Abstract

Power cables transmit electricity from offshore wind turbines (OWTs) to consumers. The configuration, design, and optimization of power cables for floating offshore wind turbines (FOWTs) are subject to various objectives, variables, and constraints. These components are outlined, and existing research gaps that need to be addressed for a more sustainable and robust design for future developments are highlighted. The main aim of power cable configuration design is to optimize performance and minimize costs. This can be achieved through thoughtful consideration of variables like power cable selection, configuration design, and the integration of specialized components and ancillaries. An extensive overview of constraints for power cable configuration design is provided, and the most important ones are identified. The local conditions determine which constraints are of key importance in optimization. Environmental factors like wind, waves, and especially currents significantly influence design processes, introducing uncertainties when comprehensive data are lacking. Marine growth posed a significant challenge in prior FOWT projects and must be considered carefully. Considering the potential impact of climate change is crucial, especially for extreme weather events. Early integration of environmental considerations and assessment of effects on socio-economic impacts is essential for a successful project. The power cable response is also influenced by its inherent limitations, including tension and compression thresholds, curvature constraints, and the necessary minimum fatigue life. A flowchart is provided to aid in choosing variables and constraints in the design and optimization processes.

1. Introduction

According to the forecast by Det Norske Veritas (DNV) [1], floating offshore wind technologies are expected to account for 15% of the total offshore wind capacity by 2050. To achieve this, around 20,000 OWTs must be mounted on floating platforms [1]. However, these technologies are in the early stages of development and require commercialization for broader adoption. Cost reduction is crucial for economic viability, with standardization, larger OWTs, and industrialization being key factors [1]. Further, larger offshore wind farms and optimized mooring and cable systems are essential to lower costs [1].

Over 20% of total project capital costs account for offshore transmission, inter-array cabling, and offshore substations, as reported by the International Energy Agency (IEA) [2]. According to GCube [3], subsea cables, both inter-array and export, accounted for a majority (30%) of all insurance claims in the offshore wind industry from 2010 to 2020 and exceeded 50% of the total claims expenditure during this period. Dynamic power cables are relatively new to the offshore wind industry and incur higher costs for floating than bottom-fixed offshore wind technologies, which do not require them. Therefore, thorough design analysis and optimization of power cable configurations are essential for successful FOWT farms. This is particularly critical with the expected growth of FOWT farm sizes and the need for a significant amount of inter-array electricity transmission. Therefore, the present study discusses the different parameters that influence the design and optimization of dynamic inter-array power cable configurations. Further, the uncertainties of the design parameters are discussed.

The present paper is organized as follows. Section 2 presents the state-of-the-art dynamic power cable configuration design processes. Section 3 comprises the rules and regulations. The design objectives are discussed in Section 4, the variables in Section 5, and the constraints in Section 6. Section 7 shows an overview of published optimization algorithms. A flowchart to determine the most relevant optimization parameters is presented in Section 7. Conclusions are drawn in Section 8. A comprehensive list of references is also presented.

2. The State of the Art of Dynamic Power Cable Configuration Design Processes

OWTs convert wind kinetic energy into electrical energy, which is transmitted to consumers through a network of power cables. The inter-array cables connect OWTs within offshore wind farms, forming feeders that link to collectors or substations [4]. From there, an export cable transmits electrical energy to consumers, such as land-based grids or offshore platforms. In offshore wind farms with bottom-fixed OWTs, inter-array cables are either statically laid on the seabed or buried. In floating offshore wind farms, the power cables connect to FOWTs. Therefore, they must be designed to account for dynamic responses caused by FOWT motions and environmental loads.

In the FOWT farms in operation today, one FOWT acts as the collector or substation of all feeders. This can be seen in commercial FOWT farms currently in operation: Hywind Scotland [5], Kincardine Offshore Wind Farm [6], Hywind Tampen [7], WindFloat Atlantic [8], and the METCentre test site [9]. Larger FOWT farms may require substations with a transformer connecting the inter-array and export cables. The test site Fukushima FORWARD is the first to have a floating substation in operation [10]. The transformer contains a significant amount of toxic oil and is an environmental threat in the case of substation failure [11]. Therefore, the substation must have a resilient mooring system with high safety levels [12]. The dynamic section of the export cable from the FOWT or the substation faces constraints like those of the inter-array cables. Nevertheless, its configuration might be designed differently than for inter-array cables in an FOWT farm, as they usually have a larger diameter and other stiffness values.

The design of a dynamic power cable configuration is usually a time-consuming iterative process performed by an experienced engineer. First, a hypothesis is made on the configuration setup that will be feasible for the given problem. Simulations are then performed, and the results are evaluated against the design constraints. Afterwards, the hypothesis is updated, and the process is repeated until it converges to a solution. Power cable configuration design is often considered after the FOWT floater and mooring system are designed. It is commonly assumed that power cable motions have a negligible influence on FOWT behavior and can be considered separate.

The design of oil and gas (O&G) industry risers and mooring systems has been performed together numerous times [13]. Ja’e et al. [14] provided an overview of such studied and implemented systems. The combined consideration is crucial for the functionality and safety of riser systems, as damage can have fatal repercussions. Similarly, the safety levels for offloading lines must be high to prevent severe incidents. Mooring systems and power cables are not as closely reliant on each other in offshore wind farms as mooring systems and O&G lines containing highly flammable fluids. That is because damaged power cables have fewer consequences on human lives and the marine environment than a damaged riser or an offloading line can have. Even though this means that lower safety levels may be applied to power cables [15], they are nevertheless a crucial part of the functionality of offshore wind farms. A damaged power cable disrupts the connection between the electrical energy-generating wind turbine and the consumer, resulting in zero revenue and possibly high repair costs for the wind farm owner and operator.

Offshore wind farm power cables are also referred to as “power umbilicals” as they are a specific type of umbilical. Umbilicals focus on providing various services to offshore equipment, whereas power cables concentrate on transmitting electrical energy over long distances from FOWTs to consumers. OWTs have already exceeded the number of facilities installed in the O&G industry by tenfold, and the demand is projected to rise [15]. That means a much larger quantity of power cables is necessary for an offshore wind farm project compared with the umbilicals needed in an O&G project. In addition, FOWTs often have response characteristics or failure modes that differ from O&G platforms [15]. FOWTs are mainly without crew and do not contain explosive hydrocarbon fluids that can threaten humans and the environment. The overall configuration design can be like the umbilical design in the O&G industry. However, caution is needed when applying umbilical configuration design practices to dynamic power cable configurations due to differences in diameters, stiffness, components, function, applications, and system-level reliability.

3. Rules and Regulations

Several rules and regulations have already been implemented for power cable configuration design. Nevertheless, limited regulations on dynamic power cable configurations are currently being established. For example, the standard DNV-ST-0119 [16] states that this is the responsibility of the supplier. The following list shows relevant codes, standards, and recommended practices:

- -

- ISO 19900 “Petroleum and natural gas industries—General requirements for offshore structures” [17]

- -

- ISO 19901-1 “Petroleum and natural gas industries—Specific requirements for offshore structures—Part 1: Metocean design and operating considerations” [18]

- -

- ISO 13628-5 “Petroleum and natural gas industries—Design and operation of subsea production systems—Part 5: Subsea umbilicals” [19]

- -

- ISO 13628-11 “Petroleum and natural gas industries—Design and operation of subsea production systems—Part 11: Flexible pipe systems for subsea and marine applications” [20]

- -

- DNV-ST-0119 “Floating wind turbine structures” [16]

- -

- DNV-ST-0359 “Subsea power cables for wind power plants” [21]

- -

- DNV-OS-E301 “Position mooring” [22]

- -

- DNV-RP-0360 “Subsea power cables in shallow water” [23]

- -

- DNV-RP-F401 “Electrical power cables in subsea applications” [24]

- -

- DNV-RP-C205 “Environmental conditions and environmental loads” [25]

- -

- NORSOK-N003 “Action and action effects” [26]

- -

- API RP 2A-LRFD “Recommended practice for planning, designing and constructing fixed offshore platforms—load and resistance factor design” [27]

- -

- API RP 2A-WSD “Recommended practice for planning, designing and constructing fixed offshore platforms—working stress design” [28]

- -

- API SPEC 17E “Specifications for subsea umbilicals” [29]

Other regulations that the configuration must comply with are defined by the government responsible for the site. This often includes environmental restrictions.

In the pursuit of cost competitiveness, there have been considerable cost reductions in the planning phase of offshore wind projects over the last decade, and thus also in production, building, and operation. However, this emphasis on cost efficiency has negatively impacted safe design concepts. Consequently, there has been a rise in both the frequency and seriousness of insurance claims within the sector [3]. Proper insurance is essential to protect the public from paying for a malfunctioning offshore wind farm project [11].

4. Design Objectives

The design objective refers to the specific goal or outcome that the design process of a project aims to achieve. For power cable configurations, they are mostly related to economic and performance indicators, which are explained in more detail in this section. Overall, the most important objective should always be to create a safe design that will work.

4.1. Economic Indicators

Most design and optimization objectives are directly or indirectly related to minimizing costs. For power cable configurations, several economic indicators can be relevant. Some key indicators considered early in the design process can help minimize long-term costs and are presented here:

- -

- Levelized Cost of Energy (LCOE): It is a widely used metric to assess cost-effectiveness by considering total lifetime costs divided by total lifetime energy output, with lower values indicating efficiency [30]. The LCOE of floating offshore wind projects is about five times as high as for bottom-fixed offshore wind projects [1]. Predictions for the future vary, including higher, equal, and lower LCOE values by 2050 for floating compared to bottom-fixed offshore wind projects [1]. Nevertheless, they all predict a decrease in the LCOE for floating offshore wind projects due to technological advancement [31].

- -

- Capital Expenditure (CapEx): This metric refers to the initial investment required to design, manufacture, and install the floating wind turbine and its associated power cables. For offshore wind projects, most lifetime costs occur for the development and construction of the project as CapEx [31].

- -

- Installation and decommissioning costs are considered parts of capital expenditure: A design can have low costs considering the price of the components involved, but it might be costly during transport, installation, and decommissioning. Improper consideration of these costs has been a major problem in past renewable energy projects, such as when removing wave energy converters (WECs). It can quickly lead to bankruptcy [32]. Further, the available equipment for installation and removal must be considered in the design process to avoid using unusual or hardly available equipment, which can be very costly. Also, the choice of ancillaries should be made considering the need for potentially new molding and their installation time, which can increase and raise costs.

- -

- Operating Expenditures (OpEx): These are the day-to-day costs, covering expenses like rent, utilities, salaries, maintenance, and other essential operational needs. Maintenance costs include regular inspections and repairs throughout the lifetime of the power cable configuration. These costs can vary based on cable design, materials used, and accessibility for maintenance crews. Critical components, such as the hang-off section and the touch-down point (TDP), are crucial for the integrity of the system. Addressing these early in the design process can prevent future repair work. Regularly removing marine growth from the power cables and ancillaries can significantly raise maintenance costs. If considered correctly, the need for removals or buoyancy additions throughout the lifetime might be limited. Rinaldi et al. [30], Garcia-Teruel et al. [33], and Yang et al. [34] present analyses including operation and maintenance costs for FOWTs.

- -

- Regulations and permits: Compliance with regulations and permitting requirements can influence design choices and costs. For example, factors such as seabed intervention (e.g., trenching or similar activities), marine life entanglement, trawling entanglement, and ghost net entanglement must be carefully assessed, as these can be regulated and require specific permits. Further, it may be necessary to obtain an initial technical qualification for a new power cable system.

- -

- Risk assessment: Economic indicators should also incorporate risk analysis at every design stage. Identifying potential failure points, downtime risks, and their financial consequences is crucial for estimating overall project costs accurately. It helps to account for unforeseen events such as supply chain disruptions or regulatory changes.

- -

- Future expansions and upgrades: Designing for future expansion and upgrades helps minimize project costs by avoiding costly modifications later. Anticipating potential expansions and technology improvements in FOWT farms, leading to increased power generation, is crucial for long-term viability.

Further economic indicators that influence the design objectives include, for instance, the selection of the discount rate for the project, the optimization of the Net Present Value (NPV) of the project, given the selected discount rate, Return on Investment (ROI), and Weighted Average Cost of Capital (WACC) [35,36].

In academic research and industrial projects, specific cost data are often unavailable. Therefore, different objectives related to cost reduction may be used, particularly for feasibility research studies and preliminary designs in early project stages. The following presents some of these objectives:

- -

- Minimize cable lengths: Shorter cable lengths reduce both electrical losses and material costs associated with cable manufacturing and installation. Power transmission efficiency can be improved by strategically planning cable configurations and routes and minimizing unnecessary detours, ensuring the electricity reaches its destination with minimal loss. However, a difference in cable length by a few percentage points may not significantly affect capital and operational costs, depending on the project.

- -

- Minimize the use of ancillaries: Ancillaries represent an additional cost to the power cable. Using as few ancillaries as possible can reduce costs as well as installation and maintenance times.

4.2. Performance Indicators

Proper design objectives are crucial for long-term project feasibility, ensuring reliability, safety, and regulatory compliance. Performance-focused goals are essential for power cable configurations, alongside economic indicators, to guarantee project viability and safety. Several possible objectives are the following:

Maximize performance: The performance of power cables relates to their ability to handle the required data transmission rates, power levels, and signal quality without significant losses or degradation. Finding the right balance between performance and cost is essential for ensuring the economic viability of the project.

Maximize reliability: For example, at some FOWT farm locations, such as off the eastern coast of Japan, the cable cannot be repaired for half a year due to the harsh environmental conditions during certain seasons [37]. Design efforts should focus on minimizing the risk of cable failures, downtime, and maintenance disruptions.

Safety and compliance: Design efforts should aim to facilitate the design to comply with relevant codes and standards.

Minimize environmental impact: The environmental impact should be considered at every project stage [33]. Offshore cable designs must minimize the environmental impact by choosing routes away from sensitive ecological areas and using installation, maintenance, and decommissioning techniques to reduce impact.

Minimize footprint: The footprint of an offshore structure refers to the area on the seabed or ocean floor that the subsea structure occupies or covers. Its size can be minimized to possibly decrease the amount of material needed, reduce the environmental impact, keep the equipment in the regulatory zones, or keep clear of fishing routes. The placement of the power cable configuration heavily depends on the environmental conditions and the mooring system, which all need to be considered together.

Extend the lifetime of the cable configuration: Offshore projects often exceed their initial timelines. To extend the life of a power cable configuration, the current system is assessed, and analyses are conducted to determine its expected lifetime. Necessary measures may be taken to make the extension feasible, such as adding buoyancy modules or redesigning hang-off sections.

5. Design Variables

A design variable is an adjustable parameter or factor that influences the design, behavior, or performance of a system. For the design and optimization of power cable configurations, key variables are the material choice of the actual cable, overall configuration design, and the design of special components and ancillaries.

5.1. Power Cable Selection

The design of the power cable is usually heavily site- and project-dependent. First, the choice of the voltage rating and between alternating current (AC) or direct current (DC) technology must be made. Usually, the inter-array cables use medium- or high-voltage AC due to the short distances covered. They are rated up to 66 kV in current projects, depending on the wind turbines and the cable length [5,38,39,40]. With OWT sizes increasing compared to OWTs that have been installed in the past [41,42] the power cable sizes increase as well, and are expected to rise to a voltage rating of 132 kV [43] and beyond [44]. Larger cable diameters lead to new challenges, especially regarding cable buckling and conductor creep [38].

The power transmission capacity within a feeder varies as the cables transmit energy from nearby and distant OWTs. A cost-effective approach is using a single cable design sized for the largest load, applicable to all inter-array cables [45]. The different feeders are combined at the collector or substation, and an export cable with a high-voltage AC or an ultra-high-voltage AC connects the FOWT farm to consumers [5,38]. With increasing FOWT farm sizes and further distances from shore or consumers, DC technology can be used for the export cable, as has been installed in fixed-bottom offshore wind farms [46,47]. Note that the electrical energy loss in DC cables is less than that in AC cables. However, the costs of a substation transforming the current from DC to AC at the farm location and back to DC at a substation near the consumers can increase capital expenditures.

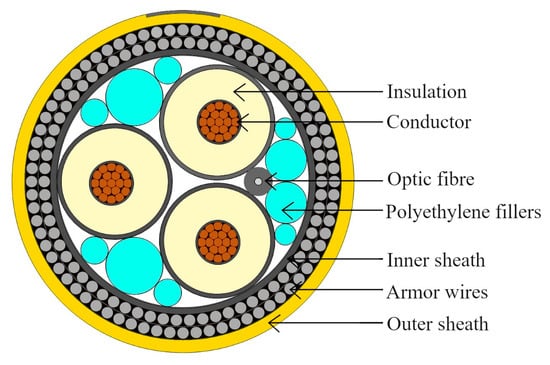

Figure 1 shows an exemplary cross-section of a power cable, including the conductors, optical fibers, insulation, and any shielding or protective layers. The conductor area determines the current capacity, with larger areas allowing higher currents. Power cables commonly have several layers of armor to define axial, bending, and torsional stiffness. Smaller diameter cables of lower current rating do not necessarily have to be equipped with armor, reducing costs and facilitating the installation and maintenance; see Ringsberg et al. [48].

Figure 1.

Exemplary power cable cross-section with copper cores.

The primary objective of various cross-sectional components is to determine the behavioral properties of the power cable and to protect the conductor core. Copper and aluminum are commonly used for cable conductor cores, with copper being the prevailing choice today. Aluminum cables were studied by Thies et al. [49], Schnepf et al. [50], and Ahmad et al. [51]. An actual aluminum cable was first implemented for the TetraSpar FOWT in the Northern North Sea, which is currently operating [52]. In cables with identical voltage ratings, the cross-sectional area of the copper conductor core is typically smaller than that of its aluminum counterparts. Additionally, copper cables exhibit a more significant weight per unit length when compared to aluminum cables of equal conductivity [53]. This difference is due to copper being more conductive than aluminum and the low density of aluminum [53]. Therefore, the submerged-weight-to-diameter ratio is usually lower for aluminum cables than for copper cables of the same conductivity [50].

5.2. Configuration Design

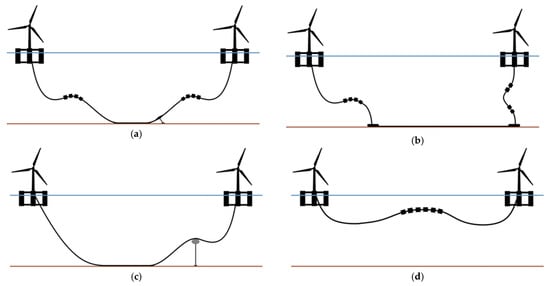

Ikhennicheu et al. [45] and Clausen and D’Souza [54] provided overviews of overall configurations successfully implemented for O&G risers, offloading hoses, and umbilicals. Figure 2 shows several configurations that can be used for dynamic power cable configurations of FOWTs.

Figure 2.

Different power cable configuration types. (a) Lazy-wave (left) and tethered-wave (right) configurations. (b) Steep-wave (left) and Chinese lantern (right) configurations. (c) Catenary (left) and lazy-S (right) configurations. (d) Suspended configuration.

A vastly researched configuration is the lazy-wave configuration shown in Figure 2a (left), which was the study subject of, for example, Rentschler et al. [4,55], Thies et al. [56], and Zhao et al. [57]. It has been installed in the FOWT farm WindFloat Atlantic [8]. The lazy-wave configuration has a section of buoyancy attached to the cable between the FOWT and the TDP on the seabed. This way, the motions of the floater can be decoupled from the lower hanging cable sections and the TDP to a large extent. It is a simple configuration that only needs buoyancy modules attached to the cable, a bend restrictor at the connection to the FOWT, and possibly cable protection at the seabed.

Double lazy-wave power cable configurations are usually considered in shallower water depths, having two buoyancy sections instead of one [57,58,59]. Such a system has been installed in the China Three Gorges (CTG) Yangxi Shapa III wind farm, where an FOWT is connected to a fixed-bottom monopile wind turbine in water depths from 29 m to 35 m [60,61].

The tethered-wave configuration is very similar to the lazy-wave configuration, and is also named the pliant-wave configuration. In addition to the lazy-wave setup, it has a tether restraining the motions of the power cable at the TDP, as shown in Figure 2a (right). This effectively limits motions at the TDP when the wave configuration decouples them from the floater. Further, it controls the TDP location throughout its lifetime, preventing damage and alterations caused by factors such as extreme weather and marine growth. On the other hand, the tethered-wave configuration needs more equipment than the lazy-wave configuration, making installation more complex. The commercial floating offshore wind farms Hywind Scotland [5] and Hywind Tampen [7] use tethered-wave configurations.

The steep-wave configuration in Figure 2b (left) is a wave configuration, with the distinction that the cable is vertically connected to a seabed junction with a bend stiffener. It has the advantage that an excursion of the cable close to the seabed can be prevented. This configuration has often been used in O&G applications to connect subsea equipment with a vessel or platform at the sea surface, for example, using a riser from a subsea wellhead to a floating production facility [62].

Chinese lantern configurations, as shown in Figure 2b (right), have been used primarily with Catenary Anchor Leg Mooring (CALM) buoys [63]. A buoyancy section to decouple the motions of the floater from the bottom location keeps the cable in a U-shape in a vertical direction. The cable is usually vertically connected to a seabed junction with a bend stiffener. This configuration is usually installed in shallower water depths [63].

The most straightforward configuration is the catenary configuration shown in Figure 2c (left), also often referred to as “free hanging”. It does not require additional equipment except for possibly a bend restrictor at the hang-off location and protection at the TDP. Nevertheless, it does not decouple the motions of the floater from the TDP, which can make it challenging to apply [4].

The lazy-S configuration in Figure 2c (right) is also like the lazy-wave configuration. However, instead of buoyancy modules attached to create an arch, it uses fewer and larger buoyancy devices, such as a buoy. That buoy can be tethered or buoyant, controlling the hog bend location. It reduces the excursions of the power cable under the current. An altered lazy-S power cable configuration with six buoys attached to a tether configuration was successfully used for two years at the Haenkaze FOWT while it was installed off Kabashima Goto, Nagasaki prefecture, Japan [64]. Another example is the Wello wave energy converter project off the coast of Scotland, United Kingdom, where the lazy-S configuration had been implemented with a buoyed loop stabilized by a chain [65]. The subsea buoy can also be implemented in a tethered-S configuration with an additional tether to control the TDP and a steep-S configuration with a vertical connection at the bottom.

The suspended power cable configuration is shown in Figure 2d. In this configuration, the cable does not touch the seabed, which can be useful for deepwater applications and reduces costs due to shorter cable lengths and less additional equipment than the other configurations. Suspended configurations are common practice for O&G offloading lines, as described by Araújo et al. [66], He et al. [67], and Kang et al. [68]. They have been researched for application with FOWTs by Beier et al. [69,70], Schnepf et al. [50,71], Ahmad et al. [51], and Li et al. [72]. Their applicability depends on the environmental conditions of the location where the cable will be installed. Buoyancy elements can be designed in one section or divided into several sections distributed over the cable length. Subsea buoys may also replace buoyancy modules to minimize drag.

The presented power cable configuration options do not depict all possible designs. They only summarize tried and tested practices in O&G and renewable energy applications. To name a few, further power cable configurations can be the double-tethered-wave, lazy-camel [54], camel-S [54], and corkscrew [73] configurations. Configurations applied in the O&G industry that have weights added in the configuration are, for example, the weight-added wave [74,75], multi-wave with weights [76], and touchdown chain-added wave [74]. Power cables usually need extra ancillary equipment, such as buoyancy modules and bend stiffeners, to successfully implement configurations with weights attached, not exceeding the maximum allowable tension values. An example of weight chains successfully implemented in an umbilical configuration is the “cage-hose” concept connecting large fish cages in the northern Norwegian Sea [77]. The configuration choice must be made based on the specific environmental conditions and further constraints it will encounter, which are all heavily site-dependent.

5.3. Special Components and Ancillaries

The tension in the power cable throughout the dynamic configuration is usually highest at the hang-off section from the FOWT [49,50,56,78]. This section must be designed to support and suspend the weight of the power cable, restrict it from overbending, and withstand the loads from the environmental conditions. It consists of clamps, connectors, and a bend stiffener or bell mouth. Typically, it is placed beneath the sea surface, although it can also be installed above sea level for ease of access. Dai et al. [79] addressed the behavior of dynamic steel tube umbilicals in a bell-mouth hang-off section. Svensson et al. [80] showed that the bell mouth is the most critical point for fatigue. The conductor of their power cable failed inside the bell mouth in their numerical models and laboratory tests. Further research on the hang-off section and its design variables should be carried out for dynamic power cable configuration design.

The lazy-wave and similar configurations employ numerous buoyancy modules between the hang-off point and the TDP. The size and number of the modules vary; they can all be customized [81]. As casting a mold is usually the most expensive part of the buoyancy module fabrication, standard sizes can be used to save costs. The attached buoyancy modules change the behavior of the flow around the cable, which must be considered in the analysis [82].

The cable section around the TDP can be designed in various ways. One decision is whether a tether should be installed and, if so, in what manner. This influences the overall configuration design significantly. The decision depends on the soil conditions and power cable motions, which can lead to damage. A cable protection device [81] can be attached to the power cable at the TDP to reduce wear and tear.

6. Design Constraints

The power cable configuration must be designed to endure the environmental conditions it is exposed to, as well as adhere to lifecycle, regulations, modeling, environmental, and socio-economic factors. This section discusses these aspects in detail.

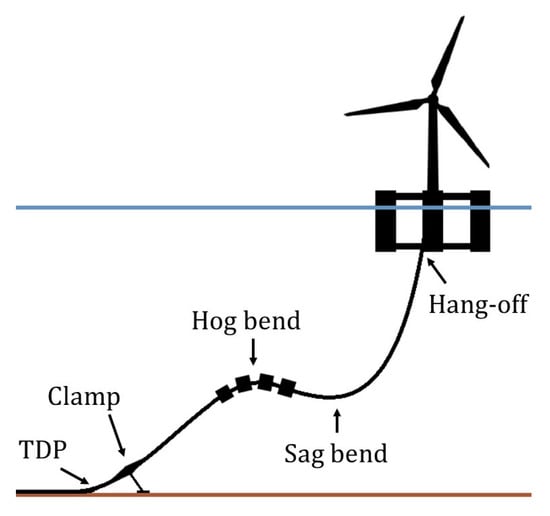

Figure 3 shows critical points of the power cable configuration to which special attention must be paid in the design. These points are the hang-off location, sag bend, hog bend, TDP, and, if applicable, the tether clamp close to the TDP with the respective bend stiffeners. Further, the attached buoyancy modules and their attachment points on the power cable need special consideration. These points are especially prone to exceeding the limits of certain constraints detailed in the following.

Figure 3.

The critical power cable configuration points in the design.

6.1. Environmental Constraints

This section describes how environmental factors impose limitations on power cable configurations. Extensive measurements and appropriate modeling methods are essential for determining statistical descriptions and extreme conditions for analysis [83,84]. Usually, the measurements must be taken directly at the site or nearby.

6.1.1. Wind and Waves

If a part of the power cable configuration extends above the sea surface, it becomes directly susceptible to wind and wave loads. Such a configuration is only chosen in rare instances. Typically, the entire power cable configuration is submerged beneath the sea surface, experiencing an indirect impact from wind and waves. Furthermore, wind and waves significantly determine the FOWT behavior and, consequently, the behavior of the power cable from its hang-off location.

According to DNV-RP-C205 [25] the modeling of waves for short durations is assumed to be stationary, with a duration of 3 h. For analysis regarding stable wind speed, a duration of 1 h is considered as per DNV-RP-C205. This can be disputed, as such stable conditions are somewhat uncommon [85]. Transient conditions, characterized by varying wind speeds and wave conditions, are frequently overlooked in the analyses and might be worth investigating if they can potentially lead to larger responses than initially assumed.

It is crucial to account for the most severe wind and wave conditions, particularly those where the FOWT exerts the greatest influence on the behavior of the power cable. These extreme conditions typically coincide with the generation of currents induced by wind and waves. The most extreme responses of FOWTs can occur during events such as hurricanes and typhoons. Such conditions can generate extreme FOWT motions and currents at the same time, which the power cable configuration must survive.

Furthermore, it is essential to consider special wave conditions, including exceptional occurrences like freak waves and tsunamis. Freak waves, often also referred to as rogue waves, are distinguished by their significantly greater height than the surrounding waves. These phenomena can occur across varying water depths and arise abruptly. Certain regions exhibit a higher statistical occurrence of freak waves, notably the North Atlantic, the North Sea, the waters surrounding Australia, and the Agulhas Current south of Africa [86,87]. Their formation is attributed to the crossing of different sea states characterized by distinct energy levels and frequencies [86], as well as other factors such as interactions between ocean currents and waves [87,88]. On the other hand, tsunamis must be considered where appropriate. Tsunamis typically originate from seismic events and have extremely high water-particle velocities, directly impacting power cable configurations. Unlike freak waves, tsunamis exhibit small wave amplitudes at sea but pose a significant threat as they grow substantially in height when approaching coastal areas.

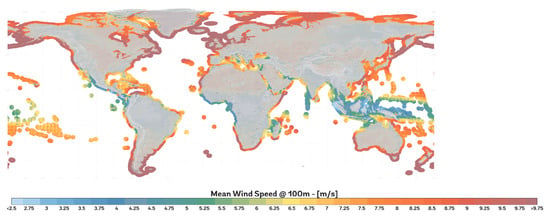

Another crucial factor to consider is the availability of sufficient wind resources, which determines the feasibility of offshore wind projects. Figure 4 shows the mean wind speeds along the coastlines of the world, with higher speeds generally indicating more favorable wind resources. Additionally, it is essential to consider the local mean wind power density, which indicates the available wind resources at a specific location [89,90].

Figure 4.

World map of mean wind speed for wind resources (Reference [89]).

6.1.2. Currents

Different currents impacting offshore structures include oceanic currents (like the Gulf Stream), upwelling/downwelling currents (bringing nutrients to the surface/transporting surface water downward), wind-generated currents (influenced by wind speed and direction), tidal currents (due to the gravitational pull of the moon and sun, causing regular patterns of water movement), and coastal currents (influenced by tidal and wind-driven forces, local topography, and storm surges). The local current that must be designed for is usually a combination of the different current types.

Knowing statistics and extreme current events is essential for the design. Most current measurements are averaged over 5 to 20 min, which might undermine “gusty” strong current events [91,92]. This can lead to an underestimation of the prevalent current and its turbulence that must be considered for the design.

Current velocity profiles show the distribution of water particle velocities at different water depths. Often, the fastest velocities occur near the surface and decrease with depth. This is also the case for the general unidirectional current profile suggested in the recommended practice DNV-RP-C205 [25] characterized as a power law function. Therefore, a common design approach for power cable configurations is to avoid strong current regions by installing large cable sections in deeper waters.

Currents can exhibit varying degrees of directionality, ranging from unidirectional to bidirectional or even multidirectional. In unidirectional current profiles, water flows consistently in a single direction, such as in a river or an oceanic current. Bidirectional profiles occur when currents exhibit a reversal in the flow direction, for example, caused by tidal influences. Multidirectional profiles indicate a complex flow pattern, where currents may change direction frequently and vary in intensity. Numerous factors, including geographical features, wind patterns, tidal forces, and the presence of obstructions or constrictions in the water body, influence the directionality of current velocity profiles. Therefore, multidirectional profiles should be considered for analyzing power cable configurations according to the local conditions [93,94,95].

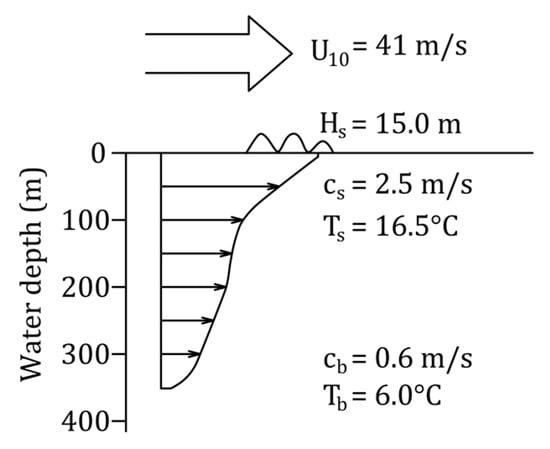

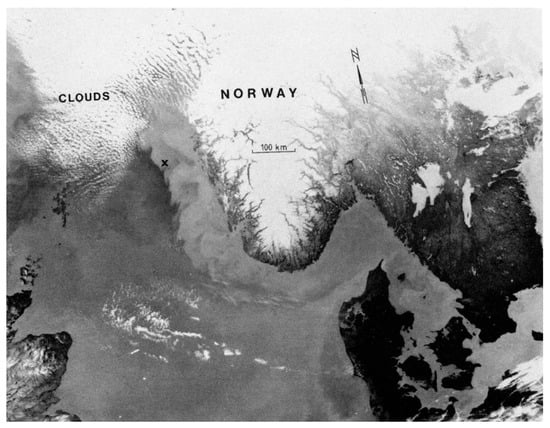

Extreme current events occur especially at the sea surface and can result from specific local circumstances. An exemplary region with very high surface current velocities is the Northern North Sea, reaching velocities of 2.5 m/s, as shown in Figure 5 [96]. The Norwegian Coastal Current (NCC) causes this. It originates primarily from the freshwater outflow from the Baltic Sea and the freshwater runoff from Norway. It flows northwards along the coast of Norway as a low-salinity current [97]. Figure 6 shows a satellite image of the outflow of the Norwegian Coastal Current from the Baltic Sea and its multidirectional meandering in eddies northwards along the Norwegian Coast. After storm surges from the North, vast amounts of water can flow out from the Baltic Sea. When combined with the tidal current, high current velocities occur along the coast of Norway [11,26,96].

Figure 5.

The 100-year metocean design criteria for the oil and gas field Troll location in the Northern North Sea. The figure shows the extreme horizontal current velocity as a function of the water depth. —mean wind velocity 10 m above mean sea surface level, —significant wave height, —surface current velocity, —current velocity at the seabed, —water temperature at the surface, and —water temperature at the seabed (see Saetre [96] and Marechal [88]). Adapted from [26] with permission from Standards Norway.

Figure 6.

A satellite image showing the Norwegian Coastal Current on 13 April 1981. Courtesy of Tromsø Telemetry Station, Norway.

Another extreme local current example is the loop current in the Gulf of Mexico. It forms from warm subtropical water streaming northwards and through the geographical shape of the Gulf [84]. It leads to large current direction and velocity variabilities throughout the entire water depth, which can also change quickly. Extreme current velocities of up to 2.10 m/s have also been measured at deeper waters, with even larger velocities at the sea surface [84]. Such extreme events can statistically occur every 50 to 100 years, making long-term measurements for currents critical, as well as proper modeling techniques to predict them [98]. Often, measurement campaigns are only carried out for a couple of months to years, which can be insufficient to estimate extreme conditions correctly.

6.1.3. Internal Waves

Internal waves are like waves at the surface of a water body. However, they occur where different water densities meet below the surface, often caused by different water temperatures [84]. The internal density gradients are significantly smaller than those at the water surface, giving the internal waves slightly different characteristics from surface waves [99]. Internal waves can have large amplitudes, wavelengths, and periods. For example, Hyder et al. [99] observed internal waves with amplitudes of about 40 m and periods of 40 min. These waves cause water particles to move both vertically and horizontally with high accelerations [100]. Hyder et al. [99] measured currents up to 0.6 m/s for their particular case of internal waves. A current with this velocity can have a significant impact on power cable configurations.

Internal waves occur in areas all over the world, often near fjords, estuaries, and straits. Some exemplary areas with potential offshore wind farm development with frequent internal wave phenomena are the South China Sea, the Sulu Sea in the southwestern Philippines, the Australian North West Shelf, and the Scotian Shelf southeast of Canada [101]. An overview of possible locations with internal waves of large amplitudes, i.e., internal solitary waves, has been provided by Global Ocean Associates (GOA) [102].

6.1.4. Water Depth

The water depth is critical in determining the dynamic subsea power cable configuration for FOWTs. Shallow waters usually require complex configurations to decouple the cable motions from the floater and the TDP [57]. Suspended configurations are not feasible in shallow water either. The currents imposed on the power cables, as well as the influence of the waves and the FOWT motions, can be significant. Additionally, the space between the seabed and the sea surface is limited, requiring complex configurations that can be prone to damage. Intermediate and deep waters facilitate power cable configuration design compared to shallow waters. However, the weight of the cable itself can pose a problem, as well as large FOWT motions, due to the large flexibility in the mooring systems, especially for deep water configurations. Nevertheless, cables at deeper water depths are less susceptible to marine growth and environmental forces, allowing different power cable setups with space for buoyancy and motion decoupled from the FOWT and the TDP or the next connection point. Furthermore, FOWTs are generally installed at intermediate to deep water depths because bottom-fixed OWTs typically have better economic viability for shallower waters. Therefore, the development of floating renewable energy technologies should focus on areas where bottom-fixed solutions are not feasible.

6.1.5. Marine Growth

Marine growth refers to the accumulation of organisms such as barnacles, mussels, algae, and others on surfaces. As FOWTs are located at the water surface, their power cables span various layers of water where they are subjected to different kinds of marine growth. The attached biomass can drastically increase the size and mass of the cable, strongly impacting its responses.

The presence of marine growth can have several detrimental effects on the power cable. First, it increases the actual diameter and roughness, and thus the hydrodynamic drag, potentially leading to higher structural loads. This can be particularly problematic when exposed to strong currents, waves, and floater motions. Second, the additional weight of marine growth can affect the load distribution on the power cable. It can lead to uneven loading and stress concentrations, potentially compromising the safety of the power cable configuration. Third, marine growth can also cause localized corrosion due to biofouling, accelerating the degradation of protective coatings and metal surfaces.

Several offshore standards, such as ISO 19901-1 [18], DNV-OS-E301 [22], NORSOK N-003 [26], and API RP 2A-LRFD [27] recommend different considerations of the marine growth effects in the design analysis of offshore structures. They agree to increase the diameter to an equivalent diameter corresponding to the roughness of the surface. Further, the drag coefficient is adjusted depending on the roughness expected at the installation location. Generally, higher water temperatures facilitate the accumulation of marine growth compared with lower water temperatures. Deeper waters have less marine growth that will be attached to the power cable than close to the surface due to the temperature, the sunlight availability, and the general flora and fauna in the different regions [26]. Accumulation can, in part, be avoided by configuring the buoyancy arc of configurations in deeper waters.

Nevertheless, the different variables used are the subject of several publications that challenge the standard. For example, Marty et al. [103] conducted experiments on cylinders with mussels and corals attached. When comparing their experimental results to calculations from DNV-OS-E301 [22] and API RP 2A-WSD [28] they found that these standards sufficiently predict drag coefficients under current conditions within the sub-critical regime but differ significantly for oscillating drag and inertia coefficients in wave and current conditions.

Further research suggests that the assumed marine growth in specific regions is insufficient when applied as described in the standards because marine growth is strongly site-specific [104]. Such an underestimation led to an incident in the Pacific Ocean in the test field off the coast of Fukushima, Japan, where a dynamic power cable connected to an FOWT became damaged due to contact with the seabed [37]. The marine growth changed the configuration of the dynamic cable so that it sank and touched the seabed in its sag point, where it was damaged and needed to be repaired. Since then, marine growth must be removed regularly, which adds costs to the research project. Okubo et al. [105] showed that the marine growth on an FOWT in the Sea of Japan (East Sea) also led to its cable sagging significantly more than expected during the design work. Later, additional installations of buoyancy devices were necessary when a sag point of the dynamic power cable configuration came critically close to the seabed. The marine growth measured at the location exceeds the general reference values suggested in DNV-OS-E301 [22]. The DNV reference values were obtained from locations in the North Sea and the Norwegian Sea, which have lower water temperatures and less marine growth than other locations with, for example, usually higher water temperatures, such as around Japan. Measurement campaigns and analyses should be carried out considering the marine growth that can occur at the specific location.

Preventive measures are often employed to manage marine growth. These can include applying antifouling coatings or materials to the surfaces of the structures to deter or minimize attachment. Okubo et al. [105] successfully applied an antifouling coating on the buoyancy modules attached to a power cable for an FOWT. Nevertheless, antifouling should be employed sparingly or ideally avoided altogether, given the significant environmental hazards stemming from its toxicity [106]. Periodic cleaning and maintenance are also carried out to remove accumulated growth and ensure the structural integrity of the power cable in several projects, as reported by Ishii et al. [37]. If unavoidable, the cost of cleaning the cable on a regular basis is usually significantly lower than risking a critical cable failure and replacement.

6.1.6. Temperature

The temperature of the surrounding environment can have significant effects on power cables. Therefore, they must be designed to withstand the different temperatures in different layers of water and the seabed while efficiently transmitting electrical power [107].

The primary concern for subsea power cables is the temperature of the conductor, which carries the electrical current. High temperatures can be generated due to the resistance of the conductor itself and the electrical load it carries. This heat must be managed to prevent cable overheating, which can lead to insulation degradation and, ultimately, cable failure [38]. Excessive heat can also accelerate the aging of the insulation materials, potentially shortening the operational lifespan. It can also affect the electrical properties of the cable, leading to losses and reduced efficiency. Cold water temperatures can reduce the conductor’s temperature. While this may help prevent overheating, it can also make the cable more brittle, which may affect its mechanical properties.

Furthermore, biofouling around the power cable can modify the heat transfer and change the temperature in the conductor, affecting its fatigue life [108]. Depending on the age of the mussels attached to the power cable in experiments by Maksassi et al. [108] the global thermal resistance led the conductor to either overheat or cool down.

6.1.7. Cold Climate

The polar regions are characterized by their unique cold climate and extensive glacial ice. These remote areas have recently become more accessible for commercial use due to technological progress and the receding sea ice. However, the polar regions have delicate ecosystems that can take considerable time to recover from even minor disruptions [109,110]. Therefore, all activities in these regions must undergo thorough environmental assessments to guarantee long-term sustainability.

Snow and icing, whether from atmospheric conditions or sea spray, can impact FOWTs, subsequently affecting the motions and loads experienced by the power cable. In colder regions, more immediate hazards to power cable setups also include sea ice and icebergs, where the latter can also be a threat to the entire wind farm. Drifting sea ice ridge keels can extend several meters below the sea surface, exceeding the hang-off location of the power cable from the FOWT. In such situations, the hang-off section and the upper part of the power cable must be equipped to withstand the presence of sea ice adhering to it or potential collisions.

6.1.8. Bathymetry and Geotechnical Conditions

Bathymetry defines the setup of the entire footprint of an FOWT farm. The primary concern when laying power cables on the seabed is the geotechnical condition of the ocean floor. Variations in sediment composition, bedrock, and unstable formations can greatly affect the stability and integrity of the power cables. Extensive geotechnical surveys must be conducted to assess the seabed conditions and make informed decisions about cable placement; these surveys should be conducted in parallel with data collection for the mooring systems. The on-bottom stability of the power cable must be considered accordingly.

In regions with soft seabed soil, there is a concern that power cables may dig themselves into the sediment over time. This phenomenon could lead to a snap load with excessive tension and potential damage when the cable is released from the soil. Burying cables over certain distances can be a solution to prevent damage. Also, more unconventional solutions, such as cable protection systems, have been implemented successfully [111]. Areas with rocky seafloor usually have rock piles or mats on top of the power cables to prevent them from moving. A solution without additional measures to keep the cable in place on the rocky seabed has been successfully tested for a power cable connected to a tidal stream turbine in the UK [112].

Certain areas have a significant risk of underwater avalanches, rock falls, and sediment shifting [113]. They can disconnect cables and create catastrophic failures in the FOWT farm, mainly due to anchor failures. On a smaller scale, the cable sections on the seabed can be suspended over distances, leading to vortex-induced vibrations (VIVs) and fatigue. Identifying and avoiding these zones is essential during the planning process of the inter-array cables and the entire FOWT farm.

6.1.9. Climate Change Impact

Due to climate change, statistics over the last decades might not always be a reliable basis to estimate future environmental conditions accurately [114,115]. The environmental conditions have been changing in the last few decades, with a general trend towards more extreme sea states. In some locations, extreme values may appear more frequently than before; this can, for example, mean that the 100-year condition is the new 50-year condition. For example, Feng et al. [115] obtained a change of 0.82 m in annual and 1.39 m in winter over 30 years of measurements in the Norwegian Sea. According to them, this is a change that never occurred that rapidly before their measurements. As another example, Taiwan experiences typhoons significantly less frequently than in the past, whereas the sea temperature around the island is rising at the same time [116,117]. This influences, for example, the wind, waves, current, and marine growth conditions that FOWTs installed there will experience. Modeling techniques and designs must consider these uncertainties and should refer to a ‘dynamic design baseline’ in the future, where appropriate.

6.2. Response Constraints

Multiple factors influence the behavior of a dynamic power cable. External factors are loads exerted by the surrounding environment and the motions of the components to which the power cable is connected. The inherent structure of the power cable not only dictates how it responds to these external forces but also constrains the flexibility of the cable. The power cable structure has specific thresholds that must not be exceeded to maintain the integrity of the system. Therefore, several methods of analysis to obtain the failure modes of the power cable components by carrying out global configuration analysis have been proposed, for example, by Ran et al. [118] and Young et al. [119]. This section is about these crucial constraints governing the responses of the power cable in the global configuration.

Each structural component and section of a power cable has a distinctive failure mode linked to its material properties and strain response. For example, when a cable is bent beyond its minimum bend radius, it can suffer from a phenomenon known as ‘bird caging’ [120]. When a typical power cable is bent too sharply, the outer layers are stretched along the outer curve of the bend while the inner layers are compressed. This unequal stretching and compression can cause the outer insulation and shield to deform and create small gaps or openings resembling a birdcage. This damage often occurs due to sharp bends during the installation of power cables. However, it can also appear during operations when the cable is subjected to excessive compression. Dobson et al. [38] provided an overview of the critical failure modes of power cables.

6.2.1. Tension and Compression Limits

The manufacturer of the power cable provides tension and compression limits. Tension limits denote the maximum tensile stress a cable can bear without undergoing permanent deformation or failure. Compression limits define the maximum compressive stress a cable can endure without buckling or collapsing. Exceeding these limits can lead to elongation, plastic deformation, or even breakage, compromising the structural stability of the entire system. Experiments are conducted to obtain these limits; see Ringsberg et al. [48], Grivas et al. [121], and Nasution et al. [122].

One particularly high-risk area for exceeding the maximum tension limit is the hang-off, where the cable experiences motions from the floater, curvature loads, and static tensile loads from the weight of the hanging cable [50,56,123]. Factors such as cable temperature, service loads, solar radiation, insulation, and mechanical and electrical loads contribute to this risk.

The sag and hog bends of the power cable configuration are usually subjected to cyclic compression and bending, which makes them a significant risk area for exceeding the maximum compression limit [118]. If buoyancy modules, bend stiffeners, and clamps are applied with excessive pressure, they can hinder the lateral movement of helical components in the cable [38]. This restriction might cause compressive overload or amplify fatigue loading in the armor or conductors, posing a severe threat to the integrity of the cable. Proper attachment techniques are essential to prevent unintended stress concentrations that could compromise the reliability of the cable.

6.2.2. Curvature Limits

The ability of a power cable to withstand maximum curvature is directly tied to its capacity for enduring compression forces. In most cases, designs allow for minimal to zero compression stresses, strictly adhering to maximum allowable curvature requirements. The manufacturer of the power cable provides the limit values. Note that the minimum bend radius is often used to ensure the maximum allowable curvature instead of the maximum curvature constraint.

An important point of the power cable configuration where exceeding the maximum curvature becomes critical is typically the TDP location. It is subjected to cyclic bending, compression, and abrasive loading due to contact with the seabed. Preventing failure at this point often involves implementing a cable protection system. Such a system restricts bending and shields the power cable from abrasion. By limiting cable movements with a tether, such as in the tethered-wave configuration, stability at the TDP can be better controlled compared with a lazy-wave configuration.

Additionally, there are other crucial locations in the design where surpassing the maximum curvature constraint can be a concern. These include the hog bend, sag bend, hang-off location, and tether clamp. The sag and hog bends must be equipped with appropriate buoyancy to support the cable and prevent overbending. Furthermore, the hang-off location requires a bend stiffener or bell mouth to prevent the power cable from overbending [79,124]. The hang-off section and the seabed tether connection are commonly custom-designed for each project to meet the specific design requirements and ensure optimal performance.

6.2.3. Fatigue

Due to the dynamic loading of the power cable configuration, the cable itself is subjected to significant fatigue. The primary cause of fatigue damage in dynamic cables is the stress resulting from cable bending rather than tension [119]. The relevant design constraint is the fatigue life, meaning the minimum lifetime the cable can operate before breaking.

In academic literature, cables are often simplified as single homogeneous materials with equivalent cross-sections, assuming infinite friction between layers, as seen in Rentscher et al. [55]. This methodology generally offers a conservative assessment of stress and strain levels, as it does not account for potential slippage between layers that might mitigate stress within the cable. Land et al. [125] supported this assumption, as the obtained strain for their full-stick cable model is significantly larger than for their full-slip model. Nevertheless, they chose to use the full-slip model to be more realistic. That the non-slip assumption is conservative can be challenged, as it might not apply to every case. Beier et al. [69] demonstrated higher stress values in their power cable model, incorporating friction, in contrast to the identical cable configuration with zero friction. This finding suggests that considering interlayer slip could result in more realistic estimations of stress and strain in cables.

Most published fatigue estimation studies primarily focus on assessing the fatigue of copper cable conductors. A more extensive study by Beier et al. [69] supports that approach, as the conductor is the first component to fail due to fatigue. The cores are typically made from electrolytic tough pitch (ETP) copper, which exhibits mechanical properties such as stress relaxation and non-linear stress–strain behaviors [125]. Therefore, when evaluating fatigue in such cables, it is recommended by Karlsen et al. [126] to use strain-cycle (ε-N) curves instead of the more common stress-cycle (σ-N) curves.

A larger transmission capacity, either by increased voltage or conductor cross-sections, increases the physical footprint of cable components or introduces new components in a dynamic cable context. For example, a radial water barrier is needed to protect the insulation system against humidity and prevent the water treeing failure mechanism [127]. Fatigue as a failure mode becomes increasingly relevant and critical where the relevant mechanisms and material selection differentiate from the lower voltage standard [44].

A notable issue encountered is the underprediction of low-frequency floater surge motions in numerical software [128,129,130,131]. Holcombe et al. [128] compared the numerical results from three potential-flow-based software to the experimental results of an FOWT exposed to waves. All three software models underpredicted the FOWT surge response in low-frequency wave regions compared to the experimental results. This can result in a considerable underestimation of power cable fatigue damage. Land et al. [125] found that by increasing the low-frequency surge responses of the FOWT by 20%, based on the findings of Robertson et al. [130] there was a notable increase of 2.1% in the curvature of the power cable. Furthermore, this adjustment led to a significant 13% increase in the annual fatigue damage compared to the simulation results that did not incorporate the increased surge responses.

6.2.4. Torsion Limits

In general, umbilicals possess relatively low torsional stiffness, making them vulnerable to damage caused by excessive torque or twisting [132]. The risk of torsion damage is particularly high during installation [132]. During operation, torsional failure is not regarded as a large threat, as it is seldom reported as an incident [133]. Torsion has a minimal impact on the structural response of umbilical cables during the global configuration analysis [134]. When the wires are coiled in a helical pattern, the power cable experiences tension when it is twisted. These loads can lead to the rupture of helical elements if applied excessively [133]. However, the torsion within helical elements is minimal and does not affect the cross-section of the umbilical cable; instead, tension induces the torsion [134]. Therefore, torsion limits are usually neglected in the analysis of power cable configurations, and often even the effect of torsion itself.

6.2.5. Snap Loading

Snap loading refers to a sudden, significantly higher load on a power cable than its rated capacity. The most common occurrence of such an event is during installation, but it can also occur during operation. This excessive load can be caused by factors such as intense drag forces on specific cable parts, like the buoyancy section, and pulling forces induced by the FOWT. A more common scenario involves the cable becoming stuck in seabed mud. If weather conditions cause substantial floater motions, the cable can be strongly pulled at the TDP, leading to a snap load. Design considerations must prevent such occurrences.

6.2.6. Resonance

The oscillations of the FOWT floater can be close to the natural frequencies of the power cable in specific degrees of freedom. Resonance poses a significant risk, potentially causing cable damage and fatigue. The fundamental frequency of the power cable setup can be adjusted, especially by positioning buoyancy at specific distances from the hang-off location. The fundamental frequency of the power cable heavily relies on the catenary between its hang-off and first buoyancy attachment [50].

When the power cable is suspended and the connected FOWTs move asynchronously, as is typical in actual sea conditions, a resonance between the movements of the FOWTs and the power cable can occur. In this context, the bending radius can be a critical factor, potentially leading to failures.

Resonance can also arise from vibrations originating in the FOWT, transmitted to the power cable through the hang-off point. This is important because the FOWT inherently vibrates due to rotor rotation and system elasticity. The configuration must be designed to avoid exposure to its natural frequencies to prevent issues.

The impact of the power cable configuration on the FOWT is usually small. The power cable is usually considerably lighter than the FOWT structure. However, when a heavy cable is used on a lightweight platform, it can substantially affect the responses of the platform. Schnepf et al. [50] showed that their suspended power cable increases the low-frequency sway and roll responses of the spar FOWT to which it is attached. If this occurs, it must be accounted for in the analysis.

6.2.7. Vortex-Induced Vibrations (VIVs)

Vortices are formed behind a structure encountering a current. These vortices impose forces on the structure, resulting in VIVs. They can cause increased drag forces in the flow direction and significant accumulated fatigue damage [101,135]. The impact angle of the current towards the power cable configuration greatly influences the VIV behavior [136]. Discrepancies between different VIV estimation software can occur [136] and should be subject to further investigations. If VIVs are present in the power cable configuration, they should be suppressed with devices such as strakes, or the configuration should be redesigned to avoid VIVs [137,138]. Optimization of the configuration to avoid VIV effects can save costs due to a longer asset lifetime [138,139].

6.3. Geometrical Constraints

Geometrical constraints involve seabed and sea surface clearance, as well as ensuring safe placement regarding other infrastructure and ancillaries.

6.3.1. Clearance to the Seabed and Sea Surface

A specified minimum distance from the seabed, i.e., seabed clearance, in specific sections, is a constraint in nearly all published optimization algorithms for power cable configurations. This requirement is crucial to prevent uncontrolled contact between the power cable and the seabed, which can damage the cable. Additionally, it aims to prevent a change in behavior in the power cable due to the near-wall effect. Among all sections of the power cable configuration, the sag bend is the most critical area where unwanted contact with the seabed can occur.

Opposite to the sag bend, the hog bend has a risk of encountering the sea surface. This must be avoided to prevent large loads on the power cable from waves. Depending on the type of optimization algorithm, a constraint on the sea surface clearance should be implemented.

6.3.2. Placement to Other Infrastructure

The power cable must be placed so that it does not cross any other lines when viewed from atop, such as other power cables, moorings, and other infrastructure. This is a primary concern in optimization algorithms for the overall layout of the inter-array cable system. Also, this needs to be considered, especially for the dynamic power cable configuration excursions. Depending on the environmental conditions, the power cable can have large excursions leading to potential interaction with mooring lines, which must be avoided. Crossing pipelines and cables can be necessary and possible with special precautions [21].

6.3.3. Inherent Constraints of Ancillaries

Ancillary components are typically designed to meet specific configuration requirements, but also have inherent limitations. For instance, buoyancy modules are rigid and cannot conform to the curvature of the power cable. Similarly, bend stiffeners are limited in their flexibility due to material constraints [140,141]. These limitations primarily stem from production constraints, such as restricted mold casting and oven sizes, which impose geometric restrictions. Additionally, it is important to guarantee that the design of ancillary components facilitates installation with minimal risk and cost.

6.4. Lifecycle Constraints

The project lifecycle for a power cable configuration can be divided into seven phases: preliminary design, detailed design, manufacturing and testing, load-out, transport and installation, commissioning, in-service, and decommissioning [21]. Each phase imposes limitations on the design, which are discussed in this section.

6.4.1. Installation

According to GCube [3] approximately 44% of their cable insurance claim expenses can be traced back to errors made by contractors during transit and cable laying. Therefore, it is crucial to consider complying with the constraints during load-out, transport, installation, and commissioning. During installation, similar response and geometrical constraints apply as those during operation. Additionally, the torsion damage risk is high, occurring below the final sheave on a laying vessel when it turns. This occurs due to the weight of the cable inducing a twist, leading to friction preventing rotation as it exits the sheave, potentially causing various failures [142]. Preventive measures involve maintaining cable tension and utilizing torque-balanced armor to minimize torsion effects. Other noteworthy risks include elongation damage and crushing, where the cable falls uncontrolled onto the seabed. Okkerstrøm et al. [143,144] provided an overview of risks and factors to consider during the installation.

6.4.2. Operation and Maintenance

The primary operational cost drivers for offshore wind farms are regular inspections and failures that necessitate maintenance and repair of moorings and cables [1]. A durable system design with minimal failure is crucial to reduce these costs. Also, the power cable configuration must be designed to guarantee adequate access for inspection, maintenance, and repair. When major repairs on FOWTs are required, they might be towed to port, as for the Hywind Scotland FOWT farm [145]. The cable will be disconnected from the FOWT and left at its current location. The design must consider how the cable can be placed in this situation. Possibilities include dropping the cable to the seabed or keeping it afloat with buoys. Measures should also be implemented to prevent entanglement with nearby fishing equipment.

6.4.3. Decommissioning

How the power cable configuration will be decommissioned must be considered from the start of the design. How the seabed will look afterwards is specified in governmental regulations. The decommissioning process of the power cable configuration needs to be planned from the initial design stage. Ongoing debates exist about whether all objects added during installation should be removed or if disturbing the seabed during cable extraction is acceptable [146]. Governmental regulations specify the post-removal seabed appearance [147]. Additionally, the recycling possibilities for power cables should influence the initial cable selection [53].

6.5. Modeling and Analysis Limitations

Efficient simulations are crucial for cost savings, sparking ongoing debates in research on minimizing simulation durations [148,149]. Fast and accurate results are crucial, especially in optimization when numerous simulations are required. The equation of motion is solved in many software, such as described by Orcina [150]. Often, a compromise between time efficiency and precision must be found. Various methods are therefore employed:

Frequency domain analyses: Analyzing power cable configurations in the frequency domain shows their responses to various frequencies. Identifying critical resonance frequencies enables adjustments in the system design to prevent resonances. Frequency domain analysis is generally fast. However, it fails to capture the dynamic responses of coupled complex systems, for example, the FOWT floater and rotor.

Static and steady-state analyses: Steadier results can sometimes be obtained through steady-state or static calculations in optimization algorithms. However, they often necessitate the use of safety factors for accuracy.

Dynamic simulations: For the most precise analyses and optimizations, dynamic time-domain simulations are employed. However, these simulations usually demand significantly more time than frequency and static analysis. Optimization typically means a compromise between time efficiency and precision.

6.6. Environmental Impacts

Installing, operating, and decommissioning subsea power cables have significant environmental impacts, as outlined by Taormina et al. [151]. Installation and decommissioning cause underwater noise and risk of chemical pollution, while burying or laying the cable on the seabed leads to sediment resuspension and habitat reworking. During operation, a primary chemical concern involves potentially releasing buried pollutants in the sediment, such as heavy metals and hydrocarbons [151], resulting from sediment resuspension at the TDP. Sediment toxicity assessments in potentially polluted areas can help cable routing planning to prevent pollutant mobilization [152]. Sea electrodes at monopolar DC cables emit harmful electrolysis by-products such as chlorine and bromine, polluting the water [151]. Artificial electromagnetic fields can disrupt the geomagnetic abilities of marine organisms [153]. Low-frequency electromagnetic fields can negatively affect various species, with evidence from studies on cockles [154], crabs [155], sponges [156], and eels [157]. Adequate shielding and cable burial can reduce exposure from sensitive species [152]. The dynamic cable section between the seabed and FOWT poses entanglement risks for animals, especially for large mammals [158,159].

On the other hand, FOWT farms can accommodate a wide variety of marine life. It can be a refuge for fish, as fishing activities cannot be carried out between the FOWTs due to mooring lines and power cables. They can also have a “reef effect” [151,153], which is the creation of artificial reefs due to the increased habitat complexity of the unburied cables. It is commonly regarded as a favorable human-caused influence since artificial reefs have higher fish and decapod biomass densities than nearby seabed areas [151]. Without the fisheries in the area, it can function as a reserve for these populations and stabilize them in the surrounding areas. That was already determined for the European lobster and the edible crab in offshore wind parks [160,161]. All potential effects of the power cables on the environment should be considered in future developments, and negative impacts should be avoided [53,162,163].

6.7. Socio-Economic Aspects

Fishing is the livelihood of many coastal communities. Ensuring that fishing activities remain undisturbed by the FOWT farm is crucial. Finding a compromise that satisfies all parties involved is essential if disturbances occur. Of particular concern are power cables, which pose significant risks to the fishing industry. Nets and crustacean traps can become entangled in the dynamic sections of these cables, while cables on the seabed can obstruct trawling operations. Fishing activities account for 52% of the causes of damage to telecom cables in the Atlantic [53]. It is essential to engage the fishing industries from the beginning of the project, ensuring their consultation and active involvement in the planning process [7].

Like the fishing industry, the placement of the FOWTs must take shipping routes into account. This is crucial to prevent collisions between ships and FOWT farm structures [164] and avoid significant detours for ships [7]. Suppose an FOWT farm is near a port where ships often anchor while waiting for entry; it poses a significant risk to the power cables. This concern should be addressed from the beginning of the project, and early engagement with local harbors and shipping industries is essential.

The primary immediate benefit of an FOWT farm, in contrast to other existing sources of electrical energy for society, lies in its offshore location, often hidden from public view. The only link between the offshore wind farm and the land where the electricity is required is through power cables. The power distribution network is frequently ill-equipped for integrating an FOWT farm, potentially requiring construction activities on land. This situation could also allow coastal communities to create new employment opportunities. For further information, Holmås et al. [165] provide an overview of the societal repercussions of the Hywind Tampen FOWT farm.

7. Optimization

This section presents the most important parameters for design and optimization in a flowchart. Further, published studies on power cable configuration design optimization, as well as for umbilical and riser configurations in the oil and gas industry, are presented and discussed.

7.1. Determining the Most Relevant Optimization Parameters

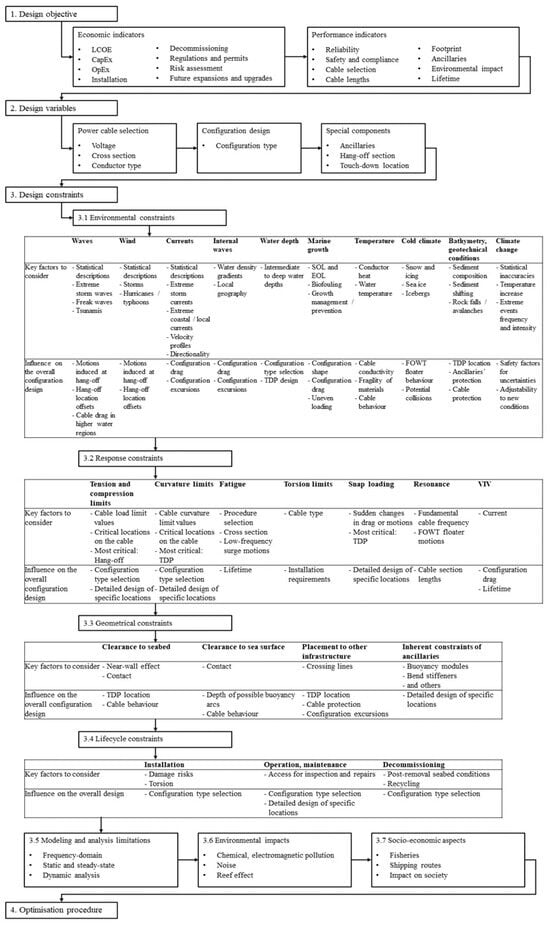

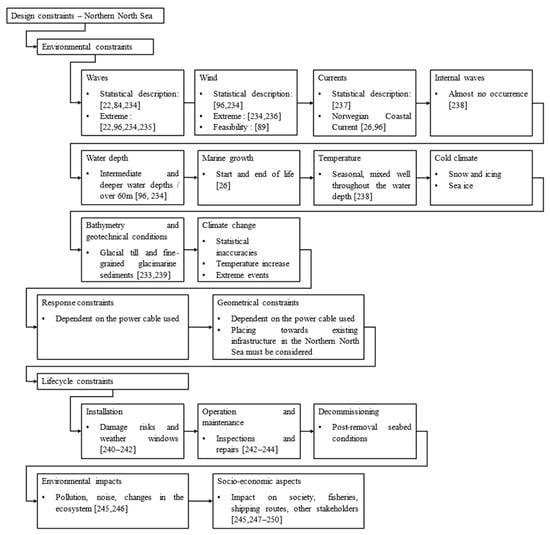

Due to limited computational capabilities and time, analysis and optimization cannot be performed on all design parameters. Further, variables and constraints on power cable configuration design are heavily site-dependent and determined by the local conditions. Therefore, choosing the most relevant variables and constraints for the specific location is crucial for a safe and efficient design. Figure 7 shows a flowchart as a reference to assist in the process of optimizing parameter selection. It is divided into the following main sections: objectives, variables, and constraints. The subsections outline the critical factors of each parameter.

Figure 7.

A flowchart outlining a step-by-step approach for identifying key optimization parameters in dynamic cable configuration design.

The key is optimizing with respect to the constraints that influence design most. In the flowchart, each constraint includes the crucial factors to consider and their influence on the design of the power cable configuration. Yet, uncertainties surrounding these constraints necessitate careful consideration and integration into the design and optimization processes. Using this flowchart as a decision-making tool aids in identifying parameters with significant design impact.