Effects of Different Biomass Types on Pellet Qualities and Processing Energy Consumption

Abstract

1. Introduction

2. Materials and Methods

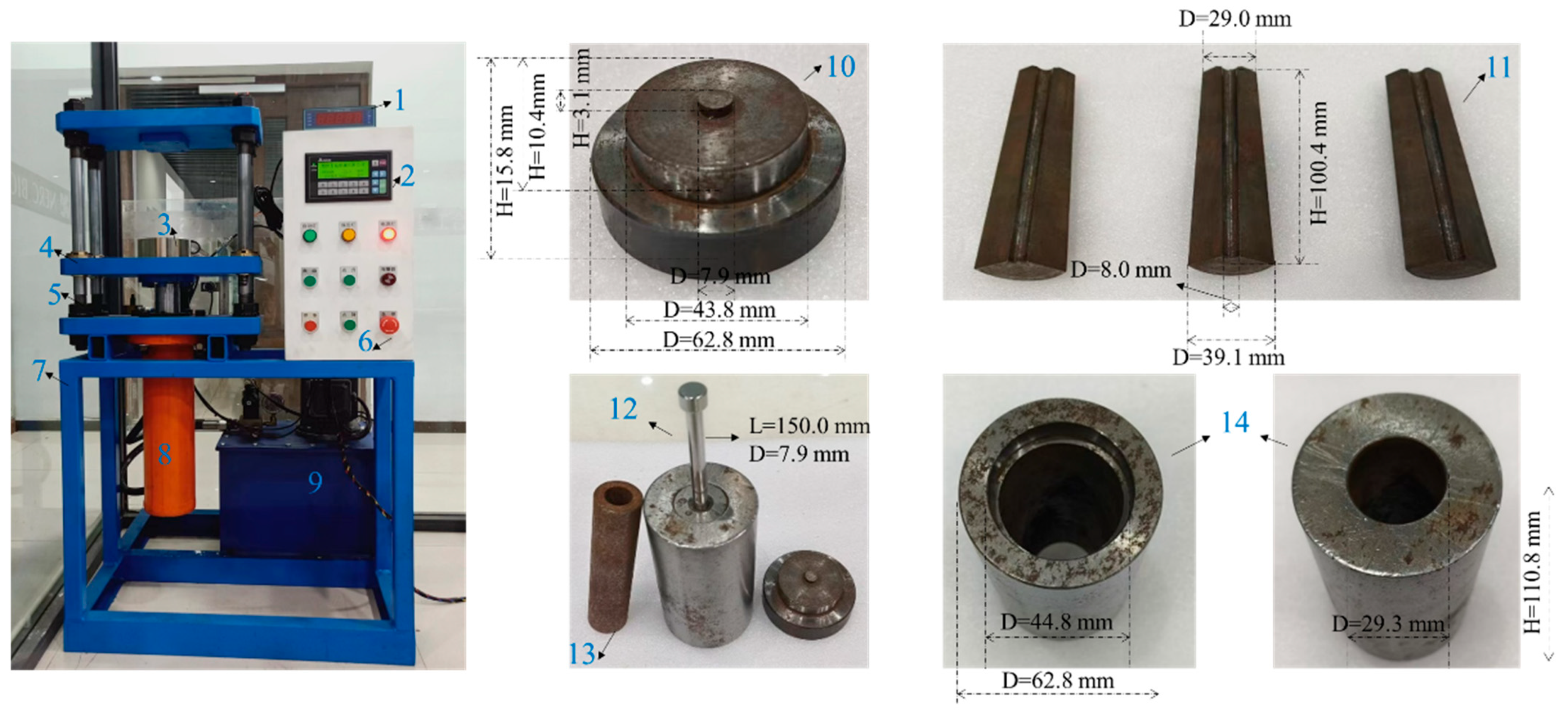

2.1. Experimental Materials and Equipment

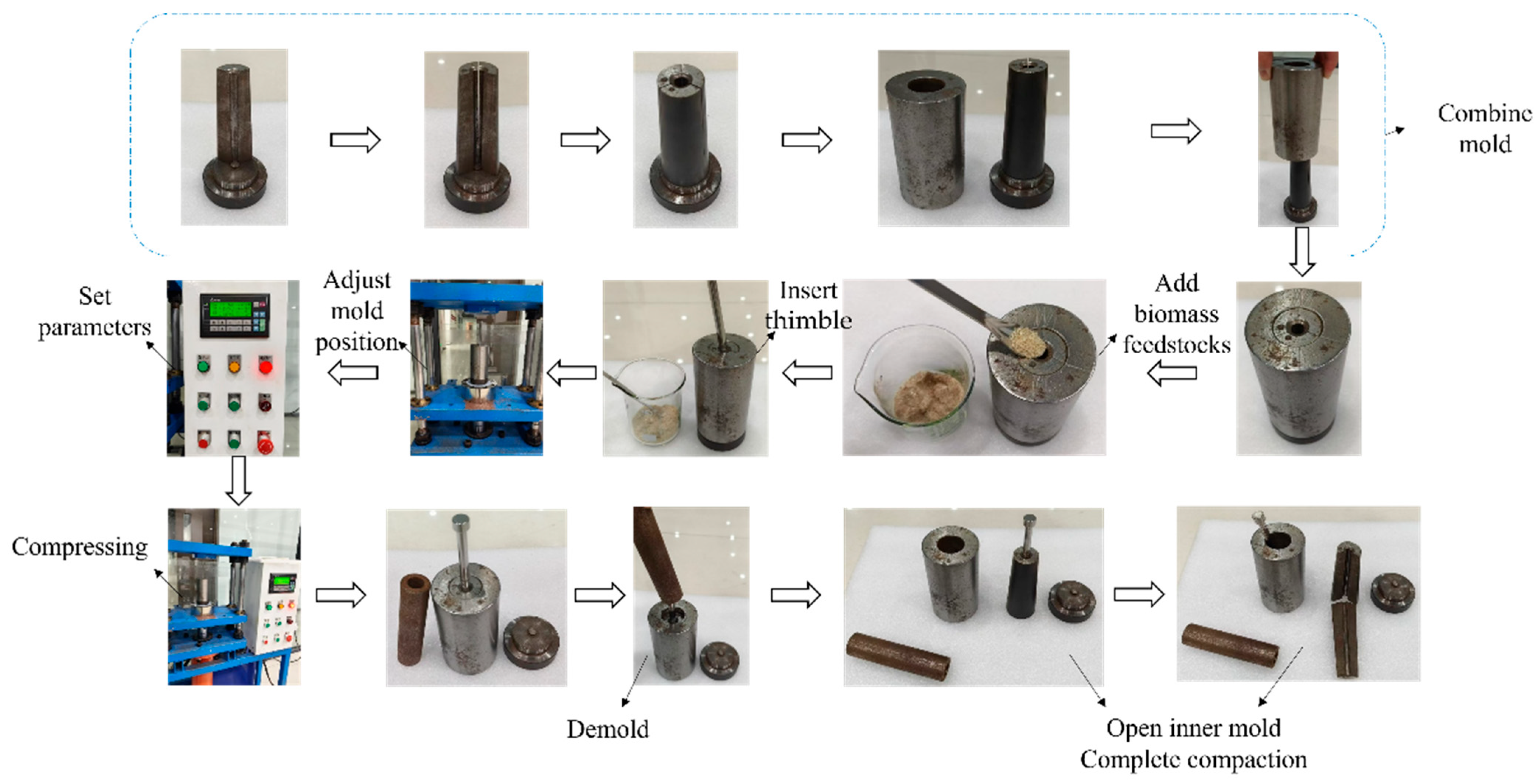

2.2. Compressing Methods

- (1)

- The biomass feedstocks should be added to the compressing mold; then, gently tap it.

- (2)

- Place the compressing mold on the workbench, adjust the vertical alignment of the thimble with the mold, keeping the end of the thimble at the same level as the top of the mold, and then set the parameters to the automatic compressing.

- (3)

- The compression should be carried out at a speed of 2.0 mm/s. Stop when the set displacement value should be reached, and maintain it for 10 s (to inhibit the rebound effect); then, the compressing force should be recorded.

- (4)

- Use the mold opener to demold, and gently tap the inner mold to ensure the integrity of the pellets with small cylinders.

- (5)

- An analytical balance with an accuracy of ±0.001 g should be used to measure the mass of pellets, and the electronic caliper with an accuracy of ±0.01 mm should be used to measure the diameter and length. Finally, the processing energy consumption is evaluated.

2.3. Determination of Physicochemical Properties of Biomass Feedstocks

2.3.1. Determination of Proximate Analysis

2.3.2. Determination of Ultimate Analysis

2.3.3. Determination of Calorific Value

2.3.4. Determination of Bulk Density and Tap Density

2.4. Evaluation Indicators and Measurement Methods for Biomass Pellets

2.4.1. Determination of Compaction Density

2.4.2. Determination of Volume Expansion

2.4.3. Determination of Durability

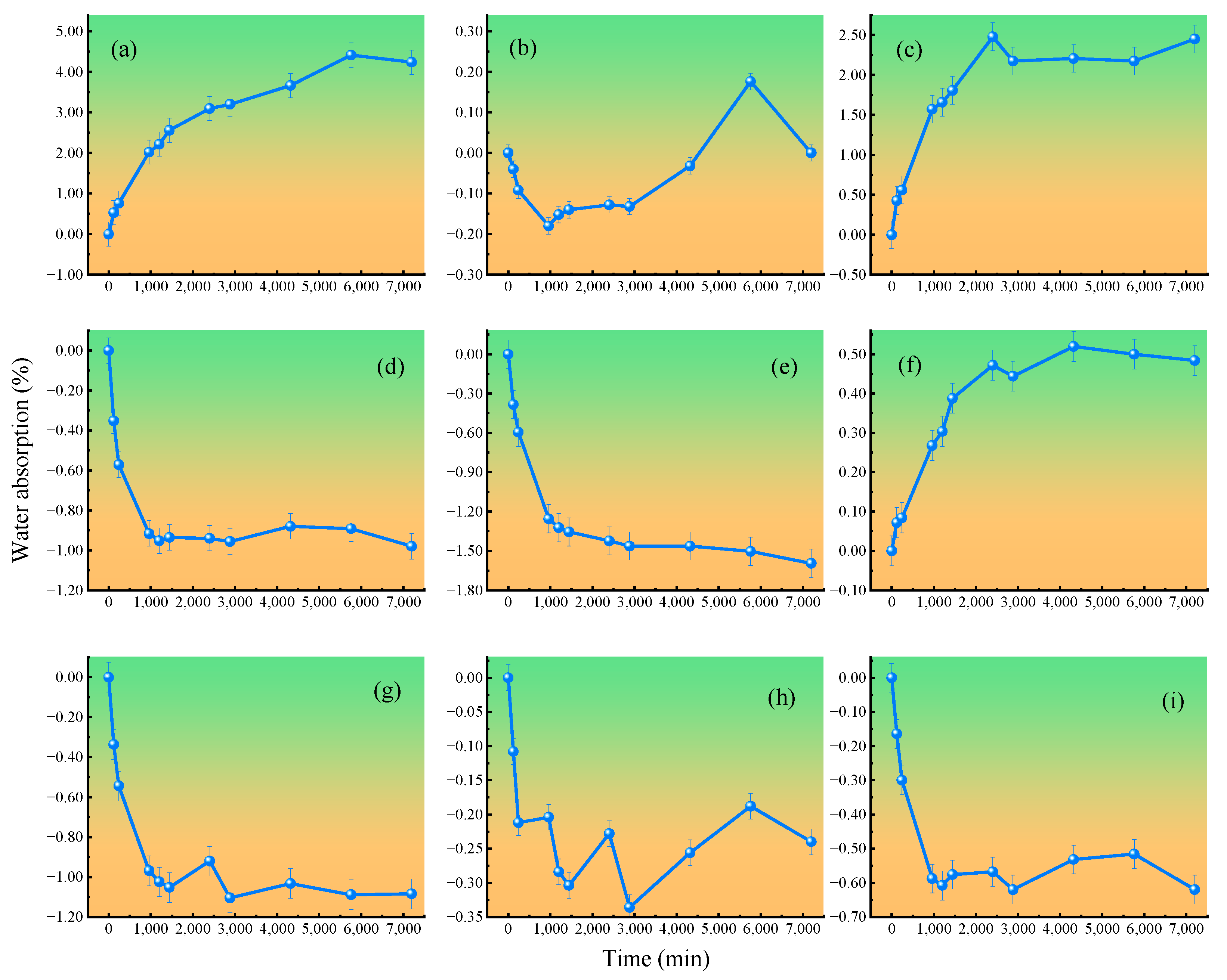

2.4.4. Determination of Hydrophobicity

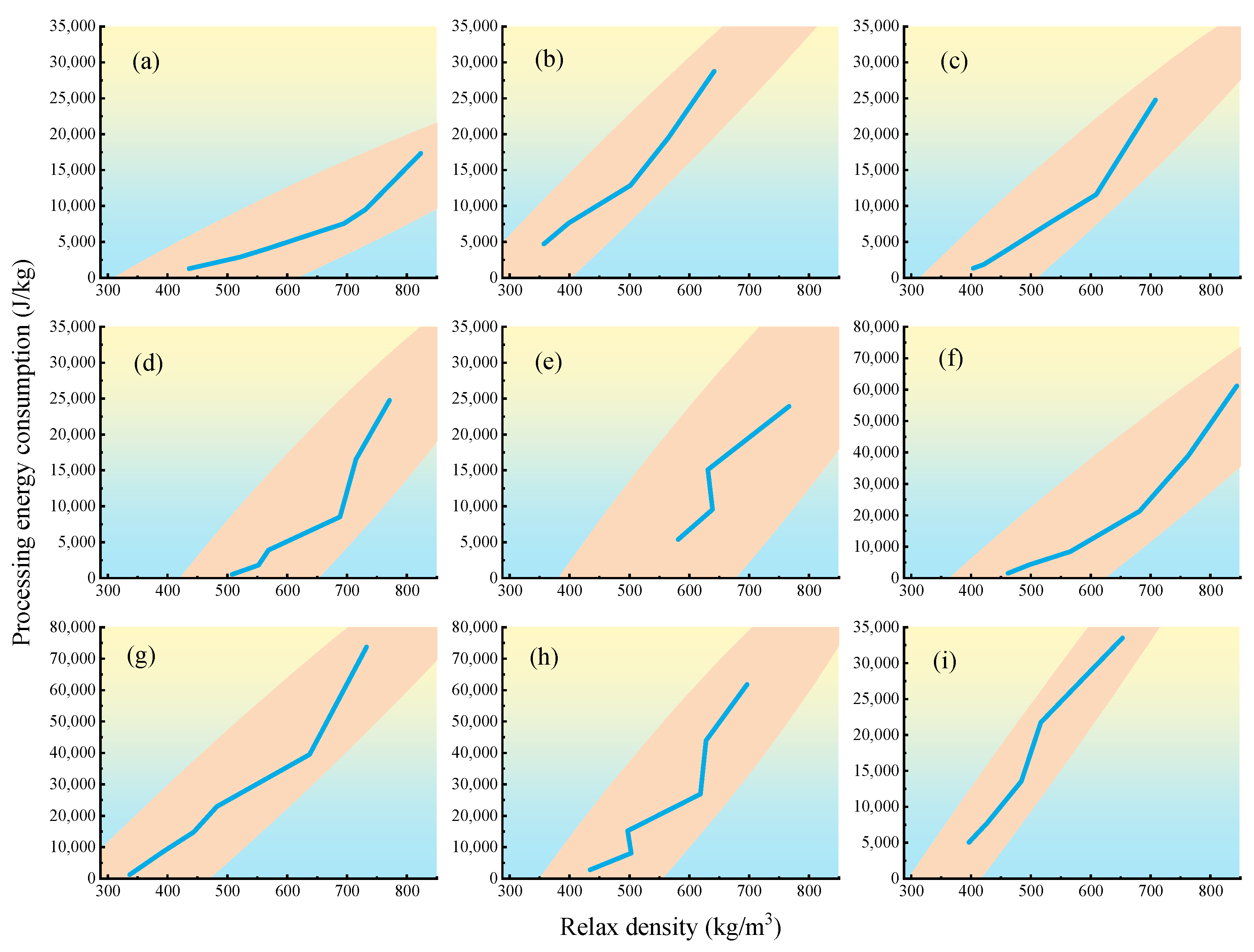

2.4.5. Determination of Processing Energy Consumption

3. Results and Discussion

3.1. Physicochemical Properties of Biomass Feedstocks

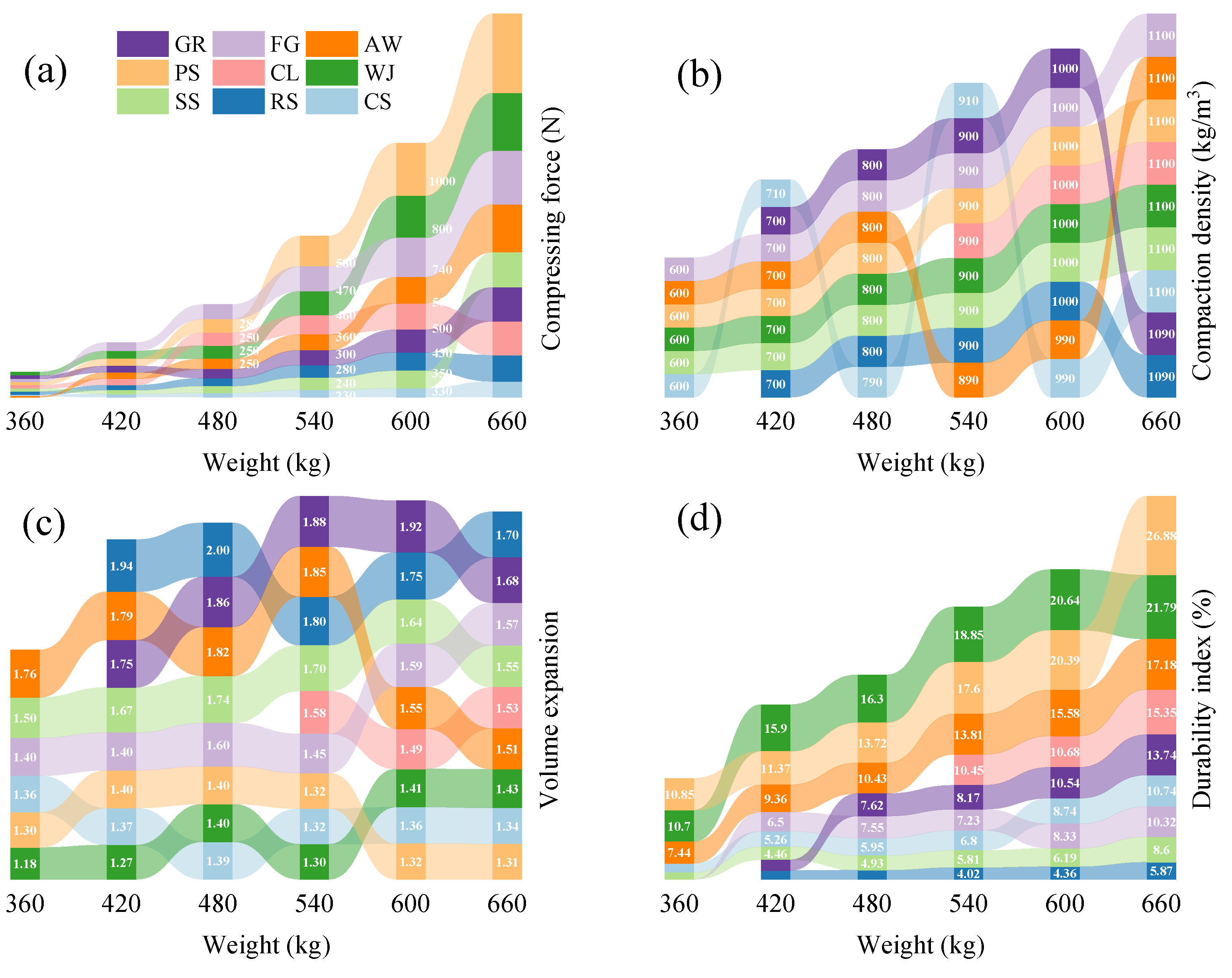

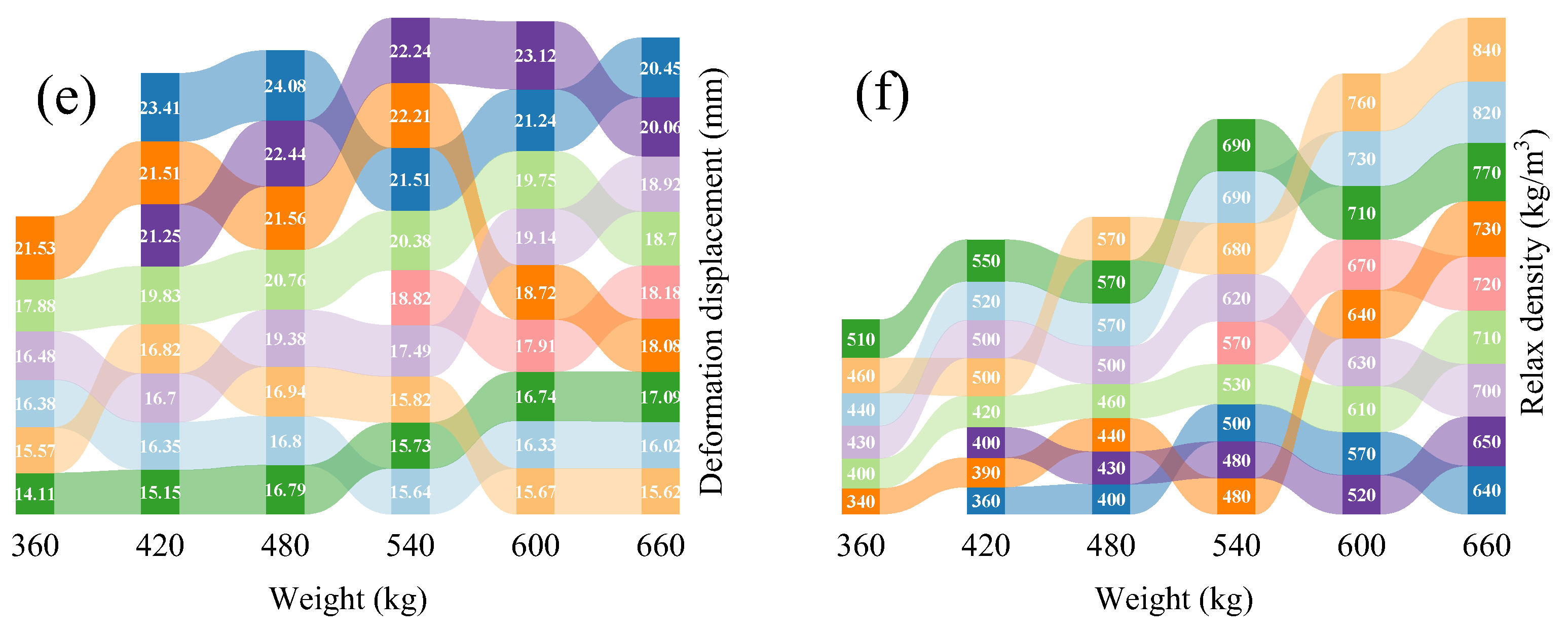

3.2. Physical Properties of Biomass Pellets

3.3. Processing Energy Consumption

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hanif, M.U.; Capareda, S.C.; Kongkasawan, J.; Iqbal, H.; Arazo, R.O.; Baig, M.A. Effects of Pyrolysis Temperature on Product Yields and Energy Recovery from Co-Feeding of Cotton Gin Trash, Cow Manure, and Microalgae: A Simulation Study. PLoS ONE 2016, 11, e0152230. [Google Scholar] [CrossRef]

- Siloto, R.M.P.; Weselake, R.J. Site saturation mutagenesis: Methods and applications in protein engineering. Biocatal. Agric. Biotechnol. 2012, 1, 181–189. [Google Scholar] [CrossRef]

- Nanda, S.; Berruti, F. Municipal solid waste management and landfilling technologies: A review. Environ. Chem. Lett. 2021, 19, 1433–1456. [Google Scholar] [CrossRef]

- Nanda, S.; Berruti, F. Thermochemical conversion of plastic waste to fuels: A review. Environ. Chem. Lett. 2021, 19, 123–148. [Google Scholar] [CrossRef]

- Ljung, K.; Schoon, P.L.; Rudolf, M.; Charrieau, L.M.; Ni, S.; Filipsson, H.L. Recent Increased Loading of Carbonaceous Pollution from Biomass Burning in the Baltic Sea br. ACS Omega 2022, 7, 35102–35108. [Google Scholar] [CrossRef] [PubMed]

- Fawzy, S.; Osman, A.I.; Doran, J.; Rooney, D.W. Strategies for mitigation of climate change: A review. Environ. Chem. Lett. 2020, 18, 2069–2094. [Google Scholar] [CrossRef]

- Guo, J.; Li, C.-Z.; Wei, C. Decoupling economic and energy growth: Aspiration or reality? Environ. Res. Lett. 2021, 16, 044017. [Google Scholar] [CrossRef]

- Wei, Z.; Cheng, Z.; Shen, Y. Recent development in production of pellet fuels from biomass and polyethylene (PE) wastes. Fuel 2024, 358, 130222. [Google Scholar] [CrossRef]

- Haykiri-Acma, H.; Yaman, S. Effect of co-combustion on the burnout of lignite/biomass blends: A Turkish case study. Waste Manag. 2008, 28, 2077–2084. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Gao, B.; Zhao, S.; Wu, P.; Han, L.; Liu, X. Optimization of a “coal-like” pelletization technique based on the sustainable biomass fuel of hydrothermal carbonization of wheat straw. J. Clean. Prod. 2020, 242, 118426. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Z.; Zhang, Y.; Wang, Y.; Yu, Y.; Ji, F.; Ahmad, R.; Dong, R. A comprehensive review on densified solid biofuel industry in China. Renew. Sustain. Energy Rev. 2016, 54, 1412–1428. [Google Scholar] [CrossRef]

- Hong, H.; Ye, W.H.; Song, B.; Zhang, X.X. An empirical study on industrialization of biomass briquette in China. Resour. Sci. 2010, 32, 2172–2178. Available online: https://www.resci.cn/EN/Y2010/V32/I11/2172 (accessed on 5 October 2024).

- Lestander, T.A.; Rudolfsson, M.; Pommer, L.; Nordin, A. NIR provides excellent predictions of properties of biocoal from torrefaction and pyrolysis of biomass. Green Chem. 2014, 16, 4906–4913. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Fenton, J. Cost Benefit of Biomass Supply and Pre-Processing. 2006. Available online: https://www.cesarnet.ca/biocap-archive/rif/report/Sokhansanj_S.pdf (accessed on 10 November 2024).

- Yue, D.; You, F.; Snyder, S.W. Biomass-to-bioenergy and biofuel supply chain optimization: Overview, key issues and challenges. Comput. Chem. Eng. 2014, 66, 36–56. [Google Scholar] [CrossRef]

- Mousa, E.; Kazemi, M.; Larsson, M.; Karlsson, G.; Persson, E. Potential for Developing Biocarbon Briquettes for Foundry Industry. Appl. Sci. 2019, 9, 5288. [Google Scholar] [CrossRef]

- Li, H.; Liu, X.; Legros, R.; Bi, X.T.; Jim Lim, C.; Sokhansanj, S. Pelletization of torrefied sawdust and properties of torrefied pellets. Appl. Energy 2012, 93, 680–685. [Google Scholar] [CrossRef]

- Chen, L.; Xing, L.; Han, L. Renewable energy from agro-residues in China: Solid biofuels and biomass briquetting technology. Renew. Sustain. Energy Rev. 2009, 13, 2689–2695. [Google Scholar] [CrossRef]

- Chen, T.; Jia, H.; Zhang, S.; Sun, X.; Song, Y.; Yuan, H. Optimization of Cold Pressing Process Parameters of Chopped Corn Straws for Fuel. Energies 2020, 13, 652. [Google Scholar] [CrossRef]

- Mostafa, M.E.; Hu, S.; Wang, Y.; Su, S.; Hu, X.; Elsayed, S.A.; Xiang, J. The significance of pelletization operating conditions: An analysis of physical and mechanical characteristics as well as energy consumption of biomass pellets. Renew. Sustain. Energy Rev. 2019, 105, 332–348. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef]

- Hansted, A.L.S.; Nakashima, G.T.; Martins, M.P.; Yamamoto, H.; Yamaji, F.M. Comparative analyses of fast growing species in different moisture content for high quality solid fuel production. Fuel 2016, 184, 180–184. [Google Scholar] [CrossRef]

- Fakhrabadi, E.A.; Kajzer, C.; Stickel, J.J.; Liberatore, M.W. Transport of Compressed Woody Biomass: Correlating Rheology and Microcompounder Measurements. Ind. Eng. Chem. Res. 2021, 60, 11470–11478. [Google Scholar] [CrossRef]

- Mundhada, S.; Chaudhry, M.M.A.; Erkinbaev, C.; Paliwal, J. Non-Destructive Quality Monitoring of Flaxseed During Storage. J. Food Meas. Charact. 2022, 16, 3640–3650. [Google Scholar] [CrossRef]

- Saeed, A.A.H.; Yub Harun, N.; Bilad, M.R.; Afzal, M.T.; Parvez, A.M.; Roslan, F.A.S.; Abdul Rahim, S.; Vinayagam, V.D.; Afolabi, H.K. Moisture Content Impact on Properties of Briquette Produced from Rice Husk Waste. Sustainability 2021, 13, 3069. [Google Scholar] [CrossRef]

- Liu, L.; Wang, D.; Gao, L.; Duan, R. Distributed heating/centralized monitoring mode of biomass briquette fuel in Chinese northern rural areas. Renew. Energy 2020, 147, 1221–1230. [Google Scholar] [CrossRef]

- Thek, G.; Obernberger, I. (Eds.) The Pellet Handbook: The Production and Thermal Utilisation of Biomass Pellets; Hardback: Carrum Downs, Victoria, 2011; p. 549. ISBN 978-1-84407-631-4. [Google Scholar] [CrossRef]

- Hedlund, F.H.; Astad, J.; Nichols, J. Inherent hazards, poor reporting and limited learning in the solid biomass energy sector: A case study of a wheel loader igniting wood dust, leading to fatal explosion at wood pellet manufacturer. Biomass Bioenergy 2014, 66, 450–459. [Google Scholar] [CrossRef]

- GB/T 28731-2012[S]; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China. Proximate Analysis of Solid Biofuels. Standard Publishing Press: Beijing, China, 2012.

- Soria-Verdugo, A.; Guil-Pedrosa, J.F.; García-Hernando, N.; Ghoniem, A.F. Evolution of solid residue composition during inert and oxidative biomass torrefaction. Energy 2024, 312, 133486. [Google Scholar] [CrossRef]

- GB/T 21354-2008[S]; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of the People’s Republic of China. Powders—Determination of Tap Density. Standard Publishing Press: Beijing, China, 2008.

- Lam, P.S.; Sokhansanj, S.; Bi, X.; Lim, C.J.; Melin, S. Energy Input and Quality of Pellets Made from Steam-Exploded Douglas Fir (Pseudotsuga menziesii). Energy Fuels 2011, 25, 1521–1528. [Google Scholar] [CrossRef]

- Xia, X.; Sun, Y.; Wu, K.; Jiang, Q. Optimization of a straw ring-die briquetting process combined analytic hierarchy process and grey correlation analysis method. Fuel Process. Technol. 2016, 152, 303–309. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, X.; Fei, B.; Jiang, Z.; Cai, Z.; Yu, Y. The properties of pellets from mixing bamboo and rice straw. Renew. Energy 2013, 55, 1–5. [Google Scholar] [CrossRef]

- Kaewtrakulchai, N.; Wongrerkdee, S.; Chalermsinsuwan, B.; Samsalee, N.; Huang, C.-W.; Manatura, K. Hydrophobicity and performance analysis of beverage and agricultural waste torrefaction for high-grade bio-circular solid fuel. Carbon Resour. Convers. 2024, 48, 100243. [Google Scholar] [CrossRef]

- Si, Y.; Hu, J.; Wang, X.; Yang, H.; Chen, Y.; Shao, J.; Chen, H. Effect of Carboxymethyl Cellulose Binder on the Quality of Biomass Pellets. Energy Fuels 2016, 30, 5799–5808. [Google Scholar] [CrossRef]

- Eisenbies, M.H.; Volk, T.A.; Therasme, O.; Hallen, K. Three bulk density measurement methods provide different results for commercial scale harvests of willow biomass chips. Biomass Bioenergy 2019, 124, 64–73. [Google Scholar] [CrossRef]

- Kellogg, R.M.; Wangaard, F.F. Variation in the cell-wall density of wood. Wood Fiber Sci. 2007, 1, 180–204. Available online: https://wfs.swst.org/index.php/wfs/article/view/1352 (accessed on 11 November 2024).

- Quyen, V.T.; Nagy, S.; Faitli, J.; Csoke, B. Determination of radial pressure distribution on the wall of the press channel of a novel biomass single die pelletiser. Eur. J. Wood Wood Prod. 2020, 78, 1075–1086. [Google Scholar] [CrossRef]

- Dai, X.; Theppitak, S.; Yoshikawa, K. Pelletization of Carbonized Wood Using Organic Binders with Biomass Gasification Residue as an Additive. Energy Fuels 2019, 33, 323–329. [Google Scholar] [CrossRef]

- Granado, M.P.P.; Suhogusoff, Y.V.M.; Santos, L.R.O.; Yamaji, F.M.; De Conti, A.C. Effects of pressure densification on strength and properties of cassava waste briquettes. Renew. Energy 2021, 167, 306–312. [Google Scholar] [CrossRef]

- Kashaninejad, M.; Tabil, L.G. Effect of microwave–chemical pre-treatment on compression characteristics of biomass grinds. Biosyst. Eng. 2011, 108, 36–45. [Google Scholar] [CrossRef]

- Rezaei, H.; Lim, C.J.; Lau, A.; Sokhansanj, S. Size, shape and flow characterization of ground wood chip and ground wood pellet particles. Powder Technol. 2016, 301, 737–746. [Google Scholar] [CrossRef]

- De-Yu, T.U.; An-Xin, L.I.; Yun, H.U.; Wei, X. Lab-scale Experimental Study on the Compressing Molding Parameters Under Cold Condition for Rice Straw Pellets. Chin. J. Agrometeorol. 2015, 36, 446–453. [Google Scholar] [CrossRef]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- He, H.; Wang, Y.; Sun, W.; Sun, Y.; Wu, K. Effects of different biomass feedstocks on the pelleting process and pellet qualities. Sustain. Energy Technol. Assess. 2024, 69, 103912. [Google Scholar] [CrossRef]

- Nielsen, S.K.; Mandø, M.; Rosenørn, A.B. Review of die design and process parameters in the biomass pelleting process. Powder Technol. 2020, 364, 971–985. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, F.-S. Effects of various solvents on the liquefaction of biomass to produce fuels and chemical feedstocks. Energy Convers. Manag. 2008, 49, 3498–3504. [Google Scholar] [CrossRef]

- Simons, S.J.R. Chapter 27 Liquid bridges in granules. In Handbook of Powder Technology; Salman, A.D., Hounslow, M.J., Seville, J.P.K., Eds.; Elsevier Science B.V.: Amsterdam, The Netherlands, 2007; Volume 11, pp. 1257–1316. [Google Scholar] [CrossRef]

- Lekounougou, S.; Kocaefe, D. Comparative study on the durability of heat-treated White Birch (Betula papyrifera) subjected to the attack of brown and white rot fungi. Wood Mater. Sci. Eng. 2012, 7, 101–106. Available online: https://api.semanticscholar.org/CorpusID:84460178 (accessed on 30 December 2024). [CrossRef]

- Liu, Z.; Zhang, F.-S. Removal of copper (II) and phenol from aqueous solution using porous carbons derived from hydrothermal chars. Desalination 2011, 267, 101–106. [Google Scholar] [CrossRef]

| The Name of Parameters | Value | Unit |

|---|---|---|

| Compressing force | 50,000 | N |

| Maximum stroke of movable beam | 250 | mm |

| Maximum opening height | 300 | mm |

| Height of the workbench from the ground | 750 | mm |

| Workbench length | 300 | mm |

| Workbench width | 200 | mm |

| The diameter of pellet | 8 | mm |

| The length of pellet | 12 | mm |

| Empty up speed | 2~3 | mm/s |

| Work speed | 1~2 | mm/s |

| Return speed | 4 | mm/s |

| Total power of the device | 1500 | W |

| Biomass Feedstocks | Proximate analysis (%, Dry Basis) | Ultimate Analysis (%, Dry Ash-Free Basis) | HHV (×106 J/kg) | Bulk Density (kg/m3) | Tap Density (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ash | Fixed Carbon | Volatile | C | H | O* | N | S | ||||

| CS | 4.84 ± 0.05 | 13.72 ± 0.14 | 81.44 ± 0.81 | 39.17 ± 0.39 | 5.78 ± 0.06 | 54.25 ± 0.54 | 0.74 ± 0.01 | 0.06 ± 0.00 | 18.64 ± 0.56 | 150 ± 1.50 | 260 ± 2.60 |

| RS | 12.55 ± 0.13 | 11.93 ± 0.12 | 75.52 ± 0.76 | 48.08 ± 0.48 | 6.57 ± 0.07 | 44.13 ± 0.44 | 0.99 ± 0.01 | 0.23 ± 0.00 | 19.82 ± 0.59 | 180 ± 1.80 | 260 ± 2.60 |

| SS | 12.81 ± 0.13 | 7.59 ± 0.08 | 79.60 ± 0.80 | 47.51 ± 0.48 | 6.80 ± 0.07 | 44.65 ± 0.45 | 0.78 ± 0.01 | 0.26 ± 0.00 | 19.86 ± 0.60 | 220 ± 2.20 | 360 ± 3.60 |

| WJ | 3.83 ± 0.04 | 13.83 ± 0.14 | 82.34 ± 0.82 | 50.34 ± 0.50 | 6.90 ± 0.07 | 40.30 ± 0.40 | 1.94 ± 0.02 | 0.52 ± 0.01 | 21.39 ± 0.64 | 330 ± 3.30 | 490 ± 4.90 |

| CL | 8.50 ± 0.09 | 1.73 ± 0.02 | 89.77 ± 0.90 | 54.98 ± 0.55 | 7.17 ± 0.07 | 36.61 ± 0.37 | 1.08 ± 0.01 | 0.16 ± 0.00 | 23.64 ± 0.71 | 320 ± 3.20 | 420 ± 4.20 |

| PS | 6.63 ± 0.07 | 9.75 ± 0.10 | 83.62 ± 0.84 | 51.77 ± 0.52 | 6.43 ± 0.06 | 39.24 ± 0.39 | 2.41 ± 0.02 | 0.15 ± 0.00 | 20.74 ± 0.62 | 230 ± 2.30 | 340 ± 3.40 |

| AW | 7.71 ± 0.08 | 4.40 ± 0.04 | 87.89 ± 0.88 | 50.46 ± 0.50 | 6.98 ± 0.07 | 40.96 ± 0.41 | 1.41 ± 0.01 | 0.19 ± 0.00 | 20.74 ± 0.62 | 150 ± 1.50 | 200 ± 2.00 |

| FG | 3.16 ± 0.03 | 6.75 ± 0.07 | 90.09 ± 0.90 | 50.12 ± 0.50 | 6.77 ± 0.07 | 42.68 ± 0.43 | 0.34 ± 0.00 | 0.09 ± 0.00 | 20.23 ± 0.61 | 180 ± 1.80 | 250 ± 2.50 |

| GR | 7.62 ± 0.08 | 4.44 ± 0.04 | 87.94 ± 0.88 | 44.52 ± 0.45 | 6.46 ± 0.06 | 47.43 ± 0.47 | 1.31 ± 0.01 | 0.28 ± 0.00 | 17.18 ± 0.52 | 180 ± 1.80 | 280 ± 2.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Song, L.; Li, Y.; Shen, Y.; Yang, M.; Wang, Y.; Zheng, H.; Qi, W.; Lei, T. Effects of Different Biomass Types on Pellet Qualities and Processing Energy Consumption. Agriculture 2025, 15, 316. https://doi.org/10.3390/agriculture15030316

Yang Y, Song L, Li Y, Shen Y, Yang M, Wang Y, Zheng H, Qi W, Lei T. Effects of Different Biomass Types on Pellet Qualities and Processing Energy Consumption. Agriculture. 2025; 15(3):316. https://doi.org/10.3390/agriculture15030316

Chicago/Turabian StyleYang, Yantao, Lei Song, Yuanna Li, Yilin Shen, Mei Yang, Yunbo Wang, Hesheng Zheng, Wei Qi, and Tingzhou Lei. 2025. "Effects of Different Biomass Types on Pellet Qualities and Processing Energy Consumption" Agriculture 15, no. 3: 316. https://doi.org/10.3390/agriculture15030316

APA StyleYang, Y., Song, L., Li, Y., Shen, Y., Yang, M., Wang, Y., Zheng, H., Qi, W., & Lei, T. (2025). Effects of Different Biomass Types on Pellet Qualities and Processing Energy Consumption. Agriculture, 15(3), 316. https://doi.org/10.3390/agriculture15030316