Automatic Precision Planting Mechanism of Garlic Seeder

Abstract

1. Introduction

2. Materials and Methods

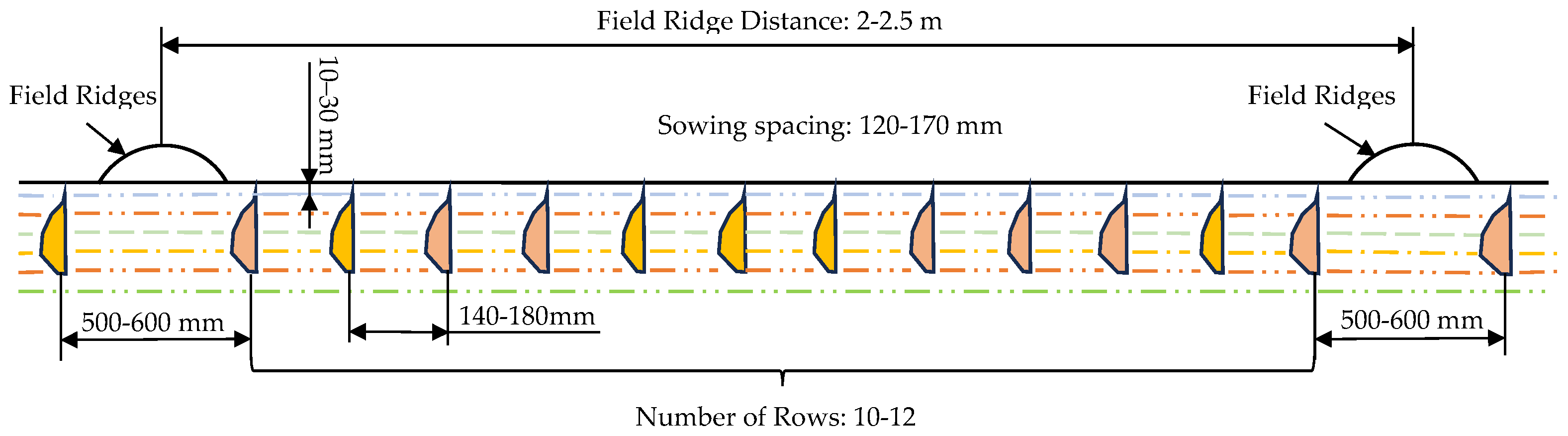

2.1. Agronomic Requirements for Garlic Cultivation

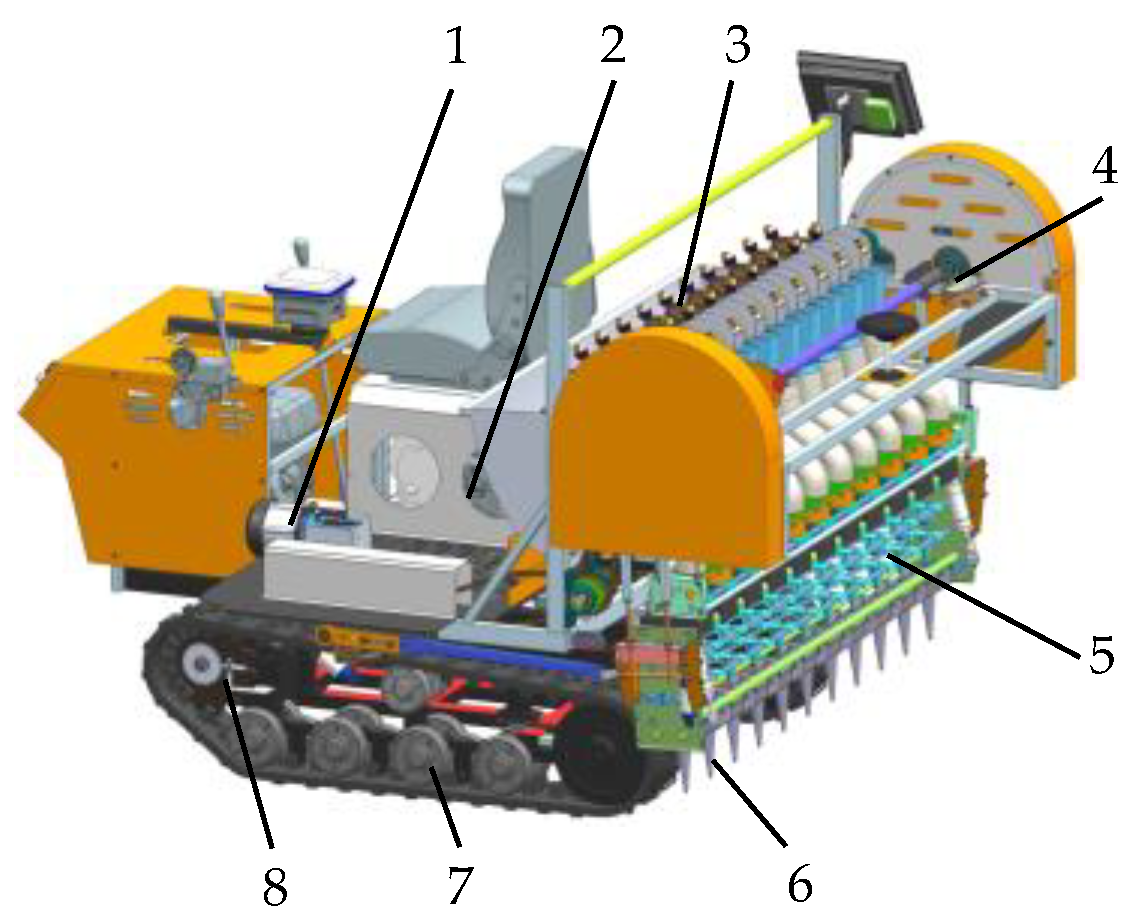

2.2. Seeding Experiment Platform and Control System

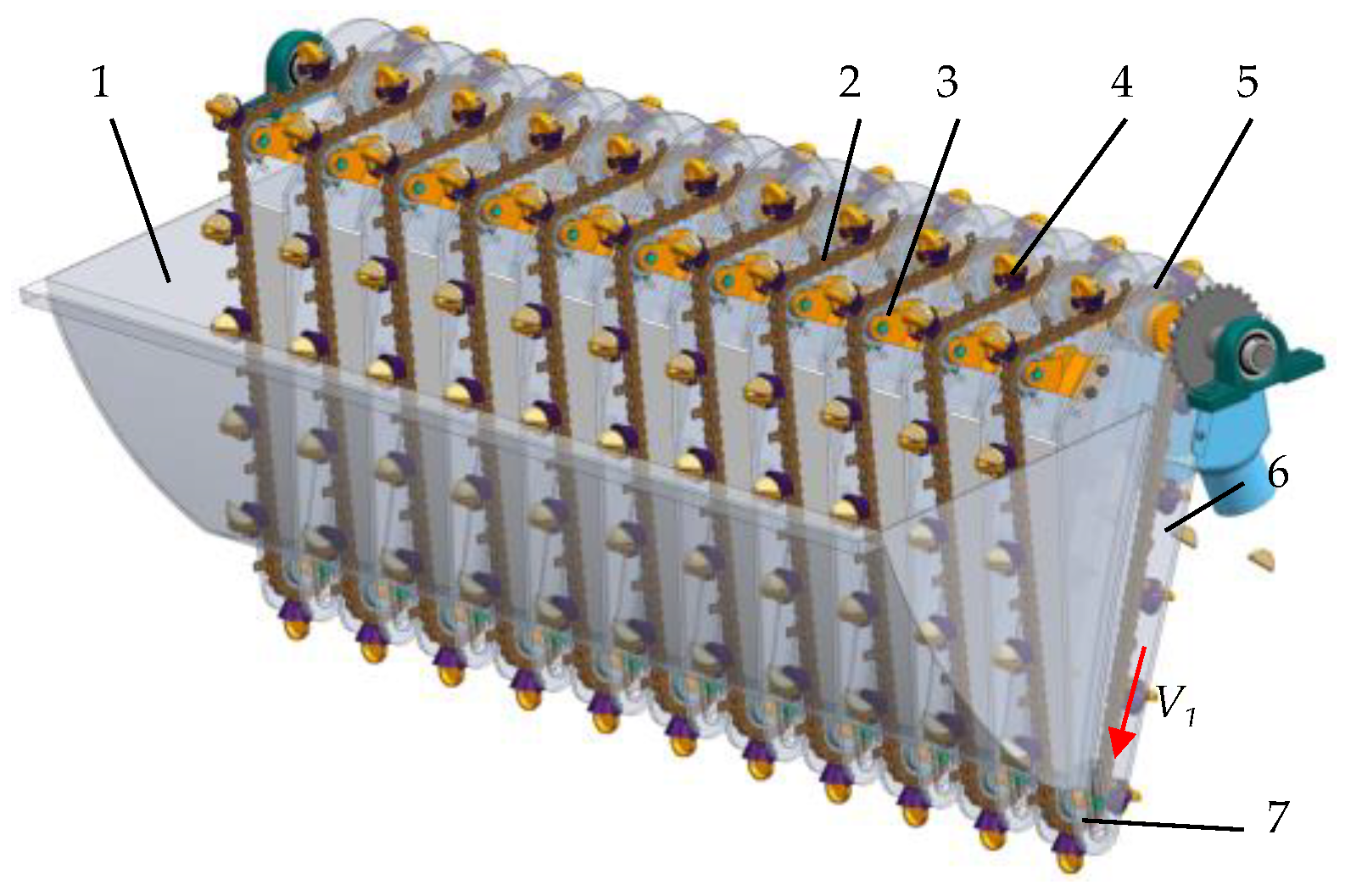

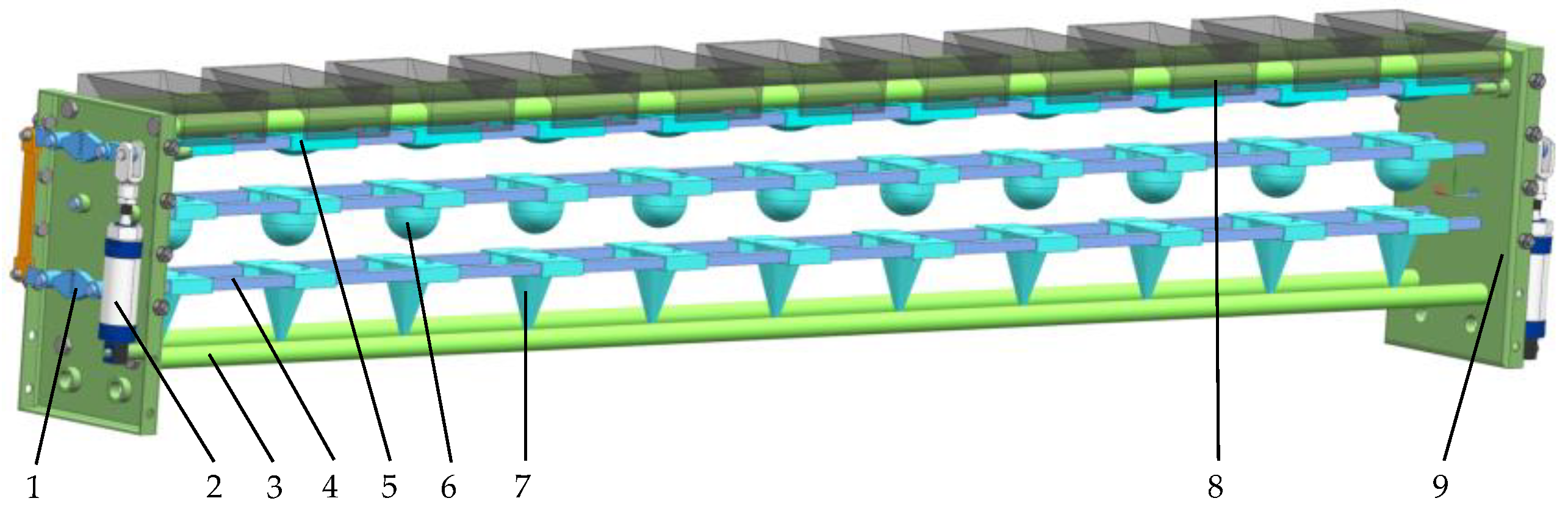

2.2.1. Experiment Platform

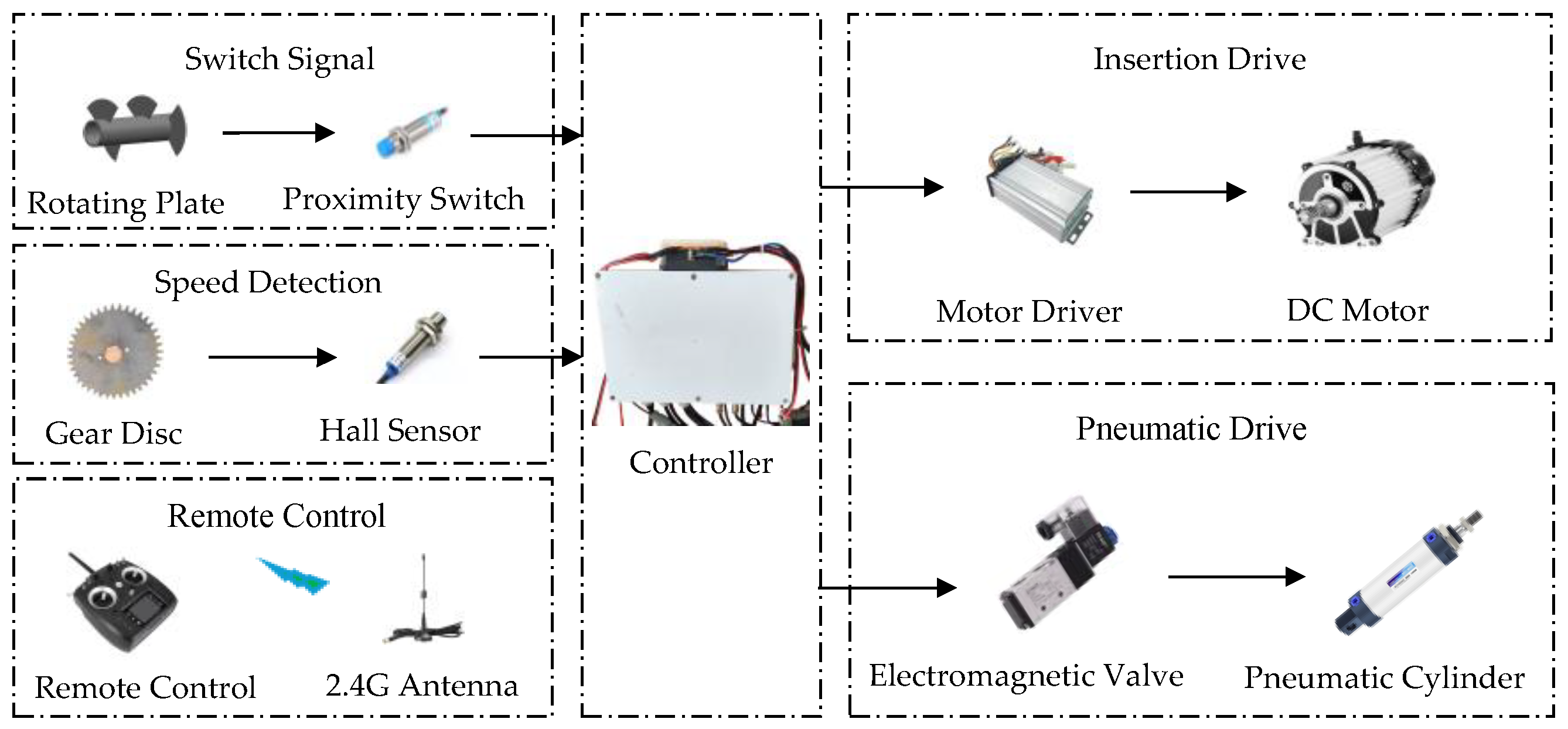

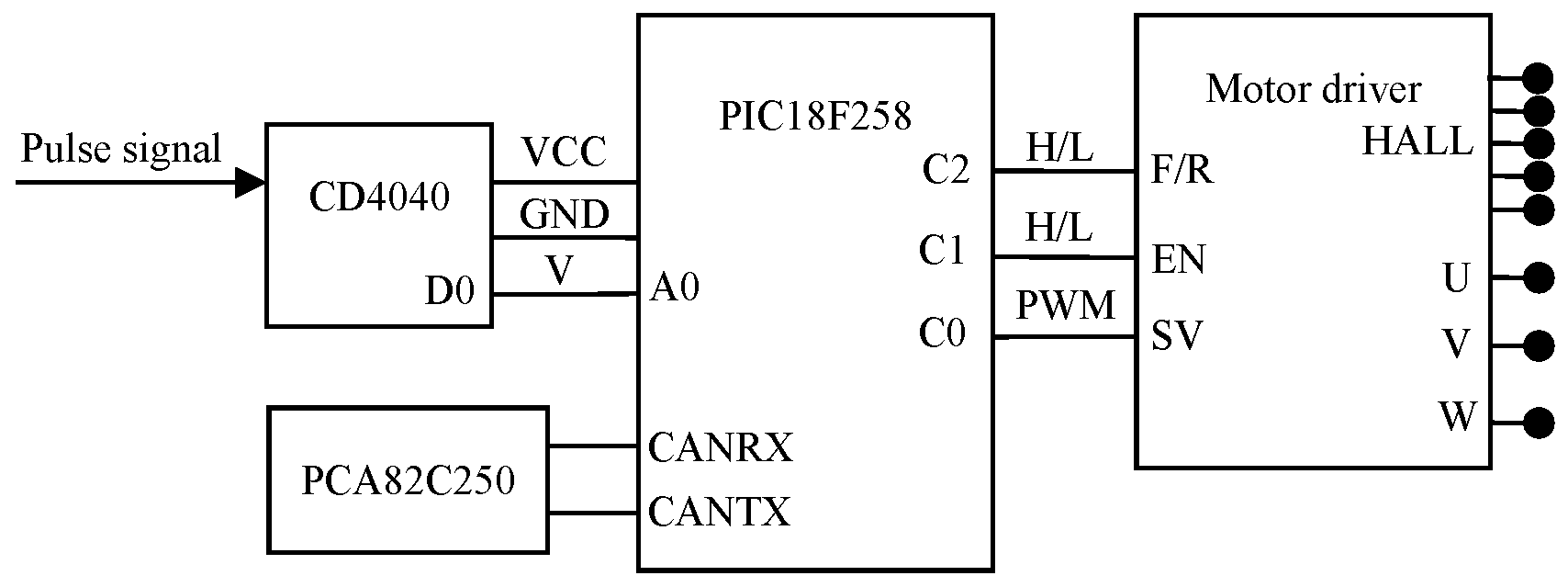

2.2.2. Control System

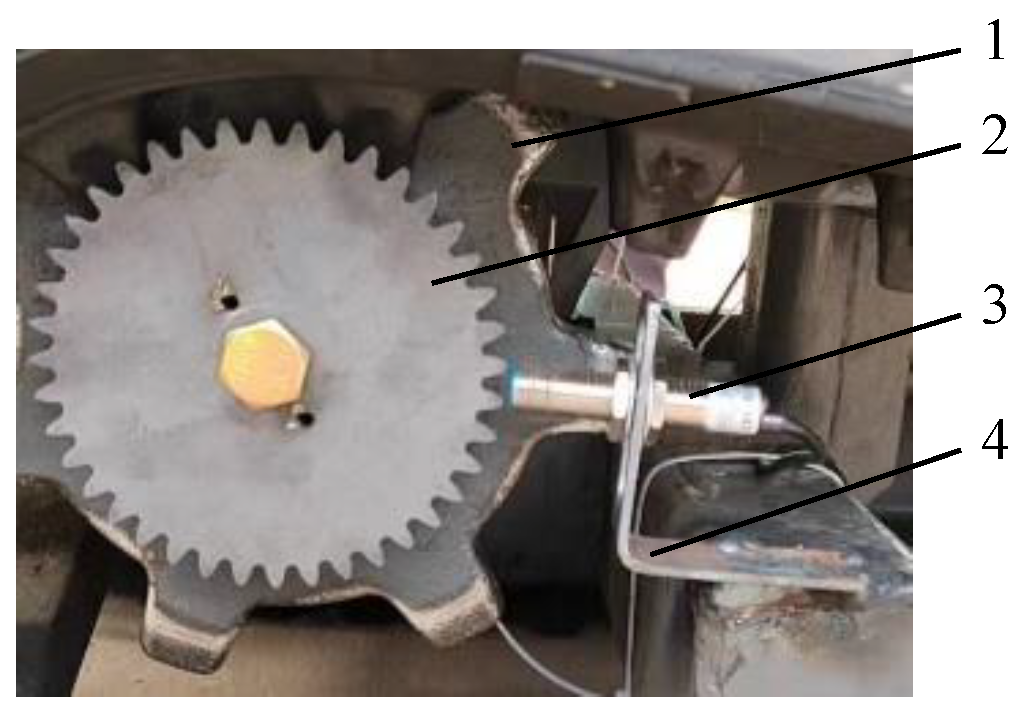

2.2.3. Speed Detection and Control

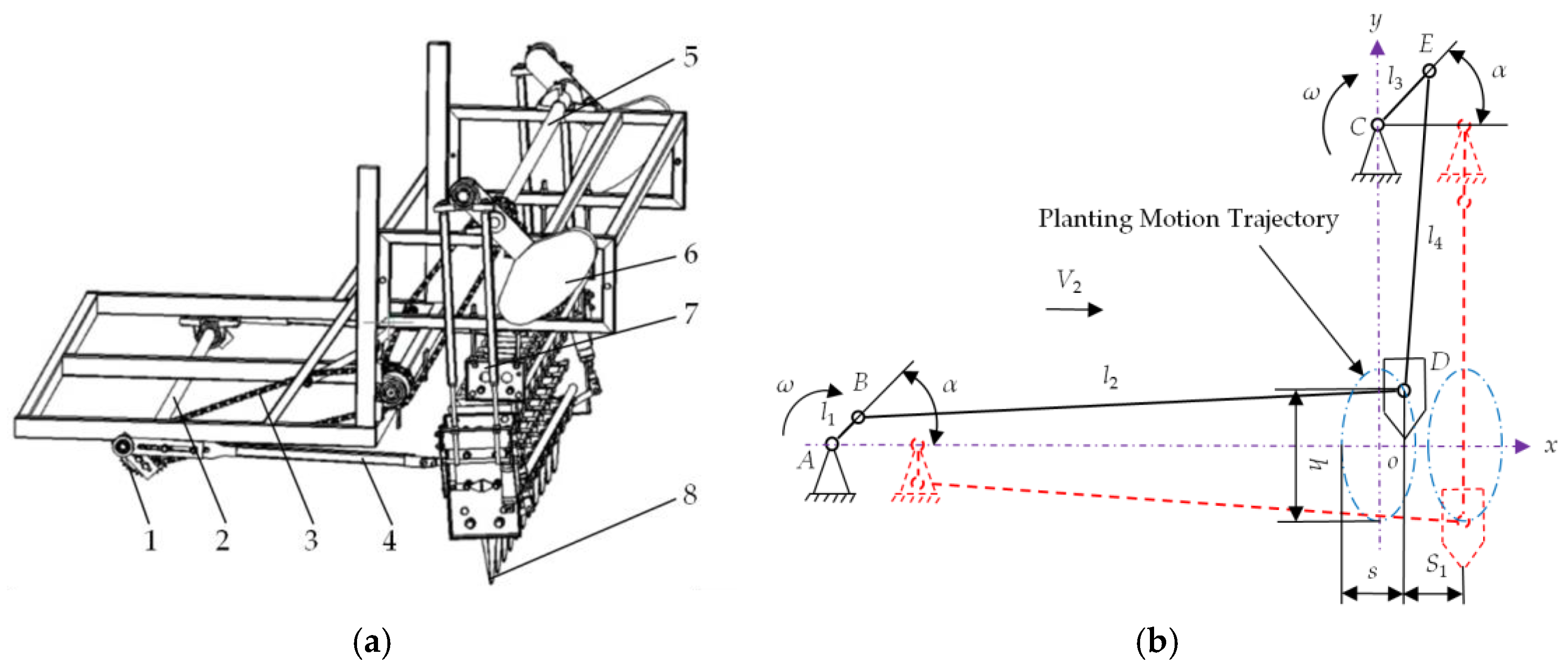

2.3. Design of the Insertion Planting Mechanism

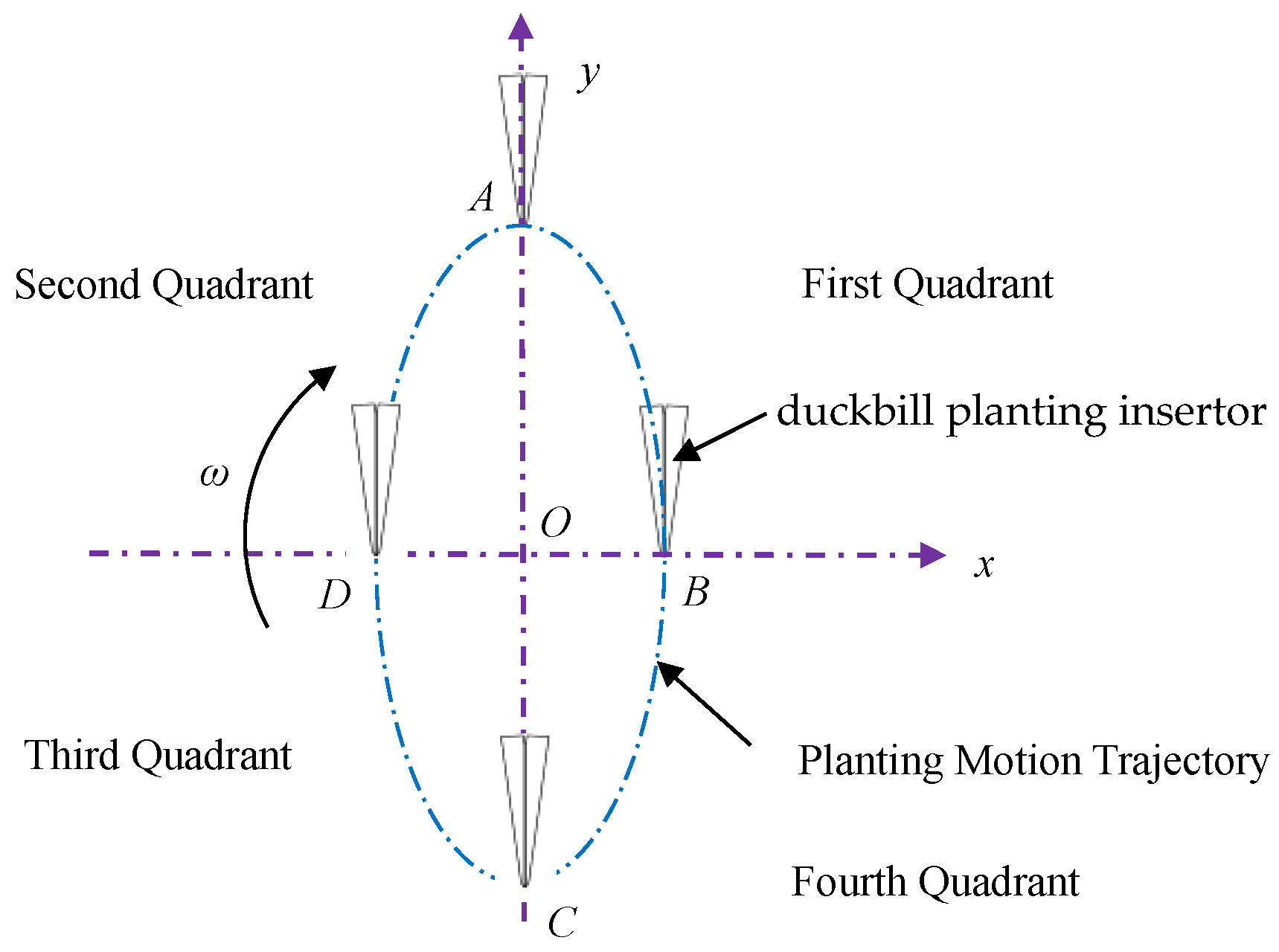

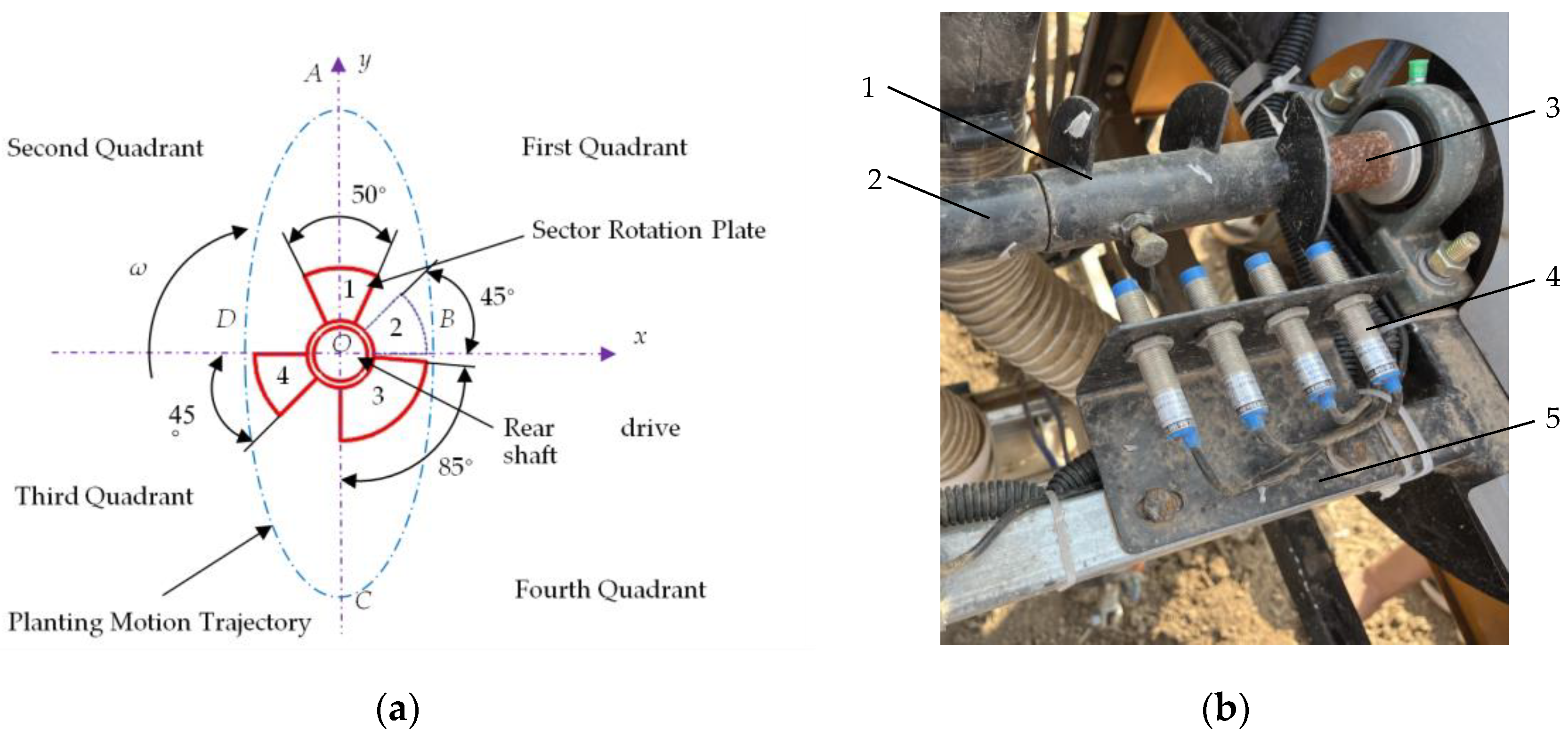

2.3.1. Kinematics Analysis of Insertion Mechanism

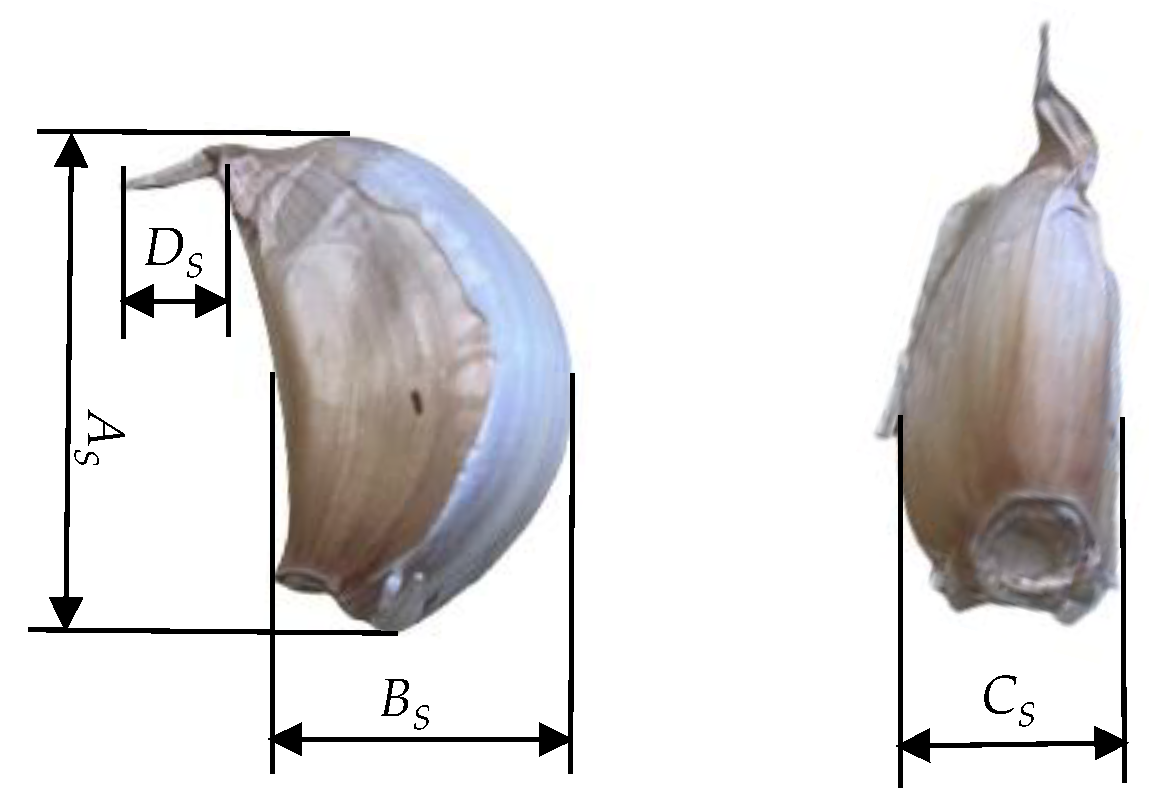

2.3.2. Design of the Single-Seed Extraction Mechanism

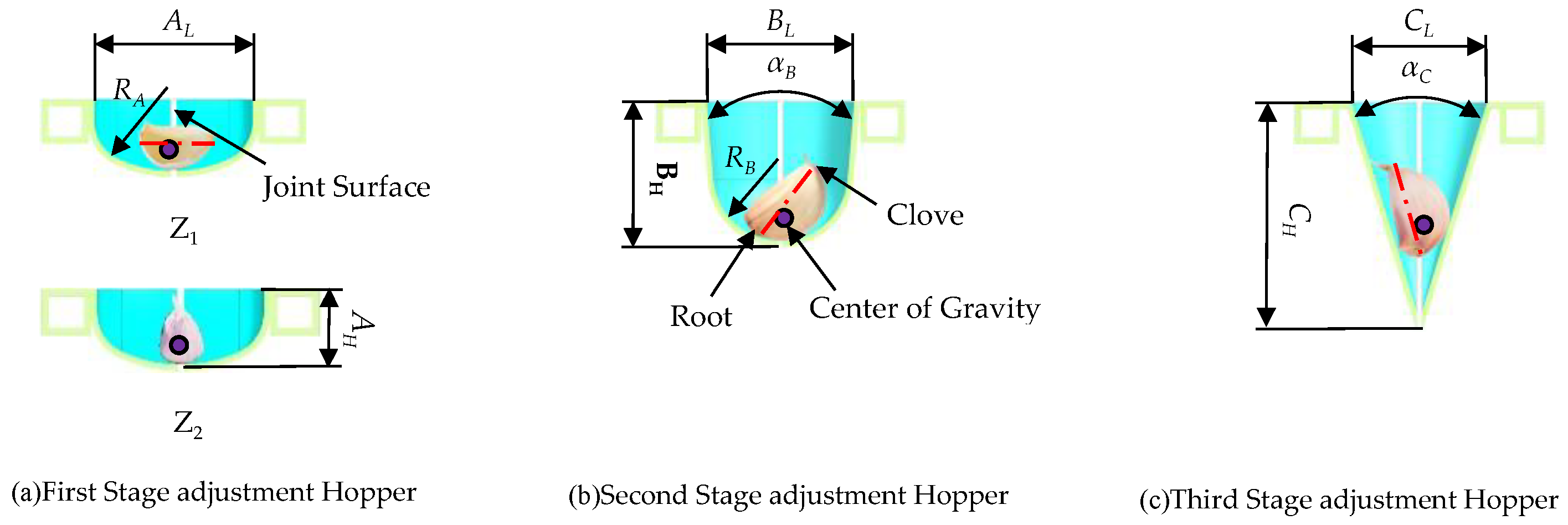

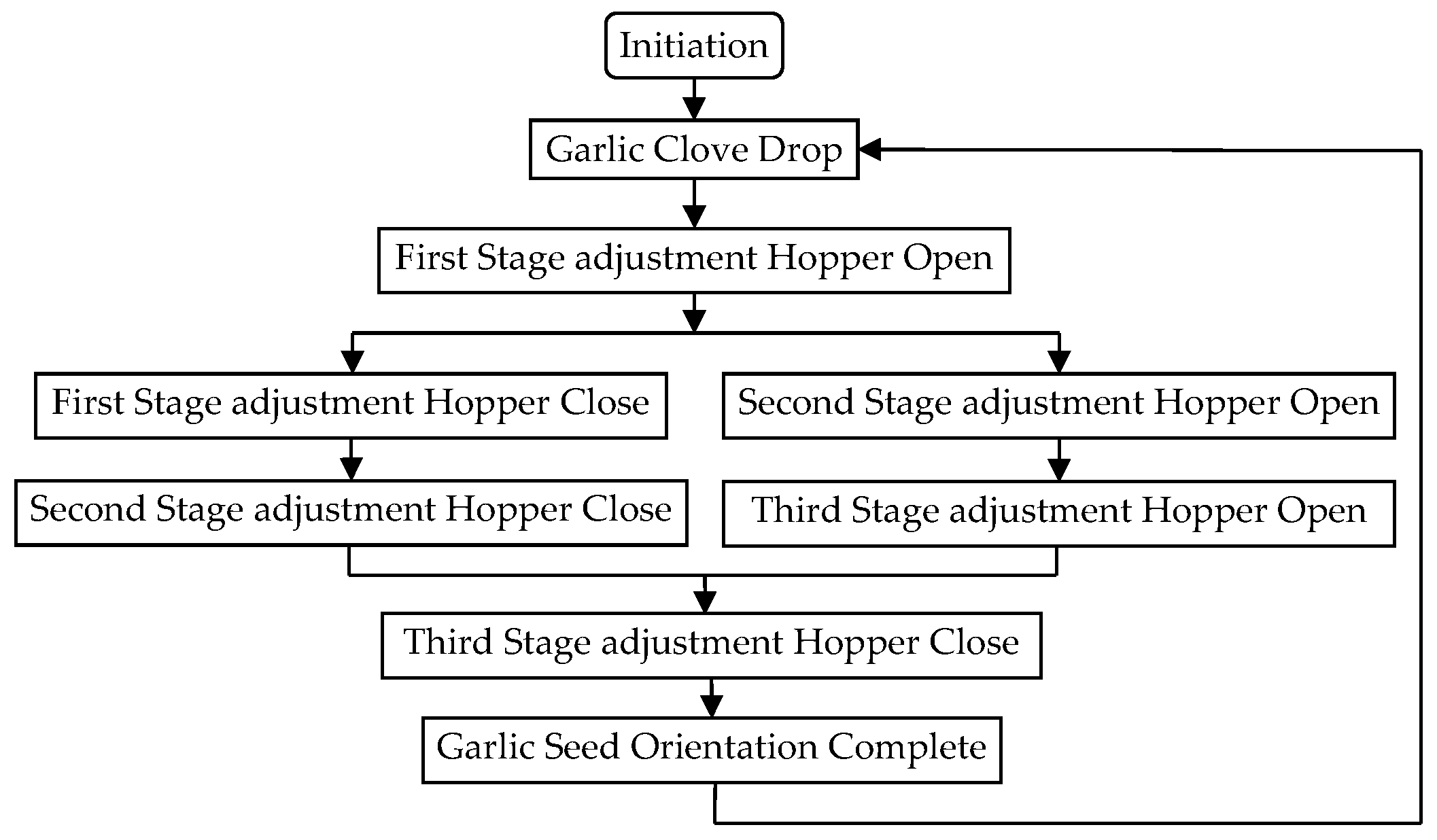

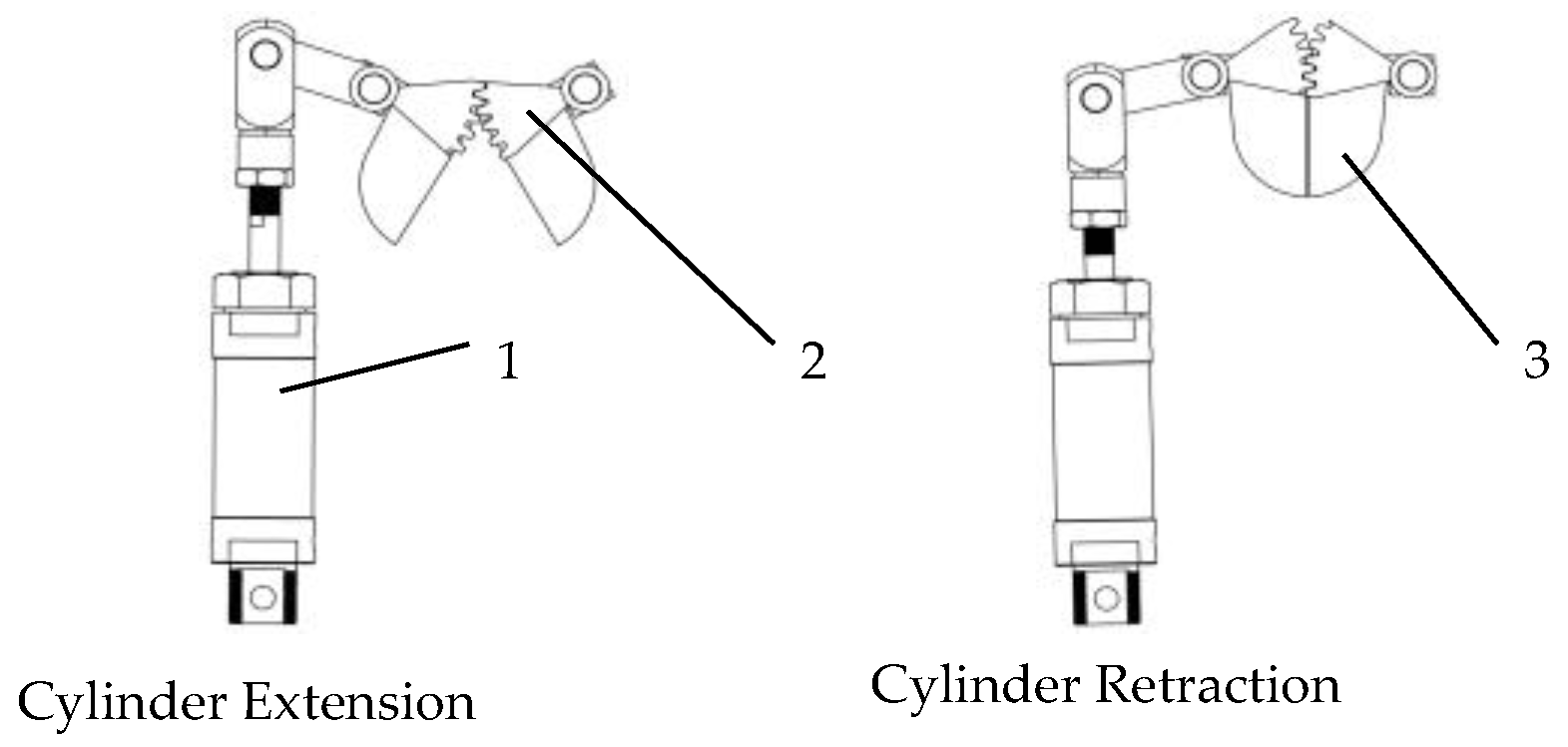

2.3.3. Design of the Adjustment Mechanism for Garlic Clove Direction

2.4. Timing Sequential Control Method

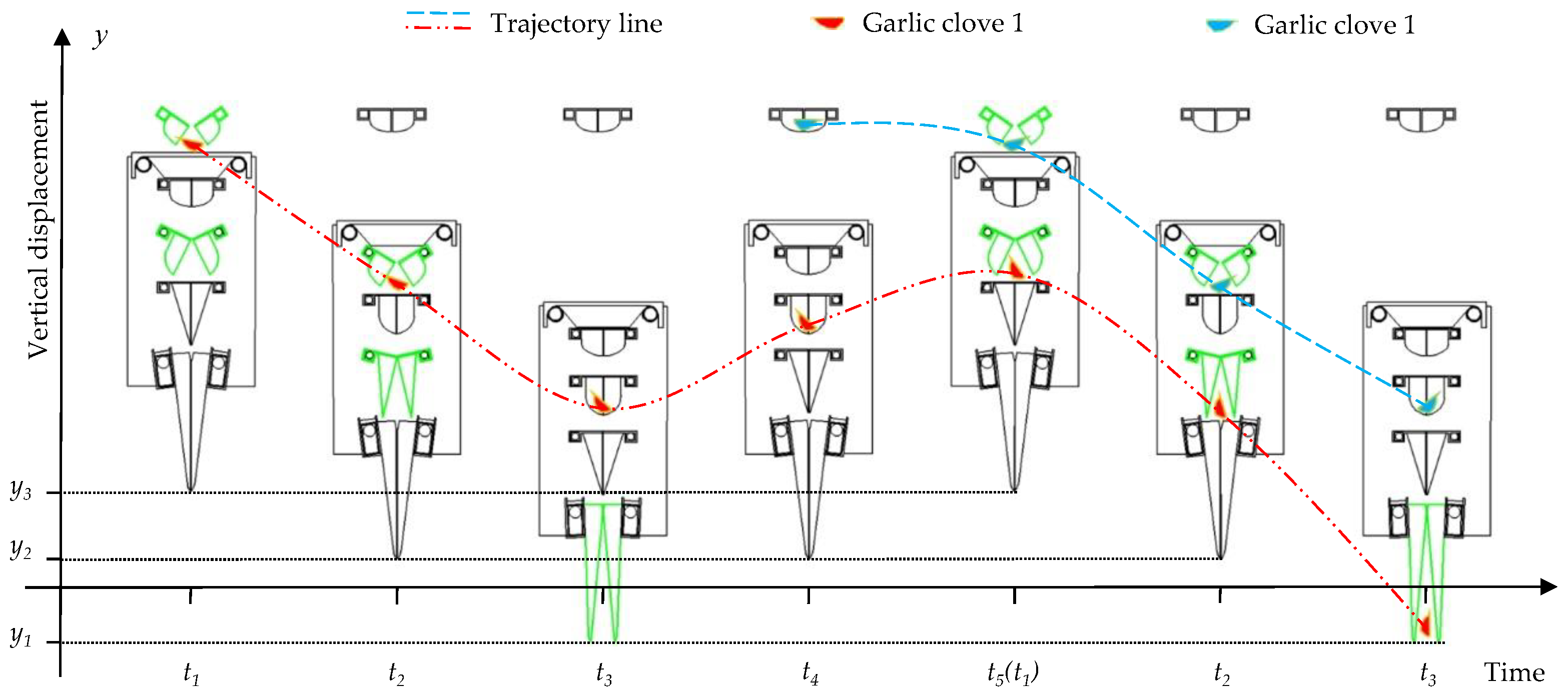

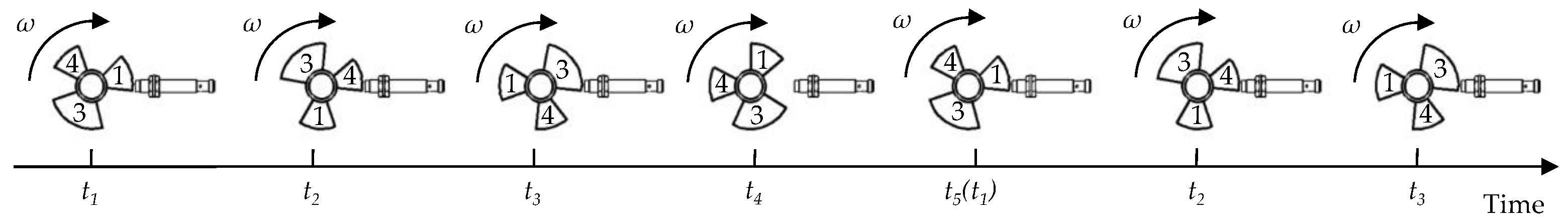

2.4.1. Time Sequence Control Method of Insertion of Planting Mechanism

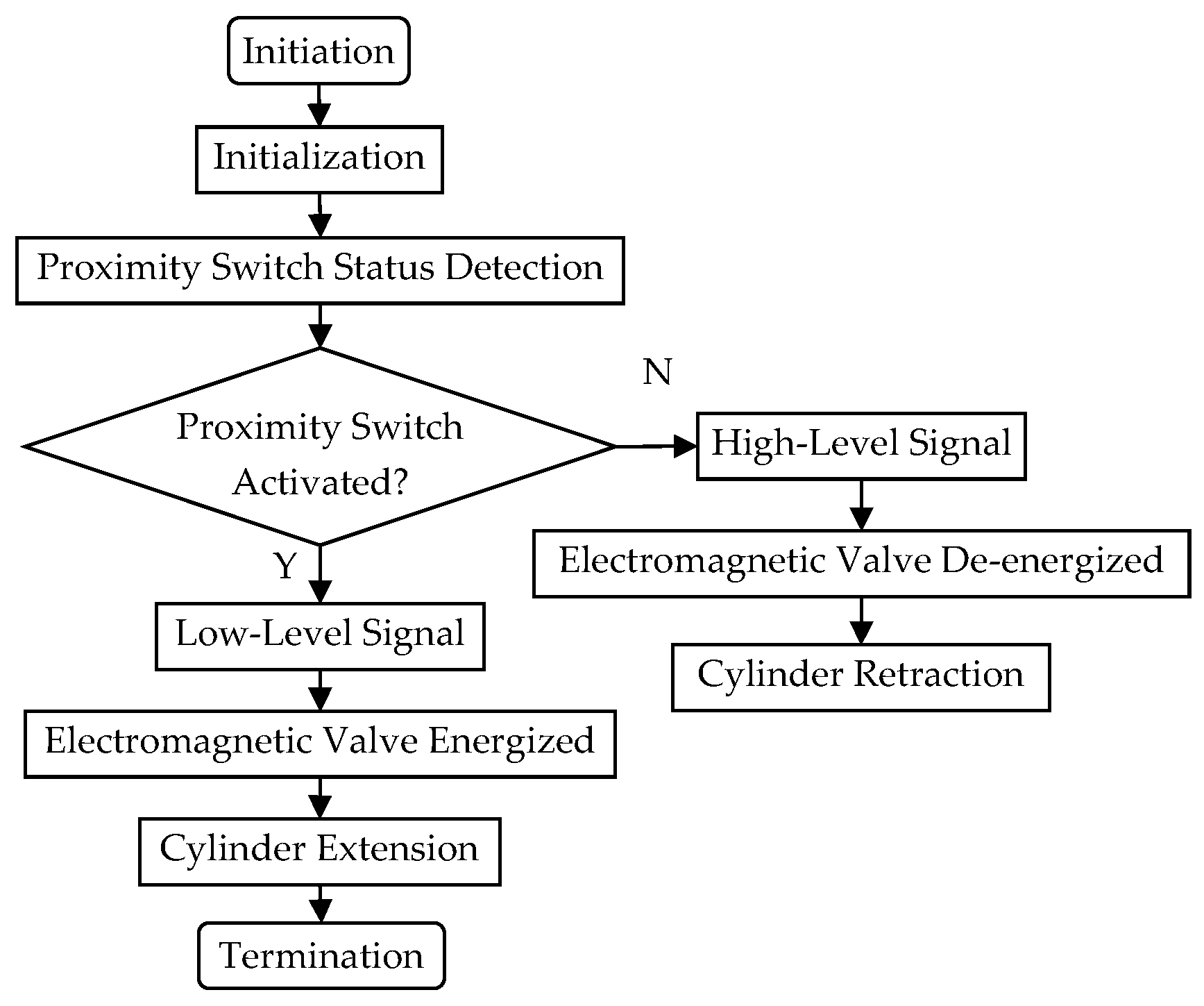

2.4.2. Design of the Time Sequence Signal

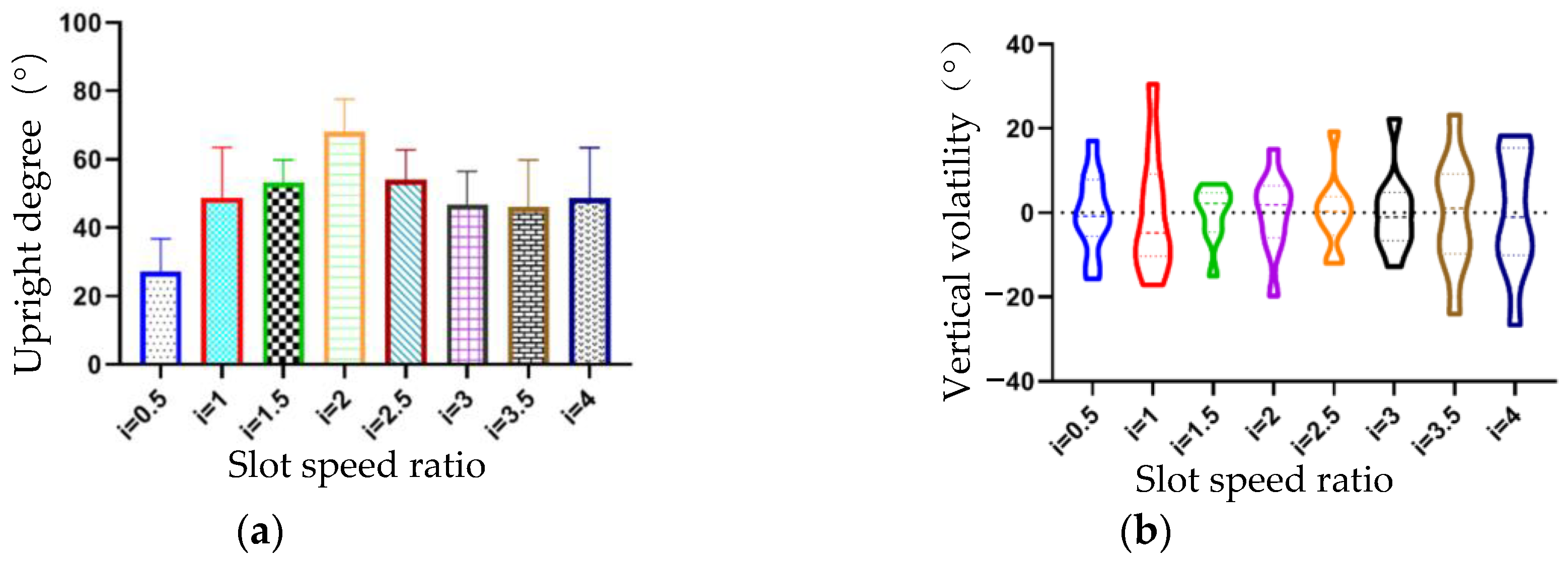

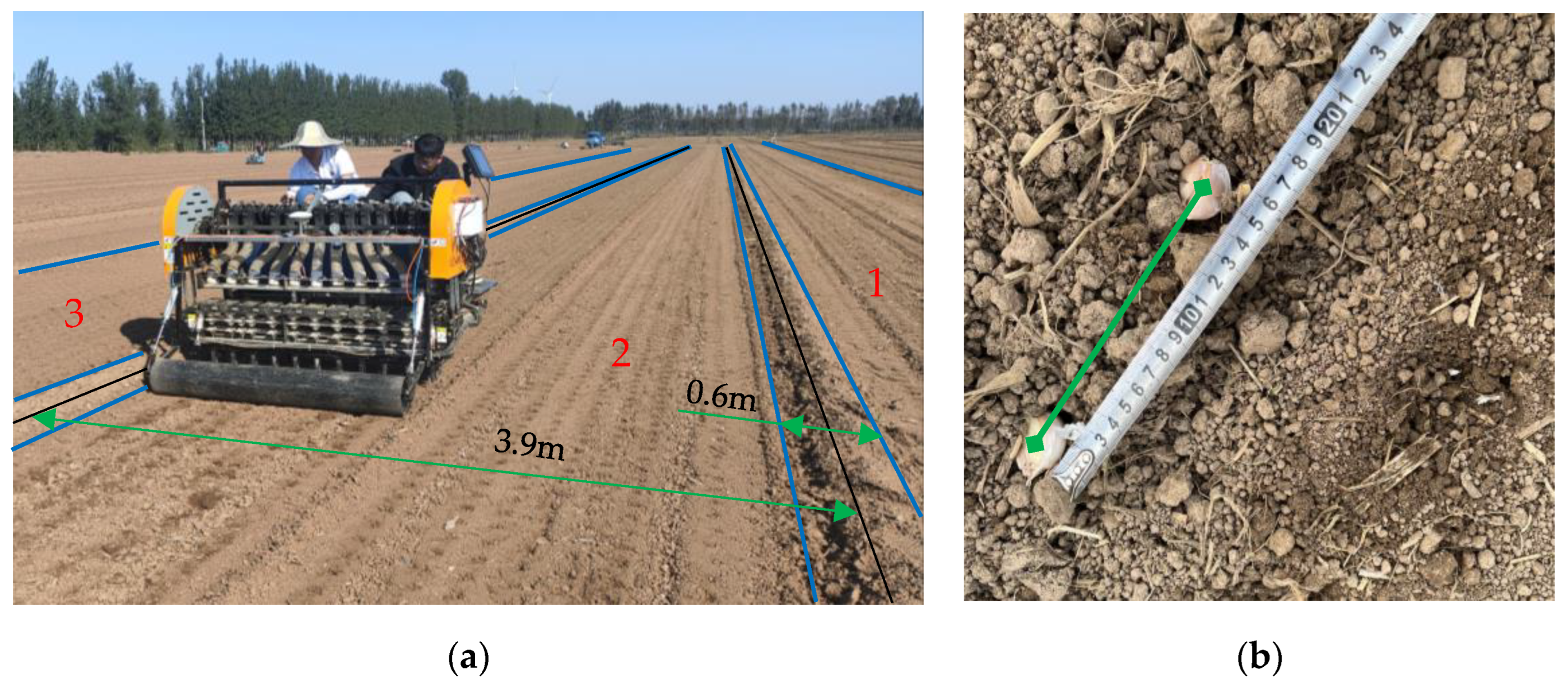

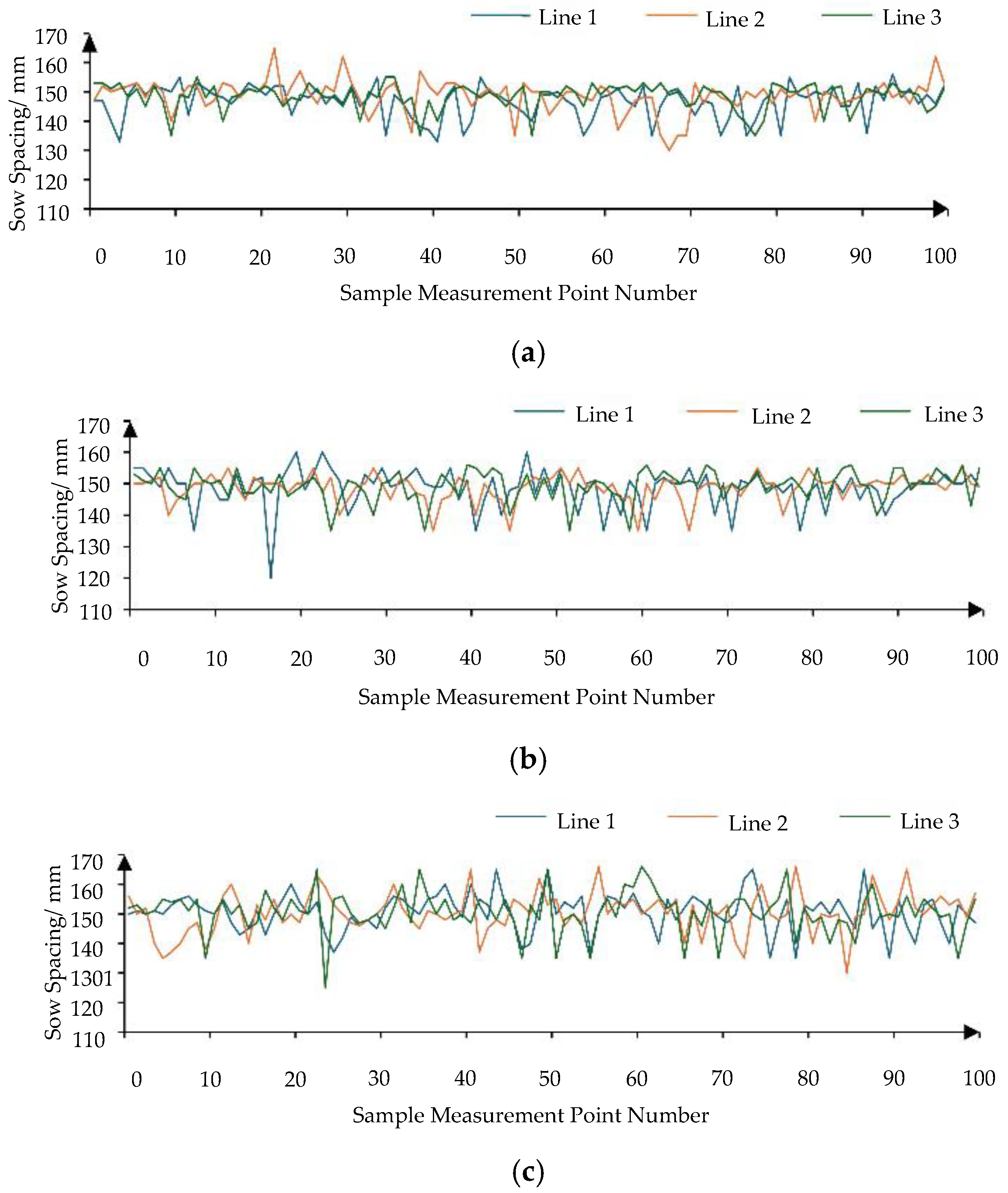

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Furdak, P.; Pieńkowska, N.; Bartosz, G.; Sadowska-Bartosz, I. Extracts of Common Vegetables Inhibit the Growth of Ovary Cancer Cells. Foods 2022, 11, 2518. [Google Scholar] [CrossRef]

- Thomas, A.; Boobyer, C.; Borgonha, Z.; van den Heuvel, E.; Appleton, K.M. Adding Flavours: Use of and Attitudes towards Sauces and Seasonings in a Sample of Community-Dwelling UK Older Adults. Foods 2021, 10, 2828. [Google Scholar] [CrossRef] [PubMed]

- Yang, X. Industrial status and development countermeasures of garlic industry in China. Chin. Fruit Veg. 2020, 40, 57–59. [Google Scholar]

- Li, C.; Feng, R.; Xu, H.; Sun, Q.; Song, J.; Jin, C. Research status and prospect of garlic seed classifier. J. Chin. Agric. Mech. 2021, 42, 91–96. [Google Scholar]

- Jin, C.Q.; Yuan, W.S.; Wu, C.Y.; Zhang, M. Experimental study on effects of the clove direction on garlic growth. Trans. Chin. Soc. Agric. Eng. 2008, 24, 155–158. [Google Scholar]

- Liu, J.; Qin, Y.; Wang, L.X.; Liu, Z.L.; Zhou, L.J.; Zhang, Y.F.; Liu, S.Q. Effects of different varieties and different planting patterns on the growth and quality and yield of aquicultural garlic seedlings. Acta Hortic. Sin. 2018, 45, 959–966. [Google Scholar]

- Geng, A.; Li, X.; Hou, J.; Zhang, Z.; Zhang, J.; Chong, J. Design and Test of Automatic Directional Garlic Planter. Trans. Chin. Soc. Agric. Eng. 2018, 34, 17–25. [Google Scholar]

- Han, Q.; Wang, X.; Hao, J.; Xie, L.; Yv, J. Design and Research of Inserting Hole Type Automatic Directional Garlic Planter. Agric. Mech. Res. 2016, 38, 172–175. [Google Scholar]

- Li, Y.; Niu, C.; Jia, S. Analysis of the Current Research Situation on Mechanized Garlic Seeding. Xinjiang Agric. Mech. 2021, 2, 29–33. [Google Scholar]

- Li, T.; Huang, S.; Niu, Z. Optimization and experiment of planting perpendicularity of planetary wheel garlic planter. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 37–45. [Google Scholar]

- Kim, L.H. Garlic Planter. KR20160007470A, 20 January 2016. [Google Scholar]

- Choi, D.-K.; Park, W.-K.; Kang, T.-G.; Park, S.-H.; Kim, H.-J.; Kwak, T.-Y.; Kim, Y.-K. Garlic Upright-Positioning and Planting Device. US2003084830A1, 8 May 2003. [Google Scholar]

- Kyoon, E.Y. Upright Arrangement Planter Device of Garlic Seed. KR20190126973A, 13 November 2019. [Google Scholar]

- Xie, D.; Zhang, C.; Wu, X. Design and Test of Garlic Seed Placer with Seed Disturbing Tooth Assisted Air Suction. Trans. Chin. Soc. Agric. Mach. 2022, 53, 47–57. [Google Scholar]

- Li, T.; Zhang, H.; Han, X.; Li, Y.; Hou, J.; Shi, G. Design and experiment of missing seed detection and the reseeding device for spoon chain garlic seeders. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2022, 38, 24–32. [Google Scholar]

- Li, Y.H.; Zhang, Z.L.; Li, T.H.; Hou, J.L. Design and experiment of wheel-spoon type garlic precision seed-picking device. Trans. Chin. Soc. Agric. Mach. 2020, 51, 61–68. [Google Scholar]

- Geng, A.J.; Li, X.Y.; Hou, J.J.; Zhang, J.; Zhang, Z.L.; Chong, J. Design and experiment of automatic garlic seed directing device. Int. J. Agric. Biol. Eng. 2020, 13, 85–93. [Google Scholar] [CrossRef]

- Hou, J.L.; Tian, L.; Li, T.H.; Niu, Z.R.; Li, Y.H. Design and experiment of test bench for garlic bulbil adjustment and seeding based on bilateral image identification. Trans. Chin. Soc. Agric. Eng. Trans. CSAE 2020, 36, 50–58. [Google Scholar]

- Cseresnyés, I.; Szitár, K.; Rajkai, K.; Füzy, A.; Mikó, P.; Kovács, R.; Takács, T. Application of electrical capacitance method for prediction of plant root mass and activity in field-grown crops. Front. Plant Sci. 2018, 9, 93. [Google Scholar] [CrossRef] [PubMed]

- Mohapatra, A.; Shanmugasundaram, S.; Malmathanraj, R. Grading of ripening stages of red banana using dielectric properties changes and image processing approach. Comput. Electron. Agric. 2017, 143, 100–110. [Google Scholar] [CrossRef]

- Akbari, A.; Kouravand, S. Developing a temperature measuring system model for agriculture dryer with consideration of fringing field effect in mathematical modeling. Comput. Electron. Agric. 2018, 146, 59–65. [Google Scholar] [CrossRef]

- Zhu, Z.; Cao, X.; Zhang, R. Optimal design of garlic clove’s orientation adjustment system based on parallel robot. J. Intell. Agric. Mech. 2023, 4, 20–25. [Google Scholar]

- Wang, X.; Cui, R.; Xu, W.; Jian, S.; Ma, J. A Garlic Seed Bud Direction Adjusting Device for Garlic Seeder. Chinese Invention Patent No. CN201420650675.6, 11 March 2015. [Google Scholar]

- Liu, J.; Geng, A.; Li, X.; Hou, J.; Han, X. Research status of garlic planting machine single seed-filling and resow. Agric. Mech. Res. 2019, 41, 262–268. [Google Scholar]

- Wei, H.; Wang, X.; Chen, J. Discussion on the present situation and development of mechanized garlic production in China. J. Chin. Agric. Mech. 2022, 43, 175–182. [Google Scholar]

- Li, X.; Geng, A.; Hou, J.; Zhang, M.; Zhang, J.; Li, W. Research status and prospect of garlic planter. Farm Mac. 2017, 2, 105–107. [Google Scholar]

- Li, Y.; Chen, J.; Liang, Z.; Ma, X.; Jiang, X. Design and Experiment of Differential Steering Mechanism for Track Combine Harvester. Trans. Chin. Soc. Agric. Mach. 2016, 47, 127–134. [Google Scholar]

- Pan, G.; Yang, F.; Sun, J.; Liu, Z. Analysis and Test of Obstacle Negotiation Performance of Small Hillside Crawler Tractor during Climbing Process. Trans. Chin. Soc. Agric. Mach. 2020, 51, 374–383. [Google Scholar]

- Shi, S.; Zhang, D.; Yang, L.; Cui, T.; Li, K.; Yin, X. Simulation and verification of the filling performance of the pneumatic combined hole-type seed metering device based on EDEM software. Trans. Chin. Soc. Agric. Eng. 2015, 31, 62–69. [Google Scholar]

- Furuhata, M.; Chosa, T.; Shioya, Y.; Tsukamoto, T.; Seki, M.; Hosokawa, H. Developing Direct Seeding Cultivation Using an Air-Assisted Strip Seeder. Jpn. Agric. Res. Q. 2015, 49, 227–233. [Google Scholar] [CrossRef]

- Ling, L.; Xiao, Y.; Huang, X.; Wu, G.; Li, L.; Yan, B.; Geng, D. Design and Testing of Electric Drive System for Maize Precision Seeder. Agriculture 2024, 14, 1778. [Google Scholar] [CrossRef]

- Miao, W.; Zhou, Z.; Xuan, J.; Cheng, D.; Cao, N. Design and simulation of ball balancing robot controller based on fuzzy PID. Transducer Microsyst. Technol. 2021, 40, 66–70. [Google Scholar]

- Fotuhi, M.J.; Ben Hazem, Z.; Bingül, Z. Modelling and Torque Control of an Non—Linear Friction Inverted Pendulum driven with a Rotary Series Elastic Actuator. In Proceedings of the 2019 3rd International Symposium on Multidisciplinary Studies and Innovative Technologies (ISMSIT), Ankara, Turkey, 11–13 October 2019; pp. 1–6. [Google Scholar]

- Lai, Q.; Jia, G.; Su, W. Design and Test of Chain-spoon Type Precision Seed-metering Device for Ginseng Based on DEM-MBD Coupling. Trans. Chin. Soc. Agric. Mach. 2022, 53, 91–104. [Google Scholar]

- Li, M.; Wu, F.; Wang, F.; Zou, T.; Li, M.; Xiao, X. CNN-MLP-Based Configurable Robotic Arm for Smart Agriculture. Agriculture 2024, 14, 1624. [Google Scholar] [CrossRef]

| Project Title | Unit | Project Parameters |

|---|---|---|

| Machine dimensions (length × width × height) | m | 2.4 × 1.9 × 1.4 |

| Power | kW | 8 |

| Operating Speed | m·s−1 | 8–12 |

| Sowing efficiency | m2·h−1 | 500–600 |

| Rows | Row | 11 |

| Row spacing | mm | 90–500 (Adjustable) |

| Sowing spacing | mm | 60–200 (Adjustable) |

| Sowing depth | mm | 30–60 (Adjustable) |

| Parameter Name | Parameter Meaning | Value |

|---|---|---|

| l1 | Length of active swing arm AB | 50–100 mm (Adjustable) |

| l3 | Length of active swing arm CE | 100 mm |

| α | The rotation angle of the active swing arm | 0–360° |

| hmax | The maximum height of the implanted device in the Y-axis direction | 2l3 |

| smax | The maximum displacement of the implant in the X-axis direction | 2l1 |

| V2 | Planter advance speed | 0–0.2 m/s (Adjustable) |

| β | The angle of the fan rotation plate | 50°, 45°, 85° |

| T | Insertion cycle | According to the operation speed and planting spacing |

| Operating Speed/m·s−1 | Sowing Spacing Deviation Error | Missing Seeding Rate/% | Upright Rate/% | Single-Seed Rate/% | |||

|---|---|---|---|---|---|---|---|

| Maximum /mm | Average /mm | RMS /mm | Coefficient of Variation | ||||

| 0.10 | 22 | 3.8 | 5.7 | 0.038 | 2.3 | 87.3 | 91.7 |

| 0.15 | 30 | 3.4 | 5.2 | 0.035 | 2.7 | 86.3 | 90.7 |

| 0.20 | 27 | 4.9 | 6.8 | 0.046 | 3.3 | 85.3 | 90.3 |

| 0.25 | 38 | 4.3 | 10.2 | 0.058 | 5.3 | 72.3 | 86.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, G.; Yao, Y.; Yi, L.; Yin, X.; Du, J.; Chong, J. Automatic Precision Planting Mechanism of Garlic Seeder. Agriculture 2025, 15, 849. https://doi.org/10.3390/agriculture15080849

Chen G, Yao Y, Yi L, Yin X, Du J, Chong J. Automatic Precision Planting Mechanism of Garlic Seeder. Agriculture. 2025; 15(8):849. https://doi.org/10.3390/agriculture15080849

Chicago/Turabian StyleChen, Guilin, Yifan Yao, Lili Yi, Xiang Yin, Juan Du, and Jun Chong. 2025. "Automatic Precision Planting Mechanism of Garlic Seeder" Agriculture 15, no. 8: 849. https://doi.org/10.3390/agriculture15080849

APA StyleChen, G., Yao, Y., Yi, L., Yin, X., Du, J., & Chong, J. (2025). Automatic Precision Planting Mechanism of Garlic Seeder. Agriculture, 15(8), 849. https://doi.org/10.3390/agriculture15080849