1. Introduction

1.1. Background and Motivation

The IMO, through the “2023 IMO Strategy on Reduction of Greenhouse Gas Emissions from Ships (MEPC.377(80)),” has set a target of reducing carbon emissions in the international shipping sector to net-zero by 2050 compared with 2008 levels. The strengthening of environmental regulations is accelerating the decarbonization of the maritime industry, making not only low carbon fuels such as LNG and methanol but also zero-carbon fuels such as ammonia and hydrogen essential. In particular, the localization of core component technologies suitable for the characteristics of alternative fuels, as well as integrated system research for propulsion systems, is directly linked to securing competitiveness in eco-friendly ship technologies.

Hydrogen is attracting attention as a representative zero carbon fuel that does not emit carbon dioxide during combustion, and is considered a key alternative energy source for achieving carbon neutrality. Among its forms, LH2 offers distinct advantages in long-distance transportation and large-scale storage, as its volume can be reduced to approximately 1/800 of its gaseous state when liquefied at −253 °C. However, the volumetric energy density of LH2 is only about 8.5 MJ/L, which corresponds to roughly 40–60% of LNG. Consequently, transporting the same amount of energy requires more than 2.5 times the cargo space and voyage frequency compared with LNG, resulting in significantly higher logistics costs and technical burdens. Furthermore, since LH2 must be handled under cryogenic conditions (−253 °C), several challenges arise, including increased boil-off gas (BOG) generation during transportation, material degradation due to hydrogen embrittlement, and potential risks of explosion and fire. These issues have been repeatedly highlighted by policymakers and industry stakeholders, indicating that systematic verification of safe and reliable storage, transfer, and vaporization technologies is indispensable for the commercialization of hydrogen as a marine fuel.

Compared with the LNG sector, test and evaluation standards to ensure the safety and performance of liquefied hydrogen storage tanks and FGSS during design, construction, and operation remain limited. First, relevant standards are fragmented across functions such as storage tanks, piping/valves, safety guidelines, control/instrumentation, and risk assessment, resulting in insufficient integration. Second, clear requirements for land-based integrated testing with shipboard application in mind are not explicitly presented. Third, inconsistencies exist among international, domestic, and classification society standards in defining test items and methods, making cross-comparison and regulatory compliance challenging. These constraints act as major obstacles to the commercialization of LH2 systems, underscoring the need for a consistent evaluation protocol prior to shipboard application.

Currently, standards such as KGS AC111 [

1], ISO/TR 15916 [

2], and CGA H-3 [

3] are available internationally, but applying them directly to domestic demonstration environments poses limitations. In particular, large-scale ships face significant risks and costs associated with handling cryogenic fuels, highlighting the need for stepwise research and development focused initially on small- to medium-sized ships, where system scale and demonstration feasibility are more favorable. Accordingly, this study establishes an FGSS test and evaluation protocol tailored to domestic demonstration environments. By analyzing and comparing existing test standards, the study proposes an integrated test and evaluation methodology applicable to LH

2 storage and supply systems for small to medium sized vessels. The proposed framework is expected not only to serve as a reliable reference in subsequent sea trials and commercialization stages but also to contribute to strengthening the competitiveness of Korea’s eco-friendly shipbuilding industry.

1.2. Research Objectives and Scope

The purpose of this study is to propose an integrated test and evaluation protocol applicable to LH2 storage tanks and fuel gas supply systems (FGSS) for small- to medium-sized vessels, based on the analysis and comparison of domestic and international standards. Through this approach, the study aims to establish a fundamental framework for reliably verifying the safety and performance of FGSS prior to shipboard application.

The specific research objectives are as follows:

Establishment of test items, methods, and acceptance criteria: Define test items focused on supply performance, vaporization/heating performance, and safety functions, and specify corresponding measurement methods and permissible tolerance ranges.

Mapping and application guidance of standards: Compare and integrate domestic and international evaluation standards to establish practical guidelines adapted to domestic demonstration environments.

Formulation of test and evaluation procedures: Develop a step-by-step protocol applicable to land-based FGSS testing, based on the above analysis and standard mapping.

The scope of this study is defined as follows:

The research is limited to FGSS for small- to medium-sized vessels, excluding applications to large-scale ships.

Considering the constraints of direct LH2 testing, LN2 is adopted as a surrogate medium. Numerical process simulations are not part of the present work and are proposed for future studies.

The study focuses on establishing test and evaluation protocols for the design, construction, and operation phases, while excluding analyses of economic feasibility, policies, and institutional frameworks.

1.3. Review of Previous Studies

Existing studies and standards related to the testing and evaluation of LH

2 storage tanks and FGSS remain in the early stages of development. The IMO provides safety requirements for ships using low-flashpoint fuels through the International Code of Safety for Ships Using Gases or Other Low-flashpoint Fuels (IGF Code) [

4]. However, explicit regulations for hydrogen fuel systems, particularly those employing LH

2, are still lacking. At present, only interim guidelines such as MSC.1/Circ.1647 (Interim Guidelines for Fuel Cell Power Installations) [

5] supplement certain safety requirements, while the SOLAS I-2-55 (Alternative Design and Arrangements) [

6] regulation is applied for alternative design and arrangement procedures.

From the perspective of international standards, ISO/TR 15916:2015 [

2] outlines fundamental safety considerations for hydrogen systems, addressing hazards such as pressure, cryogenic conditions, leakage, and hydrogen embrittlement. Similarly, CGA H-3 [

3] specifies design, construction, and inspection requirements for LH

2 storage tanks. However, these documents are primarily limited to general safety guidelines and do not present integrated testing and evaluation procedures specifically for ship applications.

In Korea, international standards have been harmonized domestically through KS B ISO/TR 15916 [

7], KGS AC111 [

1], and KGS AC115 [

8], which regulate procedures for the fabrication and inspection of pressure vessels and cryogenic storage tanks. Nevertheless, these standards are largely based on LNG testing methods and thus do not sufficiently account for BOG generation at −253 °C or material degradation due to hydrogen embrittlement.

Classification societies, including KR [

9], DNV [

10], and ABS [

11], have also developed guidelines for ships using low-flashpoint fuels. For example, DNV introduced its Gas Fuelled Hydrogen rules in 2024 to define design and inspection items for hydrogen fuel systems, while ABS issued the Requirements for Hydrogen Fueled Vessels (2023) [

11] to provide guidance for hydrogen-fueled applications. However, these documents also remain focused on design approval and safety considerations rather than on specific testing and evaluation procedures.

With regard to demonstration projects, Norway’s MF Hydra [

12] became the world’s first passenger ship equipped with an LH

2 storage tank to enter commercial operation in March 2023, while Japan’s Suiso Frontier [

13] conducted demonstration voyages for LH

2 sea transport between Japan and Australia from 2021 to 2022. In addition, EU projects such as HySHIP [

14] and AUTOSHIP [

15] have explored demonstration studies integrating LH

2 and autonomous navigation technologies. Nevertheless, these initiatives mainly focus on system integration and concept validation for large transport or passenger vessels and have not directly contributed to establishing land-based FGSS testing and evaluation procedures.

However, a closer examination reveals that most demonstration projects such as MF Hydra, Suiso Frontier, and HySHIP have primarily focused on system integration and storage-tank engineering rather than on systematic FGSS testing. The MF Hydra project validated the integration of a 350-bar gaseous hydrogen FGSS but did not include standardized testing for boil-off management or vaporization stability under cryogenic conditions. The Suiso Frontier project demonstrated large scale LH2 sea transport between Japan and Australia; however, its FGSS was intended for cargo transfer, not continuous fuel-supply operation. Likewise, HySHIP and AUTOSHIP mainly addressed propulsion and autonomous control, with limited quantitative evaluation of the fuel-gas conditioning and control performance.

These analyses indicate that, despite global progress in hydrogen ship demonstrations, there remains no reproducible, land-based test methodology to evaluate the dynamic behavior of LH2 FGSS. Prior projects have verified conceptual feasibility and overall system safety but have not defined measurable performance criteria or test reproducibility for FGSS components.

Therefore, this study directly addresses these gaps by developing a systematic and quantitative test evaluation framework for LH2 FGSS applicable to small to medium sized ships. Unlike previous studies that only cataloged or compared standards, the present research transforms descriptive regulatory mapping into a data-driven and verifiable testing methodology linking international regulations to measurable engineering parameters and acceptance criteria.

In particular, a thermodynamic LN2 and LH2 equivalence framework is introduced to enable safe surrogate testing, and a structured evaluation protocol is proposed to assess vaporization and heating performance of marine FGSS. This approach provides both a theoretical foundation and an experimental pathway for future LH2 system validation and standardization, bridging the gap between regulatory guidance and practical test implementation.

1.4. Studies Framework

Building upon the literature review, this study establishes a conceptual and methodological framework that connects the identified research gap to measurable evaluation outcomes.

The key hypothesis is that an LN2 based surrogate testing framework can reproduce the thermodynamic and operational behavior of LH2 FGSS within an acceptable tolerance band, thereby enabling safe and quantitative validation of system performance without direct hydrogen handling.

From this hypothesis, the following research questions are derived:

How can thermodynamic equivalence between LN2 and LH2 be quantitatively defined and validated?

What measurable indicators (e.g., flow rate stability, vaporization efficiency, and heating capacity) can be used to assess FGSS performance under surrogate conditions?

What acceptance criteria and tolerances (e.g., ±5% heat-balance deviation, ±3% PRV accuracy, and ≤5 s ESD response) can ensure reproducible and safe prototype testing?

To address these questions, the study constructs an integrated test–evaluation framework consisting of three sequential steps: (1) analytical comparison of existing domestic and international standards to define test boundaries, (2) development of an LN2 and LH2 thermodynamic equivalence model based on the First Law of Thermodynamics, and (3) experimental validation through controlled vaporization and heating tests.

This structured approach explicitly links the problem statement (absence of LH

2 FGSS testing standards) to measurable outcomes (quantitative performance indices and acceptance criteria), forming the scientific foundation of the proposed evaluation protocol described in

Section 3.

2. Standards and Guidelines Analysis

The land-based test procedures for LH2 storage tanks and FGSS proposed in this study were established through a comprehensive review of international standards, domestic regulations, and classification society guidelines. Since the target vessels for applying the developed procedures are planned to be constructed and operated in Korea, domestic standards were prioritized among the various international frameworks.

2.1. International Regulations and Guidelines

The IMO has established fundamental safety requirements for ships using low-flashpoint fuels through the International Code of Safety for Ships Using Gases or Other Low-flashpoint Fuels (IGF Code) [

4]. While the IGF Code covers alternative fuels such as LNG and methanol, it does not include specific provisions for hydrogen or LH

2.

The MSC.1/Circ.1647 (Interim Guidelines for Fuel Cell Power Installations) [

5] provides minimum safety requirements for ships equipped with hydrogen fuel cells. However, its scope is primarily focused on the fuel cell system itself rather than on the broader FGSS, including storage and supply arrangements.

In addition, SOLAS Regulation II-1/55 (Alternative Design and Arrangements) [

6] defines an approval process that allows the use of alternative fuels not explicitly covered by existing regulations through risk-based design approaches. This framework, however, is applied on a case-by-case basis to individual design projects and is therefore not directly linked to standardized testing and evaluation procedures.

In summary, current international regulations and guidelines provide principle-based safety frameworks for the application of low-flashpoint fuels. Nevertheless, they lack test protocols, verification methods, and evaluation criteria specifically tailored to LH2 systems, leaving a critical gap in regulatory coverage.

2.2. International Standards

With regard to international standards related to liquefied hydrogen, ISO/TR 15916:2015, Basic Considerations for the Safety of Hydrogen Systems [

2], was reviewed. This technical report provides general safety considerations for both gaseous and liquid hydrogen systems, covering major hazards such as pressure, cryogenic conditions, leakage, and hydrogen embrittlement, as well as corresponding design, operation, and emergency response measures. In particular, requirements such as ignition source control due to hydrogen’s wide flammability range (4–75% vol) and low minimum ignition energy (0.02 MJ), stepwise cool-down procedures, helium and hydrogen leak detection, open-type ventilation and explosion-proof design, and the operation of emergency shut-off devices were directly reflected in the safety management criteria of the present test protocol.

Furthermore, the international guidelines addressing hydrogen safety, including ISO/TR 15916 (2020) and CGA H-3 (2021), also emphasize the importance of material compatibility and resistance to hydrogen embrittlement for cryogenic systems. These documents recommend austenitic stainless steels and nickel-based alloys, which retain ductility and toughness at cryogenic temperatures while exhibiting relatively low hydrogen-induced degradation owing to their face-centered cubic (FCC) crystal structure. In contrast, ferritic and martensitic steels are prone to micro-cracking under hydrogen exposure and are therefore excluded from use in pressure-bearing components. The same principle has been adopted in KGS AC115 [

8], ensuring that cryogenic piping and vessel materials in hydrogen fuel systems satisfy both low-temperature fracture toughness and hydrogen compatibility requirements.

However, as general guidelines, these standards do not yet provide ship-specific applications or standardized testing and evaluation procedures. Similarly, CGA H-3 offers useful provisions for the design of liquefied hydrogen storage tanks to ensure tank safety, but it does not address the unique operational conditions of ships—such as dynamic environments, wave loads, impacts, and maritime leak response requirements—that are essential for marine applications.

2.3. Korean Standards

Domestic standards applied in this study include KS B ISO/TR 15916 (2021) [

7], KGS AC111 [

1], and KGS AC115 [

8]. KS B ISO/TR 15916 is the Korean translation of ISO/TR 15916 and contains identical content, addressing general safety concepts for hydrogen systems, including hazards such as high pressure, cryogenic conditions, leakage, hydrogen embrittlement, and explosive mixtures, as well as basic safety measures such as leak detection, ventilation, isolation, and material selection. However, as a technical report (TR), it does not provide detailed test procedures or design criteria.

KGS AC111 provides the basic framework for the fabrication and inspection of high-pressure vessels, while KGS AC115 specifies structural fabrication and testing methods for cryogenic storage tanks. Nevertheless, both documents are primarily focused on LNG applications and do not fully reflect the more extreme cryogenic conditions of LH2 (−253 °C) or adequately address hydrogen embrittlement.

In this study, the common and complementary elements of AC111 and AC115 were combined, and the specific safety requirements of ISO/TR 15916 were additionally incorporated. This approach ensures that unique safety requirements of LH2 such as cryogenic conditions, high flammability, and material embrittlement are adequately considered.

However, despite these integrations, no domestic technical standards or unified testing criteria currently exist for the manufacturing, storage, and refueling of LH2 systems. The following section therefore discusses the regulatory and institutional limitations that currently restrict hydrogen demonstration projects in Korea and highlights the need for a dedicated land-based LH2 testing and evaluation protocol.

2.4. Classification Society Guidelines

Classification societies have also developed guidelines for ships using low-flashpoint fuels. For instance, DNV introduced a new section titled Gas Fuel Hydrogen in its Rules for Classification: Ships (2024) [

10], defining requirements for hydrogen fuel system design, fuel supply connections, and inspection. ABS published the Requirements for Hydrogen Fueled Vessels (2023) [

11] and the Requirements for Fuel Cell Power Systems for Marine and Offshore Applications [

12], which present requirements and risk assessment frameworks for hydrogen-fueled vessels, covering dual-fuel engines and fuel cell systems. These documents differentiate hydrogen-specific risks from those of other gaseous fuels and provide detailed guidance on fuel cell applications.

The Korean Register (KR) issued the Rules & Guidance for Classification of Ships Using Low-flashpoint Fuels (2022) [

9], which stipulate inspection and testing requirements such as external and internal inspections of storage tanks, vacuum monitoring, insulation condition verification, non-destructive testing (NDT), pressure and tightness tests, secondary barrier performance tests, bunkering control and shut-off function tests, remote/local operation of main fuel valves, verification of double shut off and automatic shut-off functions in gas supply units, and ensuring the suitability of compressors and pumps for marine environments. These documents also provide dedicated safety and control guidelines for onboard fuel cell systems.

However, the guidelines of classification societies primarily serve as design conformity documents and do not specify standardized test procedures, environmental conditions, or quantitative acceptance criteria from an evaluation perspective.

2.5. Demonstration Projects

In Japan, the Suiso Frontier [

13], a 1250 m

3 liquefied hydrogen carrier, was constructed under the HySTRA project and conducted demonstration voyages between Japan and Australia in 2021–2022. This project verified the technical feasibility of long-distance LH

2 marine transport. However, it was focused on large-scale cargo containment systems and did not directly address test procedures for small- to medium-scale fuel tanks and FGSS.

In Europe, projects such as HySHIP [

14] and AUTOSHIP [

15] have aimed to validate the integrated design of LH

2 tanks, FGSS, and fuel cell propulsion systems in RoRo vessels. Although these projects have proposed operation models for LH

2-fueled ships from a system integration perspective, like the Japanese initiative, they were oriented toward large vessels. Land-based performance testing protocols were only addressed peripherally, and no dedicated standardized procedures were developed.

To date, demonstration cases involving LH2-fueled ships have all been limited to large-scale vessels, primarily focusing on system integration and concept validation. As such, they have not directly contributed to establishing standardized, land-based performance testing protocols for LH2 tanks and FGSS intended for small- to medium-sized vessels.

2.6. Integrated Analysis

The reviewed international regulations and guidelines provide goal and principle-based safety frameworks for ships using low-flashpoint fuels. However, they lack LH2-specific test procedures, leaving projects to rely on the Alternative Design and Arrangements pathway on a case-by-case basis. International standards provide fundamental safety guidance for hydrogen systems but do not offer ship-specific testing and evaluation methods. Korean standards present requirements for risk management, fabrication, and inspection but are still LNG-oriented and insufficiently reflect hydrogen-specific characteristics. Classification society guidelines define design requirements for ships using hydrogen and fuel cells but do not provide standardized test methods or quantitative acceptance criteria.

The comparative analysis in

Table 1 highlights that existing international and domestic frameworks collectively ensure the safety design intent of hydrogen-fueled ships but fail to establish quantitative, test-oriented protocols. While the IMO IGF Code and classification society rules define the regulatory boundary, they are primarily goal-based and qualitative. In contrast, ISO/TR 15916 and CGA H-3 specify safety considerations for cryogenic hydrogen but remain non-specific to marine FGSS configurations. The Korean KGS AC111/115 standard fills part of the procedural gap by defining fabrication and inspection requirements; however, it still reflects LNG system logic rather than LH

2 behavior. This analysis demonstrates that no existing standard integrates the design criteria, testing environment, and quantitative acceptance limits into a single, verifiable framework an absence that directly motivated the protocol development presented in

Section 3.

To bridge this gap, this study reinterprets each standard and guideline through the perspective of FGSS performance verification. The methodology involves mapping qualitative safety requirements such as ignition prevention, pressure relief, and emergency shut down into measurable parameters: ±5% flow and pressure stability, 1–2 s ESD response, and defined thermal balance ranges. This translation transforms abstract safety objectives into practical testing metrics, forming the basis of the proposed land-based LH2 evaluation protocol.

On the other hand, several demonstration projects have verified the technical feasibility of LH2 and its integrated system operation, but these efforts have been primarily focused on large-scale vessels, and standardized test procedures remain limited or undisclosed. The Suiso Frontier project demonstrated the technical feasibility of storage, transportation, and unloading procedures through long-distance maritime transport; however, the associated test protocols were either limited in scope or not publicly available. Similarly, the HySHIP project proposed an integrated operational model combining storage, supply, fuel cells, and digital systems, but no detailed testing procedures were confirmed.

The comparison in

Table 2 further shows that although these projects validated system integration and safety feasibility, they still lack transparency and standardization in testing methodology, measurement accuracy, and acceptance ranges. This reinforces the conclusion that current demonstration efforts contribute primarily to concept validation rather than to the establishment of reproducible evaluation frameworks.

Therefore, although existing international regulations, standards, classification society guidelines, and demonstration cases have demonstrated the safety and technical feasibility of LH2 fuel systems, there is still a lack of structured, quantitative, and standardized test and evaluation procedures for practical ship applications. Accordingly, it is necessary to develop a systematic protocol that translates LH2 specific design and safety requirements into well defined test items, environmental conditions, and acceptance criteria tailored for shipboard fuel system operations.

2.7. Regulatory Context in Korea

In Korea, despite ongoing revisions to the High-Pressure Gas Safety Control Act (HPGSA) and the 27 KGS Codes, there are still no detailed technical or inspection standards specifically defined for the manufacturing, storage, transportation, or refueling of LH2. As a result, both manufacturing and operational activities related to LH2 remain legally constrained.

Although Korea has enacted the world’s first dedicated Hydrogen Economy Promotion and Hydrogen Safety Management Act (Hydrogen Act), industrial practice is still largely governed by the older HPGSA, resulting in a dual regulatory structure. This overlapping framework has delayed authorization and safety validation procedures for hydrogen-related demonstration projects, thus hindering the deployment of new technologies and practical pilot operations.

To bridge this regulatory gap, the present study proposes a land based LH2 testing and evaluation protocol that aligns with international standards while ensuring compatibility with domestic regulatory requirements. This framework aims to provide a technical foundation for the establishment of national certification and demonstration systems for LH2 FGSS.

3. Materials and Methods

This section describes the overall methodology used to develop and verify the proposed test protocol, including the configuration of the FGSS, test procedures, and evaluation criteria.

In addition to describing the FGSS configuration, the present section defines the methodological framework used to conduct and verify each test. Prior to each run, the test loop was purged with gaseous nitrogen and pre-cooled to cryogenic equilibrium. All temperature sensors (Pt100, class A) were calibrated within ±0.5 °C, and flow meters (Coriolis type) were verified with ±1% accuracy. Data were recorded at 1 Hz using a 16-channel data logger, and steady-state intervals were identified using a 5-point moving-average filter to suppress transient noise. Each test was repeated three times under identical boundary conditions to confirm reproducibility. Measurement uncertainty was evaluated by combining instrument precision and repeatability errors. The expanded uncertainty of outlet temperature was estimated at ±2.1 °C (95% confidence level), ensuring the reliability and traceability of the reported results.

3.1. System Components

FGSS considered in this study is divided into four functional modules: storage section, supply section, heating section, and control/safety section.

3.1.1. Storage Section

The fuel tank is designed as a C-type cryogenic storage tank with vacuum insulation. It has a capacity on the order of several cubic meters and a design pressure of approximately 10 bar. To ensure long-term cryogenic storage, a multi layer insulation (MLI) system combined with full vacuum technology is applied. The tank material is selected from cryogenic stainless steel alloys, which provide sufficient mechanical strength and fracture toughness at cryogenic temperatures.

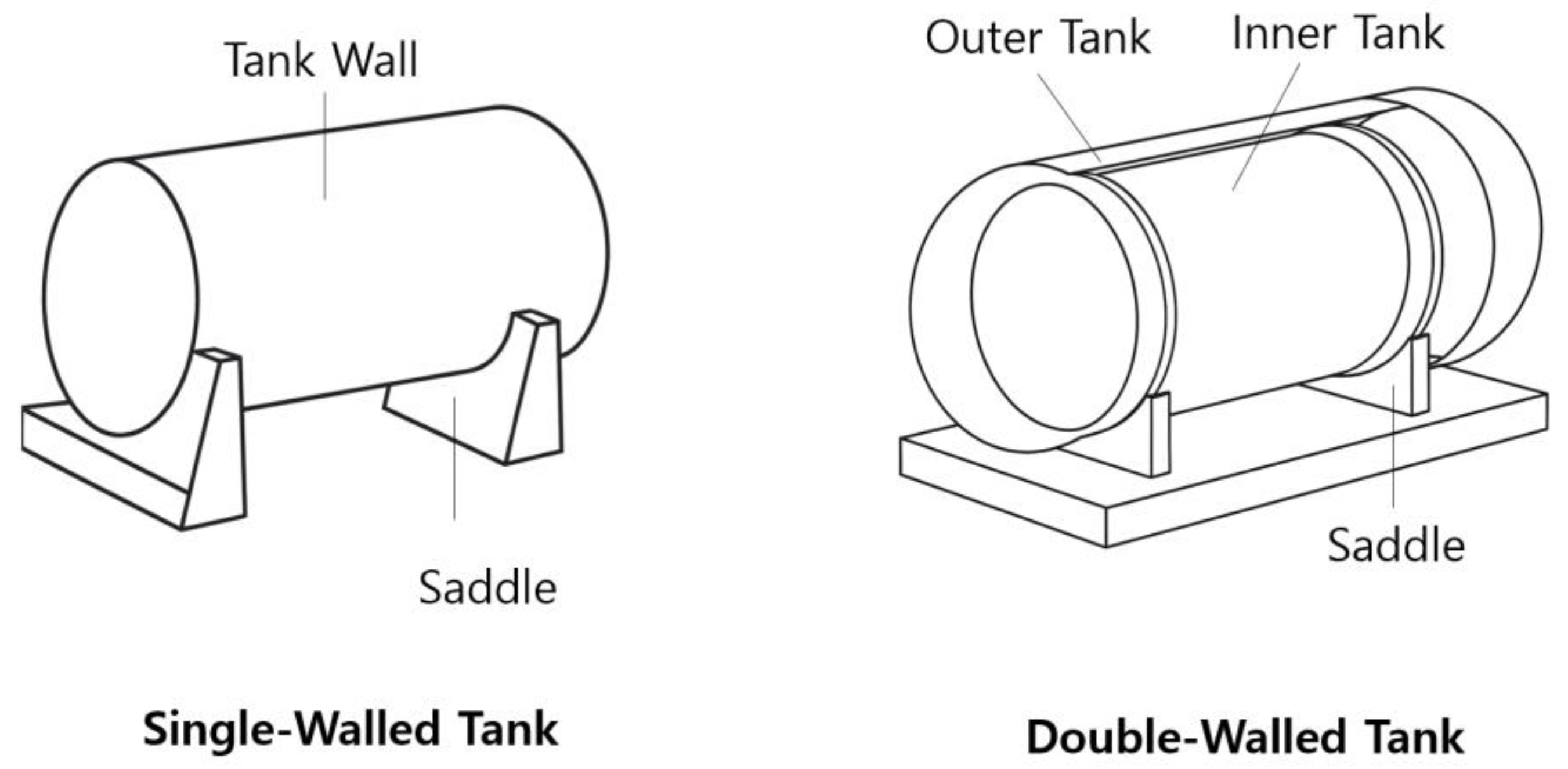

Figure 1 Comparison of conceptual schematics for single wall and double wall cryogenic storage tanks. The single Mwall tank has a simple structure and is easier to manufacture, but its insulation performance is limited. In contrast, the double-wall tank incorporates a vacuum space and multi-layer insulation (MLI) between the inner and outer walls, effectively minimizing heat transfer and reducing BOG generation, making it more suitable for long-term cryogenic fuel storage. In this study, a double-wall C-type cryogenic tank was adopted to ensure the storage stability of LH

2, providing a foundation for establishing test and evaluation procedures within the FGSS.

3.1.2. Supply Section

The cryogenic piping is divided into a primary line, extending from the tank outlet to the vaporizer, and a secondary line, extending from the vaporizer to the heater and final supply point. All valves and fittings are designed with materials and sealing structures suitable for cryogenic conditions. Pressure sensors and flowmeters are installed at the inlet and outlet of major components, allowing real-time monitoring of pressure from the tank outlet to the vaporizer outlet and heater outlet, as well as the final fuel supply flow rate.

3.1.3. Heating Section

The heating section consists of a vaporizer and a glycol water heating system. The vaporizer converts LH2 into its gaseous state, after which the gaseous fuel is stably heated to the target temperature through the glycol heater system. The heater unit comprises an electric heater with a capacity of several tens of kilowatts, a circulation pump, and a heat exchanger. A silicon-controlled rectifier (SCR) control system is applied to enable precise temperature control. The circulating medium is a glycol–water mixture, with a rated flow capacity on the order of several cubic meters per hour.

3.1.4. Control and Safety Section

All measurement data are collected and recorded in a centralized PLC (Programmable Logic Controller)-based control system. The safety interlock includes an emergency shut-down valve (ESD), pressure relief valve (PRV), and multi level alarm system. These safety devices are integrated into the real-time monitoring system to ensure immediate response in the event of abnormal operating conditions.

The key components of the FGSS include the LH2 fuel tank, cryogenic piping, pumps, heat exchangers, and the glycol heater system, which operate in an integrated manner to maintain fuel pressure, flow rate, and temperature within optimal ranges.

This study focuses on small- to medium-sized vessels with a length of approximately 12–30 m and a gross tonnage of 20–200 GT. Currently, the “Standards for the Structure and Equipment of Small Vessels” (Ministry of Oceans and Fisheries, Notification No. 2019-68 [

16]) defines small vessels as those with a length of less than 12 m. However, no official standards exist for medium-sized vessels. Therefore, this study extended the scope to vessels in the 12–30 m, 20–200 GT range. These target vessels are suitable for the development of FGSS testing procedures due to their relatively small system scale, simplified configuration, and modularization potential, which facilitate initial demonstration compared with large commercial vessels.

Figure 2 is a process flow diagram (PFD) of the fuel gas supply system. Fuel is stored in the LH

2 tank and vaporized when required. The PBU partially vaporizes the fuel to maintain the tank pressure above a defined threshold. The glycol-water system provides stable heat input for vaporization and heating, while the buffer tank stabilizes flow rate and pressure to ensure reliable fuel delivery to the fuel cell or engine. This PFD also represents the actual configuration of the experimental bench used for the LN

2 vaporization and heating tests.

Table 3 summarizes the main components of the liquefied FGSS applied in this study and their functions. The liquefied hydrogen storage tank enables long-term storage under cryogenic and high-pressure conditions, while the vaporizer converts the fuel into a gaseous state to ensure stable supply. The PBU maintains the internal tank pressure above a defined threshold, enabling stable operation, and the buffer tank mitigates instantaneous pressure fluctuations to ensure uniform supply conditions. Finally, the glycol water system serves as an auxiliary unit to maintain stable heat exchange under cryogenic operating environments and consists of a pump, heater, and heat exchanger. These components operate in an integrated manner and play a critical role in ensuring the reliability and safety of marine liquefied hydrogen fuel systems.

The test and evaluation protocol proposed in this study was established using liquid nitrogen (LN2, −196 °C) as a surrogate medium, considering that direct testing under the cryogenic conditions of liquid hydrogen (LH2, −253 °C) is practically challenging. Although LN2 liquefies at a relatively higher temperature compared to LH2, it exhibits similar cryogenic heat transfer characteristics and handling conditions. Thus, it can be effectively utilized to verify the performance and safety functions of key components such as storage tanks, vaporizers, pipelines, valves, and heat exchangers.

Furthermore, the use of process simulation is conceptually proposed to compensate for the property differences between LN

2 and LH

2. Although no numerical modeling was conducted in this study, process modeling tools such as Aspen HYSYS are suggested for future work to examine the differences in heat transfer characteristics, pressure drops, and vaporization rates between the two cryogenic fluids. Such simulations are expected to supplement the limitations of LN

2 based surrogate tests and provide valuable reference data for the interpretation of experimental results in subsequent studies. For thermodynamic modeling, the Peng–Robinson equation of state is identified as an appropriate option [

17,

18], as it is one of the most widely applied models in the oil and gas industry and can accurately predict phase equilibrium characteristics under varying pressure and temperature conditions.

The overall test procedures are divided into four functional modules: storage, supply, vaporization/heating, and control/safety. For each module, specific test items, test methods, and evaluation criteria are defined to establish a consistent protocol. The detailed contents are presented in the following sections.

3.2. Test Procedures

3.2.1. Storage Section Test Procedure

Test Items of Storage Section

The test items in this study were derived by reviewing relevant provisions from KGS AC111, ISO/TR 15916, CGA H-3, and classification society rules (KR, DNV, ABS, etc.). However, certain items that are already verified during the design and manufacturing stages were excluded from the proposed land-based testing protocol. For example, the vacuum monitoring function test is typically performed during the fabrication stage of cryogenic storage tanks (e.g., KGS AC111, AC115, KR Rule) and was therefore not included in this protocol.

Accordingly, the core test items for the storage section are defined as follows:

BOR Test: The generation rate of BOG due to external heat ingress is measured to quantitatively evaluate the insulation performance of the storage tank.

Pressure Stability Test: The internal pressure of the storage tank is verified to remain stable within the designated operating range under various operating conditions.

Test Methods of Storage Section

The storage tank is filled with LN2 and maintained under steady operating conditions.

The tank dome pressure is continuously measured during the test period, and the pressure rise rate (ΔP/Δt) is recorded.

BOG flow rate is measured using a flowmeter installed at the outlet.

Based on the measured data, the BOR is calculated, and pressure stability is analyzed in terms of average pressure, fluctuation range, and rise rate.

The results are compared under various operating modes, including normal operation, partial load, and standby conditions.

The BOR is defined by the following equation:

: Mass of boil-off gas generated during the test period (kg);

: Initial mass of stored fuel (kg);

Δt: Test duration (days or hours).

The BOR is defined as the ratio of the BOG generated over a certain period of time to the initial charged mass, normalized with respect to storage duration. It serves as a representative indicator of the insulation performance and long-term operational stability of cryogenic fuel storage systems. A lower BOR value indicates superior insulation performance of the storage tank, resulting in reduced evaporation losses, which in turn supports efficient fuel utilization and safe operation. Conversely, a higher BOR value may imply insufficient insulation performance or inefficiencies in operating conditions, highlighting the need for design improvements or operational adjustments. Therefore, the BOR equation presented in this study provides a fundamental criterion for quantitatively evaluating insulation performance and stability in storage section testing.

Evaluation Criteria of Storage Section

BOR Criterion: For LNG storage tanks, relevant regulations such as KGS AC115 specify a BOR threshold of ≤3.0%/day. However, for LH2 storage tanks, no internationally standardized BOR criterion has yet been established. Therefore, this study adopts the LNG criterion as a reference while acknowledging that further accumulation of test data and adjustments will be required in the future to account for the unique cryogenic properties of LH2 and material-specific characteristics.

Pressure Stability Criterion: Based on the functional requirements of the IMO IGF Code, stable pressure must be maintained during operation. In this study, pressure fluctuations within ±5% of the set operating pressure are considered acceptable.

3.2.2. Supply Section Test Procedure

Test Items of Supply Section

The supply section focuses on verifying whether fuel is stably delivered at the vaporizer outlet, with the core objective being the evaluation of pressure and flow stability. According to the IMO IGF Code and classification society rules, the fuel supply system must deliver fuel flow rate and pressure that meet the requirements of engines and fuel cells. Reflecting these requirements, this study proposes the Pressure and Flow Stability Test as the key test item for the supply section.

Test Methods of Supply Section

Inspect the condition of valves and sensors along the supply line before initiating the test.

Operate the vaporizer and heater to supply fuel under the designated operating mode.

Continuously measure data through the pressure sensor and flowmeter installed at the vaporizer outlet.

Compare the measured pressure and flow rate with the target values and calculate the deviation ratios.

The deviation ratios for pressure and flow rate (ε

P, ε

m)are defined as follows:

where:

and denote the measured mass flow rate and pressure, respectively.

and denote the reference values of mass flow rate and pressure under the specified operating conditions.

Evaluation Criteria of Supply Section

The evaluation criterion for the supply section is to verify whether the flow rate and pressure are stably maintained within the allowable tolerance range relative to the target values under normal operating conditions. In this study, deviations of both flow rate and pressure within ±5% are regarded as acceptable. Although this value is not explicitly specified in the IMO IGF Code or classification society rules, these regulations stipulate the functional requirement that “the fuel supply system shall provide stable pressure and flow sufficient to meet the demands of engines and fuel cells.” Therefore, the ±5% tolerance criterion can be interpreted as reflecting the minimum requirement to satisfy the operational specifications of engine manufacturers.

Moreover, previous demonstration tests of LNG FGSS and related research studies have also applied ±5% variations as an acceptable engineering tolerance. Accordingly, the ±5% tolerance proposed in this study is a justified value that integrates the functional requirements of international regulations with practical evidence from industrial demonstration cases.

A deviation of ±5% between measured and required heat duty is adopted as the acceptance band for prototype-level vaporizer tests. This choice is supported by published vaporizer studies reporting ≈5% average error between experimental and numerical results [

19]. In our LN

2–LH

2 heat-balance equivalence, the predicted LH

2 mass flow deviated by 3.8% from the design value, which lies within this band. This tolerance is thus both literature-supported and consistent with our data.

3.2.3. Vaporization & Heating Section Test Procedure

Test Items of Vaporization & Heating Section

The vaporization and heating section is responsible for converting liquefied hydrogen into a gaseous state and subsequently heating it to the temperature required by fuel cells and engines through the glycol-water heater system. In this study, two test items were defined to verify both vaporization and heating performance:

Vaporization Performance Test: Evaluates the vaporizer’s capacity to vaporize LH2 and its ability to ensure stable supply conditions.

Heating Performance Test: Verifies the temperature control performance, responsiveness, and accuracy of the glycol-water heating system.

Test Methods of Vaporization & Heating Section

The proposed test methods for the vaporization and heating section were derived to satisfy the functional requirements specified in the IMO IGF Code (2016) and ISO 21009-2:2015 [

20], which state that “fuel shall be vaporized and heated before being supplied to the engine, and control/instrumentation devices shall function properly.” However, as no detailed test procedures are prescribed in these international regulations, this study proposes complementary procedures including inlet/outlet temperature measurement, verification of responsiveness and control accuracy relative to set points, and recording of SCR (silicon-controlled rectifier) control signals.

The test methods are as follows:

Supply LN2 to the vaporizer and operate the glycol-water system to conduct vaporization and heating under the designated operating mode.

Measure the fuel temperature in real time at the vaporizer outlet and the heater outlet.

Compare the measured temperature with the target operating condition (e.g., ≥−20 °C, or engine-specific requirements) and calculate the temperature deviation ratio.

Conduct a heat balance calculation to analyze differences between the required heat load for actual LH2 operation and the conditions of the LN2 surrogate test.

Record measurement data (temperature variation, stabilization time) and extract the steady-state interval.

Define the temperature deviation ratio as follows:

where

is the measured temperature and

is the target reference temperature.

The defined temperature deviation ratio ( serves as a quantitative indicator of the difference between the measured and target values, and is used as a criterion for analyzing the control performance and stability of the system.

Evaluation Criteria of Vaporization & Heating Section

The evaluation of the vaporization and heating section was established based on two essential criteria.

System Integrity: The heater system, including pumps, electric heaters, and sensors, must operate without abnormal alarms or unplanned shutdowns.

Temperature Stability: The outlet temperature of the heater (TT) must reach the designated setpoint. During steady-state operation, the temperature is considered acceptable if it remains within ±5 °C of the setpoint.

These criteria quantitatively interpret the functional requirements of the IMO IGF Code and ISO 21009-2 [

20], which specify that “fuel shall be supplied stably within the requirements of engines and fuel cells.” The numerical tolerance values were derived by referencing the engineering tolerances commonly applied in previous LNG FGSS demonstration tests.

3.2.4. Control & Safety Section Test Procedure

Test Items of Control & Safety Section

The control and safety section is responsible for detecting abnormal operating conditions in the FGSS and responding immediately. The IMO IGF Code and classification society guidelines stipulate that emergency shut down, pressure relief, and alarm systems must be incorporated in fuel systems. Based on these requirements, the following test items are proposed:

ESD Function Test: Verify whether the emergency shut down valves are activated immediately upon emergency signal input.

PRV Test: Confirm that the relief device opens properly at the designated set pressure under overpressure conditions in the storage tank and supply line.

Alarm & Monitoring System Test: Ensure that abnormal readings of pressure, temperature, or flow sensors trigger multiple alarms and are recorded in the central control system.

Test Methods of Control & Safety Section

ESD Function Test: During normal operation, a simulated emergency signal is triggered, and the valve response time and shut-off status are recorded.

PRV Test: Tank pressure is gradually increased under test conditions to verify that the PRV opens at the set pressure, with opening pressure and resealing performance documented.

Alarm & Monitoring System Test: Abnormal sensor values or simulated signals are input to check alarm activation and central control system logging.

Evaluation Criteria of Control & Safety Section

The evaluation criteria for the control and safety section were established based on the functional requirements of the IMO IGF Code (2016) and major classification-society guidelines. These documents mandate automatic fuel shut-off, pressure-relief activation, and alarm signaling under abnormal conditions but do not specify any quantitative time or tolerance values. Therefore, the quantitative criteria used in this study were derived from internationally accepted valve standards and verified industrial practices relevant to cryogenic fuel systems.

Instrumentation and Cryogenic Sensor Technology of Control & Safety Section

Reliable instrumentation is essential for verifying the performance and safety of cryogenic FGSS. The measurement items in this protocol—pressure, temperature, flow rate, and abnormal event detection—require sensors capable of maintaining accuracy and stability under cryogenic, high-pressure, and vibration-prone conditions [

25].

Cryogenic Temperature Sensors: Resistance Temperature Detectors (RTDs, Pt100) and Cernox™ sensors are commonly used for precise temperature measurements from 300 K down to 20 K, offering ±0.1 K stability. Recent research also demonstrates the application of Fiber Bragg Grating (FBG) sensors, which provide distributed temperature monitoring with electromagnetic immunity [

26].

Pressure and Flow Sensors: Cryogenic pressure transducers based on piezoresistive and MEMS technologies achieve full-scale accuracies of ±0.25% even below −200 °C, ensuring compliance with ISO 21013-1 requirements [

27]. Coriolis-type flowmeters, modified for low-temperature operation, are employed to verify mass flow rate and density consistency.

Leak Detection and Safety Sensors: Helium mass spectrometry and hydrogen-specific catalytic sensors (ppm-level resolution) are recommended for monitoring possible leakage during long-duration LN

2 or LH

2 tests [

28].

These cryogenic sensor technologies ensure that measurement uncertainty remains within ±1% of the specified range, satisfying the precision requirements for the ±5% performance and stability criteria established in this protocol.

3.3. Thermodynamic Equivalence Framework Between LN2 and LH2

3.3.1. Fundamental Concept and Assumptions

Necessity of LN2 Surrogate Testing

Due to the extreme hazards, cost, and regulatory restrictions associated with liquid hydrogen (LH2) testing, direct cryogenic experiments using LH2 are often impractical at the prototype stage. Instead, LN2 is widely adopted as a surrogate medium because it is non-flammable and exhibits thermophysical properties and phase-change characteristics similar to LH2. By using LN2 under equivalent boundary and thermal conditions, the vaporization behavior and heat transfer characteristics of LH2 systems can be indirectly verified without the safety risks of hydrogen handling. In this study, a thermodynamic equivalence framework was derived to quantitatively convert LN2 test results into LH2 conditions using the First Law of Thermodynamics.

3.3.2. Theoretical Basis for Energy Equivalence

Application of the First Law of Thermodynamics

The total external heat input to the vaporizer (Qin) equals the enthalpy increase in the working fluid as it vaporizes and is heated from its inlet to outlet temperature. This relationship can be expressed as:

where

m: mass flow rate (kg/s),

L: latent heat of vaporization (kJ/kg),

Cp: specific heat at constant pressure (kJ/kg·K),

and T1 and T2 are inlet and outlet temperatures, respectively.

When the same vaporizer geometry, insulation, and coolant boundary conditions are used, the external heat input can be assumed equivalent between the two cryogenic fluids:

Hence, the LH

2 equivalent mass flow rate can be derived as:

Practical Application Using Experimental Data

During the LN

2 vaporization test, the outlet temperature (T

2) and mass flow rate (

) were recorded at four time intervals: 0, 5, 10, and 15 min. As shown in

Table 4, the outlet temperature gradually decreased from 59.8 °C to 44.4 °C, while the mass flow rate remained nearly constant within ±2%.

The mean outlet temperature was 53.3 °C, and the mean mass flow rate was 324.25 kg/h, adopted as representative steady state conditions for energy equivalence.

Substituting these values into the enthalpy-balance equation:

Assuming Q

in,LN2 = Q

in,LH2, the equivalent LH

2 mass flow rate is obtained as:

Therefore, under equivalent boundary conditions, an LN2 flow of 324.25 kg/h corresponds to an LH2 flow of approximately 29 kg/h, which matches the design hydrogen consumption for a fuel cell system.

During the test, flow variation remained below ±2%, confirming stable heat transfer performance. The calculated deviation between the LN2 based prediction and the actual system requirement was approximately 3.8%, which lies within a typical ±5% range considered acceptable for cryogenic vaporizer performance evaluations.

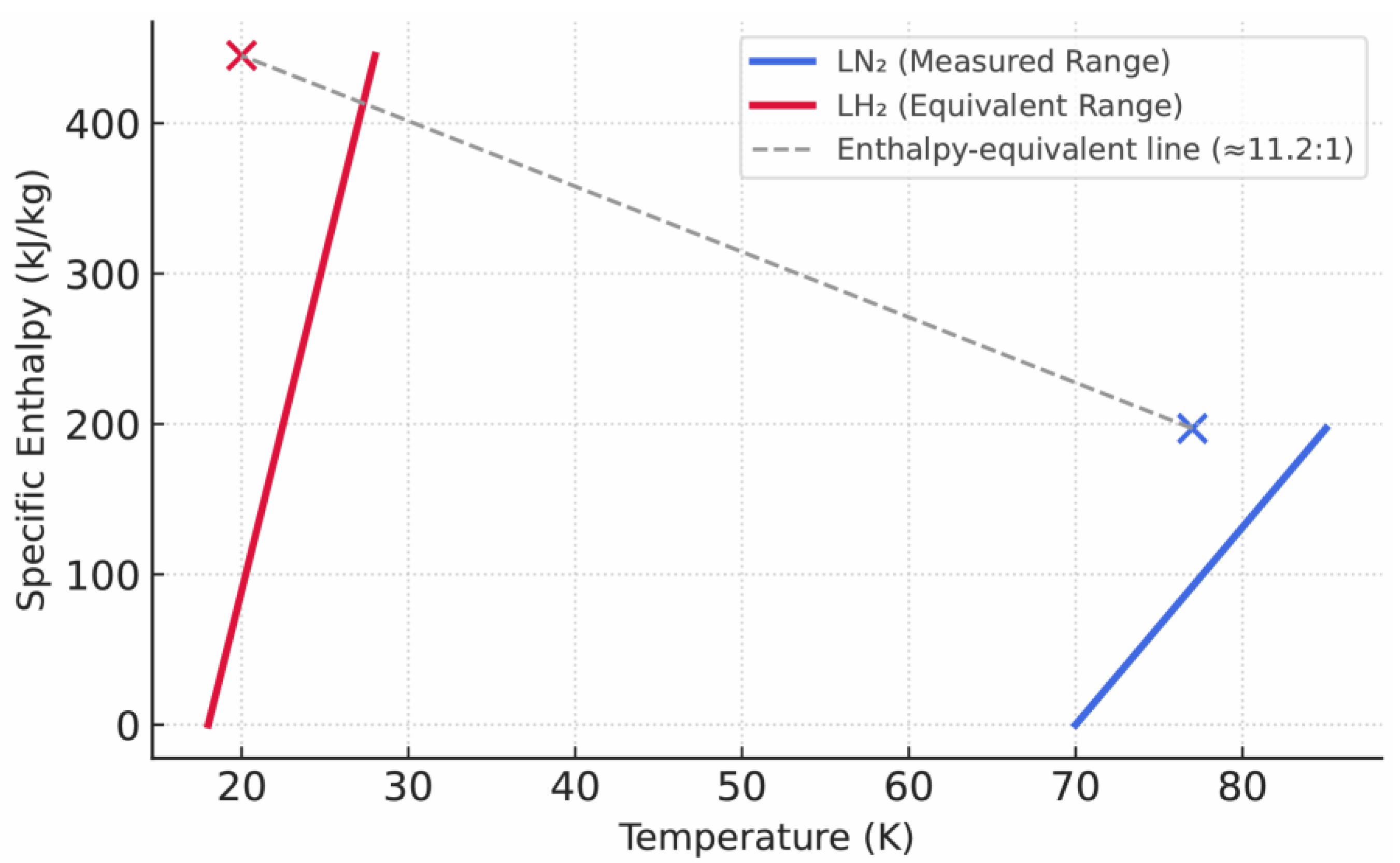

As shown in

Figure 3, the enthalpy-based correlation between LN

2 and LH

2 demonstrates that the thermal energy difference and phase-change behavior are quantitatively consistent within an equivalence ratio of approximately 11.2:1. This validates the applicability of the LN

2 surrogate testing framework for evaluating hydrogen fuel systems under comparable thermal boundary conditions.

4. Discussion

The land-based test protocol for LH

2 storage tanks FGSS proposed in this study complements existing research, which has primarily focused on LNG based cryogenic tank test methods or general safety considerations, such as those described in ISO/TR 15916 [

2] and KGS AC115 [

8]. Previous studies have emphasized safety concerns for hydrogen systems or LNG-based cryogenic tanks, but no consistent land-based test procedures applicable to marine LH

2 systems have been reported. The present study distinguishes itself by mapping and integrating the IMO IGF Code [

4], ISO/TR 15916 [

2], CGA H-3 [

3], and KGS AC111/115 [

1,

8], while also establishing quantitative evaluation criteria for each subsystem module.

Specifically, the study defined structured test items, methods, and acceptance criteria for: (i) BOR and pressure stability in the storage section, (ii) pressure and flow stability in the supply section, (iii) temperature control performance in the vaporization and heating section, and (iv) emergency shut down (ESD), pressure relief valve (PRV), and alarm systems in the control and safety section. This approach advances prior research, which largely emphasized the necessity of safety assurance, into concrete and verifiable test procedures.

In addition, recognizing the practical challenges of direct LH2 testing under cryogenic conditions, the study introduced LN2 substitution tests and recommended the use of Aspen HYSYS thermodynamic simulations to compensate for property differences between LN2 and LH2. This approach alleviates constraints in demonstration environments while ensuring the reliability of test result interpretations.

Furthermore, to strengthen the quantitative validation of the proposed protocol, the LN2 and LH2 thermodynamic equivalence framework was applied to the experimental vaporization test results. The heat-balance calculation based on the First Law of Thermodynamics demonstrated that an LN2 flow rate of 324.25 kg/h corresponds to an LH2 flow rate of approximately 29.0 kg/h under equivalent boundary conditions. The deviation between the LN2 derived prediction and the design hydrogen consumption of a fuel cell system was only 3.8%, which lies within the ±5% tolerance.

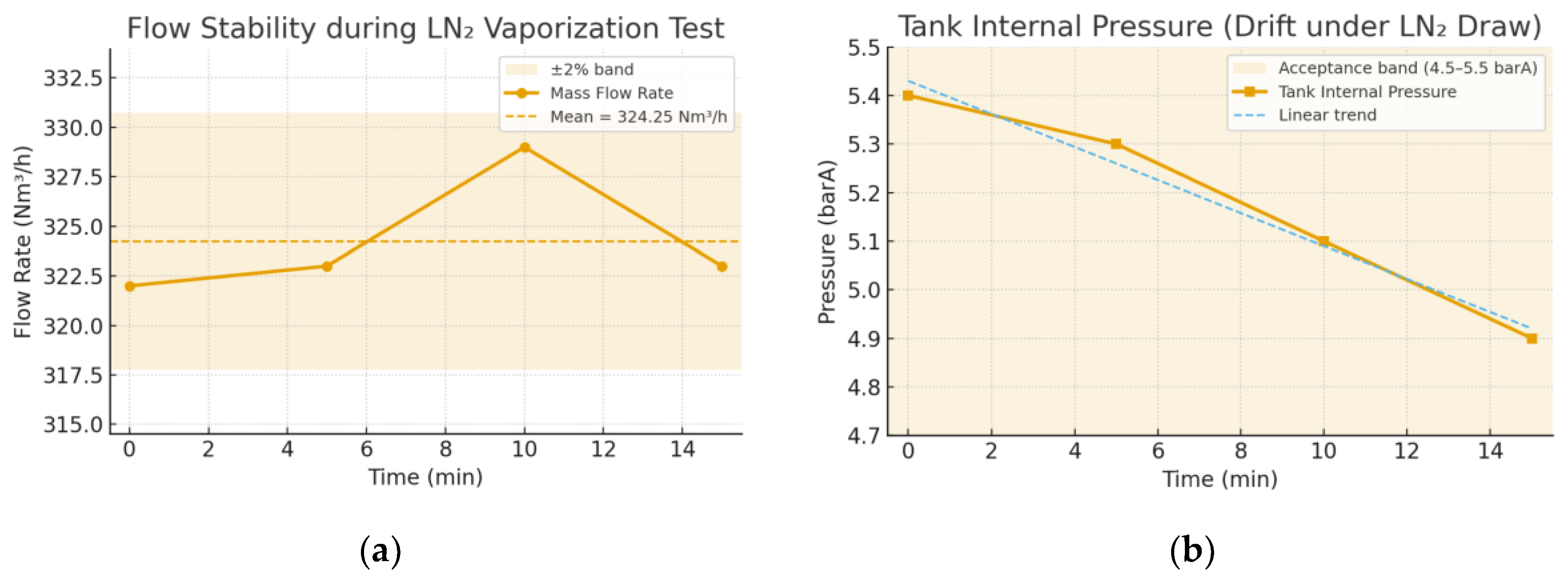

To further substantiate these results,

Figure 4a,b present the measured pressure and flow stability data obtained from the LN

2 vaporization test. As shown in

Figure 4a, the mass-flow rate remained within ±2% of the mean value (324.25 Nm

3/h), confirming stable flow control performance.

Figure 4b illustrates the tank internal pressure trend, which remained within the acceptance band of 4.5–5.5 bar, exhibiting a predictable monotonic decay as LN

2 was consumed. These results demonstrate quantitative repeatability and verify that the surrogate LN

2 test maintains stable thermal and flow conditions, thereby supporting the reliability of the proposed evaluation framework.

This quantitative agreement verifies that the LN2 surrogate test can reliably represent LH2 thermal performance at the prototype stage, providing a validated experimental basis for the proposed land-based evaluation framework. The results also confirm that the suggested protocol is not merely conceptual, but experimentally substantiated within practical and safe boundary conditions.

The findings of this study can serve as baseline data for pre-demonstration verification of marine hydrogen fuel systems and as quantified reference material in consultations with international classification societies and regulatory bodies.

Future research should address the following areas:

Material Reliability Consideration: Although this study primarily focused on functional verification, the long-term reliability of materials used in cryogenic hydrogen environments remains a critical factor for overall system safety. The austenitic stainless steels applied here offer strong resistance to hydrogen embrittlement; however, further research on material degradation under cyclic cryogenic ambient loading is encouraged to complement the functional safety framework proposed in this study.

Direct LH2 Testing: Conducting small-scale loop tests with actual LH2 to cross-validate correction factors and LN2 substitution results.

Marine Environmental Considerations: Developing test procedures that account for vibrations, shocks, and sloshing effects encountered during ship operations.

Functional Safety Enhancement: Applying Safety Integrity Level (SIL)-based quantitative validation to ESD, PRV, and alarm logic.

Standardization Contribution: Establishing common acceptance ranges through academia industry government collaboration to facilitate the development of international guidelines.

It should be emphasized that the Aspen HYSYS simulation and the Peng–Robinson EOS were not implemented in the present study. Their inclusion aimed to suggest a viable modeling pathway for future work, once sufficient LH2 test data become available. The current research focused on experimental validation of the LN2 and LH2 thermodynamic equivalence framework, which forms the empirical foundation for subsequent simulation and sensitivity analysis efforts.

In future studies, the proposed simulation framework will be expanded to include a Global Sensitivity Analysis (GSA) to identify dominant parameters affecting vaporization efficiency and flow stability. GSA quantitatively evaluates how variations in input parameters contribute to output uncertainty, enabling model calibration and uncertainty propagation assessment. Similar methodologies have been successfully applied in other engineering domains, including the evaluation of hot-mix asphalt dynamic modulus parameters [

29] and the seismic performance of shear walls with high-strength steel bars and recycled aggregate concrete [

30]. The adoption of GSA for LH

2 system modeling is expected to enhance prediction reliability and parameter optimization in subsequent research.

The proposed protocol functions as a pre-standardized framework for land-based verification of LH2 FGSS. A closed validation loop with classification societies or field LH2 demonstrations has not yet been achieved. As a preliminary verification, LN2 surrogate vaporization experiments were performed to calibrate the thermodynamic equivalence model with measurable performance data. Direct benchmarking with existing LNG or LH2 campaigns was not feasible due to confidentiality constraints; however, the proposed validation concept is designed to be extendable for future verification through integrated land-based tests and internationally accredited witness testing scheduled for 2025–2026.

5. Conclusions

This study established a land-based test protocol for LH

2 storage tanks and FGSS for small- and medium-sized vessels, addressing the limitations of existing LNG-based test standards. By systematically comparing and mapping relevant regulations—including the IMO IGF Code [

4], ISO/TR 15916 [

2], KGS AC111 [

1], KGS AC115 [

8], and CGA H-3 [

3]—the study proposed quantifiable acceptance criteria across four functional modules: storage, supply, vaporization/heating, and control/safety. This approach differentiates the present work from prior studies, which primarily remained at the level of general safety considerations.

Furthermore, acknowledging the constraints of direct LH2 testing under cryogenic conditions, this study established LN2 substitution tests as a practical evaluation route and proposes process simulations as a future pathway to extend and cross-validate the present equivalence framework. This hybrid approach provides a reproducible and practical evaluation framework within the domestic demonstration environment. Importantly, it represents the first attempt to move beyond the simple application of existing LNG or hydrogen guidelines toward a verifiable protocol explicitly tailored for marine LH2 systems.

Looking ahead, the protocol should be extended through partial LH2 tests and reproduction of transient maritime operating conditions (e.g., vibration, shock, sloshing). The accumulation of such experimental data will not only expand the applicability of the proposed protocol but also serve as a robust evidence base to drive consensus in international standardization processes with classification societies and regulatory authorities.

Although the Aspen HYSYS modeling and Peng Robinson EOS based simulations were not conducted in this work, they are suggested as prospective tools for sensitivity analysis and reliability verification to extend the current equivalence framework toward comprehensive LH2 FGSS modeling.