Abstract

This paper addresses the growing concern over air pollutant emissions (NOx, SOx, PM, CO2) from ocean-going vessels in harbor areas and the role of Onshore Power Supply (OPS) systems in mitigating these emissions during vessel berthing. However, the slow progress in global shore power facilities is attributed to safety- and specification-related concerns. Our study conducts a comprehensive analysis, comparing international shore power regulations, with a specific focus on the IEC/IEEE 80005-1 standard and guidelines from various ship classification societies. We introduce checklists, scoring tables, and spider diagrams to evaluate the regulatory content, highlighting the strengths and weaknesses of each approach. Furthermore, this paper emphasizes the significance of a well-defined operational process for high-voltage shore connection (HVSC) to ensure the safety of OPS operations. We present process diagrams for key operational stages, based on IEC/IEEE 80005-1 specifications and evaluation criteria. The ultimate goal of this research is to drive the global adoption of shore power and foster the establishment of shore power facilities worldwide. This aligns with the broader environmental protection objectives of achieving cleaner ports and reducing emissions for a sustainable future.

1. Introduction

Globalization and international trade have led to a significant increase in the number of seagoing vessels and port facilities. In 2022, approximately 80% of the world’s trade volume was conducted through maritime channels, and over 70% of the global merchandise value was transported by sea [1]. However, this growth in shipping activity has also led to an increase in pollutant emissions. These pollutants, including sulfur oxides (SOx), nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) are emitted by ships while underway and while docked, and pose a threat to the oceans, ports, and human health [2]. Recent research indicates that a significant portion, at least 70%, of emissions from ships on international voyages occur within 400 km of coastlines. It has been determined that ships docked at ports are responsible for approximately 55 to 77% of the total emissions in areas near these ports [3].

To address this problem, the International Maritime Organization (IMO) has established emission standards for ship generators in Annex VI of the International Convention for the Prevention of Pollution from Ships (MARPOL) [4]. Ports around the world are actively working to control air pollution by taking various measures, such as using low-sulfur fuel, limiting ship speed, and implementing shore power systems to achieve cleaner air quality in ports. Shore power supply, also known as cold ironing (CI), alternative maritime power supply (AMP), or onshore power supply (OPS), is a technique that allows ships to reduce pollutant emissions during berthing by using shore power instead of on-board diesel generators (DGs) [5]. Utilizing shore power can significantly enhance air quality in port areas and aid in meeting the greenhouse gas (GHG) goals of the international Paris Agreement on climate change by the year 2050 [6].

California has taken the lead in regulating high-voltage shore power in ports worldwide, publishing “California’s Shore Power Requirements” in 2014, with the goal of increasing the percentage of ships using shore power to 80% by 2020 [7]. In addition, all European ports must offer shore power services by the end of 2025 [8]. As of June 2020, 45 major ports worldwide in the Americas, Europe, and Asia are equipped with the capability to use OPS [9]. Shore power, a crucial technology for the sustainable growth of maritime shipping, has demonstrated its effectiveness in decreasing pollutant emissions from ships [8,9].

While shore power significantly reduces air pollution and carbon emissions for ships at ports, it does not eliminate carbon emissions due to the electricity generation process. As a result, recent initiatives have focused on integrating a cold ironing system with various renewable energy solutions to achieve genuine decarbonization or net-zero emissions when ships are docked [10,11,12,13]. Furthermore, research has been conducted into optimizing shore power systems, including studies on the selection of power grids for berths and their supply characteristics [14]. Green ships equipped with hybrid energy systems using shore power have employed energy management strategies, effectively reducing electricity costs through optimal control and model predictive control (MPC) methods [15]. The growth of big data analytics and artificial intelligence technologies has also played a role, offering more accurate predictions for berth allocation and energy management using data-driven and neural network approaches, thereby enhancing the efficiency of shore power systems [16].

However, the adoption of OPS faces challenges due to the high cost of the required equipment in ports and on ships, as well as policy regulations on incentives and mandatory use. Comparisons between costs and oil prices, as well as concerns about power stability, operations, and safety, have contributed to limited installation of shore power systems [17]. Issues to consider include reliable power sources, voltage and frequency specifications, connection procedures, and electric shock hazards [18]. To ensure compatibility between OPS for connecting ships and ports around the world, organizations such as the International Electrotechnical Commission (IEC), the International Organization for Standardization (ISO), and the Institute of Electrical and Electronics Engineers (IEEE) are working on the concept of “every ship, every port” by establishing specifications for equipment, including power supplies, outlets, receiving boxes, cables, and conversions [19]. For example, drilling ships operate in diverse territorial waters of many countries with varying technical standards. The proper standards are crucial to boost safety and environmental protection without incurring extra certification costs [20]. In 2012, IEEE, IEC, and ISO jointly issued the High Voltage Shore Connection (HVSC) standard called IEC/ISO/IEEE 80005-1 to ensure the reliability of vessel operations in OPS [21,22]. Despite the environmental and economic benefits of OPS, implementation can be challenging due to varying port regulations and testing standards. Therefore, the development of further technical standards and specifications is necessary to keep pace with international trends and solve problems with current standards, especially in China [23].

To ensure the successful implementation of shore power, it is essential to distinguish between international standards and ship classification society specifications. Ship classification societies are critical to overseeing the construction, maintenance, and inspection of ships, making them important beneficiaries of the shore power system [24]. Therefore, a comprehensive understanding of the rules established by the world’s leading ship classification societies for ships using shore power is of paramount importance. However, these rules and standards include complicated regulations and operating procedures related to shore power system design, equipment specifications, safety, and operating guidelines. This complexity could hinder the widespread adoption of OPS. Therefore, it is essential to help port authorities, ship owners, and engine crews understand the complicated regulations and standards associated with shore power. The main goal of this article is to address this vital issue and contribute to the overall promotion of shore power. By providing clarity on these issues, we aim to contribute to greater acceptance and use of shore power and ultimately promote environmental protection through cleaner ports. This article serves as a valuable reference for ports and vessels in the design and use of HVSC.

The literature delves into the topic of port pollution, examines the IMO’s pollution prevention regulations, defines shore power, discusses the advancement and technological progress of shore power systems, and emphasizes the necessity of creating international standards for shore power, along with an analysis of shore power regulations proposed by classification societies. This article aims to analyze the standards and regulations issued by IEC/IEEE and ship classification societies for power lines. The following sections of this article are organized as follows: Section 2 introduces the HVSC standard, guidelines, and its development and explains the method of comparison; Section 3 introduces and discusses the IEC/IEEE HVSC system standard, compares, and analyzes it with the guidelines issued by the ship classification societies; and Section 4 describes and proposes the flowchart of each stage of HVSC. Finally, Section 5 provides a summary of this article.

2. HVSC Standards and Methodology

2.1. HVSC Standards and Classification Society Guidelines

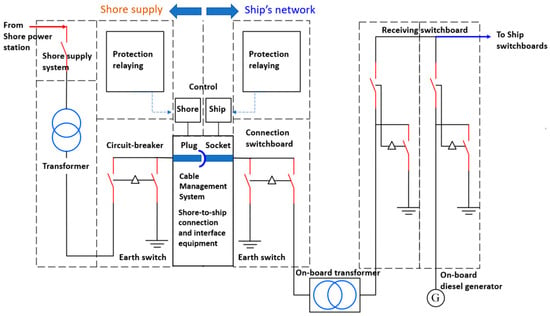

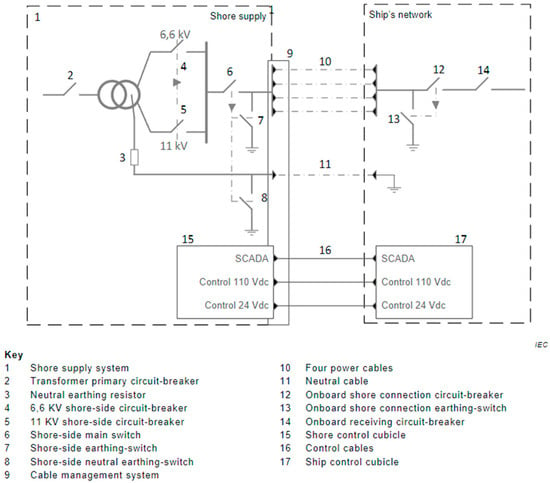

The OPS system comprises various subsystems, such as the power supply station, the connection between the ship and shore, and the systems on board the vessel for receiving power. Specifically, the HVSC features three primary components: a shore-based substation that steps down the voltage to 11.4 or 6.6 kV, a power-receiving panel on the ship that receives power via a junction box, and a cable management system responsible for handling the cables. Figure 1 shows an illustration of HVSC systems as defined in the IEC/IEEE 80005-1 standard [25]. The IEC/IEEE 80005-1 standard outlines protocols for connecting, transmitting, converting, distributing, controlling, and monitoring HVSC systems. While it regulates the power system, equipment, and outlets, the underlying technology and specifications can be intricate. HVSC systems are typically segmented into two components: the shore-side infrastructure and the ship-side setup. The shore-side power system and equipment must comply with national standards and the rules of the port’s power supplier. To complement the structure shown in Figure 1, Figure 2 presents the detailed specifications for the system functionalities of cruise ships, as outlined in Annex C of IEC/IEEE 80005-1. The content indicates the schematic connections of power and control circuits and voltage-level markings.

Figure 1.

IEEE/IEC 80005-1 HVSC systems block diagram.

Figure 2.

IEEE/IEC 80005-1 Cruise ship HVSC system functional diagram [21].

On the other hand, the classification society is responsible for inspecting the equipment, design, and maintenance and acts as a certification organization, inspecting the structure and equipment of ships. When discussing shore power standards, it is important to compare them with classification society regulations or guidelines. This study examined shore power regulations of well-known classification societies that have made significant progress at OPS. Table 1 provides a summary of the shore power regulations of the classification societies that were used for comparison in this study.

Table 1.

List of shore power regulations/rules/guidelines of classification societies.

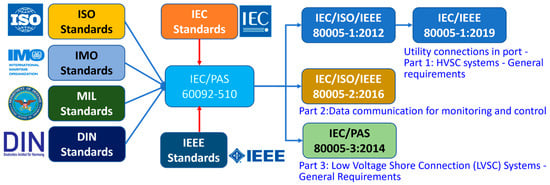

The IEC/IEEE 80005-1 standard is the successor to its predecessor, IEC/ISO/IEEE 60092-510, which was published by the IEC in 2009. After the development process, the IEC/ISO/IEEE 80005-1:2012 standard was published, providing a systematic summary of the power aspect in HVSC systems. In addition, two other standards have been issued: the communication interface specification for the high-voltage part, IEC/ISO/IEEE 80005-2, published in 2016 [30], and the low-voltage part and standard 80005-3 [31], published in 2014.

For each standard published—whether it is the informal version IEC/PAS 60092-510 published in 2009, the edition of IEC/ISO/IEEE 80005-1 published in 2012, or the latest version, IEC/IEEE 80005-1:2019—numerous IEC specifications are cited, indicating that the formulation is based on IEC standards. In addition, the standard includes specifications from international organizations such as ISO and IEEE, as well as some U.S. military standards (Military Standard, MIL) and German national standards (Deutsches Institut fuer Normung e.V., DIN). Figure 3 shows a development diagram illustrating the course of these standards.

Figure 3.

Evolution relationship of IEC/IEEE 80005 series standards. Standard IEC/IEEE 80005-1:2019 [21], Standard IEC/IEEE 80005-2:2016 [30], Standard IEC/IEEE P80005-3:2014 [31].

2.2. Assessment Methods

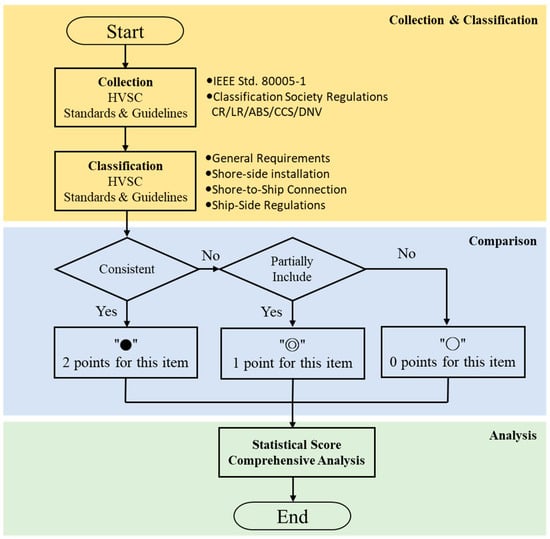

This study focuses on the contents of Chapters 4 to 8 of the IEC/IEEE 80005-1 standard [21]. It compares and examines the detailed regulations of different classification societies for HVSC. This study uses the guidelines of five classification societies, as listed in Table 1. We compare and evaluate five aspects: general requirements, shore-side installation, ship-to-shore connection requirements, ship-side requirements, and comprehensive analysis. The area of operational safety is also considered. We will compare guidelines content qualitatively using a quantitative scoring method for ease of understanding. Scores are calculated to evaluate the performance of each classification society in each area. These scores are based on the criteria described in the IEC/IEEE 80005-1 standard. To illustrate the differences between classification society guidelines and international standards, we will use a scoring method that divides the IEC/IEEE 80005-1 standard into various main and sub-criteria for comparison. Each criterion will be meticulously compared against the corresponding shore power regulations set forth by different classification societies. A complete alignment with the critical requirements of the IEEE/IEC 80005-1 standard, where regulations are explicitly defined, will earn 2 points. If the guidelines partially meet the standard, 1 point will be awarded. The absence of regulation results in zero points. The points for each criterion are summed to derive the score for that comparison aspect. The cumulative scores from all requirements within each category are then tallied to compute the overall score achieved by each classification society. The scores are then converted into a percentage scale from 0% to 100% (corresponding to values between 0 and 1.0). The analysis results are presented using spider diagrams that visually represent the results.

Figure 4 presents a flowchart comparing HVSC standards with regulations of different classification societies in this study. The standards and regulations are collected and classified according to the above scope, and a comparison table is prepared. Then, the analysis is carried out, and the differences are shown in the spider diagrams for reference and application.

Figure 4.

The analysis flowchart of this study. Standard IEC/IEEE 80005-1:2019 [21], Standard IEC/IEEE 80005-2:2016 [30], Standard IEC/IEEE P80005-3:2014 [31].

3. Comparison of IEC/IEEE HVSC Standards and Classification Society Regulations

3.1. General Requirements

Chapters 4 and 5 of the IEC/IEEE 80005-1 standards identify eight major points and 31 sub-points that must be considered. The architecture, design, and system requirements of HVSC are defined. Table 2 provides an overview comparing these standard points and the corresponding scores. In this article, the tables follow a specific notation to indicate compliance of the classification societies’ rules with the IEC/IEEE 80005-1 standard specifications. These symbols are used to clarify the degree of correspondence between the rules of the classification societies and the IEC/IEEE 80005-1 standard. The symbols used are as follows:

Table 2.

General requirements comparison between IEC/IEEE 80005-1 and classification societies.

“⚫” (black circle): Indicates full compliance with the IEC/IEEE 80005-1 standard. This means that the items are subject to specific rules within the guidelines of the classification society, for which 2 points are awarded.

“◎” (hollow circle): Indicates that the IEC/IEEE 80005-1 standard is partially included or referenced. It may not be explicitly stated in the classification society’s guidelines and is awarded 1 point.

“◯” (empty circle): Indicates that there is no regulation for a particular content. It has no mention or specification in the classification society guidelines; therefore, it is awarded 0 points.

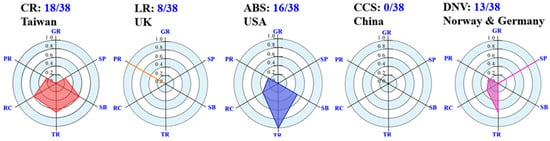

In addition to the tabular comparison, spider diagrams (as shown in Table 2 and Figure 5) compare the prescriptions of the different classification societies. From Table 2 and Figure 5, the comparison items and the scoring situation can be clearly understood. Moreover, through individual spider chart comparisons, we can better understand the focus and areas in need of supplementation in the shore power regulations set by each classification society. To enhance readability and presentation, we have annotated the top of the spider diagram in Figure 5 with the names of the classification societies, their scores, and overall scores from Table 2, as well as the countries in which these societies are based. This approach is consistently applied to Figure 6 and Figure 7 as well. The area of each classification society’s spider diagram reflects the extent of development in various areas, such as compatibility assessment, environmental design, electrical requirements, and system research. The analysis shows that CCS has the highest score and the most significant area, indicating thorough development has occurred in the above areas. However, supplementation may be needed in system design, operations, and personnel safety in the form of incorporating other standards or international standards. The CR features system descriptions, equipotential bonding connections, and compatibility testing. It also provides comprehensive regulations for emergency stops. However, the content regarding electrical requirements is relatively limited. The ABS has specific requirements for emergency stop switches and system evaluation, while the DNV has extensive regulations for personnel safety and system design but no content regarding electrical requirements. Of the five classification societies, LR makes the most comprehensive provisions for personnel safety, underscoring the importance of operational safety conditions for power lines. The LR and DNV have relatively few items and spider maps, in part since shore power regulations are integrated into the rules for steel vessels rather than being stated independently and explicitly, as is the case with other classification societies. This table provides an overview of the most essential aspects and missing parts of the HVSC regulations of the different classification societies and helps the readers to refer to them.

Figure 5.

Spider diagrams of general requirements comparison.

Figure 6.

Spider diagrams of shore-to-ship connection comparison.

Figure 7.

Spider diagrams of ship requirements comparison.

3.2. Shore-Side Installation

The land-based requirements of IEC/IEEE 80005-1 are described in Chapter 6 and include 5 major points and 22 subpoints. These primarily address transformers, circuit breakers, grounding resistors, equipment grounding, electrical protection systems, HV interlocks, and shore converter equipment within the HVSC.

Of the five guidelines, only the CCS scored full marks in each category and demonstrated excellent latency and high correlation. The remaining four guidelines correlate poorly with IEC/IEEE 80005-1 in this part of the specification, primarily because the classification societies’ rules focus on ship specifications, and the shore substations’ regulations are beyond their scope. For the central part of the shore-based requirements, it is recommended to follow IEC/IEEE 80005-1. Due to the low scores of the other rules, no detailed explanation is given in this section. Further results are presented in the comprehensive analysis section.

3.3. Shore-to-Ship Connection and Interface Equipment

This section addresses the shipboard provisions described in Chapter 8 of IEC/IEEE 80005-1. The checklist for this section includes 6 significant items and 19 subitems. Table 3 provides a comprehensive summary of the ratings assigned to these items. In addition, Figure 6 shows a spider diagram that visually represents the strengths and weaknesses of each classification society and provides valuable insight into their respective capabilities.

Table 3.

Shore-to-ship connection comparison between IEC/IEEE 80005-1 and classification societies.

Based on Table 3 and the spider diagram in Figure 6, CR and ABS have similar levels of comprehensive regulation. However, they differ regarding protecting the ship’s electrical distribution system, shore connection panel, shipboard transformer, and shipboard receiving panel connection point. While CR is more comprehensive overall, ABS performs better regarding transformer specifications. Nevertheless, both classification societies have identified deficiencies and would benefit from being supplemented by the specifications of the IEC/IEEE 80005-1 standard.

DNV’s regulations comply with the IEC/IEEE 80005-1 standard for protecting shipboard distribution systems. LR stands out primarily in shipboard power restoration, while CCS has minimal regulations for shipboard equipment. The spider diagrams for both classification societies show a straight line and origin, indicating a need for comprehensive rules in various aspects.

In summary, the spider diagrams and analysis of shipboard regulations indicate areas where classification societies can improve their policies. It is recommended that their regulations be supplemented with the specifications of the IEC/IEEE 80005-1 standard to increase completeness and ensure compliance with industry standards.

3.4. Ship-Side Requirements

This section addresses the shipboard provisions described in Chapter 8 of IEC/IEEE 80005-1. The checklist for this section includes 6 major items and 19 subitems. Table 4 provides a comprehensive summary of the ratings assigned to these items. In addition, Figure 7 shows a spider diagram that visually represents the strengths and weaknesses of each classification society and provides valuable insight into their respective capabilities.

Table 4.

Ship requirements comparison between IEC/IEEE 80005-1 and classification societies.

Based on Table 4 and the spider diagram in Figure 7, CR and ABS have similar levels of comprehensive regulation. However, they differ in terms of protection of the ship’s electrical distribution system, shore connection panel, shipboard transformer, and shipboard receiving panel connection point. While CR is more comprehensive overall, ABS performs better in terms of transformer specifications. Nevertheless, both classification societies have identified deficiencies and would benefit from being supplemented by the specifications of the IEC/IEEE 80005-1 standard.

DNV’s regulations are fully compliant with the IEC/IEEE 80005-1 standard for the protection of shipboard distribution systems. LR stands out primarily in the area of shipboard power restoration, while CCS has minimal regulations for shipboard equipment. The spider diagrams for both classification societies show a straight line and origin, indicating a lack of comprehensive regulations in various aspects.

In summary, the spider diagrams and analysis of shipboard regulations indicate areas where classification societies can improve their policies. It is recommended that their regulations be supplemented with the specifications of the IEC/IEEE 80005-1 standard to increase completeness and ensure compliance with industry standards.

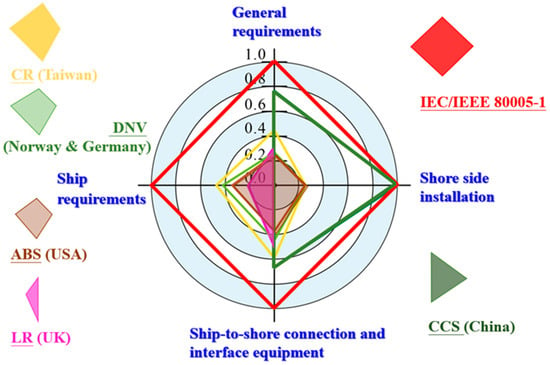

3.5. Comprehensive Analysis

This article contains a comprehensive analysis divided into four parts and a spider diagram shown in Figure 8. In Figure 8, the legend color blocks on both sides represent the score areas resulting from the comparison between IEC/IEEE 8005-1 and the regulations of various classification societies, arranged from top to bottom based on the size of the area (score). Among the classification societies studied, CCS has the most conspicuous area in the spider diagram, like the IEC/IEEE 80005-1 standard. However, CCS lacks specific provisions for shipboard specifications. Classification societies are ranked based on the size of their areas in the spider diagram: CCS, CR, DNV, ABS, and LR. The deficiencies identified in the classification societies’ rules may be supplemented or directly adopted by the specifications listed in the IEC/IEEE 80005-1 standard. While the regulations of the various classification societies are somewhat consistent with international standards, they need more specific details. The regulations of the various classification societies are in need of improvement and revision, especially regarding the general specifications, grounding interlocks, personnel safety, and operational safety regulations. Overall, the findings underscore the need for further development and refinement of the rules and guidelines provided by the classification societies. Improving the specificity and scope of these rules while aligning them more closely with international standards will enhance safety and operating practices in shore power facilities.

Figure 8.

Spider diagram of a comprehensive comparison of classification society regulations; IEC/IEEE 80005-1 standard: [21].

4. Safety Operation of HVSC Systems

Within the IEC/IEEE 80005-1 standard framework, this study undertakes a comparative analysis and synthesis of global shore power regulations and the various ship classification societies. The goal is to comprehensively examine the multi-layered regulations surrounding HVSC. The analysis process highlighted that specific regulations or procedures are interrelated and that it is necessary to cross-reference between chapters to gain a comprehensive understanding. In addition, shore power operations require exemplary coordination between shore and shipboard systems, personnel, and equipment to ensure safety. The intricacies of HVSC operation and the associated protection of the power supply significantly influence stakeholders’ willingness to adopt this system.

To improve port management authorities’, ship owners’, and engine room personnel’s understanding of the regulations and related assessment components and to promote the adoption of OPS systems, this study divides the IEC/IEEE 80005-1 HVSC standard into three segments: pre-installation assessment, setup of HVSC, and safety processes for power delivery and operation. Essential process diagrams and standard comparisons are presented to help involved personnel navigate the regulations associated with shore power, ensure a smooth assessment, and promote the safe use of HVSC. Each of the following sections provides a detailed introduction and explanation of these parts.

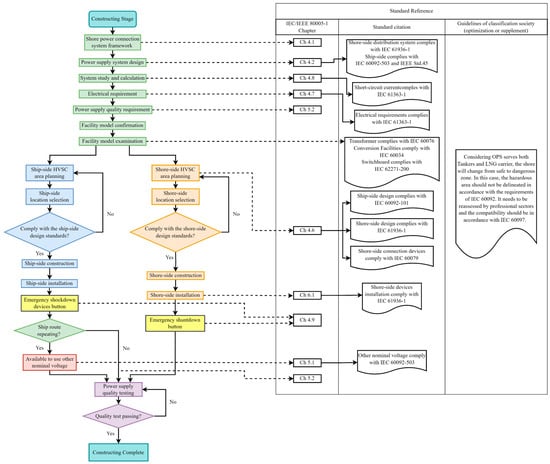

4.1. Pre-Installation Assessment

Shore power system design is a critical step to ensure safety in terms of future connections, operation, and power supply. It requires separate HVSC designs for shore and ship, including careful data calculations and compatibility assessments for a wide range of electrical, equipment, and system components. Figure 9 shows the flowchart illustrating the significant OPS system-building steps.

Figure 9.

Flowchart of on-shore power supply (OPS) construction standards and projects. Standard IEC/IEEE 80005-1:2019 [21].

We have also referenced the standard chapters and IEC standards in the dashed area on the right. This allows readers to review the content in detail. IEC/IEEE 80005-1 includes numerous IEC standards as additional electrical equipment specifications critical to power supply safety.

Sections 5.1–5.4 of the classification societies’ CCS regulations also contain content optimized and expanded by the classification societies. These regulations emphasize that shore power services apply to oil tankers and natural gas vessels. The areas where these vessels dock can transition from safe (noncombustible) to hazardous (explosive) environments. Therefore, these situations require a reassessment of safety.

Using this flowchart, all procedures, precautions, and chapters of the reference standards related to shore power construction can be effectively understood, resulting in more efficient design and evaluation processes.

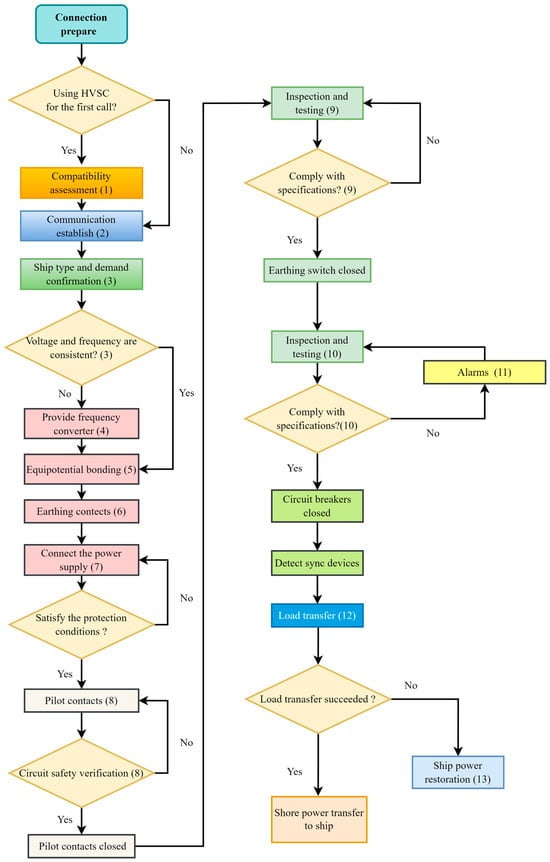

4.2. Setup of HVSC

Before beginning the power transfer from shore to ship, careful preliminary work is required to ensure efficient power flow and the safety of the personnel and equipment involved. Great care must be taken in each operation. Figure 10 of this study shows that several processes must be reviewed and controlled to ensure a successful power transfer.

Figure 10.

Flowchart of setup for power delivery in HVSC. Standard IEC/IEEE 80005-1:2019 [21].

These processes include an initial compatibility check of shore power for initial use when the vessel docks in port, confirmation of power supply voltage and frequency, equipotential bonding, circuit protection, earthing, and load transfer. The exchange and confirmation of information between the ship and the shore are crucial, as they ensure the safety and correct operation of the berthing process. Particular attention should be paid to the sequence of equipment connections and the appropriate safety procedures. Circuit breaker activation should occur from shore to ship, and power should not be applied until all other safety precautions have been taken.

Each procedure box in the diagram contains numbers that refer to chapters and references from the IEC/IEEE 80005-1 standard and other relevant international regulations. A detailed compilation of this information can be found in Table 5, which provides the reader with detailed information. For example, once shore power is prepared, the following load transfer process is critical and should follow the guidelines of IEC/IEEE 80005-1 Sections 8.6 and 9.2–9.3.

Table 5.

Setup for power delivery operation processes reference standard index table.

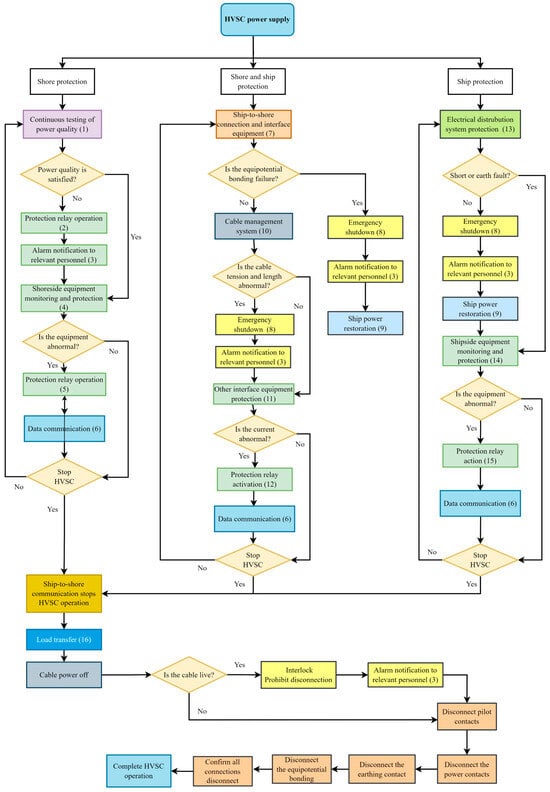

4.3. Safety Processes for Power Delivery and Operation

During the power-delivering process, the protection of equipment and personnel safety is of paramount importance. Thus, real-time monitoring is crucial to ensure a regular and safe power supply. Responsible personnel must pay attention to alarm notifications and messages to ensure power supply safety issues are resolved in a timely manner. Therefore, understanding the power supply process is extremely important. This article presents a process diagram based on the analysis of IEC/IEEE 80005-1 that reflects the textual description of the regulations, as shown in Figure 11, which outlines the HVSC procedure and operational safety flowchart, along with Table 6, which provides a comparison of referenced regulations.

Figure 11.

Flowchart of power-delivering and operation safety processes. Standard IEC/IEEE 80005-1:2019 [21].

Table 6.

Power-delivering and operation safety processes reference standard index table.

Figure 11 shows that the primary role of the shore-side is to maintain the regular operation of the shore power system, which includes testing the power quality and monitoring and protecting various devices. For example, the process of “monitoring and protecting shore-side equipment” is achieved by the electrical protection systems between the shore and ship, which monitor the status of the power supply and fault conditions. During this process, protective relays are used to trip the circuit breaker and alarms and notifications are issued to ensure the safety of personnel and equipment. For detailed regulatory information, refer to the specifications listed in Table 6.

The shore/ship interface focuses on monitoring the equipotential bonding connection, cable voltage, and length. These two conditions trigger the emergency shutdown procedure. On the ship side, the principle is to protect the distribution system. In the event of a short circuit or fault, an emergency shutdown of the power supply occurs, and the power supply on board is restored.

5. Conclusions

This methodology assesses the impact of OPS on air pollutant emissions from seagoing vessels during berthing. The increasing demand for environmentally friendly ports has driven the popularity of OPS as an effective solution. However, the development of onshore power has resulted in challenges related to different standards, regulations, construction costs, operational complexity, and safety concerns. The fact that classification societies present shore power regulations as guidelines has led to an inconsistent impact on the HVSC financing process, resulting in a lack of uniformity in standards and specifications.

The assessment compared the classification societies’ regulations with the international standard IEC/IEEE 80005-1 using dot and spider diagrams. The analysis highlighted the need for adjustments or additions to ensure compatibility between ships and shore power installations in different ports worldwide, focusing on general rules, earthing interlocks, personnel safety, and operational safety rules. The study provided valuable insights into the comparison, evaluation, and importance of regulations and safety measures for shore power facilities. It highlighted the importance of standardized and comprehensive guidelines for the safe and efficient use of shore power facilities in various port environments. In addition, a comprehensive comparison and analysis of shore power regulations led to three informative flowcharts. These flowcharts serve as valuable tools to help relevant personnel understand the content and manage the complexity of HVSC operations. These flowcharts can facilitate the implementation and use of shore power with increased efficiency and safety.

Port managers, shipowners, shipyards, and other stakeholders can efficiently and thoroughly examine pertinent regulations and standards at various stages, including the planning, installation, and operation of shore power systems, through the comparative charts and tables featured in this article. This facilitates detecting and correcting or enhancing any shortcomings, thereby increasing the inclination to implement shore power systems and diminishing barriers to their adoption. In summary, this study contributes to advancing cleaner port operations by providing practical tools and insights to ensure the successful global implementation of OPS systems. Our findings support the promotion of cleaner ports, lower emissions, and a more sustainable future through the widespread adoption of shore power technology.

Author Contributions

Conceptualization, S.-H.H. and F.-M.T.; data curation, S.-H.H.; formal analysis, S.-H.H., C.-W.H. and Y.-D.C.; methodology, S.-H.H.; software, C.-W.H. and Y.-D.C.; validation, S.-H.H. and F.-M.T.; writing—original draft preparation, S.-H.H. and Y.-D.C.; review and editing, S.-H.H. and F.-M.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partly supported by the National Science Council, Taiwan, R.O.C., under Grant No. MOST 111-2222-E-035-001.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, X.; Du, D.; Peng, Y. Assessing the Importance of the Marine Chokepoint: Evidence from Tracking the Global Marine Traffic. Sustainability 2024, 16, 384. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, Q.; Zhang, Z.; Li, Z.; Qin, C.; Chen, J.; Peng, C. A Study on Monitoring and Supervision of Ship Nitrogen-Oxide Emissions and Fuel-Sulfur-Content Compliance. Atmosphere 2023, 14, 175. [Google Scholar] [CrossRef]

- Paternina-Arboleda, C.D.; Agudelo-Castañeda, D.; Voß, S.; Das, S. Towards Cleaner Ports: Predictive Modeling of Sulfur Dioxide Shipping Emissions in Maritime Facilities Using Machine Learning. Sustainability 2023, 15, 12171. [Google Scholar] [CrossRef]

- Aakko-Saksa, P.T.; Lehtoranta, K.; Kuittinen, N.; Järvinen, A.; Jalkanen, J.-P.; Johnson, K.; Jung, H.; Ntziachristos, L.; Gagné, S.; Takahashi, C.; et al. Reduction in Greenhouse Gas and Other Emissions from Ship Engines: Current Trends and Future Options. Prog. Energy Combust. Sci. 2023, 94, 101055. [Google Scholar] [CrossRef]

- Yin, M.; Wang, Y.; Zhang, Q. Policy Implementation Barriers and Economic Analysis of Shore Power Promotion in China. Transp. Res. Part D Transp. Environ. 2020, 87, 102506. [Google Scholar] [CrossRef]

- Abu Bakar, N.N.; Bazmohammadi, N.; Vasquez, J.C.; Guerrero, J.M. Electrification of Onshore Power Systems in Maritime Transportation towards Decarbonization of Ports: A Review of the Cold Ironing Technology. Renew. Sustain. Energy Rev. 2023, 178, 113243. [Google Scholar] [CrossRef]

- Wang, W.; Wang, S.; Zhen, L. Optimal Subsidy Design for Energy Generation in Ship Berthing. Marit. Policy Manag. 2023, 1–14. [Google Scholar] [CrossRef]

- Zis, T.P.V. Prospects of Cold Ironing as an Emissions Reduction Option. Transp. Res. Part A Policy Pract. 2019, 119, 82–95. [Google Scholar] [CrossRef]

- Nguyen, D.-H.; Lin, C.; Cheruiyot, N.K.; Hsu, J.-Y.; Cho, M.-Y.; Hsu, S.-H.; Yeh, C.-K. Reduction of NOx and SO2 Emissions by Shore Power Adoption. Aerosol Air Qual. Res. 2021, 21, 210100. [Google Scholar] [CrossRef]

- Koričan, M.; Frković, L.; Vladimir, N. Electrification of Fishing Vessels and Their Integration into Isolated Energy Systems with a High Share of Renewables. J. Clean. Prod. 2023, 425, 138997. [Google Scholar] [CrossRef]

- Colarossi, D.; Principi, P. Optimal Sizing of a Photovoltaic/Energy Storage/Cold Ironing System: Life Cycle Cost Approach and Environmental Analysis. Energy Convers. Manag. 2023, 291, 117255. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Koričan, M. Electrification of Inland Waterway Ships Considering Power System Lifetime Emissions and Costs. Energies 2021, 14, 7046. [Google Scholar] [CrossRef]

- Frković, L.; Ćosić, B.; Pukšec, T.; Vladimir, N. The Synergy between the Photovoltaic Power Systems and Battery-Powered Electric Ferries in the Isolated Energy System of an Island. Energy 2022, 259, 124862. [Google Scholar] [CrossRef]

- Sciberras, E.A.; Zahawi, B.; Atkinson, D.J. Electrical Characteristics of Cold Ironing Energy Supply for Berthed Ships. Transp. Res. Part D Transp. Environ. 2015, 39, 31–43. [Google Scholar] [CrossRef]

- Tang, R.; Wu, Z.; Li, X. Optimal Operation of Photovoltaic/Battery/Diesel/Cold-Ironing Hybrid Energy System for Maritime Application. Energy 2018, 162, 697–714. [Google Scholar] [CrossRef]

- Bakar, N.N.A.; Bazmohammadi, N.; Çimen, H.; Uyanik, T.; Vasquez, J.C.; Guerrero, J.M. Data-Driven Ship Berthing Forecasting for Cold Ironing in Maritime Transportation. Appl. Energy 2022, 326, 119947. [Google Scholar] [CrossRef]

- Williamsson, J.; Costa, N.; Santén, V.; Rogerson, S. Barriers and Drivers to the Implementation of Onshore Power Supply—A Literature Review. Sustainability 2022, 14, 6072. [Google Scholar] [CrossRef]

- Radwan, M.E.; Chen, J.; Wan, Z.; Zheng, T.; Hua, C.; Huang, X. Critical Barriers to the Introduction of Shore Power Supply for Green Port Development: Case of Djibouti Container Terminals. Clean Technol. Environ. Policy 2019, 21, 1293–1306. [Google Scholar] [CrossRef]

- Peterson, K.L.; Islam, M.; Cayanan, C. State of Shore Power Standards for Ships. In Proceedings of the 2007 IEEE Petroleum and Chemical Industry Technical Conference, Calgary, AB, Canada, 17 September 2007; pp. 1–6. [Google Scholar]

- Brkić, D.; Praks, P. Proper Use of Technical Standards in Offshore Petroleum Industry. J. Mar. Sci. Eng. 2020, 8, 555. [Google Scholar] [CrossRef]

- IEC/IEEE 80005-1:2019; IEC/IEEE International Standard—Utility Connections in Port—Part 1: High Voltage Shore Connection (HVSC) Systems—General Requirements. ISO: Geneva, Switzerland, 2019.

- Høven, T. Standardization of Utility Connections in Ports: Cold Ironing of Ships in Ports. IEEE Electrif. Mag. 2023, 11, 18–24. [Google Scholar] [CrossRef]

- He, J.; Li, X.; Xu, H.; Zhu, J.; Dai, P.; Chu, H. Review and Discussion on Standards for Shore-to-Ship Power Supply System. In Proceedings of the 4th Annual International Conference on Material Engineering and Application (ICMEA 2017); Atlantis Press: Dordrecht, The Netherlands, 2018; pp. 22–26. [Google Scholar]

- Li, K.; Du, K. Research on Onshore Power Supply System in Port for Ships. IOP Conf. Ser. Earth Environ. Sci. 2020, 558, 052022. [Google Scholar] [CrossRef]

- Parise, G.; Parise, L.; Malerba, A.; Sabatini, S.; Chavdarian, P.; Su, C.-L. High Voltage Shore Connections (HVSC), an IEC/ISO/IEEE 80005-1 Compliant Solution: The Neutral Grounding System. In Proceedings of the 2016 IEEE Industry Applications Society Annual Meeting, Portland, OR, USA, 2 October 2016; pp. 1–6. [Google Scholar]

- ABS Guide for High Voltage Shore Connection 2011. Available online: https://ww2.eagle.org/content/dam/eagle/rules-and-guides/archives/conventional_ocean_service/182_highvoltage/hv_shore_connection_guide_e-nov11.pdf (accessed on 8 November 2023).

- Lloyd’s Register of British Shipping Rules and Regulations for the Classification of Ships, Part 7 Chapter 13 On-Shore Power Supplies 2022. Available online: https://www.lr.org/en/knowledge/lloyds-register-rules/rules-and-regulations-for-the-classification-of-ships/ (accessed on 8 November 2023).

- DNV Electrical Shore Connections/Cold Ironing. Available online: https://rules.dnv.com/servicedocuments/dnvpm/?_ga=2.163607677.377069448.1667113586-952268649.1667113586 (accessed on 8 May 2023).

- CR Guidelines for High Voltage Shore Connection Systems 2020. Available online: https://www.crclass.org/guidelines/ (accessed on 8 November 2023).

- IEC/IEEE 80005-2:2016; IEC/IEEE International Standard—Utility Connections in Port—Part 2: High and Low Voltage Shore Connection Systems—Data Communication for Monitoring and Control. ISO: Geneva, Switzerland, 2016.

- IEC/IEEE P80005-3:2014; IEC/IEEE Draft International Standard—Utility Connections in Port—Part 3: Low Voltage Shore Connection (LVSC) Systems—General Requirements. ISO: Geneva, Switzerland, 2014.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).