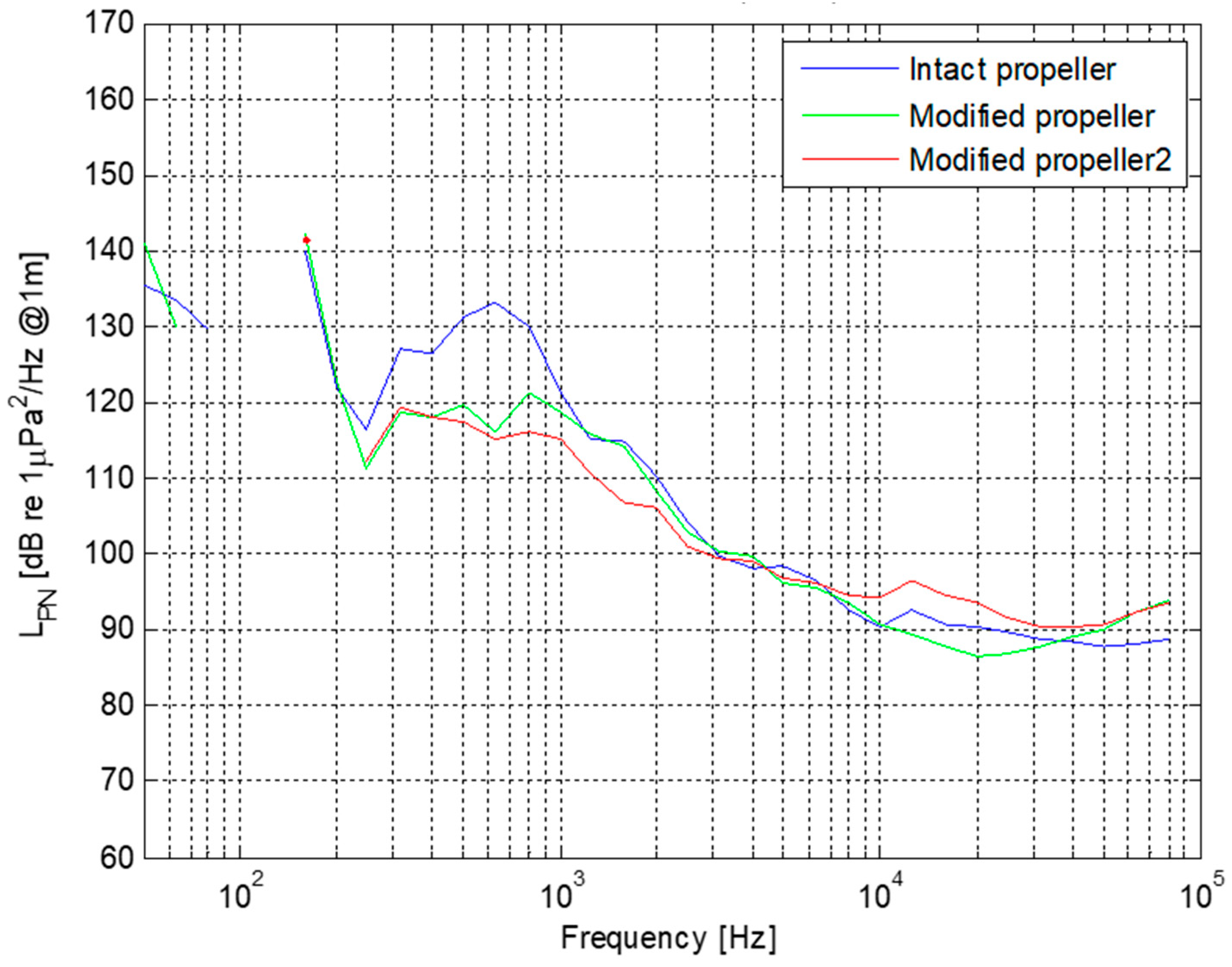

3.2. Radiated Noise Measurements

- Signal to noise ratio higher than 10 dB: No correction made

- Signal to noise ratio higher than 3 dB but lower than 10dB:

- Signal to noise ratio lower than 3 dB:Results disregarded

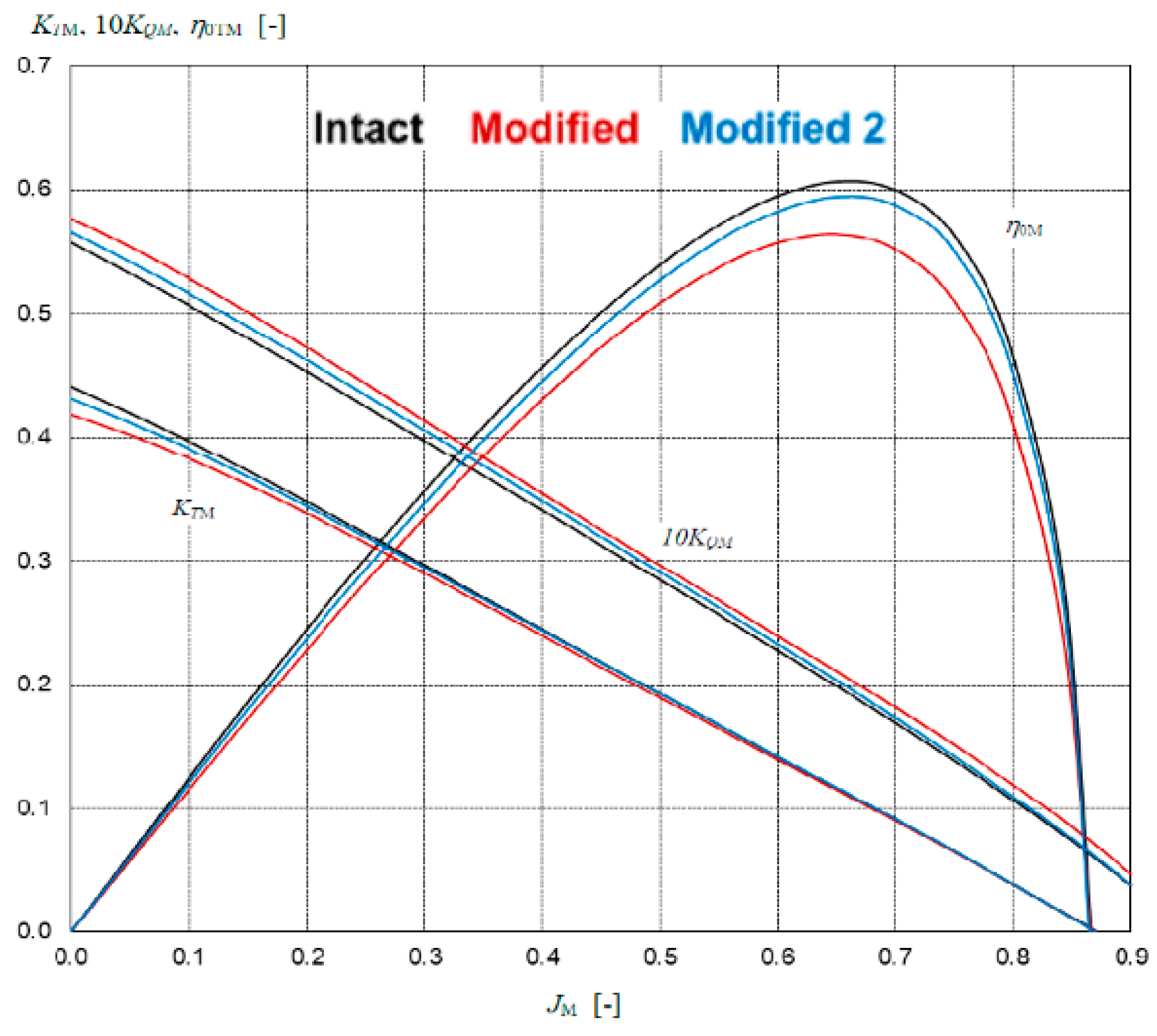

3.3. Propeller Performance Tests

4. Numerical Investigations (CFD Approach)

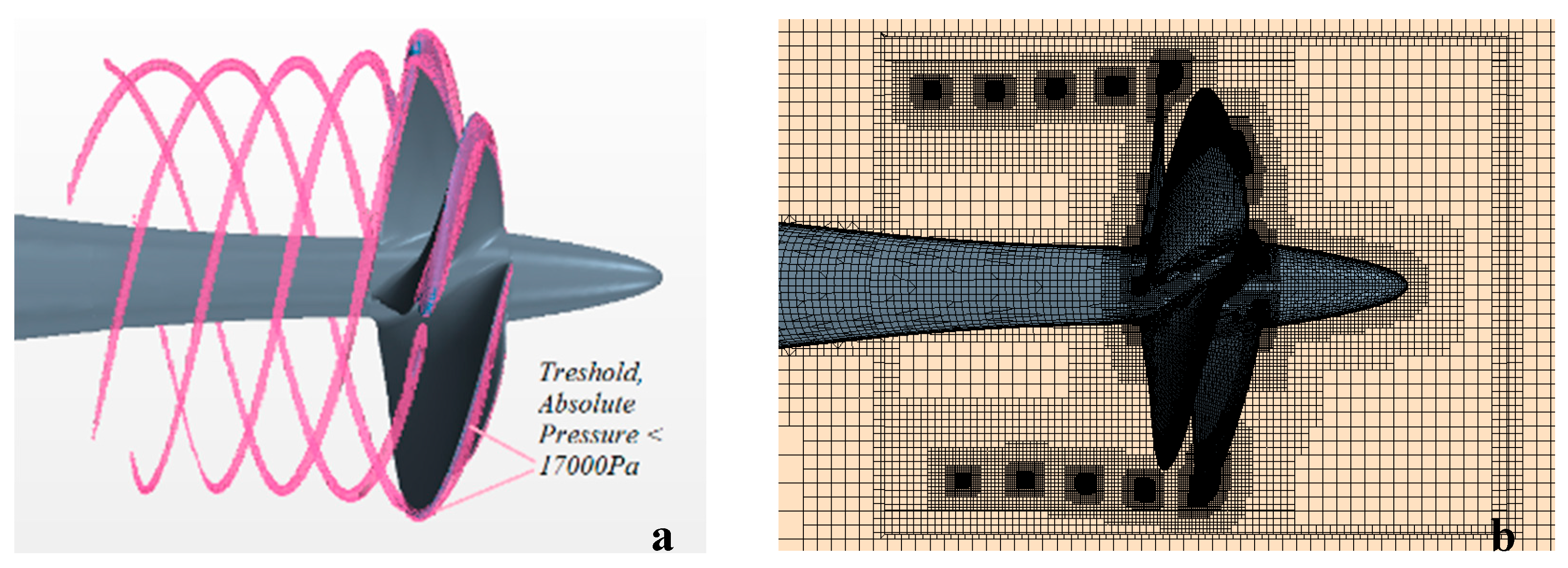

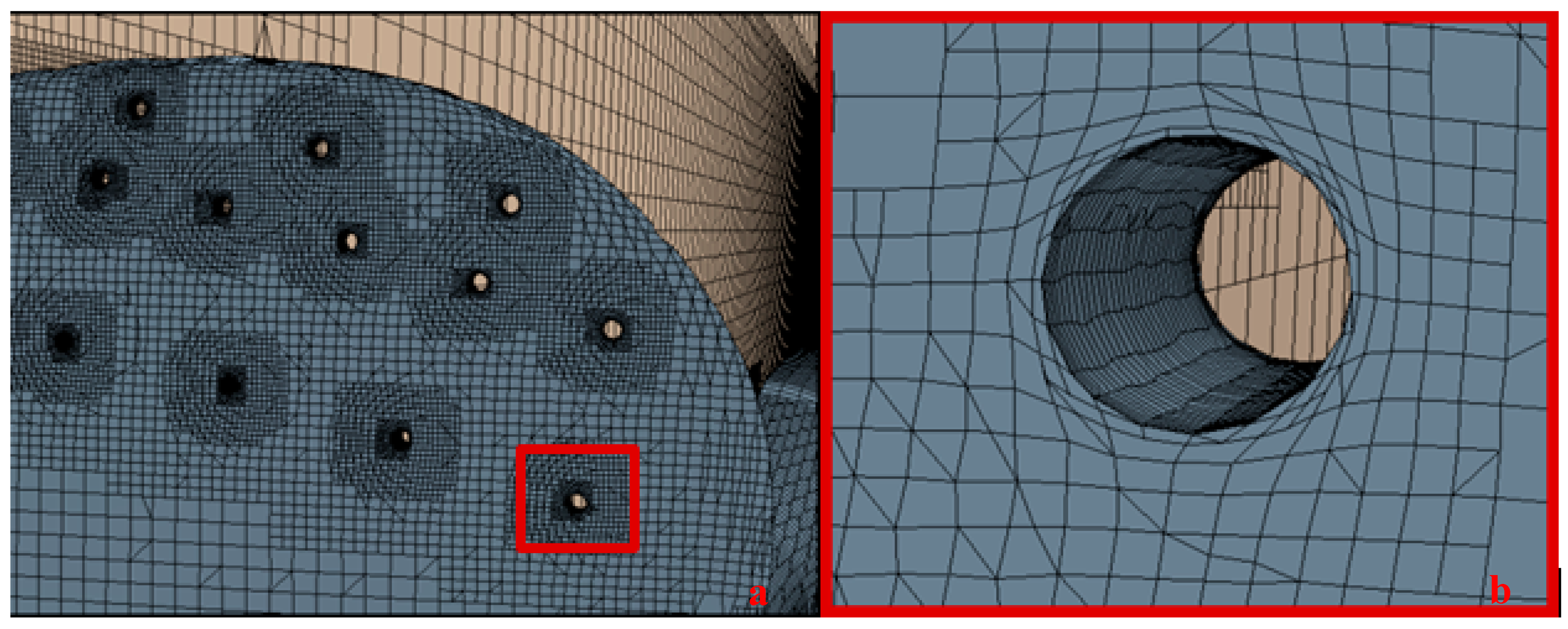

4.1. Mesh Adaption Refinement Approach for Cavitation Simulations (MARCS)

4.2. Numerical Model

4.3. Results

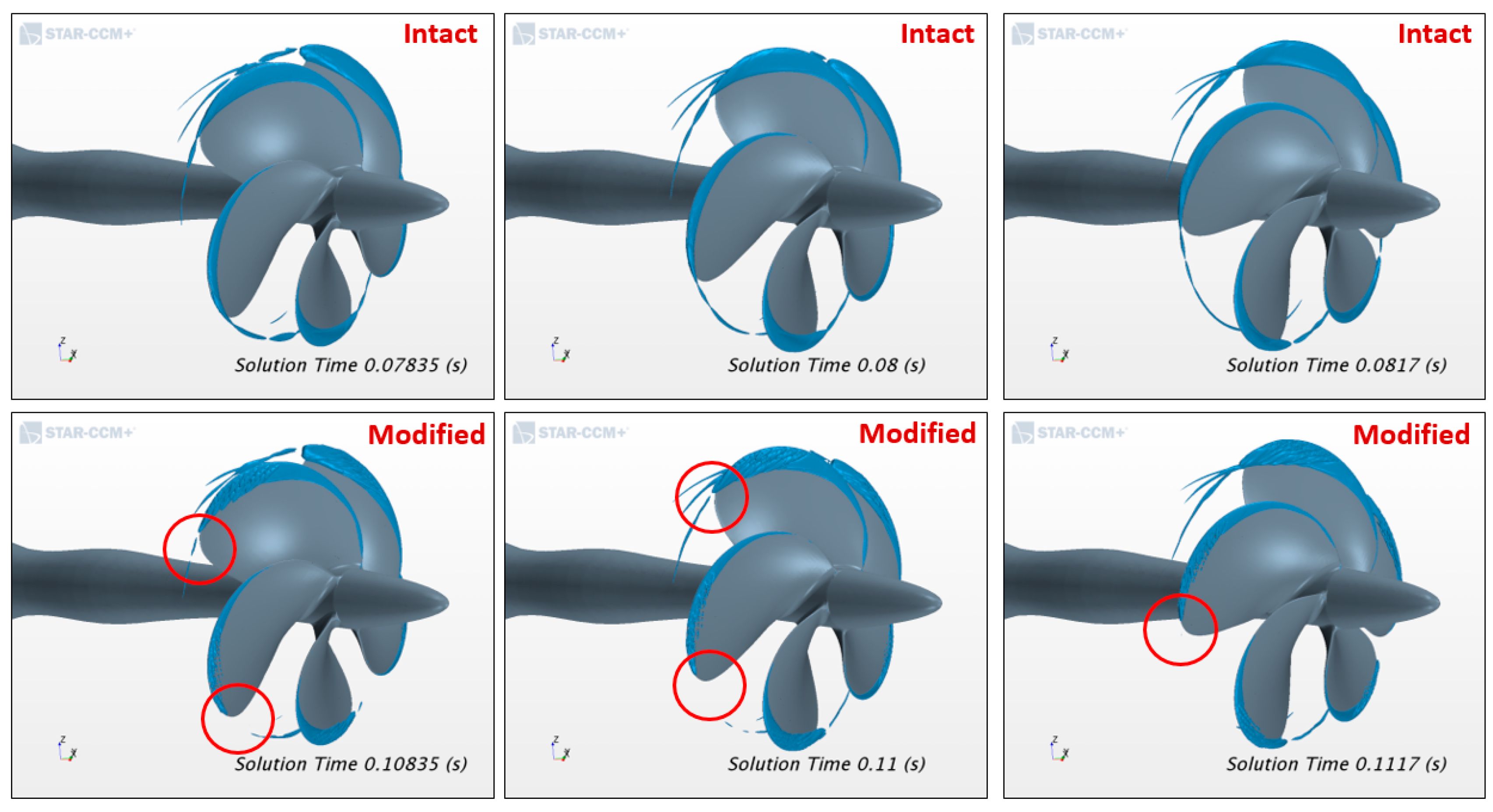

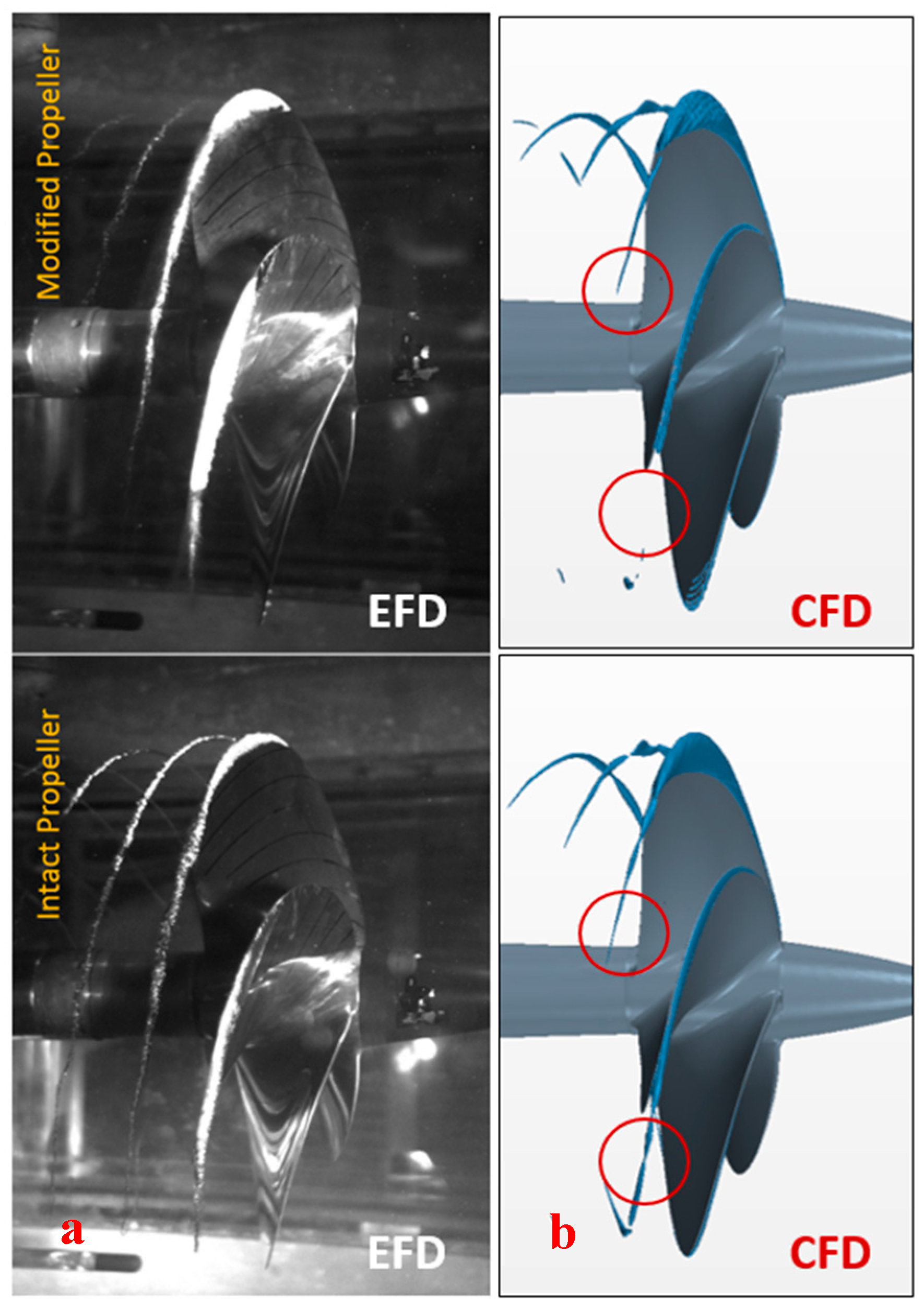

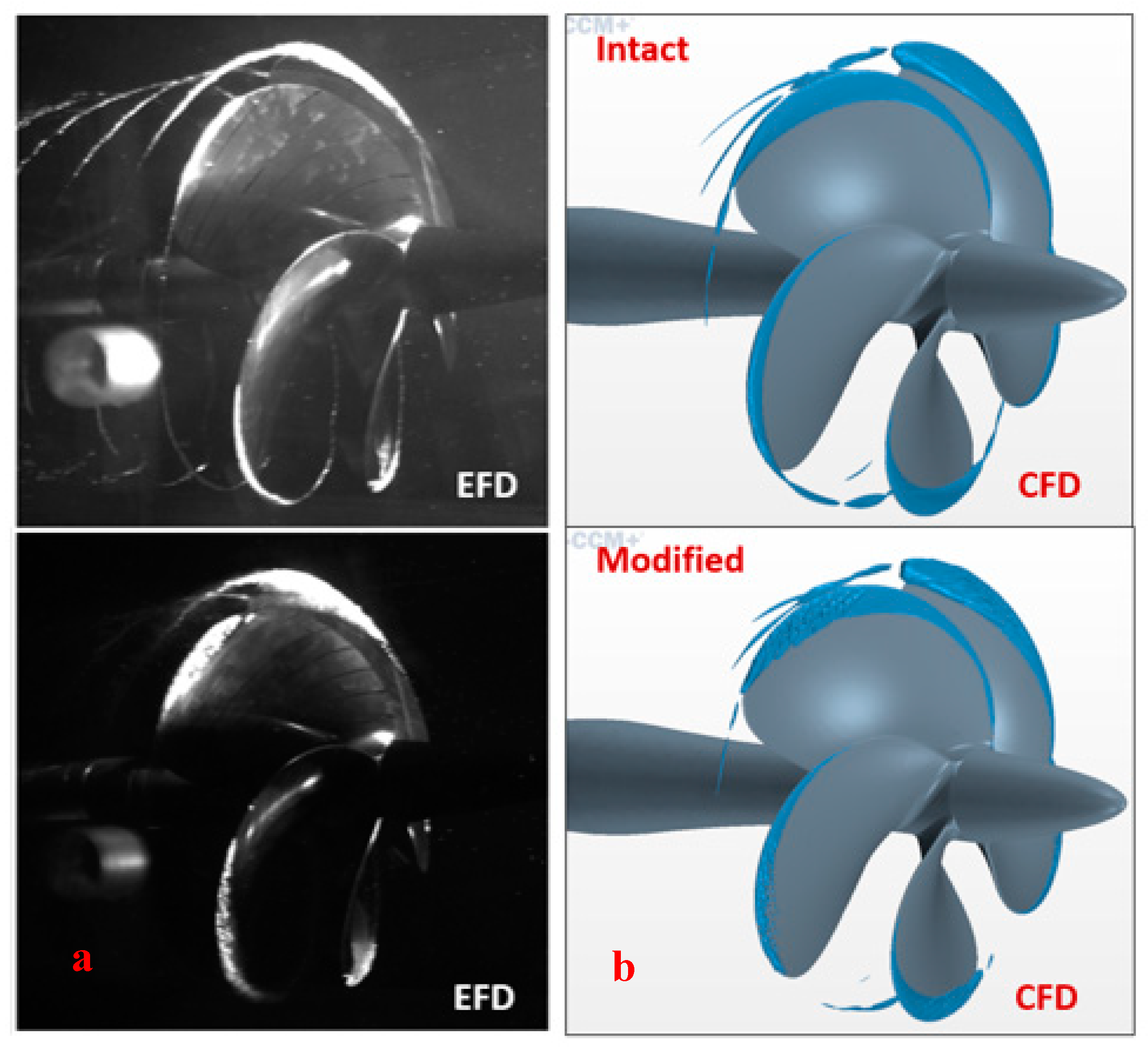

Cavitation Pattern including TVC

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- International Maritime Organization. Noise from commercial shipping and its adverse impacts, on marine life. Mar. Environ. Prot. Comm. Int. Marit. Organ. (MEPC) 2013, 66, 17. [Google Scholar]

- Ross, D. Mechanics of Underwater Noise; Peninsula Publishing: CA, USA, 1976. [Google Scholar]

- Frisk, G.V. Noiseonomics: The relationship between ambient noise levels in the sea and global economic trends. Sci. Rep. 2012, 2, 2–5. [Google Scholar] [CrossRef]

- Richardson, W.J.; Greene, C.R., Jr.; Malme, C.I.; Thomson, D.H. Marine mammals and noise. J. Exp. Mar. Biol. Ecol. 2013, 210, 161–163. [Google Scholar]

- White, P.; Pace, F. The Impact of Underwater Ship Noise on Marine Mammals. In Proceedings of the 1st IMarEST Ship Noise and Vibration Conference, London, UK, 27–28 January 2010. [Google Scholar]

- Chekab, M.A.F.; Ghadimi, P.; Djeddi, S.R.; Soroushan, M. Investigation of Different Methods of Noise Reduction for Submerged Marine Propellers and their Classification. Am. J. Mech. Eng. 2013, 1, 34–42. [Google Scholar] [CrossRef]

- Mautner, T.S. A Propeller Skew Optimization Method; Naval Ocean Systems Center: San Diego, CA, USA, 1987. [Google Scholar]

- Mosaad, M.A.; Mosleh, M.; El-Kilani, H.; Yehia, W. Propeller Design for Minimum Induced Vibrations. Port Said Eng. Res. J. 2011, 10, 2. [Google Scholar]

- Ji, B.; Luo, X.; Wu, Y. Unsteady cavitation characteristics and alleviation of pressure fluctuations around marine propellers with different skew angles. J. Mech. Sci. Technol. 2014, 28, 1339–1348. [Google Scholar] [CrossRef]

- Andersen, P.; Kappel, J.; Spangenberg, E. Aspects of Propeller Developments for a Submarine. In The First International Symposium on Marine Propulsors: Smp’09; Norwegian Marine Technology Research Institute (MARINTEK): Trondheim, Norway, 2009; pp. 551–561. [Google Scholar]

- Hyung-Sik, P.; Su-Hyun, C.; Nho-Seong, K. Identification of Propeller Singing Phenomenon through Vibration Analysis of Propeller Blade. In Proceedings of the 15th International Offshore and Polar Engineering Conference, (The International Society of Offshore and Polar Engineers), Seoul, Korea, 19–24 June 2005. [Google Scholar]

- Sharma, S.D.; Mani, K.; Arakeri, V.H. Cavitation noise studies on marine propellers. J. Sound Vib. 1990, 138, 255–283. [Google Scholar] [CrossRef]

- Xydis, K. Investigation into Pressure Relieving Holes on Propeller Blades to Mitigate Cavitation and Noise. Master’s Thesis, Newcastle University, Newcastle, UK, 2015. [Google Scholar]

- Aktas, B.; Yilmaz, N.; Atlar, M. Pressure-Relieving Holes to Mitigate Propeller Cavitation and Underwater Radiated Noise; Department of Naval Architecture Ocean and Marine Engineering; Strathclyde University: Glasgow, UK, 2018. [Google Scholar]

- Atlar, M.; Aktas, B.; Sampson, R.; Seo, K.C.; Viola, I.M.; Fitzsimmons, P.; Fetherstonhaug, C. A Multi-Purpose Marine Science & Technology Research Vessel for Full-Scale Observations and Measurements. In Proceedings of the International Conference on Advanced Model Measurement Technologies for the Marine Industry, Gdansk, Poland, 17–18 September 2013. [Google Scholar]

- Yilmaz, N.; Atlar, M.; Khorasanchi, M. An Improved Mesh Adaption and Refinement Approach to Cavitation Simulation (MARCS) of Propellers. J. Ocean Eng. 2019, 171, 139–150. [Google Scholar] [CrossRef]

- Korkut, E.; Takinaci, A.C. 18M Research Vessel Wake Measurements; Istanbul Technical University Faculty of Naval Architecture and Ocean Engineering: İstanbul, Turkey, 2013; p. 6. [Google Scholar]

- ITTC. Model-scale Propeller Cavitation Noise Measurements. Recommended Procedures and Guidelines 7.5-02-01-05. Available online: https://ittc.info/media/4052/75-02-01-05.pdf (accessed on 19 February 2020).

- ANSI. Quantities and Procedures for Description and Measurement of Underwater Sound from Ships – Part 1: General Requirements. American National Standard ANSI/ASAS. 2009. Available online: https://www.iso.org/obp/ui/#iso:std:iso:pas:17208:-1:ed-1:v1:en (accessed on 29 February 2020).

- Yilmaz, N.; Khorasanchi, M.; Atlar, M. An Investigation into Computational Modelling of Cavitation in a Propeller’s Slipstream. In Proceedings of the Fifth International Symposium on Marine Propulsion SMP’17, Espoo, Finland, 12–5 June 2017. [Google Scholar]

- Yilmaz, N. Investigation of Cavitation Influence on Propeller-Rudder-Hull Interaction. Ph.D. Thesis, University of Strathclyde, Glasgow, Scotland, 2019. [Google Scholar]

- Stern, F.; Wilson, R.V.; Coleman, H.W.; Paterson, E.R. Comprehensive Approach to Verification and Validation of CFD Simulations-Part1: Methodology and Procedures. J. Fluids Eng. 2001, 123, 793–802. [Google Scholar] [CrossRef]

- Siemens. STAR-CCM+ User Guide. 2018. Available online: https://www.plm.automation.siemens.com/media/global/en/Siemens%20PLM%20Simcenter%20STAR-CCM_tcm27-62845.pdf (accessed on 29 February 2020).

- The International Towing Tank Conference. ITTC Recommended Procedures and Guidelines, Practical Guidelines for Ship-Propulsion CFD, 7.5-03-03-01; The International Towing Tank Conference: Bournemouth, UK, 2014. [Google Scholar]

| Parameters | Value | Unit |

|---|---|---|

| Number of blades | 5 | − |

| Full scale propeller diameter | 0.75 | (m) |

| Model scale propeller diameter | 0.22 | (m) |

| Pitch ratio | 0.8475 | − |

| Blade area ratio | 1.057 | − |

| Rake | 0 | (deg) |

| Condition | Engine (RPM) | Shaft (rps) | STW (kn) | KT | 10KQ | σN (nD) |

|---|---|---|---|---|---|---|

| V1 | 1500 | 14.3 | 10.5 | 0.211 | 0.323 | 1.91 |

| V2 | 2000 | 19.0 | 15.1 | 0.188 | 0.318 | 1.07 |

| Performance Characteristics | Symbol | Formula |

|---|---|---|

| Thrust coefficient | KT | |

| Torque coefficient | KQ | |

| Advance coefficient | J | |

| Efficiency | η0 |

| Condition | KT | σN | “Intact Propeller” Observations | “Modified Propeller” Observations | “Modified Propeller-2” Observations |

|---|---|---|---|---|---|

| V1 | 0.211 | 1.91 | TVC everywhere, starting from blade L.E.; S.S. sheet cavitation at 0°, from 0.8R to the tip, for 15% of the chord at 0.8R, 100% at 0.97R; S.S. sheet cavitation at 180°, from 0.85R to the tip, for 10% of the chord at 0.85R. | Pores cavitation everywhere; TVC at 0° and 180°, only cloudy vortex at other positions; S.S. sheet cavitation at 0°–45° from 0.8R for 10% of the chord, merging with holes cavitation at outer radii; S.S. sheet cavitation at 180°, from 0.85R for 5% of the chord, merging with holes cavitation at outer radii. | Pores cavitation everywhere; TVC everywhere, at 90° and 270° the cavitating core is at inception; S.S. sheet cavitation at 0°, from 0.8R, for 15% of the chord, at 180°, from 0.85R for 10% of the chord. |

| V2 | 0.188 | 1.07 | TVC everywhere, starting from blade L.E.; double vortex at 0°–60°; S.S. sheet cavitation at 0°, from 0.8R to the tip, for 50% of the chord at 0.8R, 100% at 0.85R; S.S. sheet cavitation at 90° and 270°, from 0.9R for 10% of the chord; S.S. sheet cavitation at 180°, from 0.83R to the tip, for 50% of the chord at 0.83R, 100% of the chord at 0.92R | Pores cavitation everywhere; TVC everywhere, with double vortex at 0°–60°; S.S. sheet cavitation at 0°–45° from 0.8R for 30% of the chord, merging with holes cavitation at outer radii; S.S. sheet cavitation at 180°, from 0.83R for 20% of the chord, merging with holes cavitation at outer radii. | Pores cavitation everywhere; TVC everywhere, the cavitating core is now well developed but still presents unstable behaviour; double vortex at 0°; S.S. sheet cavitation at 0° from 0.8R for 40% of the chord, at 180° from 0.8R for 30% of the chord. |

| Intact Propeller | ||

|---|---|---|

| EFD | CFD | |

| KT | 0.211 | 0.225 |

| Δ% KT | - | 6.6% |

| CFD | ||

|---|---|---|

| Intact | Modified | |

| Cavitation volume (m3) | 8.11 × 10−6 | 6.47 × 10−6 |

| KT | 0.225 | 0.222 |

| Δ% KT | − | −1.3% |

| Δ% cavitation volume | − | −20.1% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aktas, B.; Yilmaz, N.; Atlar, M.; Sasaki, N.; Fitzsimmons, P.; Taylor, D. Suppression of Tip Vortex Cavitation Noise of Propellers using PressurePoresTM Technology. J. Mar. Sci. Eng. 2020, 8, 158. https://doi.org/10.3390/jmse8030158

Aktas B, Yilmaz N, Atlar M, Sasaki N, Fitzsimmons P, Taylor D. Suppression of Tip Vortex Cavitation Noise of Propellers using PressurePoresTM Technology. Journal of Marine Science and Engineering. 2020; 8(3):158. https://doi.org/10.3390/jmse8030158

Chicago/Turabian StyleAktas, Batuhan, Naz Yilmaz, Mehmet Atlar, Noriyuki Sasaki, Patrick Fitzsimmons, and David Taylor. 2020. "Suppression of Tip Vortex Cavitation Noise of Propellers using PressurePoresTM Technology" Journal of Marine Science and Engineering 8, no. 3: 158. https://doi.org/10.3390/jmse8030158

APA StyleAktas, B., Yilmaz, N., Atlar, M., Sasaki, N., Fitzsimmons, P., & Taylor, D. (2020). Suppression of Tip Vortex Cavitation Noise of Propellers using PressurePoresTM Technology. Journal of Marine Science and Engineering, 8(3), 158. https://doi.org/10.3390/jmse8030158