Study on the Performance of an Electric-Field-Enhanced Oil–Water Separator in Treating Heavy Oil with High Water Cut

Abstract

:1. Introduction

2. The Oil–Water Separator Design

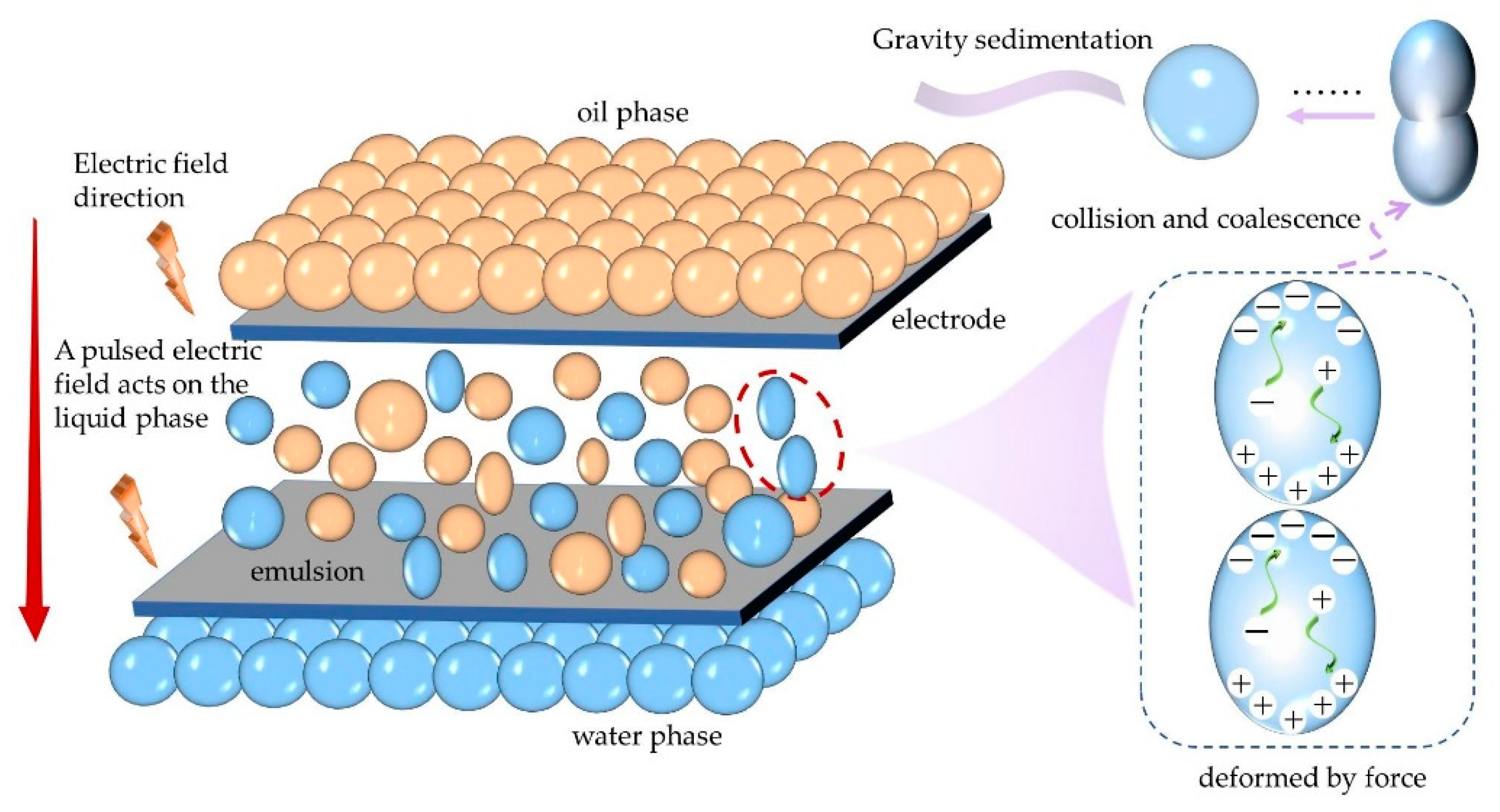

2.1. Coalescer and Settlement Performance Theory

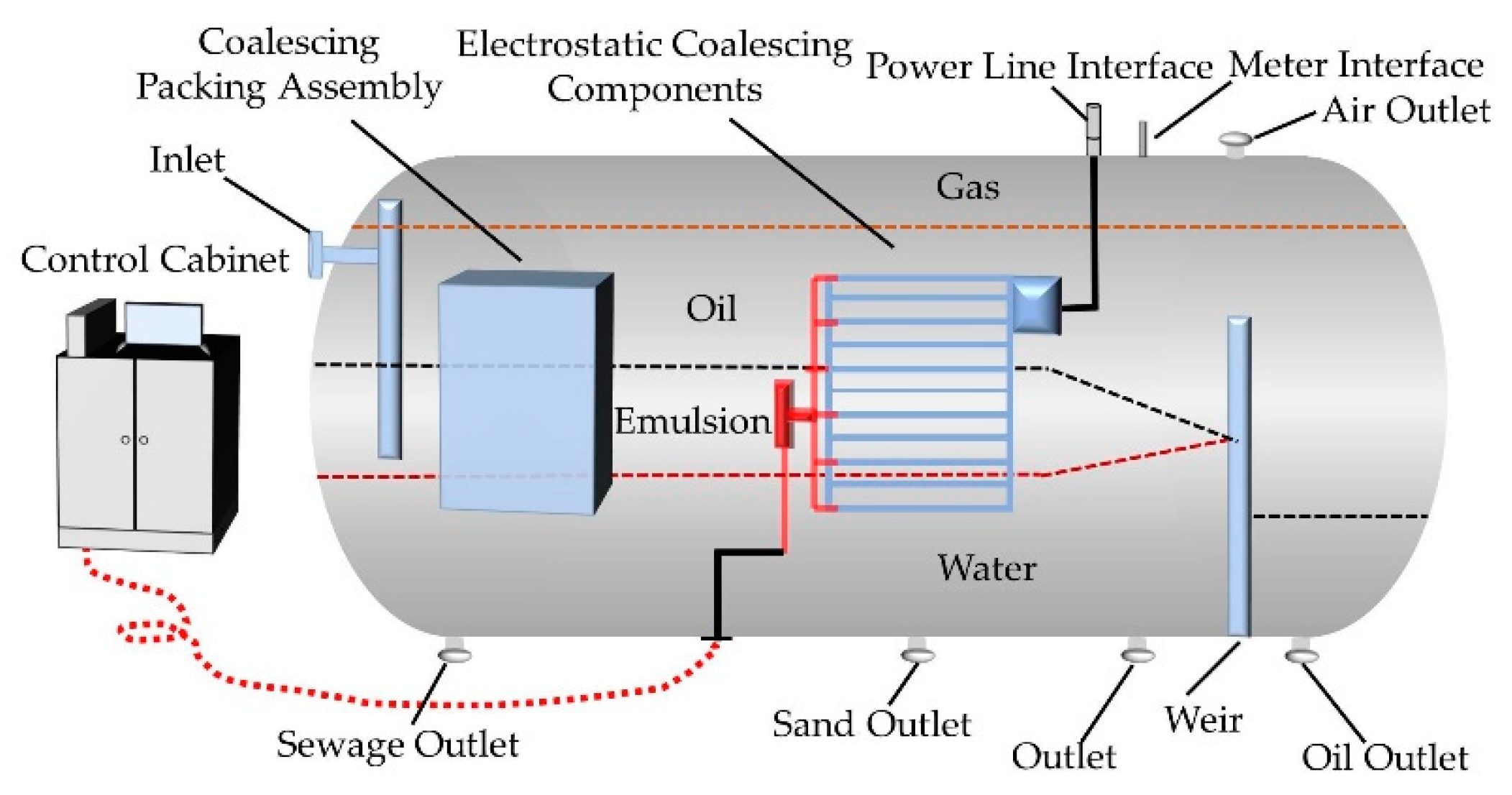

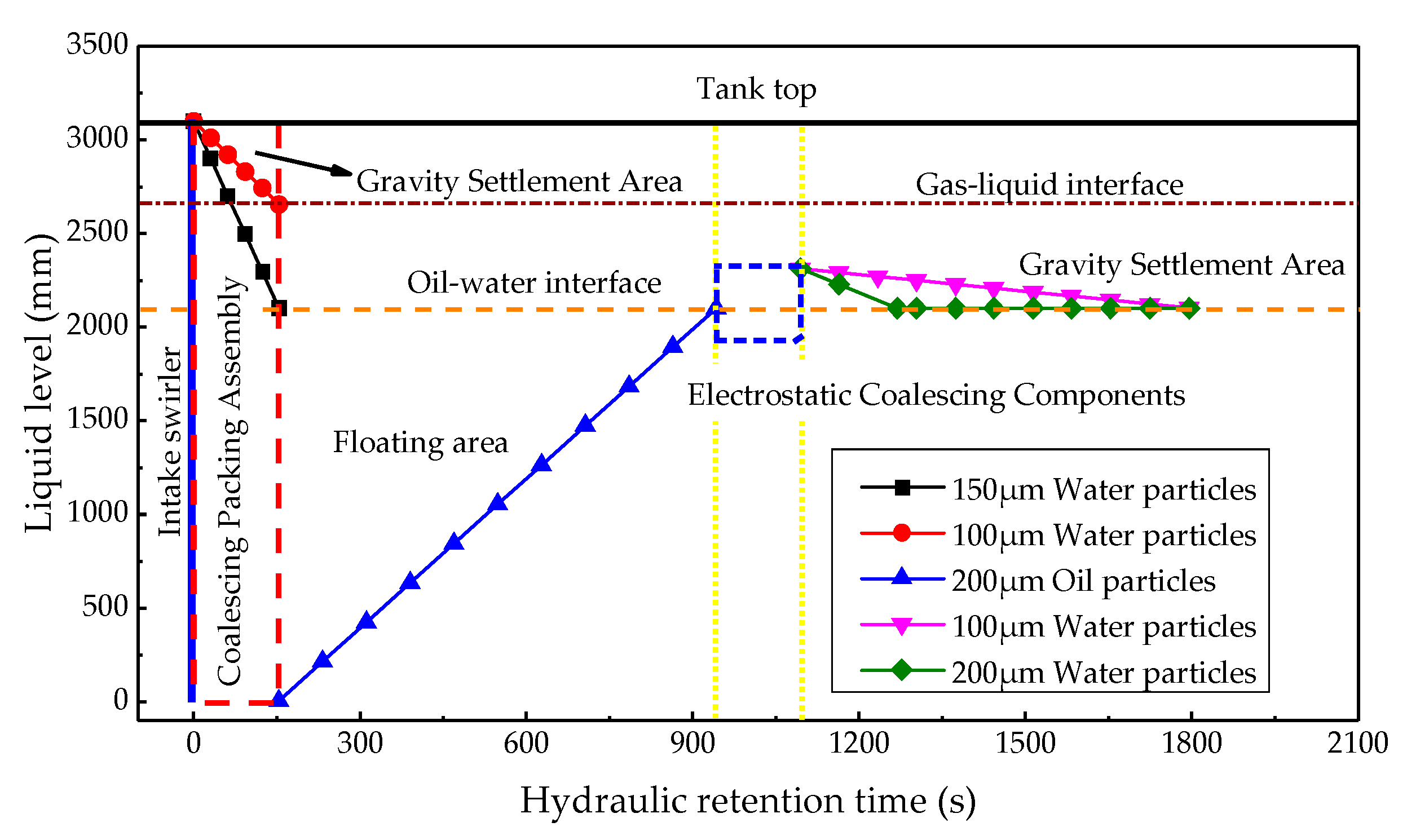

2.2. The Oil–Water Separator Structure

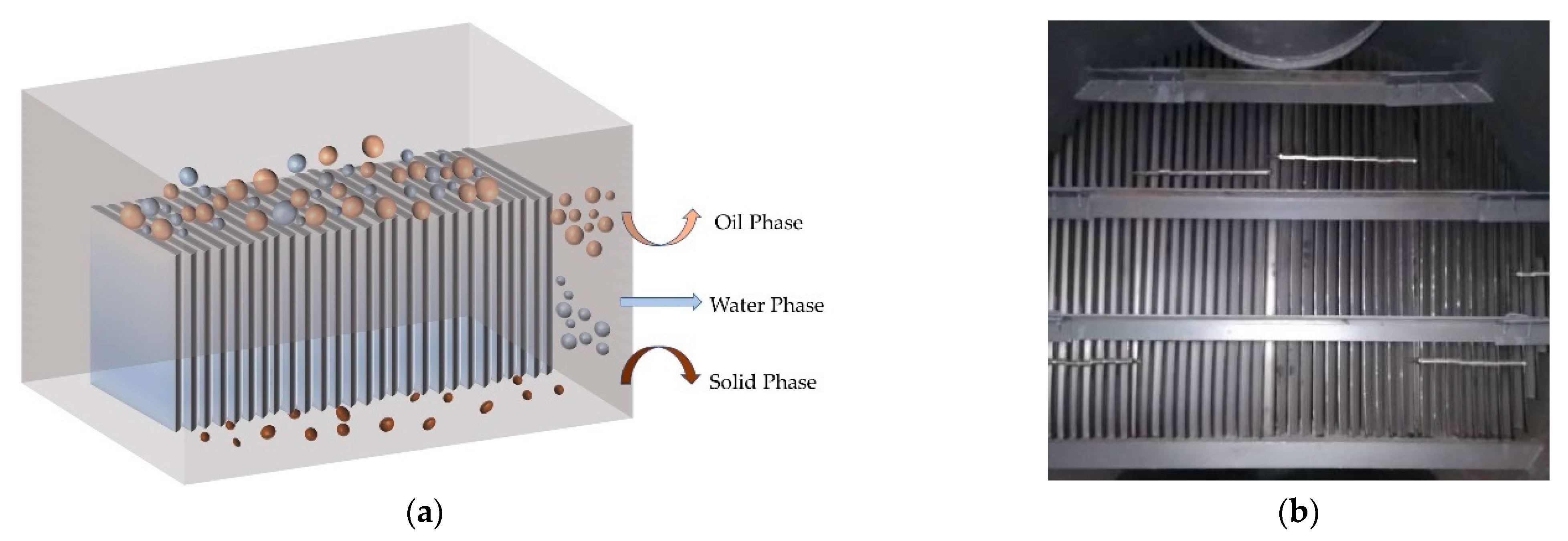

2.2.1. Parameter Design of the Coalescing Packing Assembly

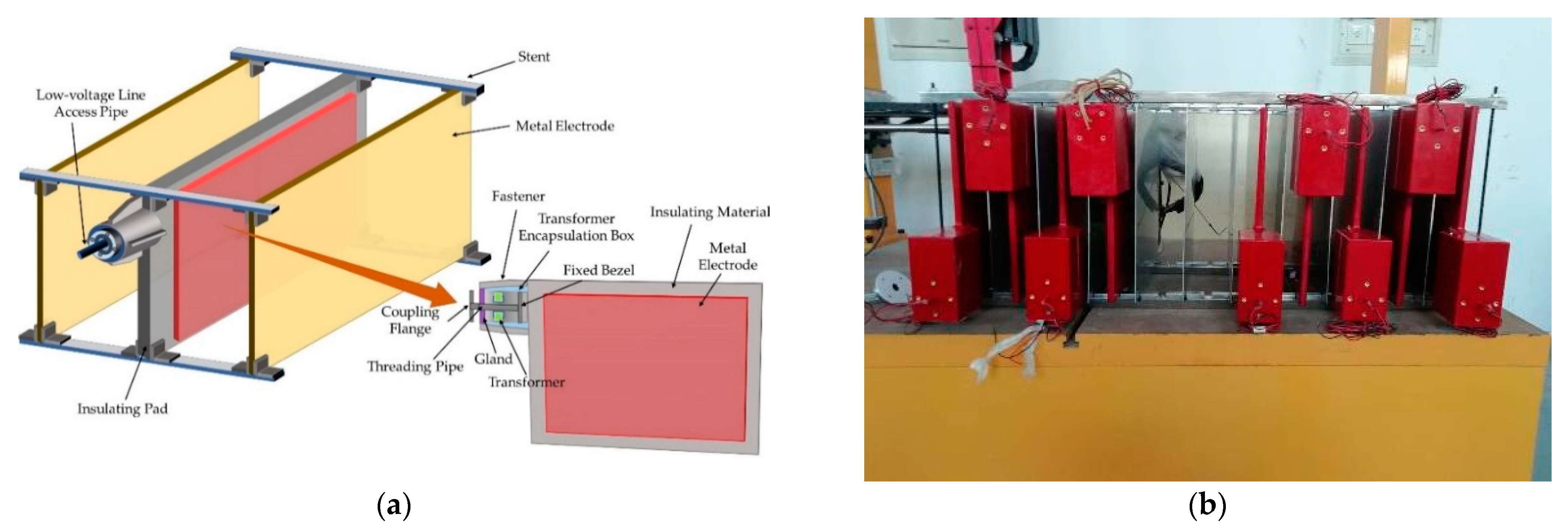

2.2.2. Parameter Design of the VIEC Components

- The electrode assembly inside the three-phase separator;

- The connector assembly through the separator wall; and

- The power and its control devices that were located in the nearby control room.

- The space in front of the VIEC components ensured that the oil particles at the bottom of the tank could float to the oil phase, and the height of oil–water interface (Hw) had to be higher than the bottom of the VIEC to ensure that all the oil could enter the flow channel;

- The space downstream of the VIEC components ensured that the water particles of after coalescing under the electric field force had enough time to settle. In order to strictly ensure the safety performance of the device, its top had to be at least 0.2 m below the gas–liquid interface [37].

3. Experimental Set-Up and Process

3.1. Experimental Set-Up

3.2. Process

4. Results and Discussion

4.1. Influence of the Electric Field Frequency

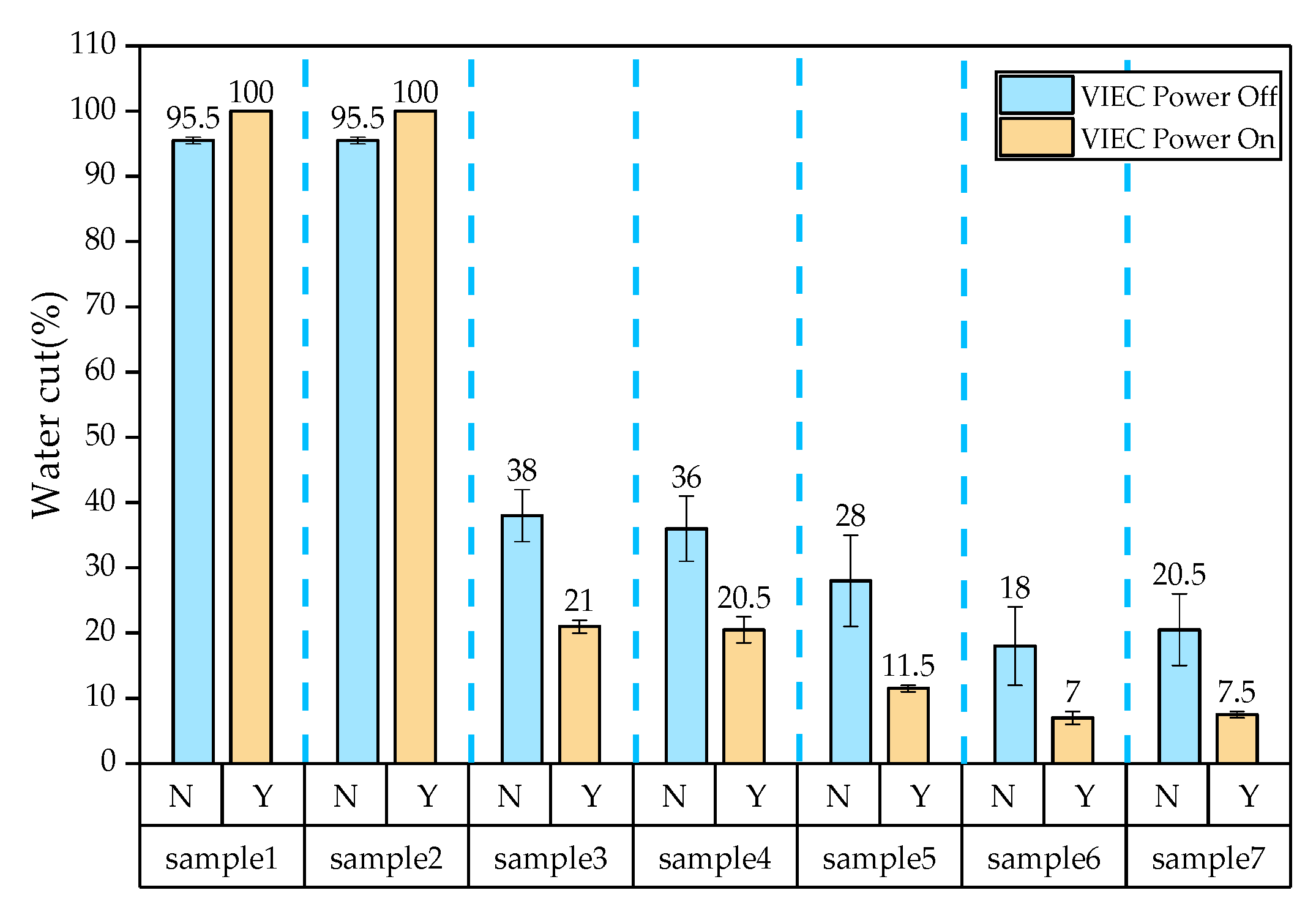

4.2. The Influence of Flow on the Dehydration Effect

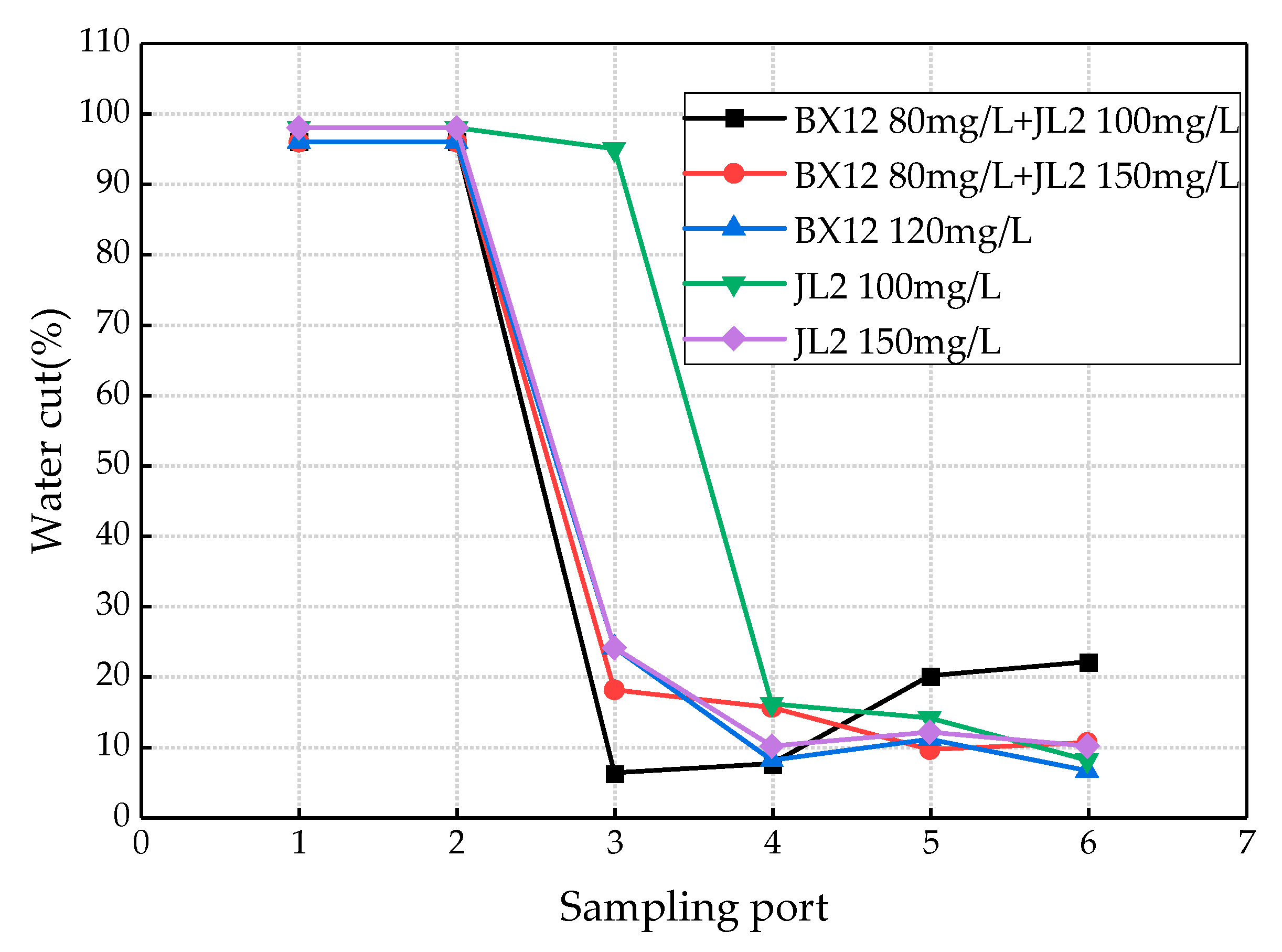

4.3. Influence of Chemicals on the Dehydration Effect

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Urdahl, O.; Nordstad, K.; Berry, P.; Wayth, N.; Williams, T.; Bailey, A.; Thew, M. Development of a new, compact electrostatic coalescer concept. SPE Prod. Facil. 2001, 16, 4–8. [Google Scholar] [CrossRef]

- Bahú, J.O.; Miranda, N.T.; Khouri, N.G.; Batistella, C.B.; Concha, V.O.C.; Maciel, M.R.W.; Schiavon, M.I.R.B.; Filho, R.M. Crude oil emulsion breaking: An investigation about gravitational and rheological stability under demulsifiers action. J. Pet. Sci. Eng. 2022, 210, 110089. [Google Scholar] [CrossRef]

- Shi, Y.; Chen, J.; Pan, Z. Experimental study on the performance of a novel compact electrostatic coalescer with helical electrodes. Energies 2021, 14, 1733. [Google Scholar] [CrossRef]

- Chen, J.; Chu, Q.; Zhang, B.; Ding, Y.; Wang, C. Compact electrostatic pre-coalescence technology for crude oil dehydration (2). China Pet. Mach. 2009, 37, 77–82. [Google Scholar]

- Han, F.; He, Z.; Ye, T.; Guo, P. Coalescing assemblies structure optimization of compact electrostatic coalescer. Oil-Gasfield Surf. Eng. 2012, 31, 15–18. [Google Scholar]

- Mhatrea, S.; Vivacqua, V.; Ghadiri, M.; Abdullah, A.M.; Al-Marri, M.J.; Hassanpour, A.; Hewakandamby, B.; Azzopardi, B.; Kermani, B. Electrostatic phase separation: A review. Chem. Eng. Res. Des. 2015, 96, 177–195. [Google Scholar] [CrossRef]

- Parvasi, P.; Hesamedini, A.K.; Jahanmiri, A.; Rahimpour, M.R. A Comparative Study on Droplet Coalescence in Heavy Crude Oil Emulsions Subjected to Microwave and Ultrasonic Fields. Sep. Ence 2013, 48, 1591–1601. [Google Scholar] [CrossRef]

- Issaka, S.A.; Nour, A.H.; Yunus, R.M. Review on the fundamental aspects of petroleum oil emulsions and techniques of demulsification. J. Pet. Environ. Biotechnol. 2015, 6, 1. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Bukosky, S.C.; Ristenpart, W.D. Low-voltage electrical demulsification of oily wastewater. Ind. Eng. Chem. Res. 2018, 57, 8341–8347. [Google Scholar] [CrossRef]

- Wolff, E.A.; ABB Offshore Systems; Knutsen, T.L.; Hydro, N.; Piasecki, W.; ABB Corporate Research; Hansson, P.; ABB Offshore Systems; Nilsen, P.J.; ABB Offshore Systems. Advanced Electrostatic Internals in the 1st Stage Separator Enhance Oil/Water Separation and Reduce Chemicals Consumption on the Troll C Platform; Offshore Technology Conference: Houston, TX, USA, 2004; pp. 3–6. [Google Scholar]

- Lee, C.M.; Sams, G.W.; Wagner, J.P. Power consumption measurements for ac and pulsed dc for electrostatic coalescence of water-in-oil emulsions. J. Electrost. 2001, 53, 1–24. [Google Scholar] [CrossRef]

- Wood, D.J.; Kolbu, J.; Nilsen, P.J. Modelling of the VIEC-A New Device which Aids Separation. In Fourth International Conference on CFD in the Oil and Gas; Metallurgical & Process Industries, SINTEF/NTNU Trondheim: Trondheim, Norway, 2005; pp. 6–8. [Google Scholar]

- Fortuny, M.; Oliveira, C.B.Z.; Melo, R.L.F.V.; Nele, M.; Coutinho, R.C.C.; Santos, A.F. Effect of salinity, temperature, water content, and pH on the microwave demulsification of crude oil emulsions. Energy Fuels 2007, 21, 1358–1364. [Google Scholar] [CrossRef]

- Fjeldly, T.A.; Hansen, E.B.; Nilsen, P.J. Novel Coalescer Technology in First-Stage Separator Enables One-Stage Separation and Heavy-Oil Separation; Offshore Technology Conference: Houston, TX, USA, 2006; pp. 1–4. [Google Scholar]

- Less, S.; Hannisdal, A.; Bjørklund, E.; Sjöblom, J. Electrostatic destabilization of water-in-crude oil emulsions: Application to a real case and evaluation of the Aibel VIEC technology. Fuel 2008, 87, 2572–2581. [Google Scholar] [CrossRef]

- Aryafard, E.; Farsi, M.; Rahimpour, M.R. Modeling and simulation of crude oil desalting in an industrial plant considering mixing valve and electrostatic drum. Chem. Eng. Processing: Process Intensif. 2015, 95, 383–389. [Google Scholar] [CrossRef]

- Kakhki, N.A.; Farsi, M.; Rahimpour, M.R. Effect of current frequency on crude oil dehydration in an industrial electrostatic co-alescer. J. Taiwan Inst. Chem. Eng. 2016, 67, 1–10. [Google Scholar] [CrossRef]

- Kothmire, P.P.; Bhalerao, Y.J.; Naik, V.M. Experimental studies on the performance and analysis of an electrostatic coalescer under different electrostatic boundary conditions. Chem. Eng. Res. Des. 2020, 154, 273–282. [Google Scholar] [CrossRef]

- Mhatre, S.; Thaokar, R. Electrocoalescence in non-uniform electric fields: An experimental study. Chem. Eng. Processing Process Intensif. 2015, 96, 28–38. [Google Scholar] [CrossRef]

- Mhatre, S.; Deshmukh, S.; Thaokara, R.M. Electrocoalescence of a drop pair. Phys. Fluids 2015, 27, 092106. [Google Scholar] [CrossRef]

- Ismail, A.S.; Menchaca, A.E.; Balk, W.; Akdim, M.R. High-Performance Electrostatic Coalescer–A Novel Technology for Improving the Economics of Oil-Water Separation; Abu Dhabi International Petroleum Exhibition: Abu Dhabi, United Arab Emirates, 2020; pp. 9–12. [Google Scholar]

- Kharoua, N.; Khezzar, L.; Saadawi, H. CFD modelling of a horizontal three-phase separator: A population balance approach. Am. J. Fluid Dyn. 2013, 3, 101–118. [Google Scholar]

- Liu, Y.; Cheng, Q.; Zhang, B.; Tian, F. Three-phase hydrocyclone separator–A review. Chem. Eng. Res. Des. 2015, 100, 554–560. [Google Scholar] [CrossRef]

- Piasecki, W.; Florkowski, M.; Fulczyk, M.; Sipowicz, J. Vessel Internal Electrostatic Coalescer (VIEC) Novel oil-water separation technology. Innov. Eng. 2004, 4, 69–70. [Google Scholar]

- Song, F.; Wang, W.; Chen, Q.; Fan, J. Coalescence characteristics of the double droplets under electric field. CIESC J. 2021, 72, 371–381. [Google Scholar]

- Zhang, L.; Chen, J.; Li, W.; Zhuang, G.; Hu, C.; Xi, J.; Meng, H. Three-phase separation and electric field demulsification and dehydration integration (VIEC) technology and its performance research. Pet. Plan. Eng. 2017, 28, 8–12+16+54. [Google Scholar]

- Zhang, J.; He, H.; Huang, G. Simulation of droplet deformation in uniform electric field with dissipative particle dynamics approach. CIESC J. 2014, 65, 3872–3877. [Google Scholar]

- Hiesa, M.; Melheim, J.; Pedersen, A.; Ingebrigtsen, S.; Berg, G. Forces acting on water droplets falling in oil under the influence of an electric field: Numerical predictions versus experimental observations. Eur. J. Mech. B/Fluids 2005, 24, 717–732. [Google Scholar]

- Pethig, R. Dielectrophoresis: Status of the theory, technology, and applications. Biomicrofluidics 2010, 4, 022811. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Olson, M.D.; Grave, E.J.; Juarez, J.C.; Gul, K. Performance Testing of an Integrated, Subsea Compact Separation System with Elec-trocoalescence for Deepwater Applications; Offshore Technology Conference: Houston, TX, USA, 2015; pp. 4–7. [Google Scholar]

- Ni, L.; He, L. Experimental Studies of Separating Behavior of Gravitational Oil-Water Separator with a Coalescing Internal Installed. Oil Field Equip. 2007, 10, 61–64. [Google Scholar]

- AlQahtani, A. Vessel Internal Electrostatic Coalescer Technology (VIEC); International Production and Operations Conference & Exhibition: Doha, Qatar, 2012; pp. 66–70. [Google Scholar]

- Zhang, M.; Shang, C.; Wang, H.; Zheng, X.; Wang, C. Prospect of offshore electrostatic coalescence crude oil dehydration technology. Ocean. En-Gineering Equip. Technol. 2017, 4, 86–90. [Google Scholar]

- Xu, M.; Zhang, Z.; Hao, B.; Shen, B.; Lv, Z. Application of novel electrostatic coalescence dehydration technology in oil-water separator. China Offshore Platf. 2020, 35, 84–89. [Google Scholar]

- Raya, S.A.; Mohd Saaid, I.; Abbas Ahmed, A.; Umar, A.A. A critical review of development and demulsification mechanisms of crude oil emulsion in the petroleum industry. J. Pet. Explor. Prod. Technol. 2020, 10, 1711–1728. [Google Scholar] [CrossRef] [Green Version]

- Xiong, H.; Zhang, B.; Chen, J.; Hu, C.; Zhang, X.; Huang, S.; Xi, J. Crude oil dehydration technology by vessel internal electrostatic coalescer in three-phase separator. China Pet. Mach. 2016, 44, 108–112. [Google Scholar]

- Zhang, L.; Xiao, H.; Zhang, H.; Xu, L.; Zhang, D. Optimal design of a novel oil–water separator for raw oil produced from ASP flooding. J. Pet. Sci. Eng. 2007, 59, 213–218. [Google Scholar] [CrossRef]

- Huang, S.; He, X.; Li, W.; Jiao, X.; Chen, J. An AC Pulse Crude Oil Dehydration Power Supply Device with the Function of Increasing the Voltage in Sections within the Pulse Width. China Patent CN113179028A, 27 July 2021. [Google Scholar]

- Tang, X.; Zhang, Y.; Wang, X.; Chen, J. Application research of electric field enhanced oil-water separation in oilfield produced liquid. Ind. Water Treat. 2022, 42, 168–171+177. [Google Scholar]

- Kang, W.; Li, M.; Yang, H.; Kang, X.; Wang, F.; Jiang, H.; Zhang, M.; Zhu, T.; Sarsenbekuly, B. Coalescence behavior of aqueous drops in water-in-oil emulsions under high-frequency pulsed AC fields. J. Ind. Eng. Chem. 2021, 93, 415–422. [Google Scholar] [CrossRef]

- Dong, J.; Chen, J.; Ji, Y.; Wang, C.; Shang, C.; Zhang, M. Performance test of compact tubular high-voltage electric field coalescers. Process Eng. 2021, 40, 1390–1400. [Google Scholar]

- Shi, Y.; Chen, J.; Meng, H. Experimental study on the performance of an electric field enhanced separator for crude oil production fluid. J. Pet. Sci. Eng. 2022, 212, 110315. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Design flowrate | 10 m3/h | Water density at 50 °C | 992 kg/m3 |

| Tank size | 5.2 m × 2.4 m × 3.695 m | Oil density at 50 °C | 932 kg/m3 |

| Water content | 90% | Oil viscosity at 50 °C | 6.47 × 10−3 Pa·s |

| Temperature | 50 °C | Water viscosity at 50 °C | 5.57 × 10−4 Pa·s |

| Flow (m3/h) | Inlet Water Cut (%) | Water Cut of Each Sampling Point (%) | Dehydration Rate (%) | VIEC Power | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | ||||

| 6.5 | 90 | 90 | 92 | 38 | 37 | 25 | 15 | 16 | 82.2 | Off |

| 86 | 98 | 98 | 32 | 30 | 16 | 21 | 16 | 81.4 | ||

| 78 | - | - | - | - | - | - | 12 | 84.6 | On | |

| 82 | - | - | - | - | - | - | 12 | 85.4 | ||

| 10 | 90 | 95 | 95 | 34 | 31 | 21 | 12 | 15 | 83.3 | Off |

| 96 | 96 | 96 | 42 | 41 | 35 | 24 | 27 | 71.9 | ||

| 95 | 100 | 100 | 22 | 22.5 | 11 | 8 | 8 | 91.6 | On | |

| 90 | 100 | 100 | 20 | 19 | 12 | 6 | 6 | 93.3 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.; He, X.; Chen, J.; Wang, X.; Zhang, J.; Dong, J.; Zhang, B. Study on the Performance of an Electric-Field-Enhanced Oil–Water Separator in Treating Heavy Oil with High Water Cut. J. Mar. Sci. Eng. 2022, 10, 1516. https://doi.org/10.3390/jmse10101516

Huang S, He X, Chen J, Wang X, Zhang J, Dong J, Zhang B. Study on the Performance of an Electric-Field-Enhanced Oil–Water Separator in Treating Heavy Oil with High Water Cut. Journal of Marine Science and Engineering. 2022; 10(10):1516. https://doi.org/10.3390/jmse10101516

Chicago/Turabian StyleHuang, Songtao, Xue He, Jiaqing Chen, Xiujun Wang, Jian Zhang, Jianyu Dong, and Baosheng Zhang. 2022. "Study on the Performance of an Electric-Field-Enhanced Oil–Water Separator in Treating Heavy Oil with High Water Cut" Journal of Marine Science and Engineering 10, no. 10: 1516. https://doi.org/10.3390/jmse10101516

APA StyleHuang, S., He, X., Chen, J., Wang, X., Zhang, J., Dong, J., & Zhang, B. (2022). Study on the Performance of an Electric-Field-Enhanced Oil–Water Separator in Treating Heavy Oil with High Water Cut. Journal of Marine Science and Engineering, 10(10), 1516. https://doi.org/10.3390/jmse10101516