Computer Vision and Image Processing Approaches for Corrosion Detection

Abstract

:1. Introduction

2. Background

2.1. Corrosion

2.2. Computer Vision and Image Processing

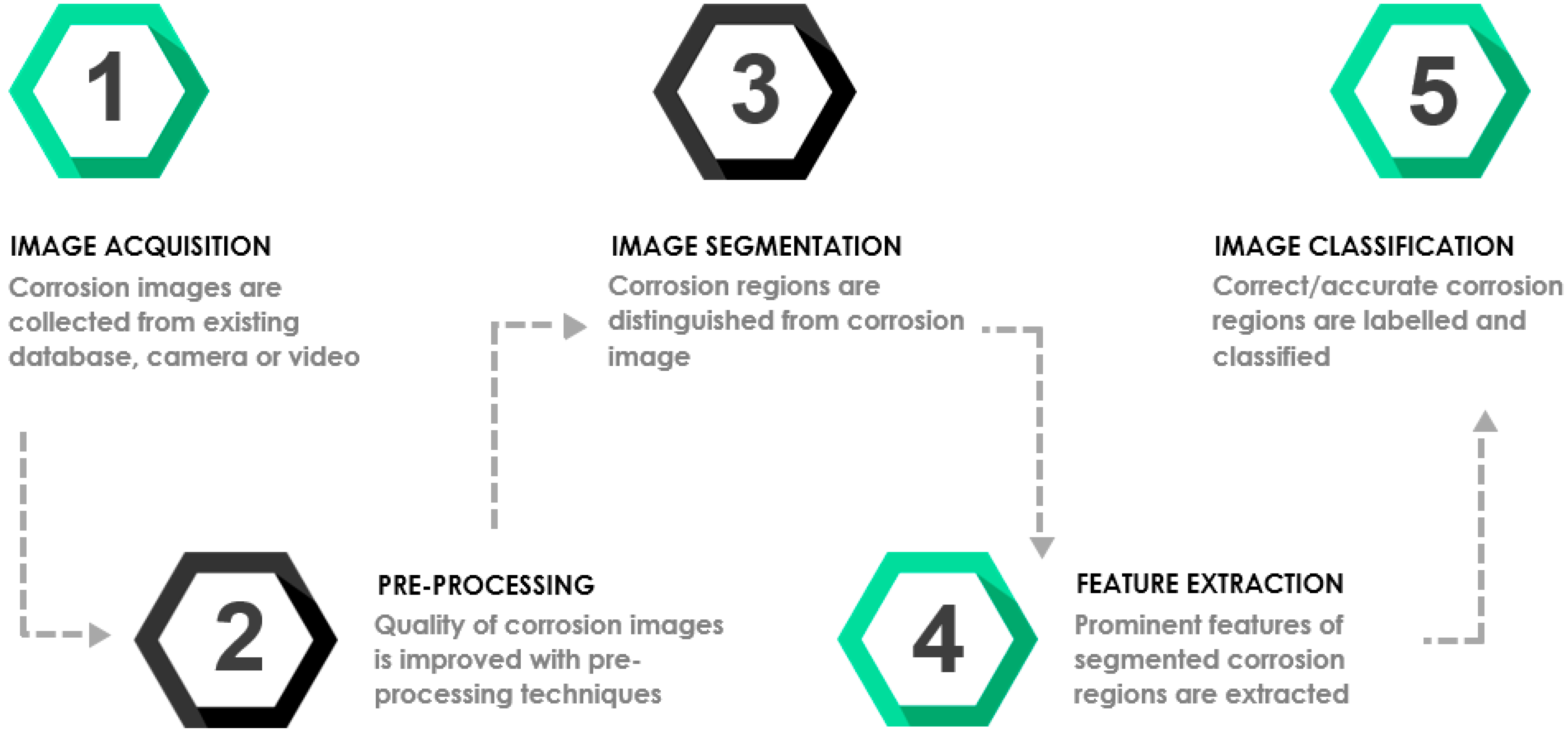

2.3. Corrosion Detection Process

2.3.1. Image Acquisition

2.3.2. Image Pre-Processing

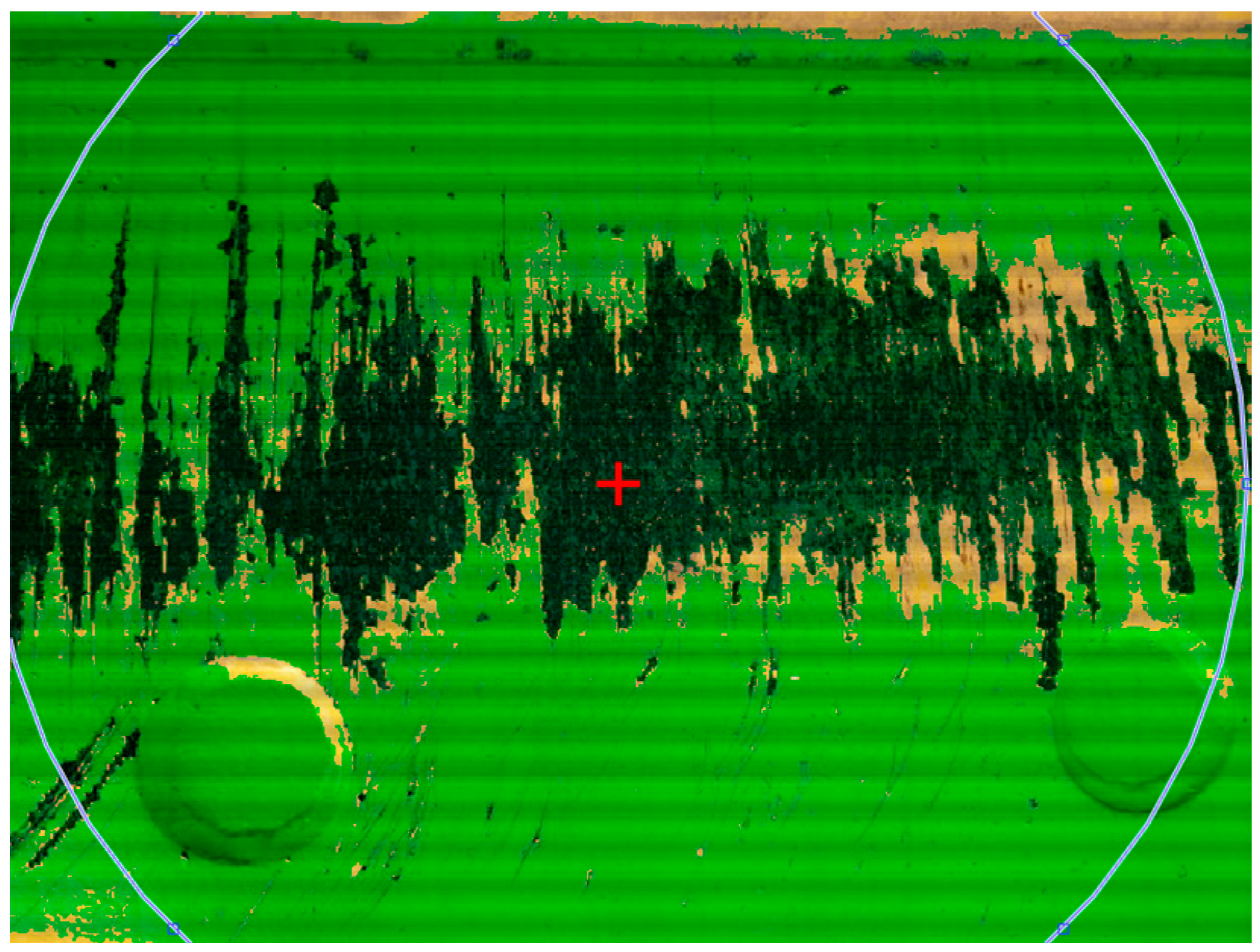

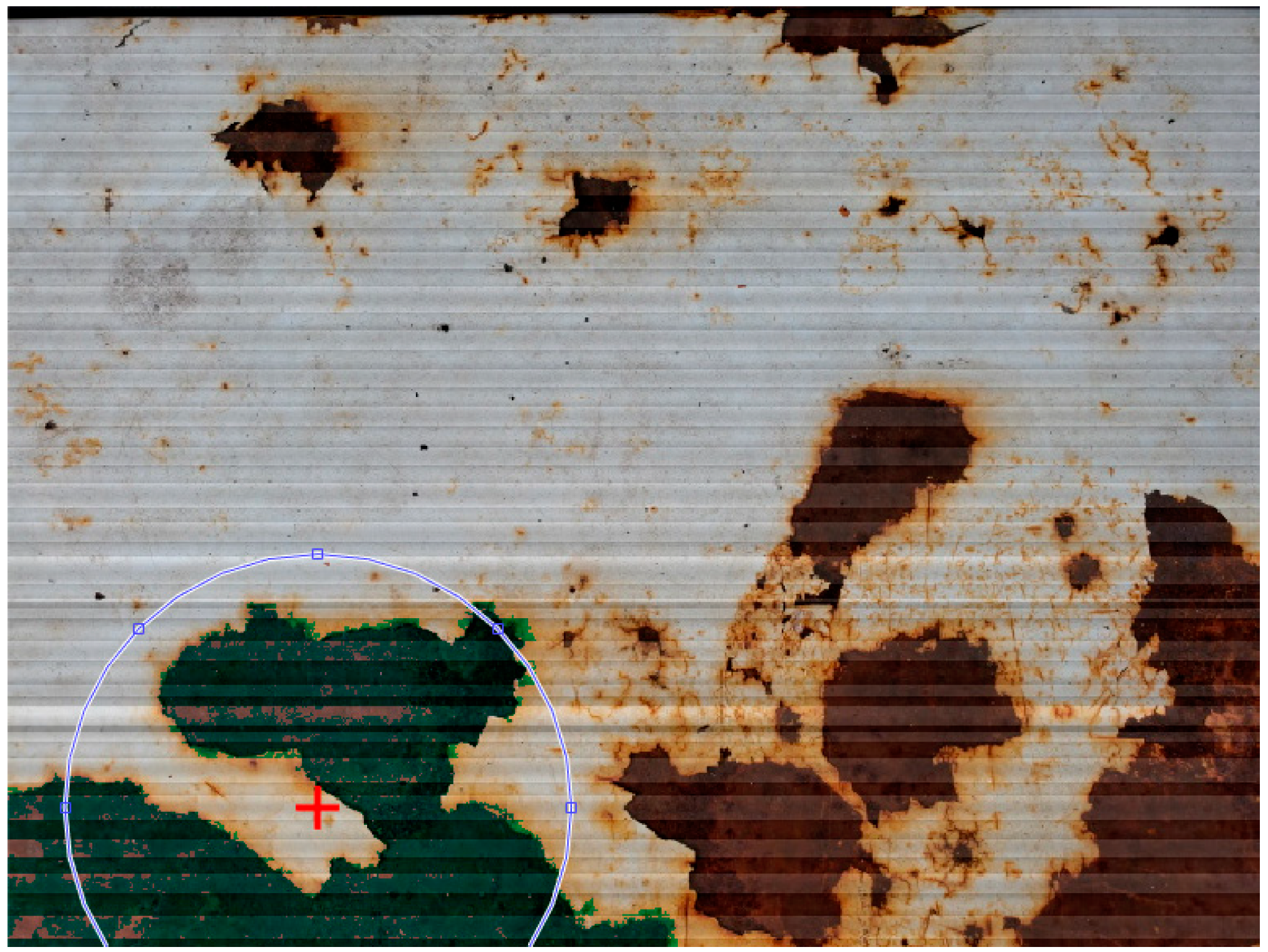

2.3.3. Image Segmentation

- Region-based: This segmentation technique locates connected pixels of similar colors and intensities in an image. Normally, similar pixel regions are classified using some predefined rules between adjacent pixels. The segmented regions are obtained from the neighboring pixels and they are connected to the seed pixels. This technique works better with high contrast images.

- Edge detection: This technique detects object boundaries by locating and identifying points of brightness discontinuities or sharp changes in an image. These points are also called the image edges. Widely used edge detection methods include Canny edge, Prewitt edge, Sobel edge, and Laplacian edge methods. The aim of edge detection methods is to reduce the probability of detecting wrong edges in an image by optimizing edge detection algorithms.

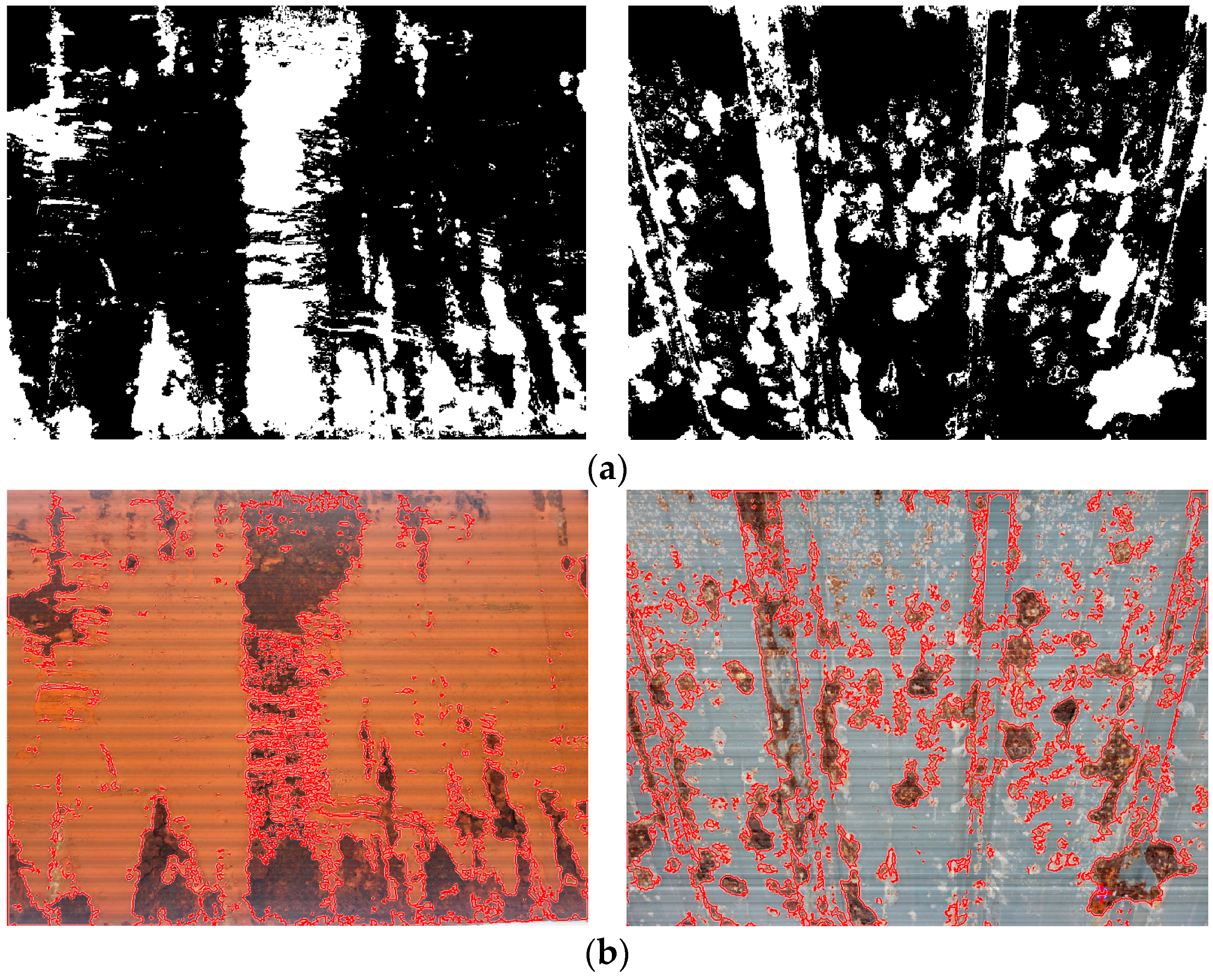

- Threshold-based: This segmentation method converts color or grayscale images into binary images based on a threshold value. The threshold value is obtained from the original image’s pixel intensity. The pixels in the original images are converted for easier image analyzation. This method separates the desired object from the background pixels.

- Clustering: This technique partitions an image into clusters or groups by identifying the relationship between adjacent pixels in an image. Then, groups of similar patterns are clustered to explore during data analysis. The most used clustering methods are the fuzzy c-means, k-means, improved k-means, and hierarchical methods.

- Pattern matching: Pattern matching, or template matching, is a technique that allows template localization in images. The patterns in images are matched to each other in terms of their special features by restricting the searching region. The corroded region can be segmented by matching a predefined template with the small parts of an image. Examples of pattern matching include Hamming distance and Harris corners.

- ANN segmentation: This method uses an encode–decoder structure for the segmentation of 3D images [12]. It works with the height, width, and channel number. The first two dimensions represent the image resolution. Moreover, the third dimension represents the red, green, and blue channels. This segmentation technique uses machine learning in its segmentation process.

2.3.4. Feature Extraction

2.3.5. Image Classification

3. Corrosion Prediction Model

3.1. Knowledge-Based Model

3.2. Probabilistic Model

3.3. Statistical Model

3.4. Deterministic Model

4. Corrosion Detection Approaches

4.1. Ground Penetrating Radar

4.2. Thermography

4.3. Computed Tomography

4.4. Color Space Detection

4.5. Wavelet Domain

4.6. Classification with SVM

4.7. Damage Analysis with NDE and SOM

4.8. Texture Analysis

5. Challenges in Corrosion Detection

6. Discussion and Future Recommendation

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Foorginezhad, S.; Mohseni-Dargah, M.; Firoozirad, K.; Aryai, V.; Razmjou, A.; Abbassi, R.; Garaniya, V.; Beheshti, A.; Asadnia, M. Recent advances in sensing and assessment of corrosion in sewage pipelines. Process Saf. Environ. Prot. 2021, 147, 192–213. [Google Scholar] [CrossRef]

- Sun, P.; Wang, Z.; Lu, Y.; Shen, S.; Yang, R.; Xue, A.; Parker, T.; Wang, J.; Wang, Q. Analysis of the corrosion failure of a semiconductor polycrystalline distillation column. Process Saf. Environ. Prot. 2020, 135, 244–256. [Google Scholar] [CrossRef]

- Yang, F.; Massey, I.Y. Exposure routes and health effects of heavy metals on children. Biometals 2019, 32, 563–573. [Google Scholar]

- Kuchhal, P.; Sharma, U.C. Battery waste management. Environ. Sci. Eng. 2019, 5, 141–155. [Google Scholar]

- Shi, L.; Song, Y.; Zhao, P.; Wang, H.; Dong, K.; Shan, D.; Han, E.H. Variations of galvanic currents and corrosion forms of 2024/Q235/304 tri-metallic couple with multivariable cathode/anode area ratios: Experiments and modeling. Electrochim. Acta 2020, 359, 136947. [Google Scholar] [CrossRef]

- Srivastava, P.; Abbassi, R.; Yadav, A.K.; Garaniya, V.; Asadnia, M. A review on the contribution of electron flow in electroactive wetlands: Electricity generation and enhanced wastewater treatment. Chemosphere 2020, 254, 126926. [Google Scholar] [CrossRef]

- Goyal, M.; Kumar, S.; Bahadur, I.; Verma, C.; Ebenso, E.E. Organic corrosion inhibitors for industrial cleaning of ferrous and non-ferrous metals in acidic solutions: A review. J. Mol. Liq. 2018, 256, 565–573. [Google Scholar] [CrossRef]

- Ng, D.Q.; Lin, J.K.; Lin, Y.P. Lead release in drinking water resulting from galvanic corrosion in three-metal systems consisting of lead, copper and stainless steel. J. Hazard. Mater. 2020, 398, 122936. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Deng, Y.; Chen, J.; Zou, D.; Su, W. Integrated process to recover NiMH battery anode alloy with selective leaching and multistage extraction. Ind. Eng. Chem. Res. 2017, 56, 7551–7558. [Google Scholar] [CrossRef]

- Han, X.; Yang, D.Y.; Frangopol, D.M. Probabilistic life-cycle management framework for ship structures subjected to coupled corrosion–fatigue deterioration processes. J. Struct. Eng. 2019, 145, 04019116. [Google Scholar] [CrossRef]

- Ahuja, S.K.; Shukla, M.K. A survey of computer vision based corrosion detection approaches. In Proceedings of the International Conference on Information and Communication Technology for Intelligent Systems 2017, Ahmedabad, India, 25 March 2017. [Google Scholar]

- Kaushik, R.; Kumar, S. Image segmentation using convolutional neural network. Int. J. Sci. Technol. Res. 2019, 8, 667–675. [Google Scholar]

- Jamaludin, S.; Zainal, N.; Zaki, W.M.D.W. A fast specular reflection removal based on pixels properties method. Bull. Electr. Eng. Inform. 2021, 9, 2358–2363. [Google Scholar] [CrossRef]

- Jamaludin, S.; Ayob, A.F.M.; Norzeli, S.M.; Mohamed, S.B. Adaptive initial contour and partly-normalization algorithm for iris segmentation of blurry iris images. J. Inf. Commun. Technol. 2022, 21, 411–435. [Google Scholar]

- Hassan, S.I.; Dang, L.M.; Mehmood, I.; Im, S.; Choi, C.; Kang, J.; Park, Y.S.; Moon, H. Underground sewer pipe condition assessment based on convolutional neural networks. Autom. Constr. 2019, 106, 102849. [Google Scholar] [CrossRef]

- Yin, X.; Chen, Y.; Bouferguene, A.; Zaman, H.; Al-Hussein, M.; Kurach, L. A deep learning-based framework for an automated defect detection system for sewer pipes. Autom. Constr. 2020, 109, 102967. [Google Scholar] [CrossRef]

- Dang, L.M.; Hassan, S.I.; Im, S.; Mehmood, I.; Moon, H. Utilizing text recognition for the defects extraction in sewers CCTV inspection videos. Comput. Ind. 2018, 99, 96–109. [Google Scholar] [CrossRef]

- Kumar, S.S.; Wang, M.; Abraham, D.M.; Jahanshahi, M.R.; Iseley, T.; Cheng, J.C. Deep learning–based automated detection of sewer defects in CCTV videos. J. Comput. Civ. Eng. 2020, 34, 04019047. [Google Scholar] [CrossRef]

- Xie, Q.; Li, D.; Xu, J.; Yu, Z.; Wang, J. Automatic detection and classification of sewer defects via hierarchical deep learning. IEEE Trans. Autom. Sci. Eng. 2019, 16, 1836–1847. [Google Scholar] [CrossRef]

- Cheng, J.C.; Wang, M. Automated detection of sewer pipe defects in closed-circuit television images using deep learning techniques. Autom. Constr. 2018, 95, 155–171. [Google Scholar] [CrossRef]

- Vince, P. Advances in condition assessment of water pipelines. Corrosion 2020, 76, 511–519. [Google Scholar] [CrossRef]

- Bastian, B.T.; Jaspreeth, N.; Ranjith, S.K.; Jiji, C.V. Visual inspection and characterization of external corrosion in pipelines using deep neural network. NDT E Int. 2019, 107, 102134. [Google Scholar] [CrossRef]

- Amaya-Gómez, R.; Riascos-Ochoa, J.; Muñoz, F.; Bastidas-Arteaga, E.; Schoefs, F.; Sánchez-Silva, M. Modeling of pipeline corrosion degradation mechanism with a Lévy process based on ILI (In-Line) inspections. Int. J. Press. Vessel. Pip. 2019, 172, 261–271. [Google Scholar] [CrossRef]

- Aryai, V.; Baji, H.; Mahmoodian, M.; Li, C.Q. Time-dependent finite element reliability assessment of cast-iron water pipes subjected to spatio-temporal correlated corrosion process. Reliab. Eng. Syst. Saf. 2020, 197, 106802. [Google Scholar] [CrossRef]

- Zhang, M.; Song, H.; Lim, S.; Akiyama, M.; Frangopol, D.M. Reliability estimation of corroded RC structures based on spatial variability using experimental evidence, probabilistic analysis and finite element method. Eng. Struct. 2019, 192, 30–52. [Google Scholar] [CrossRef]

- Zhang, M.; Akiyama, M.; Shintani, M.; Xin, J.; Frangopol, D.M. Probabilistic estimation of flexural loading capacity of existing RC structures based on observational corrosion-induced crack width distribution using machine learning. Struct. Saf. 2021, 91, 102098. [Google Scholar] [CrossRef]

- Hoang, N.D. Image processing-based pitting corrosion detection using metaheuristic optimized multilevel image thresholding and machine-learning approaches. Math. Probl. Eng. 2020, 2020, 6765274. [Google Scholar] [CrossRef]

- Wang, K.; Li, C.; Lu, J.; Nan, C.; Zhang, Q.; Zhang, H. Intelligent evaluation of marine corrosion of q420 steel based on image recognition method. Coatings 2022, 12, 881. [Google Scholar] [CrossRef]

- Milimonfared, R.; Oskouei, R.H.; Taylor, M.; Solomon, L.B. An intelligent system for image-based rating of corrosion severity at stem taper of retrieved hip replacement implants. Med. Eng. Phys. 2018, 61, 13–24. [Google Scholar] [CrossRef]

- Karimi, A.M.; Fada, J.S.; Parrilla, N.A.; Pierce, B.G.; Koyutürk, M.; French, R.H.; Braid, J.L. Generalized and mechanistic PV module performance prediction from computer vision and machine learning on electroluminescence images. IEEE J. Photovolt. 2020, 10, 878–887. [Google Scholar] [CrossRef]

- Perumal, P.; Ramanathan, K.; Ganesan, L.; Subramanian, B.; Ganesh, V.; Stalin, B. Investigation of TiN coating uniformity and its corrosion behaviour using image process. Mater. Res. Express 2019, 6, 046411. [Google Scholar] [CrossRef]

- Dong, B.; Ding, W.; Qin, S.; Fang, G.; Liu, Y.; Dong, P.; Han, S.; Xing, F.; Hong, S. 3D visualized tracing of rebar corrosion-inhibiting features in concrete with a novel chemical self-healing system. Constr. Build. Mater. 2018, 168, 11–20. [Google Scholar] [CrossRef]

- Abbas, M.H.; Norman, R.; Charles, A. Neural network modelling of high pressure CO2 corrosion in pipeline steels. Process Saf. Environ. Prot. 2018, 119, 36–45. [Google Scholar] [CrossRef]

- Bado, M.F.; Tonelli, D.; Poli, F.; Zonta, D.; Casas, J.R. Digital twin for civil engineering systems: An exploratory review for distributed sensing updating. Sensors 2022, 22, 3168. [Google Scholar] [CrossRef] [PubMed]

- Florindo, J.B.; Metze, K. A cellular automata approach to local patterns for texture recognition. Expert Syst. Appl. 2021, 179, 115027. [Google Scholar] [CrossRef]

- Venketeswaran, A.; Lalam, N.; Wuenschell, J.; Ohodnicki, P.R., Jr.; Badar, M.; Chen, K.P.; Lu, P.; Duan, Y.; Chorpening, B.; Buric, M. Recent advances in machine learning for fiber optic sensor applications. Adv. Intell. Syst. 2022, 4, 2100067. [Google Scholar] [CrossRef]

- Nash, W.; Drummond, T.; Birbilis, N. A review of deep learning in the study of materials degradation. npj Mater. Degrad. 2018, 2, 37. [Google Scholar] [CrossRef]

- Abbas, M.; Shafiee, M. An overview of maintenance management strategies for corroded steel structures in extreme marine environments. Mar. Struct. 2020, 71, 102718. [Google Scholar] [CrossRef]

- Zaki, A.; Megat Johari, M.A.; Wan Hussin, W.M.A.; Jusman, Y. Experimental assessment of rebar corrosion in concrete slab using ground penetrating radar (GPR). Int. J. Corros. 2018, 2018, 5389829. [Google Scholar] [CrossRef]

- Al-Hameedawi, M.M.; Thabit, J.M.; Al-Menshed, F.H.; Conyers, L. Integrating electrical resistivity tomography and ground-penetrating radar methods to map archaeological walls near northern Ishtar gate, ancient Babylon city, Iraq. Archaeol. Prospect. 2022, 29, 293–304. [Google Scholar] [CrossRef]

- Sun, H.; Pashoutani, S.; Zhu, J. Nondestructive evaluation of concrete bridge decks with automated acoustic scanning system and ground penetrating radar. Sensors 2018, 18, 1955. [Google Scholar] [CrossRef]

- Doshvarpassand, S.; Wu, C.; Wang, X. An overview of corrosion defect characterization using active infrared thermography. Infrared Phys. Technol. 2019, 96, 366–389. [Google Scholar] [CrossRef]

- Zhang, X.; Saniie, J.; Heifetz, A. Detection of defects in additively manufactured stainless steel 316L with compact infrared camera and machine learning algorithms. JOM 2020, 72, 4244–4253. [Google Scholar] [CrossRef]

- Omar, T.; Nehdi, M.L.; Zayed, T. Infrared thermography model for automated detection of delamination in RC bridge decks. Constr. Build. Mater. 2018, 168, 313–327. [Google Scholar] [CrossRef]

- Zhao, Y.; Addepalli, S.; Sirikham, A.; Roy, R. A confidence map based damage assessment approach using pulsed thermographic inspection. NDT E Int. 2018, 93, 86–97. [Google Scholar] [CrossRef]

- Park, J.; Han, H.S.; Park, J.; Seo, H.; Edwards, J.; Kim, Y.C.; Ok, M.R.; Seok, H.K.; Jeon, H. Corrosion behavior of biodegradable Mg-based alloys via femtosecond laser surface melting. Appl. Surf. Sci. 2018, 448, 424–434. [Google Scholar] [CrossRef]

- Wang, L.; Dai, L.; Bian, H.; Ma, Y.; Zhang, J. Concrete cracking prediction under combined prestress and strand corrosion. Struct. Infrastruct. Eng. 2019, 15, 285–295. [Google Scholar] [CrossRef]

- Nair, R.B.; Arora, H.S.; Grewal, H.S. Microwave synthesized complex concentrated alloy coatings: Plausible solution to cavitation induced erosion-corrosion. Ultrason. Sonochemistry 2019, 50, 114–125. [Google Scholar] [CrossRef] [PubMed]

- Karimi, A.M.; Fada, J.S.; Hossain, M.A.; Yang, S.; Peshek, T.J.; Braid, J.L.; French, R.H. Automated pipeline for photovoltaic module electroluminescence image processing and degradation feature classification. IEEE J. Photovolt. 2019, 9, 1324–1335. [Google Scholar] [CrossRef]

- Lee, H.S.; Singh, J.K.; Ismail, M.A.; Bhattacharya, C.; Seikh, A.H.; Alharthi, N.; Hussain, R.R. Corrosion mechanism and kinetics of Al-Zn coating deposited by arc thermal spraying process in saline solution at prolong exposure periods. Sci. Rep. 2019, 9, 3399. [Google Scholar] [CrossRef]

- Xi, X.; Yang, S. Investigating the spatial development of corrosion of corner-located steel bar in concrete by X-ray computed tomography. Constr. Build. Mater. 2019, 221, 177–189. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, L.; Behnamian, Y.; Song, S.; Wang, R.; Gao, Z.; Hu, W.; Xia, D.H. Metal pitting corrosion characterized by scanning acoustic microscopy and binary image processing. Corros. Sci. 2020, 170, 108685. [Google Scholar] [CrossRef]

- Ni, X.; Fritz, N.K.; Wardle, B.L. In situ testing using synchrotron radiation computed tomography in materials research. MRS Adv. 2019, 4, 2831–2841. [Google Scholar] [CrossRef]

- Kichanov, S.; Saprykina, I.; Kozlenko, D.; Nazarov, K.; Lukin, E.; Rutkauskas, A.; Savenko, B. Studies of ancient Russian cultural objects using the neutron tomography method. J. Imaging 2018, 4, 25. [Google Scholar] [CrossRef]

- Ulum, M.F.; Caesarendra, W.; Alavi, R.; Hermawan, H. In-vivo corrosion characterization and assessment of absorbable metal implants. Coatings 2019, 9, 282. [Google Scholar] [CrossRef]

- Saadi, S.B.; Ranjbarzadeh, R.; Amirabadi, A.; Ghoushchi, S.J.; Kazemi, O.; Azadikhah, S.; Bendechache, M. Osteolysis: A literature review of basic science and potential computer-based image processing detection methods. Comput. Intell. Neurosci. 2021, 2021, 4196241. [Google Scholar] [CrossRef] [PubMed]

- David, D.S. Parasagittal meningioma brain tumor classification system based on MRI images and multi phase level set formulation. Biomed. Pharmacol. J. 2019, 12, 939–946. [Google Scholar] [CrossRef]

- Jamaludin, S.; Zainal, N.; Zaki, W.M.D.W. GPU implementation of sub-iris technique in iris recognition system. Pertanika J. Sci. Technol. 2017, 25, 263–274. [Google Scholar]

- Khayatazad, M.; De Pue, L.; De Waele, W. Detection of corrosion on steel structures using automated image processing. Dev. Built Environ. 2020, 3, 100022. [Google Scholar] [CrossRef]

- Xiong, J.; Yu, D.; Wang, Q.; Shu, L.; Cen, J.; Liang, Q.; Chen, H.; Sun, B. Application of histogram equalization for image enhancement in corrosion areas. Shock Vib. 2021, 2021, 8883571. [Google Scholar] [CrossRef]

- Forkan, A.R.M.; Kang, Y.B.; Jayaraman, P.P.; Liao, K.; Kaul, R.; Morgan, G.; Ranjan, R.; Sinha, S. CorrDetector: A framework for structural corrosion detection from drone images using ensemble deep learning. Expert Syst. Appl. 2022, 193, 116461. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, X.; Zhang, Y.; Zhao, L. A method of identifying rust status of dampers based on image processing. IEEE Trans. Instrum. Meas. 2020, 69, 5407–5417. [Google Scholar] [CrossRef]

- Wu, G.L.; Zhong, Y.; Ren, X.; Hao, J.; Wang, Q.; Wang, X.P. Atmospheric corrosion state evaluation based on surface corrosion morphology for electrical metal frame equipment in chongqing power grid. Key Eng. Mater. 2019, 815, 89–95. [Google Scholar] [CrossRef]

- Upadhyay, N.; Ravi Shankar, A.; Singh, S.S.; Anandkumar, B. Electrochemical noise studies on the effect of nitrogen on the pitting corrosion of stainless steel using wavelet analysis. Corros. Eng. Sci. Technol. 2022, 2022, 531–541. [Google Scholar] [CrossRef]

- May, Z.; Alam, M.K.; Nayan, N.A.; Rahman, N.A.I.A.; Mahmud, M.S. Acoustic emission corrosion feature extraction and severity prediction using hybrid wavelet packet transform and linear support vector classifier. PLoS ONE 2021, 16, e0261040. [Google Scholar] [CrossRef] [PubMed]

- Jeon, J.Y.; Kim, D.; Park, G.; Flynn, E.; Kang, T.; Han, S. 2D-wavelet wavenumber filtering for structural damage detection using full steady-state wavefield laser scanning. NDT E Int. 2020, 116, 102343. [Google Scholar] [CrossRef]

- Ramkumar, G. Hybrid model for detection of corrosion in water pipeline images using CNN and comparing accuracy with SVM. ECS Trans. 2022, 107, 13861. [Google Scholar]

- Hong, X.; Huang, L.; Gong, S.; Xiao, G. Shedding damage detection of metal underwater pipeline external anticorrosive coating by ultrasonic imaging based on HOG + SVM. J. Mar. Sci. Eng. 2021, 9, 364. [Google Scholar] [CrossRef]

- Lv, Y.J.; Wang, J.W.; Wang, J.; Xiong, C.; Zou, L.; Li, L.; Li, D.W. Steel corrosion prediction based on support vector machines. Chaos Solitons Fractals 2020, 136, 109807. [Google Scholar] [CrossRef]

- Li, X.; Guo, Y.; Li, Y. Particle swarm optimization-based SVM for classification of cable surface defects of the cable-stayed bridges. IEEE Access 2019, 8, 44485–44492. [Google Scholar] [CrossRef]

- Yang, J.; Li, R.; Chen, L.; Hu, Y.; Dou, Z. Research on equipment corrosion diagnosis method and prediction model driven by data. Process Saf. Environ. Prot. 2022, 158, 418–431. [Google Scholar] [CrossRef]

- Le, M.; Luong, V.S.; Nguyen, D.K.; Le, D.K.; Lee, J. Auto-detection of hidden corrosion in an aircraft structure by electromagnetic testing: A machine-learning approach. Appl. Sci. 2022, 12, 5175. [Google Scholar] [CrossRef]

- Deng, L.; Guo, Y.; Chai, B. Defect detection on a wind turbine blade based on digital image processing. Processes 2021, 9, 1452. [Google Scholar] [CrossRef]

- Xu, P.; Huang, L.; Song, Y. An optimal method based on HOG-SVM for fault detection. Multimed. Tools Appl. 2022, 81, 6995–7010. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Z.; Yang, C.; Xu, Y.; Zhou, J. Application of image stitching method in corrosion morphology analysis. J. Electron. Imaging 2019, 28, 013045. [Google Scholar] [CrossRef]

- Kim, H.; Ahn, E.; Shin, M.; Sim, S.H. Crack and noncrack classification from concrete surface images using machine learning. Struct. Health Monit. 2019, 18, 725–738. [Google Scholar] [CrossRef]

- Li, J.; Liu, H.; Shi, L.; Lan, J. Imaging feature analysis-based intelligent laser cleaning using metal color difference and dynamic weight dispatch corrosion texture. Photonics 2020, 7, 130. [Google Scholar] [CrossRef]

- Li, M.; Duan, Y.; He, X.; Yang, M. Image positioning and identification method and system for coal and gangue sorting robot. Int. J. Coal Prep. Util. 2022, 42, 1759–1777. [Google Scholar] [CrossRef]

- Tada, Y.; Miura, T.; Nakamura, H. Detection method of corrosion area of rebar and corrosion induced internal crack by using electromagnetic wave radar. In Proceedings of the Bridge Maintenance, Safety, Management, Life-Cycle Sustainability and Innovations 2021, Sapporo, Japan, 28 June 2020. [Google Scholar]

- Li, D.; Tan, M.; Zhang, S.; Ou, J. Stress corrosion damage evolution analysis and mechanism identification for prestressed steel strands using acoustic emission technique. Struct. Control Health Monit. 2018, 25, e2189. [Google Scholar] [CrossRef]

- Key, J.W.; Kacher, J. Establishing first order correlations between pitting corrosion initiation and local microstructure in AA5083 using automated image analysis. Mater. Charact. 2021, 178, 111237. [Google Scholar] [CrossRef]

- Atha, D.J.; Jahanshahi, M.R. Evaluation of deep learning approaches based on convolutional neural networks for corrosion detection. Struct. Health Monit. 2018, 17, 1110–1128. [Google Scholar] [CrossRef]

- Prithivirajan, S.; Narendranath, S.; Desai, V. Analysing the combined effect of crystallographic orientation and grain refinement on mechanical properties and corrosion behaviour of ECAPed ZE41 Mg alloy. J. Magnes. Alloy. 2020, 8, 1128–1143. [Google Scholar] [CrossRef]

- Bondada, V.; Pratihar, D.K.; Kumar, C.S. Detection and quantitative assessment of corrosion on pipelines through image analysis. Procedia Comput. Sci. 2018, 133, 804–811. [Google Scholar] [CrossRef]

- Jan, M.M.; Zainal, N.; Jamaludin, S. Region of interest-based image retrieval techniques: A review. IAES Int. J. Artif. Intell. 2020, 9, 520–528. [Google Scholar]

- Imran, M.M.H.; Jamaludin, S.; Ayob, A.F.M.; Ali, A.A.I.M.; Ahmad, S.Z.A.S.; Akhbar, M.F.A.; Suhrab, M.I.R.; Zainal, N.; Norzeli, S.M.; Mohamed, S.B. Application of artificial intelligence in marine corrosion prediction and detection. J. Mar. Sci. Eng. 2023, 11, 256. [Google Scholar] [CrossRef]

- Jamaludin, S.; Zainal, N.; Zaki, W.M.D.W. Comparison of iris recognition between active contour and hough transform. J. Telecommun. Electron. Comput. Eng. 2016, 8, 53–58. [Google Scholar]

- Jamaludin, S.; Zainal, N.; Zaki, W.M.D.W. Deblurring of noisy iris images in iris recognition. Bull. Electr. Eng. Inform. 2021, 10, 156–159. [Google Scholar] [CrossRef]

- Rossouw, E.; Doorsamy, W. Predictive maintenance framework for cathodic protection systems using data analytics. Energies 2021, 14, 5805. [Google Scholar] [CrossRef]

- Vu, V.T.; Dong, D.T. Hull girder ultimate strength assessment considering local corrosion. J. Mar. Sci. Appl. 2020, 19, 693–704. [Google Scholar] [CrossRef]

- Canca, A.; Kökkülünk, G. Is existing maintenance system adequate for sulphur 2020 amendments? J. ETA Marit. Sci. 2020, 8, 302–308. [Google Scholar] [CrossRef]

- Bouzaffour, K.; Lescop, B.; Talbot, P.; Gallée, F.; Rioual, S. Development of an embedded UHF-RFID corrosion sensor for monitoring corrosion of steel in concrete. IEEE Sens. J. 2021, 21, 12306–12312. [Google Scholar] [CrossRef]

- Yarveisy, R.; Khan, F.; Abbassi, R. Data-driven predictive corrosion failure model for maintenance planning of process systems. Comput. Chem. Eng. 2022, 157, 107612. [Google Scholar] [CrossRef]

- Kim, D.K.; Wong, E.W.C.; Cho, N.K. An advanced technique to predict time-dependent corrosion damage of onshore, offshore, nearshore and ship structures: Part I = generalisation. Int. J. Nav. Archit. Ocean Eng. 2020, 12, 657–666. [Google Scholar] [CrossRef]

- Cheliotis, M.; Lazakis, I.; Theotokatos, G. Machine learning and data-driven fault detection for ship systems operations. Ocean Eng. 2020, 216, 107968. [Google Scholar] [CrossRef]

- Makridis, G.; Kyriazis, D.; Plitsos, S. Predictive maintenance leveraging machine learning for time-series forecasting in the maritime industry. In Proceedings of the 2020 IEEE 23rd International Conference on Intelligent Transportation Systems, Rhodes, Greece, 20–23 September 2020. [Google Scholar]

- Kim, K.; Lee, G.; Park, K.; Park, S.; Lee, W.B. Adaptive approach for estimation of pipeline corrosion defects via Bayesian inference. Reliab. Eng. Syst. Saf. 2021, 216, 107998. [Google Scholar] [CrossRef]

- Anyfantis, K.N. An abstract approach toward the structural digital twin of ship hulls: A numerical study applied to a box girder geometry. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2021, 235, 718–736. [Google Scholar] [CrossRef]

- Jimenez, V.J.; Bouhmala, N.; Gausdal, A.H. Developing a predictive maintenance model for vessel machinery. J. Ocean Eng. Sci. 2020, 5, 358–386. [Google Scholar] [CrossRef]

- Imran, M.M.H.; Ayob, A.F.M.; Jamaludin, S. Applications of artificial intelligence in ship berthing: A review. Indian J. Geo Mar. Sci. 2021, 50, 855–863. [Google Scholar]

- Ayob, A.F.M.; Jalal, N.I.; Hassri, M.H.; Rahman, S.A.; Jamaludin, S. Neuroevolutionary autonomous surface vehicle simulation in restricted waters. TransNav Int. J. Mar. Navig. Saf. Sea Transp. 2020, 14, 865–873. [Google Scholar] [CrossRef]

- Ali, F.I.; Awwad, F.; Greish, Y.E.; Abu-Hani, A.F.; Mahmoud, S.T. Fabrication of low temperature and fast response H2S gas sensor based on organic-metal oxide hybrid nanocomposite membrane. Org. Electron. 2020, 76, 105486. [Google Scholar] [CrossRef]

- Hittini, W.; Greish, Y.E.; Qamhieh, N.N.; Alnaqbi, M.A.; Zeze, D.; Mahmoud, S.T. Ultrasensitive and low temperature gas sensor based on electrospun organic-inorganic nanofibers. Org. Electron. 2020, 81, 105659. [Google Scholar] [CrossRef]

- Panasiuk, O.; Hedström, A.; Langeveld, J.; de Haan, C.; Liefting, E.; Schilperoort, R.; Viklander, M. Using distributed temperature sensing (DTS) for locating and characterising infiltration and inflow into foul sewers before, during and after snowmelt period. Water 2019, 11, 1529. [Google Scholar] [CrossRef]

- Kessili, A.; Vollertsen, J.; Nielsen, A.H. Automated monitoring system for events detection in sewer network by distribution temperature sensing data measurement. Water Sci. Technol. 2018, 78, 1499–1508. [Google Scholar] [CrossRef] [PubMed]

- Duong, H.D.; Shin, Y.; Rhee, J.I. Development of fluorescent pH sensors based on a sol-gel matrix for acidic and neutral pH ranges in a microtiter plate. Microchem. J. 2019, 147, 286–295. [Google Scholar] [CrossRef]

- Grengg, C.; Müller, B.; Staudinger, C.; Mittermayr, F.; Breininger, J.; Ungerböck, B.; Borisov, S.M.; Mayr, T.; Dietzel, M. High-resolution optical pH imaging of concrete exposed to chemically corrosive environments. Cem. Concr. Res. 2019, 116, 231–237. [Google Scholar] [CrossRef]

- Hasan, T.; Jamaludin, S.; Wan Nik, W.B. Analysis of intelligent solar ICU water ambulance to optimize energy. Ann. Med. Surg. 2022, 2022, 104141. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Wu, K.; Kan, L.; Wu, M. Current understanding on microbiologically induced corrosion of concrete in sewer structures: A review of the evaluation methods and mitigation measures. Constr. Build. Mater. 2020, 247, 118539. [Google Scholar] [CrossRef]

- Jamaludin, S.; Ayob, A.F.M.; Akhbar, M.F.A.; Ali, A.A.I.M.; Imran, M.M.H.; Norzeli, S.M.; Mohamed, S.B. Efficient, accurate and fast pupil segmentation for pupillary boundary in iris recognition. Adv. Eng. Softw. 2023, 175, 103352. [Google Scholar] [CrossRef]

| Prediction Model | Description | Application/Method |

|---|---|---|

| Knowledge-Based |

| |

| Probabilistic |

| |

| Statistical |

|

|

| Deterministic |

|

| Detection Approach | Description | Limitation |

|---|---|---|

| Rossouw and Doorsamy [89] |

|

|

| Vu and Dong [90] |

|

|

| Canca and Kokkulunk [91] |

|

|

| Bouzaffour et al. [92] |

|

|

| Yarveisy et al. [93] |

|

|

| Kim et al. [94] |

|

|

| Cheliotis et al. [95] |

|

|

| Makridis et al. [96] |

|

|

| Kim et al. [97] |

|

|

| Anyfantis [98] |

|

|

| Jimenez et al. [99] |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, A.A.I.M.; Jamaludin, S.; Imran, M.M.H.; Ayob, A.F.M.; Ahmad, S.Z.A.S.; Akhbar, M.F.A.; Suhrab, M.I.R.; Ramli, M.R. Computer Vision and Image Processing Approaches for Corrosion Detection. J. Mar. Sci. Eng. 2023, 11, 1954. https://doi.org/10.3390/jmse11101954

Ali AAIM, Jamaludin S, Imran MMH, Ayob AFM, Ahmad SZAS, Akhbar MFA, Suhrab MIR, Ramli MR. Computer Vision and Image Processing Approaches for Corrosion Detection. Journal of Marine Science and Engineering. 2023; 11(10):1954. https://doi.org/10.3390/jmse11101954

Chicago/Turabian StyleAli, Ahmad Ali Imran Mohd, Shahrizan Jamaludin, Md Mahadi Hasan Imran, Ahmad Faisal Mohamad Ayob, Sayyid Zainal Abidin Syed Ahmad, Mohd Faizal Ali Akhbar, Mohammed Ismail Russtam Suhrab, and Mohamad Riduan Ramli. 2023. "Computer Vision and Image Processing Approaches for Corrosion Detection" Journal of Marine Science and Engineering 11, no. 10: 1954. https://doi.org/10.3390/jmse11101954

APA StyleAli, A. A. I. M., Jamaludin, S., Imran, M. M. H., Ayob, A. F. M., Ahmad, S. Z. A. S., Akhbar, M. F. A., Suhrab, M. I. R., & Ramli, M. R. (2023). Computer Vision and Image Processing Approaches for Corrosion Detection. Journal of Marine Science and Engineering, 11(10), 1954. https://doi.org/10.3390/jmse11101954