Abstract

To address the limitations of traditional single-point detection methods in monitoring the sulfur content of ship fuel (FSC), which are inadequate in meeting the regulatory demands of high-traffic ports, this study proposes an integrated analytical approach based on artificial intelligence. This approach synthesizes multi-source heterogeneous data, including historical fuel testing records, Automatic Identification System (AIS) trajectory data, ship and operator profiles, technical specifications, fuel supply chain documentation, fundamental ship attributes and so on. Following rigorous data cleaning and preprocessing procedures, a refined dataset comprising 3046 records collected between 2017 and 2024 from the Port of Ningbo was utilized. Initially, multiple linear regression analysis was con-ducted to identify key factors influencing sulfur emissions, resulting in an R2 value of 0.67. Based on these findings, a deep neural network model was developed using TensorFlow to enable real-time estimation of FSC and classification of compliance risk levels. The results indicate that the proposed method exhibits high estimated accuracy and robustness. An AI-based intelligent monitoring module, developed based on this research, has been integrated into the ship exhaust gas detection system at the Port of Ningbo. This module enables real-time analysis of inbound ships and intelligent identification of potentially non-compliant ships, thereby significantly improving the precision and efficiency of port regulatory operations. This study not only contributes to the theoretical framework for ship fuel compliance monitoring but also provides a practical and scalable technical solution for intelligent port governance.

1. Introduction

In recent years, the global maritime shipping industry has faced unprecedented transformation challenges driven by the dual pressures of trade expansion and environmental concerns [1,2,3,4]. As the international shipping network connects the world’s major economies and facilitates the vast majority of global trade volume [5], freight transportation demand continues to demonstrate a consistent upward trajectory. However, the sector is increasingly affected by a range of uncertainties, including the rising frequency of extreme climate events [6], navigational restrictions in key international waterways [7], and fluctuations in energy prices [8]. These factors have collectively intensified operational volatility within the industry. With the continuous expansion of global shipping capacity, emissions from ship fuel combustion—particularly sulfur compounds and greenhouse gases—have become a focal point of international attention [9]. These emissions pose serious threats not only to public health but also to marine and atmospheric ecosystems through long-term cumulative effects. In response to these challenges, the adoption of green shipping practices and intelligent port operations has gained widespread recognition as an essential strategy for advancing sustainable development in the maritime sector.

During maritime operations, ships consume substantial quantities of heavy fuel oil, the combustion of which generates emissions containing sulfur oxides (SOx), nitrogen oxides (NOx), carbon monoxide, particulate matter (PM), and carbon dioxide (CO2)—a recognized greenhouse gas (GHGs) [10,11,12]. These emissions pose significant threats to both environmental quality and public health. Specifically, SOx and NOx can react with atmospheric moisture and oxygen to form acidic compounds, contributing to the formation of acid rain. Acid rain has been associated with long-term degradation of agricultural lands, forest ecosystems, and aquatic habitats. In contrast, PM can penetrate the human respiratory system, thereby increasing the risk of respiratory and cardiovascular diseases. Meanwhile, CO2 is widely recognized as a major driver of global climate change. In response to these environmental challenges, the International Maritime Organization (IMO) adopted the International Convention for the Prevention of Pollution from Ships and its Annex VI [13]. Under the provisions of this convention, the global sulfur content limit for marine fuels was initially set at 0.5% (m/m) in 2012 and later reduced to 0.35% (m/m) in 2020 [6,7]. Furthermore, the IMO has designated four Emission Control Areas (ECAs), including the Baltic Sea, the North Sea, North American coastal waters, and the Caribbean Sea waters of the United States. Since 2015, the sulfur content limit for fuels used within these ECAs has been restricted to 0.1% (m/m) [14].

In recent years, the IMO has actively promoted the establishment and enhancement of ECAs, with policy frameworks primarily aimed at reducing SOx, NOx, and GHGs [15]. The Mediterranean ECA officially came into effect on 1 May 2025, requiring a maximum FSC of 0.1% (m/m). This regulation affects approximately 20% of global maritime trade and is projected to reduce regional sulfur emissions by 80%, thereby significantly improving air quality and marine ecosystems for over 150 million coastal residents. Additionally, the newly designated emission control areas in the Canadian Arctic waters and the Norwegian Sea have received formal approval. Under these regulations, the NOx Tier III standards will take effect on 1 March 2026, applying to newly constructed ships, while the SOx limit (≤0.1% (m/m)) will be enforced starting 1 March 2027. These measures are intended to protect the fragile Arctic ecosystem and reduce the impact of black carbon emissions on glacial melting.

The establishment of ECAs has proven to be an effective strategy for mitigating air pollution caused by maritime emissions. Traditionally, maritime authorities have relied on boarding ships and extracting fuel oil samples for laboratory analysis as a method of regulatory enforcement. However, this approach suffers from a lack of targeting, random ship selection, and relatively low operational efficiency. More importantly, it is not applicable for monitoring ships that are in transit. In response to these limitations, researchers have proposed alternative methods that involve measuring ship exhaust plumes to estimate the FSC being used. In 2005, coinciding with the enforcement of the International Convention for the Prevention of Pollution from Ships (MARPOL), Chalmers University of Technology in Sweden launched the Identification of Gross Polluting Ships (IGPS) project [16]. This initiative explored the use of optical and “sniffing” techniques to detect ship plumes and identify ships violating high-sulfur fuel regulations in the Port of Rotterdam. Following this pioneering work, numerous research institutions across Europe and North America conducted similar studies, gradually establishing this field as a key area of research within maritime and atmospheric environmental science [17,18]. In recent years, East Asia has also seen a surge in ship emission monitoring activities [19]. In major ports across China, South Korea, and Japan, shore-based sniffing systems, unmanned aerial vehicle (UAV)-based monitoring, and infrared spectroscopy technologies have been deployed for real-time detection of sulfur content in marine fuels. These efforts aim to address regional air quality concerns and support compliance with international emission reduction obligations.

The determination of ship FSC based on exhaust gas measurement results—expressed in terms of convertible sulfur oxide emission factors—has increasingly become a crucial technical approach for maritime authorities in enforcing ECA policies. More importantly, the accurate and reliable quantification of sulfur oxide emission factors constitutes a core component in the development of comprehensive ship emission inventories and serves as a foundational basis for assessing the environmental impact of maritime emissions. However, as ECA regulations continue to evolve with increasingly stringent sulfur content limits, and as the shipping industry progresses toward energy efficiency and emission reduction through the adoption of exhaust gas cleaning systems and alternative clean fuels. This study aims to develop a machine learning-based model integrated with multi-source data fusion techniques to analyze the sulfur content of marine fuels, with the objective of improving regulatory efficiency and expanding monitoring coverage in high-traffic ports. In contrast to conventional approaches that predominantly rely on single-point exhaust measurements, this research proposes a systematic integration of AIS trajectories, fueling records, historical compliance data, and real-time exhaust monitoring information, thereby establishing a estimated framework capable of dynamically assessing ship compliance risks. By synthesizing behavioral patterns and historical datasets, the proposed methodology enables the identification of systemic non-compliance trends—such as those associated with specific ship types, fuel suppliers, or shipping routes—ultimately facilitating more targeted and informed regulatory decision-making.

2. Overview of the Main Measurement Methods of Ship Emissions

Ships represent mobile waterborne emission sources, posing greater monitoring challenges compared to stationary or more accessible emission sources such as power plants, volcanoes, and motor vehicles. Based on the type of platform hosting the monitoring equipment, ship exhaust measurement methods can be classified into four primary categories: laboratory-based analysis, shipborne platform monitoring, aerial monitoring via small aircraft or UAV, and shore-based monitoring station observations.

2.1. Laboratory-Based Analysis

Laboratory testing constitutes a foundational methodology for evaluating FSC in maritime exhaust research. By simulating the combustion processes of ship engines under controlled conditions, this approach effectively mitigates meteorological interference and minimizes multi-source measurement errors inherent in field observations, thereby substantially improving data reliability and reproducibility [20]. Standard experimental configurations generally comprise combustion simulation chambers, exhaust sampling systems, and high-precision gas analyzers. Through precise regulation of operational parameters—including temperature, pressure, and airflow—these systems enable accurate replication of real-world ship emission environments. Among the analytical techniques employed, the sulfur-to-carbon ratio (S/C) method, which calculates FSC based on measured concentrations of SO2 and CO2, has emerged as a widely accepted standard for laboratory-based sulfur content determination [20]. Research indicates that combustion parameters such as temperature and excess air coefficient exert significant influence on sulfur oxidation rates and SO2 formation. Elevated temperatures and adequate air supply typically result in increased SO2 emissions, whereas the use of low-sulfur fuels or desulfurization agents can effectively curtail such emissions [21]. Furthermore, variations in engine load can alter emission profiles, with low-load operating conditions potentially causing incomplete combustion and consequent increases in SO2 levels [21].

In recent years, remote sensing technologies have shown promise for FSC estimation. For example, ultraviolet imaging techniques integrated with convolutional neural net-works (CNN) enable feature extraction from emission plumes, facilitating non-invasive sulfur content estimation [22]. Additionally, multi-task deep learning frameworks combined with mid-infrared spectroscopy imaging allow for simultaneous monitoring of multiple pollutants—such as SO2 and CO2—and inversion of sulfur content data [23]. Nevertheless, these approaches continue to confront challenges including high instrumentation costs, limited model generalizability, and constrained environmental adaptability. Future research should prioritize advancements in sensor miniaturization, improvements in algorithmic robustness, and enhanced laboratory validation of emission characteristics associated with emerging green fuels—such as hydrogen, ammonia, and biofuels—to develop FSC estimation models that align more effectively with the evolving landscape of maritime energy transition.

2.2. Shipborne Platform Monitoring

Shipboard monitoring, which involves direct sampling of exhaust gases from ship exhaust pipes or chimneys, has emerged as a critical methodology for estimating FSC under real-world operational conditions. It plays a vital role in emission characterization studies and compliance verification [24]. The system typically comprises high-temperature and corrosion-resistant sampling tubes, gas analysis mod-ules—including ultraviolet fluorescence SO2 analyzers and non-dispersive infrared CO2 analyzers—and integrated data acquisition units. Capable of continuous monitoring across varying engine loads, ship speeds, and sea states, it effectively captures dynamic sulfur emission patterns. This makes it particularly suitable for investigating the combined effects of fuel composition, engine performance, and operational parameters on SO2 formation.

Field measurement data indicate a strong positive correlation between FSC and exhaust gas SO2 concentrations, with higher SO2 emissions typically observed under high-load engine conditions compared to low-load scenarios. While the use of low-sulfur fuels can substantially reduce SO2 emissions, it may concurrently lead to increased particulate matter emissions, such as black carbon [25]. Ships equipped with desulfurization technologies—such as exhaust gas scrubbing systems—can comply with Emission Control Area (ECA) regulations even when operating on high-sulfur fuels. Moreover, significant variations in emission factors have been observed between offshore and inland fishing ships, which are closely linked to differences in fuel composition and operational parameters [26]. These findings provide valuable insights for refining shipboard monitoring techniques and developing targeted emission control policies.

From a technical application standpoint, portable emission measurement systems (PEMS) serve as the core instrumentation for shipboard monitoring. These systems are capable of capturing exhaust plumes and directly measuring pollutant concentrations, thereby enabling high-precision data acquisition for real-time sulfur content inversion [27]. Nevertheless, challenges remain, including high operational costs, complex installation procedures, demanding maintenance requirements, and the limitation of single-ship monitoring per deployment. These constraints hinder the rapid large-scale adoption of PEMS across extensive ship fleets. Consequently, shipboard monitoring is currently more applicable for in-depth emission characterization and for validating the accuracy of alternative monitoring approaches, rather than for comprehensive regulatory oversight.

2.3. Aerial Monitoring via Small Aircraft or UAV

As an emerging technology for ship exhaust gas monitoring, the unmanned aerial vehicle (UAV) “sniffing” system has gained increasing adoption in real-time FSC estimation and emission regulation. This is attributed to its notable ad-vantages, including high operational flexibility, rapid deployment capability, and relatively low operating costs. The system typically integrates electrochemical SO2 sensors, non-dispersive infrared CO2 sensors, sampling units, and data logging modules. By traversing the ship’s exhaust plume at close proximity—typically within a range of 50 to 200 m—and applying sulfur-to-carbon (S/C) ratio algorithms, it enables rapid inversion of FSC. Studies have demonstrated that within a sulfur content range of 0.035% to 0.24%, the UAV-based system can achieve measurement accuracies with deviations below 0.03% [28]. To further improve monitoring efficiency, recent research has concentrated on multi-UAV cooperative path planning and scheduling optimization models, aiming to maximize ship coverage under the constraint of limited battery endurance [29]. Moreover, the integration of ultraviolet and infrared imaging technologies allows the system to capture the spatial distribution of exhaust plumes, thereby supporting emission dispersion modeling and spatiotemporal forecasting of sulfur emissions. Despite these advancements, several challenges remain, including limited adaptability under adverse meteorological conditions, reduced measurement accuracy of lightweight sensors at ultra-low sulfur levels, and constraints imposed by battery capacity. In anticipation of increasingly stringent sulfur emission regulations, further development of sensor calibration algorithms and robust anti-interference mechanisms is essential to enhance the reliability of FSC estimation.

2.4. Shore-Based Monitoring

Shore-based monitoring establishes a stable and cost-efficient methodology for long-term, continuous estimation and assessment of FSC by deploying monitoring equipment at fixed locations such as ports, key waterways, and bridges. This approach passively captures exhaust plumes from passing ships, enabling reliable data acquisition over extended periods. The system typically integrates ultraviolet fluorescence (UVF) SO2 analyzers and non-dispersive infrared (NDIR) CO2 analyzers, and is synchronized with the AIS to facilitate ship identification and data linkage. FSC estimation is subsequently performed using sulfur-to-carbon (S/C) ratio calculations. To enhance plume source attribution and dispersion modeling capabilities, supplementary technologies such as video surveillance and meteorological sensors are frequently employed [30]. Long-term observational data reveal distinct seasonal variations and compliance discrepancies in ship emissions within port regions. For instance, Alfoldy et al. [31] reported a bimodal distribution of SO2 emission factors, which they associated with differences in main and auxiliary engine fuel usage and operational switching behaviors. These findings underscore the necessity of incorporating ship operational status and fuel management strategies when interpreting FSC from shore-based measurements. To improve the spatial representativeness of monitoring, several studies have applied Gaussian plume modeling techniques to optimize sensor placement, thereby increasing the likelihood of effective plume detection [32,33]. Furthermore, shore-based systems can be integrated with unmanned aerial vehicle (UAV)-based monitoring to establish a hybrid regulatory framework combining “initial screening” with “on-site verification”, significantly improving compliance monitoring efficiency within emission control areas [34].

2.5. Challenges and Responses

While ship exhaust gas measurement systems offer direct and real-time sulfur oxide emission data, enabling rapid estimation of FSC, their inherent limitations have become increasingly evident in the context of modern, high-volume port operations. As critical nodes in global trade networks, ports handle massive daily ship traffic, characterized by frequent arrivals and departures of diverse ship types. Conventional exhaust monitoring approaches represent discrete, instantaneous “snapshot” measurements, which are inherently limited in both spatial coverage and statistical representativeness. Given the operational constraints, it is impractical for busy ports to conduct continuous and comprehensive emission monitoring for every berthing or transiting ship, resulting in significant regulatory gaps concerning fuel usage compliance. The sampling-based nature of such monitoring not only restricts its effectiveness in achieving broad coverage but also renders it susceptible to evasion strategies, such as pre-monitoring fuel switching to compliant low-sulfur alternatives. More critically, isolated measurement data lack contextual information and are insufficient to identify underlying patterns, emerging trends, or systemic compliance risks. For instance, these systems cannot effectively address key regulatory questions: Which shipping routes or operators exhibit higher non-compliance rates? Is there widespread fuel quality inconsistency among specific bunkering ports or suppliers? Do certain ship types or older ships demonstrate persistent non-compliance tendencies? In the face of complex and high-density maritime traffic, reliance on single-point monitoring proves inefficient, costly, and inadequate for achieving robust enforcement and targeted regulatory control. There is, therefore, an urgent need for more intelligent, integrated, and comprehensive monitoring frameworks.

To address the inherent limitations of single-point measurement and effectively manage regulatory challenges in high-traffic port environments, the development of AI-driven comprehensive analysis systems represents a necessary evolutionary trajectory. The fundamental principle lies in transcending the constraints imposed by single-source data through the establishment of an intelligent analytical framework capable of integrating multi-dimensional maritime data. This includes the aggregation of heterogeneous datasets such as historical fuel inspection records (encompassing both compliance and violation cases), ship AIS trajectories (including port call history, route patterns, and navigational behavior), ship and company profiles (covering shipowner and manager identities, compliance histories, and corporate risk indicators), technical specifications (engine type, power output, and scrubber installation status), fuel supply chain intelligence (bunkering port origins, supplier reputations, and historical fuel quality metrics), as well as basic ship attributes (such as type, length, gross tonnage, and age). Through the application of advanced machine learning techniques—including supervised learning for risk ship classification, unsupervised learning for anomaly cluster detection, and time series modeling for trend forecasting—AI models can identify latent correlations and behavioral patterns within this complex data ecosystem. This enables the dynamic assessment, accurate estimation, and stratified management of marine fuel compliance risks. For example, the system can autonomously flag high-risk ships that exhibit recurrent refueling at identified high-risk bunkering ports, operate along routes with historically low enforcement rates, and are affiliated with companies possessing prior non-compliance records. These flagged ships can then be prioritized for targeted inspections, thereby optimizing the allocation of regulatory resources. By shifting regulatory oversight from reactive, random “point” sampling to proactive, intelligence-driven “area” analysis, this AI-enhanced approach significantly improves regulatory efficiency, reduces compliance monitoring costs, and ultimately supports the global shipping industry in achieving more sustainable and equitable operational practices.

3. Method

3.1. Dataset

The data employed in this research were sourced from Ningbo Port, recognized as one of the world’s largest ports in terms of cargo throughput and serving as a key maritime hub and designated emission control zone along the Chinese coastline. In collaboration with the Ningbo Maritime Safety Administration, we obtained a comprehensive five-year dataset derived from actual ship fuel monitoring procedures. This dataset was compiled through structured enforcement activities, including routine inspections, random fuel sampling, real-time exhaust gas measurements conducted on ships calling at the port and so on. Following a thorough process of data cleaning and preprocessing, a total of 3046 valid records spanning the period from 2017 to 2024 were finalized for modeling purposes.

Following data cleaning and preprocessing procedures, a total of 3046 valid records were retained for modeling purposes, spanning the period from 2017 to 2024. The dataset comprises a wide range of key variables, including ship name, identification number, receiving port, fuel supplier, sampling date, sample seal number, sulfur content limit standard, testing agency, fuel type, original and adjusted sulfur content, gross tonnage, main engine power, ship length, beam, deadweight tonnage, ship type, port of registry, port entry and exit status, sea/river ship classification, reporting institution, port name, berth, and loading/unloading port. The dataset covers over forty distinct types of marine fuel and more than thirty categories of ships, with port of registry information representing over seventy cities across China. This comprehensive dataset provides a robust empirical foundation for accurate sulfur emission estimation and effective compliance monitoring in maritime operations.

3.2. Workflow

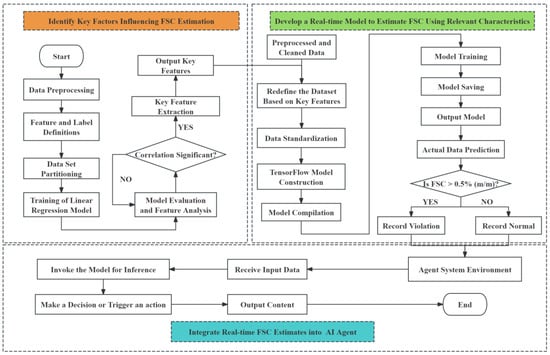

As illustrated in Figure 1, This study’s research methodology is structured into three sequential phases: the analysis of ship sulfur content-related characteristics, the estimation of FSC based on these characteristics, and the integration of the estimated model into an AI agent framework. Initially, the dataset is constructed using preprocessed data, including cleaned historical records. In this context, FSC is designated as the target variable, while other parameters—such as historical fuel test reports, AIS trajectory data, vessel and operator profiles, technical specifications, fuel supply chain documentation, and fundamental ship attributes—are treated as input features. Key influential factors are identified through regression coefficient magnitudes and statistical significance, including main engine power, ship length, ship width, and gross tonnage. These variables serve as critical indicators influencing sulfur content and provide a theoretical foundation for subsequent estimated modeling. This phase primarily employs a linear regression model to extract features that exhibit statistically significant correlations from extensive empirical datasets.

Figure 1.

Flowchart of the method. Among them, FSC is the abbreviation of fuel sulfur content.

Building upon the insights gained from the characteristic analysis, a deep learning model is developed using TensorFlow to enable high-precision estimation of ship fuel sulfur content. The model utilizes the previously selected features as input variables and leverages neural networks to capture the complex, nonlinear relationships between these features and FSC. A primary objective of this model is to accurately determine whether the FSC exceeds the regulatory threshold of 0.5% (m/m), thereby serving as a crucial decision-making tool for the development of an intelligent early warning system.

Finally, the trained estimated model is embedded within an AI agent framework, enabling functionalities such as risk warning, intelligent query handling, and decision support. This integration significantly enhances the intelligence level of maritime emission management. The methodology for correlation analysis of the linear regression model, as well as the structural design and training procedures of the TensorFlow-based estimated model, are elaborated in Section 3.3 and Section 3.4, respectively. Based on the aforementioned methods, we conducted experimental evaluations using the dataset described in Section 3.1, and the corresponding results along with detailed analyses are presented in Section 4. Furthermore, the specific implementation plan for integrating this model into an AI agent and using it for FSC estimation in maritime supervision is described in Section 5.

3.3. Multiple Linear Regression

To systematically elucidate the comprehensive influence of multi-source heterogeneous data on marine FSC, this research initially applies Multiple Linear Regression (MLR) methodology to consolidate multidimensional ship-related information into a unified analytical framework. This approach enables quantitative assessment of the statistical relationships between various estimated features and sulfur content levels. In contrast to conventional regression techniques that depend exclusively on isolated static parameters, the dataset employed in this study encompasses diverse dimensions spanning ship operations, management profiles, technical specifications, and historical behavioral patterns, including:

- A.

- Historical fuel testing data: covering compliance and non-compliance records, reflecting the long-term fuel quality and sulfur emission levels of ships.

- B.

- Ship AIS trajectory information: including port call records, route history, and navigation patterns, used to capture the operational mode of ships and regulatory exposure risks.

- C.

- Ship and company profiles: containing background information of the ship owner and management company, operational history, and compliance records, used to assess the potential impact of management level on fuel quality.

- D.

- Ship technical parameters: such as main engine type and power, whether equipped with a scrubber, propulsion system configuration, etc., directly affecting fuel combustion efficiency and emission levels.

- E.

- Fuel supply chain information: including fuel supply ports, reputation of fuel suppliers, and historical supply quality, used to identify potential high-risk fuel sources.

- F.

- Ship basic attributes: such as ship type, length, tonnage, and age, serving as structural indicators influencing fuel consumption and emission patterns.

Before constructing the FSC estimation model for ships, systematic preprocessing of multi-source heterogeneous data is required. For continuous features such as ship length, gross tonnage, and rated power of the main engine, Z-score standardization is adopted to eliminate dimensional differences:

Among them, is the sample mean and is the standard deviation, ensuring that the features follow a distribution with a mean of 0 and a standard deviation of 1. After the above processing, the feature values of all dependent variables are integrated into a unified feature matrix , where n is the number of samples and m is the feature dimension, corresponding to the target variable (the actual value of FSC) . Based on the feature matrix X and the target variable Y, a multiple linear regression model is constructed:

Then, a regression model is constructed based on the feature matrix X and the target variable Y:

Among them, is the coefficient fitted by regression analysis, is the value of the ship’s characteristic information, and is the intercept term.

Before integrating the above multi-source data, feature engineering processing is required. For the dependent variables (such as ship length, gross tonnage, main engine power, etc.), Z-score standardization is adopted to eliminate the dimensional differences; for qualitative variables (such as ship type, fuel supply port category, etc.), they are transformed into numerical features. After processing, a unified feature matrix X is formed, corresponding to the target variable–the observed value of FSC Y.

By fitting this model and based on the coefficient of determination () of the regression analysis, the strength of the observed association between the feature and sulfur content can be objectively evaluated, which is unlikely to be caused solely by random sampling error, thereby identifying the truly statistically significant key influencing factors. The calculation method of in regression analysis is shown in Formula (3):

Among them, is the coefficient of determination, directly indicating the proportion of the variation in the target variable (sulfur content) explained by the model out of the total variation. The closer is to 1, the stronger the correlation of the model with the target variable; SSE represents the sum of squared residuals, indicating the unexplained fluctuations by the model; SST is the total sum of squares; refers to the actual sulfur content observation value of the i-th ship; refers to the average sulfur content of all ships (sample mean); refers to the sulfur content estimation value of the i-th ship by the model.

Through the analysis of regression coefficients and their significance levels, the influence direction and degree of different dimensional features can be clearly identified. For example, variables such as historical violation rate, frequent refueling from high-risk fuel supply ports, and poor compliance records of the affiliated company may have a significantly positive impact on sulfur content; while ships equipped with desulfurization towers and using low-sulfur fuel may have negative regression coefficients. This analysis not only reveals the role of individual variables but also provides feature selection and weight reference for subsequent sulfur content estimation models based on deep learning.

3.4. Real-Time Estimation and Risk Grading of Sulfur Content Based on TensorFlow

Following the completion of multiple linear regression analysis and the identification of key influencing factors, this research further develops a Deep Neural Network (DNN) model based on the TensorFlow framework to enable real-time estimation of sulfur content in marine fuel and dynamic risk classification. The proposed model effectively captures the intricate nonlinear relationships between multi-source heterogeneous features and sulfur content through multi-layered nonlinear transformations.

This study constructs a deep learning model using TensorFlow (version 2.18.0 under Python 3.10), supported by pandas for structured data manipulation and numpy for numerical computation and array preprocessing. During the training process, a multi-layer fully connected neural network is defined via the Keras API. The Adam optimizer is employed with mean squared error as the loss function. The resulting high-precision estimated model is saved in HDF5 format for deployment.

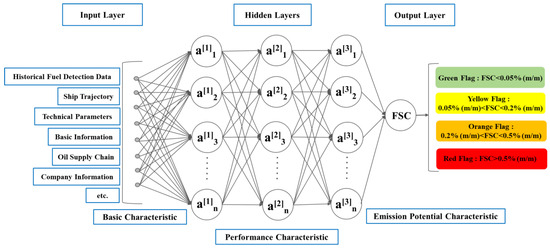

As shown in Figure 2, the model consists of an input layer, a hidden layer, and an output layer. The input layer comprises multi-dimensional ship feature variables, including fundamental parameters such as gross tonnage, main engine power, ship beam (width), and overall length. Following standardization preprocessing, these normalized features are fed into the first layer of the neural network. The hidden layer is structured as a three-layer fully connected network, with each layer comprising multiple neuron nodes designed to extract hierarchical feature representations. The first layer primarily focuses on basic construction features, such as the geometric dimensions and gross tonnage of ships. The second layer extracts performance characteristics closely associated with the operational status of ships, including main engine power and operational efficiency. The third layer captures potential emission-related characteristics, reflecting the emission potential and elucidating the comprehensive influence of various technological and operational factors on sulfur emissions.

Figure 2.

Real-time estimation of sulfur content and risk grading based on TensorFlow.

The output layer consists of a single neuron responsible for generating the estimated sulfur content of marine fuel. This estimation serves not only as a basis for real-time estimation but also supports risk classification when integrated with threshold criteria. Consequently, ships can be categorized into three risk levels: low-risk, medium-risk and high-risk targets.

During the model training phase, the input feature dataset is divided into training, validation, and test sets in a certain proportion to ensure the generalization ability of the model. The estimated sulfur content values generated by the model can be further evaluated against regulatory thresholds to establish a risk classification framework. Specifically, ships with estimated values significantly below the limit are categorized as low-risk; those with values approaching the threshold are classified as medium-risk (subjects of heightened scrutiny); and those exhibiting values exceeding or nearing non-compliance levels are designated as high-risk, and are prioritized for inclusion in inspection programs. Furthermore, by integrating regression coefficients with feature importance analysis from the neural network—such as gradient-based interpretability techniques—key contributing factors to high-risk classifications can be identified, such as refueling activities at high-risk supply ports or a management company’s history of regulatory violations. This provides regulatory agencies with a transparent and traceable analytical basis for decision-making.

4. Results

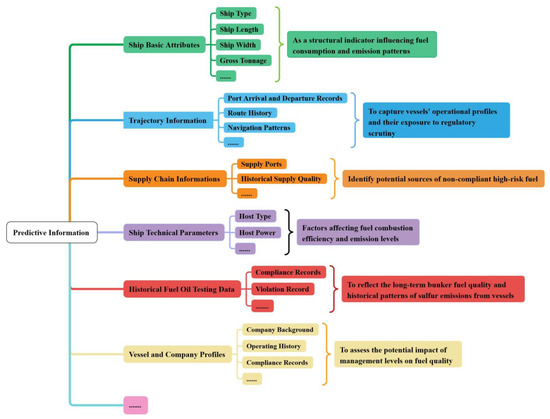

Figure 3 presents a systematic overview of the multi-source data framework employed in this study for monitoring and estimating sulfur content in marine fuels. The framework organizes the data into six distinct categories: basic ship attributes, port activities, fuel supply history, technical specifications, compliance records, and historical fuel test data. Each category contributes unique insights into various aspects of emission behavior analysis. Collectively, these features facilitate a comprehensive evaluation of ship operational patterns, regulatory exposure, fuel combustion characteristics, and operator reliability. The integration of these diverse and heterogeneous data sources constitutes the foundational basis for the AI-driven model, thereby improving its precision and real-world applicability in detecting non-compliant ships under complex maritime operational conditions.

Figure 3.

Analytical data chart.

The dataset utilized in this research encompasses sulfur content measurements and operational records of ships across multiple ports from 2017 to 2024, comprising a total of 3046 data entries. It includes a diverse range of ship types and offers notable advantages in terms of temporal span, broad geographical coverage, and multi-dimensional feature representation. The dataset effectively captures the compliance dynamics before and after the enforcement of the IMO global sulfur cap in 2020. It spans from small- and medium-sized ships to ultra-large ocean-going ships, as well as ships ranging from newly constructed to those exceeding 20 years in age. In terms of fuel quality assessment, sulfur content values range from 0.01% (m/m) to 3.5% (m/m). Following 2020, a substantial decline in sulfur levels has been observed, with most values concentrated within the 0.01% (m/m)–0.5% (m/m) range. Nevertheless, non-compliant or near-threshold samples persist, indicating ongoing compliance risks. Fuel supply chain information reveals variability in compliance performance across ports and suppliers, with certain ports and providers linked to a higher incidence of violations, thereby exhibiting elevated risk profiles. Additionally, port entry/exit and cargo loading/unloading records allow for more precise characterization of ship movement patterns. Data sources include both official regulatory authorities and independent third-party testing institutions, ensuring data diversity and enabling cross-validation. Overall, the dataset demonstrates strong representativeness in terms of scale, feature richness, and temporal relevance. It not only facilitates the identification of key drivers influencing sulfur emissions through multiple linear regression analysis but also provides comprehensive input features and real-world risk scenarios for training deep learning models using TensorFlow. This robust data foundation supports the development of an intelligent and dynamic monitoring system for ship FSC.

As illustrated in Figure 4, the impact of various ship characteristics on sulfur emissions demonstrates notable variation across different years. Ship dimensional parameters—such as main engine power, ship width, ship length, and gross tonnage—exhibit consistently strong correlations over multiple years, particularly in 2018 and 2024, where their regression coefficients reach relatively high levels of significance. This suggests that physical dimensions and propulsion capacity serve as key explanatory variables for sulfur emission levels. In comparison, operational and managerial factors—including fuel suppliers, upstream and downstream ports, and the port of registry—exert a comparatively limited overall influence on sulfur emissions, with their statistical significance showing temporal fluctuations. Overall, structural ship parameters constitute the primary determinants of sulfur emissions, whereas operational and managerial variables may function as secondary influencing factors under specific temporal or contextual conditions.

Figure 4.

Regression analysis results chart.

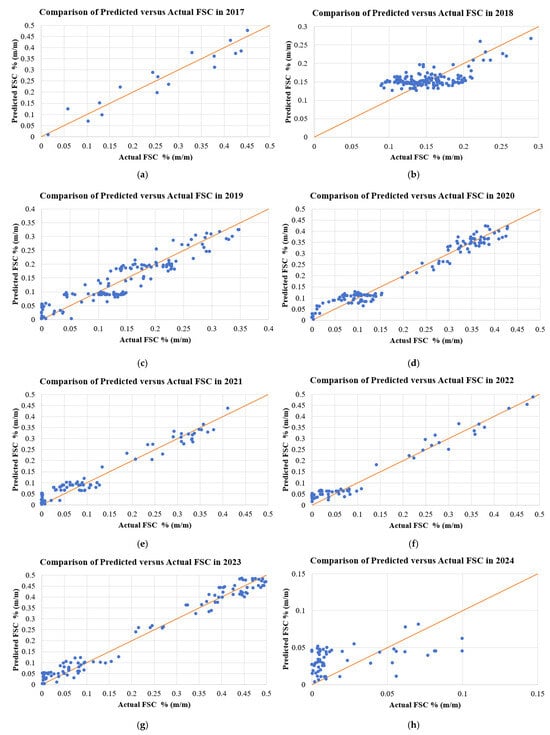

This research is based on an eight-year continuous dataset (2017–2024) of sulfur content in marine fuels. A hybrid estimation framework integrating multiple linear regression and deep learning models has been developed to estimate fuel sulfur levels, with annual comparisons conducted between estimated and empirically measured values. During the experimental phase, the model incorporates multi-source heterogeneous input features, including fundamental ship parameters, fuel supply chain data, historical compliance records, and operational trajectory information, generating corresponding sulfur content estimations for each fuel sample. To assess model performance, statistical metrics such as the coefficient of determination () and mean squared error (MSE) are employed to evaluate the degree of fit between estimated and observed values. Furthermore, independent modeling and validation are performed on yearly subsets of the dataset to investigate the model’s adaptability and robustness across policy transitions and varying market conditions.

The experimental results indicate that the model achieved high fitting accuracy throughout the 2017–2024 period, with estimated values demonstrating strong statistical consistency with observed measurements. This suggests that the developed model possesses substantial explanatory capability regarding sulfur emissions from marine fuels. During the policy transition phase (2017–2019), the model maintained stable estimation accuracy, effectively capturing the influence of fuel usage characteristics on emission levels. Following the enforcement of the IMO global sulfur cap in 2020, the discrepancy between estimated and measured values declined significantly, highlighting the positive impact of policy-driven fuel transition on model performance. The discrepancy between estimated and observed values in 2020 was reduced by 21.16% compared to that in 2019, indicating an improvement in model accuracy over the consecutive years. A moderate fluctuation in estimated accuracy was observed between 2021 and 2022, which may be attributed to variations in the pace of clean fuel adoption and alternative energy deployment across the market. By 2023–2024, the model’s estimations once again aligned closely with actual measurements, demonstrating its adaptability to evolving market dynamics and technological advancements. The discrete pattern observed in the 2024 data presented in Figure 5 can be primarily attributed to two key factors. First, the dataset obtained from the Ningbo Maritime Safety Administration only includes records up to April 2024, resulting in a relatively limited sample size. This constraint may compromise the stability and reliability of the statistical outcomes for that year. Second, the implementation of stricter emission control policies, along with the widespread adoption of low-sulfur fuels, has led to a substantial decrease in actual FSC values in 2024 compared to previous years. Specifically, the upper limit of the FSC value on the 2024 axis is set at 0.15% (m/m), whereas the upper limit in the earlier figures was 0.5% (m/m). Although the 2024 data exhibit greater variability, the absolute deviation between the estimated and observed values remains minimal. This consistency indicates that the model retains a high level of estimated accuracy, even amidst rapidly evolving regulatory frameworks. Overall, this study confirms the temporal applicability and robustness of the estimated approach integrating multi-dimensional data with a deep learning architecture, offering a reliable foundation for real-time monitoring and regulatory enforcement of sulfur content in ship fuel.

Figure 5.

(a–h) Experimental results graph, based on an eight-year continuous dataset (2017–2024). The blue dots represent the actual FSC in comparison to the estimated values. The orange line denotes the y = x reference line for visual interpretation.

The experimental results demonstrate that the developed model achieves high fitting performance and estimated accuracy across multi-year datasets spanning from 2017 to 2024. It effectively captures the integrated influence of ship structural parameters, operational behaviors, and fuel supply chain factors on sulfur emissions. Notably, following the enforcement of the global sulfur cap regulation in 2020, the discrepancy between estimated and observed values substantially decreased, confirming the method’s applicability and robustness under evolving policy frameworks and dynamic market conditions. Furthermore, the findings indicate that ship-scale parameters—such as gross tonnage, main engine power, length, and beam—exhibit a stronger explanatory capacity for sulfur emission levels, whereas managerial and operational dimensions exert a moderating influence within specific timeframes, offering empirical support for future policy development and regulatory enhancement.

Nonetheless, certain limitations persist in this study. The multi-source data underpinning the model—including AIS trajectories, fuel reports, and company records—vary in terms of collection timing, measurement accuracy, and spatial coverage, potentially introducing noise and bias. Particularly in cases of missing data or inconsistent labeling, estimation outcomes may be compromised. Although the features selected through multiple linear regression analysis demonstrate statistical significance ( = 0.67), they do not encompass all potential influencing factors, such as crew operational practices, real-time meteorological conditions, or variability in fuel blending processes. These omissions partially constrain the model’s comprehensiveness and generalization capability. Additionally, external uncontrollable variables—such as abrupt policy shifts or fuel market volatility—may also lead to estimation deviations during exceptional periods.

5. Application

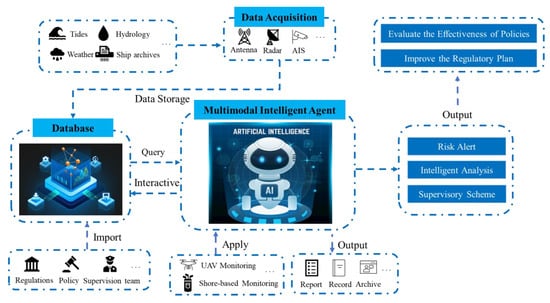

Figure 6 illustrates the workflow of an AI-driven intelligent supervision framework centered on a multimodal intelligent agent. A centralized database is constructed by collecting multi-source data—including tidal patterns, meteorological conditions, weather information, and ship records—through various devices such as drones, radars, and shore-based sniffers. This database is further enriched with relevant laws and regulations concerning ship sulfur content and information on law enforcement personnel. At the core of the system lies a multi-modal intelligent agent, which interfaces with the database to integrate and analyze the aforementioned multi-source heterogeneous data. Leveraging artificial intelligence technologies, including machine learning and natural language processing, the agent performs intelligent data analysis and risk warning. Based on the analytical outcomes, the system generates optimized supervision plans, continuously evaluates the effectiveness of current policies, and dynamically adjusts regulatory strategies. Ultimately, the intelligent agent produces structured outputs such as reports, archives, and records, along with risk estimations and intelligent risk identification results.

Figure 6.

Logical architecture diagram of the agent system.

Based on the experimental results and model validation mentioned above, this study further established an AI agent in the ship exhaust gas detection system of Ningbo Port to achieve real-time monitoring and dynamic risk assessment of the sulfur content in ship fuel. This agent is driven by multi-source heterogeneous data, inputting fuel testing records, AIS track information, ship technical parameters, and fuel supply chain information into a deep learning model. Combined with historical compliance and estimation results, it outputs the estimated FSC and the risk level. During operation, the system can automatically screen ships entering and leaving the port, quickly identify potential high-risk target ships, and generate a priority list for reference by regulatory authorities for spot checks, thereby effectively improving the allocation efficiency of detection resources and the accuracy of law enforcement. The deployment of this AI agent has verified the feasibility and practicality of the research method in actual port supervision scenarios, providing important technical support for promoting intelligent and refined ship emission control.

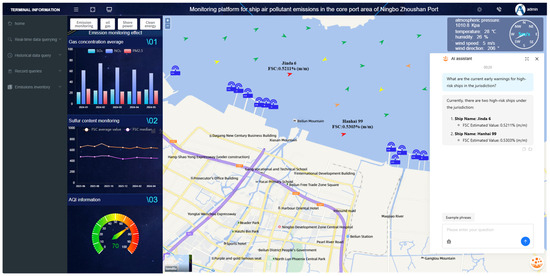

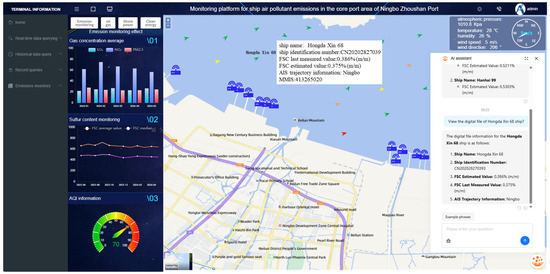

This intelligent agent is deployed within the ship exhaust monitoring system of Ningbo Port, integrating multi-source heterogeneous data with deep learning models to enable real-time estimation and risk assessment of FSC. The system performs comprehensive analysis on incoming ships by synthesizing fuel inspection records, AIS trajectory data, fuel supply chain information, and ship technical specifications, generating estimated sulfur content levels and corresponding risk classifications. Additionally, the system visually displays ship distribution on a map interface, allowing the intelligent agent to automatically identify and flag ships suspected of exceeding sulfur limits, thereby supporting regulatory authorities in accurately targeting high-risk ships. This application marks a transition from traditional spot-checking to intelligent estimated monitoring, significantly improving the scientific rigor and operational efficiency of port supervision.

The AI agent deployed in the ship exhaust gas detection system at Ningbo Port has been put into practical use as shown in Figure 7 and Figure 8. Its functions are mainly reflected in two aspects: First, comprehensive analysis. The agent can conduct multi-dimensional feature fusion analysis on the monitored ships, integrating fuel detection data, AIS trajectories, ship attributes, and fuel supply chain information, etc., to output the estimated sulfur content of the ship’s fuel in real time. It also classifies ships based on historical compliance records, assisting regulatory authorities in targeted control. Second, intelligent screening. The system visually presents the distribution of ships within the port area on the map interface. The AI agent can automatically mark and screen out ships suspected of having sulfur content exceeding standards, indicating potential violations, thereby providing decision-making references for on-site law enforcement. Through this application, the AI agent has effectively enhanced the intelligence level of port supervision, transforming the traditional passive spot-checking model into proactive estimation and precise targeting, providing practical technical support for efficient and compliant supervision in large-scale port environments.

Figure 7.

Application diagram of intelligent agents. The green arrows in the figure denote ships with FSC below 0.05% (m/m); yellow arrows correspond to ships with FSC ranging from 0.05% (m/m) to 0.2% (m/m); orange arrows indicate ships with FSC between 0.2% (m/m) and 0.5% (m/m); and red arrows represent ships with FSC exceeding 0.5% (m/m).

Figure 8.

Schematic diagram of agent system application. The green arrows in the figure denote ships with FSC below 0.05% (m/m); yellow arrows correspond to ships with FSC ranging from 0.05% (m/m) to 0.2% (m/m); orange arrows indicate ships with FSC between 0.2% (m/m) and 0.5% (m/m); and red arrows represent ships with FSC exceeding 0.5% (m/m).

6. Discussion

This study successfully achieved high-precision estimation of sulfur content in ship fuel and intelligent classification of compliance risks through the integration of multi-source heterogeneous data using linear regression techniques, as well as the development of a deep neural network model based on TensorFlow. Compared with conventional single-detection approaches, the AI-driven methodology proposed in this paper not only demonstrated substantial explanatory capacity in terms of goodness of fit (R2 = 0.67), but also validated its practical effectiveness within the regulatory framework of Ningbo Port. By systematically integrating ship-related information, the approach enhances the robustness and accuracy of sulfur emission estimation under the synergistic influence of multi-dimensional features. Notably, following the full enforcement of the global sulfur limit regulation, the model maintained strong estimated stability even under extreme low-sulfur conditions, underscoring the distinct advantages of artificial intelligence in complex maritime regulatory environments.

Therefore, future maritime supervision in port areas must go beyond the limitations of traditional exhaust monitoring approaches by integrating multi-source data—including ship dynamic behavior, onboard equipment status, fuel traceability information, and remote sensing of exhaust emissions—to develop an intelligent risk assessment model. This model is expected to not only accurately identify ships with non-compliant fuel sulfur levels but also optimize the allocation of enforcement resources, thereby enabling “low-interference, high-efficiency” compliance management within emission control zones and ultimately contributing to improved air quality in global port cities.

Despite the promising outcomes achieved in both theoretical and applied dimensions, several limitations warrant further investigation. For instance, the current model does not yet account for real-time meteorological conditions or inland waterway traffic dynamics—factors that may influence emission behaviors. Additionally, its cross-regional generalization capability requires further validation. Future research should aim to develop a more comprehensive feature engineering framework, incorporate uncertainty quantification techniques to improve model resilience under abnormal or extreme conditions, and explore the potential of federated learning for multi-port collaborative governance, thereby supporting the global advancement of intelligent and interconnected emission control systems.

7. Conclusions

Against the backdrop of the growing trend toward ultra-low emissions from ship exhaust, intelligent monitoring of FSC has emerged as a critical research direction for enhancing maritime regulatory capabilities and addressing environmental pollution challenges. The development of an intelligent risk assessment model that integrates multi-source real-time data not only facilitates the accurate identification of non-compliant ships and the optimization of law enforcement resource allocation, but also provides core technical support for achieving “low-interference, high-efficiency” compliance management within emission control areas. This advancement holds significant theoretical value and practical relevance in promoting sustained improvements in air quality across global ports.

This study proposes an AI-driven approach for monitoring ship FSC through the integration of multi-source heterogeneous data, overcoming the limitations of conventional single-point detection and static feature analysis. Key findings demonstrate that multiple linear regression can effectively identify key influencing factors of sulfur emissions (R2 = 0.67). Furthermore, a deep neural network implemented using TensorFlow enables real-time estimation and risk classification of sulfur content, exhibiting high model accuracy and stability. In practical implementation, the research team successfully deployed an AI-based intelligent supervision module at Ningbo Port, enabling real-time monitoring, risk stratification, and automated screening of non-compliant ships entering and exiting the port. This has significantly enhanced regulatory efficiency and accuracy, offering a scalable and replicable technical framework for the field.

Despite notable theoretical and practical advancements, this research presents certain limitations. For instance, the model does not fully account for dynamic variables such as real-time meteorological and hydrological conditions, variations in crew operational behaviors, or inconsistencies in fuel mixing uniformity. Additionally, it does not comprehensively address the challenges posed by regional policy differences that may affect model generalization. Future research will focus on strengthening feature engineering and uncertainty quantification to enhance model robustness in complex environments; integrating multimodal data—including satellite remote sensing, real-time supply chain dynamics, and atmospheric diffusion parameters—to develop a more comprehensive intelligent perception system; and exploring cross-domain collaborative monitoring mechanisms to support the integrated and intelligent governance of global shipping emissions.

Author Contributions

F.Z.: data curation, conceptualization, methodology, writing—original draft, writing—review and editing. Y.W.: data curation, methodology, visualization, investigation. Y.Z.: data curation. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Hubei Engineering Research Center for Intelligent Detection and Identification of Complex Parts (grant number KYQDJF2025006). We thank the support of the Haifeng International Young Faculty Industry-Academia-Research Assistance Program.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zaman, I.; Pazouki, K.; Norman, R.; Younessi, S.; Coleman, S. Challenges and opportunities of big data analytics for upcoming regulations and future transformation of the shipping industry. Procedia Eng. 2017, 194, 537–544. [Google Scholar] [CrossRef]

- Du, S.; Zhang, H.; Kong, Y. Sustainability Implications of the Arctic Shipping Route for Shanghai Port Logistics in the Post-Pandemic Era. Sustainability 2023, 15, 16017. [Google Scholar] [CrossRef]

- Andersson, K.; Baldi, F.; Brynolf, S.; Lindgren, J.F.; Granhag, L.; Svensson, E. Shipping and the Environment. In Shipping and the Environment: Improving Environmental Performance in Marine Transportation; Springer: Berlin/Heidelberg, Germany, 2016; pp. 3–27. [Google Scholar]

- Ali, I. The world’s maritime industry in the 21st century: Challenges, expectations, and directions. South East Asian Mar. Sci. J. 2025, 2, 64–75. [Google Scholar] [CrossRef]

- Zou, Y.; Xiao, G.; Li, Q.; Biancardo, S.A. Intelligent Maritime Shipping: A Bibliometric Analysis of Internet Technologies and Automated Port Infrastructure Applications. J. Mar. Sci. Eng. 2025, 13, 979. [Google Scholar] [CrossRef]

- Panahi, R.; Ng, A.K.; Afenyo, M.K.; Haeri, F. A novel approach in probabilistic quantification of risks within the context of maritime supply chain: The case of extreme weather events in the Arctic. Accid. Anal. Prev. 2020, 144, 105673. [Google Scholar] [CrossRef]

- Elmi, Z.; Singh, P.; Meriga, V.K.; Goniewicz, K.; Borowska-Stefańska, M.; Wiśniewski, S.; Dulebenets, M.A. Uncertainties in liner shipping and ship schedule recovery: A state-of-the-art review. J. Mar. Sci. Eng. 2022, 10, 563. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, X.; Chai, J. The dynamic impacts of the global shipping market under the background of oil price fluctuations and emergencies. Complexity 2021, 2021, 8826253. [Google Scholar] [CrossRef]

- Zannis, T.C.; Katsanis, J.S.; Christopoulos, G.P.; Yfantis, E.A.; Papagiannakis, R.G.; Pariotis, E.G.; Vallis, A.G.; Rakopoulos, D.C.; Rakopoulos, C.D. Marine exhaust gas treatment systems for compliance with the IMO 2020 global sulfur cap and tier III NOx limits: A review. Energies 2022, 15, 3638. [Google Scholar] [CrossRef]

- Wang, T.; Xiao, G.; Li, Q.; Biancardo, S.A. The impact of the 21st-Century Maritime Silk Road on sulfur dioxide emissions in Chinese ports: Based on the difference-in-difference model. Front. Mar. Sci. 2025, 12, 1608803. [Google Scholar] [CrossRef]

- Xiao, G.; Caleb, A.; Wang, T.; Li, Q.; Biancardo, S.A. Evaluating the impact of ECA policy on sulfur emissions from the five busiest ports in America based on difference in difference model. Front. Mar. Sci. 2025, 12, 1609261. [Google Scholar] [CrossRef]

- Chen, J.; Wan, Z.; Zhang, H.; Liu, X.; Zhu, Y.; Zheng, A. Governance of shipping emission of SOx in China’s coastal waters: The SECA policy, challenges, and directions. Coast. Manag. 2018, 46, 191. [Google Scholar] [CrossRef]

- Karim, M.S. Prevention of pollution of the marine environment from vessels. J. Mar. Poll 2015, 30, 50–75. [Google Scholar]

- Zetterdahl, M.; Moldanova, J.; Pei, X.; Pathak, R.K.; Demirdjian, B. Impact of the 0.1% fuel sulfur content limit in SECA on particle and gaseous emissions from marine vessels. Atmos. Environ. 2016, 145, 338–345. [Google Scholar] [CrossRef]

- Browne, S.; Weiss, T.G. The UN Development System: Origins, Structure, Status. In Routledge Handbook on the UN and Development; Routledge: Oxford, UK, 2020; pp. 9–31. [Google Scholar]

- Van Roy, W.; Van Nieuwenhove, A.; Scheldeman, K.; Van Roozendael, B.; Schallier, R.; Mellqvist, J.; Maes, F. Measurement of sulfur-dioxide emissions from ocean-going vessels in Belgium using novel techniques. Atmosphere 2022, 13, 1756. [Google Scholar] [CrossRef]

- Rumin, J.; Nicolau, E.; Gonçalves de Oliveira Junior, R.; Fuentes-Grünewald, C.; Flynn, K.J.; Picot, L. A bibliometric analysis of microalgae research in the world, Europe, and the European Atlantic area. Mar. Drugs 2020, 18, 79. [Google Scholar] [CrossRef]

- Moshiul, A.M.; Mohammad, R.; Hira, F.A.; Maarop, N. Alternative marine fuel research advances and future trends: A bibliometric knowledge mapping approach. Sustainability 2022, 14, 4947. [Google Scholar] [CrossRef]

- Shaaban-Nejad, S.; Shirazi, F. ICT and Environmental Sustainability: A Comparative Study. Sustainability 2022, 14, 8651. [Google Scholar] [CrossRef]

- Anand, A.; Wei, P.; Gali, N.K.; Sun, L.; Yang, F.; Westerdahl, D.; Zhang, Q.; Deng, Z.; Wang, Y.; Liu, D.; et al. Protocol development for real-time ship fuel sulfur content determination using drone based plume sniffing microsensor system. Sci. Total Environ. 2020, 744, 140885. [Google Scholar] [CrossRef]

- Ma, Z.; Yang, Y.; Sun, P.; Duan, S.; Qu, H.; Zou, Y. Analysis of marine diesel engine emission characteristics of different power ranges in China. Atmosphere 2021, 12, 1108. [Google Scholar] [CrossRef]

- Cao, K.; Zhang, Z.; Li, Y.; Zheng, W. Ship fuel sulfur content prediction based on convolutional neural network and ultraviolet camera images. Environ. Pollut. 2021, 273, 116501. [Google Scholar] [CrossRef]

- Cao, K.; Zhang, Z.; Li, Y.; Zheng, W. Surveillance of ship emissions and fuel sulfur content based on imaging detection and multi-task deep learning. Environ. Pollut. 2021, 288, 117698. [Google Scholar] [CrossRef]

- Peng, Z.; Ge, Y.; Tan, J.; Fu, M.; Wang, X.; Chen, M.; Yin, H.; Ji, Z. Em issions from several in-use ships tested by portable emission measurement system. Ocean Eng. 2016, 116, 260–267. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, Y.; Tian, C.; Lou, D.; Li, J.; Zhang, G.; Matthias, V. Emission factors for gaseous and particulate pollutants from offshore diesel engine vessels in China. Atmos. Chem. Phys. 2016, 16, 6319–6334. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, Y.; Chen, Q.; Feng, Y.; Shang, Y.; Yang, X.; Gao, H.; Tian, C.; Li, J.; Zhang, G.; et al. Real-world emission factors of gaseous and particulate pollutants from marine fishing boats and their total emissions in China. Environ. Sci. Technol. 2018, 52, 4910–4919. [Google Scholar] [CrossRef] [PubMed]

- Juwono, A.M.; Johnson, G.R.; Mazaheri, M.; Morawska, L.; Roux, F.; Kitchen, B. Investigation of the airborne submicrometer particles emitted by dredging vessels using a plume capture method. Atmos. Environ. 2013, 73, 112–123. [Google Scholar] [CrossRef]

- Zhou, F.; Pan, S.; Chen, W.; Ni, X.; An, B. Monitoring of compliance with fuel sulfur content regulations through unmanned aerial vehicle (UAV) measurements of ship emissions. Atmos. Meas. Tech. 2019, 12, 6113–6124. [Google Scholar] [CrossRef]

- Zhang, S.; Zeng, Y.; Zhang, R. Cellular-enabled UAV communication: A connectivity-constrained trajectory optimization perspective. IEEE Trans. Commun. 2018, 67, 2580–2604. [Google Scholar] [CrossRef]

- Dou, Z.; Liu, Z.; Li, L.; Zhou, H.; Wang, Q.; Zhang, J.; Chen, L. Atmospheric dispersion prediction of accidental release: A review. Emerg. Manag. Sci. Technol. 2022, 2, 1–20. [Google Scholar] [CrossRef]

- Alföldy, B.; Lööv, J.B.; Lagler, F.; Mellqvist, J.; Berg, N.; Beecken, J.; Weststrate, H.; Duyzer, J.; Bencs, L.; Horemans, B.; et al. Measurements of air pollution emission factors for marine transportation in SECA. Atmos. Meas. Tech. 2013, 6, 1777–1791. [Google Scholar] [CrossRef]

- Mao, T.; Li, Y.; Chang, F. Research progress of monitoring technology of ship-source air pollutants in China emission control area. In E3S Web of Conferences; EDP Sciences: Ulis, France, 2020; Volume 206, p. 02006. [Google Scholar]

- Conti, G.O.; Heibati, B.; Kloog, I.; Fiore, M.; Ferrante, M. A review of AirQ Models and their applications for forecasting the air pollution health outcomes. Environ. Sci. Pollut. Res. 2017, 24, 6426–6445. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, K.; Xing, W.; Li, H.; Yang, Z. Applications, evolutions, and challenges of drones in maritime transport. J. Mar. Sci. Eng. 2023, 11, 2056. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).