Installation Disturbance of Helical Anchor in Dense Sand and the Effect on Uplift Capacity Based on Discrete Element Method

Abstract

1. Introduction

2. Method and Models

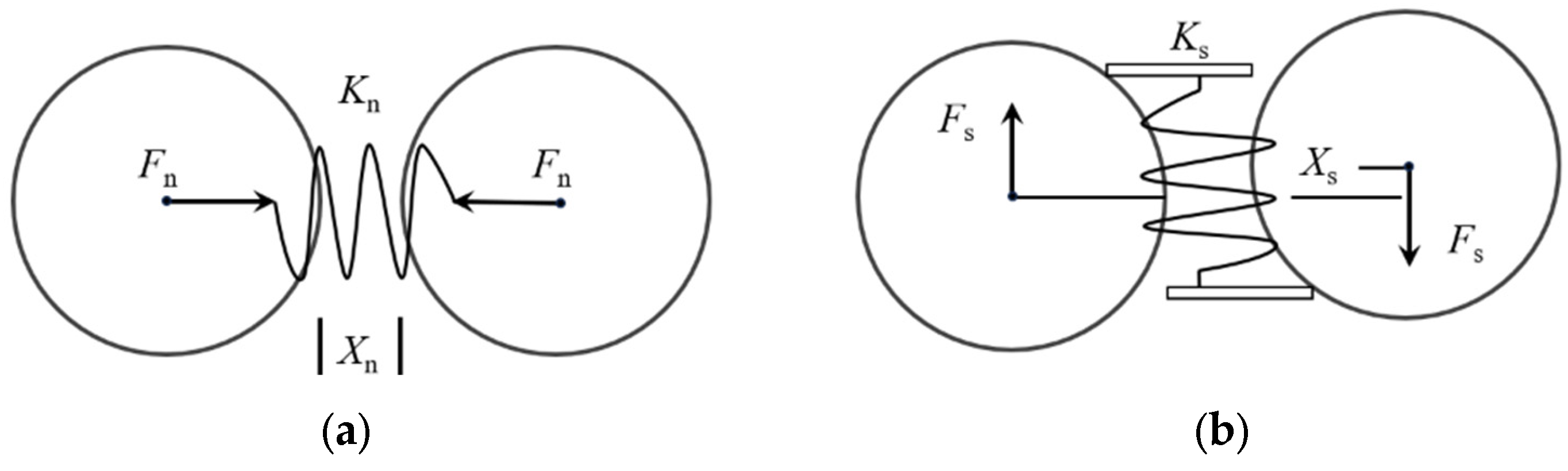

2.1. Introduction to MatDEM and Contact Model

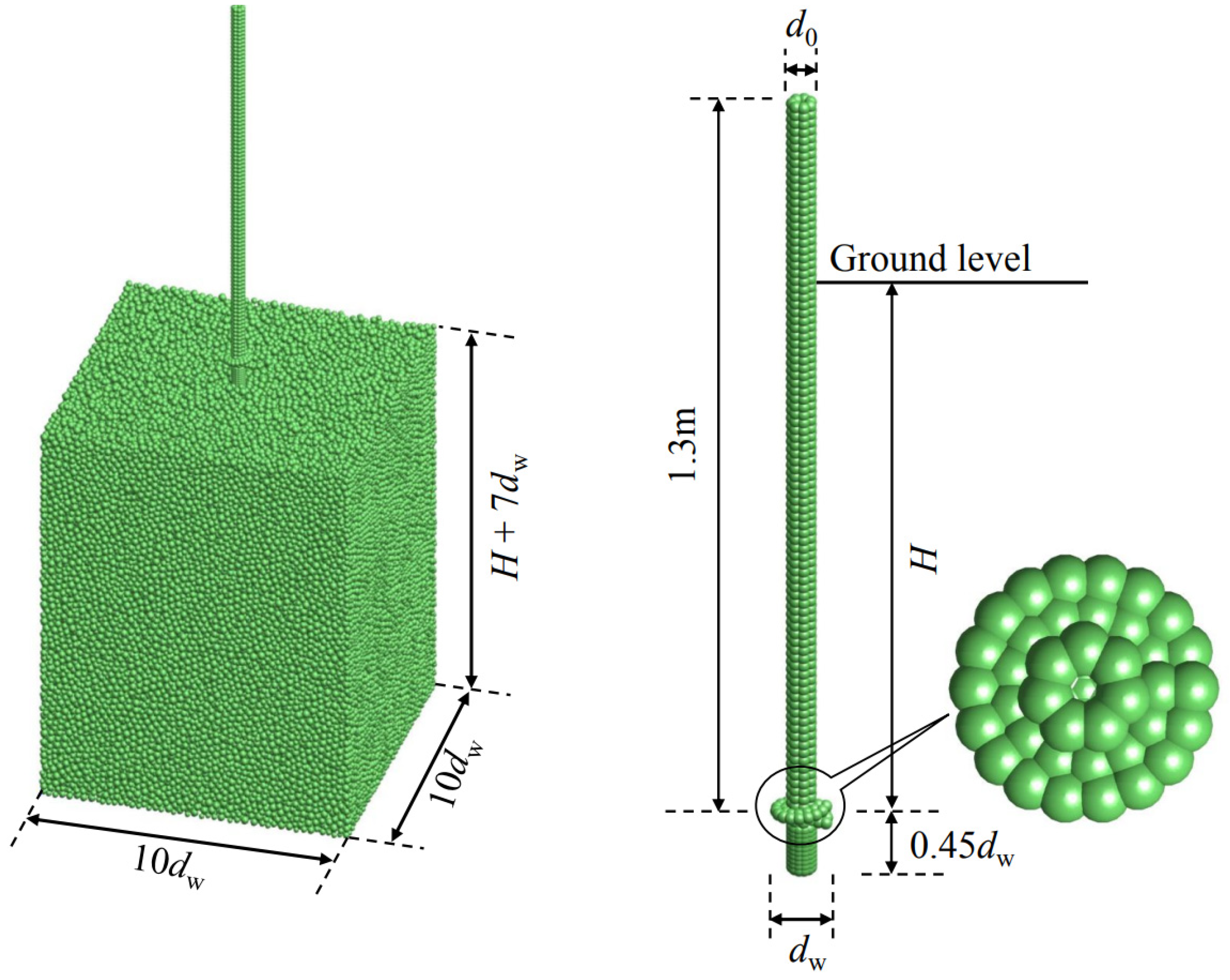

2.2. Model Establishment Steps and Model Parameter Calibration

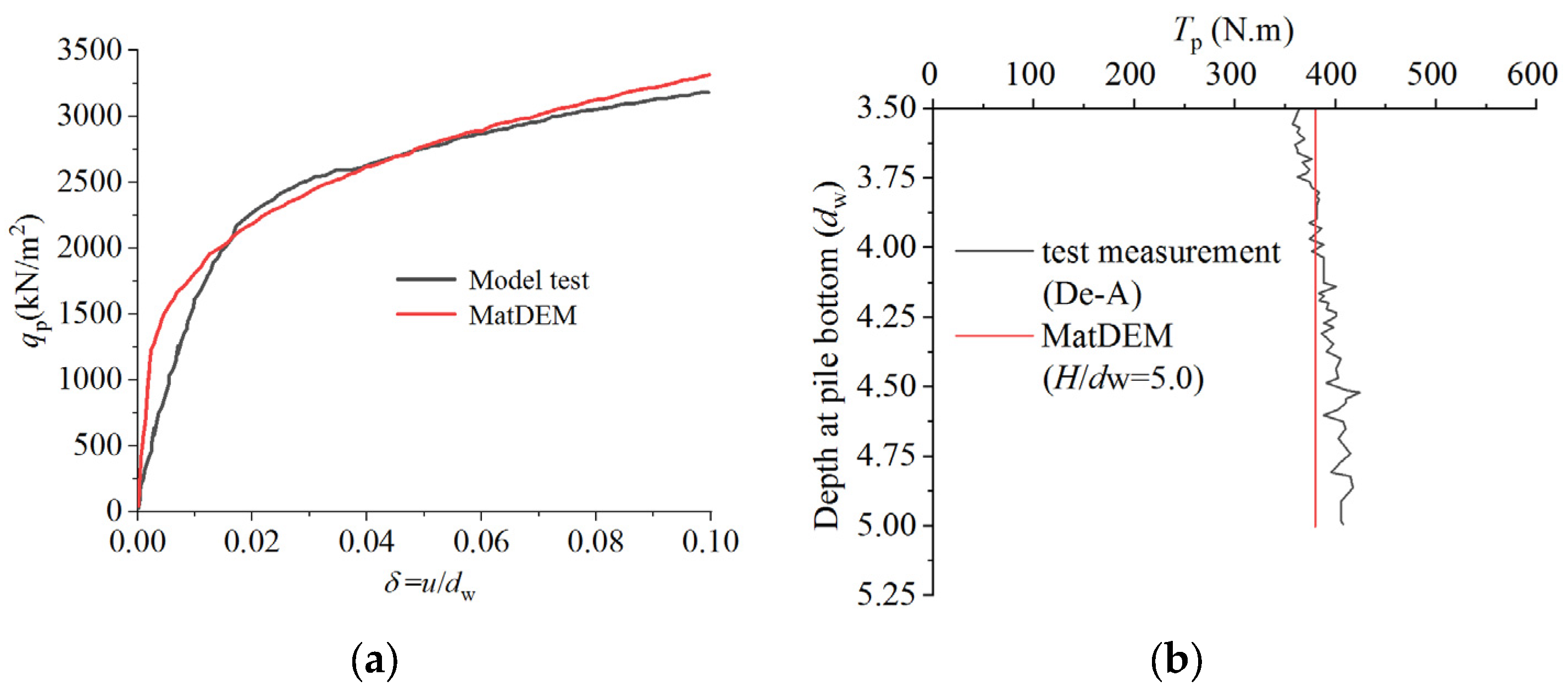

2.3. Particle Contact Parameter Calibration

2.4. Simulation Scheme

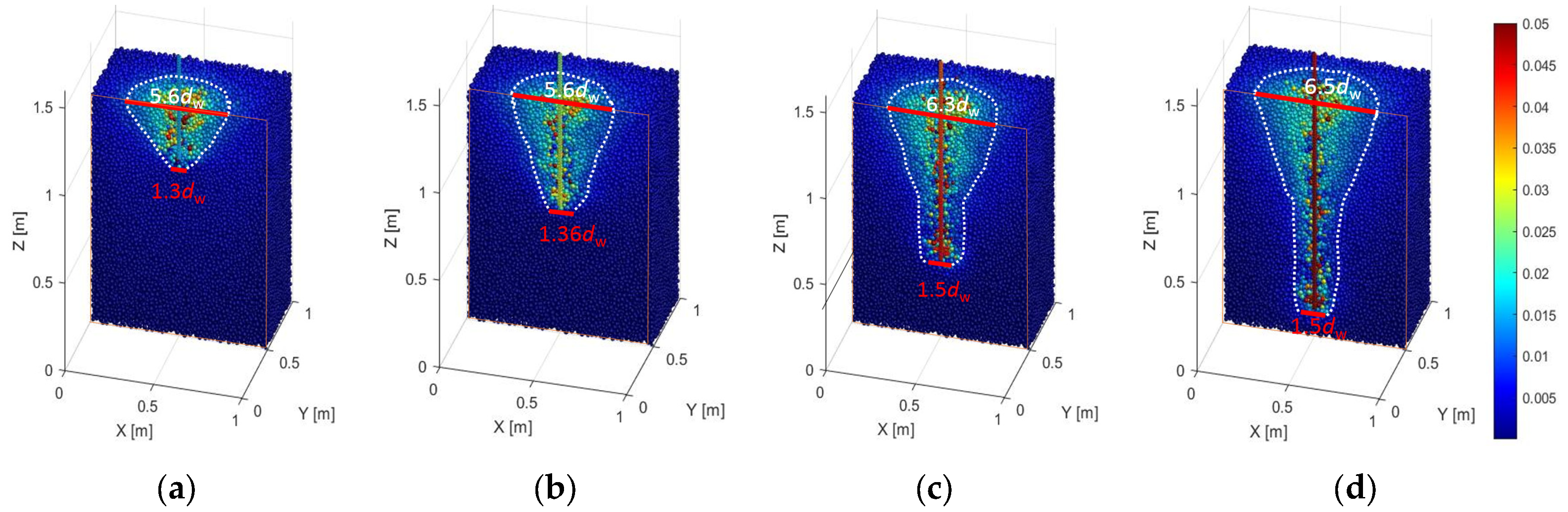

3. Particle Motion Induced by Installation

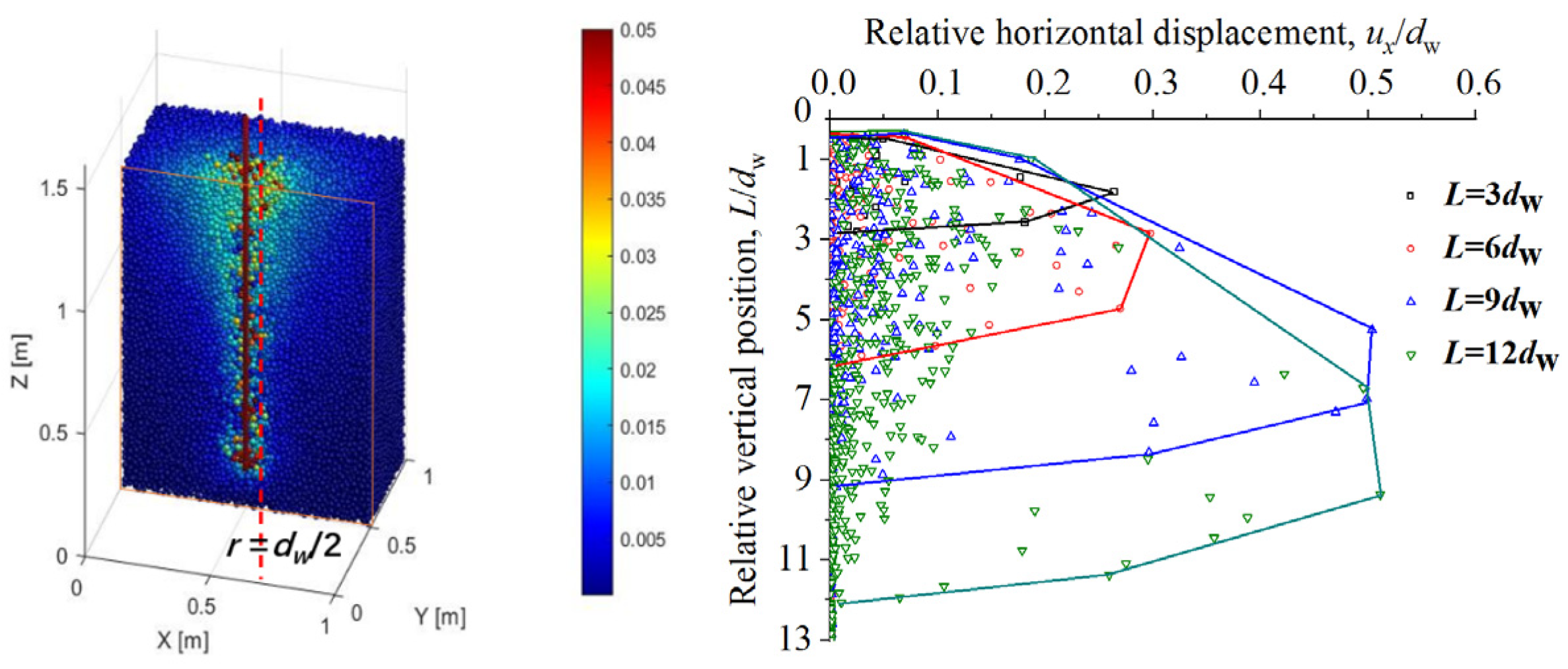

3.1. Single-Helix Anchor Installed at AR = 1 (Surcharge p = 100 kPa)

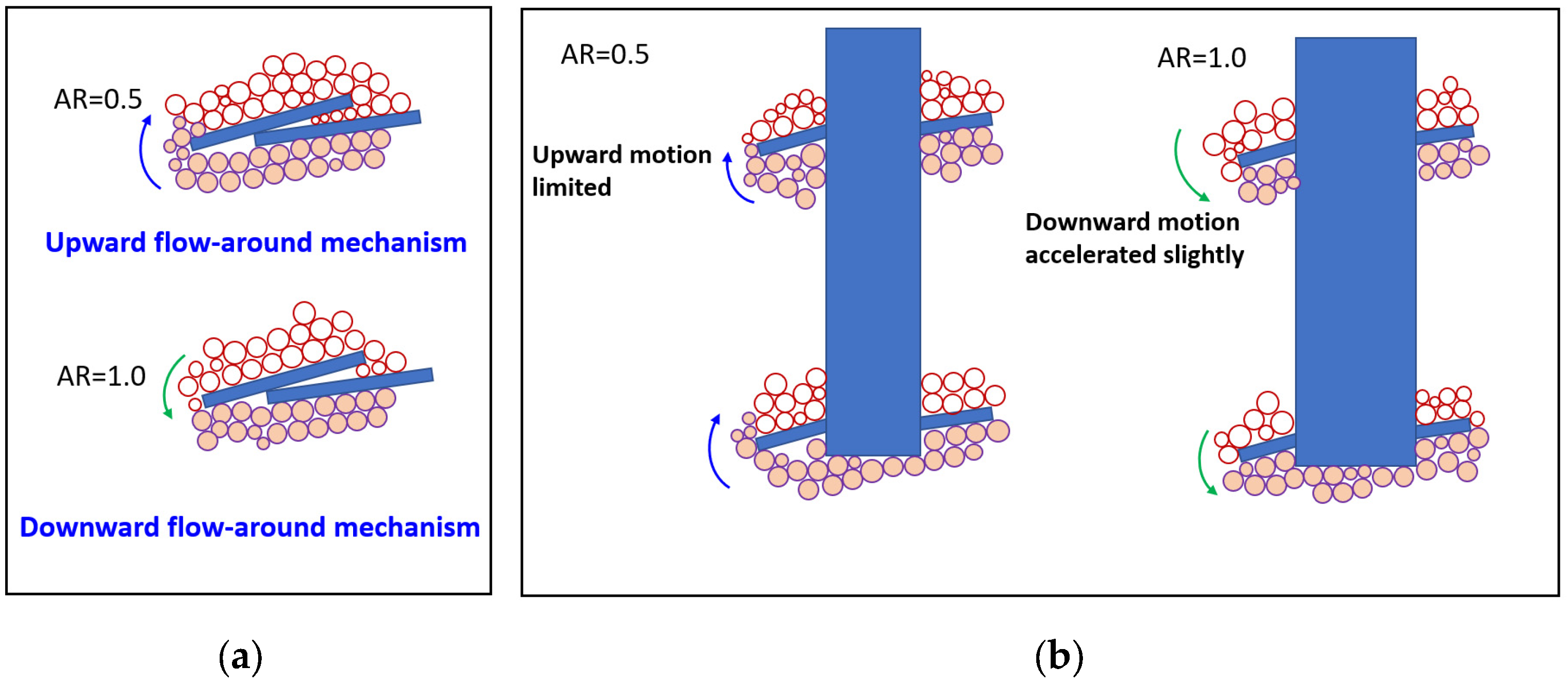

3.2. Single-Helix Anchors Installed at Different Advancement Ratios (ARs)

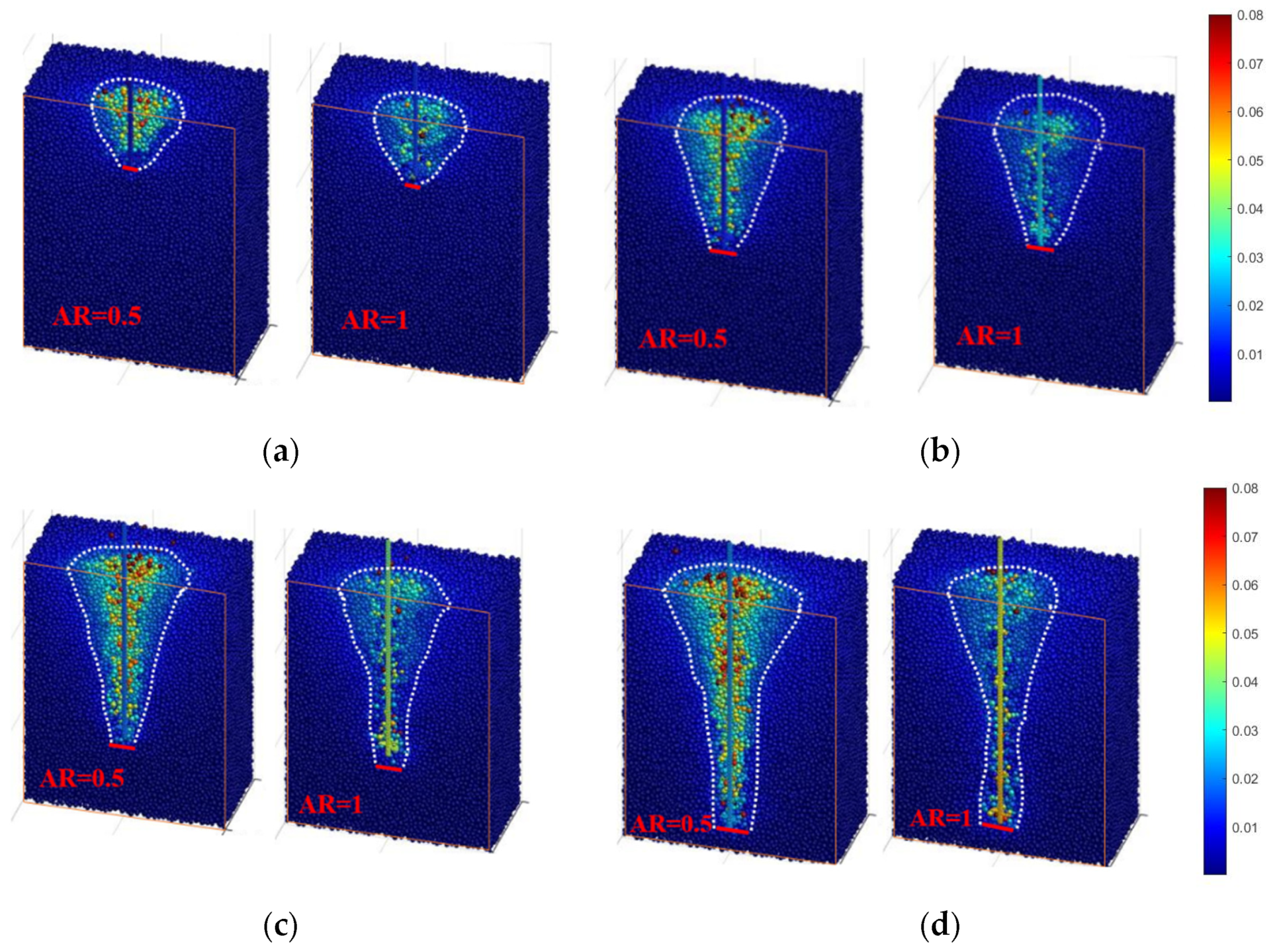

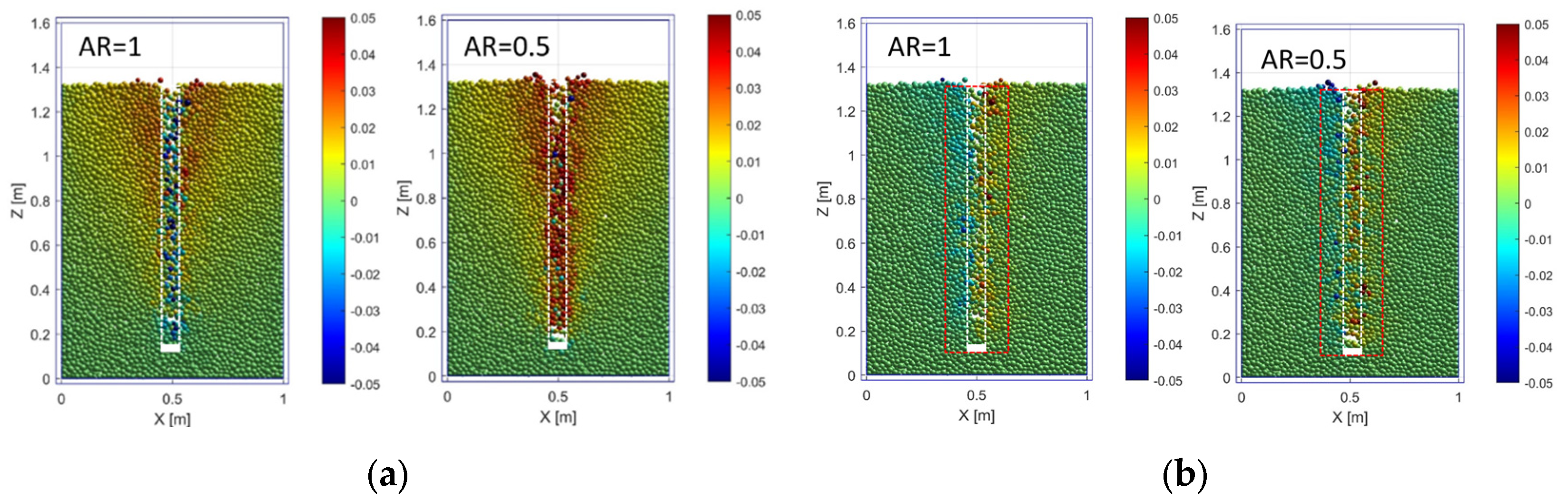

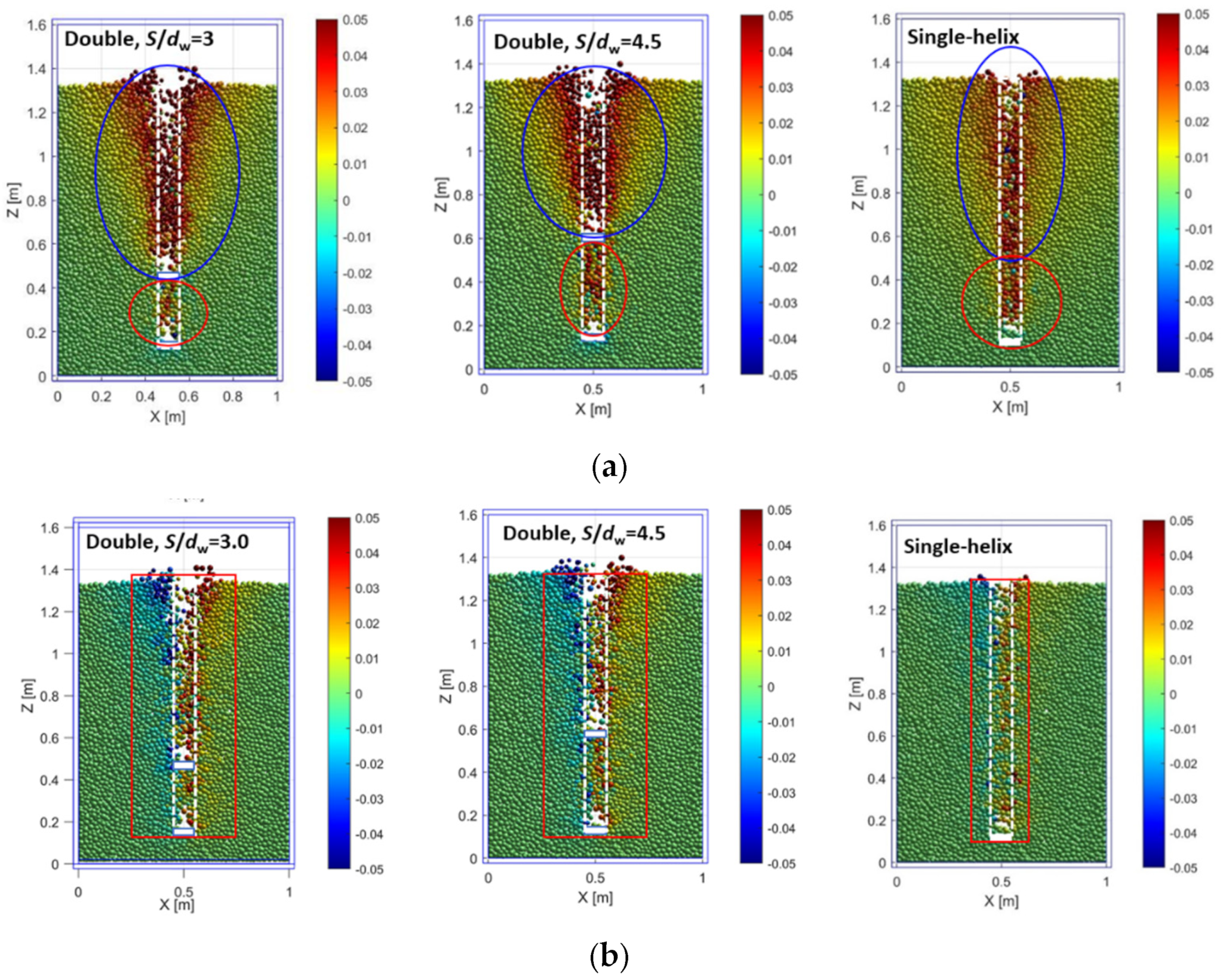

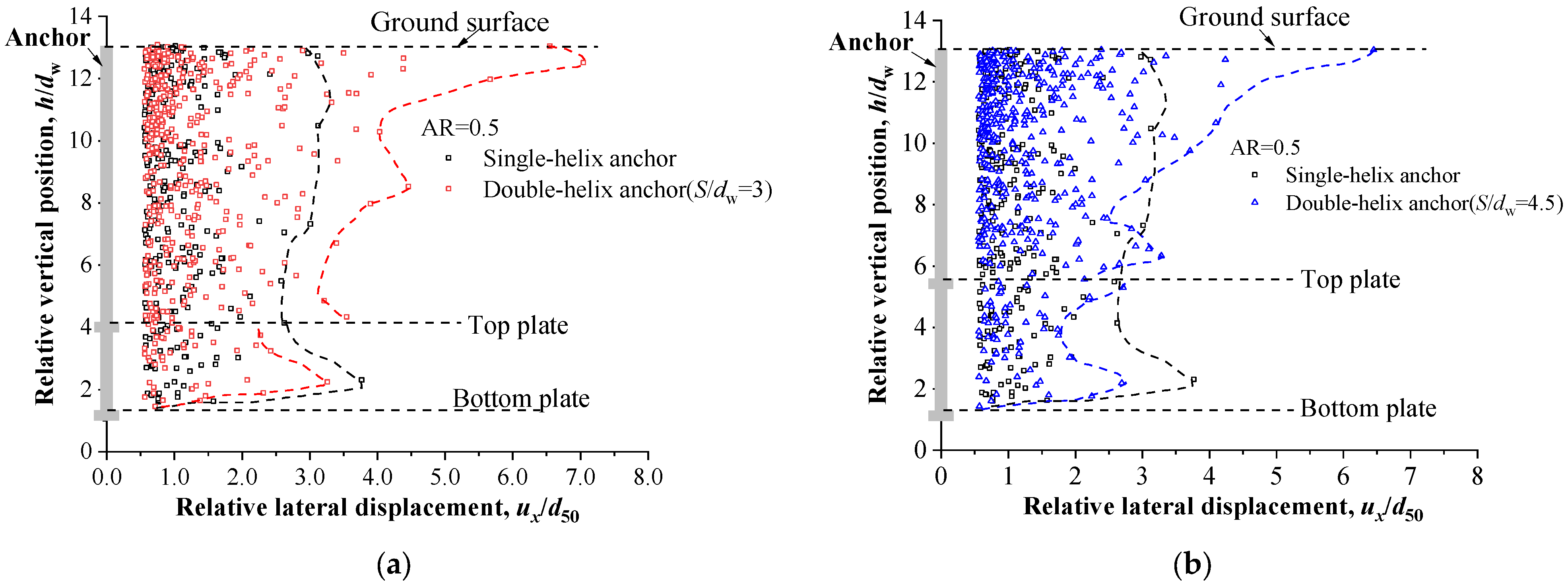

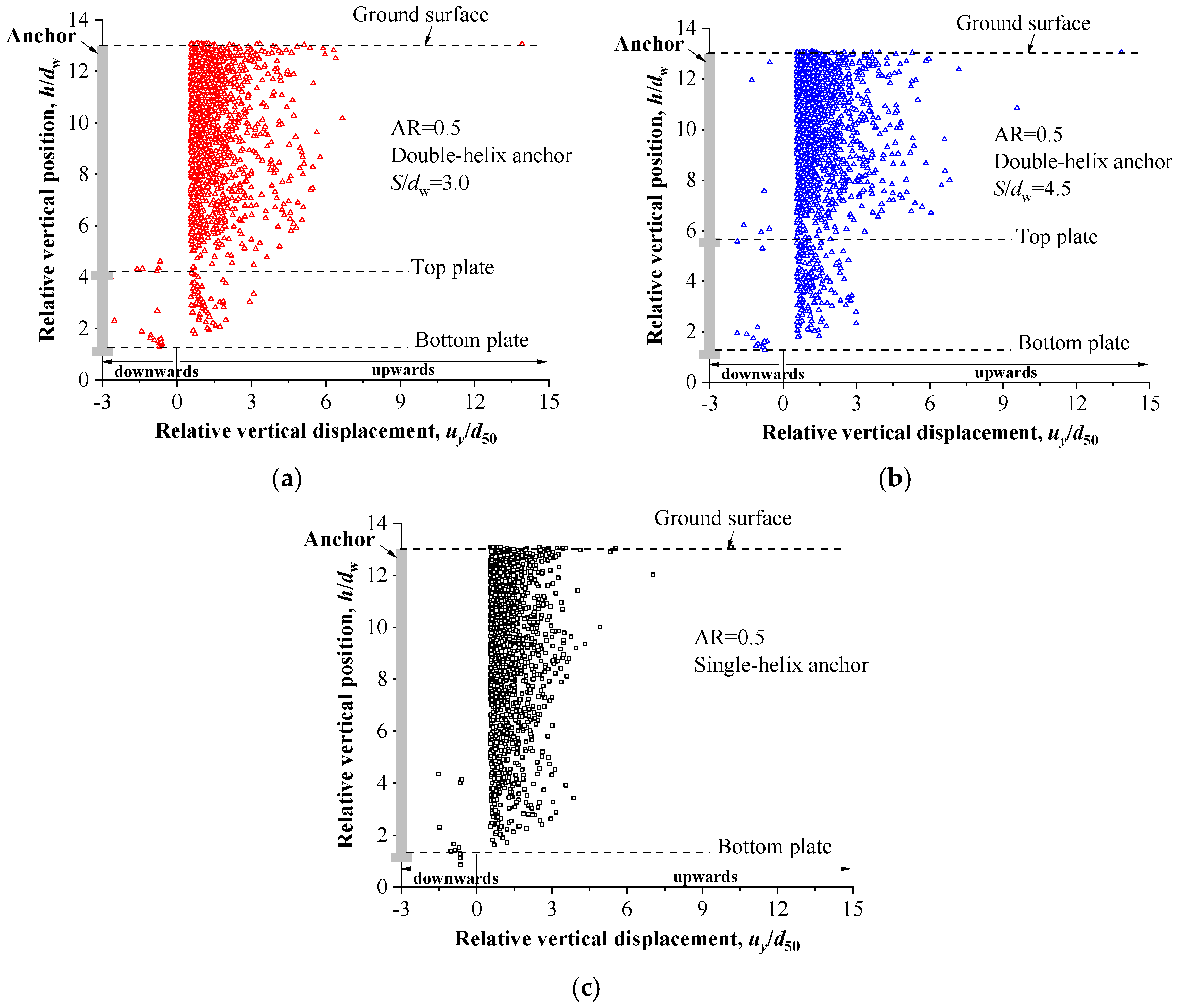

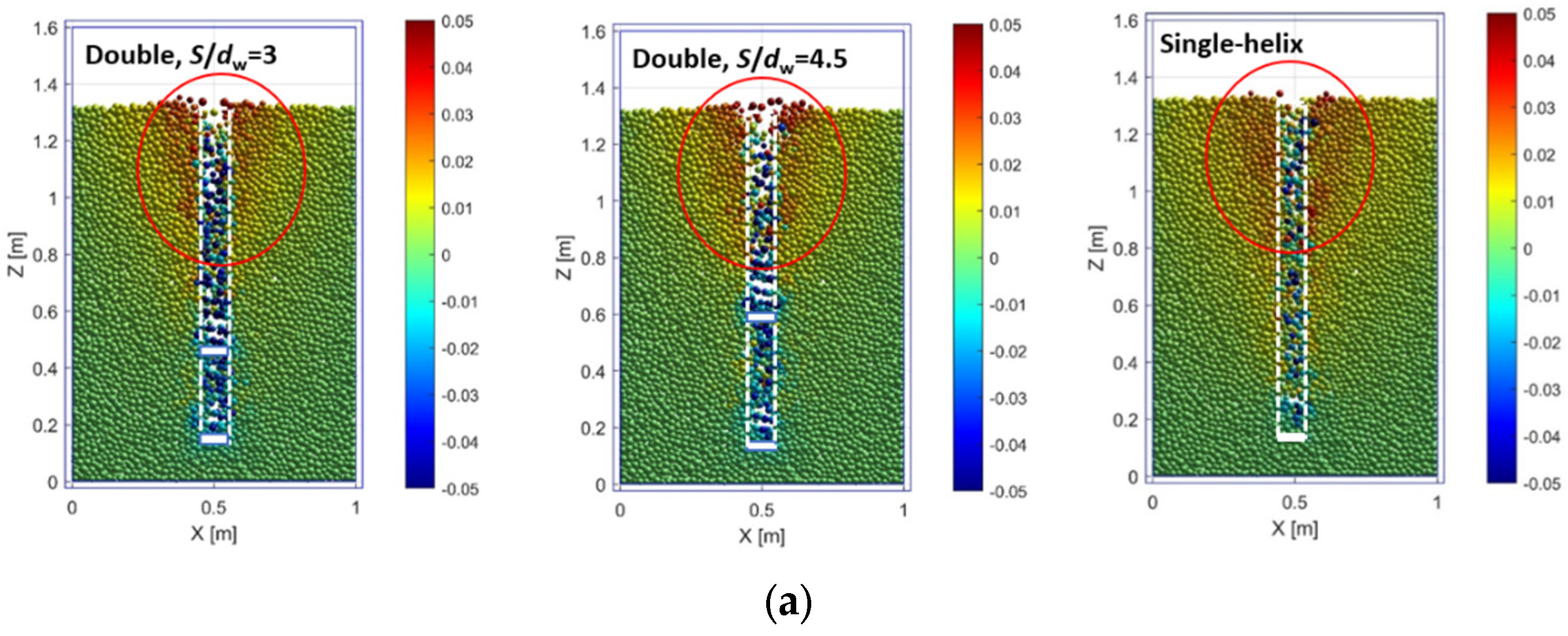

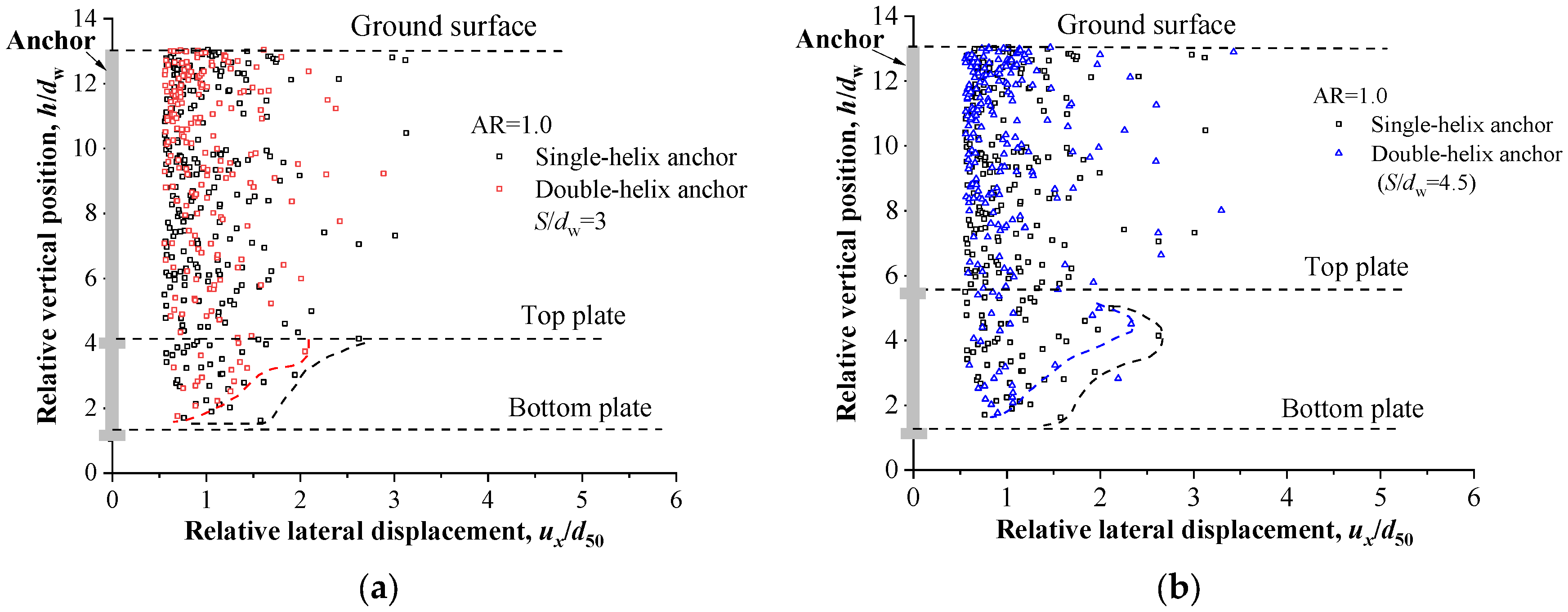

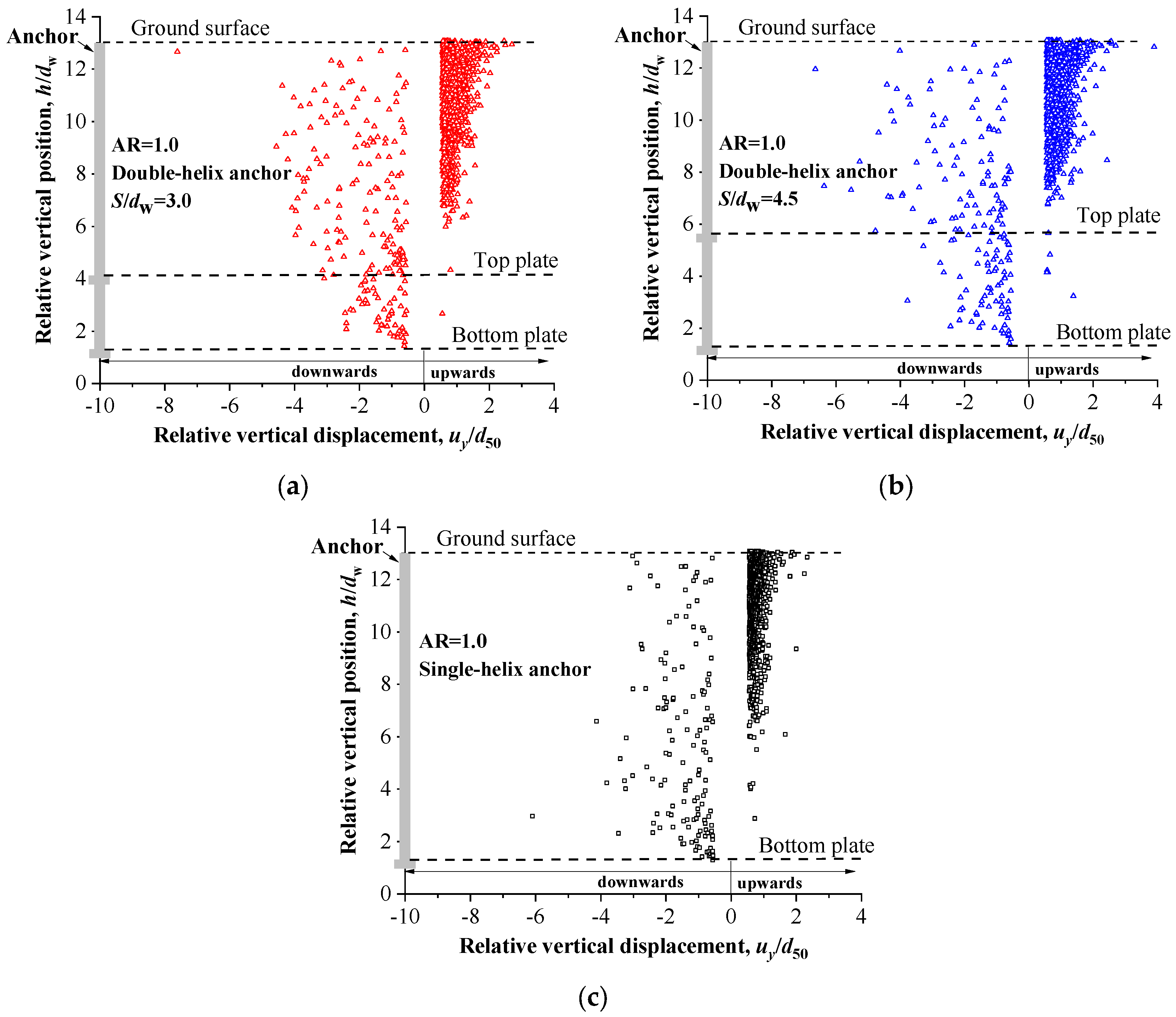

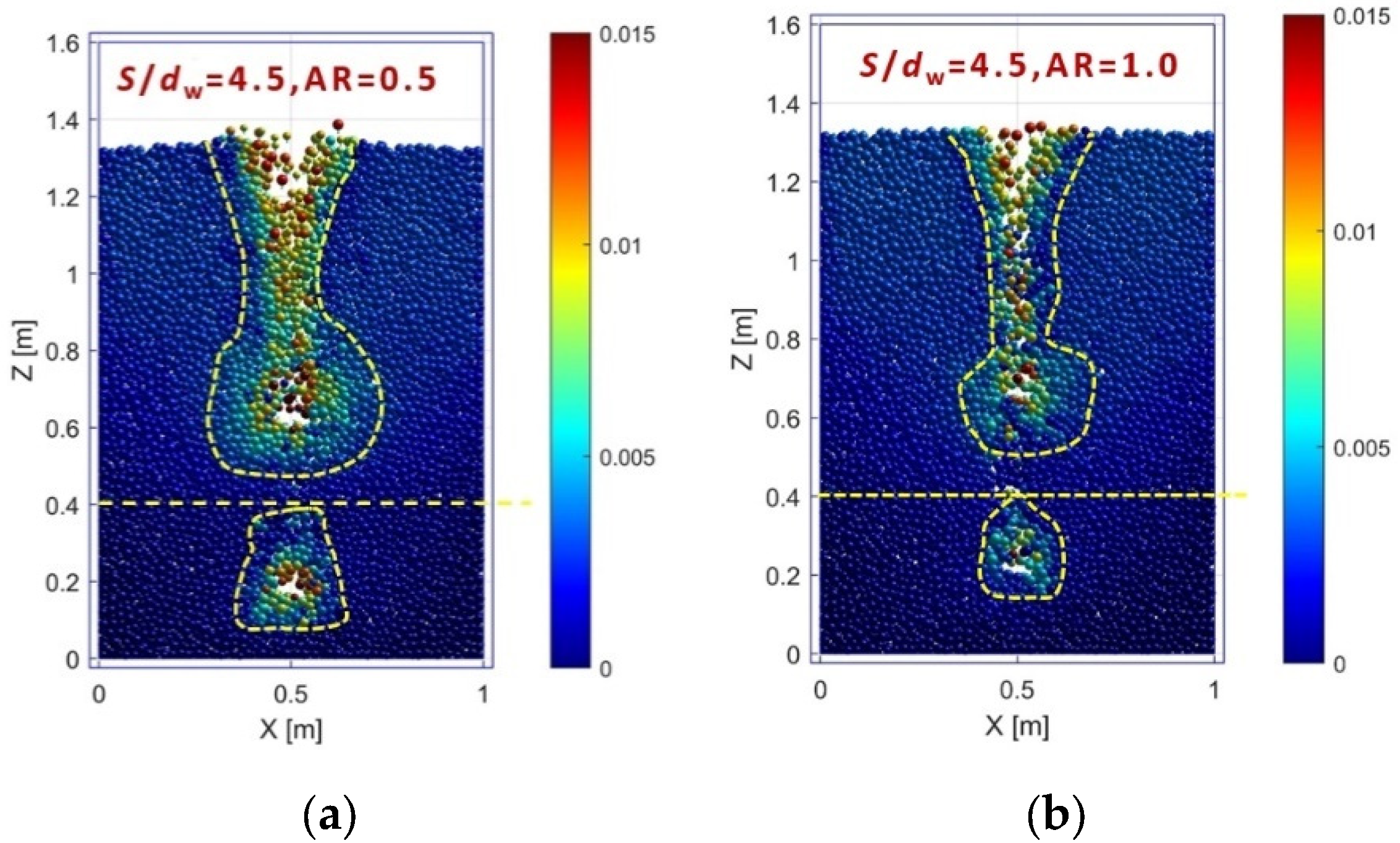

3.3. Double-Helix Anchors Installed at Different Advancement Ratios

4. Effects of Installation on Uplift Capacity

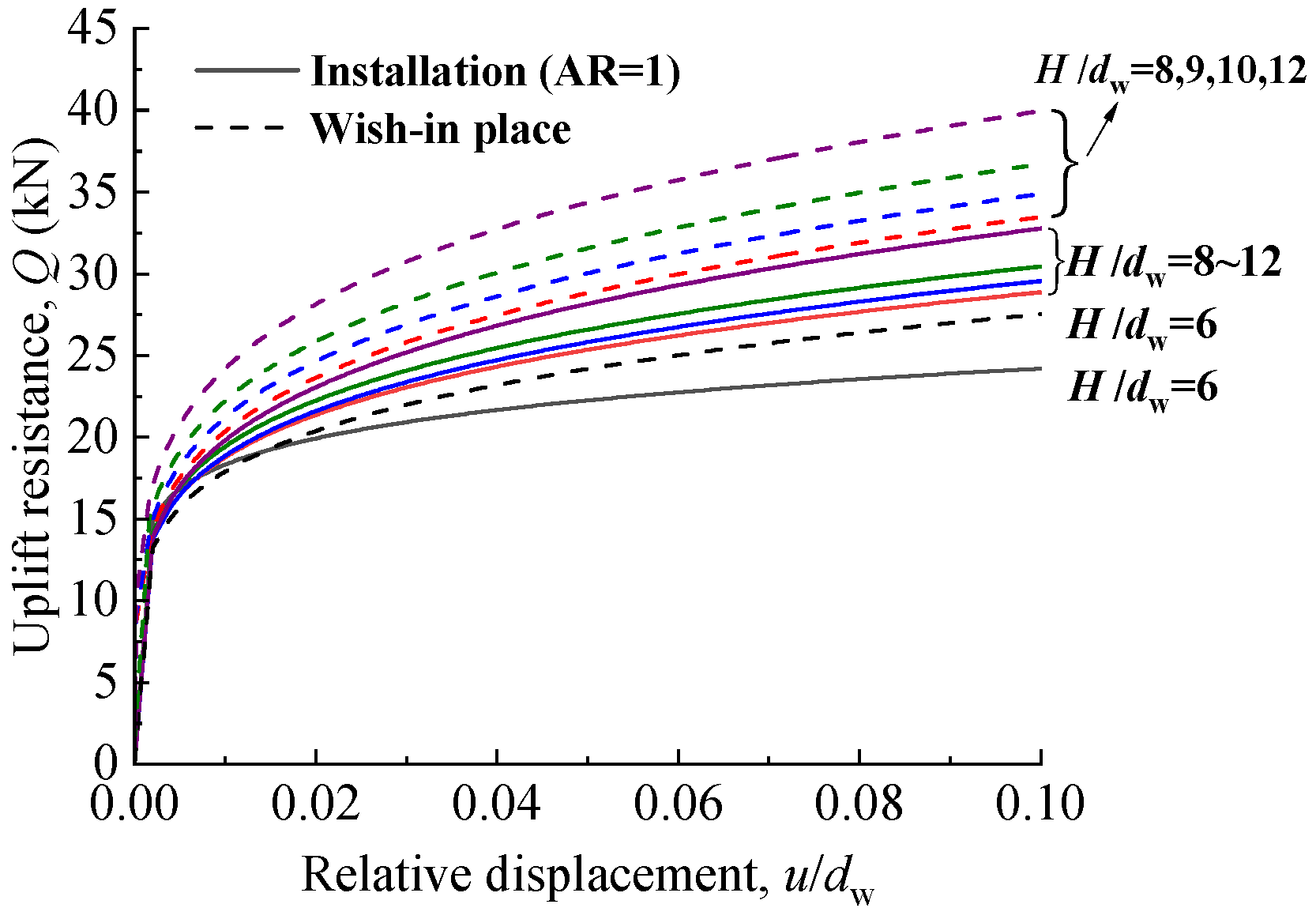

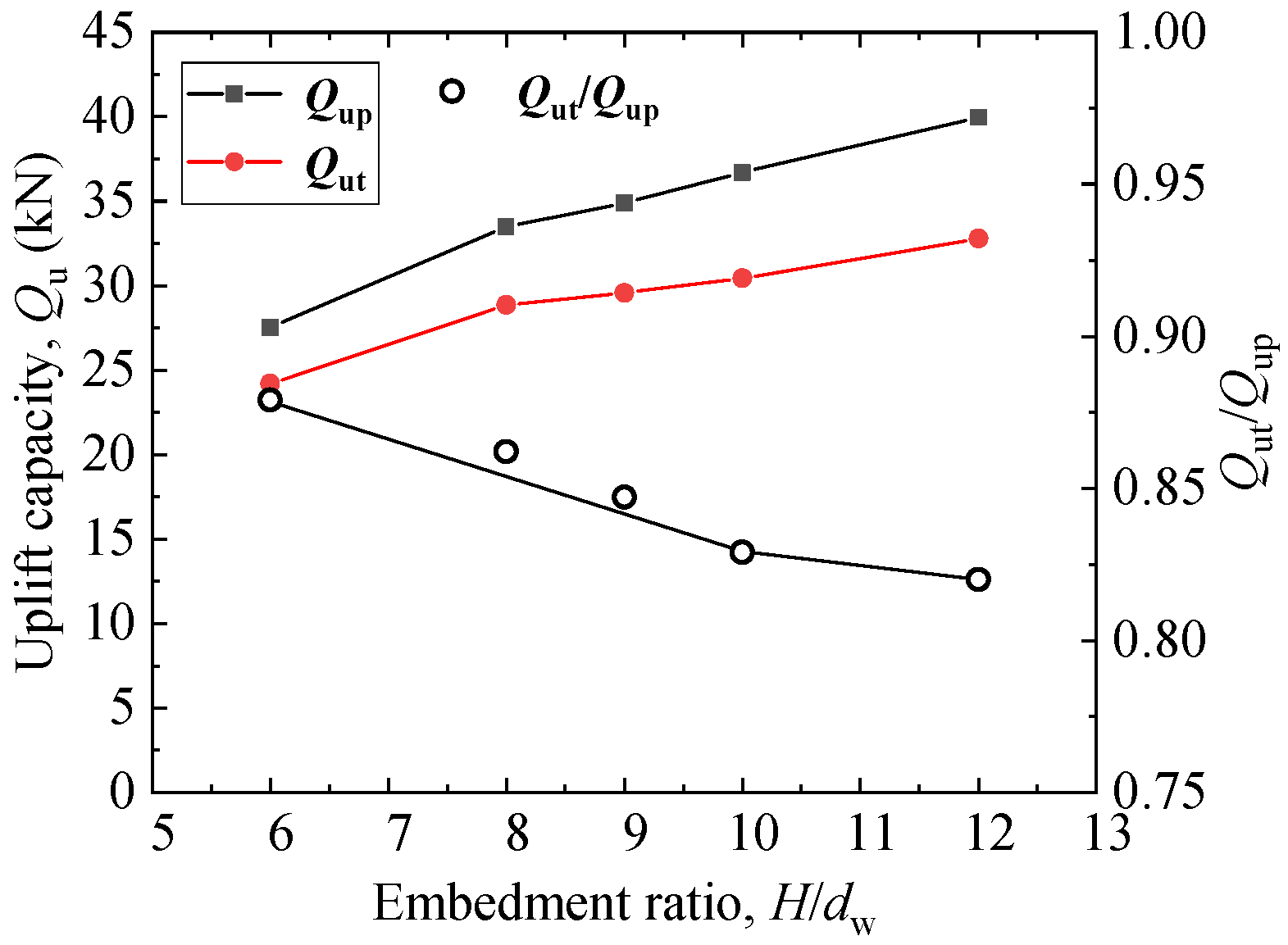

4.1. Single-Helix Anchors Pre-Embedded and Installed at AR = 1 (Surcharge p = 100 kPa)

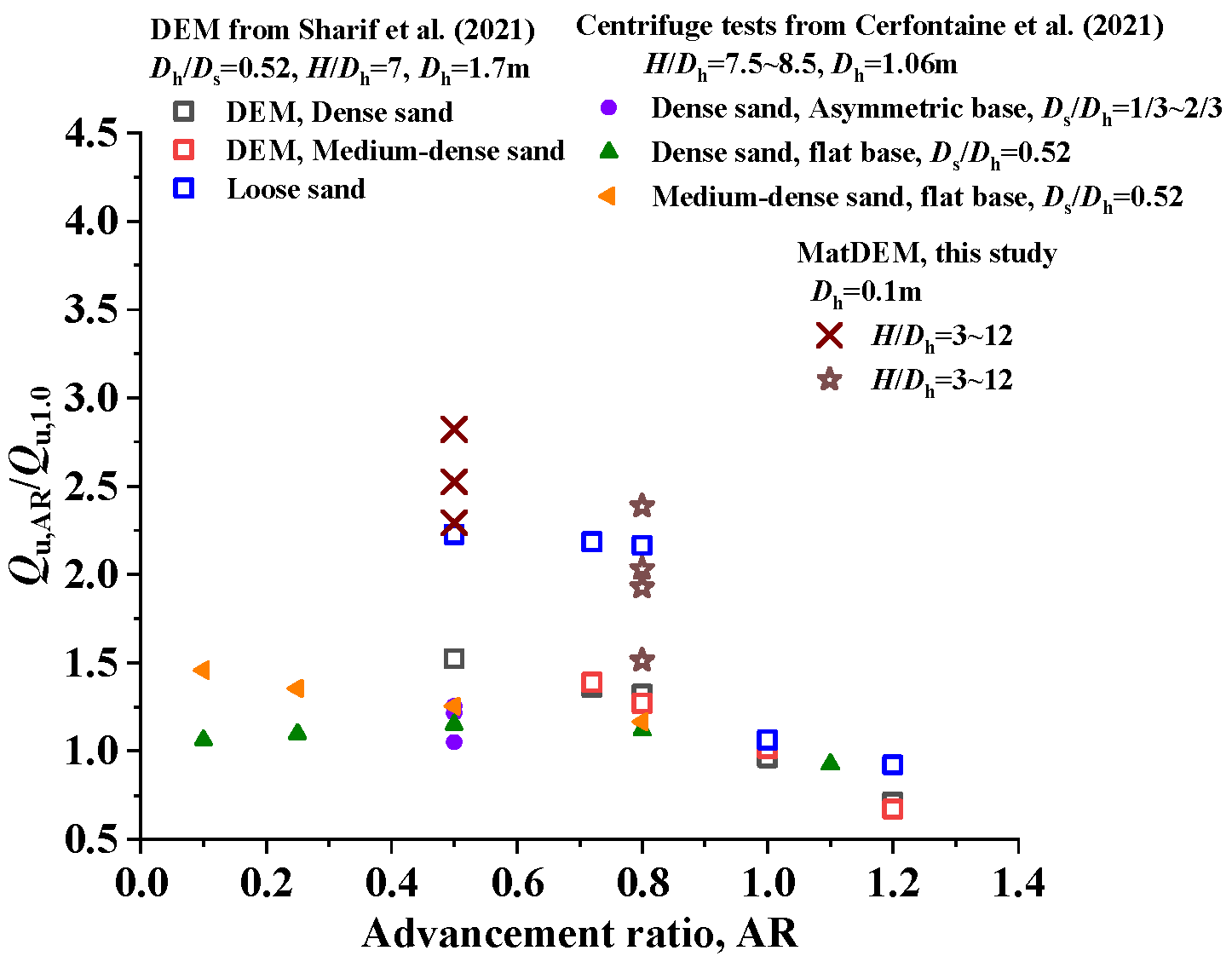

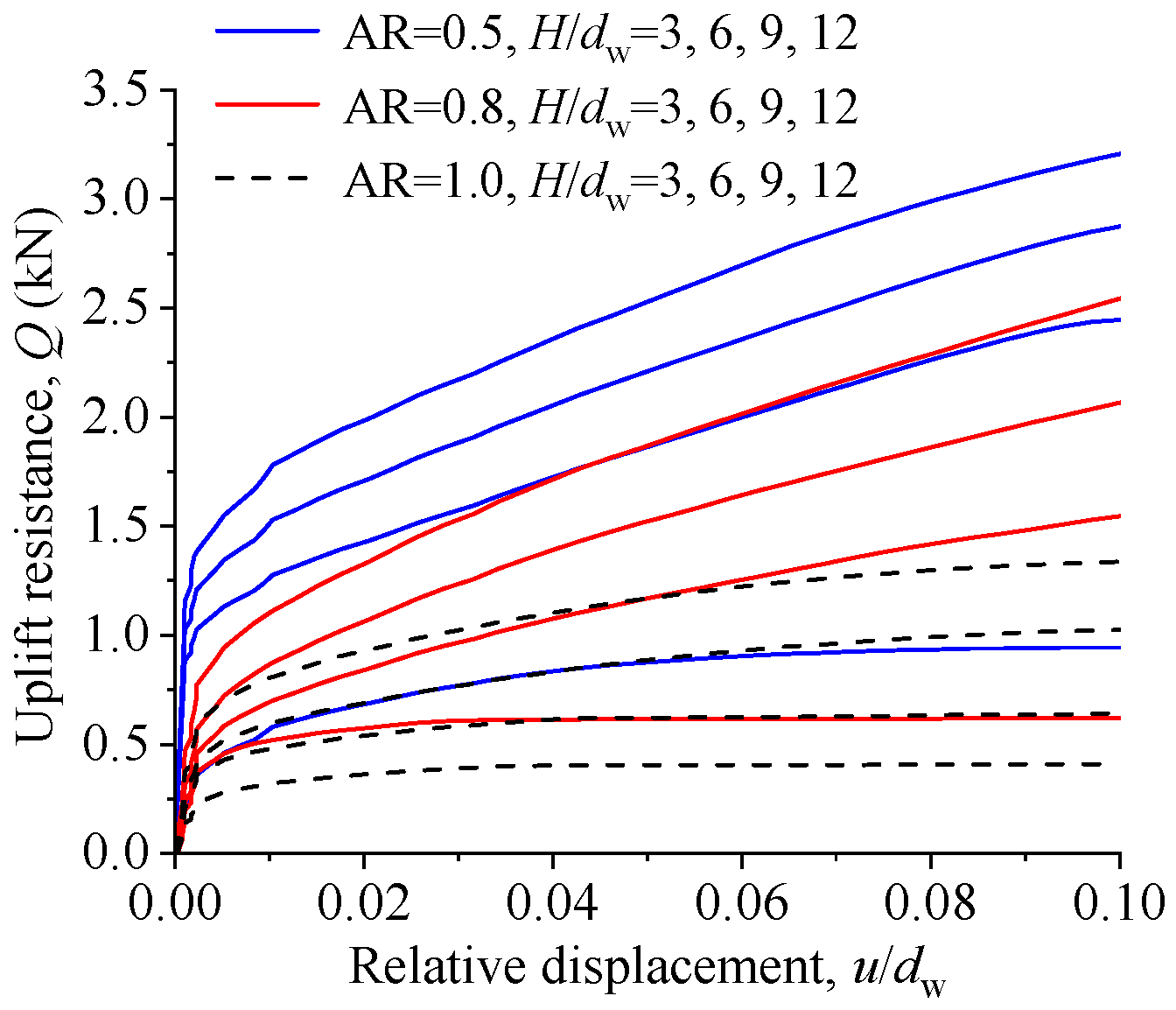

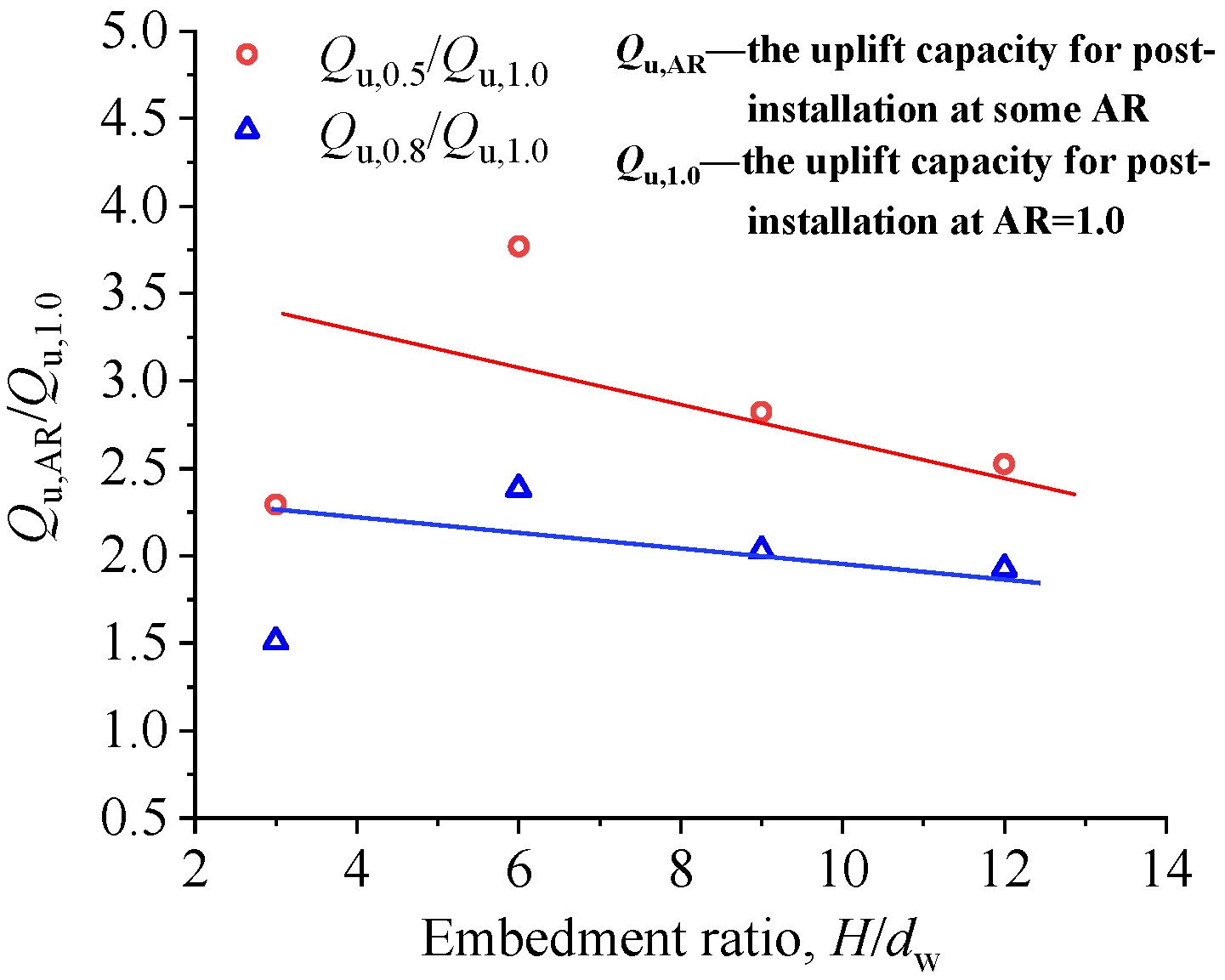

4.2. Single-Helix Anchors Installed at Different Advancement Ratios

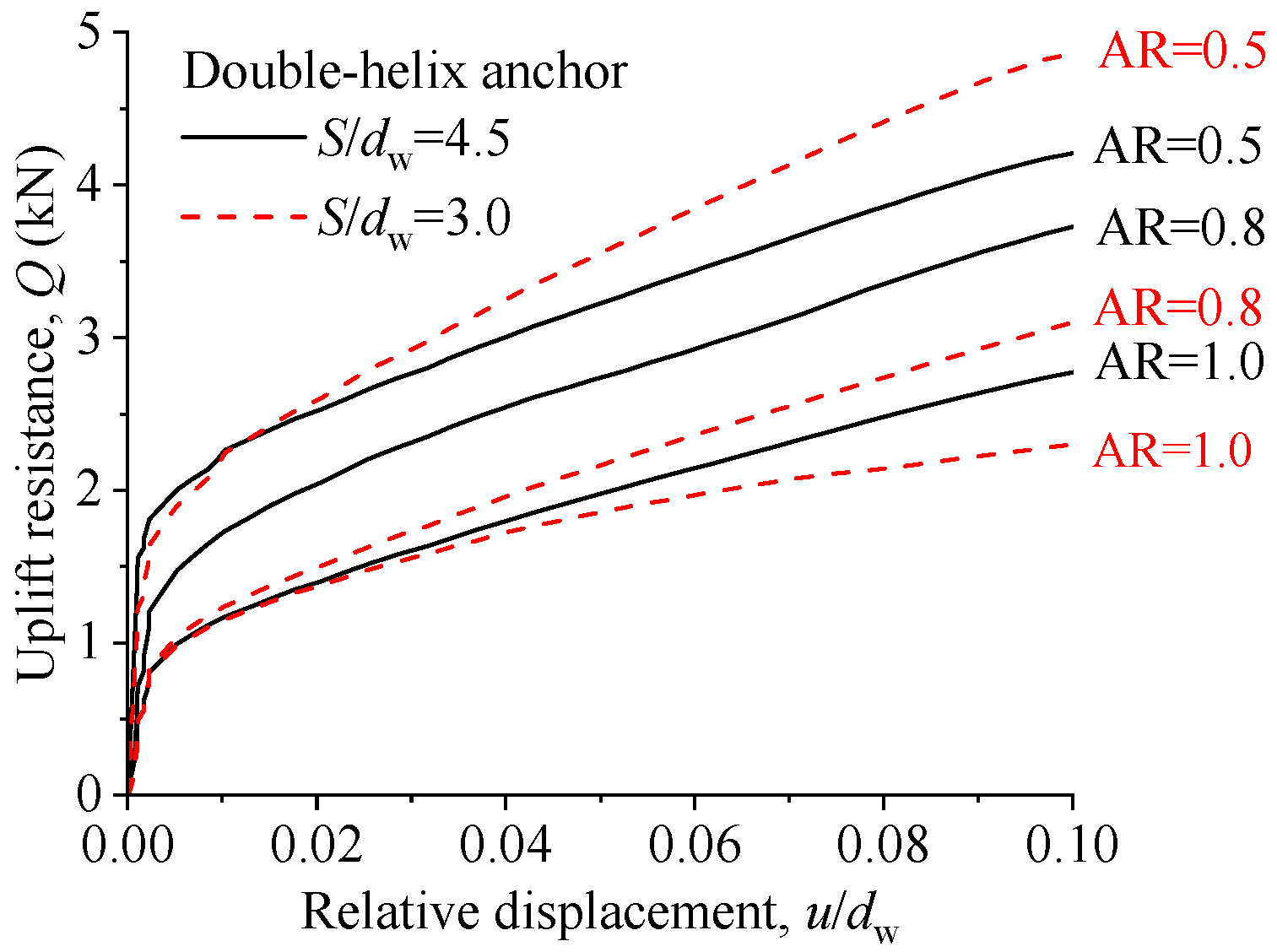

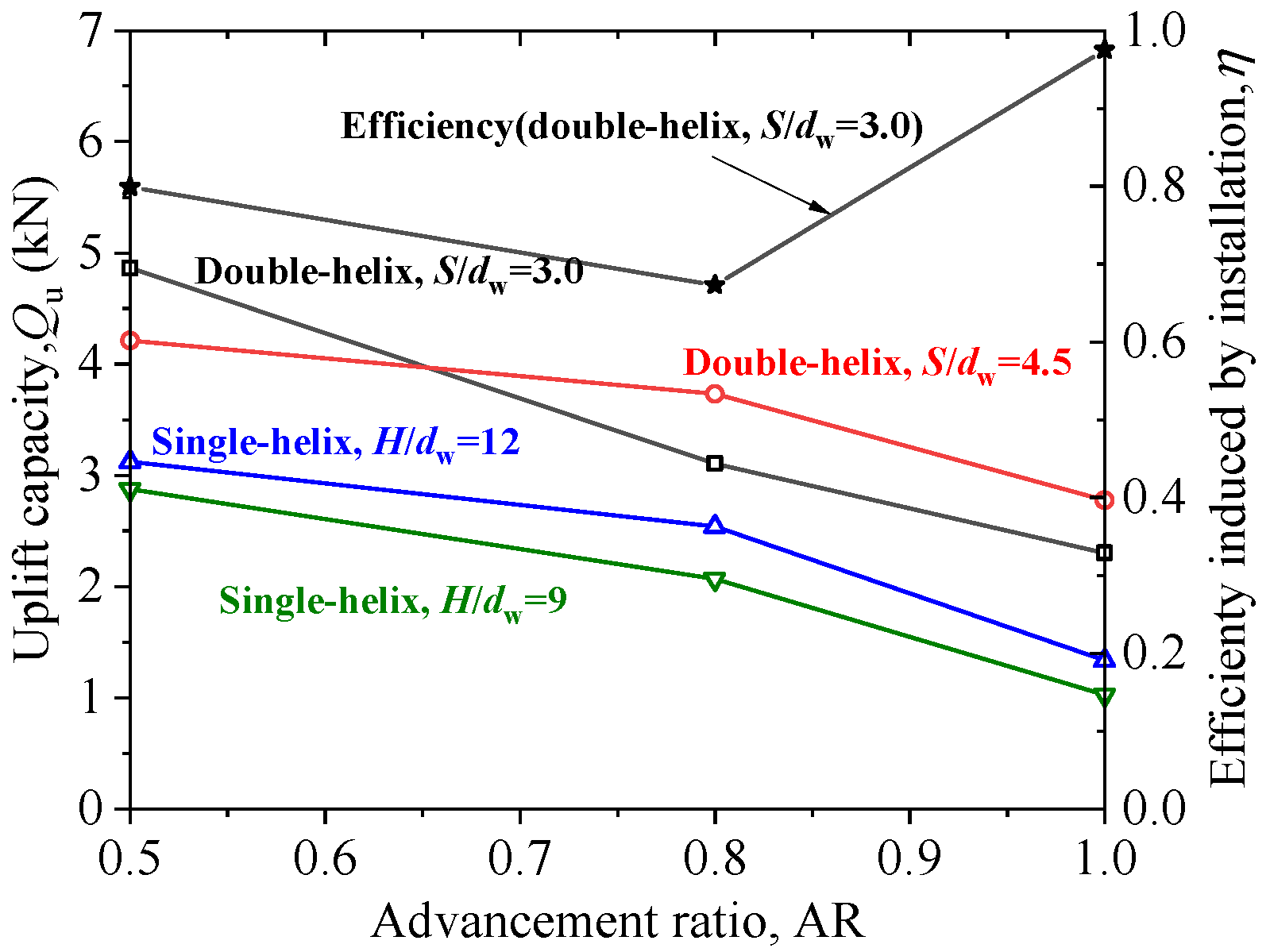

4.3. Double-Helix Anchors Installed at Different Advancement Ratio

5. Conclusions

- (1)

- When the helical anchor is drilled into a shallow depth, the particle motion zone is the shape of an inverted cone, and when drilled into a deep depth (L > 9 dw), the overall disturbed zone is funnel-shaped. For the double-helix anchor, the soil above the upper helical plate is disturbed more obviously than with the single-helix anchor because it has been penetrated twice.

- (2)

- When a single-helix anchor is installed at an AR of less than 1, the particles around the plate are encouraged to move upwards, and the back flow-around mechanism occurs. And when installed at AR = 1, the flow-around mechanism occurs.

- (3)

- For a double-helix anchor, the lateral displacements of the particles between the two plates are smaller than those for a single-helix anchor regardless of the AR value. When AR = 0.5, the upward motions of the particles below the top plate are limited and the upward displacement is smaller than that of a single-helix anchor, while when AR = 1, the downward motion of the particles above the top plate is accelerated slightly and the downward displacement is slightly greater than that of a single-helix anchor.

- (4)

- The pitch-matched installation (AR = 1) of a single-helix anchor will make the uplift capacity decrease compared with the cases of wish-in-place conditions (undisturbed conditions). As the embedment ratio increases, the uplift capacity loss caused by installation disturbance (AR = 1) gradually increases. However, when the embedment depth can make deep failure mode occur, the impact rate of the installation disturbance on the uplift capacity becomes slow with the increase of embedment depth.

- (5)

- The uplift capacities of both single-helix and double-helix anchors increase with the decrease in the AR (AR = 0.5~1). The efficiency induced by installation is close to 1 for the case of AR = 1, indicating that the impact of the top plate during installation is minimal when AR = 1.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hao, D.; Che, J.; Chen, R.; Zhang, X.; Yuan, C.; Chen, X. Experimental investigation on behavior of single-helix anchor in sand subjected to uplift cyclic loading. J. Mar. Sci. Eng. 2022, 10, 1338. [Google Scholar] [CrossRef]

- Lin, Y.; Xiao, J.; Le, C.; Zhang, P.; Chen, Q.; Ding, H. Bearing characteristics of helical pile foundations for offshore wind turbines in sandy Soil. J. Mar. Sci. Eng. 2022, 10, 889. [Google Scholar] [CrossRef]

- Lutenegger, A.J. Historical development of iron screw-pile foundations: 1836–1900. Int. J. Hist. Eng. Technol. 2011, 81, 108–128. [Google Scholar] [CrossRef]

- Meng, Z.; Chen, J.; Zhang, L.; Wang, J.; Yao, J. Field tests to investigate the installation effects of drilled displacement piles with screw-shaped shaft in clay. J. Geotech. Geoenviron. Eng. 2015, 141, 06015010. [Google Scholar] [CrossRef]

- Huang, Z.M. Construction and development of EHV transmission line in China. China Electr. Power 1996, 29, 9–12. (In Chinese) [Google Scholar]

- Cerato, A.B.; Victor, R. Effects of helical anchor geometry on long-term performance of small wind tower foundations subject to dynamic loads. J. Deep Found. Inst. 2008, 2, 30–41. [Google Scholar] [CrossRef]

- Tsuha, C.H.C.; Aoki, N. Relationship between installation torque and uplift capacity of deep helical piles in sand. Can. Geotech. J. 2010, 47, 635–647. [Google Scholar] [CrossRef]

- Kulhawy, F.H. Uplift behavior of shallow soil anchors—An overview: Uplift behavior of anchor foundations in soil. In Uplift Behavior of Anchor Foundations in Soil; ASCE: Reston, VA, USA, 1985; pp. 1–25. [Google Scholar]

- Dijkstra, J.; Broere, W.; Bezuijen, A.; Bezuijen, A.; Van Tol, A.F. Density changes near an advancing displacement pile in sand. In Proceedings of the Second BGA International Conference on Foundations, Dundee, UK, 24–27 June 2008; pp. 545–554. [Google Scholar]

- Perez, Z.A.; Schiavon, J.A.; Tsuha, C.H.C.; Dias, D.; Thorel, L. Numerical and experimental study on influence of installation effects on behaviour of helical anchors in very dense sand. Can. Geotech. J. 2018, 55, 1067–1080. [Google Scholar] [CrossRef]

- Clemence, S.P.; Pepe, F.D. Measurement of lateral stress around multihelix anchors in sand. Geotech. Test. J. 1984, 7, 145–152. [Google Scholar] [CrossRef]

- George, B.E.; Banerjee, S.; Gandhi, S.R. Helical piles installed in cohesionless soil by displacement method. Int. J. Geomech. 2019, 19, 0401907. [Google Scholar] [CrossRef]

- Lutenegger, A.J.; Tsuha, C.H.C. Evaluating installation disturbance from helical piles and anchors using compression and tension tests. In Proceedings of the Pan-American Conference on Soil Mechanics and Geotechnical Engineering, Buenos Aires, Argentina, 15–19 November 2015; pp. 373–381. [Google Scholar]

- Saleem, M.A.; Malik, A.A.; Kuwano, J. Model study of screw pile installation impact on ground disturbance and vertical bearing behaviour in dense sand. Earth Environ. Sci. 2021, 710, 012056. [Google Scholar] [CrossRef]

- Davidson, C.; Brown, M.J.; Cerfontaine, B.; Al-Baghdadi, T.; Knappett, J.; Brennan, A.; Augarde, C.; Coombs, W.; Wang, L.; Blake, A.; et al. Physical modelling to demonstrate the feasibility of screw piles for offshore jacket-supported wind energy structures. Géotechnique 2020, 72, 108–126. [Google Scholar] [CrossRef]

- Cerfontaine, B.; Brown, M.J.; Knappett, J.A.; Davidson, C.; Sharif, Y.; Huisman, M.; Ottolini, M.; Ball, J.D. Control of screw pile installation to optimise performance for offshore energy applications. Géotechnique 2023, 73, 234–249. [Google Scholar] [CrossRef]

- Sakr, M. Relationship between installation torque and axial capacities of helical piles in cohesionless soils. Can. Geotech. J. 2015, 52, 747–759. [Google Scholar] [CrossRef]

- Shi, D.; Yang, Y.; Deng, Y.; Xue, J. DEM modelling of screw pile penetration in loose granular assemblies considering the effect of drilling velocity ratio. Granul. Matter 2019, 21, 74. [Google Scholar] [CrossRef]

- Bradshaw, A.S.; Zuelke, R.; Hildebrandt, L.; Robertson, T.; Mandujano, R. Physical modelling of a helical pile installed in sand under constant crowd. In Proceedings of the 1st International Symposium on Screw Piles for Energy Applications (ISSPEA), Dundee, UK, 27–28 May 2019; pp. 109–115. [Google Scholar]

- Cerfontaine, B.; Brown, M.J.; Davidson, C.; Sharif, Y.U.; Huisman, M.; Ottolini, M. Optimised screw pile design for offshore jacket foundations in medium–dense sand. Geotech. Lett. 2022, 12, 114–119. [Google Scholar] [CrossRef]

- Hao, D.X.; Chen, R.; Fu, S.N. Experimental study on uplift capacity of multi-helix anchors in sand. Chin. J. Geotech. Eng. 2015, 37, 126–132. (In Chinese) [Google Scholar]

- Jeffrey, J.; Brown, M.J.; Knappett, J.A.; Ball, J.D.; Caucis, K. CHD pile performance: Part I-physical modelling. Proc. ICE Geotech. Eng. 2016, 169, 43–54. [Google Scholar] [CrossRef]

- Komatsu, A. Development on battered pile with screw pile method (NS-ECO pile). In Proceedings of the International Workshop on Recent Advances of Deep Foundations, Yokosuka, Japan, 1–2 February 2007; pp. 253–257. [Google Scholar]

- Clemence, S.P.; Smithling, A.P. Dynamic uplift capacity of helical anchors in sand. In Proceedings of the 4th Australia-New Zealand Conference on Geomechanics, Perth, Australia, 14–18 May 1984; Volume 1, pp. 88–93. [Google Scholar]

- Ilamparuthi, K.; Dickin, E.A.; Muthukrisnaiah, K. Experimental investigation of the uplift behaviour of circular plate anchors embedded in sand. Can. Geotech. J. 2002, 39, 648–664. [Google Scholar] [CrossRef]

- Cerato, A.B.; Victor, R. Effects of long-term dynamic loading and fluctuating water table on helical anchor performance for small wind tower foundations. J. Perform. Constr. Facil. ASCE 2009, 23, 251–261. [Google Scholar] [CrossRef]

- Hao, D.; Wang, D.; O’Loughlin, C.D.; Gaudin, C. Tensile monotonic capacity of helical anchors in sand: Interaction between helices. Can. Geotech. J. 2019, 56, 1534–1543. [Google Scholar] [CrossRef]

- Tsuha, C.H.C.; Aoki, N.; Rault, G.; Thorel, L.; Garnier, J. Evaluation of the efficiencies of helical anchor plates in sand by centrifuge model tests. Can. Geotech. J. 2012, 49, 1102–1114. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, P.; Ding, H.; Tian, Y.; Qi, X. The uplift capacity of single-plate helical pile in shallow dense sand including the influence of installation. Mar. Struct. 2020, 71, 102697. [Google Scholar] [CrossRef]

- Nagai, H.; Tsuchiya, T.; Shimada, M. Influence of installation method on performance of screwed pile and evaluation of pulling resistance. Soils Found. 2018, 58, 355–369. [Google Scholar] [CrossRef]

- Cerfontaine, B.; Ciantia, M.; Brown, M.J.; Sharif, Y.U. DEM study of particle scale and penetration rate on the installation mechanisms of screw piles in sand. Comput. Geotech. 2021, 139, 104380. [Google Scholar] [CrossRef]

- Sharif, Y.U.; Brown, M.J.; Cerfontaine, B.; Davidson, C.; Ciantia, M.O.; Knappett, J.A.; Brennan, A.; Ball, J.D.; Augarde, C.; Coombs, W.M.; et al. Effects of screw pile installation on installation requirements and in-service performance using the discrete element method. Can. Geotech. J. 2021, 58, 1334–1350. [Google Scholar] [CrossRef]

- Sharif, Y.U.; Brown, M.J.; Ciantia, M.O.; Cerfontaine, B.; Davidson, C.; Knappett, J.A.; Ball, J.D. Assessing single-helix screw pile geometry on offshore installation and axial capacity. Proc. Inst. Civ. Eng. Geotech. Eng. 2021, 174, 512–529. [Google Scholar] [CrossRef]

- Kurian, N.P.; Shah, S.J. Studies on the behavior of screw piles by the finite element method. Can. Geotech. J. 2009, 46, 627–638. [Google Scholar] [CrossRef]

- Rawat, S.; Gupta, A.K. Numerical modelling of pullout of helical soil nail. J. Rock Mech. Geotech. Eng. 2017, 9, 648–658. [Google Scholar] [CrossRef]

- Chen, R.; Fu, S.N.; Hao, D.X.; Shi, D.D. Scale effects of uplift capacity of circular anchors in dense sand. Chin. J. Geotech. Eng. 2019, 41, 78–85. (In Chinese) [Google Scholar]

- Cerfontaine, B.; Knappett, J.A.; Brown, M.J.; Davidson, C.S.; AI-Baghdadi, T.; Sharif, Y.U.; Brennan, A.; Augarde, C.; Coombs, W.M.; Wang, L. A finite element approach for determining the full load–displacement relationship of axially loaded shallow screw anchors, incorporating installation effects. Can. Geotech. J. 2021, 58, 565–582. [Google Scholar] [CrossRef]

- Shao, K.; Su, Q.; Liu, J.; Liu, K.; Xiong, Z.; Wang, T. Optimization of inter-helix spacing for helical piles in sand. J. Rock Mech. Geotech. Eng. 2022, 14, 936–952. [Google Scholar] [CrossRef]

- Yuan, C.; Hao, D.; Chen, R.; Zhang, N. Numerical investigation of uplift failure mode and capacity estimation for deep helical anchors in sand. J. Mar. Sci. Eng. 2023, 11, 1547. [Google Scholar] [CrossRef]

- Hao, D.X.; Fu, S.N.; Chen, R.; Zhang, Y.J.; Hou, L.Q. Experimental investigation of uplift behavior of anchors and estimation of uplift capacity in sands. Chin. J. Geotech. Eng. 2015, 37, 2101–2106. (In Chinese) [Google Scholar]

- Liu, C.; Pollard, D.D.; Shi, B. Analytical solutions and numerical tests of elastic and failure behaviors of close-packed lattice for brittle rocks and crystals. J. Geophys. Res. Solid Earth 2013, 118, 71–82. [Google Scholar] [CrossRef]

- Morgan, J.K.; Boettcher, M.S. Numerical simulations of granular shear zones using the distinct element method. Shear zone kinematics and the micromechanics of localization. J. Geophys. Res. Solid Earth 1999, 104, 2703–2719. [Google Scholar] [CrossRef]

- Kuhn, M.R.; Bagi, K. Contact rolling and deformation in granular media. Int. J. Solids Struct. 2004, 41, 5793–5820. [Google Scholar] [CrossRef]

- Ergenzinger, C.; Seifried, R.; Eberhard, P. A discrete element model to describe failure of strong rock in uniaxial compression. Granul. Matter 2011, 13, 341–364. [Google Scholar] [CrossRef]

- Liu, C.; Shi, B.; Gu, K.; Sun, Y.J. Development and application of large-scale discrete element simulation system for rock and soil. J. Eng. Geol. 2014, 22, 551–557. (In Chinese) [Google Scholar]

- Arroyo, M.; Butlanska, J.; Gens, A.; Calvetti, F.; Jamiolkowski, M. Cone penetration tests in a virtual calibration chamber. Géotechnique 2011, 61, 525–531. [Google Scholar] [CrossRef]

- Bradshaw, A.S.; Cullen, L.; Miller, Z. Field study of group effects on the pullout capacity of “deep” helical piles in sand. Can. Geotech. J. 2022, 59, 538–545. [Google Scholar] [CrossRef]

| Macro-Parameters | Micro-Parameters | ||||

|---|---|---|---|---|---|

| Dense Sand | Anchor | Dense Sand | Anchor | ||

| Modulus, (E/GPa) | 0.162 | 5.4 | Normal stiffness Kn/(MN/m) | 3.0322 | 112.31 |

| Poisson’s ratio, v | 0.16 | 0.24 | Shear stiffness Ks (MN/m) | 0.5228 | 19.363 |

| Tensile strength (Tu/kPa) | 0.06 | 1.2 × 104 | Breaking displacement Xb (m) | 2.04 × 10−9 | 1.363 × 10−5 |

| Compression strength (Cu/kPa) | 1.3 | 1.3 × 104 | Friction coefficient, μp | 0.2828 | 0 |

| Internal friction coefficient, μi | 0.75 | 0.3 | Shear resistance Tf (N) | 0.0421 | 866.67 |

| Density ρ/(kg·m−3) | 2011 | 9341 | |||

| Group | Influence Factor | Installation Mode | Helix Diameter, dw(mm) | Embedment Ratio, H/dw | Relative Spacing S/dw | Surcharge Pressure (kPa) |

|---|---|---|---|---|---|---|

| Single-helix anchor | Embedment depth, installation mode | Wish-in-place AR = 1 | 100 | 6, 8, 9, 10, 12 | - | 100 |

| AR = 0.5, 0.8, 1 | 100 | 3, 6, 9, 12 | - | - | ||

| Double-helix anchor | Helix number, relative spacing | AR = 0.5, 0.8, 1 | 100 | 3, 6, 9, 12 | 3, 4.5 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, R.; Liu, H.; Hao, D.; Liu, Z.; Yuan, C. Installation Disturbance of Helical Anchor in Dense Sand and the Effect on Uplift Capacity Based on Discrete Element Method. J. Mar. Sci. Eng. 2024, 12, 422. https://doi.org/10.3390/jmse12030422

Chen R, Liu H, Hao D, Liu Z, Yuan C. Installation Disturbance of Helical Anchor in Dense Sand and the Effect on Uplift Capacity Based on Discrete Element Method. Journal of Marine Science and Engineering. 2024; 12(3):422. https://doi.org/10.3390/jmse12030422

Chicago/Turabian StyleChen, Rong, Hu Liu, Dongxue Hao, Zhaoguo Liu, and Chi Yuan. 2024. "Installation Disturbance of Helical Anchor in Dense Sand and the Effect on Uplift Capacity Based on Discrete Element Method" Journal of Marine Science and Engineering 12, no. 3: 422. https://doi.org/10.3390/jmse12030422

APA StyleChen, R., Liu, H., Hao, D., Liu, Z., & Yuan, C. (2024). Installation Disturbance of Helical Anchor in Dense Sand and the Effect on Uplift Capacity Based on Discrete Element Method. Journal of Marine Science and Engineering, 12(3), 422. https://doi.org/10.3390/jmse12030422