3.1. Simulation Scheme

Previous studies have shown that the lithological properties of hydrate reservoirs had a large influence on the cumulative volume of methane produced from a well. The order of the significance of geologic conditions on V

P has been reported to be k > Φ > S

H > initial temperature > initial pressure > thickness of the hydrate-bearing layer [

4]. Therefore, this study focused on the three factors (k, Φ and S

H) that had the greatest influence on reservoir productivity.

The initial values of the three lithological parameters were stratified and assigned according to the analyses of the well-logging date. Porosity was based on the logging density (

) curve and calculated according to the equation:

, where

is grain density (2.65 g/cm

3) and

is water density (1.03 g/cm

3). The S

H was based on the logging resistivity curve and was calculated according to the Archie equation. Permeability was calculated based on the Kozeny-Carman model. In the calculation, the CHR model used 4 m as the depth of a layer, while the SHR model used 3 m. The average value of each layer was taken to form the basic scheme. On this basis, according to the logging curve and actual geological characteristics (high Φ, low k, high S

H) of the CHR model and actual geological characteristics (high k, high S

H) of the SHR model, two schemes with the minimum and maximum values of each factor in each layer of the two models were determined respectively. The two schemes were obtained by an equal-scale interpolation. A total of 15 modeling schemes were designed for each model.

Table 4 and

Table 5 list the values of each factor under different schemes.

According to logging curve, the Φ of the W11 and AT1 sites varied slightly in the vertical direction. The Φ of the base scheme (A0) was 0.50 based on the logging curve in the CHR model, and considering the high Φ of the hydrate reservoir at W11, the Φ of the minimum scheme (A2) was 0.35 and the Φ of the maximum scheme (A4) was 0.65. Through equal-scale interpolation, the Φ of the A1 and A2 schemes was determined to be 0.42 and 0.58, respectively. The Φ of the base scheme(B0) was 0.40 based on the logging curve in the SHR model. Because the size range of hydrate reservoir rocks at AT1 was large and small particles would fill in the pores of large particles, the Φ could not be large. The Φ of the minimum scheme (B2) was 0.30 and the Φ of the maximum scheme (B4) was 0.55. Through equal-scale interpolation, the Φ of the B1 and B3 schemes was 0.35 and 0.50, respectively.

The simulation lasted for 1 year, and the T+H code was used to calculate the VP under each scheme at any time. The sensitivity coefficient of each lithological parameter was obtained by calculating the average value through the formula . In the formula, is the cumulative gas production, and is the value of each lithological parameter. The larger the value of , the more sensitive the was to the lithological parameter. Finally, combined with the simulation process, the evolution of seepage parameters in the depressurizing production of the hydrate reservoirs under different lithology was compared and analyzed.

3.2. Effect of Hydrate Reservoir Φ on Productivity

The Φ is the ratio of the pore volume in the rock to the rock’s volume, including its pores.

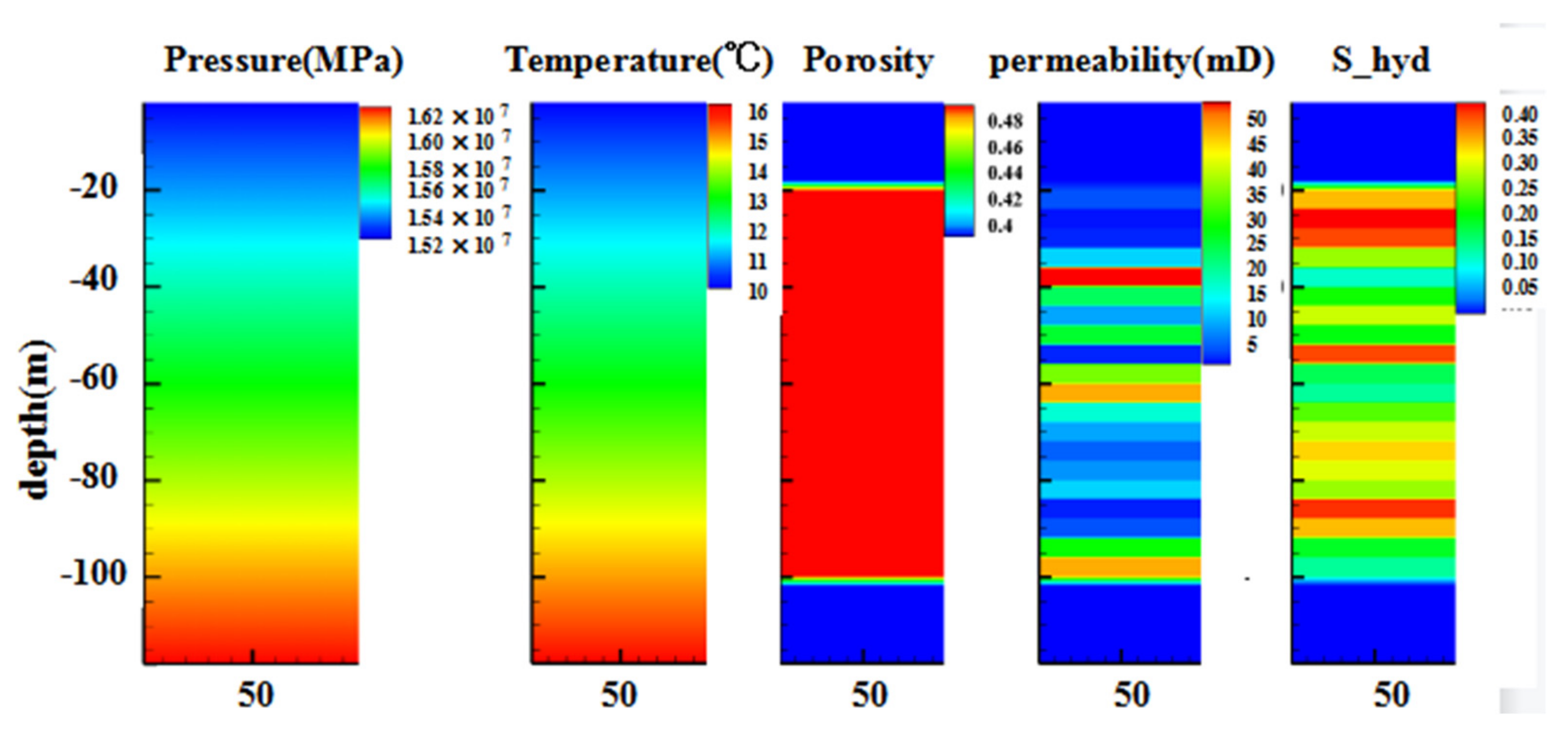

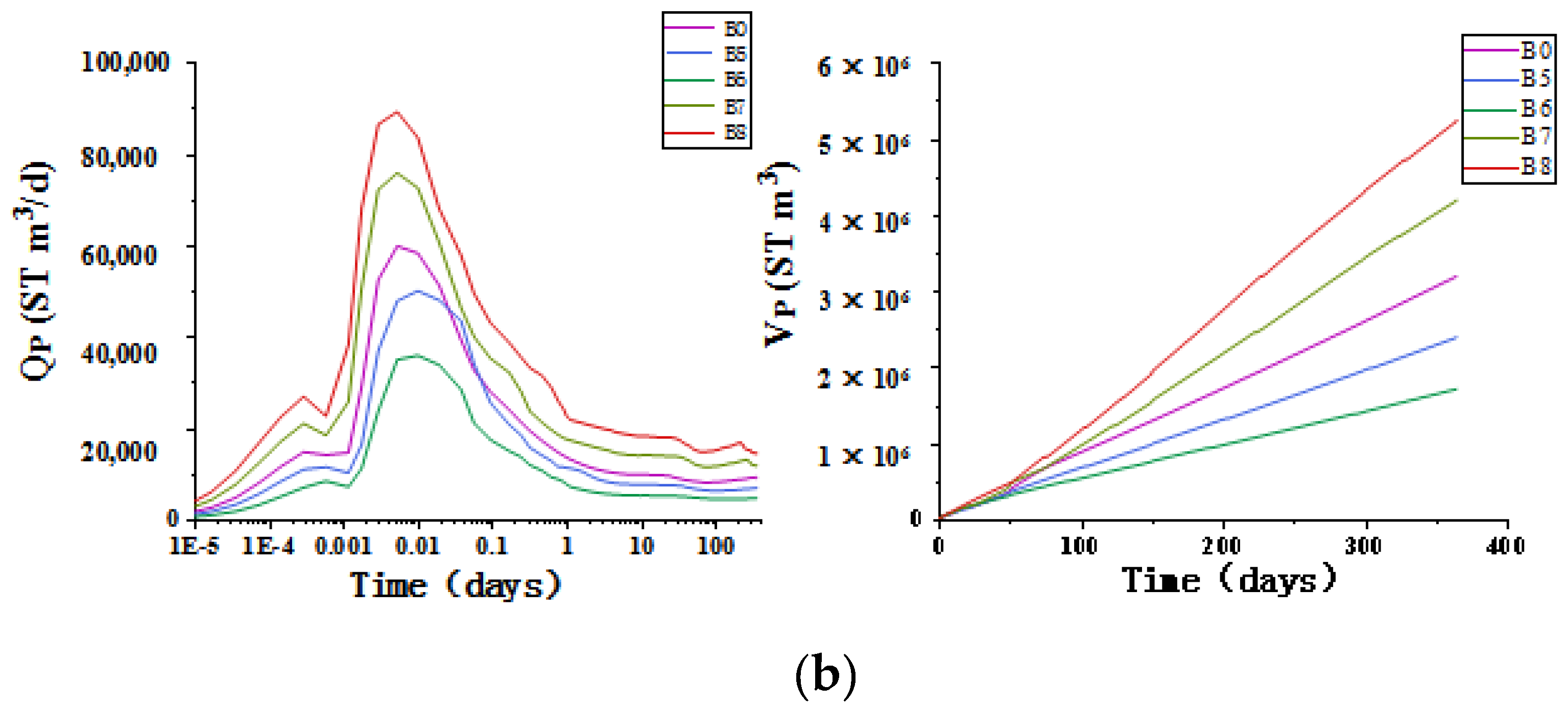

Figure 6 shows that the trend in the volumetric rate of methane (Q

P) obtained by the different schemes was similar. In the early stage of depressurization, the huge pressure-drop made a large amount of hydrate decompose quickly, and the Q

P soon reached first peak. Due to the decrease of temperature around the well, hydrate exploitation was limited, and the Q

P first time declined. As the temperature in the cooling area recovered, there is enough heat to supply hydrate decomposition, the Q

P rose to second peak. Because of the pressure-drop transmission and the decomposition of hydrate around the well, the Q

P decreased sharply to reach a steady value. With the exploitation of hydrate, the V

P increased monotonically increasing. There was a rapid increase in the early stage, but it tended to increase at a uniform speed in the later stage.

The trend of VP depends on the decomposition process of hydrate. The SHR has larger the sensible heat and the heat conduction velocity, and the hydrate decomposition is less limited by heat supply, so the VP of SHR following straight. The sensible heat and the heat conduction velocity of CHR is weaker, and the heat supply becomes more and more difficult, the growth of the hydrate exploitation slows down, so the VP of CHR following convex curve.

Porosity impacts on reservoir productivity by affecting both the solid framework and hydrate content per unit volume. In the CHR model, taking 1 h as the dividing line, the greater the Φ was before this time point, the great the hydrate content per unit volume. More hydrate decomposed due to the pressure-drop at the higher Q

P and V

P values. A large hydrate decomposition would lead to a sharp drop in the temperature around the mining well, which would not be conducive to subsequent hydrate exploitation. A cooling period (the period in

Figure 6 in which the Q

P first declined and then increased) would occur. The heat absorbed was mainly the sensible heat of the reservoir and heat transferred from the overburden and underburned layers. A reservoir with low Φ can provide more heat to replenish the cooling zone and encourage the pressure-drop to spread more rapidly. Therefore, at the end of the simulation the lowest Φ was associated with the highest Q

P and V

P. On the basis of the A0 base case, the V

P of each Φ scheme A1–A4 changed by +2.0%, +5.6%, −2.7%, and −3.4%, respectively. In the SHR, because there was rapid heat conduction and convection, a low Φ was always associated with a high Q

P and V

P in the simulation period. At the end of the simulation, on the basis of the B0 base case, the V

P of each Φ scheme B1–B4 changed by +1.8%, +5.1%, −7.1%, and −11.6%, respectively.

Table 6 shows the sensitivity of productivity to Φ.

At W11 in the South China Sea, the CHR was characterized by high Φ, with an average Φ of about 0.5. The average Φ of the SHR in Nankai Trough in Japan was about 0.4. The Φ of the SHR was relatively smaller than the Φ of CHR, and therefore the SHR provided more sensible heat, and had the characteristics of rapid heat conduction and convection. The problem of the rapid decrease of temperature inhibiting hydrate production was therefore less serious in the SHR. This phenomenon is shown in

Figure 6, which indicated that the cooling period was longer in the CHR than in the SHR. Overall, the heat conduction and convection ability of the CHR were weaker than for the SHR, which made it difficult to recover the low-temperature area caused by hydrate decomposition in a timely manner. Therefore, technical methods need to be considered to ensure the formation of warming around the well.

3.3. Effect of Hydrate Reservoir k on Productivity

Permeability is a parameter that characterizes a reservoir’s ability to transport water or other fluids. It depends only on the rock’s characteristics and not dependent on the properties of the liquid flowing through it.

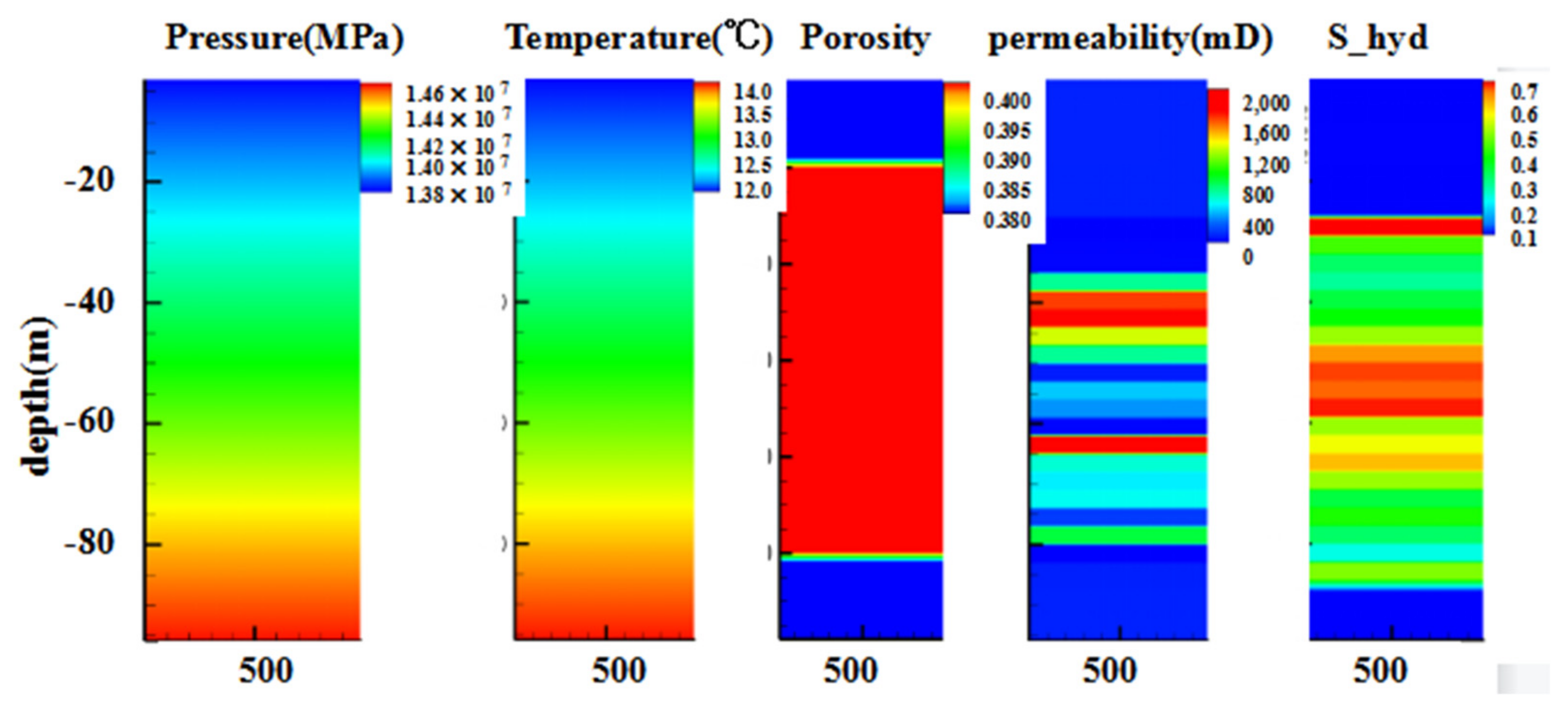

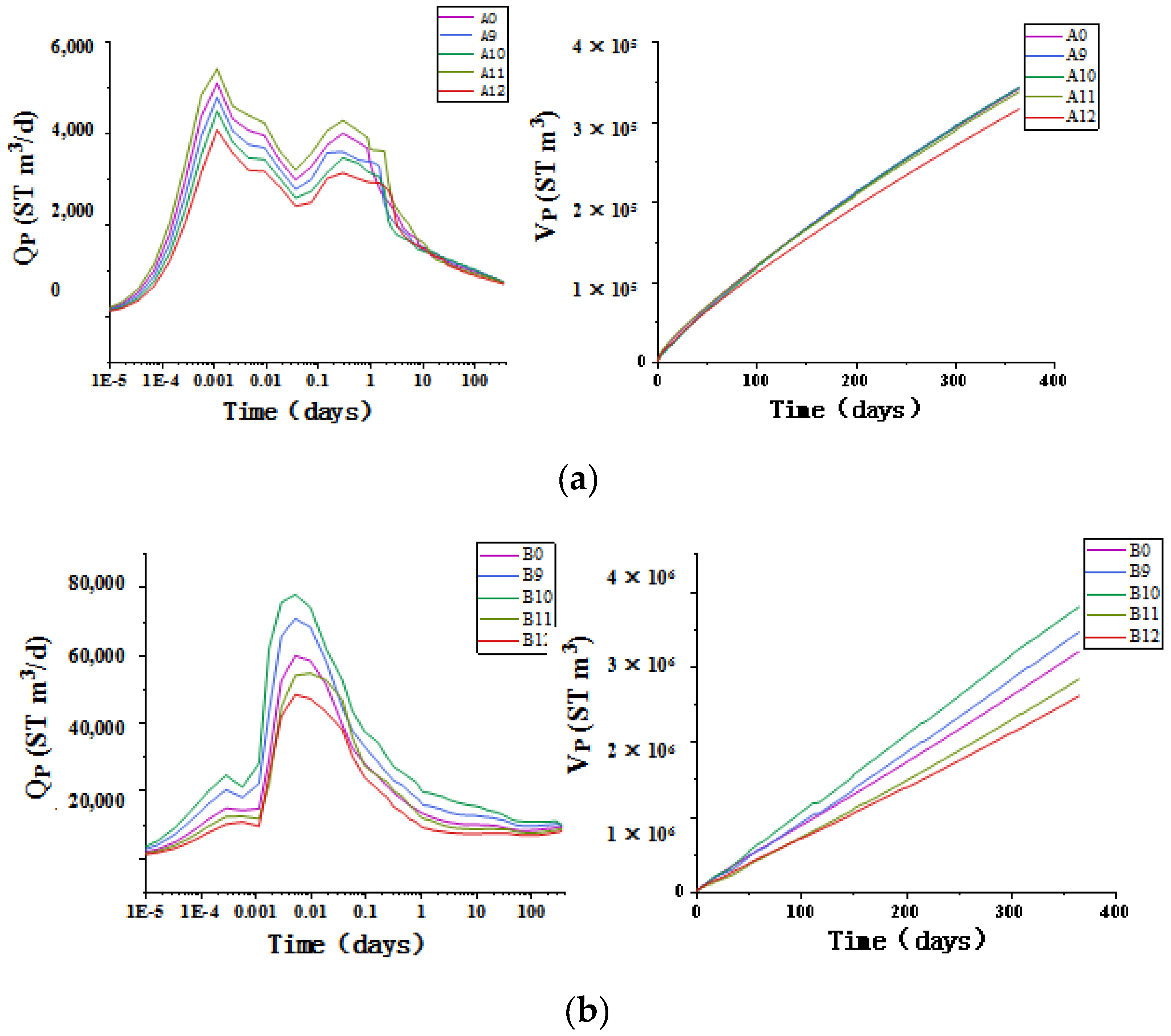

Permeability affects reservoir productivity by affecting both the propagation velocity of the pressure-drop and the discharge velocity of methane gas. On the one hand, the larger the k, the larger the spatial extent of the pressure-drop will be, and the more hydrates will be decomposed. On the other hand, with an increase in k, the decomposed methane gas can be discharged more quickly. Otherwise, the increase in the free gas concentration would maintain a certain pressure inside the reservoir. This would reduce the actual pressure difference between the reservoir and the producing well, which is not conducive to hydrate decomposition. A high k was always associated with high Q

P and V

P in both the CHR and SHR. As shown in

Figure 7, on the basis of the A0 base case, the V

P of each k scheme A5–A8 changed by −19.1%, −40.6%, +15.7%, and +31.9% in the CHR, respectively. On the basis of the B0 base case, the V

P of each k scheme B5–B8 changed by −25.0%, −46.3%, +31.5%, and +64.3% in the SHR, respectively.

Table 7 shows the sensitivity of productivity to k.

The k of the CHR at W11 in the South China Sea ranged from serval to tens of mD, which resulted in a slow thermal convection and heat conduction velocity. When the k was high, the sensible heat supply from the distant reservoir reached the area around the production well, which then rapidly cooled due to the large amount of hydrate decomposition. These conditions were conducive to hydrate recovery. The k of the SHR in the Nankai Trough in Japan ranged from tens to thousands of mD. The gas production of the hydrate reservoir in the South China Sea was therefore more severely restricted by k. This was the main reason why the VP of W11 in China was far less than that of AT1 in Japan in the same period. Therefore, during the exploitation of the clayey silt hydrate reservoir in the South China Sea, some measures of reservoir reconstruction that could greatly increase the k of the hydrate reservoir were required.

3.4. Effect of Reservoir SH on Productivity

Hydrate saturation is the ratio of the concentrations of gas hydrate’s and saturated gas hydrates, and is also expressed as the ratio of the volume of gas hydrates in the reservoir pores to the pore volume. It reflects the abundance of hydrates in the pores of the reservoir.

The S

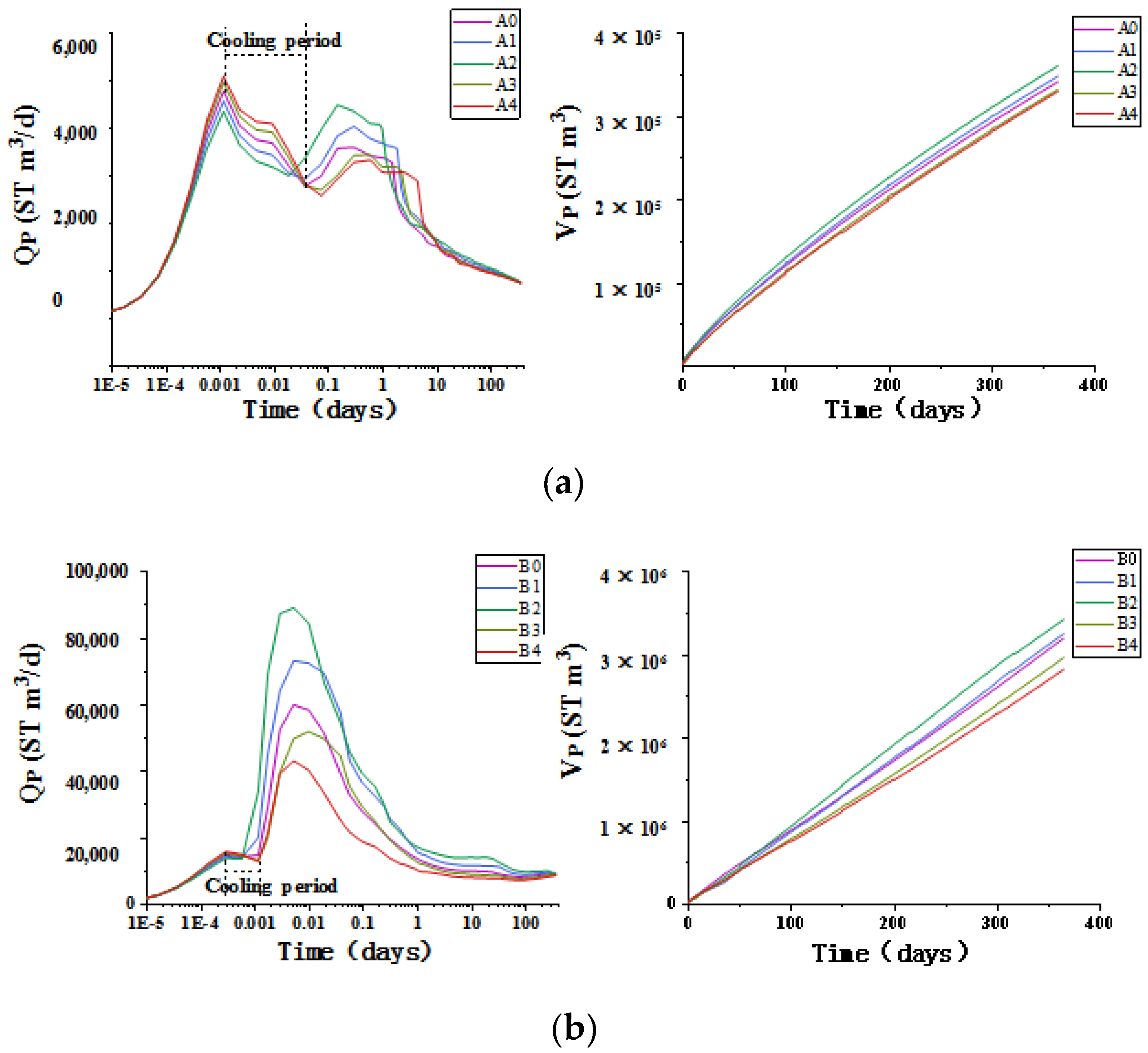

H affects reservoir productivity by impacting on both the hydrate content per unit volume and the seepage capacity. As shown in

Figure 8, taking 125 days as the dividing line in the CHR, the higher the S

H is before this time point, the more hydrates were decomposed around the wellbore. The decomposed gas could be discharged more rapidly at higher Q

P and V

P values. However, led to a significant decrease in the temperature around the wellbore, resulting in a larger cooling period. It is not therefore conducive to subsequent hydrate exploitation. When more of the effective pores were occupied the k decreased, which was not conducive to a further pressure-drop transmission, and the methane gas could not be discharged rapidly in the later stage. The lower the k in the undecomposed zone of hydrates, the more unfavorable the transmission of the pressure-drop and gas discharge. Therefore, at the end of the simulation the lowest S

H was associated with the highest Q

P and V

P values. On the basis of the A0 base case, the V

P of each S

H scheme A9–A12 changed by +0.6%, +0.3%, −1.2%, and −7.4%, respectively. In the SHR, due to the high S

H, there was enough hydrate in the reservoir for production during the simulation period. The seepage capacity had large influence on hydrates decomposition, and therefore the lowest S

H was always associated with the highest Q

P and V

P. At the end of the simulation, on the basis of the B0 base case, the V

P of each S

H scheme B9–B12 changed by +8.3%, +18.9%, −11.3%, and −18.3%, respectively.

Table 8 shows the sensitivity of productivity to S

H.

The higher SH in the early stage of exploitation was conducive to the greater QP and VP in the CHR, but the VP under the A12 scheme with the highest SH was always the lowest among all schemes. This was because a SH that was too large would severely reduce the seepage capacity of the reservoir and slow down the rate of the pressure-drop transmission and methane gas discharge. Therefore, the SH had an influence on productivity only over a certain SH range.

The SH of the CHR at W11 in the South China Sea was about 0.28, while the SH of the SHR in the Nankai Trough in Japan was about 0.51. The SH of the CHR was smaller than that of the SHR. Therefore, when the SH decreased in the CHR, the amount of hydrate decomposition decreased within 125 days, and therefore the productivity was still low despite the timely heat supply. Due to the rapid supply of sensible heat, the cooling period become shorter, and therefore the reservoir productivity of the CHR improved after 125 days. The SH of the SHR was high, and even if it decreased, there would still be enough hydrate for exploitation. The heat transfer was improved at a lower SH. Therefore, a low SH was always associated with a high QP and VP in the SHR. In summary, to assess the reservoir exploitation potential of both the CHR in the Shenhu Sea area of the South China Sea and the SHR in the Eastern Nankai Trough of Japan there is a need to not only rely on the hydrate content or seepage capacity to judge the reservoir exploitation potential, but also to fully consider the combined effect of the two.

In addition, considering that the significance of the SH was related to the total amount of hydrate in the reservoir, and the amount of hydrate decomposed in the simulation period was small compared with the total amount of hydrate in the reservoir, the SH mainly affected productivity by affecting the k and thermal performance of the reservoir. Over a long time-scale, as hydrate was gradually exhausted, the SH mainly affected the productivity of the hydrate reservoir by determining the hydrate content of the reservoir. At this point, its degree of influence increased significantly, but on the other hand the higher SH could increase reservoir productivity.

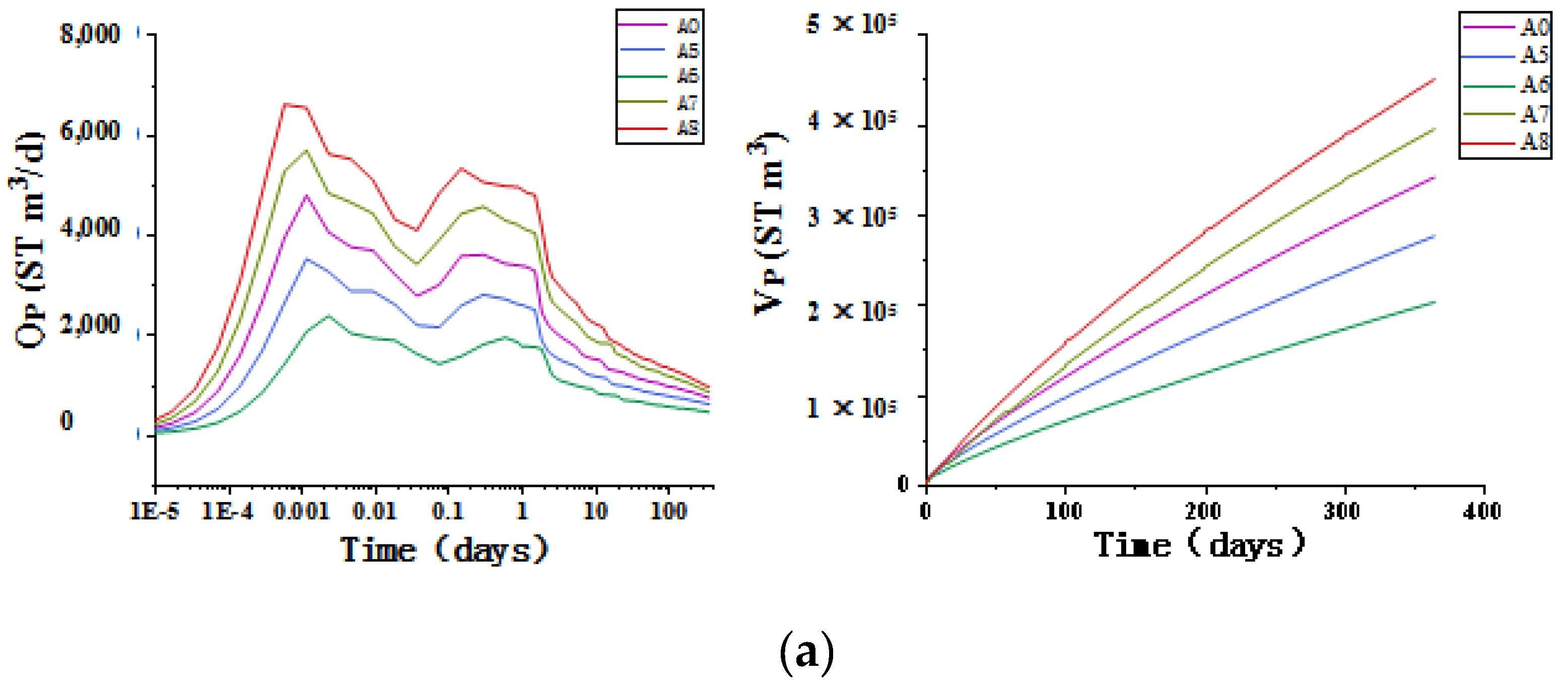

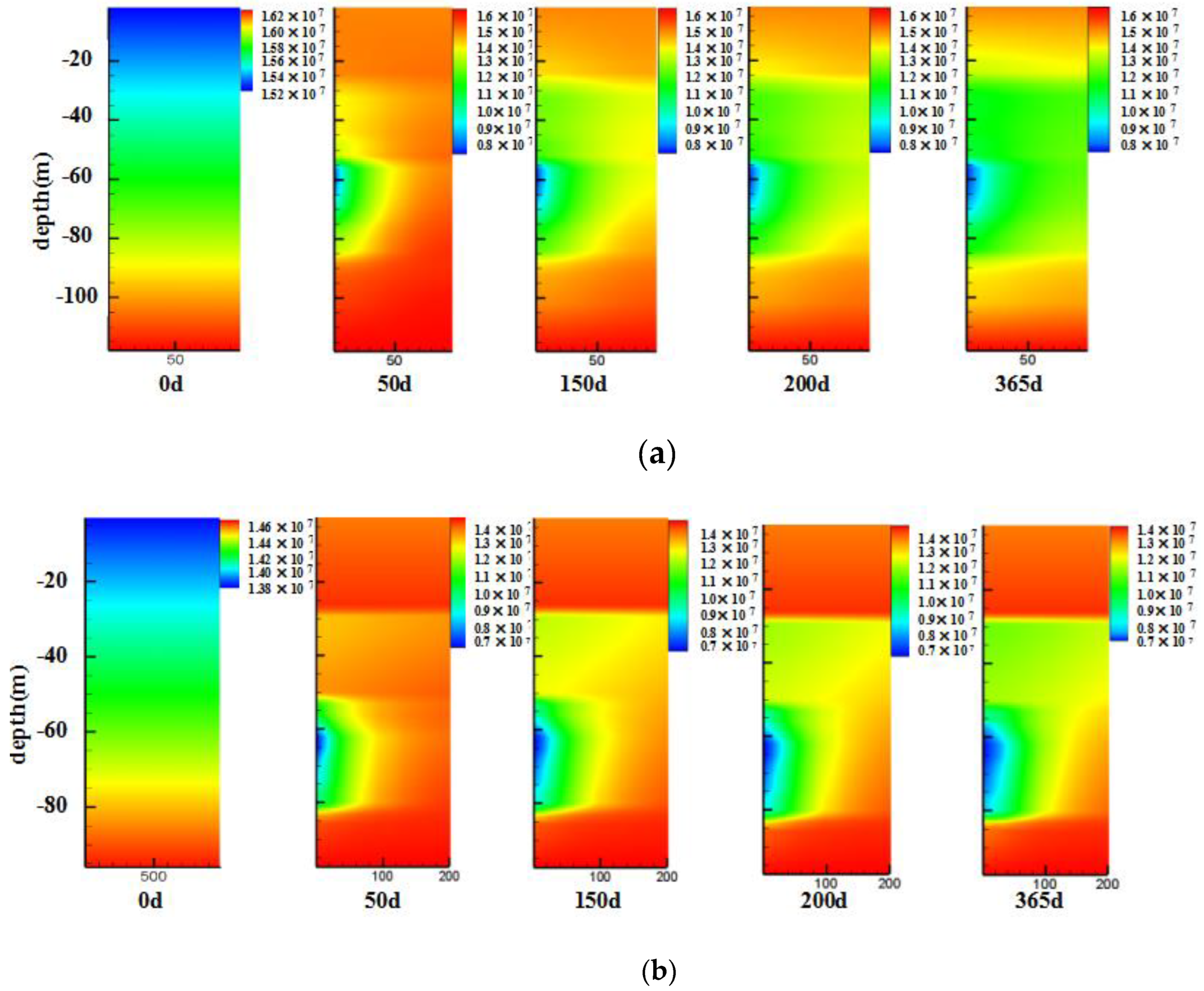

3.5. Spatial Evolution of Seepage Parameters in the Process of Production

Unlike a homogeneous simulation model, in which all geological parameters are averaged, a heterogeneous simulation model can better describe the heterogeneous structure of the formation and reflect the actual characteristics of the parameters [

42]. In an actual hydrate reservoir, there are areas with relatively good k and other areas with relatively poor k. The rapid

transmission of the pressure drawdown in the areas with good k will caused a large amount of hydrate decomposition and a significant decrease in reservoir temperature. In the areas with relatively poor k, the pressure drawdown

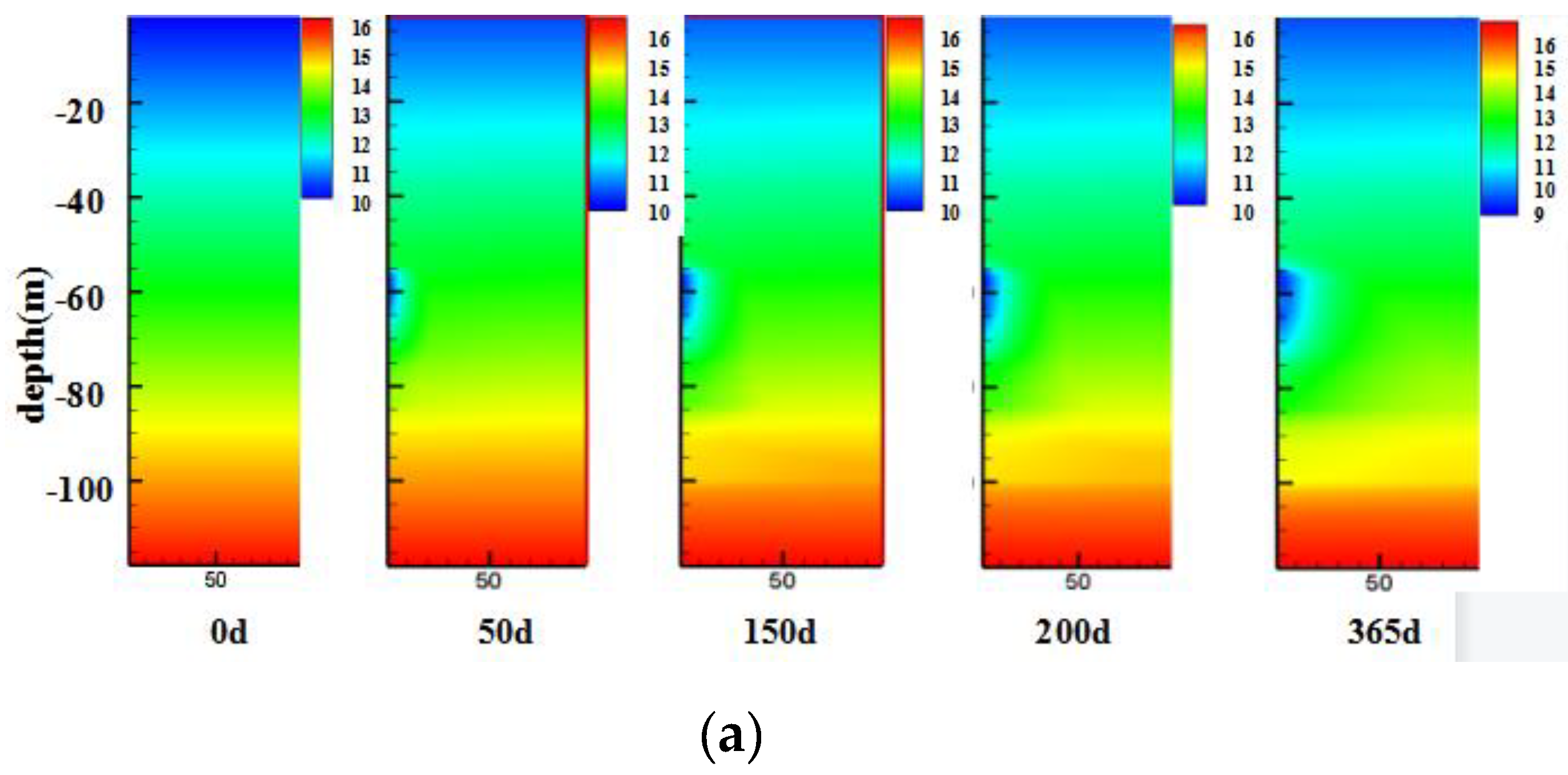

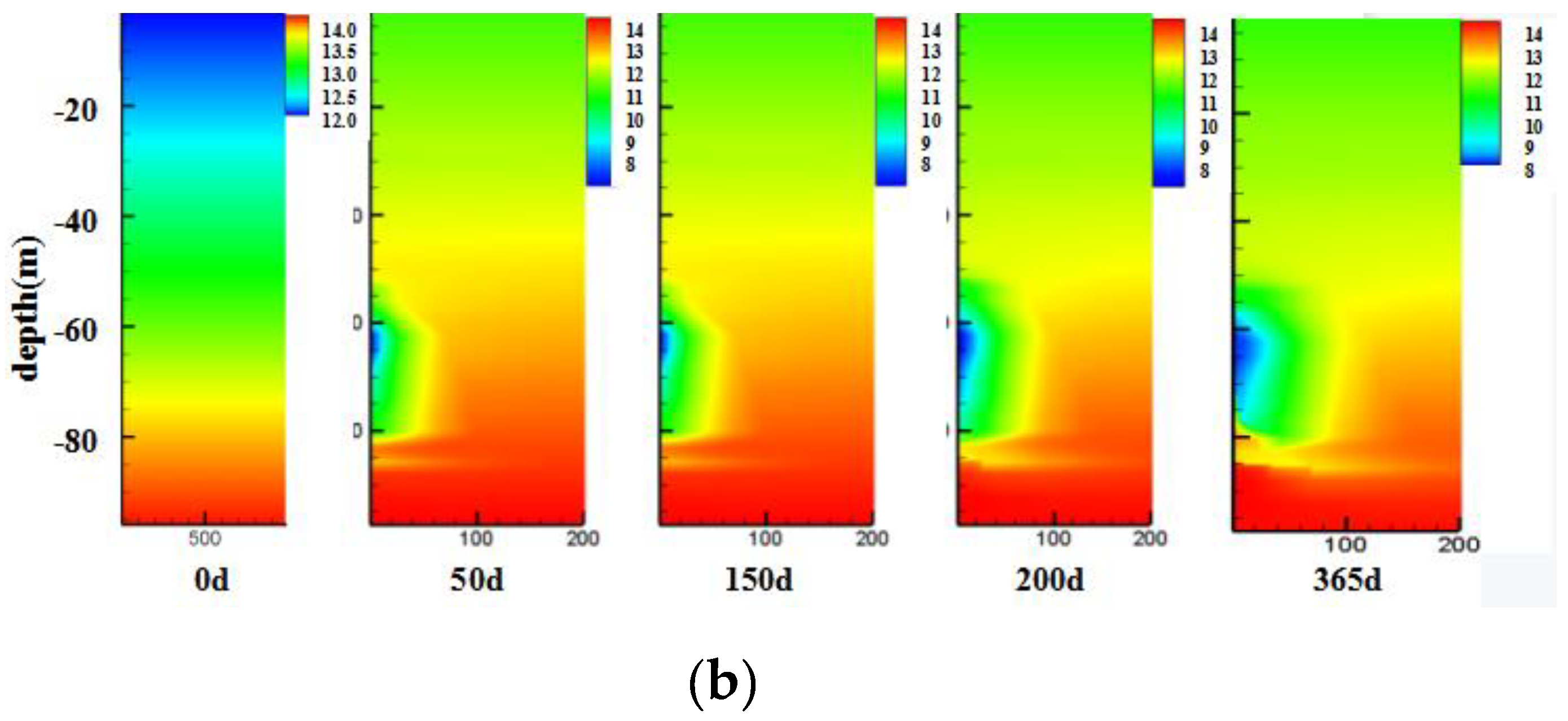

transmission was slower, and the hydrate decomposition was lower. The rock maintained higher temperature, and then the heat in the areas with relatively poor k is transferred to areas with relatively high k, which further promoted hydrate decomposition in areas with high k. Therefore, as shown in

Figure 9, hydrate decomposition mainly occurred along the radial direction in the perforated zone.

Both of the reservoirs had an obvious heterogeneous dissociation front of S

H, which was caused by the non-uniform hydrate decomposition due to the different propagation velocities of the pressure-drop in areas with a different k. The k of the CHR varied over a small range, while the SHR was an interbedded sand-shale reservoir, with the k even reaching about 2000 mD in some sandstone areas. In some mudstone areas the k was about 5 mD, and therefore it varied by up to two orders of magnitude. The heterogeneous decomposition of hydrate caused by the non-uniform transmission of pressure drawdown was therefore more prominent in the CHR. This was apparent from the diagram showing the changes in S

H. Taking

Figure 9 as an example, the areas of hydrate decomposition in the CHR were relatively uniform, while the areas of hydrate decomposition in the SHR had a stronger heterogeneity, and the front of hydrate decomposition extended for more than 100 m in some layers at the end.

As shown in

Figure 10 and

Figure 11, the temperature and pressure reduction zones in the two heterogeneous hydrate reservoirs had uneven distribution characteristics, and the reservoir cooling was mainly due to the heat absorption of hydrate decomposition. This also confirmed that the hydrate decomposition front mainly extended in the reservoir along the radial direction. This was because in the heterogeneous reservoirs, areas with relatively high k and S

H rapidly formed an effective pressure drawdown and propagate along the radial direction under the hydraulic restriction of relatively low k areas. The hydrate decomposition further promoted the propagation of the pressure drawdown in the relatively high k area by increasing the k of the hydrate decomposition area. Therefore, in these layered heterogeneous reservoirs, temperature and pressure transfer and hydrate decomposition were concentrated in areas with relatively a large k.

At the same time, it was found that the temperature and pressure change area of the CHR was concentrated in the 11th layer, in the vicinity of the area where the horizontal well was laid. The temperature and pressure change area of the SHR was concentrated in the 13th layer, in the vicinity of the area where the horizontal well was laid, which was an area with a high k, although the changes in the distant areas were small. Taking

Figure 9 as an example, combined with the analysis of the spatial variation of S

H, it can be seen that the S

H also changed in these areas, whereas there was almost no change in S

H in the remaining areas. This was because two horizontal wells were laid in the highest k areas of the reservoirs. The k of the 11th layer in the CHR was 47 mD, while the k in the 9th and 13th layers suddenly changed to less than 10 mD. The k of the 13th layer in the SHR was 1700 mD, while the k in the 12th and 19th layers suddenly changed to less than 10 mD. Therefore, the pressure drawdown could quickly spread in the area with high k, causing hydrate decomposition. The pressure drawdown was restricted when it underwent a vertical transmission to low k areas. On the one hand, the hydraulic restriction further promoted the radial transmission of pressure drawdown in the area with a relatively high k. On the other hand, the pressure drawdown in the relatively low k area spread slowly, and even beyond the areas with relatively low k there were areas with high k or S

H. Due to the limited pressure drawdown transmission, it was difficult for large-scale hydrate decomposition to occur in these areas. Therefore, the variations in the area of the temperature and pressure fields and S

H were concentrated near the layer of horizontal wells.

Permeability affected the productivity of the hydrate reservoir by impacting on the discharge rate of methane gas and the transfer rate of pressure drawdown. A heterogeneous reservoir can better reflect the advantages of pressure drawdown transfer in areas with a relatively good k. The changes in Φ directly affected the sensible heat of the reservoir from the solid skeleton. The SH determined the amount of hydrate decomposition in the early stage and then determined the changes in the temperature field of the reservoir. The supply of sensible heat to the decomposition zone mainly occurs at the decomposition front in homogeneous reservoirs, but in heterogeneous reservoirs the sensible heat exchange occurs not only at the decomposition front, but also between interbedded structures, which is also advantageous for the exploitation of hydrate. Therefore, the heterogeneous model better described the heat compensation mechanism of the reservoir and the processes by which lithological parameters influenced hydrate decomposition under depressurization. When studying the process of hydrate exploitation, it is therefore necessary to build a numerical simulation model that considers reservoir heterogeneity.

3.6. Effect of Water Salinity on Productivity

Water salinity is used to express the mass fraction of salts in seawater. Previous study have shown that the salinity affects the phase equilibrium of hydrate, and the increase of salinity makes the hydrate phase equilibrium curve shift to the left. As the same temperature, the higher the salinity is, the larger the phase equilibrium pressure of hydrate is [

43,

44]. Therefore, the initial water salinity of hydrate reservoir affects the reservoir productivity.

The formation of hydrate absorbs water molecules, resulting in the increase of water salinity. The initial salinity of CHR is generally higher than that of SHR [

45], the initial salinity of site W11 in the South China Sea is 3.15%, and that of site AT1 in Japan is 3.0%. Based on this data, the schemes of the two models were designed respectively(as shown in

Table 9), and then the effect of water salinity on the gas production of hydrate reservoirs with different lithology was studied.

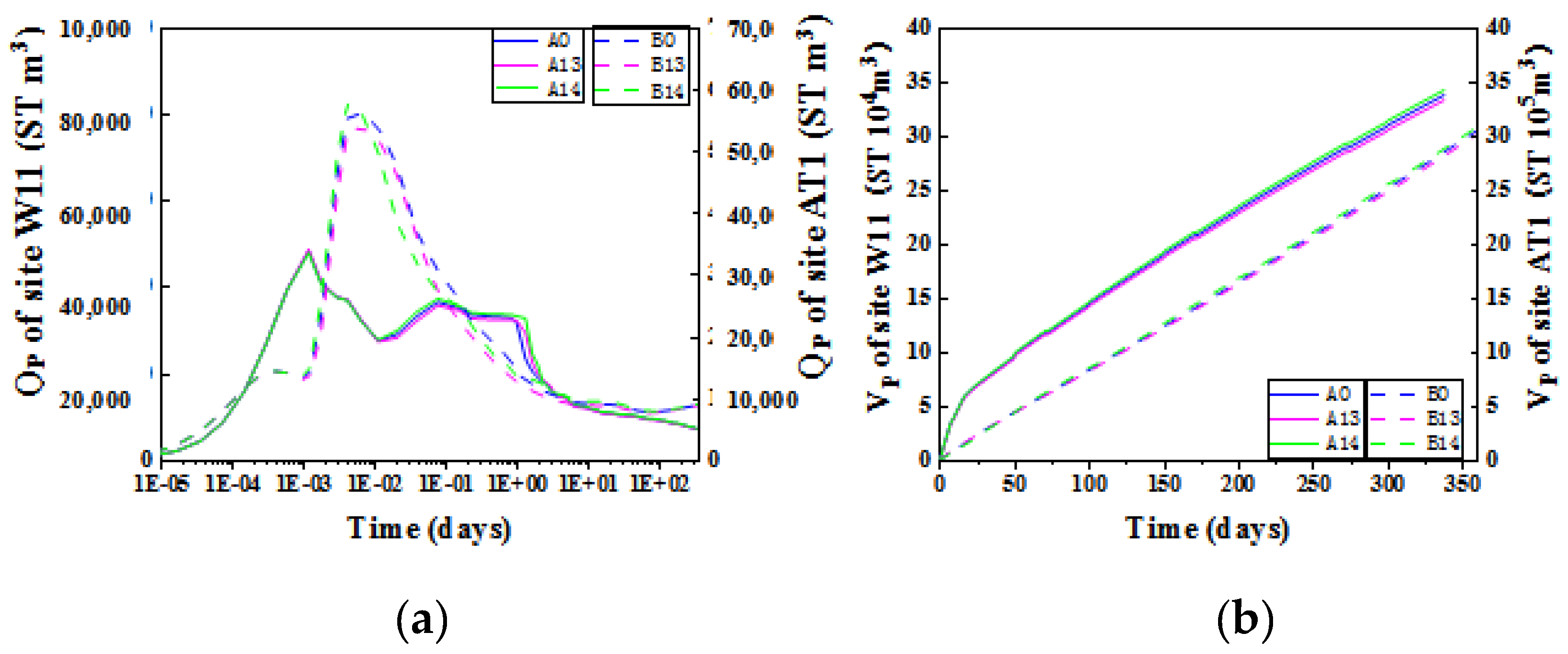

Figure 12 shows that the trend in the QP and VP was similar to the previous analysi, and a high water salinity always associated with high QP and VP in the CHR and SHR. On the basis of the base case (A0), the VP of the scheme A13-14 changed by −1.37% and +1.38% in the CHR, respectively. On the basis of the base case (B0), the VP of the scheme B13-14 changed by −1.45% and +1.03% in the SHR, respectively. This is because under the high salinity, the phase equilibrium temperature of hydrate is low, the decomposition of hydrate was less limited by heat supply. Therefore, the high initial water salinity is conducive to gas hydrate decomposition.

Table 10 shows that the water salinity has a great impact on reservoir productivity, and S

salinity is similar to S

k. The water salinity of the China four seas ranges from 3.0–3.5%, and the variation range is small. Therefore, considering the actual situation, the effect of water salinity on reservoir productivity is limited.