Attitude Control Method and Model Test for the Wave-Absorbing Buoy of the Sharp Eagle Wave Energy Converter Under All-Sea-State Operations

Abstract

1. Introduction

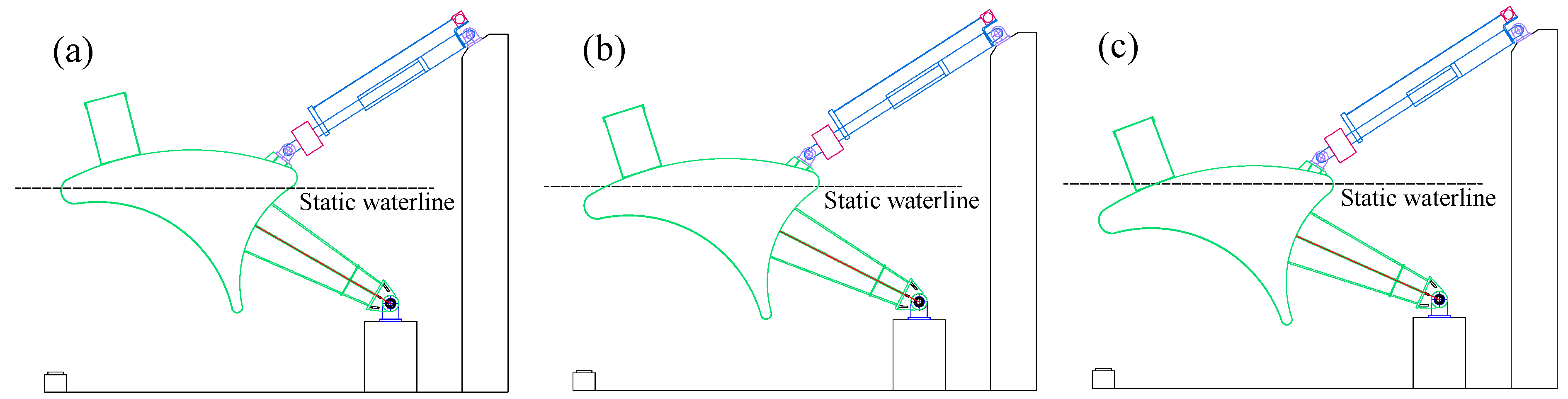

- Under moderate to rough sea conditions, the wave energy capture efficiency can be maximized by adjusting the ballast and static angle;

- Under severe sea conditions, the static angle is reduced by increasing the ballast to proactively lower the wave energy capture efficiency, restrict the piston movement range of the energy conversion hydraulic cylinders, avoid overpower operation of the generator set, and prevent rigid collisions between the buoys and end-stop structures;

- Under extreme sea conditions, since conventional adjustments can no longer meet safety requirements, we adopted a special control method of buoy submersion and locking to achieve emergency safety protection for the converter.

2. Attitude Control Method for the Buoys

2.1. Attitude Characteristics of the Buoys

- Wave parameters (e.g., significant wave height and peak period);

- Buoy structural parameters (e.g., draft depth and wave-facing area);

- Hydraulic cylinder operating parameters (e.g., accumulator pressure and damping coefficient).

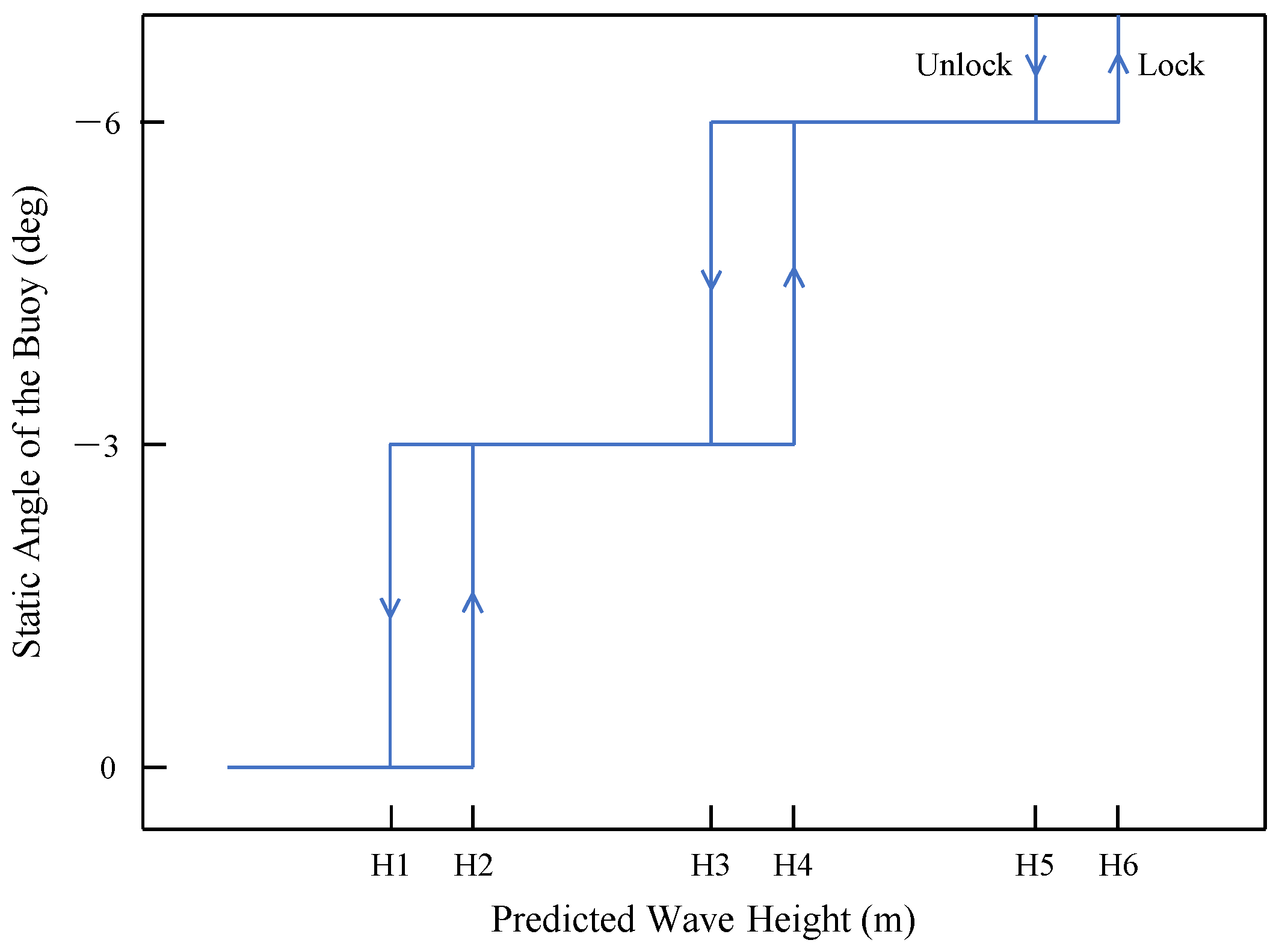

2.2. Feedforward Hysteresis Control of the Static Angle for the Buoys

- represents the output of the controller (unit: deg except Lock);

- represents the controller’s previous output (unit: deg except Lock); and

- represents the weather forecast wave height, while to was shown in Figure 3.

2.3. Feedback Control of the Load Pressure of the Hydraulic Cylinders

- If the pistons frequently reach the upper-limit protection points, the pressure of the accumulators is too low, which leads to insufficient load damping of the hydraulic cylinders; thus, a pressure increase command needs to be issued.

- If the pistons frequently reach the lower-limit protection points, the pressure of the accumulators is too high, which inhibits the normal motion of the buoys; thus, a pressure decrease command needs to be issued.

- If the pistons always move within the preset safe ranges without frequent contact with the protection boundaries, the current pressure is maintained.

- represents the setpoint of the controller;

- represents the previous setpoint of the controller;

- represents the adjustment step of the controller; and

- and are, respectively, the upper and lower protection limits for the displacement of the hydraulic cylinder piston.

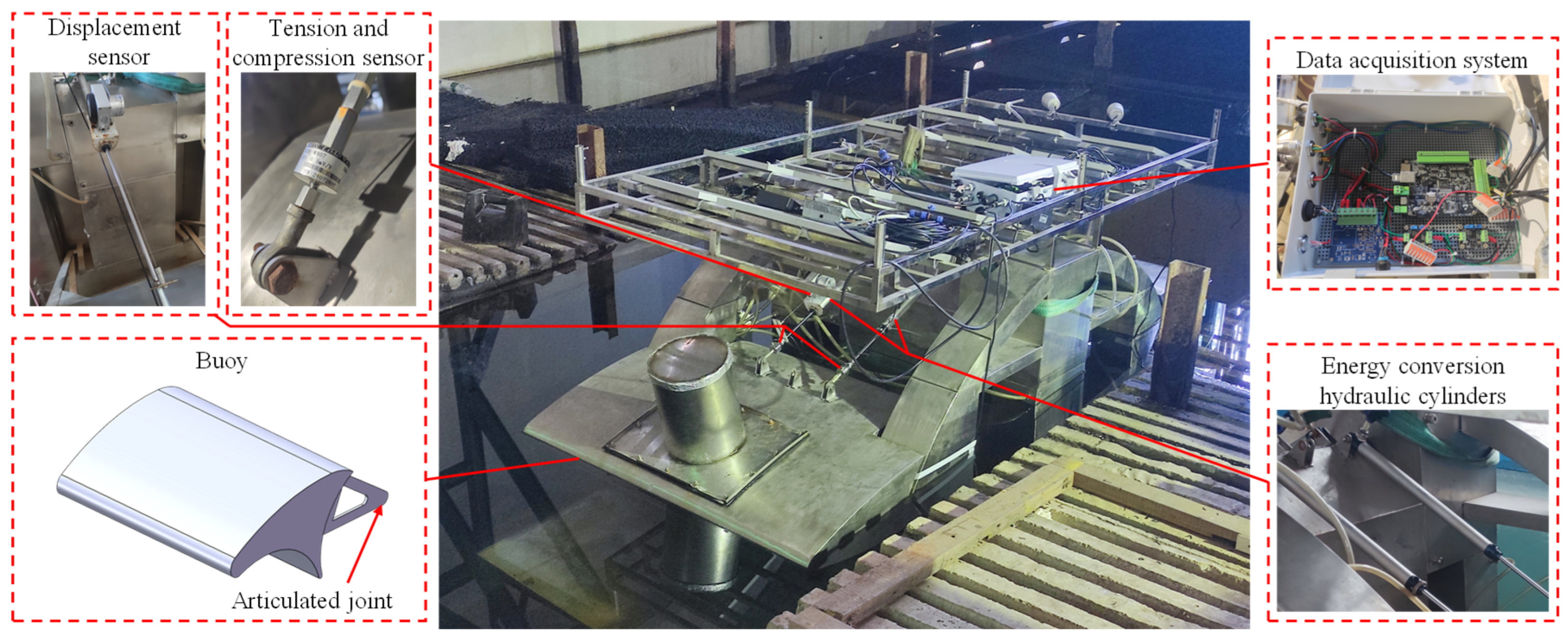

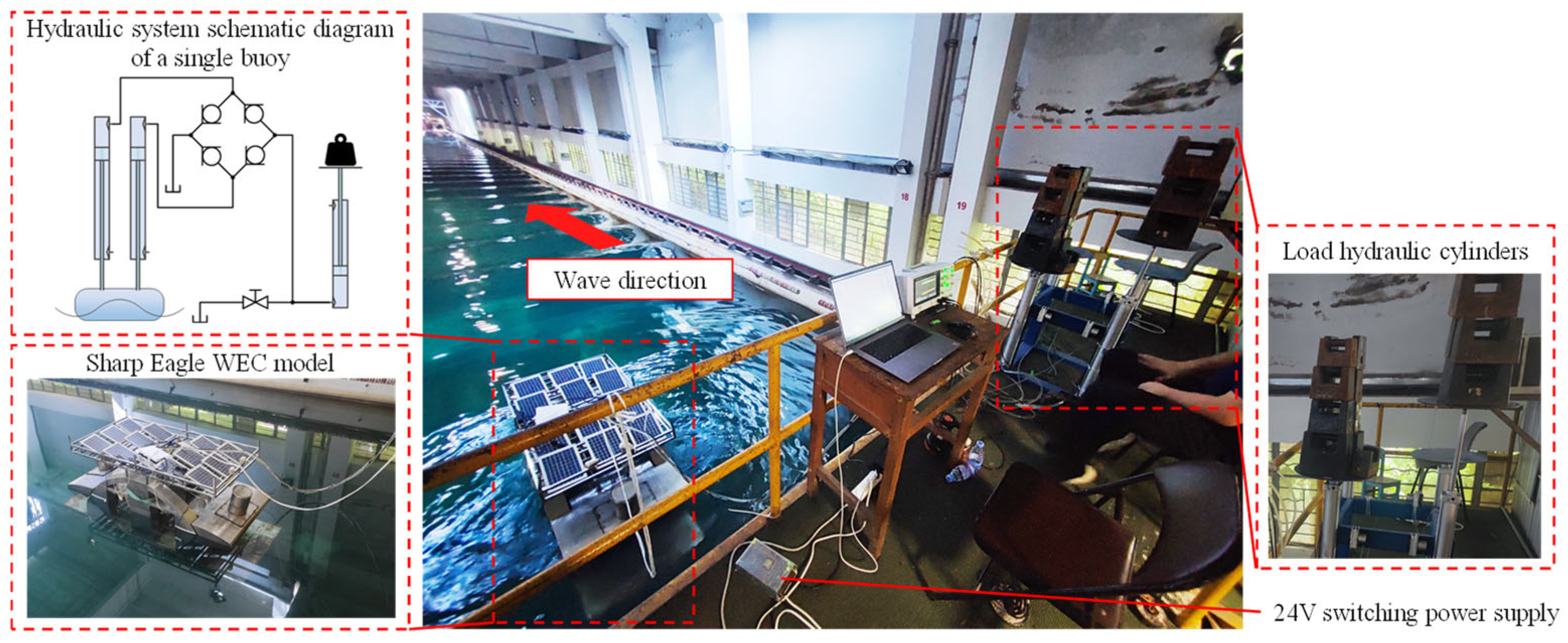

3. Experimental Design

3.1. Experimental Model

- During the downward movement phase of the buoy, the energy conversion hydraulic cylinders complete fluid replenishment;

- During the upward movement phase of the buoy, the energy conversion hydraulic cylinders are pressurized, thereby displacing the hydraulic fluid through a one-way valve into the load hydraulic cylinder and driving the latter’s piston upward, thereby realizing the conversion of wave energy into gravitational potential energy of the counterweights and tray.

3.2. Experimental Data Processing Methods

- represents the incident wave power (unit: W);

- represents the water density (unit: kg/m3);

- represents the wave height (unit: m);

- represents the wave-facing width of the device (unit: m);

- represents the group velocity (unit: m/s).

- represents the axial force of the piston that is exerted by the buoy on the energy conversion hydraulic rod;

- represents the movement velocity of the hydraulic cylinder piston that is driven by the buoy.

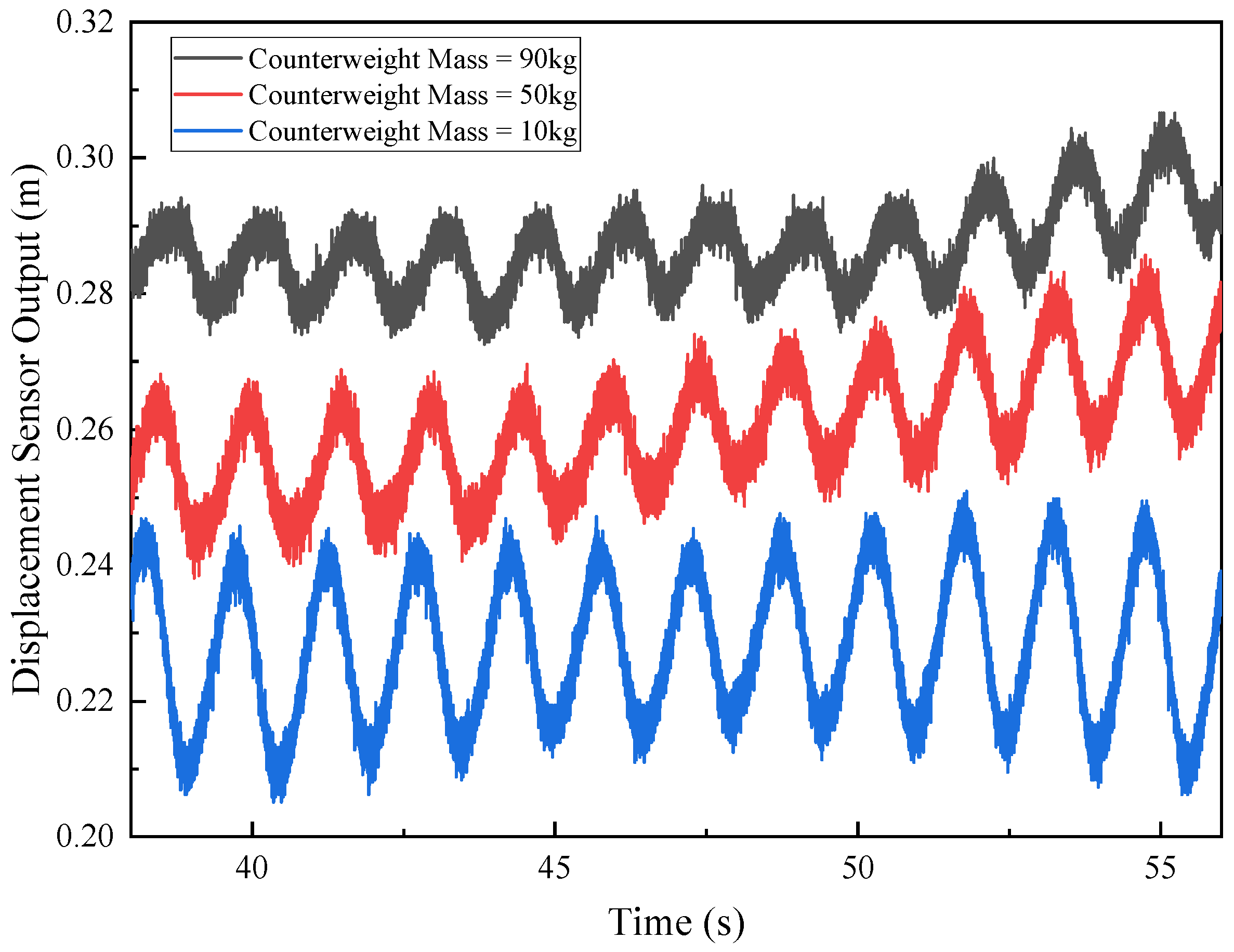

- represents the displacement output of the sensor at time ;

- represents the sampling period.

3.3. Experimental Operating Conditions

4. Results and Analysis

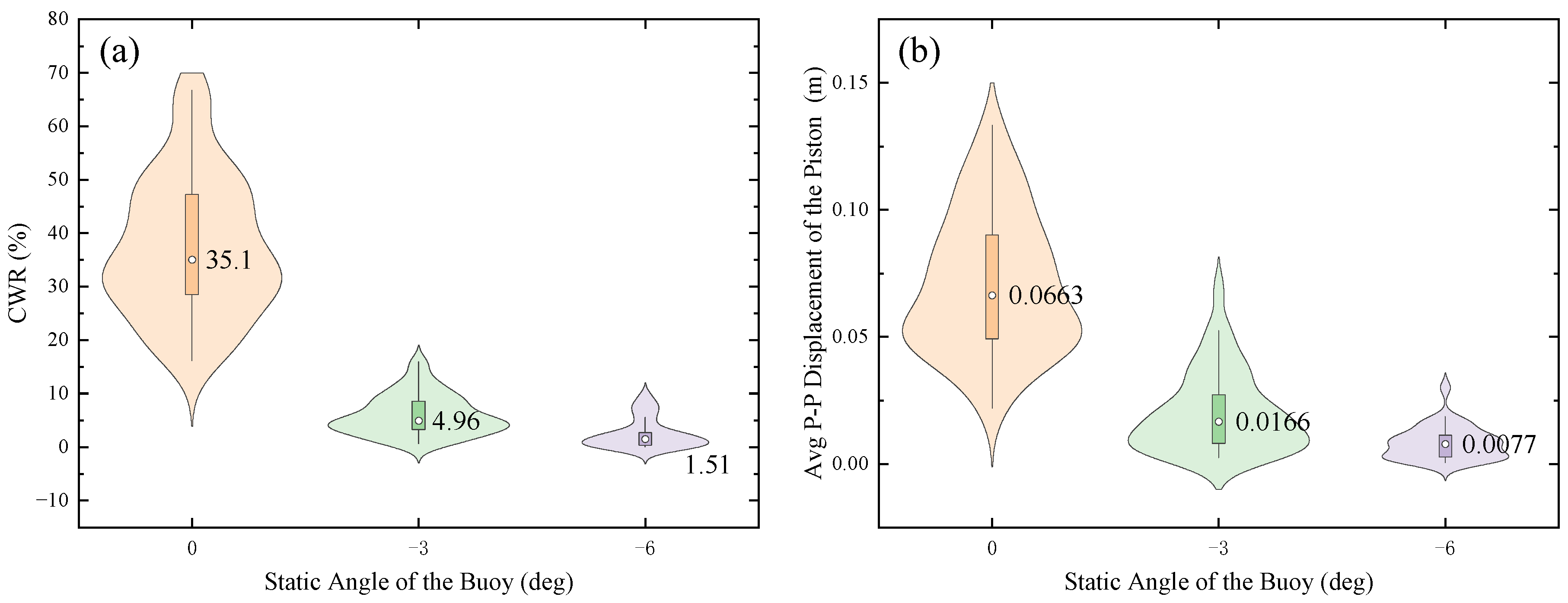

4.1. Analysis of the Influence of the Static Angle of the Buoy

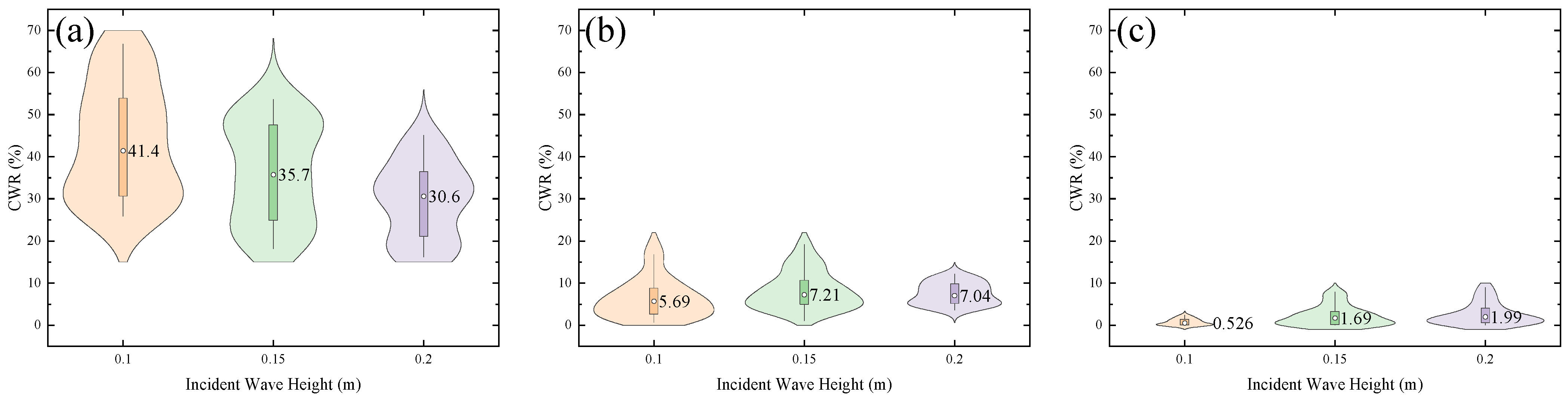

4.2. Analysis of the Influence of the Incident Wave Height

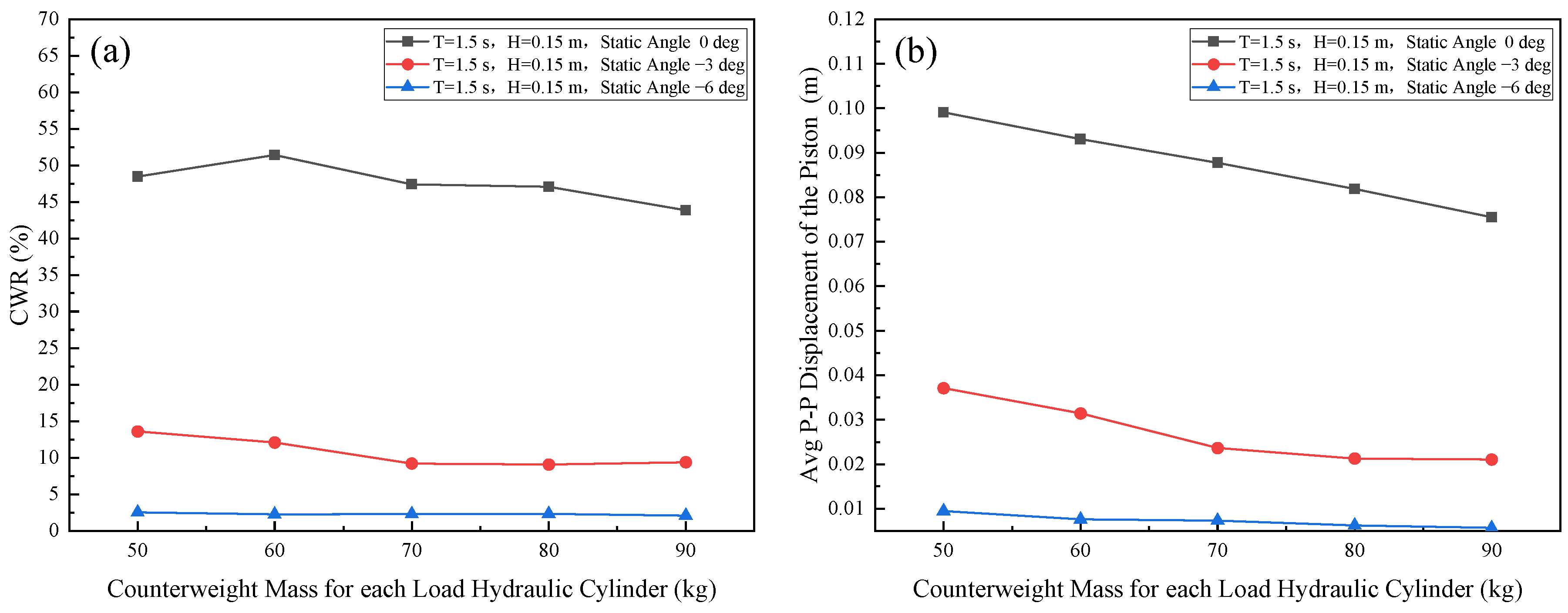

4.3. Analysis of the Influence of the Counterweight Mass of the Load Hydraulic Cylinder

4.4. Verification and Analysis of the Attitude Control Strategy for Sharp Eagle Buoys

- After conversion by wave-to-electricity efficiency, the wave energy that is captured by the buoy should not exceed the rated installed capacity for an extended period;

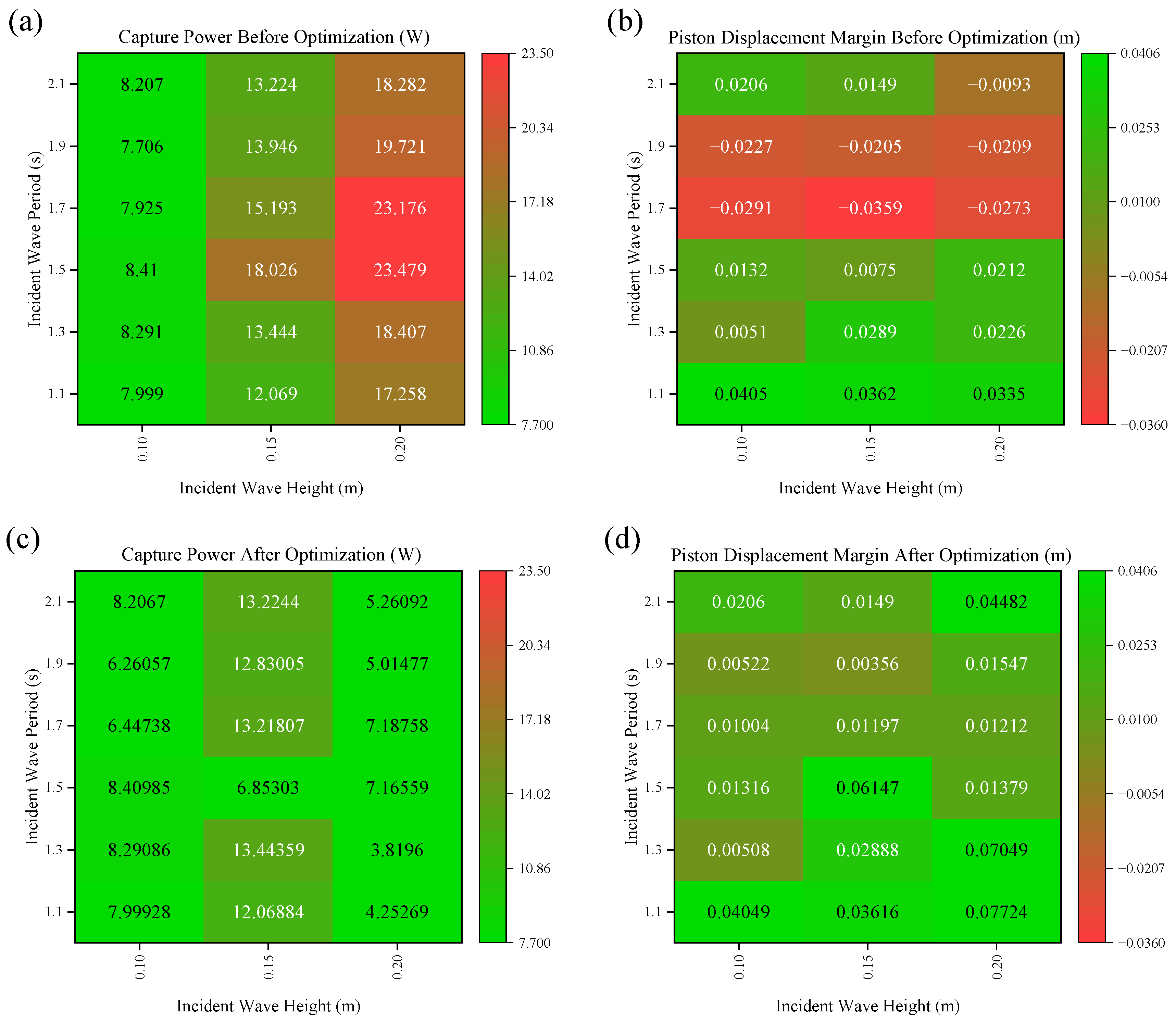

- The motion range of the Sharp Eagle buoy must be within the safe stroke of the energy conversion hydraulic cylinder.

- When the static angle of the buoy was 0°, the power capture capacity and the minimum distance from the hydraulic cylinder’s motion range to the boundary of the safe zone were as shown in Figure 13.

- When the angle of the Sharp Eagle buoy remained unchanged, dual risk events (exceeding the rated power capture capacity and the hydraulic cylinder exceeding the safe stroke) occurred under severe sea conditions.

5. Limitations

- More extreme sea conditions experimental conditions are required, and the response and transition under irregular wave input should be considered. The submersion and locking protection strategy of the buoy under extreme conditions requires further verification.

- Pipeline losses and leakage of the hydraulic system were not considered, and the power conversion efficiency of the full-scale device needs further correction on the basis of the results of this study.

- The adjustment step size of the static angle of the Sharp Eagle buoy was relatively large; hence, further refined zoning between 0° and -6° is needed, and more integration with simulations is needed to increase the precision of controlling the power capture capacity and the motion range of the energy conversion hydraulic cylinder piston.

6. Conclusions

- When the static angle of the Sharp Eagle buoy is 0°, the highest CWR can be obtained. However, the motion range of the energy conversion hydraulic cylinder piston is also larger, which may easily lead to excessive power capture capacity or the piston exceeding the safe operation range.

- Reducing the static angle of the Sharp Eagle buoy helps decrease the CWR and narrow the motion range of the energy conversion hydraulic cylinder piston under severe sea conditions, which is conducive to improving the safety margin and avoiding the risk of limit contact.

- The counterweight mass affects the average oscillation position of the hydraulic cylinder piston. When the static angle of the Sharp Eagle buoy is reduced, the pressure of the load hydraulic cylinder must be adjusted downward to ensure that the range of motion of the energy conversion hydraulic cylinder remains within the safe zone.

- A new control strategy adjusts the buoy’s ballast based on incident wave height and incorporates the displacement of the hydraulic cylinder piston into the generation of hydraulic setpoints. This can reduce the risk of the end-stop problem of the hydraulic power take-off system.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WEC | Wave energy converter |

| CWR | Capture width ratio |

| OTEC | Ocean thermal energy conversion |

| SGE | Salinity gradient energy |

| 6-DOF | Six degrees of freedom |

| Avg P-P | Average peak to peak |

References

- Su, X.; Chen, J.; Yuan, L.; Xu, W.; Xiong, C.; Wang, X. Current status of development and application of ocean renewable energy technology. Sustainability 2025, 17, 5648. [Google Scholar] [CrossRef]

- Tang, E.; Gao, J.; Huang, W.; Qian, Y. Marine renewable energy: Progress, challenges, and pathways to scalable sustainability. Energy 2025, 335, 138083. [Google Scholar] [CrossRef]

- Shao, Z.; Gao, H.; Liang, B.; Lee, D. Potential, trend and economic assessments of global wave power. Renew. Energy 2022, 195, 1087–1102. [Google Scholar] [CrossRef]

- Wen, Y.; Low, Y.M. Long-term resource assessment and decarbonization potential of wave energy. Renew. Energy 2025, 256, 124287. [Google Scholar] [CrossRef]

- Bouckaert, S.; Pales, A.F.; McGlade, C.; Remme, U.; Wanner, B.; Varro, L.; D’Ambrosio, D.; Spencer, T. Net Zero by 2050: A Roadmap for the Global Energy Sector. Available online: https://trid.trb.org/View/1856381 (accessed on 29 September 2025).

- Aderinto, T.; Li, H. Ocean wave energy converters: Status and challenges. Energies 2018, 11, 1250. [Google Scholar] [CrossRef]

- Zhou, B.; Wang, Y.; Zhang, H.; Jin, P.; Wang, L.; Zhou, Z. Wave Extraction and Attenuation Performance of A Hybrid System of An Edinburgh Duck WEC and A Floating Breakwater. China Ocean Eng. 2022, 36, 167–178. [Google Scholar] [CrossRef]

- Mo, L.; Bu, Y. Sharp Eagle Wave Absorbing Floats of Wave Power Generation Device. J. Shanghai Ship Shipp. Res. Inst. 2023, 46, 15–21. [Google Scholar]

- Sheng, S.; Wang, K.; Lin, H.; Zhang, Y.; You, Y.; Wang, Z.; Chen, A.; Jiang, J.; Wang, W.; Ye, Y. Model research and open sea tests of 100 kW wave energy convertor Sharp Eagle Wanshan. Renew. Energy 2017, 113, 587–595. [Google Scholar] [CrossRef]

- Chen, M.; Sheng, S.; Zhang, Y.; Wang, Z.; Wang, K.; Jiang, J. Model test and sea trial of a multi-absorber 1 MW wave energy converter. Energies 2025, 18, 4711. [Google Scholar] [CrossRef]

- Wei, J.; Changjie, L.; Jie, X.; Xun, G.; Lining, Z.; Wenjun, O. Characterization and assessment of wave energy resources in guangdong offshore area. Acta Energiae Solaris Sin. 2025, 46, 476–482. [Google Scholar]

- Shi, H.; Zhang, X.; Du, W.; Li, Q.; Qu, H.; You, Z. Assessment of wave energy resources in China. J. Mar. Sci. Eng. 2022, 10, 1771. [Google Scholar] [CrossRef]

- Mahmoodi, K.; Saybani, M.; Azad, S.T. A temporal and spatial resolution wind and wave power resource assessment in the Oman Gulf. Ocean Eng. 2022, 249, 110881. [Google Scholar] [CrossRef]

- Zhang, D.; Li, C.; Bi, R.; Huang, X.; Sun, Z.; Lan, T.; Wang, Y.; Huang, T.; Qian, P. Conversion mechanism for solving the end-stop problem of hydraulic power take-off system for wave energy. Ocean Eng. 2024, 294, 116776. [Google Scholar] [CrossRef]

- McGilton, B.; Nakhai, A.Y.; McNally, J. On the Optimal Sizing of Power Take-off Systems for Wave Energy Converters. Renew. Energy 2025, 252, 123375. [Google Scholar] [CrossRef]

- Zeinali, S.; Wiktorsson, M.; Forsberg, J.; Lindgren, G.; Lindström, J. Optimizing the hydraulic power take-off system in a wave energy converter. Ocean Eng. 2024, 310, 118636. [Google Scholar] [CrossRef]

- Leon-Quiroga, J.A.; Bacelli, G.; Forbush, D.D.; Spencer, S.J.; Coe, R.G. An Efficient and Effective WEC Power Take-Off System. IEEE Trans. Sustain. Energy 2023, 14, 1526–1539. [Google Scholar] [CrossRef]

- Shifat, T.A.; Coe, R.; Bacelli, G.; Brekken, T. Real-time sea state estimation for wave energy converter control via machine learning. Appl. Sci. 2025, 15, 5772. [Google Scholar] [CrossRef]

- Dean, R.G.; Dalrymple, R.A. Water Wave Mechanics for Engineers and Scientists; World Scientific Publishing Company: Singapore, 1991; ISBN 978-981-4365-69-7. [Google Scholar]

- Åström, K.J.; Wittenmark, B. Computer-Controlled Systems: Theory and Design, 3rd ed.; Courier Corporation: Chelmsford, MA, USA, 2013. [Google Scholar]

- Lin, C.; Zhang, Q.; Sheng, S.; Zhou, B.; Xiang, R.; Wu, X.; Zhou, Z.; Jin, P. Novel design and performance evaluation of a hybrid system of floating offshore wind turbine and Sharp-Eagle WECs. Ocean Eng. 2025, 340, 122387. [Google Scholar] [CrossRef]

| Predicted Wave Height (m) | Static Angle of the Sharp Eagle Buoy (Deg) | Control Target |

|---|---|---|

| 0–H2 | 0 | Maximize Wave Absorption Efficiency |

| H1–H4 | −3 | Balance Efficiency and Stability |

| H3–H6 | −6 | Prioritize Safeguarding Structural Safety |

| >H5 | Submersion Locking | Emergency Safety Protection |

| Case | Incident Wave Period (s) | Incident Wave Height (m) | Static Angle of the Buoy (Deg) |

|---|---|---|---|

| 1~6 | 1.1, 1.3, 1.5, 1.7, 1.9, 2.1 | 0.10 | 0 |

| 7~12 | 1.1, 1.3, 1.5, 1.7, 1.9, 2.1 | 0.15 | 0 |

| 13~18 | 1.1, 1.3, 1.5, 1.7, 1.9, 2.1 | 0.20 | 0 |

| 19~24 | 1.1, 1.3, 1.5, 1.7, 1.9, 2.1 | 0.10 | −3 |

| 25~30 | 1.1, 1.3, 1.5, 1.7, 1.9, 2.1 | 0.15 | −3 |

| 31~36 | 1.1, 1.3, 1.5, 1.7, 1.9, 2.1 | 0.20 | −3 |

| 37~42 | 1.1, 1.3, 1.5, 1.7, 1.9, 2.1 | 0.10 | −6 |

| 43~48 | 1.1, 1.3, 1.5, 1.7, 1.9, 2.1 | 0.15 | −6 |

| 49~54 | 1.1, 1.3, 1.5, 1.7, 1.9, 2.1 | 0.20 | −6 |

| Incident Wave Period (s) | Incident Wave Height 0.10 m | Incident Wave Height 0.15 m | Incident Wave Height 0.2 m | |||

|---|---|---|---|---|---|---|

| Load (kg) | Static Angle (deg) | Load (kg) | Static Angle (deg) | Load (kg) | Static Angle (deg) | |

| 1.1 | 60 | 0 | 80 | 0 | 50 | −3 |

| 1.3 | 20 | 0 | 50 | 0 | 10 | −3 |

| 1.5 | 50 | 0 | 10 | −3 | 10 | −3 |

| 1.7 | 80 | 0 | 90 | 0 | 30 | −3 |

| 1.9 | 90 | 0 | 80 | 0 | 30 | −3 |

| 2.1 | 90 | 0 | 90 | 0 | 30 | −3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Chen, P.; Ye, Y.; Wang, W.; Zhang, Y.; Sheng, S. Attitude Control Method and Model Test for the Wave-Absorbing Buoy of the Sharp Eagle Wave Energy Converter Under All-Sea-State Operations. J. Mar. Sci. Eng. 2025, 13, 2184. https://doi.org/10.3390/jmse13112184

Wang K, Chen P, Ye Y, Wang W, Zhang Y, Sheng S. Attitude Control Method and Model Test for the Wave-Absorbing Buoy of the Sharp Eagle Wave Energy Converter Under All-Sea-State Operations. Journal of Marine Science and Engineering. 2025; 13(11):2184. https://doi.org/10.3390/jmse13112184

Chicago/Turabian StyleWang, Kunlin, Peifan Chen, Yin Ye, Wensheng Wang, Yaqun Zhang, and Songwei Sheng. 2025. "Attitude Control Method and Model Test for the Wave-Absorbing Buoy of the Sharp Eagle Wave Energy Converter Under All-Sea-State Operations" Journal of Marine Science and Engineering 13, no. 11: 2184. https://doi.org/10.3390/jmse13112184

APA StyleWang, K., Chen, P., Ye, Y., Wang, W., Zhang, Y., & Sheng, S. (2025). Attitude Control Method and Model Test for the Wave-Absorbing Buoy of the Sharp Eagle Wave Energy Converter Under All-Sea-State Operations. Journal of Marine Science and Engineering, 13(11), 2184. https://doi.org/10.3390/jmse13112184