Mechanism of Permeability Evolution in Coral Reef Limestone Under Variable Confined Pressure Using Nuclear Magnetic Resonance Technology

Abstract

1. Introduction

2. Test Sample and Test Methods

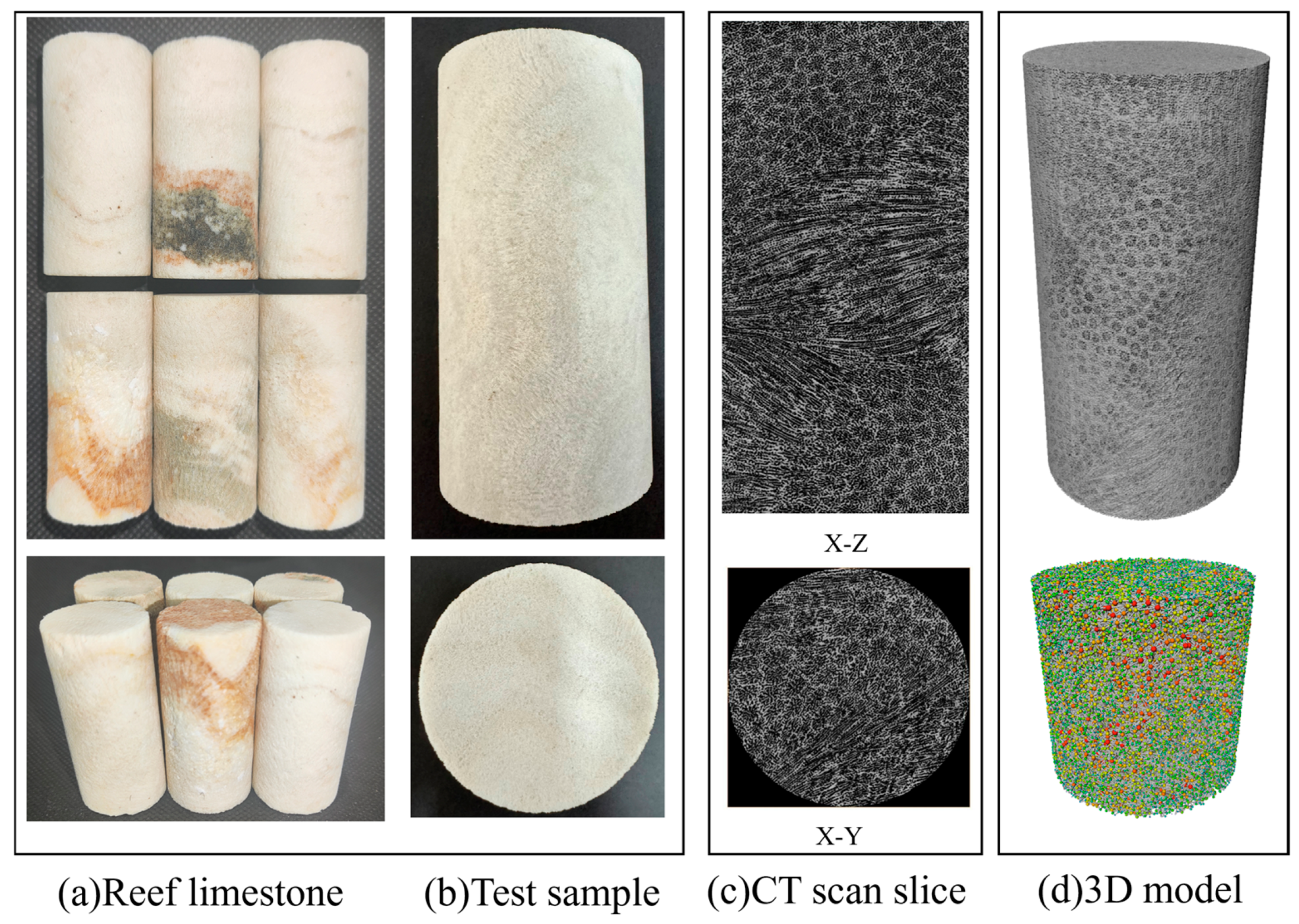

2.1. Physical Properties of Sample

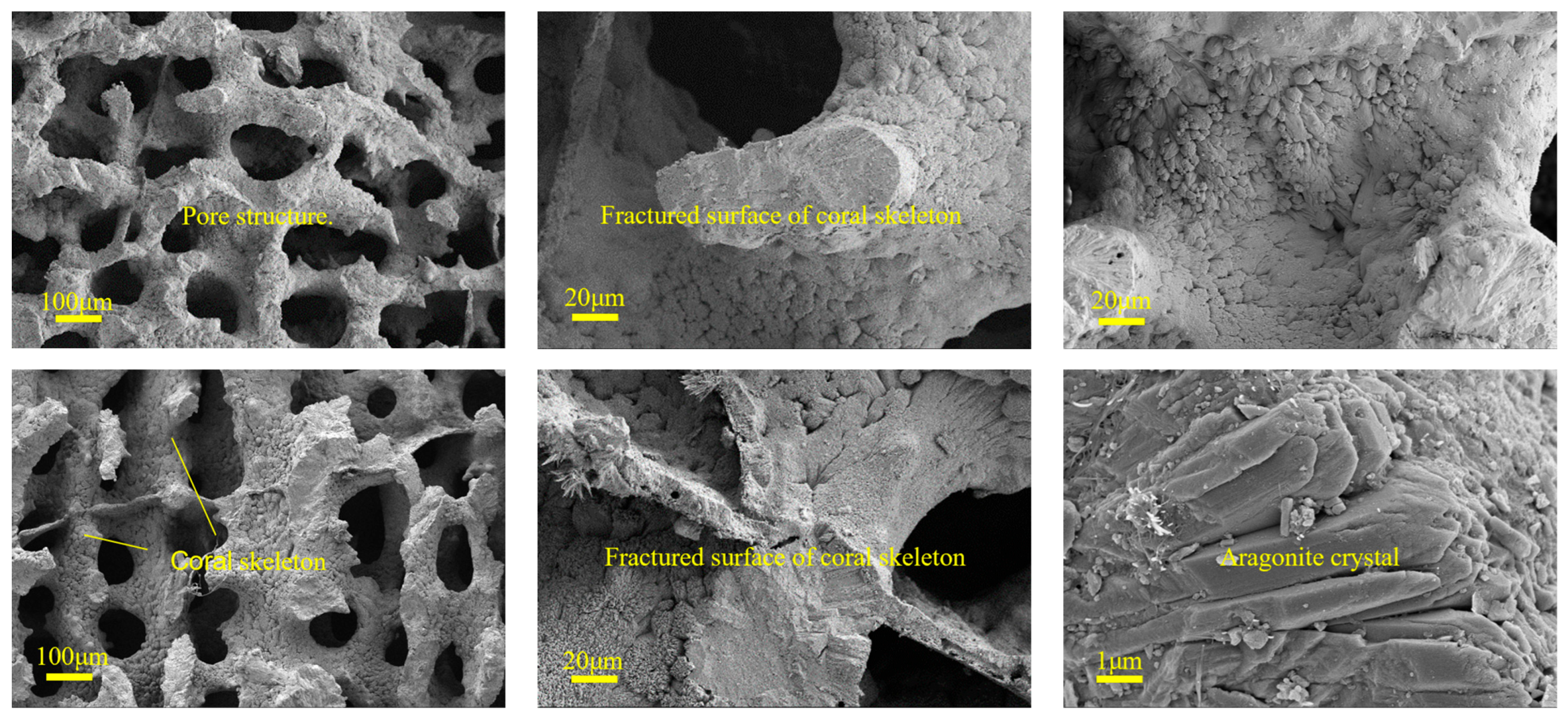

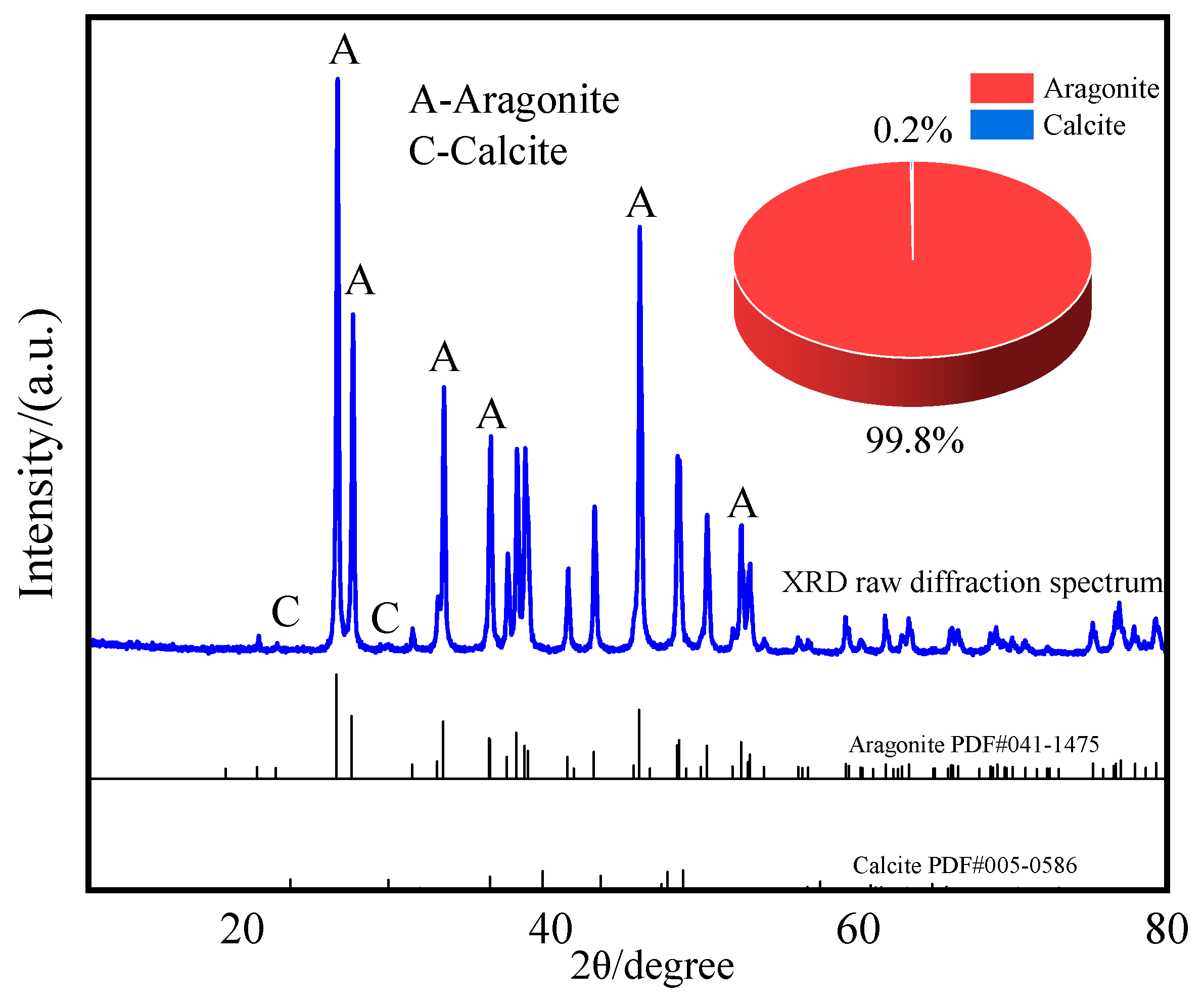

2.2. Microstructural Characteristics and Mineral Composition of the Sample

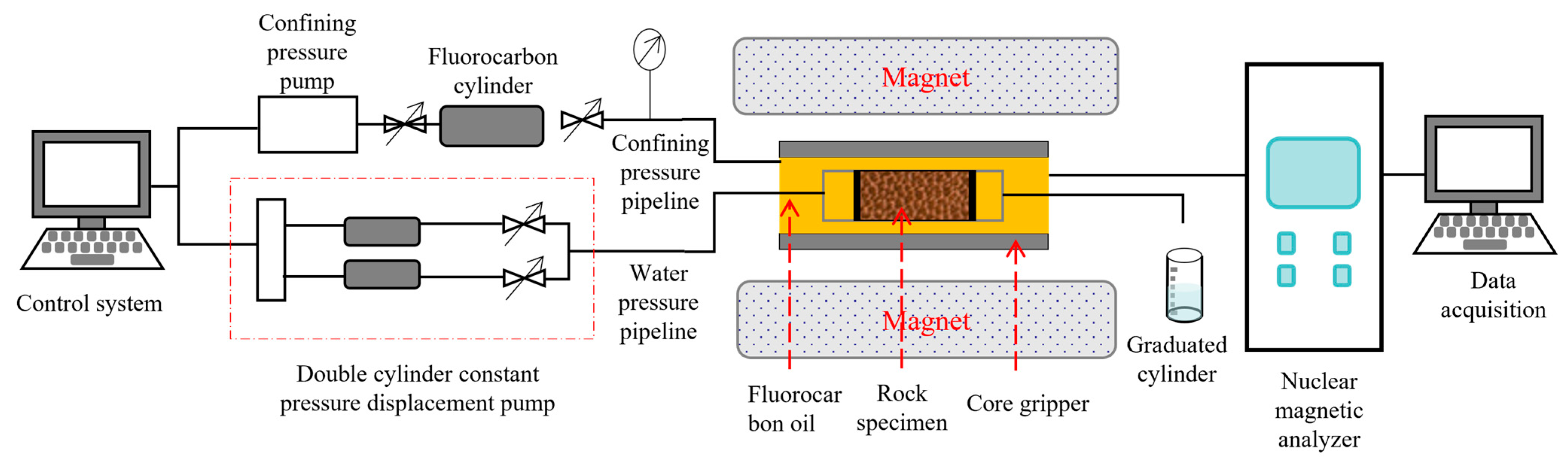

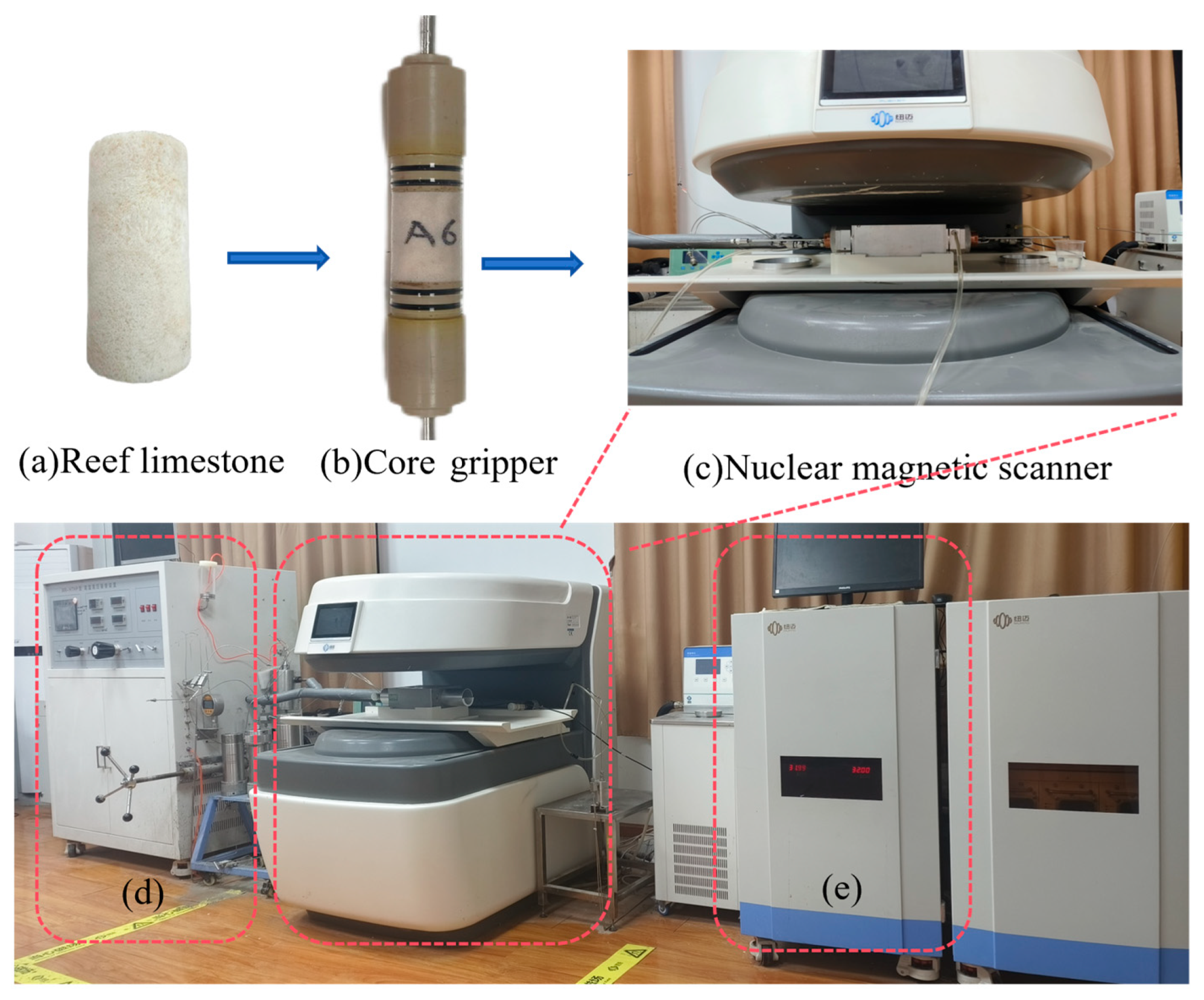

2.3. Test Apparatus

2.4. Principles of Nuclear Magnetic Resonance

2.5. Test Procedure and Program

3. Analysis of Test Results

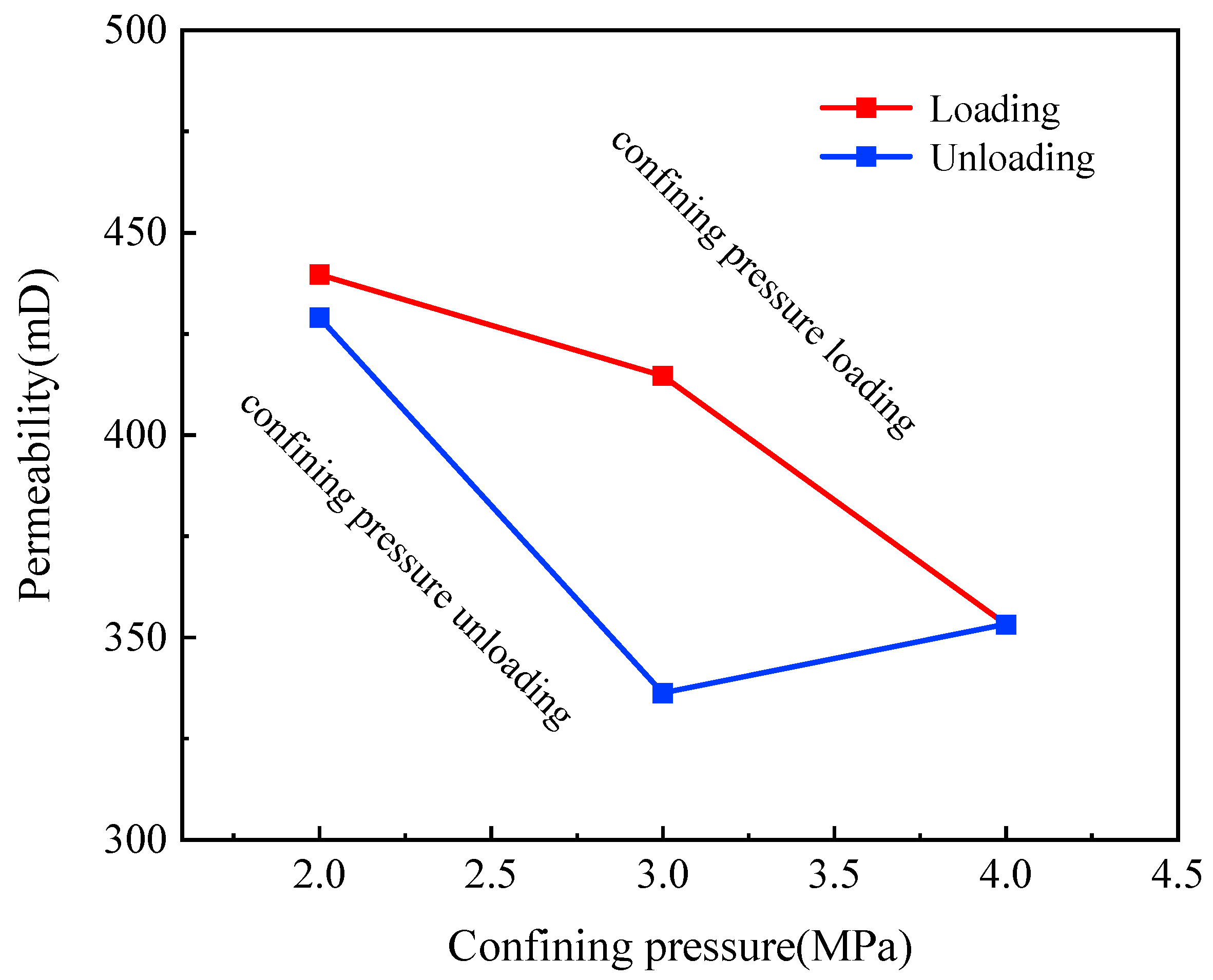

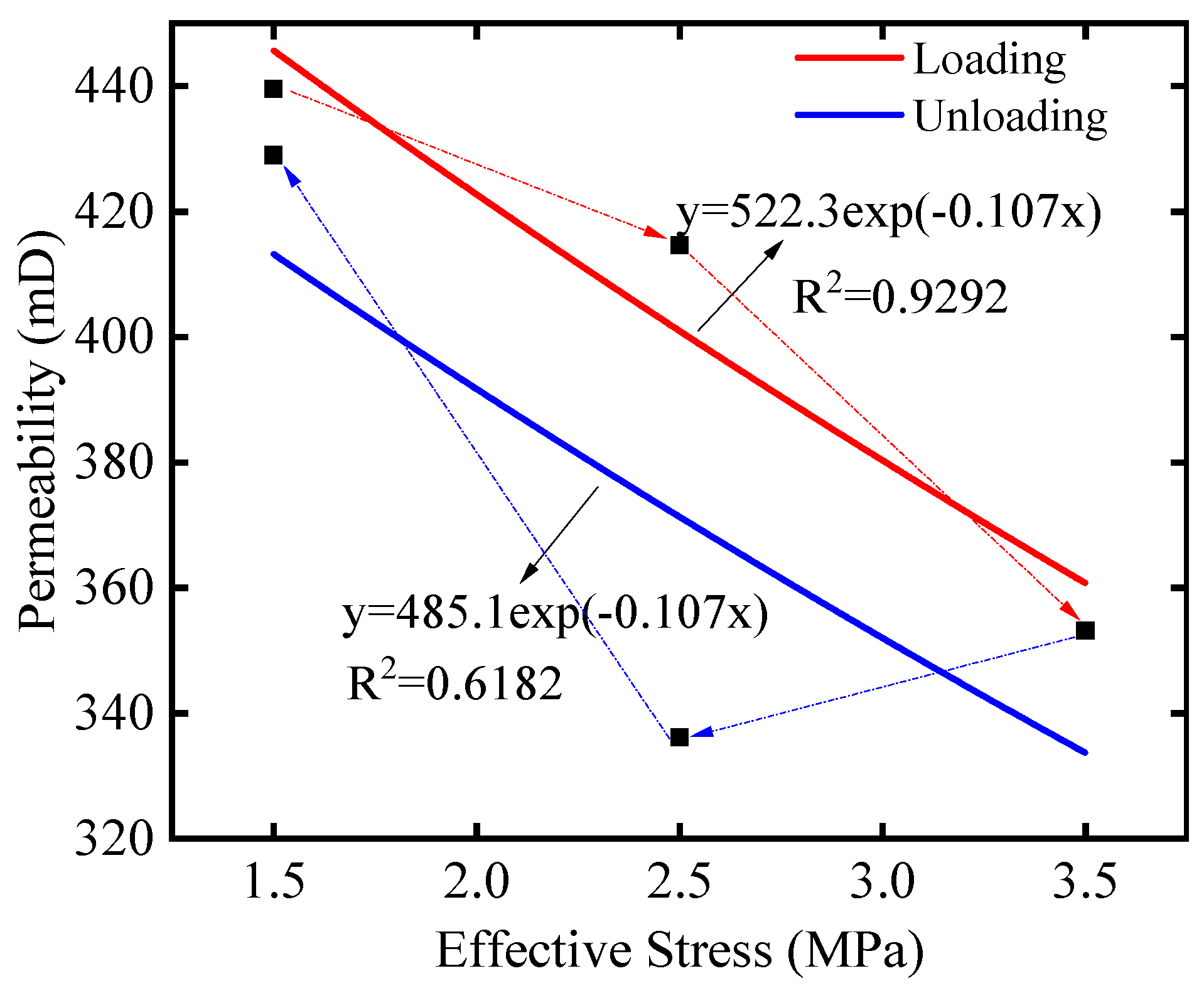

3.1. Permeability Evolution

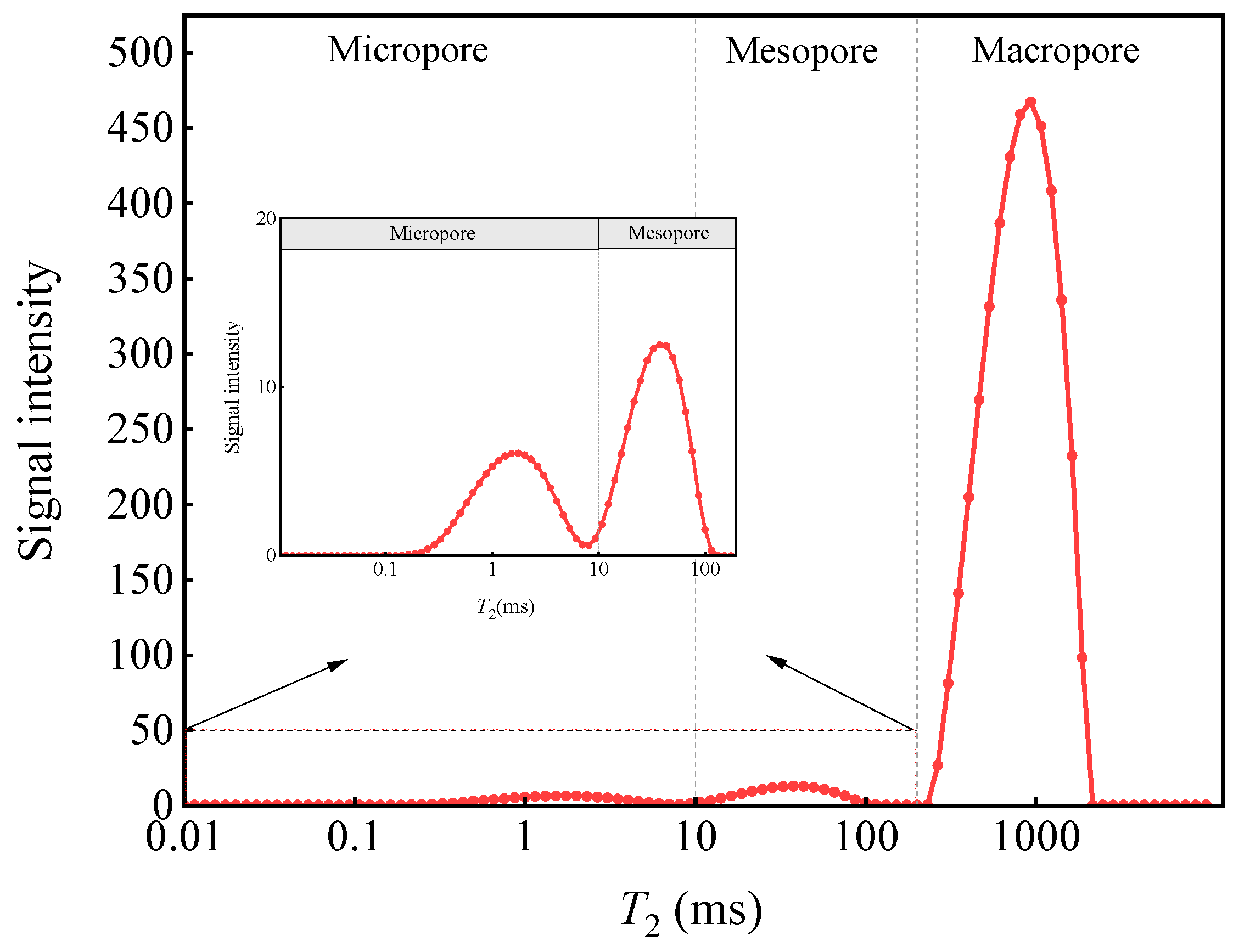

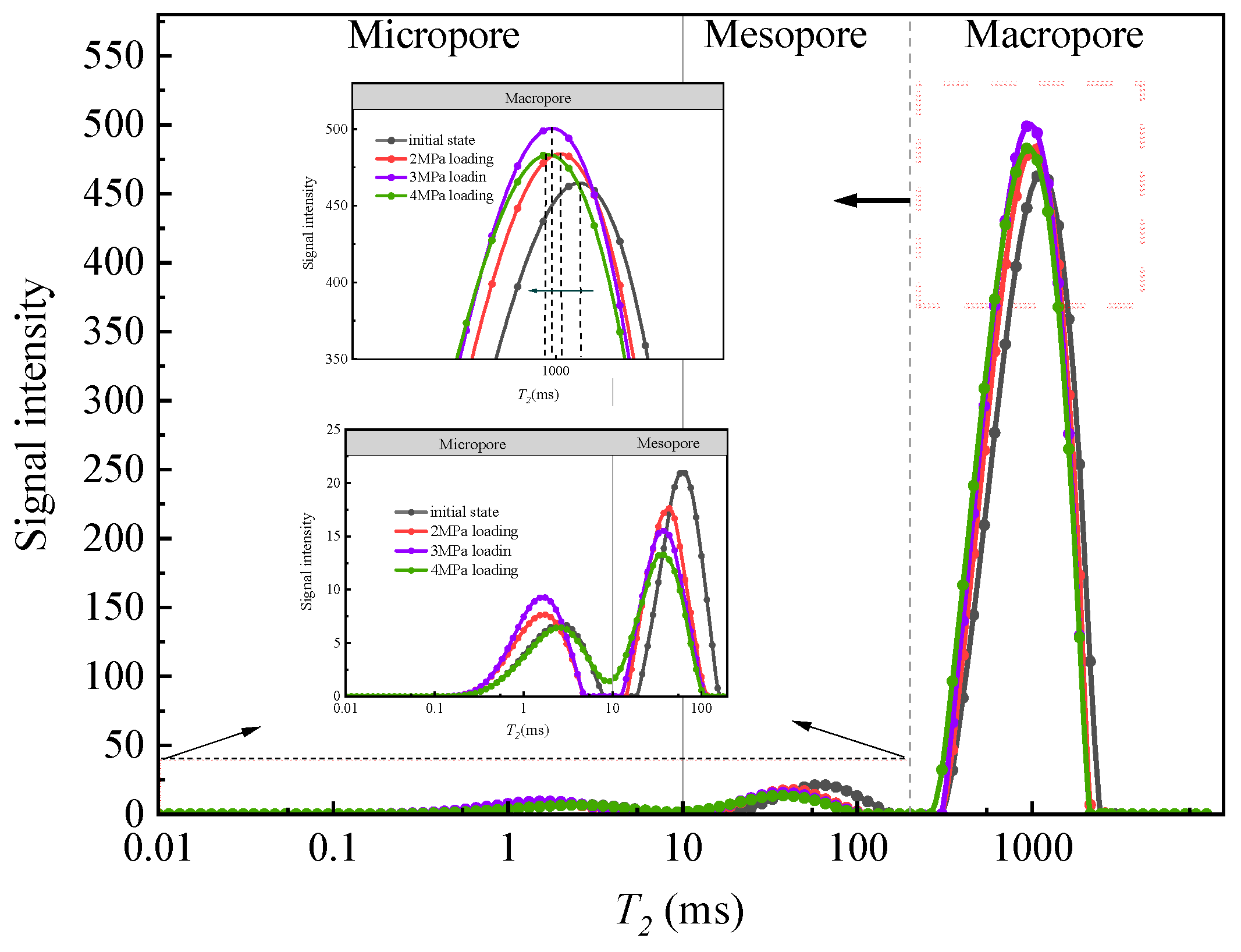

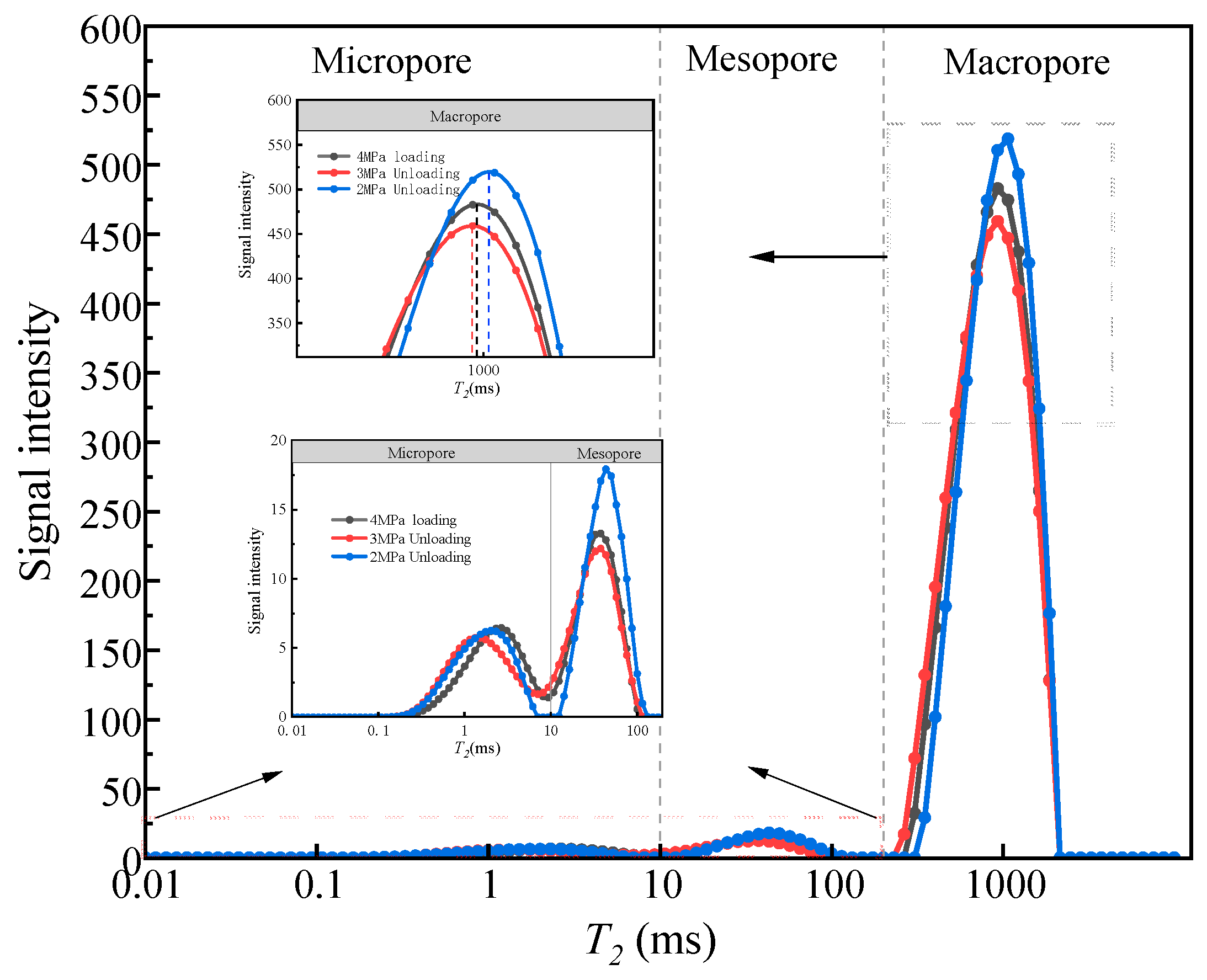

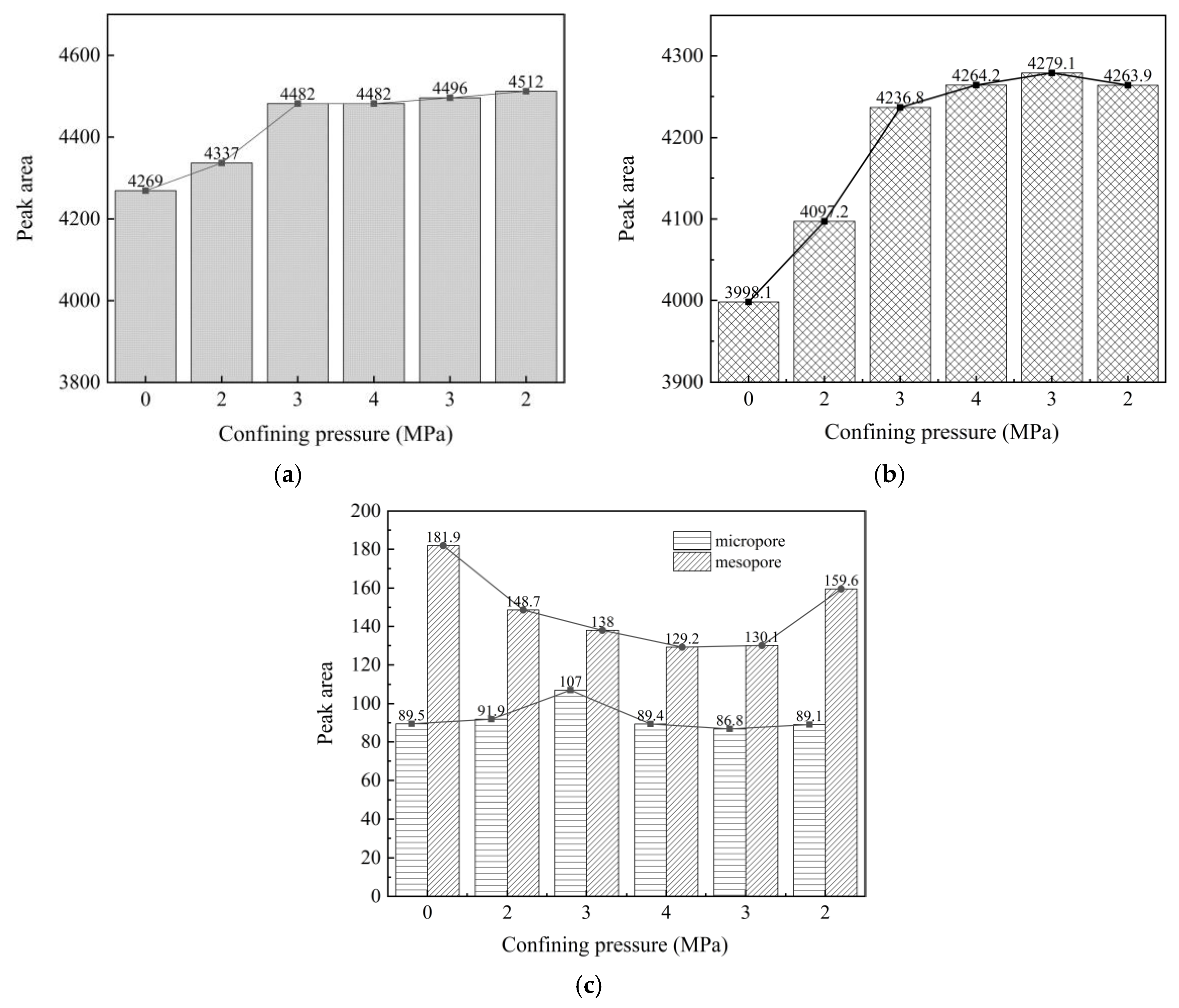

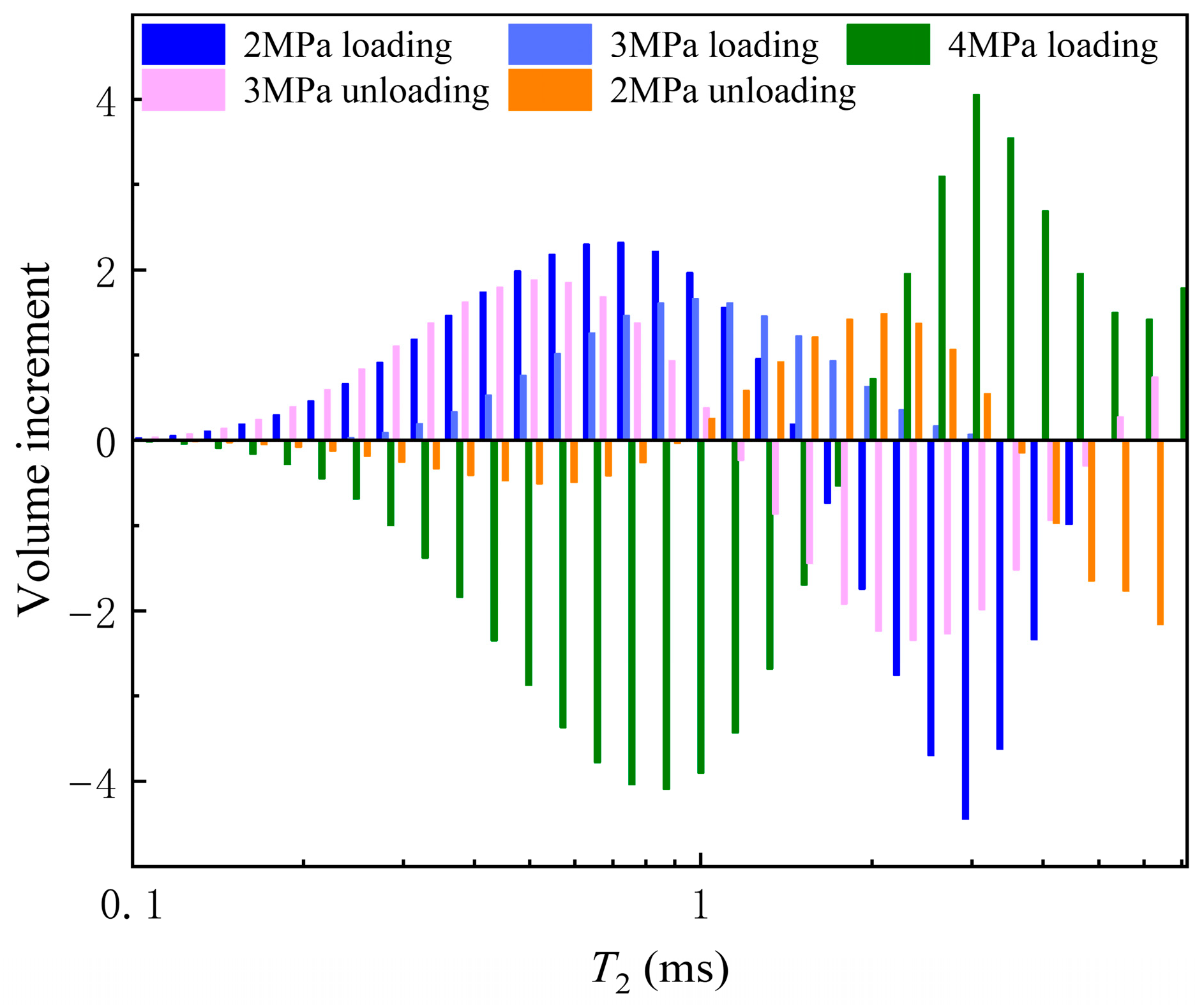

3.2. Evolution of Pore Distribution in Reef Limestone

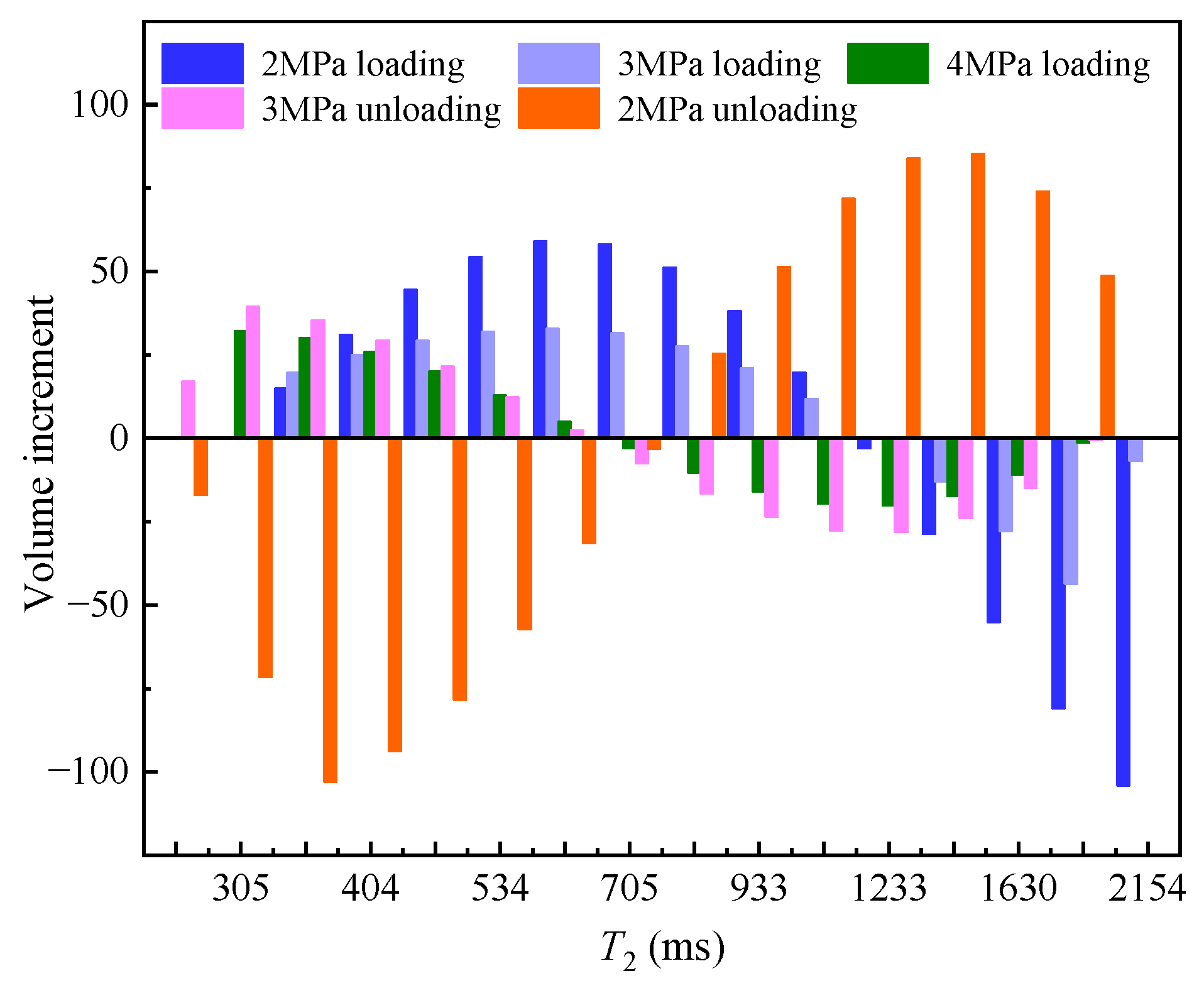

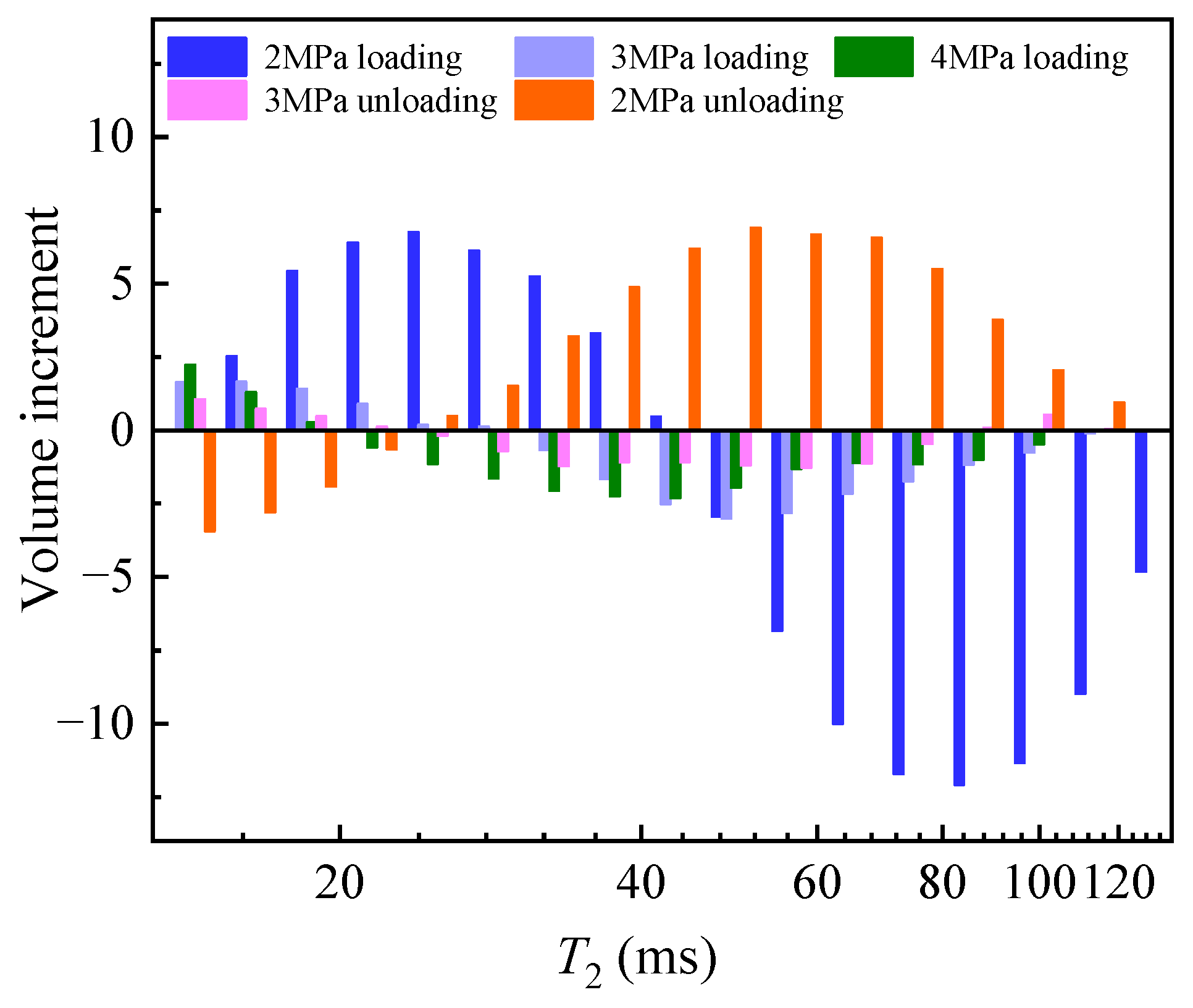

3.3. Relationship Between Pore Volume Increment and Permeability

3.4. Permeability Damage Rate

3.5. Stress Sensitivity of Permeability

4. Discussion

5. Conclusions

- (1)

- Reef limestone samples have a significant primary pore structure, with a highly developed pore network. The T2 transverse relaxation time of the sample in a saturated state is mainly distributed between 100 ms and 10,000 ms, with large pores dominating the sample.

- (2)

- The permeability of the reef limestones is mainly controlled by the dominant flow channels formed by large pores, rather than the total pore volume. During the confining pressure loading process, the pore structure inside the sample undergoes reorganization, with compression of large pores and generation of smaller pores, resulting in a decrease in effective flow paths and a decrease in permeability.

- (3)

- During the unloading stage, there is a significant hysteresis effect in the permeability recovery. Due to irreversible damage caused by pore structure compression and collapse during the loading stage, the permeability of the sample cannot fully recover when unloaded to the initial stress state, with an irreversible permeability damage rate of 2.4%.

- (4)

- Based on the experimental results, the permeability stress sensitivity coefficient of reef limestones is calculated to be 1.1 × 10−1 MPa−1. This is higher than that of conventional terrestrial rocks. The results of this study will enhance researchers’ and engineers’ understanding of biogenic rocks in marine environments. The conclusions of this study provide important design references for excavation and support design in reef limestone formations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, R.; Yu, K.; Wang, Y.; Bian, L. The diagenesis of coral reefs. Adv. Earth Sci. 2017, 32, 221–233. [Google Scholar]

- Meng, Q.; Wu, K.; Zhou, H.; Qin, Q.; Wang, C. Mesoscopic damage evolution of coral reef limestone based on real-time CT scanning. Eng. Geol. 2022, 307, 106781. [Google Scholar] [CrossRef]

- Wu, K.; Meng, Q.; Luo, L.; Qin, Q.; Wang, C.; Wang, X.; Shen, T.; Ding, H. A unique time-dependent deformation behavior of coral reef limestone. J. Rock. Mech. Geotech. Eng. 2025, 17, 1862–1875. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, C.; Zheng, K.; Ma, C.; Yi, M. Crack Initiation and Damage Evolution of Micritized Framework Reef Limestone in the South China Sea. Rock. Mech. Rock. Eng. 2021, 54, 5591–5601. [Google Scholar] [CrossRef]

- Khitab, U.; Umar, M.; Jamil, M. Microfacies, Diagenesis and Hydrocarbon Potential of Eocene Carbonate Strata in Pakistan. Carbonates Evaporites 2020, 35, 70. [Google Scholar] [CrossRef]

- Zhu, C.; Zhou, B.; Liu, H. Micro-structures and fundamental engineering properties of beach calcarenite from south China sea. Chin. J. Rock. Mech. Eng. 2015, 34, 683–693. [Google Scholar] [CrossRef]

- Liu, H.; Ma, C.; Zhu, C. X-ray Micro CT Based Characterization of Pore-Throat Network for Marine Carbonates from South China Sea. Appl. Sci. 2022, 12, 2611. [Google Scholar] [CrossRef]

- Zheng, K.; Meng, Q.; Wang, R.; Yu, J.; Wu, W. Advances in study of engineering geological characteristics of coral reef limestone. Mar. Geol. Quat. Geol. 2020, 40, 42–49. [Google Scholar] [CrossRef]

- Zhang, H.; Ren, H.; Mu, C.; Wu, X.; Huang, K.; Zhang, H.; Wang, F. Experimental study on dynamic mechanical properties and damage characteristics of coral reef limestone. Constr. Build. Mater. 2023, 384, 131007. [Google Scholar] [CrossRef]

- Wang, X.; Wang, R.; Meng, Q. Research on characteristics of coral reef calcareous rock in nan sha islands. Chin. J. Rock. Mech. Eng. 2008, 27, 2221–2226. [Google Scholar]

- Amour, F.; Nick, H. Porosity and permeability variability across a chalk reservoir in the Danish North Sea: Quantitative impacts of depositional and diagenetic processes. Eng. Geol. 2021, 285, 106059. [Google Scholar] [CrossRef]

- Kimura, S.; Kaneko, H.; Noda, S.; Ito, T.; Minagawa, H. Shear-induced permeability reduction and shear-zone development of sand under high vertical stress. Eng. Geol. 2018, 238, 86–98. [Google Scholar] [CrossRef]

- Zhang, P.; Zhao, C.; Hou, J.; Li, T. Experimental study on seepage characteristics of deep sandstone under high temperature and different hydraulic pressures. Chin. J. Rock. Mech. Eng. 2020, 39, 1117–1128. [Google Scholar] [CrossRef]

- Huang, Z.; Jiang, Z.; Zhu, S.; Wu, X.; Yang, L. Influence of structure and water pressure on the hydraulic conductivity of the rock mass around underground excavations. Eng. Geol. 2016, 202, 74–84. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, H.; Wang, W.; Cheng, W.; Xin, L. Experimental Study on the Pore Structure Fractals and Seepage Characteristics of a Coal Sample Around a Borehole in Coal Seam Water Infusion. Transp. Porous Media. 2018, 125, 289–309. [Google Scholar] [CrossRef]

- Zhou, G.; Zhang, Q.; Bai, R.; Ni, G. Characterization of Coal Micro-Pore Structure and Simulation on the Seepage Rules of Low-Pressure Water Based on CT Scanning Data. Minerals 2016, 6, 78. [Google Scholar] [CrossRef]

- Wang, J.; Huang, X.; Xu, J.; Zhang, Z.; Wang, S. Network analysis of pore structure of coral reef limestone and its implications for seepage flow. Eng. Geol. 2023, 318, 107103. [Google Scholar] [CrossRef]

- Qin, X.; Xia, Y.; Qiao, J.; Chen, J.; Zeng, J.; Cai, J. Modeling of Multiphase Flow in Low Permeability Porous Media: Effect of Wettability and Pore Structure Properties. J. Rock. Mech. Geotech. Eng. 2024, 16, 1127–1139. [Google Scholar] [CrossRef]

- Chu, Z.; Wu, Z.; Liu, Q.; Weng, L.; Xu, X. Preliminary investigation on the hydrophysical properties and fracture seepage characteristics of 3D-printed gypsum specimens based on nuclear magnetic resonance technology. Sci. Sin. Technol. 2023, 53, 1871–1884. [Google Scholar] [CrossRef]

- Fu, T.; Xu, T.; Heap, M.; Meredith, P.; Yang, T.; Mitchell, T.; Nara, Y. Analysis of capillary water imbibition in sandstone via a combination of nuclear magnetic resonance imaging and numerical DEM modeling. Eng. Geol. 2021, 285, 106070. [Google Scholar] [CrossRef]

- Rezaee, R.; Saeedi, A.; Clennell, B. Tight gas sands permeability estimation from mercury injection capillary pressure and nuclear magnetic resonance data. J. Petrol. Sci. Eng. 2012, 88–89, 92–99. [Google Scholar] [CrossRef]

- Sun, Y.; Zhai, C.; Xu, J.; Cong, Y.; Qin, L. Characterisation and evolution of the full size range of pores and fractures in rocks under freeze-thaw conditions using nuclear magnetic resonance and three-dimensional X-ray microscopy. Eng. Geol. 2020, 271, 105616. [Google Scholar] [CrossRef]

- Wan, H.; Huang, X.; Wang, J.; Zhang, Z. Importance of Appropriate Segmentation in Pore Structure Analysis of Coral Reef Limestone from CT Images. Mar. Georesour. Geotechnol. 2024, 42, 327–347. [Google Scholar] [CrossRef]

- Bai, J.; Huang, X.; Lei, Q. Characterizing the Permeability Anisotropy of Coral Reef Limestone Based on CT Scanning and CFD Modeling. Rock Mech. Rock Eng. 2025, 58, 11715–11737. [Google Scholar] [CrossRef]

- Wang, J.; Huang, X.; Xu, J.; Wang, S.; Jin, G.; Zhang, Z. Identifying the Pore Structure and Permeability Anisotropy of Coral Reef Limestone Based on CT Image Analysis. Mar. Georesour. Geotechnol. 2023, 42, 993–1010. [Google Scholar] [CrossRef]

- Wu, Z.; Lu, H.; Weng, L.; Liu, Q.; Shen, J. Investigations on the seepage characteristics of fractured sandstone based on NMR real-time imaging. Chin. J. Rock. Mech. Eng. 2021, 40, 263–275. [Google Scholar] [CrossRef]

- Li, K.; Yang, B.; Qin, Q. Experimental study on unloading damage and permeability of dolomite based on nuclear magnetic resonance technique. China J. Rock. Mech. Geotech. Eng. 2019, 38, 3493–3502. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Sun, D.; Lin, C.; Yu, X.; Hou, F.; Bai, Z. Permeability Evolution of Deep-Buried Coal Based on NMR Analysis: CO2 Adsorption and Water Content Effects. Energy 2024, 289, 129877. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Z.; Wei, G.; Zhou, X. Characterization of stress-dependent permeability of volcanic gas reservoir of different types of pore structure. Rock. Soil. Mech. 2012, 33, 3577–3584. [Google Scholar] [CrossRef]

- Hu, Z.; Klaver, J.; Schmatz, J.; Dewanckele, J.; Littke, R.; Krooss, B.; Amann, H. Stress sensitivity of porosity and per-meability of Cobourg limestone. Eng. Geol. 2020, 273, 105632. [Google Scholar] [CrossRef]

- Zhang, R.; Ning, Z.; Yang, F.; Zhao, H.; Du, L.; Zhou, X. Experimental study of stress sensitivity of shale reservoirs. Chin. J. Rock. Mech. Eng. 2015, 34, 2617–2622. [Google Scholar] [CrossRef]

- Catinat, M.; Fleury, M.; Brigaud, B.; Antics, M.; Ungemach, P. Estimating Permeability in a Limestone Geothermal Reservoir from NMR Laboratory Experiments. Geothermics 2023, 111, 102707. [Google Scholar] [CrossRef]

- Ge, X.; Fan, Y.; Liu, J.; Zhang, L.; Han, Y.; Xing, D. An Improved Method for Permeability Estimation of the Bioclastic Limestone Reservoir Based on NMR Data. J. Magn. Reson. 2017, 283, 96–109. [Google Scholar] [CrossRef]

- Arnold, J. Mobile NMR for Rock Porosity and Permeability. Ph.D. Thesis, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, Germany, 2007. [Google Scholar]

- GB/T 42035-2022; Determination of Pore Size Distribution of Coal and Rock, Nuclear Instruments Magnetic Resonance Method. National Standard of the People’s Republic of China: Beijing, China, 2022.

- Morrow, C.A.; Zhang, B.C.; Byerlee, J.D. Effective Pressure Law for Permeability of Westerly Granite under Cyclic Loading. J. Geophys. Res. Solid. Earth. 1986, 91, 3870–3876. [Google Scholar] [CrossRef]

- Wang, H.L.; Xu, W.Y.; Cai, M.; Xiang, Z.P.; Kong, Q. Gas Permeability and Porosity Evolution of a Porous Sandstone Under Repeated Loading and Unloading Conditions. Rock. Mech. Rock. Eng. 2017, 50, 2071–2083. [Google Scholar] [CrossRef]

- SY/T 5358-2010; Experimental Evaluation Method of Reservoir Sensitivity Flow. Oil and Gas Industry Standard of the People’s Republic of China: Beijing, China, 2010.

- David, C.; Wong, T.F.; Zhu, W.; Zhang, J. Laboratory measurement of compaction-induced permeability change in porous rocks: Implications for the generation and maintenance of pore pressure excess in the crust. Pure Appl. Geophysics. 1994, 143, 425–456. [Google Scholar] [CrossRef]

- Wang, Y.; Meng, F.; Wang, X. Effective Stress Law for the Permeability and Deformation of Four Porous Limestones. J. Geophys. Res. Solid. Earth. 2018, 123, 4707–4729. [Google Scholar] [CrossRef]

| ρd (g/cm3) | ρsat (g/cm3) | ws (%) | vsat (m/s) |

|---|---|---|---|

| 0.87 | 1.46 | 67.0 | 2500.0 |

| Osmotic Pressure/kPa | Confining Pressure (MPa) | Stress Path | Permeability (mD) |

|---|---|---|---|

| 500 | 2 | Loading | 439.6 |

| 3 | Loading | 414.6 | |

| 4 | Loading | 353.2 | |

| 3 | Unloading | 336.2 | |

| 2 | Unloading | 429.0 |

| Penetration Damage Rate (%) | Damage Degree |

|---|---|

| D ≤ 5 | None |

| 5 < D ≤ 30 | Weak |

| 30 < D ≤ 50 | Moderately weak |

| 50 < D ≤ 70 | Moderately strong |

| D > 70 | Strong |

| Stress Path | Effective Stress (MPa) | Penetration Damage Rate (%) | Damage Degree |

|---|---|---|---|

| Loading | 2.5 | 5.7 | Weak |

| 3.5 | 19.6 | Weak | |

| Unloading | 2.5 | 23.5 | Weak |

| 1.5 | 2.4 | Weak |

| Source | Rock Type | Confining Pressure (MPa) | Stress Sensitivity Coefficient/(MPa−1) |

|---|---|---|---|

| This study | Reef limestone | 2–4 | 1.1 × 10−1 |

| David 1994 [39] | Adamswiller | 80.5–151 | 1.2 × 10−2 |

| Fontainebleau | 80.5–151 | 1 × 10−2 | |

| Berea | 80.5–151 | 1 × 10−2 | |

| Rothbach | 80.5–151 | 1.8 × 10−2 | |

| Boise | 80.5–151 | 0.7 × 10−2 | |

| Wang 2018 [40] | Purbeck limestone | 6–18 | 3.6 × 10−3 |

| Indiana limestone | 3–15 | 3.2 × 10−3 | |

| Thala limestone | 7–15 | 1.2 × 10−3 | |

| Leitha limestone | 7–15 | 1.1 × 10−3 | |

| Hu 2020 [30] | Cobourg limestone | 5–20 | 4.5 × 10−2–7.1 × 10−2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mo, Y.; Liu, H.; Zhang, Y.; Zhai, S.; Chen, P.; Qu, R.; Ji, F. Mechanism of Permeability Evolution in Coral Reef Limestone Under Variable Confined Pressure Using Nuclear Magnetic Resonance Technology. J. Mar. Sci. Eng. 2025, 13, 2218. https://doi.org/10.3390/jmse13122218

Mo Y, Liu H, Zhang Y, Zhai S, Chen P, Qu R, Ji F. Mechanism of Permeability Evolution in Coral Reef Limestone Under Variable Confined Pressure Using Nuclear Magnetic Resonance Technology. Journal of Marine Science and Engineering. 2025; 13(12):2218. https://doi.org/10.3390/jmse13122218

Chicago/Turabian StyleMo, Yang, Haifeng Liu, Yongtao Zhang, Shun Zhai, Peishuai Chen, Ru Qu, and Fuquan Ji. 2025. "Mechanism of Permeability Evolution in Coral Reef Limestone Under Variable Confined Pressure Using Nuclear Magnetic Resonance Technology" Journal of Marine Science and Engineering 13, no. 12: 2218. https://doi.org/10.3390/jmse13122218

APA StyleMo, Y., Liu, H., Zhang, Y., Zhai, S., Chen, P., Qu, R., & Ji, F. (2025). Mechanism of Permeability Evolution in Coral Reef Limestone Under Variable Confined Pressure Using Nuclear Magnetic Resonance Technology. Journal of Marine Science and Engineering, 13(12), 2218. https://doi.org/10.3390/jmse13122218