An Integrated Delphi-AHP Study on the Systematic Improvement of Sea Anchors for Fishing Operations

Abstract

1. Introduction

2. Materials and Methods

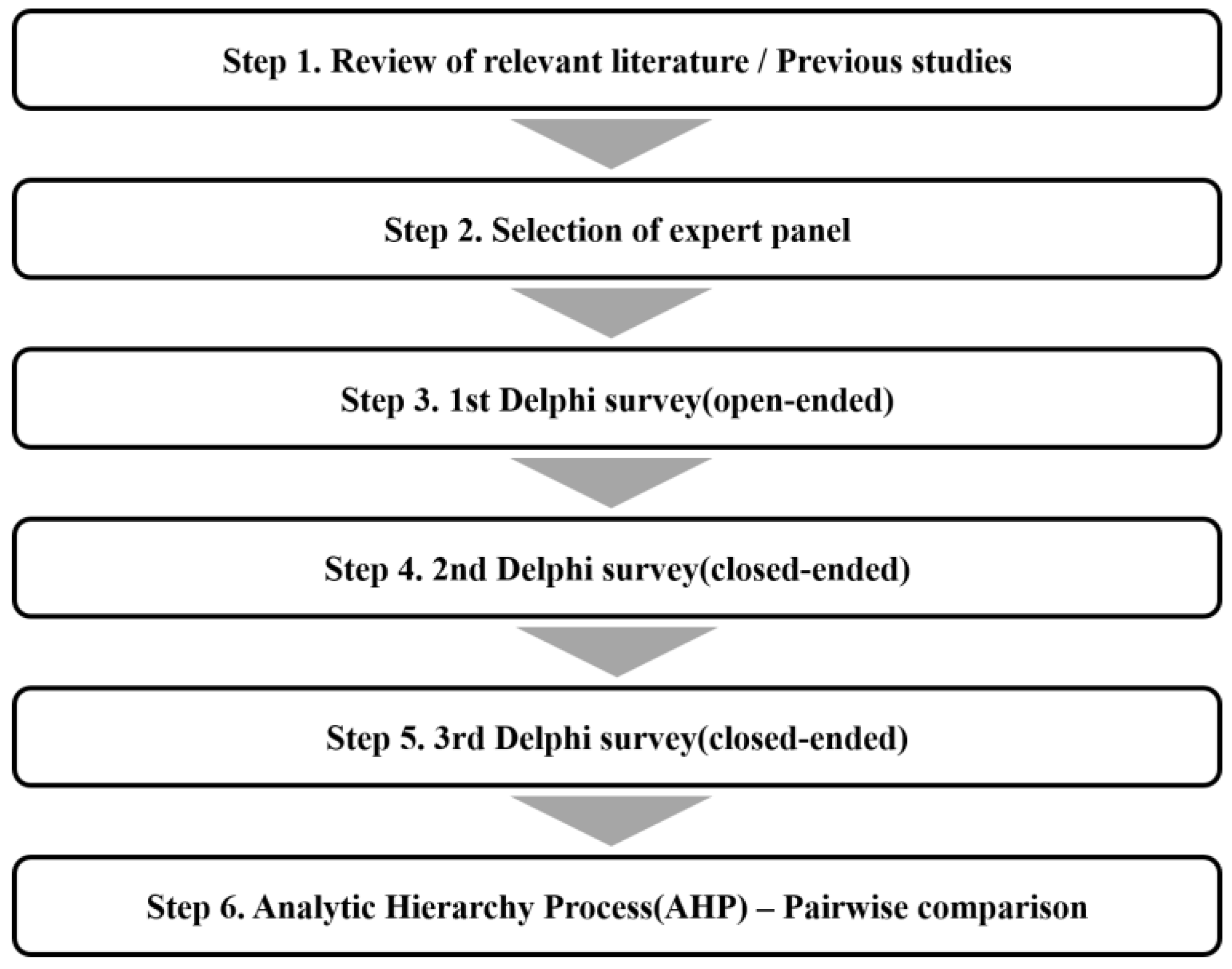

2.1. Study Procedure

2.2. Delphi Method

- Delphi design and protocol

- 2.

- Evaluation indices and criteria

2.3. Analytic Hierarchy Process (AHP)

- 3.

- AHP protocol

2.4. Expert Panel Selection

3. Results and Discussion

3.1. Delphi Analysis Results

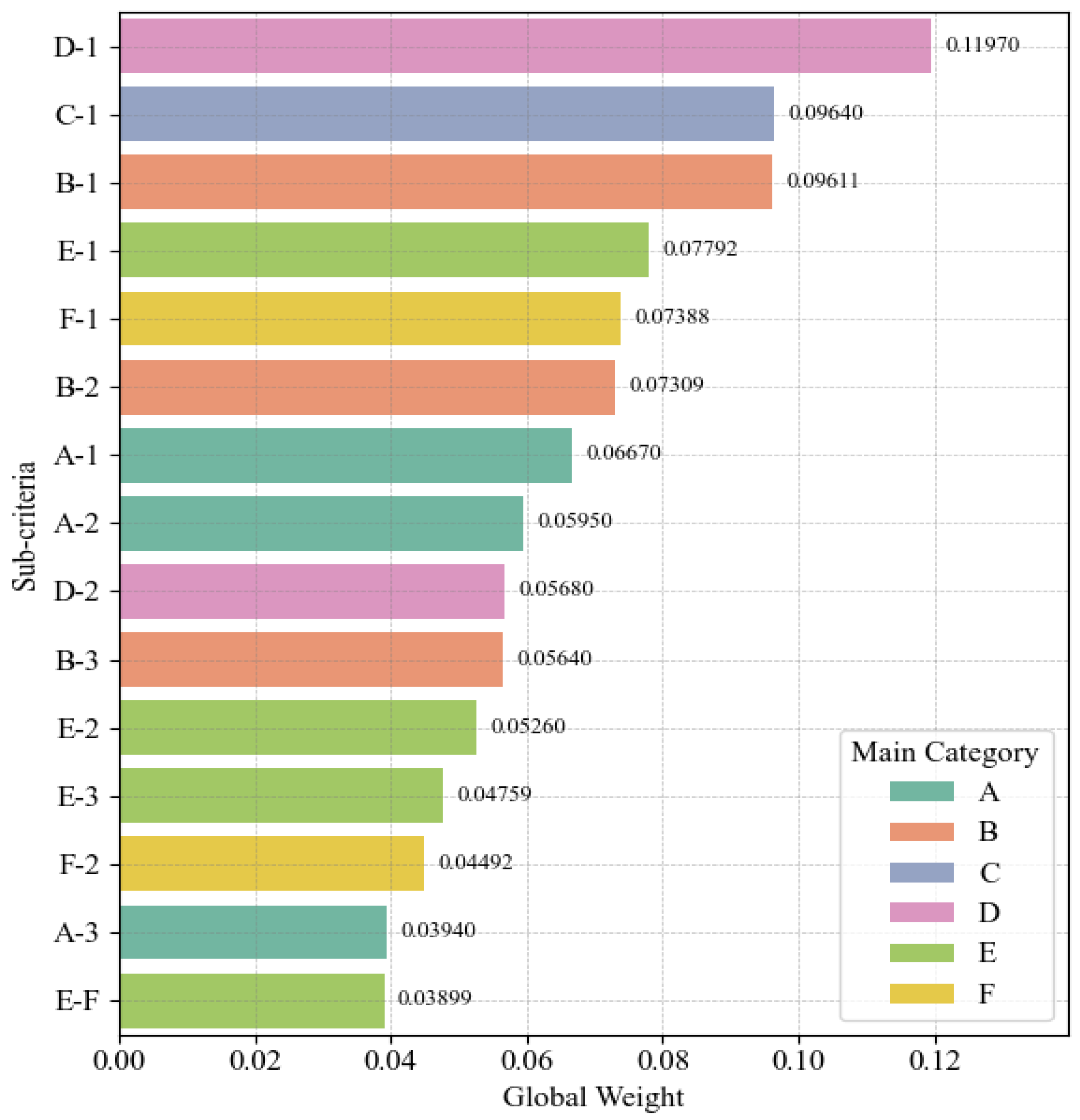

3.2. AHP Analysis Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AHP | Analytic Hierarchy Process |

| Aw | Matrix Multiplication of A and w |

| CI | Consistency Index |

| CR | Consistency Ratio |

| CV | Coefficient of Variation |

| CVR | Content Validity Ratio |

| IQR | Interquartile Range |

| M | Mean |

| Max | Maximum |

| Min | Minimum |

| MCDM | Multi-Criteria Decision-Making |

| NPFC | North Pacific Fisheries Commission |

| PES | Polyester |

| PA | Polyamide |

| RI | Random Index |

| SD | Standard Deviation |

| λ | Eigenvalue |

| λmax | Maximum Eigenvalue |

| w | Weight Vector |

References

- An, H.C. Development and Hydrodynamic Characteristics of Sea Anchor for Squid Jigging Vessel. Ph.D. Thesis, Pukyong National University, Busan, Republic of Korea, 2000. [Google Scholar]

- Chong, D.Y. A study on the legal status of vessels laying sea anchor—Focused on the judgments of KMST. Marit. Law Res. 2022, 34, 81–104. [Google Scholar] [CrossRef]

- Kim, N.; Kim, S.H.; Lee, Y.W.; Ryu, K.J. Field experiments to analyze the canopy drying performance of sea anchors used for fishing operations. J. Mar. Sci. Eng. 2025, 13, 389. [Google Scholar] [CrossRef]

- Hyun, Y.K.; Kim, J.K.; Kwon, B.G.; An, H.C. The relationship between resistance and shape of sea anchor used in squid jigging boats. J. Korean Soc. Fish. Ocean Technol. 1998, 34, 359–365. [Google Scholar]

- Rodhouse, P.G. C2. World squid resources. In Review of the State of World Marine Fishery Resources; FAO Fisheries Technical Paper No. 457; FAO: Rome, Italy, 2005; pp. 175–187. [Google Scholar]

- Arkhipkin, A.I.; Rodhouse, P.G.K.; Pierce, G.J.; Sauer, W.; Sakai, M.; Allcock, L.; Arguelles, J.; Bower, J.R.; Castillo, G.; Ceriola, L.; et al. World squid fisheries. Rev. Fish. Sci. Aquac. 2015, 23, 92–252. [Google Scholar] [CrossRef]

- Chen, X.; Chen, Y.; Tian, S.; Liu, B.; Qian, W. An assessment of the west winter–spring cohort of neon flying squid (Ommastrephes bartramii) in the Northwest Pacific Ocean. Fish. Res. 2008, 92, 221–230. [Google Scholar] [CrossRef]

- Jiang, M.; Wang, J.; Li, G.; Liu, B.; Chen, X. Is seasonal closure an effective way to conserve oceanic squids—Taking Chinese autonomic seasonal closure on the high seas as an example. Fish. Res. 2024, 271, 106914. [Google Scholar] [CrossRef]

- Global Fishing Watch. Rise in Unregulated Squid Fishing Challenges Opportunity. 2023. Available online: https://globalfishingwatch.org/article/rise-in-unregulated-squid-fishing-challenges-opportunity/ (accessed on 3 September 2025).

- Ministry of Oceans and Fisheries. 2024 Implementation Plan for the Promotion of Recreational Fishing [2024 Nakksijinheung Sihaenggyehoek]; Ministry of Oceans and Fisheries: Sejong, Republic of Korea, 2023. [Google Scholar]

- Kim, N. A Study on the Standardization of Fishery Sea Anchor. Master’s Thesis, Pukyong National University, Busan, Republic of Korea, 2022. [Google Scholar]

- Ryu, K.J.; Kim, N.; Lee, Y.W. A study on the performance test of canopy cloth on the fishery sea anchor. J. Korean Soc. Fish. Ocean Technol. 2023, 59, 110–116. [Google Scholar] [CrossRef]

- Sato, M. Information the sea anchor. J. Naut. Soc. Jpn. 1967, 36, 153–158. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Oikawa, K. Full scale test on the parachute type sea anchor. J. Naut. Soc. Jpn. 1970, 43, 51–57. [Google Scholar] [CrossRef] [PubMed]

- Kim, N.; Kim, H.S.; Lee, Y.W.; Ryu, K.J. A study on standardization through the analysis of the survey on the use of fishery sea anchor. J. Korean Soc. Fish. Ocean Technol. 2022, 58, 10–18. [Google Scholar] [CrossRef]

- Jung, J.M.; Kim, H.S. A study on the underwater stability according to the composition of the sea anchor. J. Korean Soc. Fish. Ocean Technol. 2022, 58, 289–298. [Google Scholar] [CrossRef]

- Li, K.; Wang, Z.; Ma, Y.; Wang, Y.; Li, H. Research on the inflation process of underwater parachute by numerical simulation and model test. Ocean Eng. 2024, 293, 116554. [Google Scholar] [CrossRef]

- Saaty, T.L. What is the Analytic Hierarchy Process? In Mathematical Models for Decision Support; Springer: Berlin/Heidelberg, Germany, 1988; pp. 109–121. [Google Scholar] [CrossRef]

- Skulmoski, G.J.; Hartman, F.T.; Krahn, J. The Delphi method for graduate research. J. Inf. Technol. Educ. Res. 2007, 6, 1–21. [Google Scholar] [CrossRef]

- Rowe, G.; Wright, G. The Delphi technique as a forecasting tool: Issues and analysis. Int. J. Forecast. 1999, 15, 353–375. [Google Scholar] [CrossRef]

- Lee, K.S.; Kim, T.H.; Kim, T.H.; Park, S.H. Analysis of risk factor for sinkhole formation by using Delphi. J. Korea Contents Assoc. 2016, 16, 65–75. [Google Scholar] [CrossRef][Green Version]

- Lawshe, C.H. A quantitative approach to content validity. Pers. Psychol. 1975, 28, 563–575. [Google Scholar] [CrossRef]

- Lee, M.W.; Shin, H.; Ga, S.H.; Kim, C.J. Analysis of the components of action competence for climate change using the Delphi method. Korean J. Environ. Educ. 2021, 34, 288–305. [Google Scholar]

- Saaty, T.L. The Analytic Hierarchy Process (AHP). J. Oper. Res. Soc. 1980, 41, 1073–1076. [Google Scholar]

- Shin, C.; Kang, D.Y.; Kim, H.Y.; Park, S. The study on selecting a marking method for the gillnet deposit system using analytical hierarchy process (AHP). J. Korean Soc. Fish. Ocean Technol. 2025, 61, 78–87. [Google Scholar] [CrossRef]

- Oh, M.H. Inter-Country Tourism Industry Competitiveness Evaluation—Index Development Using Delphi Technique and AHP. Ph.D. Thesis, Sejong University, Seoul, Republic of Korea, 2013. [Google Scholar]

- Kang, H.C. A Study on the Main Factors for the Growth of North Korean Enterprises Using Delphi and AHP. Ph.D. Thesis, Chung-Ang University, Seoul, Republic of Korea, 2019. [Google Scholar]

- Vargas, L.G. An overview of the analytic hierarchy process and its applications. Eur. J. Oper. Res. 1990, 48, 2–8. [Google Scholar] [CrossRef]

- Ashton, R.H. Combining the judgments of experts: How many and which ones? Organ. Behav. Hum. Decis. Process. 1986, 38, 405–414. [Google Scholar] [CrossRef]

- Bolger, F.; Wright, G. Assessing the quality of expert judgment: Issues and analysis. Decis. Support Syst. 1994, 11, 1–24. [Google Scholar] [CrossRef]

- Ewing, D.M. Future Competencies Needed in the Preparation of Secretaries in the State of Illinois Using the Delphi Technique. Ph.D. Thesis, University of Illinois at Urbana-Champaign, Urbana, IL, USA, 1991. [Google Scholar]

- Waltz, C.F.; Strickland, O.L.; Lenz, E.R. Measurement in Nursing and Health Research, 4th ed.; Springer Publishing Company: New York, NY, USA, 2010; pp. 1–491. [Google Scholar]

- Kim, N.; Kim, S.H.; Lee, Y.W.; Ryu, K.J. Comparison of Canopy Materials to Improve the Performance of Sea Anchors Used for Fishing Operations. J. Mar. Sci. Technol. 2025, 33, 6. [Google Scholar] [CrossRef]

| Importance | Verbal Judgment | Explanation |

|---|---|---|

| 1 | Equal importance | Both elements contribute equally to the objective |

| 2 | Between equal and moderate | A compromise between equal and moderate importance. |

| 3 | Moderate importance | One element is slightly more important than the other. |

| 4 | Between moderate and strong | A compromise between moderate and strong importance. |

| 5 | Strong importance | One element is clearly more important than the other. |

| 6 | Between strong and very strong | A compromise between strong and very strong importance. |

| 7 | Very strong importance | One element is demonstrably more important than the other. |

| 8 | Between very strong and extreme | A compromise between very strong and extreme importance. |

| 9 | Extreme importance | One element is overwhelmingly more important than the other. |

| Matrix Order (n) | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| RI | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.51 |

| Classification | Number of Respondents | Proportion (%) | |

|---|---|---|---|

| Gender | Male | 25 | (100) |

| Female | 0 | (0) | |

| Affiliation | Squid jigging vessel captains | 7 | (28) |

| Recreational fishing boat captains | 6 | (24) | |

| Manufacturers | 5 | (20) | |

| Research/education institutions | 7 | (28) | |

| Age | 30s | 3 | (12) |

| 40s | 5 | (20) | |

| 50s | 6 | (24) | |

| 60s | 6 | (24) | |

| 70s and older | 5 | (20) | |

| Industry experience | 5–10 years | 8 | (32) |

| 10–15 years | 5 | (20) | |

| Over 15 years | 12 | (48) | |

| Sea anchor related experience | 5–10 years | 10 | (40) |

| 10–15 years | 5 | (20) | |

| Over 15 years | 10 | (40) | |

| Affiliation | No. of Experts | Response Rate (%) | |||

|---|---|---|---|---|---|

| Delphi | AHP | ||||

| 1st | 2nd | 3rd | |||

| Squid jigging vessel captains | 7 | 6 (85.7) | 7 (100) | 7 (100) | 6 (85.7) |

| Recreational fishing boat captains | 6 | 5 (83.3) | 6 (100) | 6 (100) | 5 (83.3) |

| Manufacturers | 5 | 5 (100) | 5 (100) | 5 (100) | 4 (80) |

| Research/education institutions | 7 | 7 (100) | 7 (100) | 7 (100) | 7 (100) |

| Total | 25 | 23 (92.0) | 25 (100) | 25 (100) | 22 (88.0) |

| Main Category | Sub-Category |

|---|---|

| (A) Structural design and shape optimization | (1) Design for improved deployment speed, (2) structural enhancement to increase deployment force, (3) optimization of vent size and design, (4) optimization of canopy shape, (5) optimization of the internal angle of the canopy, (6) minimization of shroud line quantity, (7) rational weight of metal components, (8) optimization of rope materials and diameter |

| (B) Improvement of usability | (1) Minimization and optimization of storage volume, (2) improvement of recovery, (3) enhancement of quick recovery, (4) improvement of portability, (5) improvement of handling convenience, (6) improvement of maintenance convenience, (7) weight reduction in the product, (8) easier component replacement |

| (C) Improvement of economic efficiency | (1) Reduction in purchase cost, (2) reduction in maintenance cost, (3) shortening of production lead time, (4) shortening of repair time, (5) application of low-cost, high-efficiency materials, (6) simplification and efficiency improvement of production process, (7) design for minimized maintenance |

| (D) Improvement of functionality | (1) Improvement of sinking performance, (2) enhancement of fabric drying performance, (3) improvement of fabric air permeability, (4) improvement of fabric absorption, (5) optimization of fabric buoyancy, (6) optimization of fabric specific gravity, (7) enhancement of nighttime visibility, (8) reduction in shroud line entanglement and twisting |

| (E) Enhanced durability | (1) Enhancement of fabric tensile strength, (2) use of seawater-resistant materials, (3) enhancement of UV resistance, (4) improvement of abrasion resistance, (5) improvement of degradation resistance, (6) improvement of colorfastness, (7) enhancement of corrosion resistance of metal components, (8) Improvement of durability under repeated use, (9) Extension of product life cycle, (10) reduction in shroud line sagging, (11) enhancement of shroud line tensile strength, (12) reinforcement of stitching at fabric joints |

| (F) Additional technologies and technical applications | (1) Application of eco-friendly materials, (2) enhancement of product use safety, (3) product quality certification, (4) automatic vent hole adjustment system, (5) provision of a user manual, (6) measurement of current and resistance in sea anchor, (7) measurement of sinking depth, (8) measurement of deployment force, (9) deployment and recovery monitoring system |

| Category | CVR | M | SD | Convergence | Consensus | CV | Decision | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main | Sub | 2nd | 3rd | 2nd | 3rd | 2nd | 3rd | 2nd | 3rd | 2nd | 3rd | 2nd | 3rd | |

| A | (1) | 0.44 | 0.52 | 4.04 | 4.16 | 0.98 | 0.90 | 1 | 0.5 | 0.5 | 0.75 | 0.24 | 0.22 | Retained |

| A | (2) | 0.52 | 0.68 | 4.16 | 4.32 | 0.90 | 0.85 | 0.5 | 0.5 | 0.75 | 0.8 | 0.22 | 0.20 | Retained |

| A | (3) | 0.52 | 0.68 | 4.08 | 4.28 | 0.86 | 0.84 | 0.5 | 0.5 | 0.75 | 0.75 | 0.21 | 0.20 | Retained |

| B | (2) | 0.44 | 0.84 | 4.04 | 4.32 | 0.98 | 0.75 | 1 | 0.5 | 0.5 | 0.75 | 0.24 | 0.17 | Retained |

| B | (4) | 0.52 | 0.68 | 4.00 | 4.28 | 1.19 | 0.98 | 0.5 | 0.5 | 0.75 | 0.8 | 0.30 | 0.23 | Retained |

| B | (7) | 0.52 | 0.76 | 4.12 | 4.28 | 1.24 | 0.98 | 0.5 | 0.5 | 0.8 | 0.8 | 0.30 | 0.23 | Retained |

| C | (1) | 0.44 | 0.36 | 3.92 | 3.84 | 1.08 | 1.21 | 1 | 1 | 0.5 | 0.5 | 0.27 | 0.32 | Excluded |

| C | (5) | 0.60 | 0.76 | 4.12 | 4.40 | 1.01 | 0.82 | 0.5 | 0.5 | 0.75 | 0.8 | 0.25 | 0.19 | Retained |

| D | (1) | 0.44 | 0.28 | 3.60 | 3.56 | 1.26 | 1.19 | 0.5 | 0.5 | 0.75 | 0.75 | 0.35 | 0.34 | Excluded |

| D | (2) | 0.44 | 0.84 | 4.08 | 4.40 | 1.12 | 0.91 | 1 | 0.5 | 0.5 | 0.8 | 0.27 | 0.21 | Retained |

| D | (8) | 0.44 | 0.60 | 4.20 | 4.32 | 0.96 | 0.90 | 1 | 0.5 | 0.6 | 0.8 | 0.23 | 0.21 | Retained |

| E | (1) | 0.44 | 0.68 | 4.12 | 4.16 | 0.93 | 0.69 | 1 | 0.5 | 0.5 | 0.75 | 0.23 | 0.17 | Retained |

| E | (3) | 0.68 | 0.92 | 4.16 | 4.52 | 0.94 | 0.87 | 0.5 | 0.5 | 0.75 | 0.8 | 0.23 | 0.19 | Retained |

| E | (4) | 0.44 | 0.68 | 4.04 | 4.32 | 0.98 | 0.95 | 1 | 0.5 | 0.5 | 0.8 | 0.24 | 0.22 | Retained |

| E | (12) | 0.60 | 0.68 | 4.16 | 4.20 | 0.94 | 0.71 | 0.5 | 0.5 | 0.75 | 0.75 | 0.23 | 0.17 | Retained |

| F | (2) | 0.44 | 0.60 | 4.04 | 4.12 | 0.89 | 0.83 | 1 | 0.5 | 0.5 | 0.75 | 0.22 | 0.20 | Retained |

| F | (3) | 0.44 | 0.76 | 4.04 | 4.32 | 0.89 | 0.80 | 1 | 0.5 | 0.5 | 0.75 | 0.22 | 0.19 | Retained |

| F | (5) | 0.44 | 0.04 | 3.64 | 3.52 | 1.19 | 1.05 | 0.5 | 0.5 | 0.75 | 0.75 | 0.33 | 0.30 | Excluded |

| Main Category | Sub-Category | ||

|---|---|---|---|

| A | Structural design and shape optimization | (1) | Design for improved deployment speed |

| (2) | Structural enhancement to increase deployment force | ||

| (3) | Optimization of vent size and design | ||

| B | Improvement of usability | (1) | Improvement of recovery |

| (2) | Improvement of portability | ||

| (3) | Weight reduction in the product | ||

| C | Improvement of economic efficiency | (1) | Application of low-cost, high-efficiency materials |

| D | Improvement of functionality | (1) | Enhancement of fabric drying performance |

| (2) | Reduction in shroud line entanglement and twisting | ||

| E | Enhanced durability | (1) | Enhancement of fabric tensile strength |

| (2) | Enhancement of UV resistance | ||

| (3) | Improvement of abrasion resistance | ||

| (4) | Reinforcement of stitching at fabric joints | ||

| F | Additional technologies and technical applications | (1) | Enhancement of product use safety |

| (2) | Product quality certification | ||

| Main Category | Weight | Priority | CR |

|---|---|---|---|

| Improvement of usability | 0.2256 | 1 | 0.0014 |

| Enhanced durability | 0.2171 | 2 | |

| Improvement of functionality | 0.1765 | 3 | |

| Structural design and shape optimization | 0.1656 | 4 | |

| Additional technologies and technical applications | 0.1188 | 5 | |

| Improvement of economic efficiency | 0.0964 | 6 |

| Main Category (Weight) | Sub-Criteria | Local Weight | Global Weight | CR | |

|---|---|---|---|---|---|

| (A) Structural design and shape optimization (0.1656) | (1) | Optimization of vent size and design | 0.4028 | 0.06670 | 0.00187 |

| (2) | Structural enhancement to increase deployment force | 0.3593 | 0.05950 | ||

| (3) | Design for improved deployment speed | 0.2379 | 0.03940 | ||

| (B) Improvement of usability (0.2256) | (1) | Improvement of recovery | 0.4260 | 0.09611 | 0.00015 |

| (2) | Weight reduction in the product | 0.3240 | 0.07309 | ||

| (3) | Improvement of portability | 0.2500 | 0.05640 | ||

| (C) Improvement of economic efficiency (0.0964) | (1) | Application of low-cost, high-efficiency materials | 1.0000 | 0.09640 | - |

| (D) Improvement of functionality (0.1765) | (1) | Enhancement of fabric drying performance | 0.6782 | 0.11970 | - |

| (2) | Reduction in shroud line entanglement and twisting | 0.3218 | 0.05680 | ||

| (E) Enhanced durability (0.2171) | (1) | Enhancement of UV resistance | 0.3589 | 0.07792 | 0.00274 |

| (2) | Reinforcement of stitching at fabric joints | 0.2423 | 0.05260 | ||

| (3) | Enhancement of fabric tensile strength | 0.2192 | 0.04759 | ||

| (4) | Improvement of abrasion resistance | 0.1796 | 0.03899 | ||

| (F) Additional technologies and technical applications (0.1188) | (1) | Product quality certification | 0.6219 | 0.07388 | - |

| (2) | Enhancement of product use safety | 0.3781 | 0.04492 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, N.; Yu, Y.; Lee, Y.-W.; Ryu, K.-J. An Integrated Delphi-AHP Study on the Systematic Improvement of Sea Anchors for Fishing Operations. J. Mar. Sci. Eng. 2025, 13, 1796. https://doi.org/10.3390/jmse13091796

Kim N, Yu Y, Lee Y-W, Ryu K-J. An Integrated Delphi-AHP Study on the Systematic Improvement of Sea Anchors for Fishing Operations. Journal of Marine Science and Engineering. 2025; 13(9):1796. https://doi.org/10.3390/jmse13091796

Chicago/Turabian StyleKim, Namgu, Youngjae Yu, Yoo-Won Lee, and Kyung-Jin Ryu. 2025. "An Integrated Delphi-AHP Study on the Systematic Improvement of Sea Anchors for Fishing Operations" Journal of Marine Science and Engineering 13, no. 9: 1796. https://doi.org/10.3390/jmse13091796

APA StyleKim, N., Yu, Y., Lee, Y.-W., & Ryu, K.-J. (2025). An Integrated Delphi-AHP Study on the Systematic Improvement of Sea Anchors for Fishing Operations. Journal of Marine Science and Engineering, 13(9), 1796. https://doi.org/10.3390/jmse13091796