3.1. Thick Soft Mud Layers

Soft mud layers are defined as layers of marine facies cohesive soils, with low shear strengths (8–50 kPa), low deformation moduli (0.1–2 MPa), high water contents (50–100%), high porosity ratios (1.2–2.3) and sensitive structural properties [

75,

76]. During transgression–regression cycles, fine materials from deeper waters, including clay, silt, organic matters and minerals, are transported back to the coast by hydraulic forces. Marine facies soft mud layers are eventually formed by the continuous deposition of the fine materials along the coast [

77,

78]. The formations and distributions of soft mud layers are influenced by various factors, including the supply rate of terrigenous sediments, the hydrodynamic condition and the seabed topography. The compositions of soft mud layers tend to vary. In the near-shore areas, the sediments contain sand, silt and abundant terrigenous materials. In the deeper waters, the sediments contain more clay. In the areas adjacent to a river mouth, the sediments may contain more sand [

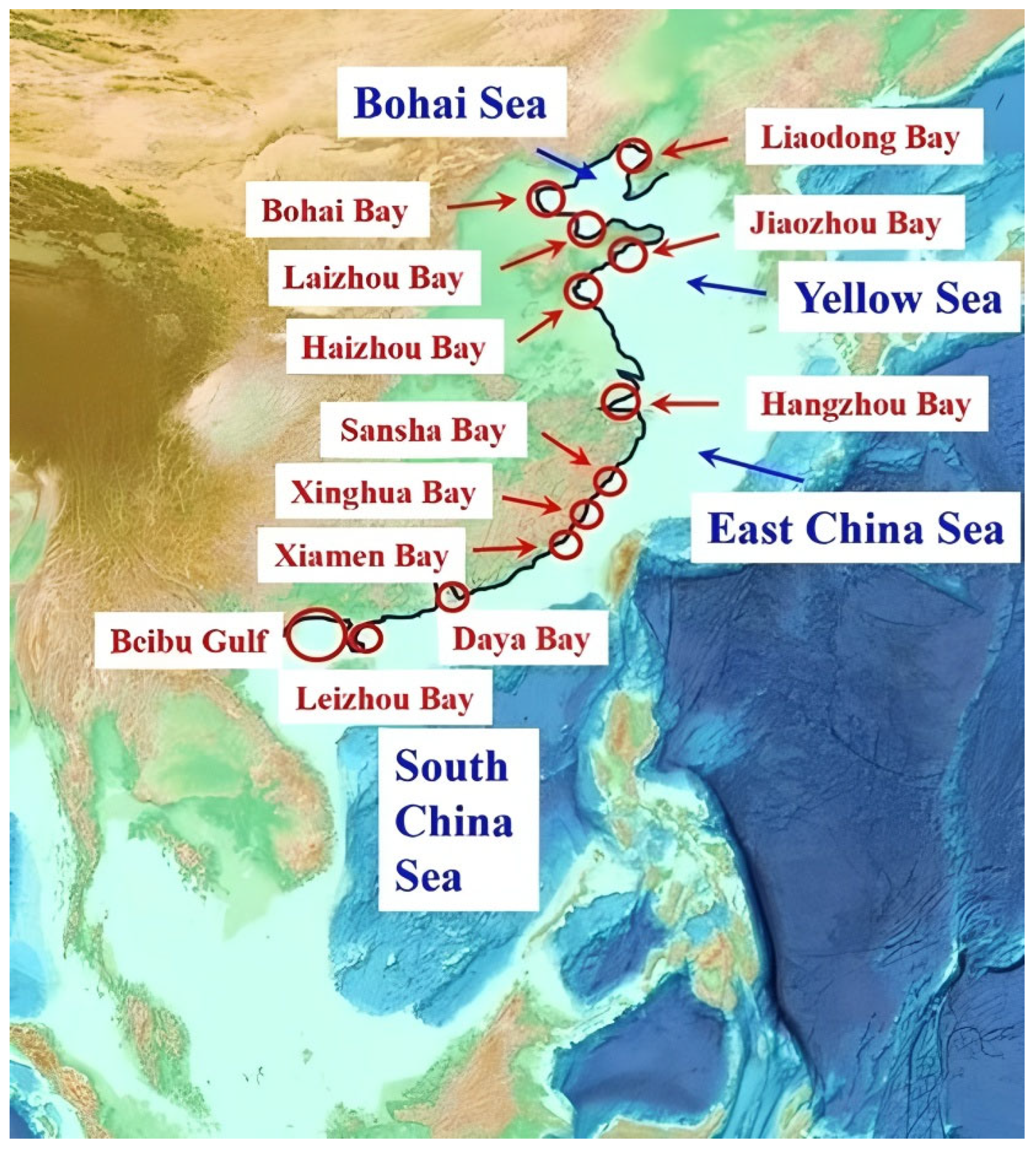

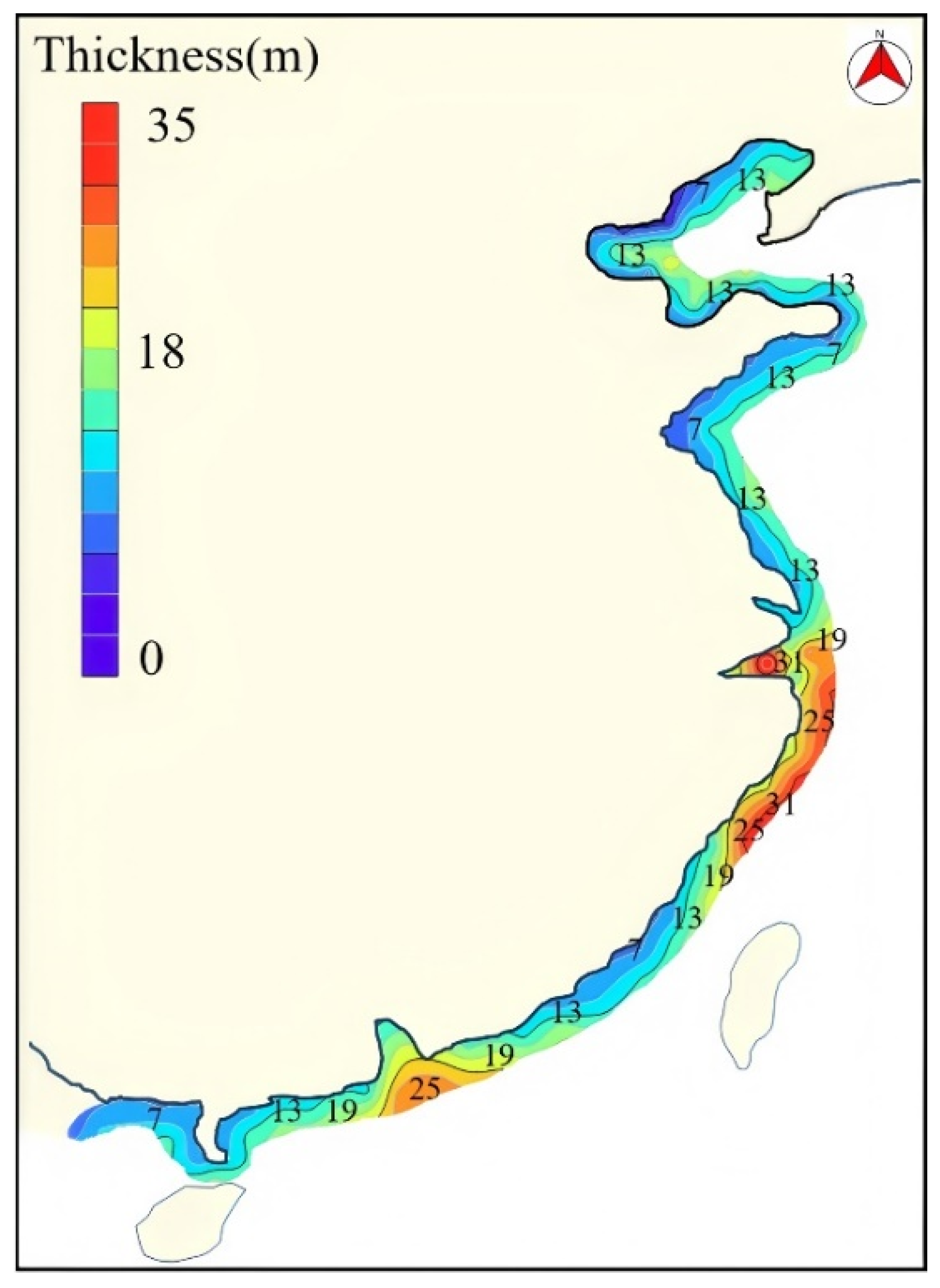

64]. The total thickness of a soft mud layer generally ranges from 10 m to 30 m along China’s coasts (

Figure 3).

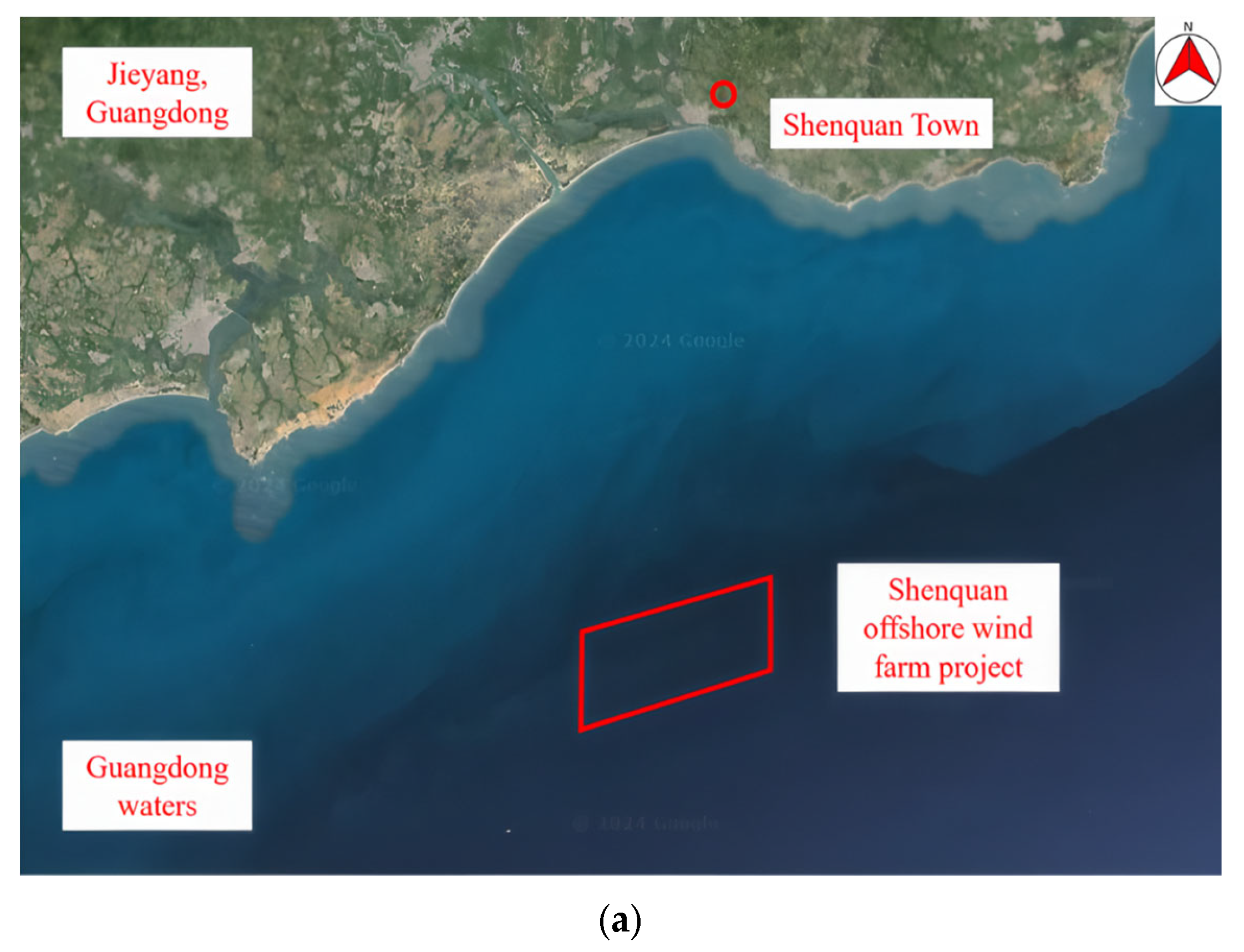

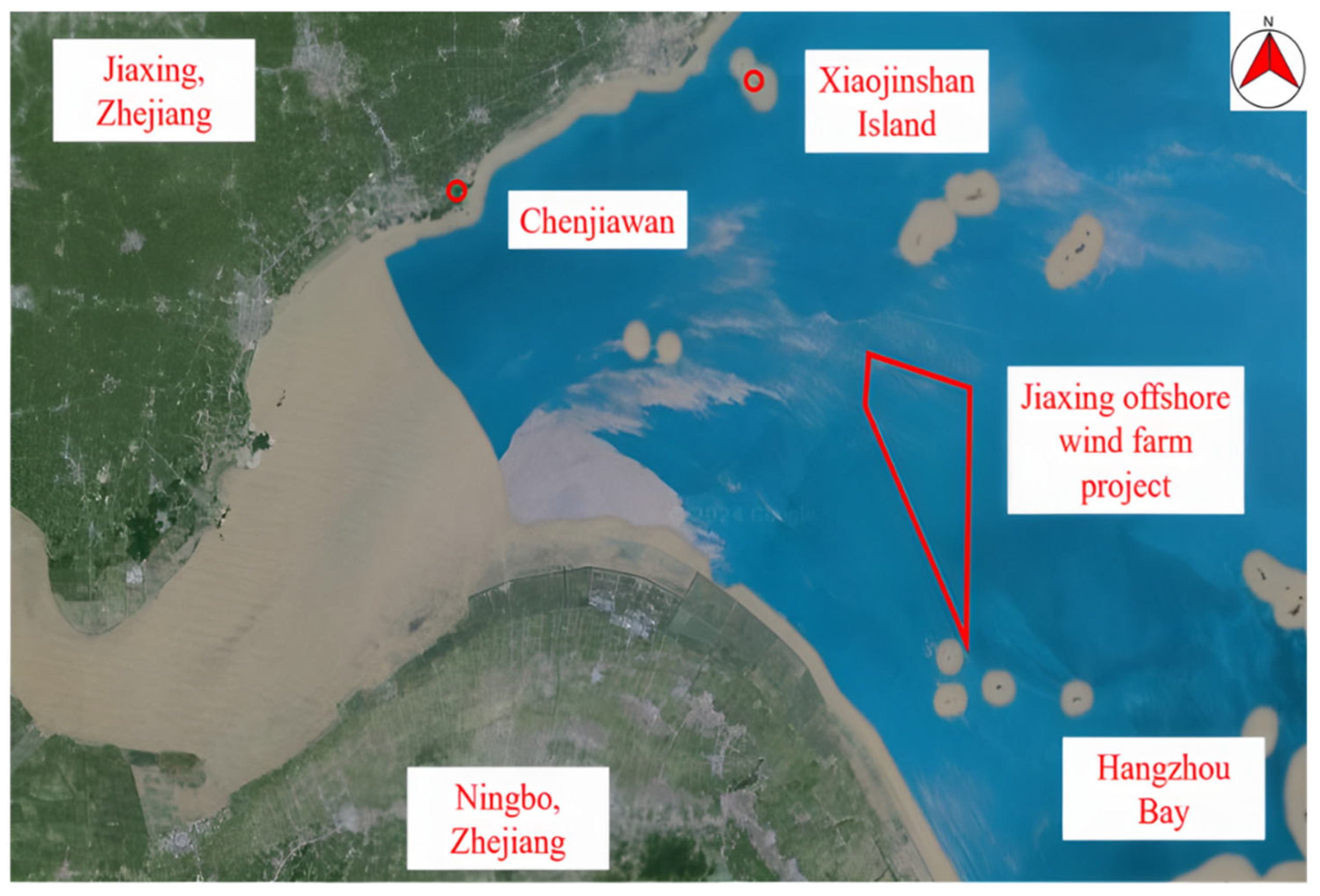

Due to the low bearing capacity and susceptibility to significant settlement, soft mud layers are a common challenge in offshore geotechnical engineering. During the Shenquan offshore wind farm project in the Guangdong offshore areas, three layers (Layers 1-1, 1-2 and 2-1) of soft mud were identified (

Figure 4a). The site is located approximately 26 km offshore, with a water depth ranging from 32 to 37 m and covers an area of about 64 km

2. The project planned to install 66 wind turbines with a total wind power capacity of 400 MW. The seabed soil properties were obtained by a combination of drilling and CPTU tests. The soil types, shear strengths and stratigraphy were interpreted from the CPTU data, i.e., the tip resistance

qc, the friction resistance

fs and the pore pressure

u2 [

21,

89], with an example presented in

Figure 4b. The detailed soil stratigraphy is outlined as in

Table 1, and the soft mud layers are described as follows:

Layer 1-1: This layer consists of silt mixed with mud, and it is grey, saturated and predominantly loose, with some areas slightly dense. The main minerals are quartz and feldspar, with poor gradation. This layer includes shell debris and contains a large amount of fine-grained soil, partially in the form of silt mixed with sand, which is indicative of marine sedimentation. In the CPTU, the tip resistance qc ranges from 0.93 to 3.00 MPa, with an average of 1.71 MPa, while the friction resistance fs ranges from 8.2 to 24.6 kPa, with an average of 13.0 kPa. The thickness of this layer is between 4.9 and 13.5 m.

Layer 1-2: This layer consists of muddy silty clay with silt, and it is grey and plastic, containing silt particles and organic matter with a noticeable odour. Shell fragments with size of 0.2–0.5 cm are visible in some parts, along with a thin layer of silt. The measured cone tip resistance qc falls within the range of 0.48–2.00 MPa, and the sleeve friction fs varies from 6.8 to 28.9 kPa. The layer thickness is observed to be between 0.7 and 15.5 m.

Layer 2-1: This layer consists of silty clay, and it is grey and soft plastic, containing fine sand, with occasional organic matter and shell fragments. The cone tip resistance qc ranges from 1.29 to 2.82 MPa, and the sleeve friction fs varies from 11.8 to 57.7 kPa. The thickness of this layer ranges between 0.6 and 24.3 m.

Based on interpretation of CPTU data, the average undrained shear strength

su of the shallow soft mud layers is approximately 20 kPa. This strength is inadequate to serve as a bearing stratum for monopile foundations supporting wind turbines. According to the API RP 2A-WSD:2014 guidelines, the ultimate axial compressive capacity

Qd of a single pile includes the side resistance

Qf and the tip resistance

Qp as follows:

where

f denotes the unit side resistance,

As represents the total shaft area of the pile,

q indicates the unit end resistance and

At refers to the base area of the pile. For soft mud layers, the unit side resistance

f is determined as follows:

where

P0 represents the overburden pressure and α denotes a reduction coefficient. The unit tip resistance

q is computed using the following formula:

At the base of the initial soft mud layer, which has a depth of 10 m, the calculated unit side resistance f amounts to 19.8 kN/m2 while the unit tip resistance q is measured at 180 kN/m2. Given a pile diameter of 6 m, the ultimate axial compressive capacity Qd is determined to be as low as 8821 kN. This indicates that the soft mud layers are unsuitable to be a bearing stratum.

The risk of seismic subsidence from earthquakes should also be considered for soft mud layers when the design seismic intensity is equal to or greater than 7. If the equivalent shear wave velocity of the soil layer exceeds the critical value specified in

Table 2, the effects of seismic subsidence may be considered negligible. Otherwise, the further assessment of seismic subsidence potential is recommended. Due to the complex hydraulic environment underwater, conventional reinforcement techniques for soft soils on land, such as vibro-compaction, deep soil mixing and prefabricated vertical drains, are not applicable to seabed soft mud layers. Consequently, in offshore engineering design, it is advisable to avoid selecting soft mud layers as the bearing strata for undersea structures.

3.2. Shallow Gas and Pockmarks

Shallow gas refers to natural gas that accumulates locally within shallow seabed strata. Shallow gas can be categorized into two types according to origin, namely biogenic and thermogenic gases [

90]. Biogenic gas originates from the decomposition of shallow terrestrial organic matter through bacterial activities and is found at depths ranging from a few metres to hundreds of metres. It is primarily located in harbours (e.g., Hangzhou Bay, Xiamen Bay) [

91,

92], buried paleo-deltas [

93] and paleo-channels [

94]. Thermogenic gas is the accumulation of free gas that is released from source rocks at depths of thousands of metres through faults. It is mainly stored near marine hydrocarbon-rich basins, such as the Yinggehai Basin [

95,

96]. In coastal plains and offshore areas of China, shallow gas is predominantly stored in incised Quaternary valleys and erosion grooves in the form of high-pressure gas pockets. The distribution of the shallow gas off China’s coasts is presented in

Figure 5. A gas-bearing soil layer often has excessive pore waters, resulting in a significant reduction in soil shear strength. With sustained external loading, the soil may creep and lead to anisotropic sliding and severe settlement [

97]. Consequently, such a soil layer is unsuitable to be the bearing stratum for undersea structures. When geotechnical investigation instruments are pulled out of the gas-bearing soil stratum, gas can leak or even blow out into the water, posing a risk of explosion if the gas concentration reaches a certain level. There have been reports of injuries and structural damage caused by gas burns and the induced shock waves. In engineering practices, the pre-releasing of gas by digging a vent well is an effective method to mitigate shallow gas hazards [

98,

99].

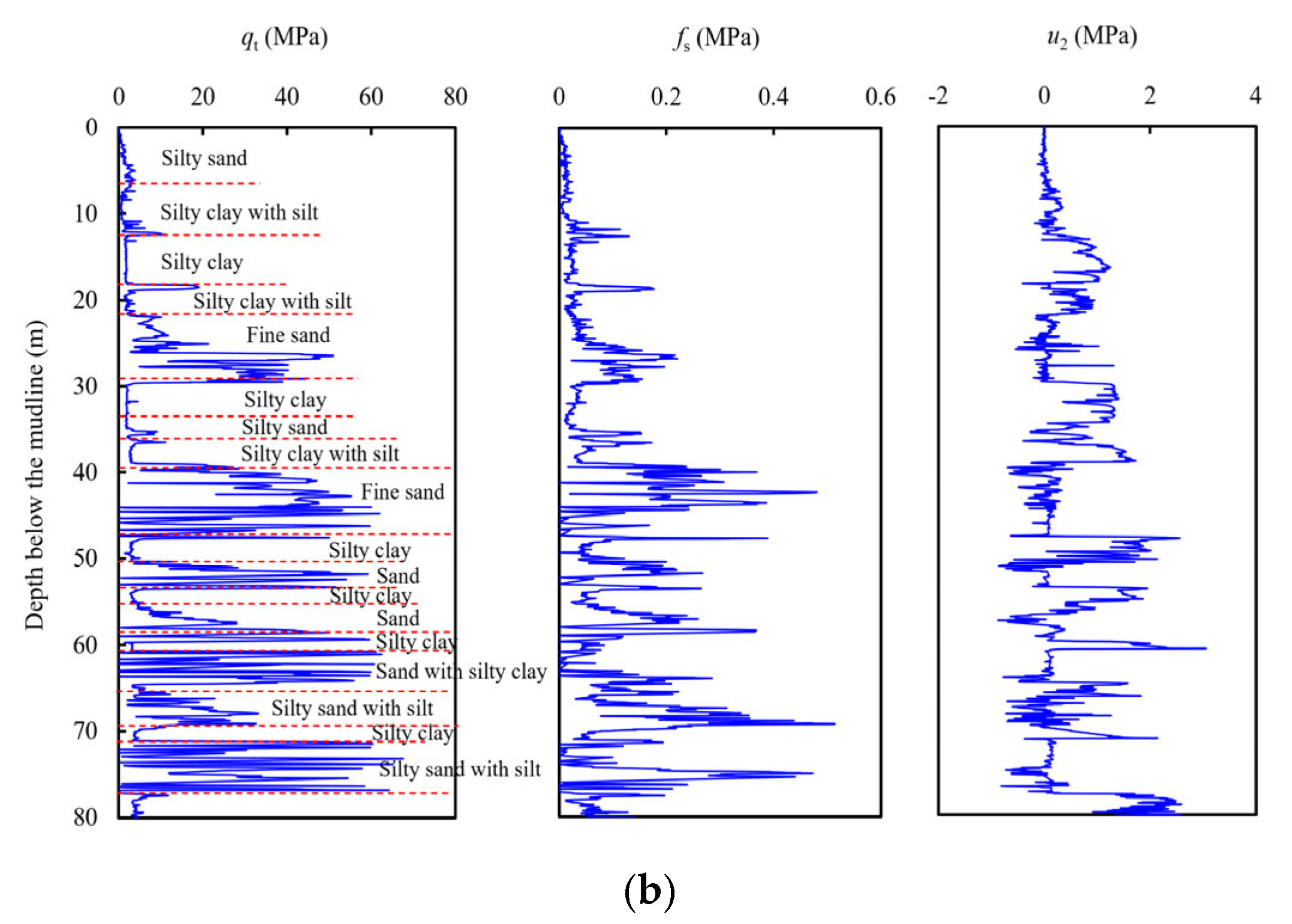

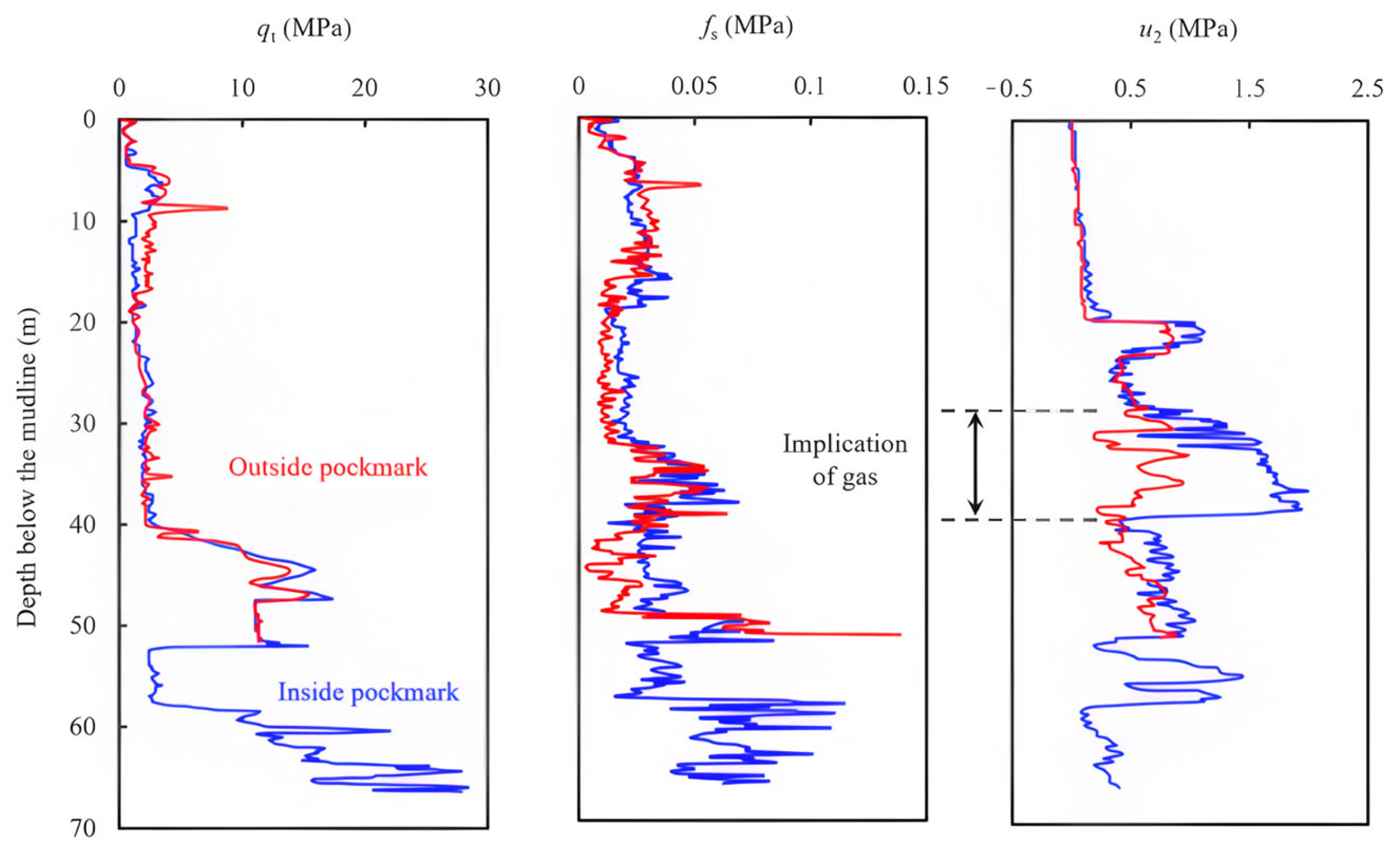

Shallow gas was found at the Pinghu area of the Hangzhou Bay during the Jiaxing offshore wind farm project (

Figure 6). The entire project site is roughly 9 km from the east to the west and 2 to 17 km from north to south. There were roughly 20 km offshore at the centre of the wind farm. The water depth ranges between 8 and 12 m. With a maximum slope of less than 1°, the seabed topography is comparatively flat. The project plans include the installation of 72 wind turbines with a single unit capacity of 4.0 MW and 2 wind turbines with a single unit capacity of 6.0 MW, yielding a total wind energy capacity of 300 MW. Shallow gas was detected through drilling and CPTU at wind turbine Positions 37#, 38#, 40#, 46#, 52#, 60#, 61#, 65#, 66#, 70# and 73#, as well as at the offshore booster station Position SJT1 (

Table 3). When the cone of the CPTU stops penetrating at a certain depth, the pore water pressure starts to dissipate gradually to a stable value [

105]. Shallow gas can be identified by a stable value greater than zero. At the Jiaxing offshore wind farm project site, the shallow gas is mainly buried in early Holocene silty clays, silty sands and clayey silts. The silty sands and clayey silts with large particles and high porosity serve as effective gas storage layers. The silty clay, rich in organic matters and humus, such as mica and shells, acts as both a gas source layer and an overburden layer, preventing shallow gas from escaping. The eruption durations at Positions 38#, 40#, 66#, 70# and 73# were very long, lasting around 7 months.

The venting of shallow gas into water is often accompanied by pockmarks, which are induced by the collapse of sediments along the gas transport channel caused by excessive pore pressure [

106]. The shear strength of sediments found in the pockmarks typically diminishes as they experience remoulding. At the wind turbine Position 40# in the Pinghu area of the Hangzhou Bay (

Table 3), CPTU tests were performed inside and outside of a pockmark on the seabed after two months after the release of shallow gas (

Figure 7). The pore pressure inside the pockmark was approximately three times that of on the outside of it at a depth of 30 to 40 m, which suggested that the shallow gas had not been completely released. This observation was confirmed by subsequent tests, which revealed that full gas release at this location took seven months.

3.3. Sand Liquefaction

Sand liquefaction is the process by which a saturated sandy soil transforms from a solid to a liquid state, accompanied by a significant loss of shear strength. Strong vibrations are the primary cause of liquefaction, which increases the pore water pressure within the sand fabric and hence decreases the intergranular contact stresses. Sand liquefaction mainly occurs in areas with predominantly sandy soils, which are common off the coasts of China, including the Laizhou Bay [

107], the Hangzhou Bay, the Fujian and Guangdong offshore areas [

108] and the Beibu Gulf [

109,

110].

In engineering practice, the preliminary assessment of soil liquefaction is based on clay content. A soil layer may be preliminarily classified as non-liquefiable if its clay content (particles < 0.005 mm) reaches or exceeds 10%, 13% and 16% under seismic intensities of 7, 8 and 9, respectively. Soil liquefaction can be further investigated using the standard penetration test (SPT), as outlined in MOHURD (2016) [

111], the 1996 NCEER guideline [

112] and BS (2004) [

113].

According to MOHURD (2016), the liquefaction is quantified by an index

IlE, which can be calculated as follows:

where

Ni and

Ncri are the blow counts and its critical value of the SPT at Point

i, respectively,

n is the total number of SPT points within a single borehole,

di is the thickness of the layer at Point

i and

wi is a dimensionless coefficient determined by the thickness and the depth of the layer at Point

i. The critical value of SPT

Ncri is calculated as follows:

where

N0 represents the reference standard penetration test (SPT) blow count,

ds denotes the depth of the penetration point,

dw indicates the groundwater table depth,

ρc refers to the clay content percentage and

β is the adjustment coefficient for the seismic group.

As recommended in the 1996 NCEER guideline, soil liquefaction can be assessed by the anti-liquefaction safety factor as follows:

where

CRR refers to the cyclic resistance ratio,

CRR7.5 denotes the cyclic resistance ratio for a magnitude 7.5 earthquake,

CSR stands for the cyclic stress ratio and

MSF is a factor associated with the design seismic intensity. For

FS ≥ 1, the soil is non-liquefiable. Otherwise, the soil is liquefiable. The cyclic stress ratio

CSR can be calculated as follows:

where

σvo represents the total vertical overburden stress, while the effective vertical overburden stress is denoted as

. The peak horizontal ground surface acceleration is denoted by

amax,

g is gravitational acceleration and

rd is the stress reduction coefficient. The value of

rd can be estimated using the following relationship [

114]:

where

z is the depth of the soil layer. The cyclic resistance ratio for a magnitude 7.5 earthquake

CRR7.5 can be derived from the SPT as follows:

where (

N1)

60cs is the corrected blow counts and is calculated as follows:

where

α and

β denote fines content-dependent correction coefficients,

Nm is the measured SPT blow count and

Cn is the overburden stress correction coefficient which also incorporates adjustments for equipment and procedures (e.g., hammer energy, borehole diameter, rod length and liner usage). It is evident that the soil layer is regarded as non-liquefiable when (

N1)

60cs ≥ 30.

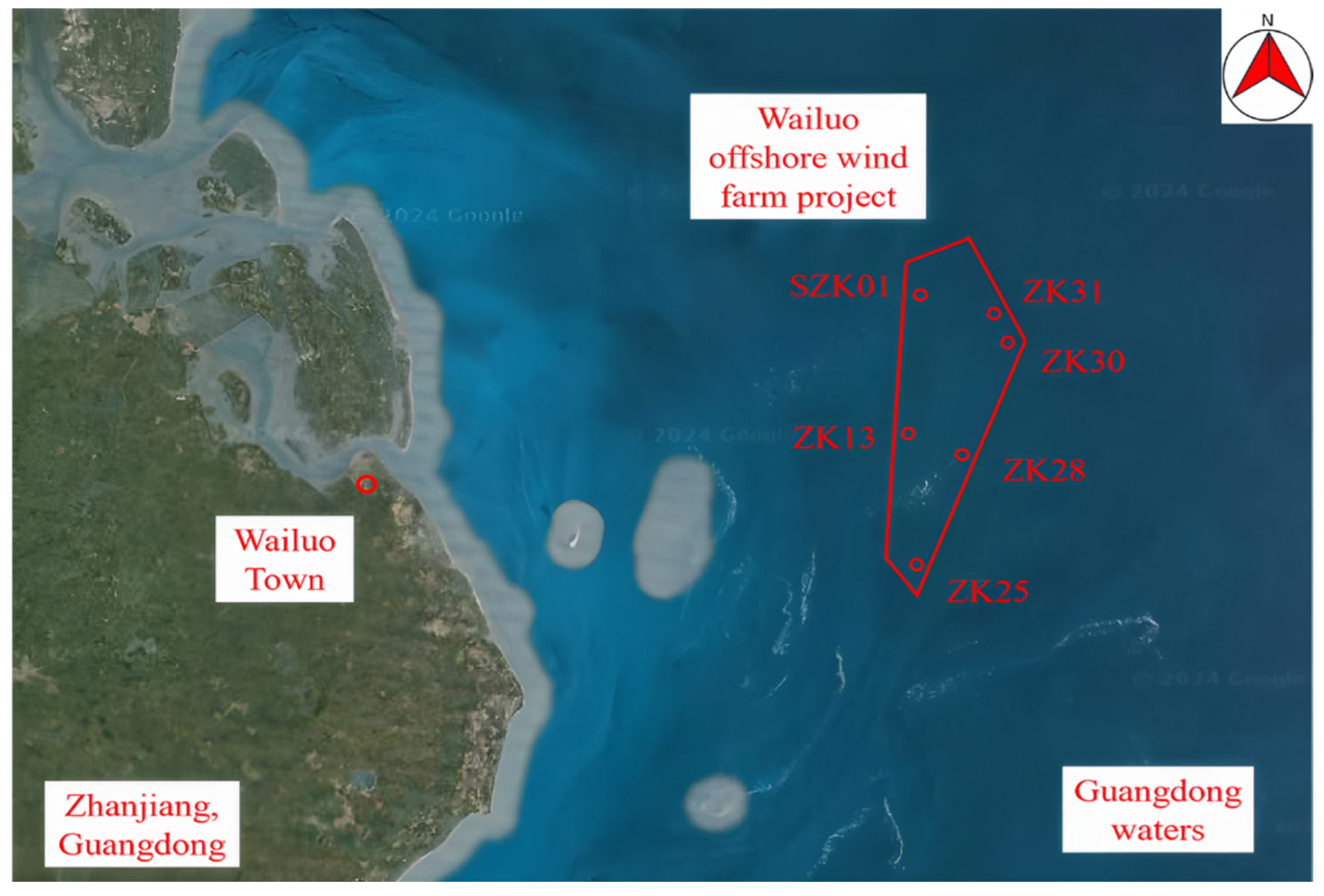

The liquefaction of the seabed soil was assessed at the Wailuo offshore wind farm in the Guangdong offshore area, located 15 km away from the mainland and spanning an area of approximately 23.22 km

2 (

Figure 8). The project planned to install 32 offshore wind turbines, each with a capacity of 6.25 MW, for a total energy capacity of 200 MW. Based on the preliminary assessment,

Table 4 presents the liquefaction evaluation results for soils at various depths across different boreholes. Among these, the N (SPT) values were obtained directly from on-site testing. Both the MOHURD (2016) code and the 1996 NCEER guideline yield similar predictions regarding the liquefaction level. Except for the Holes Z30 and SZK01, all the remaining drilling sites exhibit a high risk of liquefaction. Sand liquefaction may lead to a substantial decrease in the foundation’s bearing capacity and lateral resistance, potentially causing the significant settlement and tilting of the super-structures [

115]. Therefore, areas with a high risk of sand liquefaction should be avoided.

3.4. Dense Sand Layer

In real-world offshore engineering applications, dense sand layers are commonly encountered. These layers typically consist of uniformly fine to medium sized particles (0.03–0.2 mm) and exhibit very high compression moduli (1–10 MPa) as well as very high shear strengths (cohesion

c = 5–15 kPa, friction angle φ > 30°) [

116,

117]. Dense sand layers are a landform produced by interactions between water hydrodynamics, suspended sediments and the packed seabed. Fine particles are usually transported to more distant locations, while coarse particles are deposited in local areas. These coarse grains are tightly packed and constitute the primary framework of the dense sand layers, which are extensively present throughout China’s estuaries and coastal waters.

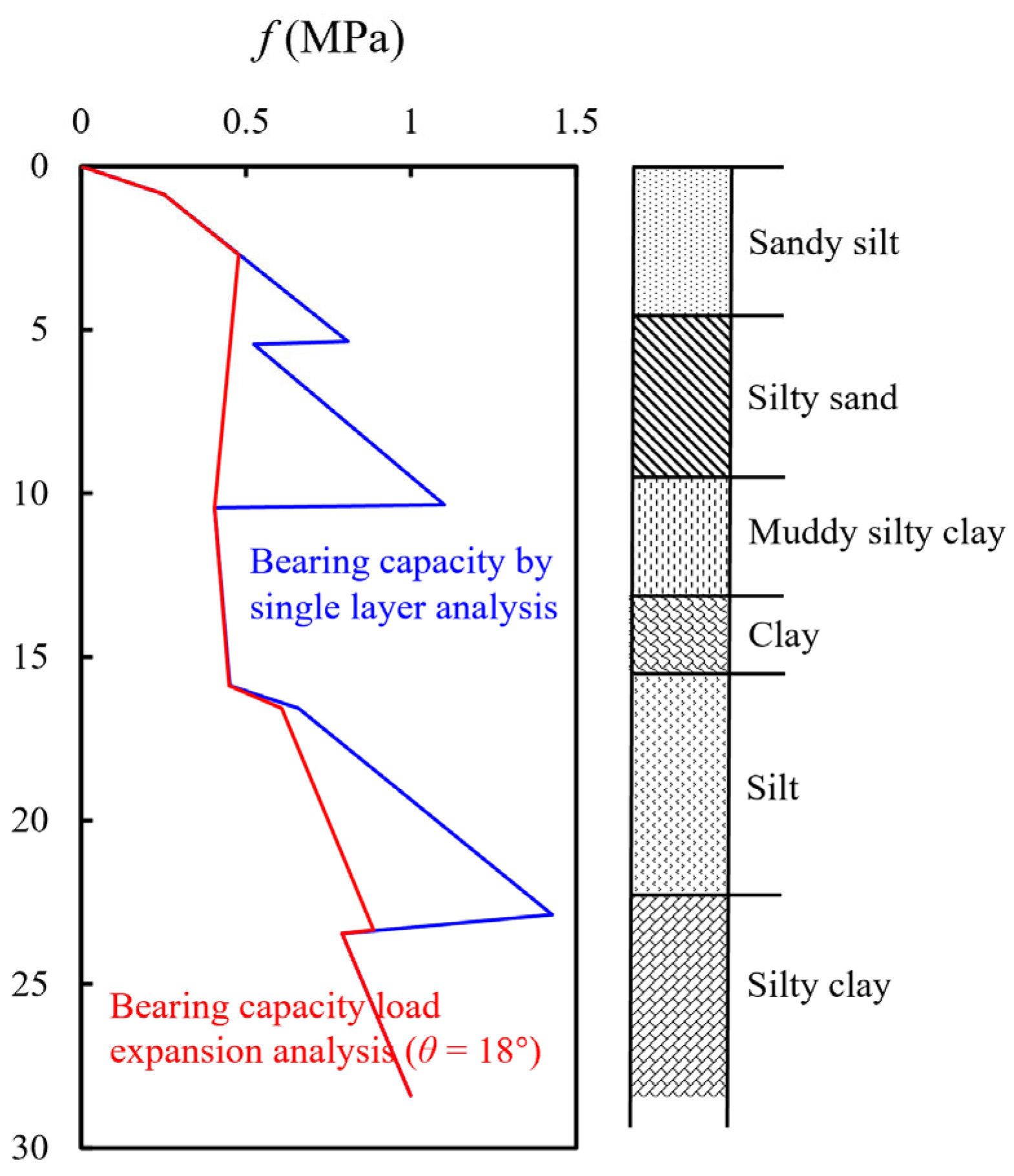

The very high shear strength of the dense sand layers poses significant challenges for in situ geotechnical investigations as probes are difficult to penetrate through such hard strata. In this case, the dense sand layers are drilled to create a hole, allowing the probe to continue advancing. The drilled sample of the dense sand layers can then be taken to a laboratory for further geotechnical tests. Dense sand layers were found at the Yellow Sea during the Binhai offshore wind farm project (

Figure 9), which are located approximately 36 km from the shore and has a water depth of about 16–19 m. The planned wind farm extends about 13 km parallel to the coastline with a width of about 6.8 km, covering an area of around 48 km

2. The project planned to install 75 offshore wind turbines, each with a capacity of 4.0 MW, for a total capacity of 300 MW. The seabed soil was found to consist of two layers (Layers 1 and 2), as presented in

Table 5. The physical and mechanical characteristics of both layers were evaluated using laboratory testing.

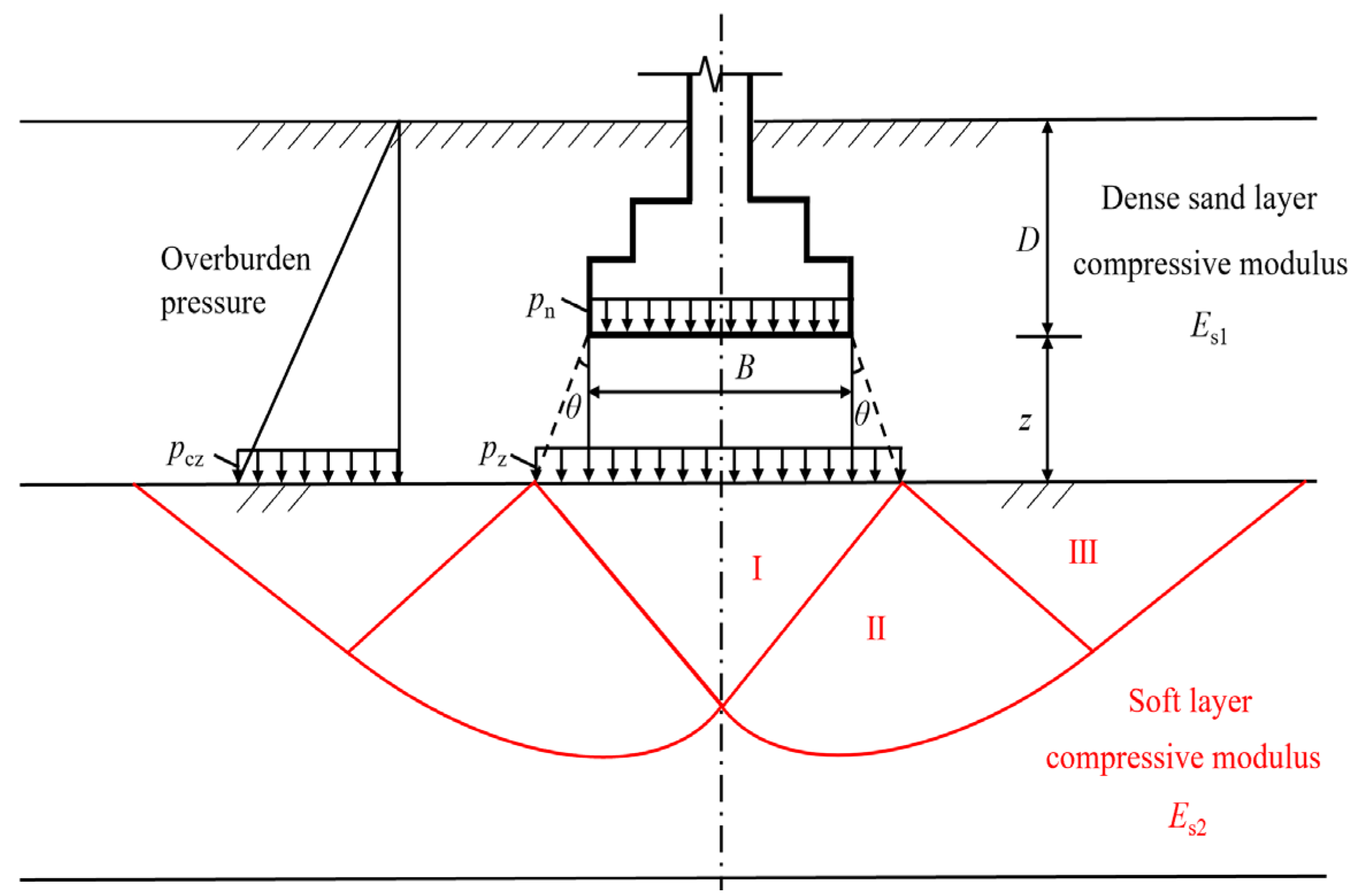

The dense sand layers, due to their very high strength values, can serve as bearing strata for offshore foundations. When the dense sand layers are underlain by a soft soil layer, it is essential to assess the potential for a ‘punch-through’ failure mechanism, where slip lines propagate through both the hard and soft layers [

118,

119]. The surcharge load on the foundation is distributed to the top surface of the underlying soft layer at a certain expansion angle (

Figure 10). The stability of the soft layer, under the combined loading of the expanded surcharge and the self-weight pressure, can be evaluated by Prandtl’s solution [

120]. The expanded surcharge can be calculated as follows:

where

pn is the surcharge pressure at the foundation base,

B is the foundation width and

z is the distance from the foundation base to the top of the soft layer. The expansion angle,

θ, can be empirically determined from

Table 6. Taking the Binhai offshore wind farm project at the South Yellow Sea as an example, both the conventional single-layer analysis and the load expansion analysis methods [

11,

13,

121] were employed to predict the bearing capacity of the soil layer (

Figure 11). If the total pressure at the bottom of foundation exceeds the bearing capacity of the underlying soft layer, a punch-through failure will occur.

3.5. Boulder Stones

Boulder stones are the remainders of the originally intact rock blocks that have undergone natural weathering. The boulder stones, also known as granite weathering balls, are generally spherical with diameters ranging from 0.5 to 8 m. The formation of the boulder stones is influenced by various factors, including lithology, joints, climate and topographic conditions [

122,

123]. The mechanical properties of scattering boulder stones greatly vary from one another and from those of the surrounding residual soils. Unlike the surrounding material, boulder stones lack joints and fissures and consist of moderately to slightly weathered rock mass with a compressive strength of up to 160 MPa.

Due to the extremely high strength of boulder stones, the probes of in situ investigation instruments are hard to penetrate through them. In such cases, the stones must be drilled out to allow the probes to advance. When boulder stones are encountered during pile driving, the pile foundation may fail to reach the designed elevation, which leads to insufficient bearing capacity and additional horizontal resistance. The bottom side of a steel pipe pile that comes into direct contact with the boulder stone is at risk of curling and undermines structural safety [

124]. To tackle the challenges posed by boulder stones during pile driving, techniques such as pile planting, pile strengthening and hole-expanding have been developed [

125,

126]. When a shield machine encounters boulder stones in a stratum, these stones pose significant threats to the shield tool and the stratum stability, potentially causing accidents such as tunnel collapse and roof failures. Consequently, drilling and blasting become the primary method for fragmenting these boulders to facilitate subsequent operations.

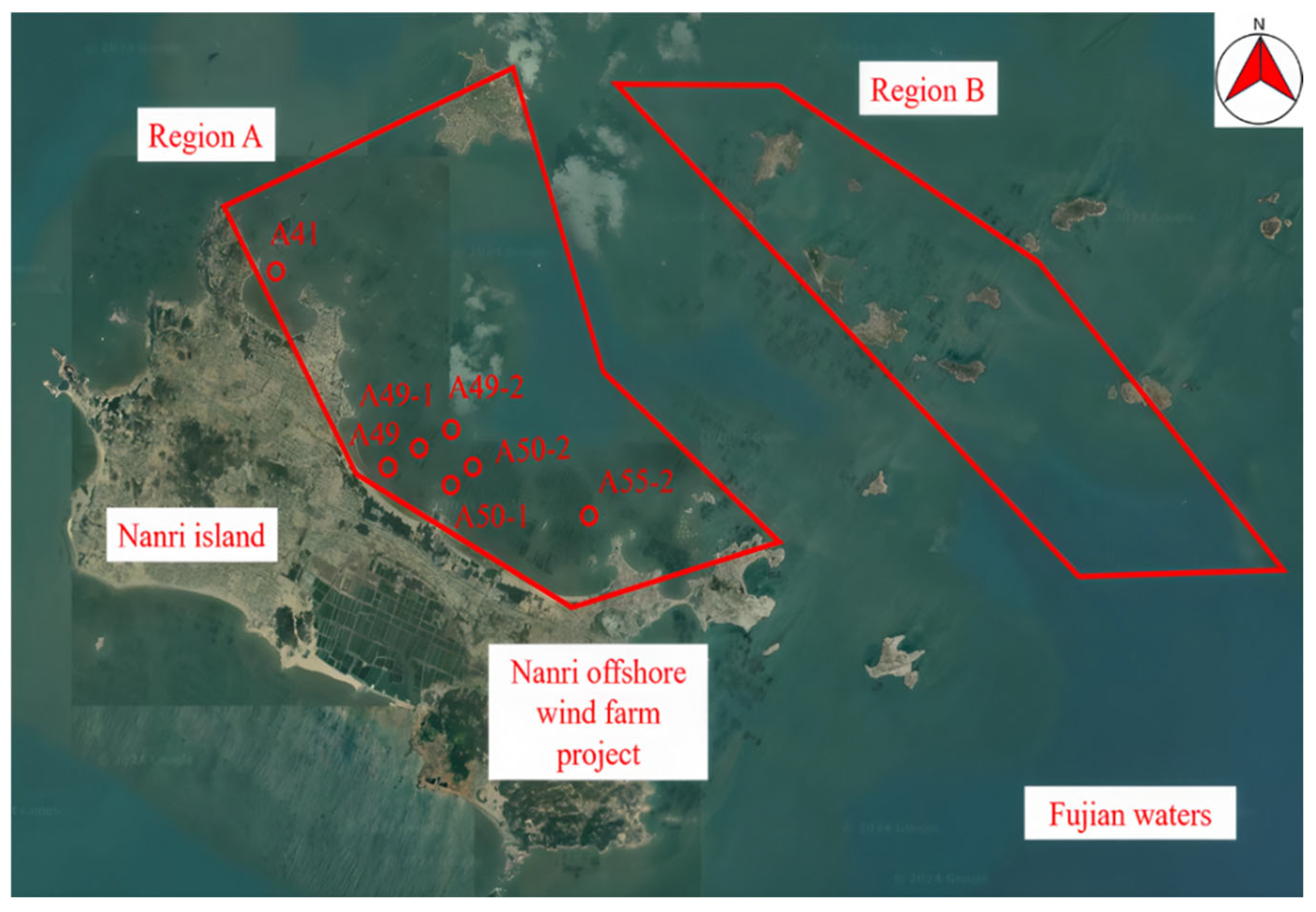

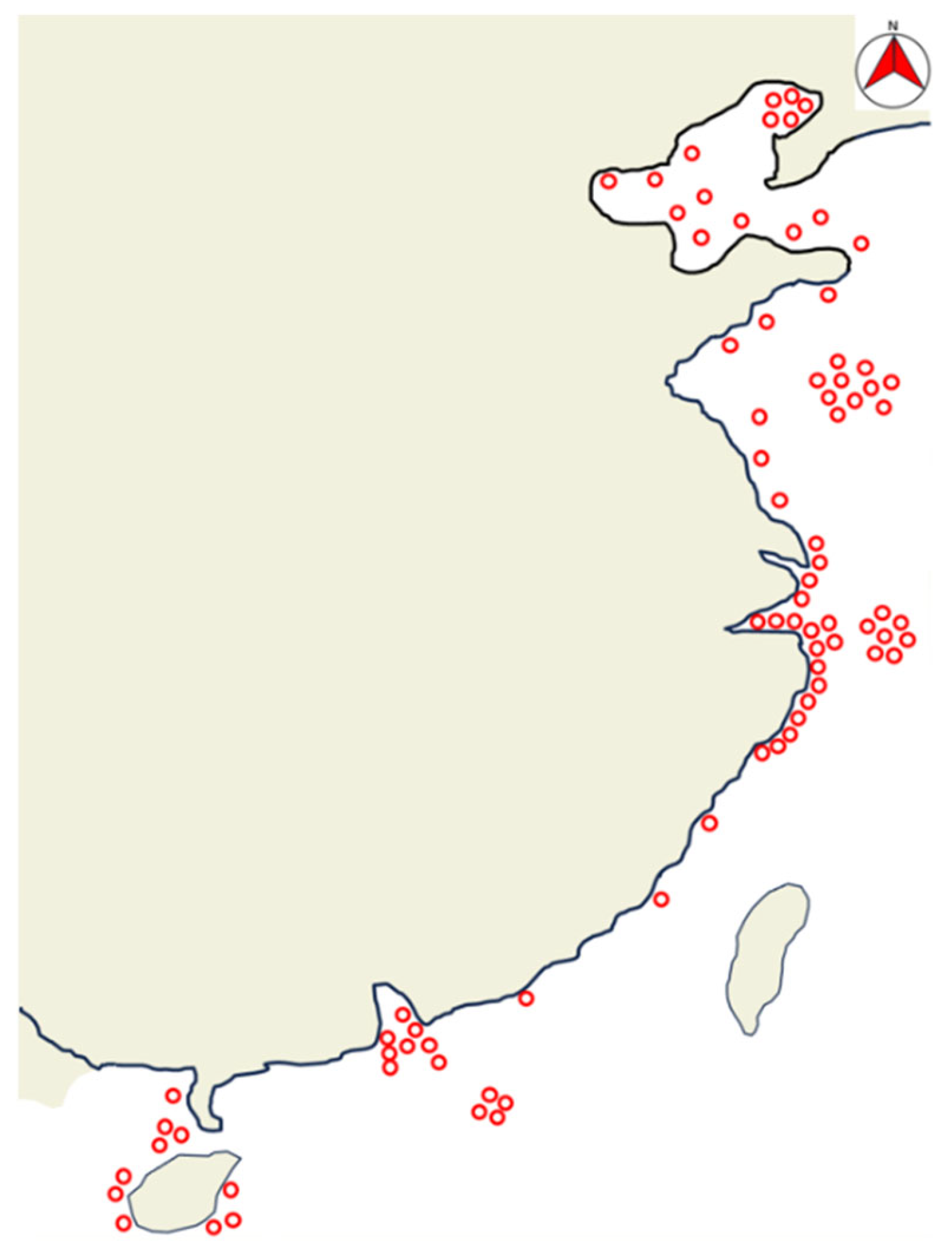

Boulder stones are a common geological phenomenon in granite regions (the eastern and southern parts of China), particularly in the Fujian and Guangdong offshore areas, where their burial and distribution are relatively random. A combination of drilling and geophysical methods is frequently used to identify boulders. Drilling provides the more accurate localization of the stones but is relatively expensive and limited by the survey area. In contrast, geo-physical techniques are more efficient but can be affected by the specific geological environment. During the Nanri offshore wind farm project, boulder stones were found at the Fujian offshore area (

Figure 12). Drilling revealed uneven medium weathering (primarily spherical weathering) of the underlying bedrock, which generated boulder stones with sizes between 0.4 and 2.8 m. The distribution of boulder stones is presented in detail in

Table 7. In engineering practices, the boulder stones need to be removed or smashed before the project is restarted.