Operational Modal Analysis of a Monopile Offshore Wind Turbine via Bayesian Spectral Decomposition

Abstract

1. Introduction

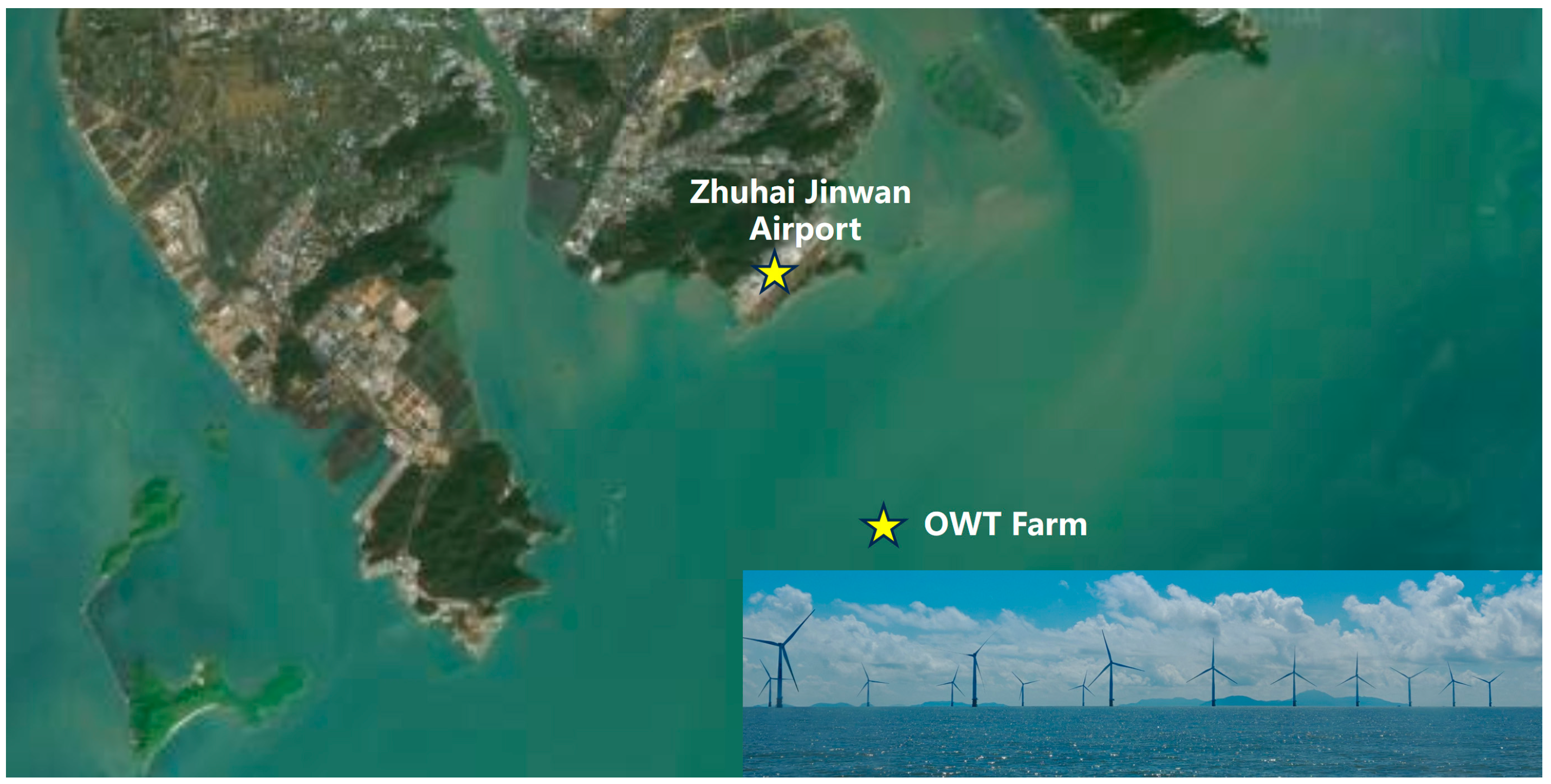

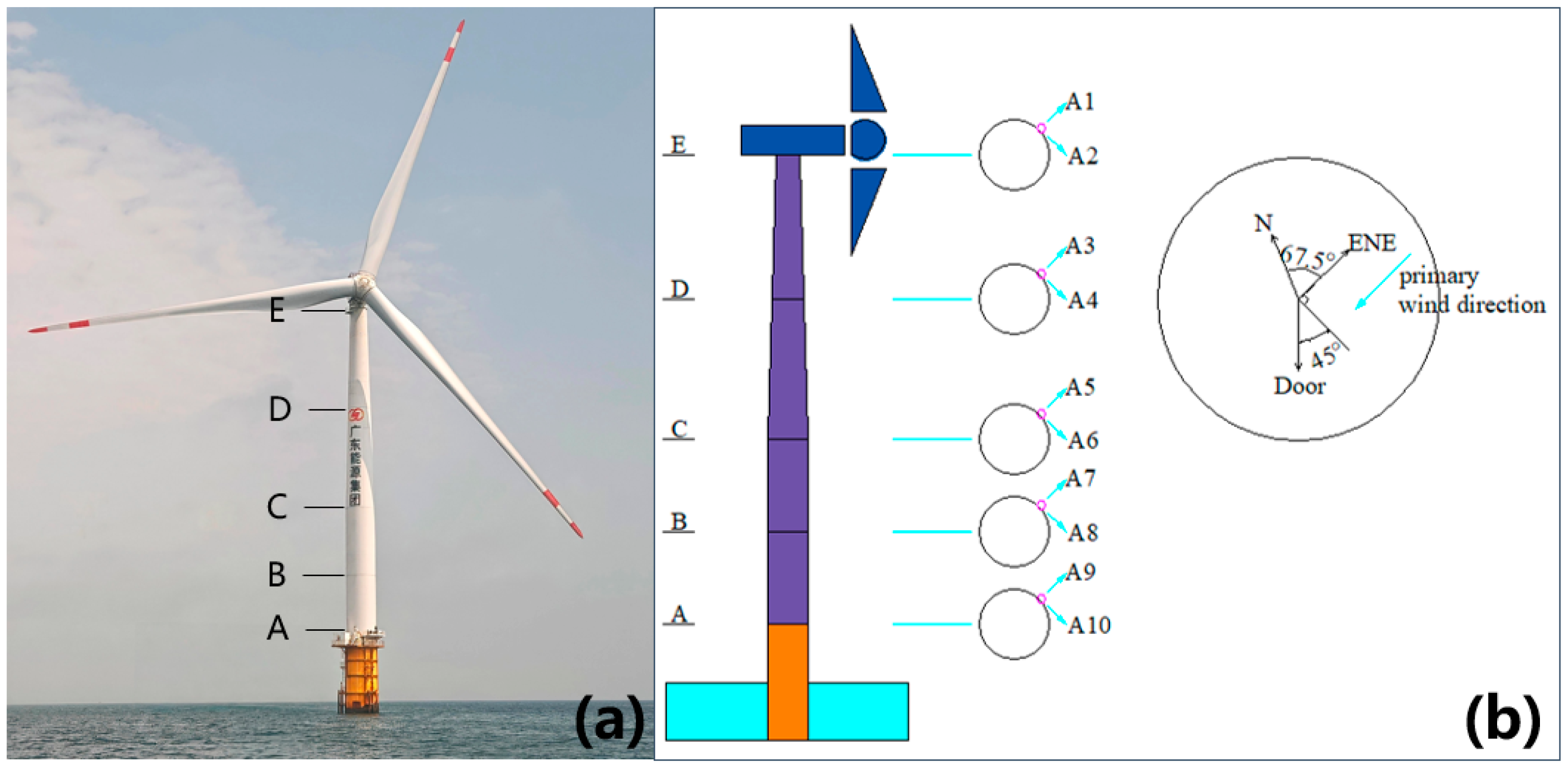

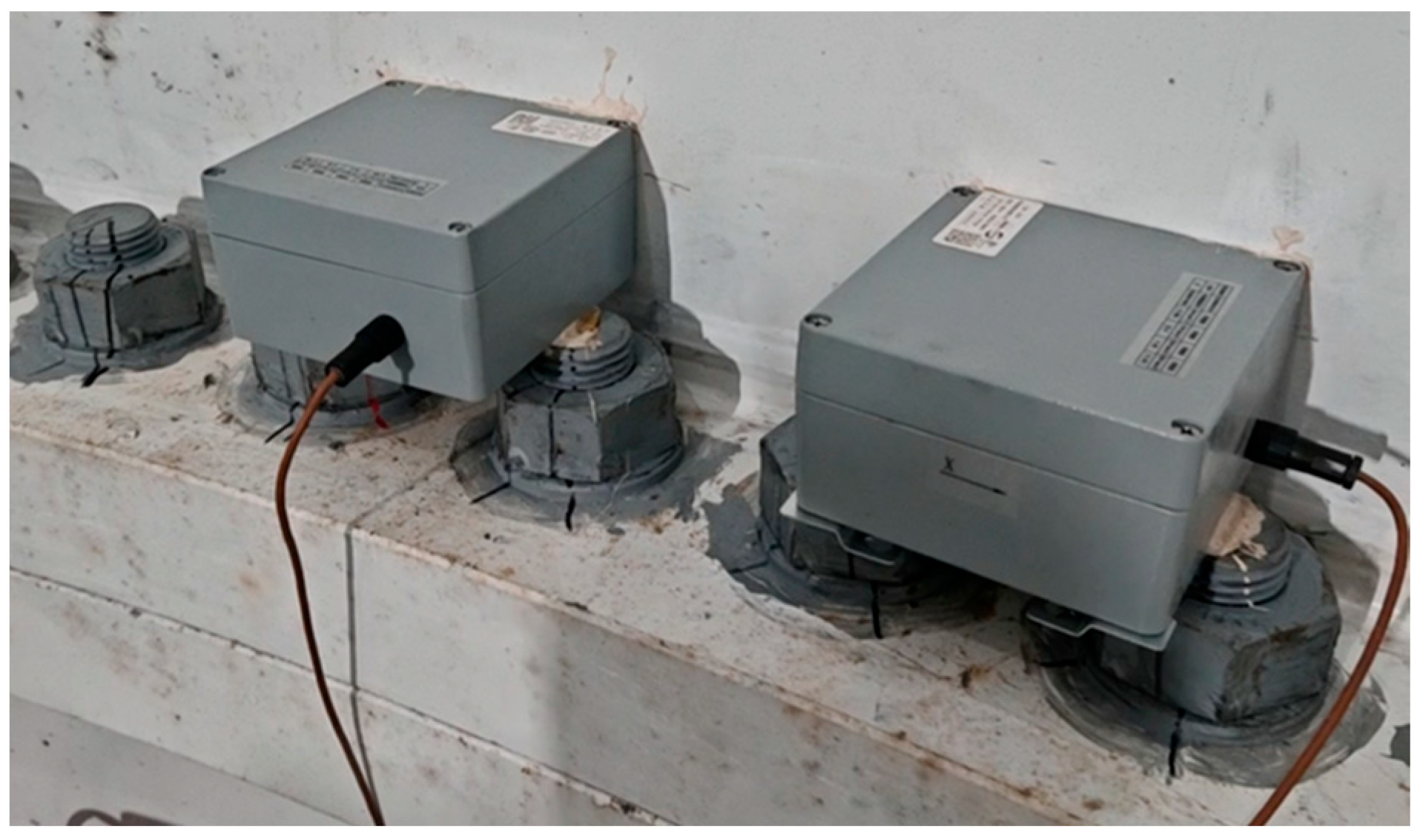

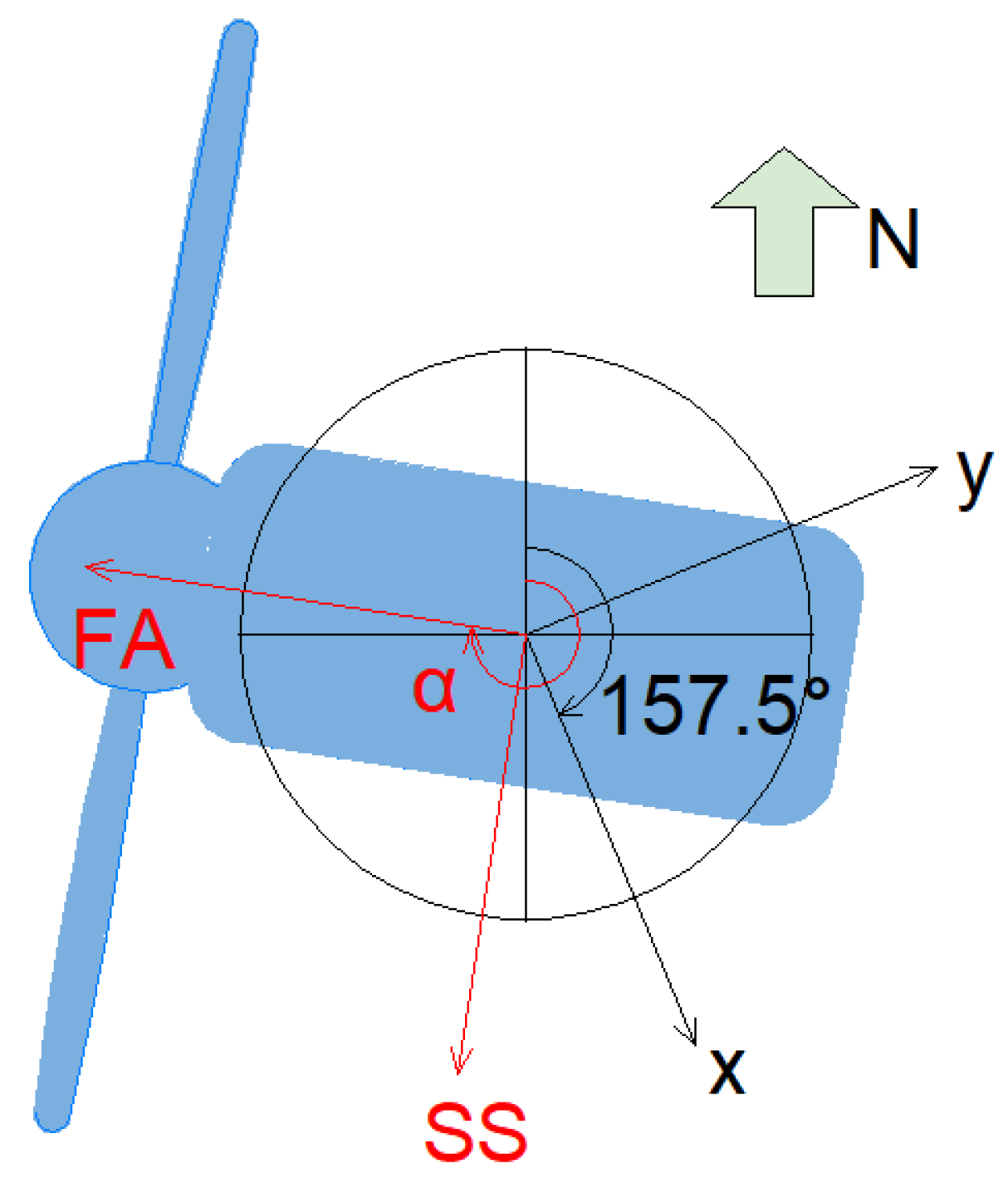

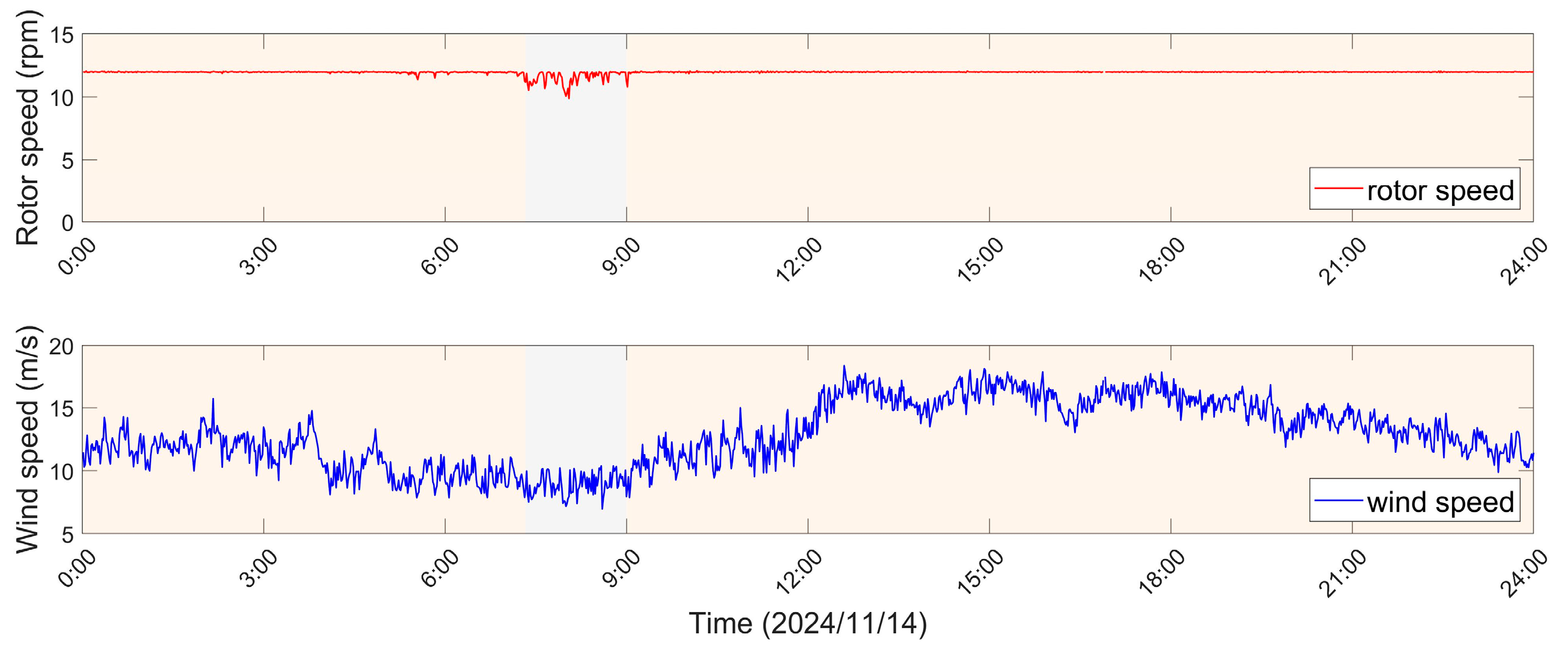

2. Monitoring of Offshore Wind Turbine and Data Preprocessing

2.1. Overview of Offshore Wind Turbines and Monitoring System

2.2. Data Preprocessing

3. Methodology of Modal Identification

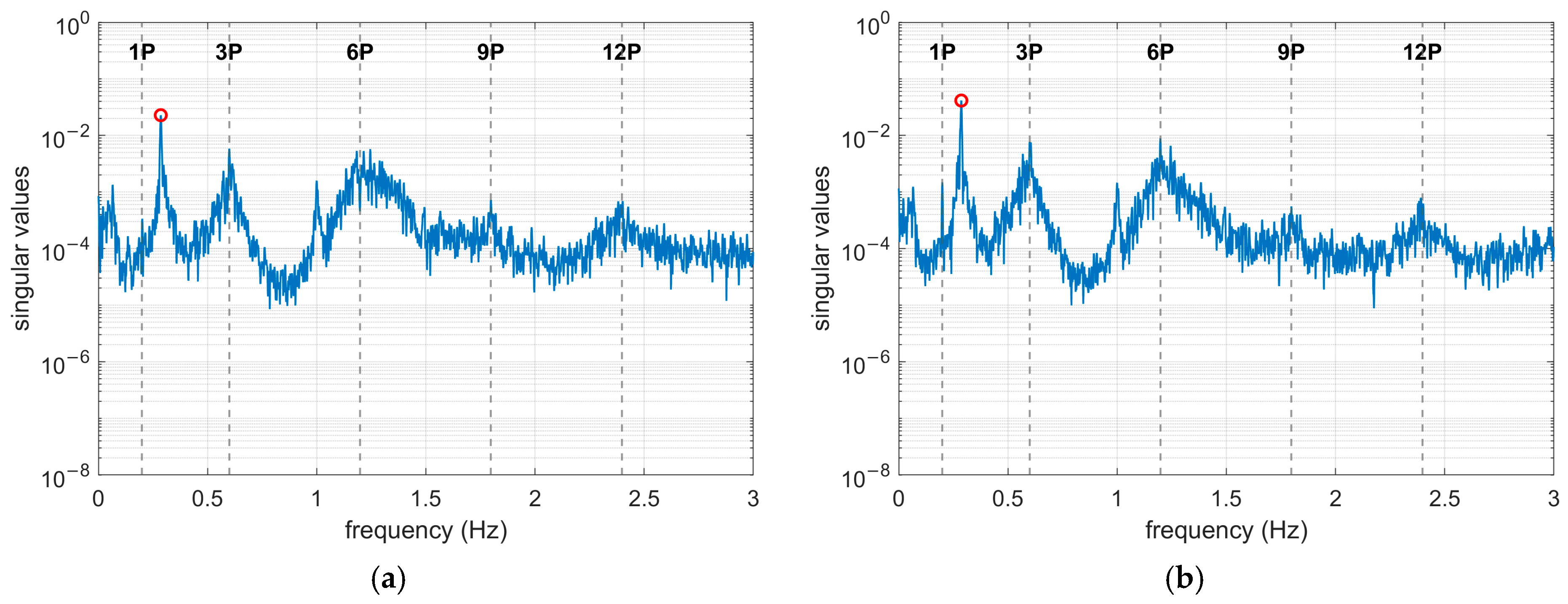

3.1. Frequency and Damping Identification by BSD Method

3.2. Mode Shape Identification by BSD Method

4. Modal Parameter Identification Results

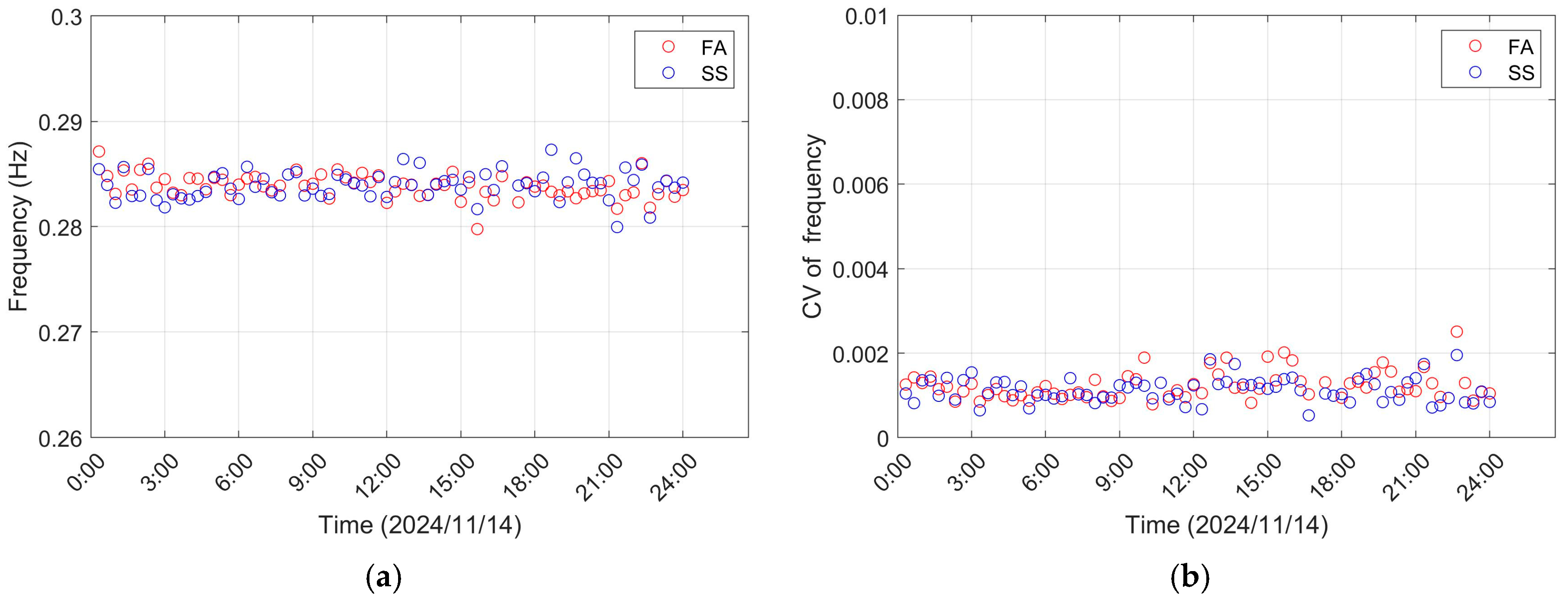

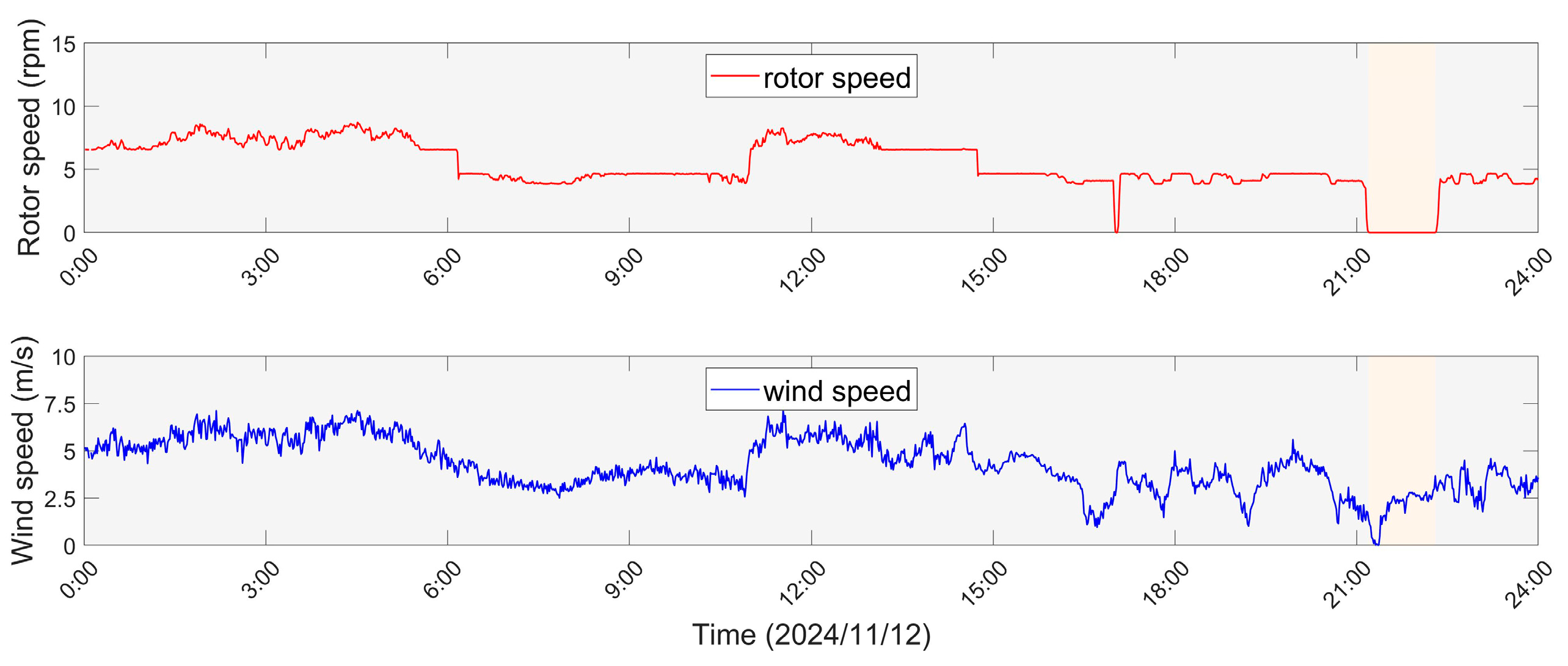

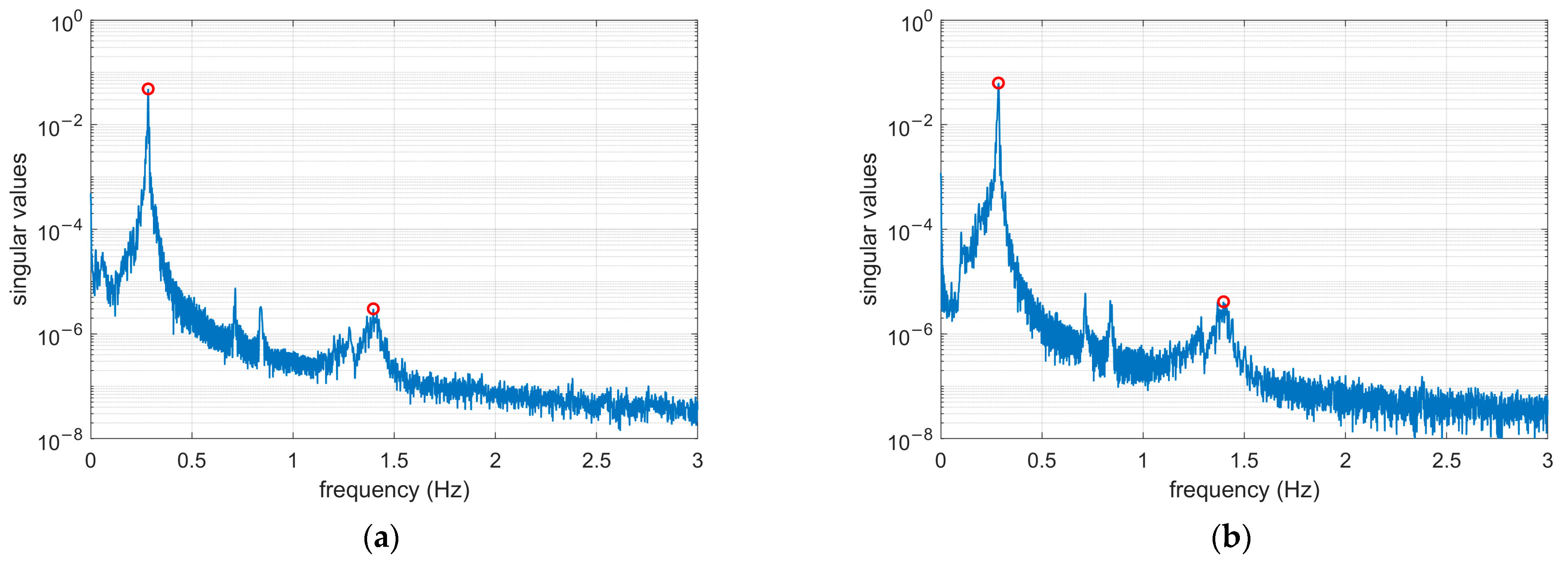

4.1. Modal Parameter Identification of the Wind Turbine at Rated Rotor Speed

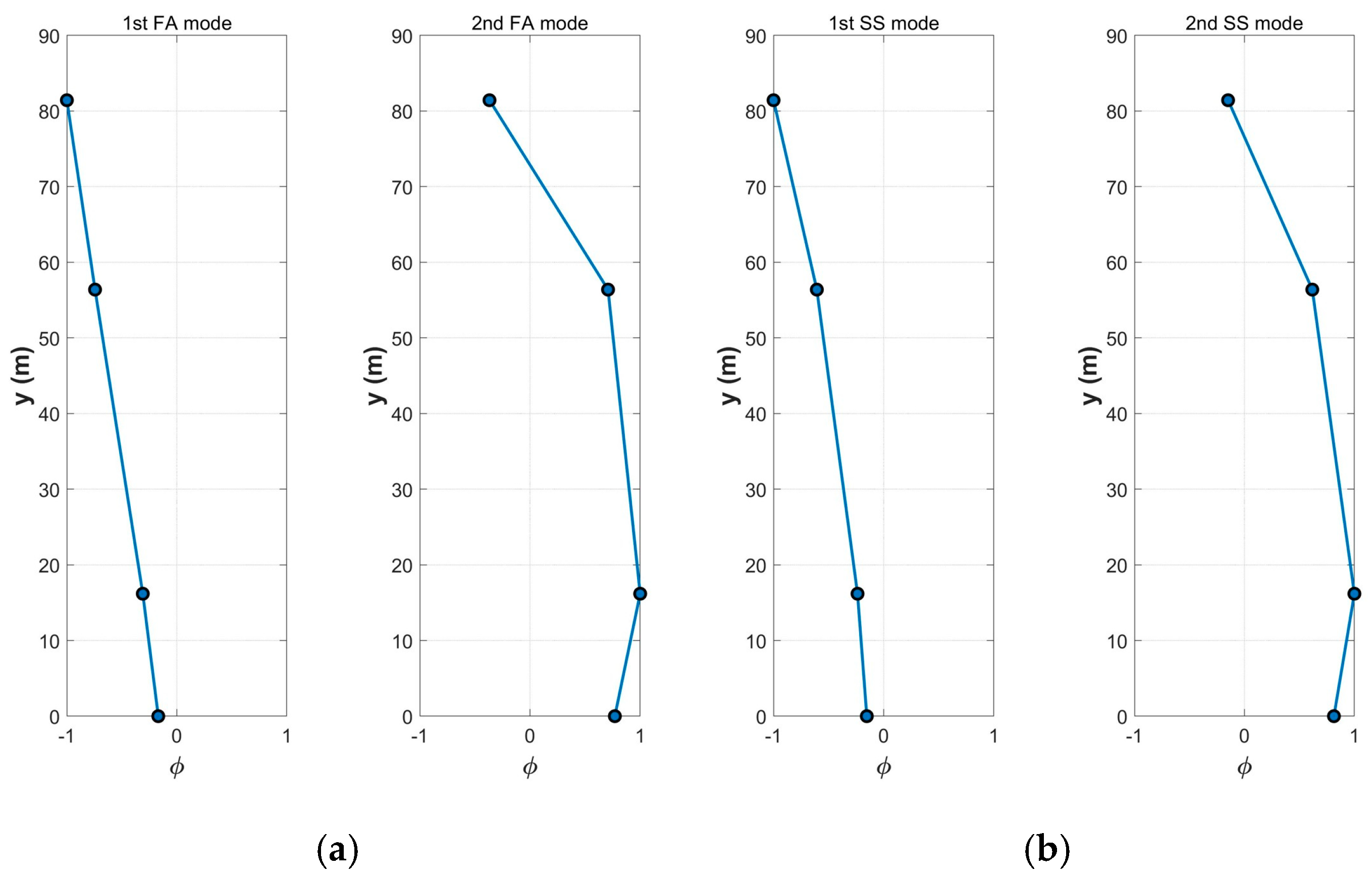

4.2. Modal Parameter Identification of the Wind Turbine at Idel State

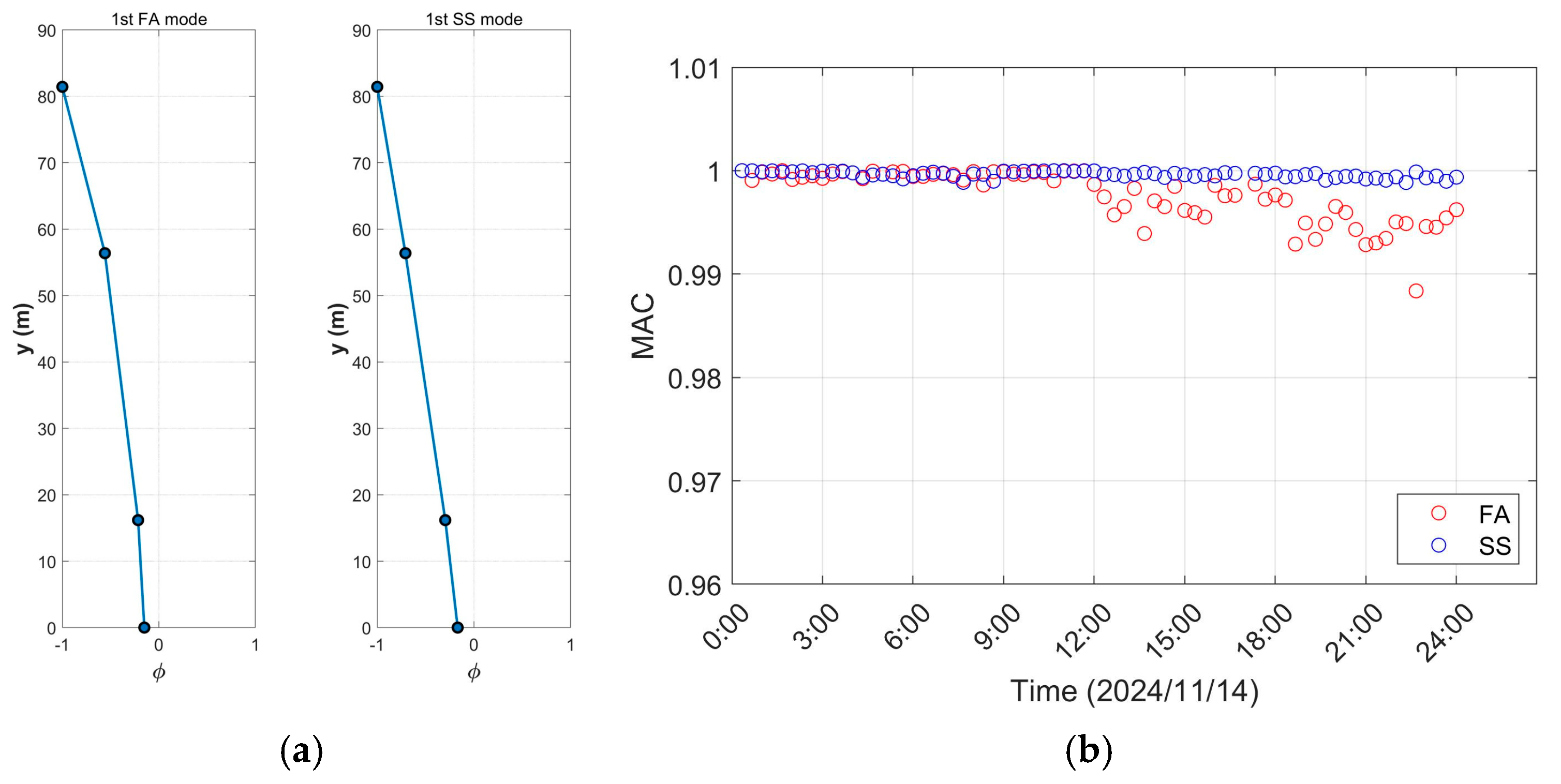

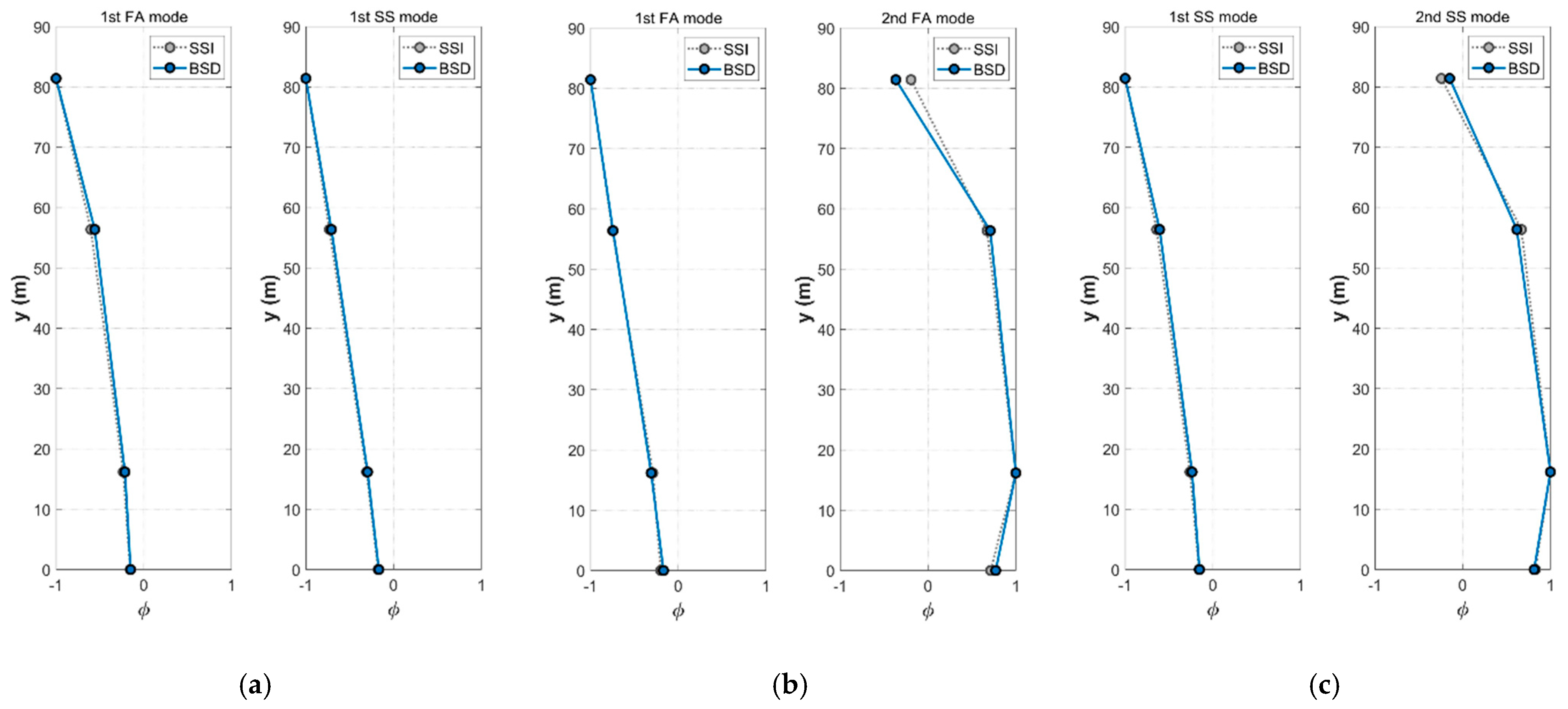

4.3. Modal Parameter Identification Results Comparison and Validation

5. Conclusions

- (1)

- The second bending mode is identifiable only under idle conditions, as rotor harmonics under rated speed mask its response. In contrast, the first bending mode and the blade-passing frequency are accurately identified. The first bending modal frequency lies between 1P and 3P, indicating that the wind turbine exhibits a typical “soft-stiff” design.

- (2)

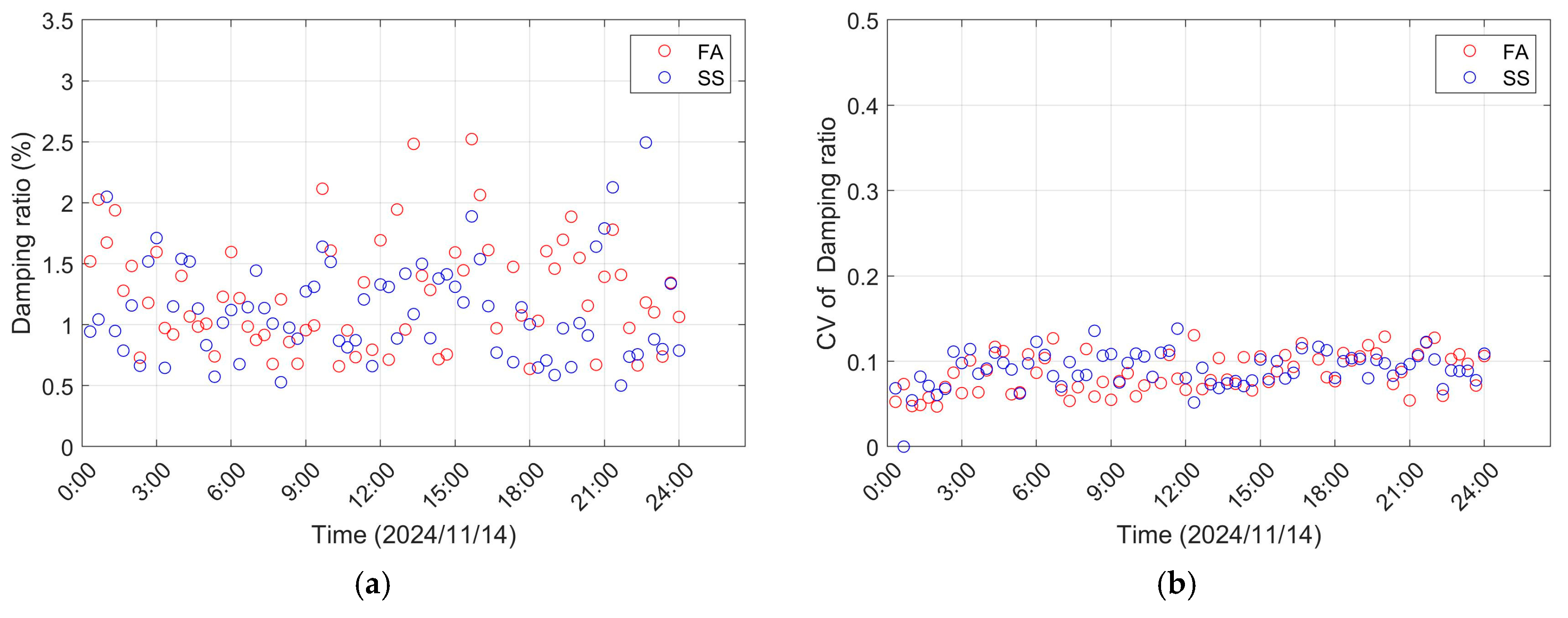

- Under rated rotor speed conditions, the tower exhibits noticeably higher damping ratios in both the FA and SS directions compared with the idle state, with a more substantial increase observed in the FA direction. Nevertheless, the fundamental bending frequency of the tower remains largely unchanged across the two operating conditions.

- (3)

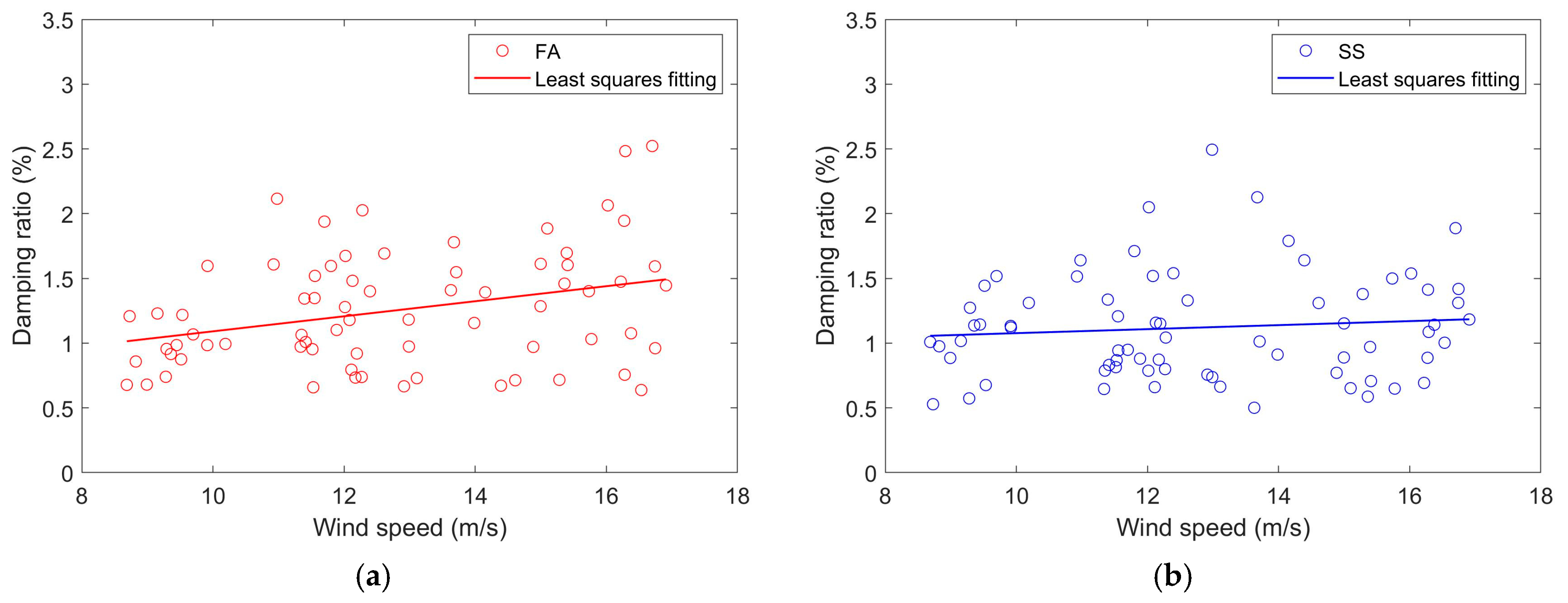

- At the rated rotor speed, the first damping ratio in the FA direction shows a clear increasing tendency with rising wind speed, whereas no evident dependence on wind speed is detected in the SS direction. This increase is primarily attributed to aerodynamic damping, indicating that it plays a dominant role in the FA response.

- (4)

- The MAC values calculated for the identified mode shapes are nearly unity under both the rated and idle states, confirming the high consistency and reliability of the identified modal shapes.

- (5)

- The BSD approach effectively and accurately identified the tower’s modal characteristics while quantifying the associated uncertainties. The analysis further reveals that the damping ratios exhibit larger uncertainty than the corresponding frequencies.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Renewables 2020: Analysis and Forecast to 2025; International Energy Agency: Washington, DC, USA, 2020.

- Chou, J.; Ou, Y.; Lin, K. Collapse Mechanism and Risk Management of Wind Turbine Tower in Strong Wind. J. Wind Eng. Ind. Aerodyn. 2019, 193, 103962. [Google Scholar] [CrossRef]

- Tchakoua, P.; Wamkeue, R.; Ouhrouche, M.; Slaoui-Hasnaoui, F.; Tameghe, T.A.; Ekemb, G. Wind Turbine Condition Monitoring: State-of-the-Art Review, New Trends, and Future Challenges. Energies 2014, 7, 2595–2630. [Google Scholar] [CrossRef]

- Kuang, R.; Zhao, J.; Zhang, T.; Li, C. Research on Parameter Influence of Offshore Wind Turbines Based on Measured Data Analysis. J. Mar. Sci. Eng. 2025, 13, 629. [Google Scholar] [CrossRef]

- Partovi-Mehr, N.; Branlard, E.; Song, M.; Moaveni, B.; Hines, E.M.; Robertson, A. Sensitivity Analysis of Modal Parameters of a Jacket Offshore Wind Turbine to Operational Conditions. J. Mar. Sci. Eng. 2023, 11, 1524. [Google Scholar] [CrossRef]

- Qu, C.-X.; Liu, C.-C.; Yang, X.-M.; Liu, H.-J.; Li, H.-N.; Zhang, Y.-F. Modal Identification of Structures by Eliminating the Effect of the High Ocean Wind. J. Mar. Sci. Eng. 2022, 10, 1509. [Google Scholar] [CrossRef]

- Tian, S.; Wang, Z.; Zhang, C. Nonlinear Resonance Characteristics of Offshore Wind Turbines with Large Diameter Monopile Foundation. Rock Soil Mech. 2025, 46, 156–164. [Google Scholar] [CrossRef]

- Bajric, A.; Hogsberg, J.; Rüdinger, F. Evaluation of Damping Estimates by Automated Operational Modal Analysis for Offshore Wind Turbine Tower Vibrations. Renew. Energy 2018, 116, 153–163. [Google Scholar] [CrossRef]

- Dai, K.; Wang, Y.; Lu, W.; Ren, X.; Huang, Z. Investigation of the Stochastic Subspace Identification Method for On-Line Wind Turbine Tower Monitoring; Wu, H., Gyekenyesi, A., Shull, P., Yu, T., Eds.; SPIE: Bellingham, WA, USA, 2017; Volume 10169. [Google Scholar]

- Zhang, P.; He, Z.; Cui, C.; Ren, L.; Yao, R. Operational Modal Analysis of Offshore Wind Turbine Tower under Ambient Excitation. J. Mar. Sci. Eng. 2022, 10, 1963. [Google Scholar] [CrossRef]

- Zhang, C.; Han, X.; Li, C.; Leira, B.J.; Sævik, S.; Lu, D.; Shi, W.; Li, X. Modal Parameter Identification of Jacket-Type Offshore Wind Turbines Under Operating Conditions. J. Mar. Sci. Eng. 2024, 12, 2083. [Google Scholar] [CrossRef]

- Oh, S.; Ishihara, T. On the Parameter Sensitivity in Structural Parameter Identification Using Eigensystem Realization Algorithm for a MW-Size Wind Turbine; IOP Publishing: Bristol, UK, 2018; Volume 1037. [Google Scholar]

- Mieloszyk, M.; Opoka, S.; Ostachowicz, W. Frequency Domain Decomposition Performed on the Strain Data Obtained from the Aluminium Model of an Offshore Support Structure; IOP Publishing: Bristol, UK, 2015; Volume 628. [Google Scholar]

- Koukoura, C.; Natarajan, A.; Vesth, A. Identification of Support Structure Damping of a Full Scale Offshore Wind Turbine in Normal Operation. Renew. Energy 2015, 81, 882–895. [Google Scholar] [CrossRef]

- Devriendt, C.; Magalhaes, F.; Weijtjens, W.; De Sitter, G.; Cunha, A.; Guillaume, P. Structural Health Monitoring of Offshore Wind Turbines Using Automated Operational Modal Analysis. Struct. Health Monit. 2014, 13, 644–659. [Google Scholar] [CrossRef]

- Hines, E.M.; Baxter, C.D.P.; Ciochetto, D.; Song, M.; Sparrevik, P.; Meland, H.J.; Strout, J.M.; Bradshaw, A.; Hu, S.-L.; Basurto, J.R.; et al. Structural Instrumentation and Monitoring of the Block Island Offshore Wind Farm. Renew. Energy 2023, 202, 1032–1045. [Google Scholar] [CrossRef]

- Song, M.; Partovi Mehr, N.; Moaveni, B.; Hines, E.; Ebrahimian, H.; Bajric, A. One Year Monitoring of an Offshore Wind Turbine: Variability of Modal Parameters to Ambient and Operational Conditions. Eng. Struct. 2023, 297, 117022. [Google Scholar] [CrossRef]

- Bayne, S.; Giesselmann, M. Effect of Blade Passing on a Wind Turbine Output. In Collection of Technical Papers. 35th Intersociety Energy Conversion Engineering Conference and Exhibit (IECEC) (Cat. No.00CH37022); IEEE: New York, NY, USA, 2000; pp. 775–781. [Google Scholar]

- Hamdi, H.; Mrad, C.; Hamdi, A.; Nasri, R. Dynamic Response of a Horizontal Axis Wind Turbine Blade under Aerodynamic, Gravity and Gyroscopic Effects. Appl. Acoust. 2014, 86, 154–164. [Google Scholar] [CrossRef]

- Zhang, F.; Kim, C.; Goi, Y. Efficient Bayesian FFT Method for Damage Detection Using Ambient Vibration Data with Consideration of Uncertainty. Struct. Control Health Monit. 2021, 28, e2659. [Google Scholar] [CrossRef]

- Yan, W.; Katafygiotis, L. A Two-Stage Fast Bayesian Spectral Density Approach for Ambient Modal Analysis. Part I: Posterior Most Probable Value and Uncertainty. Mech. Syst. Signal Process. 2015, 54–55, 139–155. [Google Scholar] [CrossRef]

- Zhang, F.; Au, S. Fast Bayesian FFT Method for Ambient Modal Identification with Separated Modes. J. Eng. Mech. 2011, 137, 214–226, Erratum in J. Eng. Mech. 2013, 139, 545. [Google Scholar] [CrossRef]

- Bhattacharya, S. Design of Foundations for Offshore Wind Turbines, 1st ed.; Wiley: Hoboken, NJ, USA, 2019; ISBN 978-1-119-12812-0. [Google Scholar]

- Feng, Z.; Zhang, J.; Wen, Q.; Shi, S. Bayesian Spectral Decomposition Method for Identifying Modal Parameters in Long-Span Cable-Stayed Bridges under Ambient Excitation. J. Vib. Eng. 2024, 1–10. Available online: https://link.cnki.net/urlid/32.1349.TB.20240830.1706.002 (accessed on 17 October 2025). (In Chinese).

- Feng, Z.; Zhang, J.; Katafygiotis, L.; Hua, X.; Chen, Z. Bayesian Spectral Decomposition for Efficient Modal Identification Using Ambient Vibration. Struct. Control Health Monit. 2024, 2024, 5137641. [Google Scholar] [CrossRef]

- Brincker, R.; Zhang, L.; Andersen, P. Modal Identification of Output-Only Systems Using Frequency Domain Decomposition. Smart Mater. Struct. 2001, 10, 441–445. [Google Scholar] [CrossRef]

- Guo, L.; Xu, Z.; Sun, Y.; Bai, Z.; Li, H.; Yao, S. Effect of Initial Shear Stress on Soft Clay around Monopile and Natural Frequency of Offshore Wind Turbine Structure. Soil Dyn. Earthq. Eng. 2025, 191, 109265. [Google Scholar] [CrossRef]

- Greś, S.; Döhler, M.; Mevel, L. Uncertainty Quantification of the Modal Assurance Criterion in Operational Modal Analysis. Mech. Syst. Signal Process. 2021, 152, 107457. [Google Scholar] [CrossRef]

- Jiang, J.; Lian, J.; Dong, X.; Zhou, H. Research on the Along-Wind Aerodynamic Damping and Its Effect on Vibration Control of Offshore Wind Turbine. Ocean Eng. 2023, 274, 113993. [Google Scholar] [CrossRef]

| Mode | Natural Frequency (Hz) | Damping Ratio (%) | ||

|---|---|---|---|---|

| Mean | Std | Mean | Std | |

| 1st FA | 0.284 | 0.0011 | 1.253 | 0.450 |

| 1st SS | 0.284 | 0.0013 | 1.120 | 0.408 |

| Mode | Data Segment | Natural Frequency (Hz) | Mean | CV | Damping Ratios (%) | Mean | CV |

|---|---|---|---|---|---|---|---|

| 1st FA | 1# | 0.283 | 0.283 | 0.0012 | 0.915 | 0.944 | 0.0830 |

| 2# | 0.283 | 0.0009 | 0.994 | 0.0687 | |||

| 3# | 0.283 | 0.0009 | 0.924 | 0.0832 | |||

| 1st SS | 1# | 0.285 | 0.284 | 0.0011 | 0.827 | 0.960 | 0.0829 |

| 2# | 0.283 | 0.0009 | 1.081 | 0.0546 | |||

| 3# | 0.283 | 0.0009 | 0.971 | 0.0526 | |||

| 2nd FA | 1# | 1.394 | 1.395 | 0.0013 | 2.827 | 2.609 | 0.0235 |

| 2# | 1.391 | 0.0009 | 2.280 | 0.0244 | |||

| 3# | 1.401 | 0.0012 | 2.719 | 0.0234 | |||

| 2nd SS | 1# | 1.393 | 1.394 | 0.0012 | 2.677 | 2.458 | 0.0237 |

| 2# | 1.390 | 0.0010 | 2.206 | 0.0249 | |||

| 3# | 1.399 | 0.0011 | 2.490 | 0.0251 |

| Data Segment | MAC * | |||

|---|---|---|---|---|

| 1st FA | 1st SS | 2nd FA | 2nd SS | |

| 1# | 1.0000 | 1.0000 | 1.0000 | 1.0000 |

| 2# | 0.9995 | 1.0000 | 0.9784 | 0.9845 |

| 3# | 0.9997 | 0.9999 | 0.9718 | 0.8903 |

| Condition | Mode | Parameter | SSI Method | BSD Method | |

|---|---|---|---|---|---|

| Identified | CV | ||||

| rated rotor speed (0:00–00:20) | 1st FA | f (Hz) | 0.286 | 0.287 | 0.0013 |

| 1.455% | 1.519% | 0.0525 | |||

| 1st SS | f (Hz) | 0.286 | 0.285 | 0.0010 | |

| 0.961% | 0.943% | 0.0684 | |||

| idle state (data segment #1) | 1st FA | f (Hz) | 0.286 | 0.283 | 0.0012 |

| 0.944% | 0.915% | 0.0830 | |||

| 1st SS | f (Hz) | 0.285 | 0.285 | 0.0011 | |

| 0.812% | 0.827% | 0.0829 | |||

| 2nd FA | f (Hz) | 1.404 | 1.394 | 0.0013 | |

| 2.876% | 2.827% | 0.0235 | |||

| 2nd SS | f (Hz) | 1.395 | 1.393 | 0.0012 | |

| 2.602% | 2.677% | 0.0237 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rao, M.; Hua, X.; Yu, C.; Feng, Z.; Deng, J.; Yang, Z.; Zhang, Y.; Deng, F.; Wu, Z. Operational Modal Analysis of a Monopile Offshore Wind Turbine via Bayesian Spectral Decomposition. J. Mar. Sci. Eng. 2025, 13, 2326. https://doi.org/10.3390/jmse13122326

Rao M, Hua X, Yu C, Feng Z, Deng J, Yang Z, Zhang Y, Deng F, Wu Z. Operational Modal Analysis of a Monopile Offshore Wind Turbine via Bayesian Spectral Decomposition. Journal of Marine Science and Engineering. 2025; 13(12):2326. https://doi.org/10.3390/jmse13122326

Chicago/Turabian StyleRao, Mumin, Xugang Hua, Chi Yu, Zhouquan Feng, Jiayi Deng, Zengru Yang, Yuhuan Zhang, Feiyun Deng, and Zhichao Wu. 2025. "Operational Modal Analysis of a Monopile Offshore Wind Turbine via Bayesian Spectral Decomposition" Journal of Marine Science and Engineering 13, no. 12: 2326. https://doi.org/10.3390/jmse13122326

APA StyleRao, M., Hua, X., Yu, C., Feng, Z., Deng, J., Yang, Z., Zhang, Y., Deng, F., & Wu, Z. (2025). Operational Modal Analysis of a Monopile Offshore Wind Turbine via Bayesian Spectral Decomposition. Journal of Marine Science and Engineering, 13(12), 2326. https://doi.org/10.3390/jmse13122326