Application of Discrete Element Method to Potato Harvesting Machinery: A Review

Abstract

1. Introduction

2. Basic Principles of the Discrete Element Method

2.1. Contact Model

2.1.1. Hertz–Mindlin No-Slip Contact Model

2.1.2. Hertz–Mindlin Bonding Contact Model

2.1.3. Hertz–Mindlin Thermal Conductivity Model

2.1.4. Temperature Update Model

2.1.5. Linear Cohesion Model

2.1.6. Linear Spring Contact Model

2.1.7. Motion Plane Contact Model

2.1.8. Frictional Electrification Contact Model

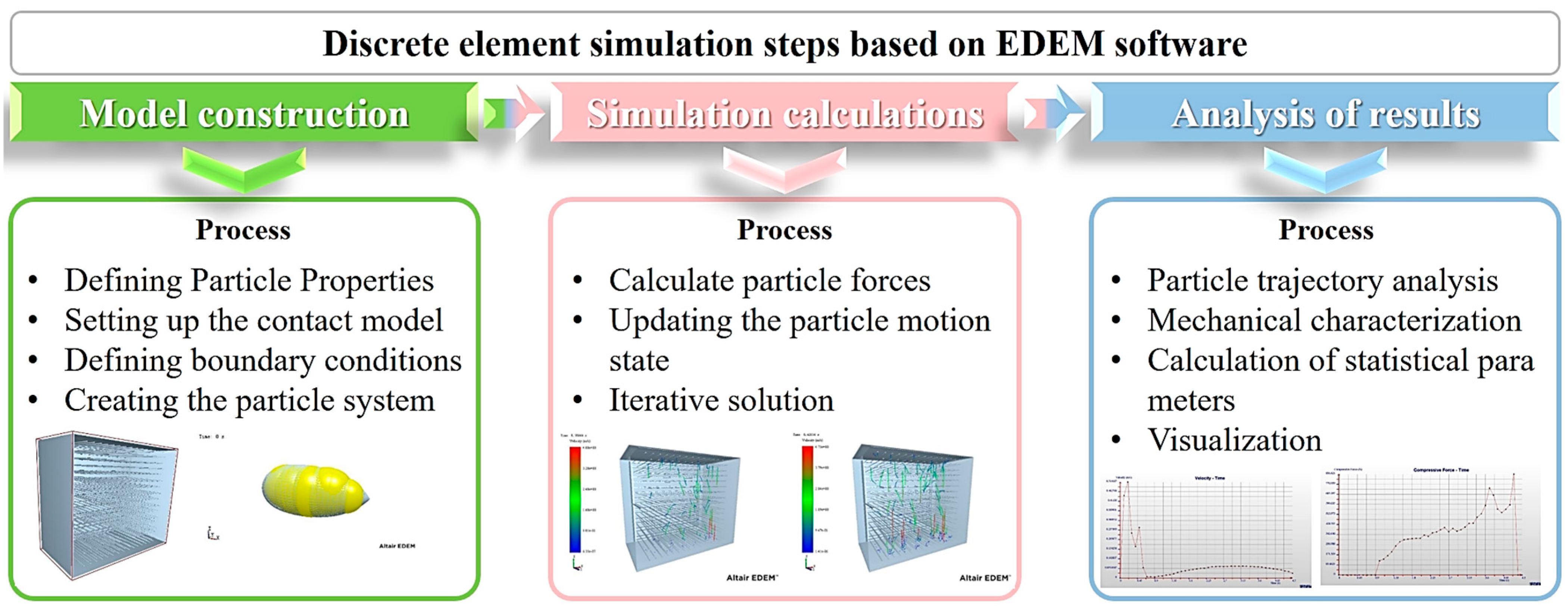

2.2. Simulation Process

2.3. DEM Interaction Design with Potato Harvesters

2.3.1. Key Steps

2.3.2. Key Technologies

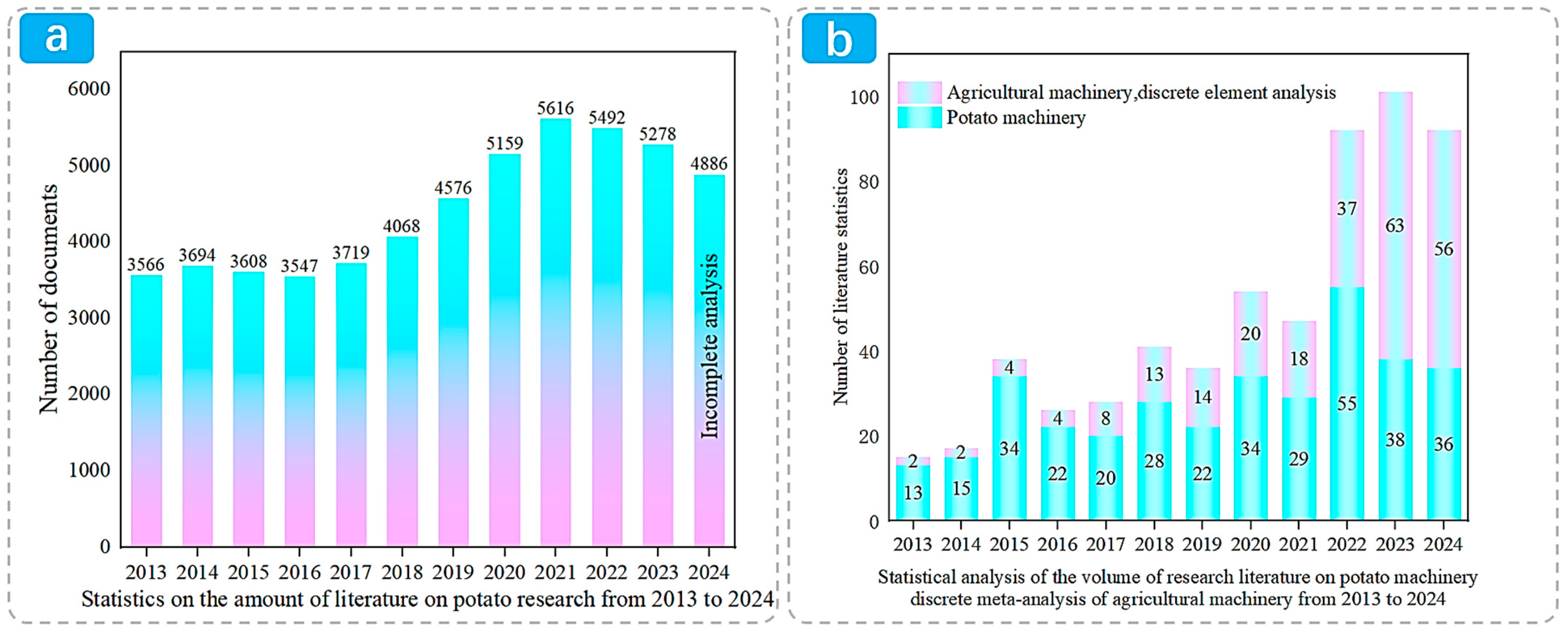

3. Global Analysis of the Current Status of Potato Harvesting Machinery

3.1. Small and Medium-Sized Potato Harvesters

3.2. Large Potato Combine Harvester

4. Application of DEM in Potato Harvesting Machinery Research

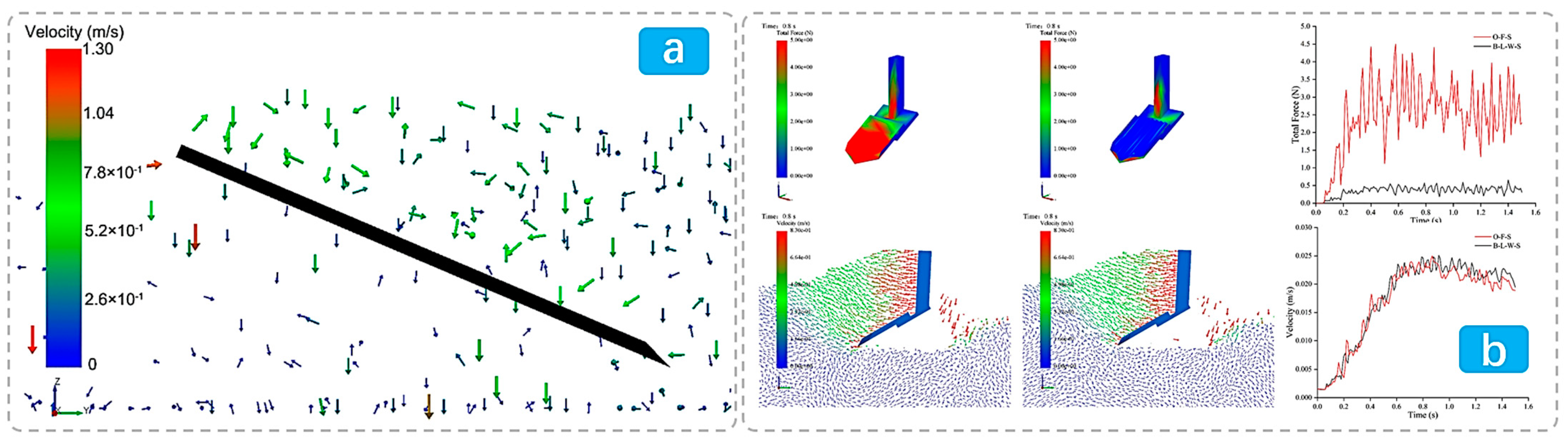

4.1. Simulation and Analysis of the Excavation Process

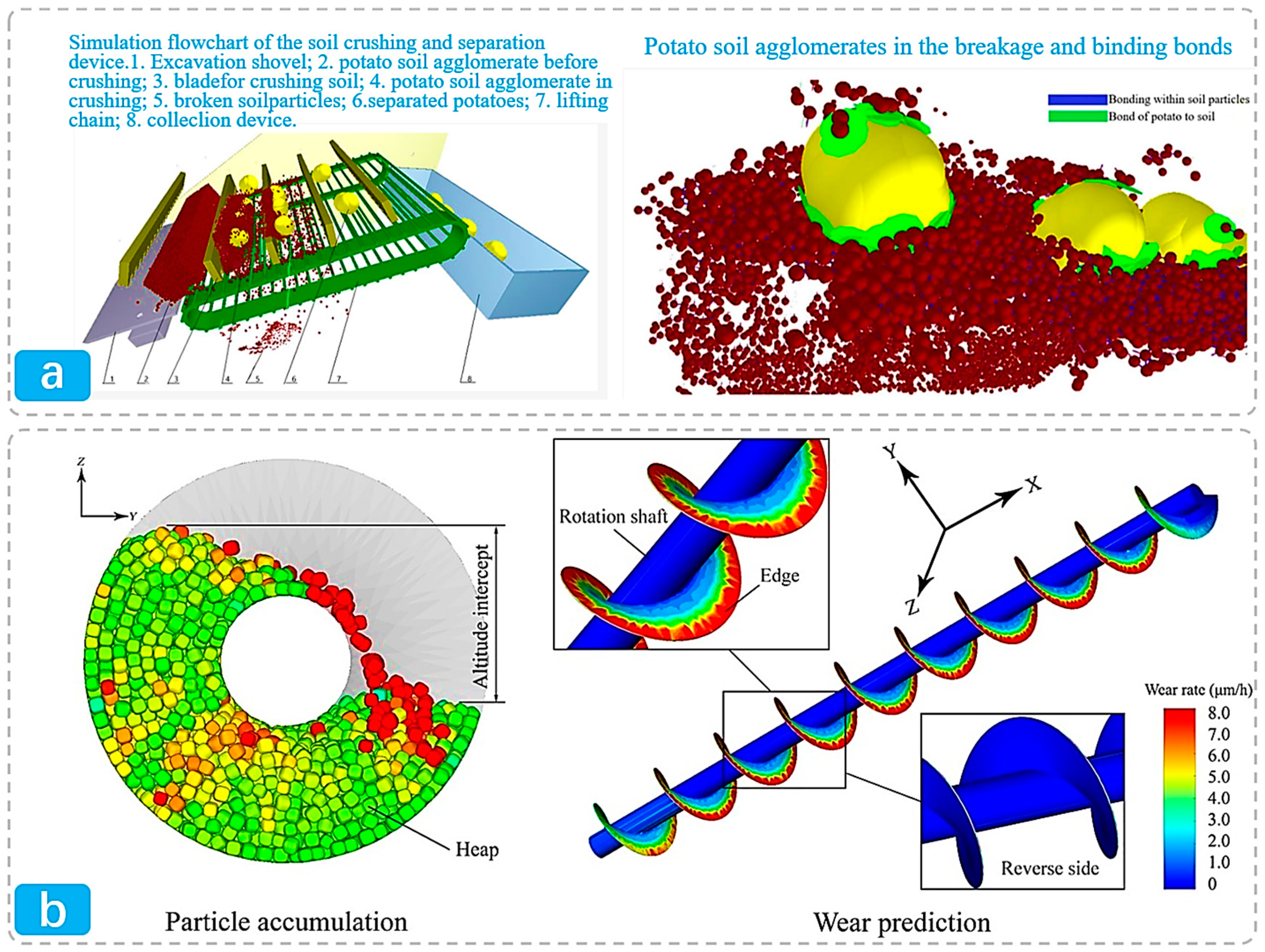

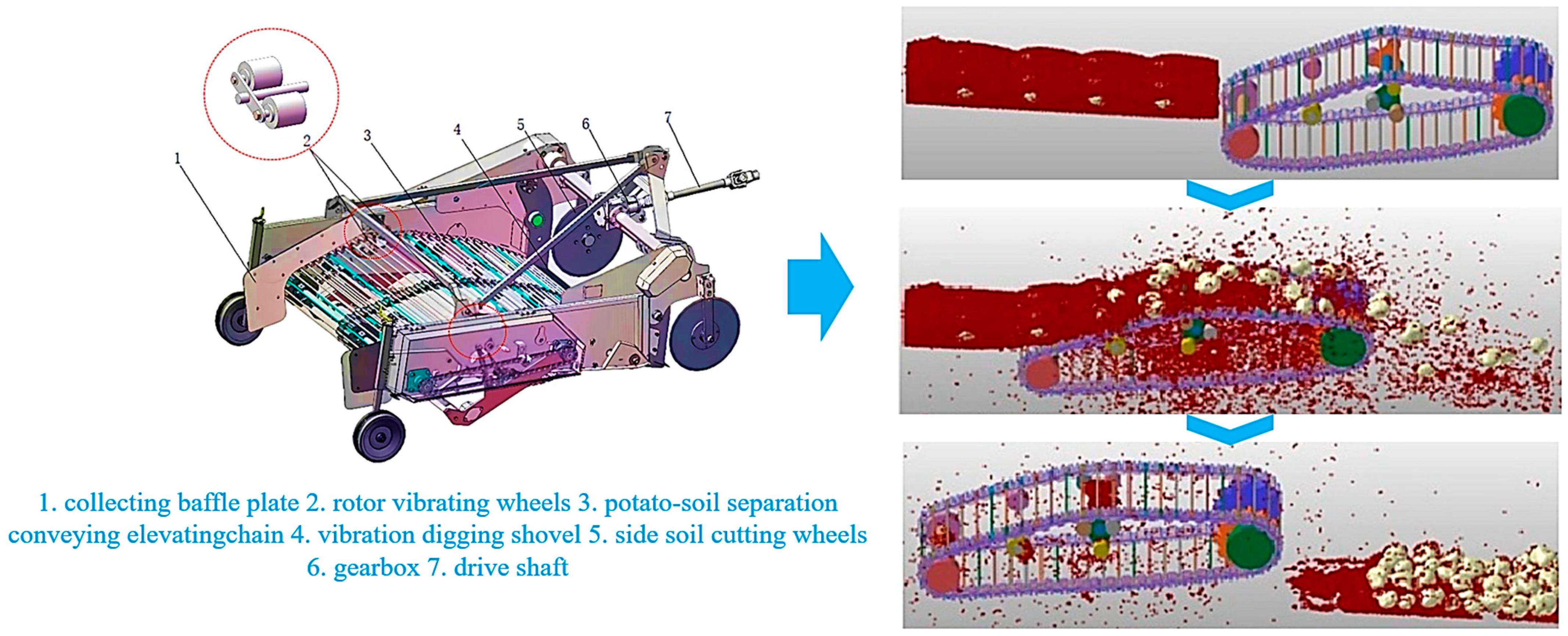

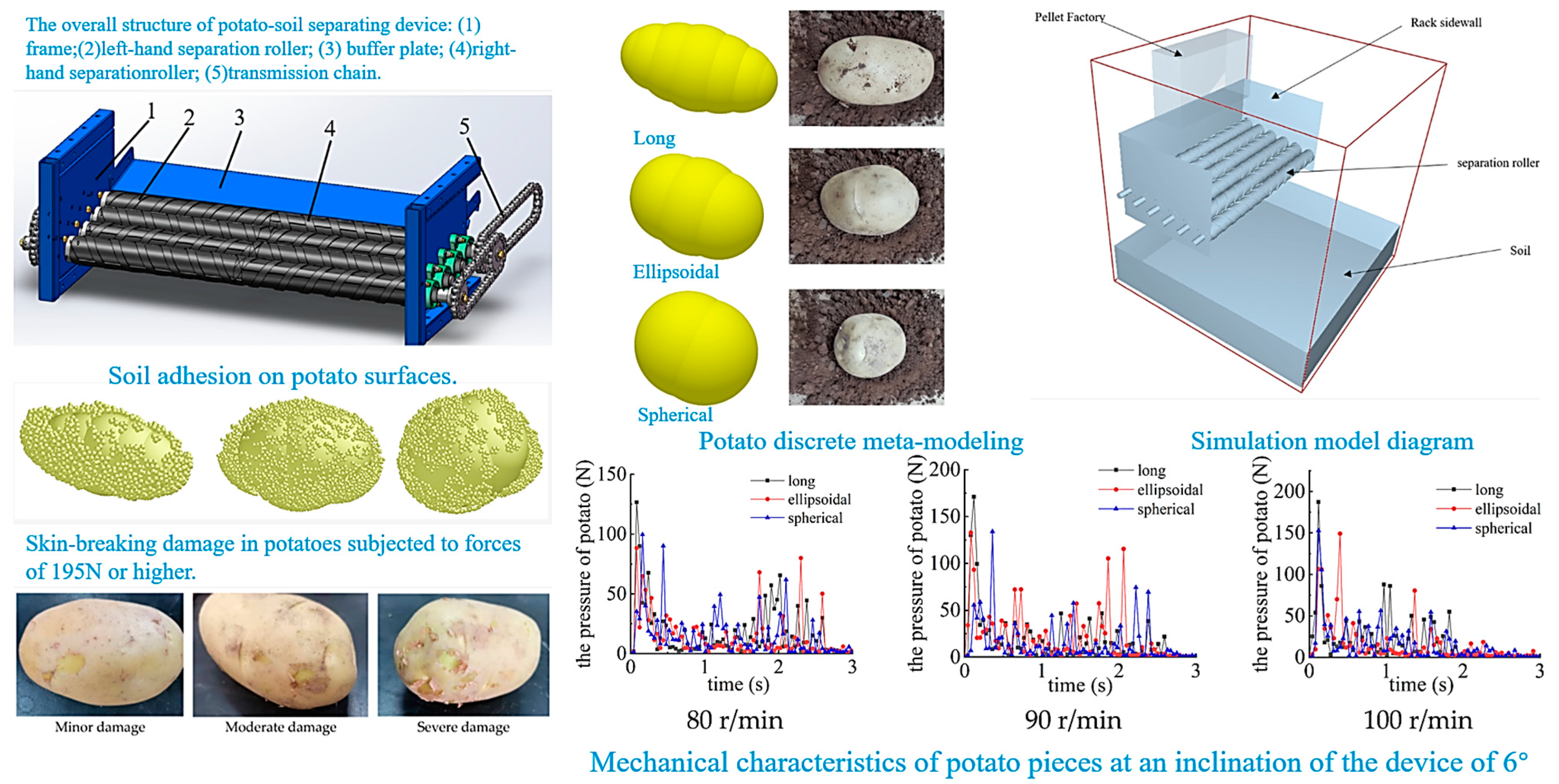

4.2. Simulation of the Potato–Soil Separation Process

4.3. Simulation of the Transportation Process

4.4. Simulation of the Collection Process

5. Summary and Outlook

- Limited model accuracy: Although the DEM has certain advantages when it comes to simulating interactions between granular materials and objects, the physical properties of materials such as potatoes and soil are very complex in practical applications, making precise modeling challenging. For example, potatoes have irregular shapes and varying sizes, while the structure and mechanical properties of soil can differ significantly across different regions and conditions. Current models often struggle to fully and accurately represent these real-world scenarios, which may lead to discrepancies between simulation results and actual outcomes.

- Difficulties in parameter calibration: The accuracy of discrete element models largely depends on the precision of model parameters, such as the friction coefficient between particles, elastic modulus, and restitution coefficient. However, accurately determining and calibrating these parameters can be challenging, requiring extensive experimental and empirical data. Moreover, the parameter values may vary under different materials and conditions, which increases the uncertainty and error in the model.

- High computational cost: The computational volume of the discrete element method increases dramatically as the complexity of the simulation increases, for example, considering higher numbers of particles, more complex mechanical structures, and motion processes. The requirements for computer hardware and computation time also increase dramatically, limiting its application in large-scale, complex systems and rapid optimization of the design in practical engineering to a certain extent.

- Insufficient treatment of multi-physical field coupling problems: The potato harvest process not only involves mechanical interactions between particles, but it may also involve multi-physical field coupling problems such as soil moisture migration and heat transfer. At present, the discrete element method has some limitations in dealing with these multi-physical field coupling problems, and it is difficult to fully and accurately simulate various physical phenomena and interactions that occur during the actual harvesting process.

- Lack of systematic research: Currently, the application of the discrete element method (DEM) in potato harvesting machinery research is mostly focused on specific components or processes, such as optimization of the digging shovel or separation screen, and systematic research and comprehensive optimization of the entire harvesting machinery system is lacking. However, potato harvesting machinery is a complex system where various components are interrelated and influence each other. To achieve optimal harvesting results, a holistic and coordinated optimization approach is necessary.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Han, X.; Yang, R.; Zhang, L.; Wei, Q.; Zhang, Y.; Wang, Y.; Shi, Y. A Review of Potato Salt Tolerance. Int. J. Mol. Sci. 2023, 24, 10726. [Google Scholar] [CrossRef] [PubMed]

- Lindqvist-Kreuze, H.; Bonierbale, M.; Gruneberg, W.J.; Mendes, T.; De Boeck, B.; Campos, H. Potato and sweetpotato breeding at the international potato center: Approaches, outcomes and the way forward. Theor. Appl. Genet. 2024, 137, 12. [Google Scholar] [CrossRef] [PubMed]

- Boivin, M.; Bourdeau, N.; Barnabe, S.; Desgagne-Penix, I. Sprout Suppressive Molecules Effective on Potato (Solanum tuberosum) Tubers during Storage: A Review. Am. J. Potato Res. 2020, 97, 451–463. [Google Scholar] [CrossRef]

- Jennings, S.A.; Koehler, A.-K.; Nicklin, K.J.; Deva, C.; Sait, S.M.; Challinor, A.J. Global Potato Yields Increase Under Climate Change with Adaptation and CO2 Fertilisation. Front. Sustain. Food Syst. 2020, 4, 519324. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, F.; Wu, Y.; Hu, H.; Dai, X. Progress of potato staple food research and industry development in China. J. Integr. Agric. 2017, 16, 2924–2932. [Google Scholar] [CrossRef]

- Dupuis, B.; Nkuriyingoma, P.; Ballmer, T. Economic Impact of Potato Virus Y (PVY) in Europe. Potato Res. 2024, 67, 55–72. [Google Scholar] [CrossRef]

- Raymundo, R.; Asseng, S.; Robertson, R.; Petsakos, A.; Hoogenboom, G.; Quiroz, R.; Hareau, G.; Wolf, J. Climate change impact on global potato production. Eur. J. Agron. 2018, 100, 87–98. [Google Scholar] [CrossRef]

- Ojeda, J.J.; Rezaei, E.E.; Kamali, B.; McPhee, J.J.; Meinke, H.; Siebert, S.; Webb, M.A.; Ara, I.; Mulcahy, F.; Ewert, F. Impact of crop management and environment on the spatio-temporal variance of potato yield at regional scale. Field Crops Res. 2021, 270, 108213. [Google Scholar] [CrossRef]

- Adekanmbi, T.; Wang, X.; Basheer, S.; Liu, S.; Yang, A.; Cheng, H. Climate change impacts on global potato yields: A review. Environ. Res. Clim. 2023, 3, 012001. [Google Scholar] [CrossRef]

- Johnson, C.M.; Auat Cheein, F. Machinery for potato harvesting: A state-of-the-art review. Front. Plant Sci. 2023, 14, 1156734. [Google Scholar] [CrossRef]

- Wang, L.; Liu, F.; Wang, Q.; Zhou, J.; Fan, X.; Li, J.; Zhao, X.; Xie, S. Design of a Spring-Finger Potato Picker and an Experimental Study of Its Picking Performance. Agriculture 2023, 13, 945. [Google Scholar] [CrossRef]

- Wei, Z.; Li, H.; Sun, C.; Su, G.; Liu, W.; Li, X. Experiments and Analysis of a Conveying Device for Soil Separation and Clod-Crushing for a Potato Harvester. Appl. Eng. Agric. 2019, 35, 987–996. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, W.; Sun, W.; Liu, X.; Shi, R.; Zhang, H.; Chen, P.; Gao, K. The Design and Experimentation of a Wheeled-Chassis Potato Combine Harvester with Integrated Bagging and Ton Bag-Lifting Systems. Agriculture 2024, 14, 1461. [Google Scholar] [CrossRef]

- Lu, K.; Xie, S.; Gai, X.; Ji, X. Design and Experiment of Toggle Lever-Type Potato Picker. Agriculture 2024, 14, 826. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Z.; Zhang, H.; Liu, X.; Li, H.; Sun, W.; Li, H. Investigation of the Traveling Performance of the Tracked Chassis of a Potato Combine Harvester in Hilly and Mountainous Areas. Agriculture 2024, 14, 1625. [Google Scholar] [CrossRef]

- Chen, K.J.; Wood, J.D.; Mohammed, I.K.; Echendu, S.; Jones, D.; Northam, K.; Charalambides, M.N. Mechanical Characterisation and modelling of the rolling process of potato-based dough. J. Food Eng. 2020, 278, 109943. [Google Scholar] [CrossRef]

- Lenartowicz, T.; Piepho, H.P.; Przystalski, M. Stability Analysis of Tuber Yield and Starch Yield in Mid-Late and Late Maturing Starch Cultivars of Potato (Solanum tuberosum). Potato Res. 2019, 63, 179–197. [Google Scholar] [CrossRef]

- Jaiswal, A.K.; Singh, B.; Mehta, A.; Lal, M. Post-Harvest Losses in Potatoes from Farm to Fork. Potato Res. 2023, 66, 51–66. [Google Scholar] [CrossRef]

- Ping, Z.; Guo, R.; Jin, T.; Zhang, G.; Ning, X. Collision simulation of potato tubers for mechanized harvesting. J. Food Process Eng. 2023, 46, e14278. [Google Scholar] [CrossRef]

- Visse-Mansiaux, M.; Tallant, M.; Brostaux, Y.; Delaplace, P.; Vanderschuren, H.; Dupuis, B. Assessment of pre- and post-harvest anti-sprouting treatments to replace CIPC for potato storage. Postharvest Biol. Technol. 2021, 178, 111540. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, Z.; Li, C.; Xu, R.; Yang, D.; Sun, L. Van der Waals materials-based floating gate memory for neuromorphic computing. Chip 2023, 2, 100059. [Google Scholar] [CrossRef]

- Deng, X.; Kang, N.; Zhang, Z. Carbon-Based Cryoelectronics: Graphene and Carbon Nanotube. Chip 2023, 22, 100064. [Google Scholar] [CrossRef]

- Kim, J.; Jeon, B. “Digital design” and three flows of ideas. J. Asian Archit. Build. Eng. 2022, 21, 1891–1907. [Google Scholar] [CrossRef]

- Han, J.S.; Kim, G. Virtual Constructions Design using 3ds Max. J. Digit. Converg. 2013, 11, 273–278. [Google Scholar]

- Li, C.; Luo, Y.; Li, W.; Yang, B.; Sun, C.; Ma, W.; Ma, Z.; Wei, Y.; Li, X.; Yang, J. The On-chip Thermoelectric Cooler: Advances, Applications and Challenges. Chip 2024, 3, 100096. [Google Scholar] [CrossRef]

- Gazquez, J.A.; Castellano, N.N.; Manzano-Agugliaro, F. Intelligent low cost telecontrol system for agricultural vehicles in harmful environments. J. Clean. Prod. 2016, 113, 204–215. [Google Scholar] [CrossRef]

- Guo, Q.; Xia, H. A review of the Discrete Element Method/Modelling (DEM) in agricultural engineering. J. Agric. Eng. 2023, 54. [Google Scholar] [CrossRef]

- Xin, C.; Yin, Y.; Song, B.; Fan, Z.; Song, Y.; Pan, F. Machine Learning-Accelerated Discovery of Novel 2D Ferromagnetic Materials with Strong Magnetization. Chip 2023, 2, 100071. [Google Scholar] [CrossRef]

- Yang, K.-S.; He, C.; Fang, J.; Cui, X.; Sun, H.; Yang, Y.; Zuo, C. Advanced RF filters for wireless communications. Chip 2023, 2, 100058. [Google Scholar] [CrossRef]

- Hao, Z.; Zou, K.; Meng, Y.; Yan, J.-Y.; Li, F.; Huo, Y.; Jin, C.-Y.; Liu, F.; Descamps, T.; Iovan, A.; et al. High-performance eight-channel system with fractal superconducting nanowire single-photon detectors. Chip 2024, 3, 100087. [Google Scholar] [CrossRef]

- Siegmann, E.; Enzinger, S.; Toson, P.; Doshi, P.; Khinast, J.; Jajcevic, D. Massively speeding up DEM simulations of continuous processes using a DEM extrapolation. Powder Technol. 2021, 390, 442–455. [Google Scholar] [CrossRef]

- Qi, L.; Chen, Y.; Sadek, M. Simulations of soil flow properties using the discrete element method (DEM). Comput. Electron. Agric. 2019, 157, 254–260. [Google Scholar] [CrossRef]

- Gong, H.; Chen, Y.; Wu, S.; Tang, Z.; Liu, C.; Wang, Z.; Fu, D.; Zhou, Y.; Qi, L. Simulation of canola seedling emergence dynamics under different soil compaction levels using the discrete element method (DEM). Soil Tillage Res. 2022, 223, 105461. [Google Scholar] [CrossRef]

- Zhao, H.; Huang, Y.; Liu, Z.; Liu, W.; Zheng, Z. Applications of Discrete Element Method in the Research of Agricultural Machinery: A Review. Agriculture 2021, 11, 425. [Google Scholar] [CrossRef]

- Du, B.; Zhao, C.; Dong, G.; Bi, J. FEM-DEM coupling analysis for solid granule medium forming new technology. J. Mater. Process. Technol. 2017, 249, 108–117. [Google Scholar] [CrossRef]

- Horabik, J.; Molenda, M. Parameters and contact models for DEM simulations of agricultural granular materials: A review. Biosyst. Eng. 2016, 147, 206–225. [Google Scholar] [CrossRef]

- Huang, L.; He, R.; Yang, Z.; Tan, P.; Chen, W.; Li, X.; Cao, A. Exploring hydraulic fracture behavior in glutenite formation with strong heterogeneity and variable lithology based on DEM simulation. Eng. Fract. Mech. 2023, 278, 109020. [Google Scholar] [CrossRef]

- Wang, P.; Yin, Z.-Y.; Hicher, P.-Y.; Cui, Y.-J. Micro-mechanical analysis of one-dimensional compression of clay with DEM. Int. J. Numer. Anal. Methods Geomech. 2023, 47, 2706–2724. [Google Scholar] [CrossRef]

- Zhong, W.; Yu, A.; Liu, X.; Tong, Z.; Zhang, H. DEM/CFD-DEM Modelling of Non-spherical Particulate Systems: Theoretical Developments and Applications. Powder Technol. 2016, 302, 108–152. [Google Scholar] [CrossRef]

- Cundall, P.A. The Measurement and Analysis of Accelerations in Rock Slopes. Ph.D. Thesis, Imperial College, London, UK, 1971. [Google Scholar]

- Cundall, P.A. A computer model for simulating progressive, large-scale movements in blocky rock systems. Proc. Int. Symp. Rock Mech. 1971, 8, 129–136. [Google Scholar]

- Martinez Morillo, G.C.; Bandeira, A.A. Discrete Element Method applied to the simulation of the stress state in granular materials. Soil Res. 2019, 57, 85–100. [Google Scholar] [CrossRef]

- Meng, J.; Huang, J.; Li, H.; Laue, J.; Li, K. A static discrete element method with discontinuous deformation analysis. Int. J. Numer. Methods Eng. 2019, 120, 918–935. [Google Scholar] [CrossRef]

- Fleissner, F.; Gaugele, T.; Eberhard, P. Applications of the discrete element method in mechanical engineering. Multibody Syst. Dyn. 2007, 18, 81–94. [Google Scholar] [CrossRef]

- Tsunazawa, Y.; Soma, N.; Iijima, M.; Tatami, J.; Mori, T.; Sakai, M. Validation study on a coarse-grained DEM-CFD simulation in a bead mill. Powder Technol. 2024, 440, 119743. [Google Scholar] [CrossRef]

- Napolitano, E.; Di Renzo, A.; Di Maio, F.P. Coarse-grain DEM-CFD modelling of dense particle flow in gas-solid cyclone. Sep. Purif. Technol. 2022, 287, 120591. [Google Scholar] [CrossRef]

- Mudarisov, S.; Farkhutdinov, I.; Khamaletdinov, R.; Khasanov, E.; Mukhametdinov, A. Evaluation of the significance of the contact model particle parameters in the modelling of wet soils by the discrete element method. Soil Tillage Res. 2022, 215, 105228. [Google Scholar] [CrossRef]

- Li, J.; Qiao, T.; Ji, S. General polygon mesh discrete element method for arbitrarily shaped particles and complex structures based on an energy-conserving contact model. Acta Mech. Sin. 2023, 39, 722245. [Google Scholar] [CrossRef]

- Xue, B.; Que, Y.; Pei, J.; Ma, X.; Wang, D.; Yuan, Y.; Zhang, H. A state-of-the-art review of discrete element method for asphalt mixtures: Model generation methods, contact constitutive models and application directions. Constr. Build. Mater. 2024, 414, 134842. [Google Scholar] [CrossRef]

- Tykhoniuk, R.; Tomas, J.; Luding, S.; Kappl, M.; Heim, L.; Butt, H.-J. Ultrafine cohesive powders: From interparticle contacts to continuum behaviour. Chem. Eng. Sci. 2007, 62, 2843–2864. [Google Scholar] [CrossRef]

- He, H.; Zheng, J.; Chen, Y.; Ning, Y. Physics engine based simulation of shear behavior of granular soils using hard and soft contact models. J. Comput. Sci. 2021, 56, 101504. [Google Scholar] [CrossRef]

- Wong, C.P.Y.; Coop, M.R. The contact mechanics of a UK railway ballast. Géotechnique 2023, 74, 1700–1712. [Google Scholar] [CrossRef]

- Jamshidi, H.; Ahmadian, H. A modified rough interface model considering shear and normal elastic deformation couplings. Int. J. Solids Struct. 2020, 203, 57–72. [Google Scholar] [CrossRef]

- Gao, W.; Feng, Y.T.; Wang, C. A coupled isogeometric/multi-sphere discrete element approach for the contact interaction between irregular particles and structures. Powder Technol. 2023, 430, 118971. [Google Scholar] [CrossRef]

- Chen, G.; Schott, D.L.; Lodewijks, G. Sensitivity analysis of DEM prediction for sliding wear by single iron ore particle. Eng. Comput. 2017, 34, 2031–2053. [Google Scholar] [CrossRef]

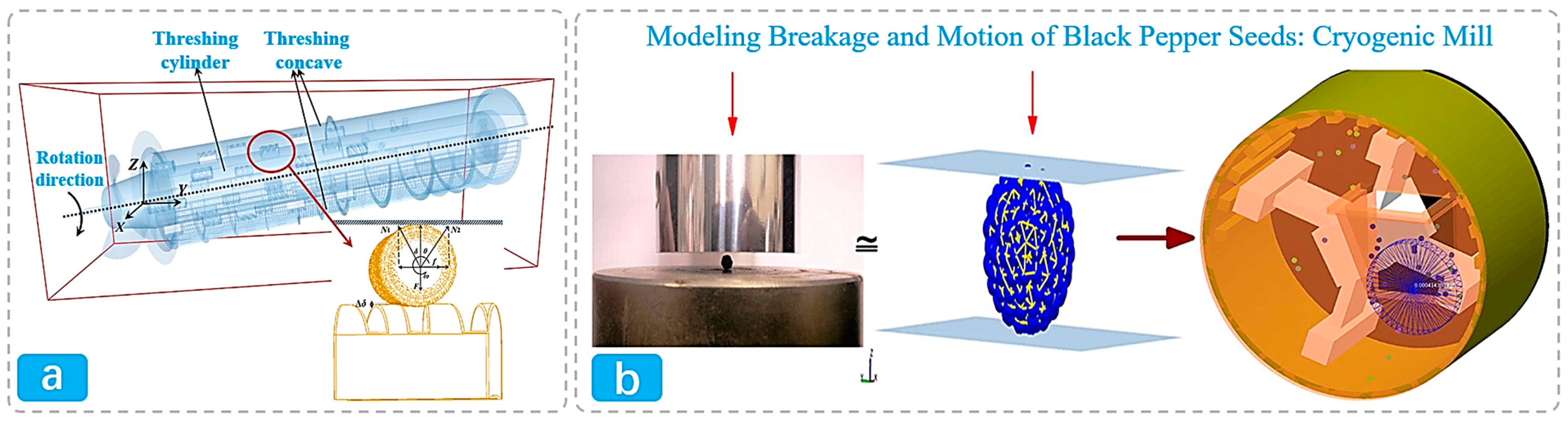

- Li, X.; Du, Y.; Liu, L.; Mao, E.; Yang, F.; Wu, J.; Wang, L. Research on the constitutive model of low-damage corn threshing based on DEM. Comput. Electron. Agric. 2022, 194, 106722. [Google Scholar] [CrossRef]

- Ghodki, B.M.; Kumar, K.; Goswami, T.K. Modeling breakage and motion of black pepper seeds in cryogenic mill. Adv. Powder Technol. 2018, 29, 1055–1071. [Google Scholar] [CrossRef]

- Shi, Y.; Jiang, Y.; Wang, X.; Thuy, N.T.D.; Yu, H. A mechanical model of single wheat straw with failure characteristics based on discrete element method. Biosyst. Eng. 2023, 230, 1–15. [Google Scholar] [CrossRef]

- Aleshin, V.; Van Den Abeele, K. Preisach analysis of the Hertz-Mindlin system. J. Mech. Phys. Solids 2009, 57, 657–672. [Google Scholar] [CrossRef]

- Ahmad, F.; Qiu, B.; Ding, Q.; Ding, W.; Khan, Z.M.; Shoaib, M.; Chandio, F.A.; Rahim, A.; Khaliq, A. Discrete element method simulation of disc type furrow openers in paddy soil. Int. J. Agric. Biol. Eng. 2020, 13, 103–110. [Google Scholar] [CrossRef]

- Wang, Z.; Li, J.; Yu, T.; Cheng, Q.; Li, F.; Li, Z. Sampling dynamic analysis and discrete element simulation on a deep layer regolith drill for extraterrestrial celestial bodies. Acta Astronaut. 2024, 225, 141–157. [Google Scholar] [CrossRef]

- Shi, J.; Shan, Z.; Yang, H. Research on the macro- and meso-mechanical properties of frozen sand mold based on Hertz-Mindlin with Bonding model. Particuology 2024, 88, 176–191. [Google Scholar] [CrossRef]

- Liu, X.; Gui, N.; Yang, X.; Tu, J.; Jiang, S. A DEM-embedded finite element method for simulation of the transient heat conduction process in the pebble bed. Powder Technol. 2021, 377, 607–620. [Google Scholar] [CrossRef]

- Gui, N.; Yan, J.; Xu, W.; Ge, L.; Wu, D.; Ji, Z.; Gao, J.; Jiang, S.; Yang, X. DEM simulation and analysis of particle mixing and heat conduction in a rotating drum. Chem. Eng. Sci. 2013, 97, 225–234. [Google Scholar] [CrossRef]

- Oschmann, T.; Kruggel-Emden, H. A novel method for the calculation of particle heat conduction and resolved 3D wall heat transfer for the CFD/DEM approach. Powder Technol. 2018, 338, 289–303. [Google Scholar] [CrossRef]

- Wu, Z.; Zhou, Y.; Fan, L. A fracture aperture dependent thermal-cohesive coupled model for modelling thermal conduction in fractured rock mass. Comput. Geotech. 2019, 114, 103108. [Google Scholar] [CrossRef]

- Mukherjee, R.; Sansare, S.; Nagarajan, V.; Chaudhuri, B. Discrete Element Modeling (DEM) based investigation of tribocharging in the pharmaceutical powders during hopper discharge. Int. J. Pharm. 2021, 596, 120284. [Google Scholar] [CrossRef]

- Zhang, T.; Lu, Y. A method to deal with constant wall flux boundary condition in a fluidized bed by CFD-DEM. Chem. Eng. J. 2021, 406, 126880. [Google Scholar] [CrossRef]

- Jiang, S.; Wan, H.; Cao, G.; Tan, Y.; Liu, J.; Yang, S.; Xiao, X.; Tong, Z.; Yu, Q.B. Optimization of the Stirring Blade Structure of the Pumping Unit Based on the Improvement of Concrete Suction Efficiency. Adv. Civ. Eng. 2022, 2022, 1255348. [Google Scholar] [CrossRef]

- Ouyang, Y.; Yang, Q.; Chen, X. Bonded-Particle Model with Nonlinear Elastic Tensile Stiffness for Rock-Like Materials. Appl. Sci. 2017, 7, 686. [Google Scholar] [CrossRef]

- Caserta, A.J.; Navarro, H.A.; Cabezas-Gómez, L. Damping coefficient and contact duration relations for continuous nonlinear spring-dashpot contact model in DEM. Powder Technol. 2016, 302, 462–479. [Google Scholar] [CrossRef]

- Wojtkowski, M.B.; Pecen, J.; Horabik, J.; Molenda, M. Rapeseed impact against a flat surface: Physical testing and DEM simulation with two contact models. Powder Technol. 2010, 198, 61–68. [Google Scholar] [CrossRef]

- Burns, S.J.; Hanley, K.J. Establishing stable time-steps for DEM simulations of non-collinear planar collisions with linear contact laws. Int. J. Numer. Methods Eng. 2017, 110, 186–200. [Google Scholar] [CrossRef]

- Wang, C.; Liu, G.; Zhai, Z.; Guo, X.Y.; Wu, Y. CFD-DEM study on the interaction between triboelectric charging and fluidization of particles in gas-solid fluidized beds. Powder Technol. 2023, 419, 118340. [Google Scholar] [CrossRef]

- Pei, C.; Wu, C.-Y.; England, D.; Byard, S.J.; Berchtold, H.; Adams, M.J. Numerical analysis of contact electrification using DEM-CFD. Powder Technol. 2013, 248, 34–43. [Google Scholar] [CrossRef]

- Rasera, J.N.; Cruise, R.D.; Cilliers, J.J.; Lamamy, J.; Hadler, K. Modelling the tribocharging process in 2D and 3D. Powder Technol. 2022, 407, 117607. [Google Scholar] [CrossRef]

- Yang, X. Design and experimental study of potato harvester in hilly and mountainous areas. INMATEH Agric. Eng. 2021, 64, 151–158. [Google Scholar] [CrossRef]

- Mino, Z. 1700/1710 potato combine harvester. Mod. Agric. Machinery 2012, 40. Available online: https://www.nongjitong.com/product/maen_1710b_potato_harvester.html (accessed on 23 January 2025).

- No.8 2014 Model Guide. Farm Machinery 2014, 63–70. Available online: https://kns.cnki.net/kcms2/article/abstract?v=OJyTKzW6Fepy5vUkJVPEWtlQecCtHJ-H7mS1OxQu6L29hKanbBbDnWeTOMYGjn8i_WFd56B7n-0aooK4QdYZ3ADXZXBmzTDXZYrmFMcEOZPUfsKmK8ieR6eYbnH1QNnFHkP899WFWOz_Tg_2ITXH_y-zYJ4IiwQqi0LQ-0pZKi7_uL2SJ9_EN_wNPqOVLeuc&uniplatform=NZKPT&language=CHS (accessed on 23 January 2025).

- Hongzhu 4U-170 potato harvester. Farmers Get Rich 2015, 27. Available online: https://www.nongjitong.com/product/qdhongzhu_4u-170_potato_harvester.html (accessed on 23 January 2025).

- Wei, H.; Zhang, J.; Yang, X.; Huang, X.; Dai, L.; Sun, G.; Liu, X. Improved design and experiment of 4UFD-1400 potato combine harvester. Trans. Chin. Soc. Agric. Eng. 2014, 30, 12–17. [Google Scholar]

- Zhao, M. Design of Crawler Self-Propelled Potato Harvester. Master’s Thesis, Ningxia University, Ningxia, China, 2023. [Google Scholar] [CrossRef]

- Wang, H. Design and experiment of mountain self-propelled potato combine harvester. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2021. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, W.; Sun, W.; Zhang, H.; Liu, X.; Li, H. Research progress on potato mechanized harvesting technology and equipment. Trans. Chin. Soc. Agric. Eng. 2023, 39, 1–22. [Google Scholar]

- Shi, M.; Wei, H.; Hu, Z.; Liu, X.; Yang, X. Investigation on the current situation of potato harvesting machinery products at home and abroad. Farm Mach. 2019, 40, 206–210. [Google Scholar]

- Zhao, Z.; Wu, M.; Jiang, X. A Review of Contact Models’ Properties for Discrete Element Simulation in Agricultural Engineering. Agriculture 2024, 14, 238. [Google Scholar] [CrossRef]

- Kim, Y.-S.; Siddique, M.A.A.; Kim, W.-S.; Kim, Y.-J.; Lee, S.-D.; Lee, D.-K.; Hwang, S.-J.; Nam, J.-S.; Park, S.-U.; Lim, R.-G. DEM simulation for draft force prediction of moldboard plow according to the tillage depth in cohesive soil. Comput. Electron. Agric. 2021, 189, 106368. [Google Scholar] [CrossRef]

- Pasha, M.; Hare, C.; Ghadiri, M.; Gunadi, A.; Piccione, P.M. Inter-particle coating variability in a rotary batch seed coater. Chem. Eng. Res. Des. 2017, 120, 92–101. [Google Scholar]

- Ren, D.; Yu, H.; Zhang, R.; Li, J.; Zhao, Y.; Liu, F.; Zhang, J.; Wang, W. Research and Experiments of Hazelnut Harvesting Machine Based on CFD-DEM Analysis. Agriculture 2022, 12, 2115. [Google Scholar] [CrossRef]

- Capdeville, P.J.; Kuang, S.; Yu, A. Unrevealing energy dissipation during iron ore transfer through chutes with different designs. Powder Technol. 2024, 435, 119446. [Google Scholar] [CrossRef]

- Tong, J.; Mohammad, M.; Zhang, J.; Ma, Y.; Rong, B.; Chen, D.; Menon, C. DEM Numerical Simulation of Abrasive Wear Characteristics of a Bioinspired Ridged Surface. J. Bionic Eng. 2010, 7, 175–181. [Google Scholar] [CrossRef]

- Zidek, M.; Zegzulka, J.; Jezerská, L.; Rozbroj, J.; Gelnar, D.; Nečas, J. Simulation model of loading bin bottom by bulk material. Chem. Eng. Res. Des. 2020, 154, 151–161. [Google Scholar] [CrossRef]

- Kesner, A.L.; Chotěborský, R.; Linda, M.; Hromasová, M.; Katinas, E.; Sutanto, H. Stress distribution on a soil tillage machine frame segment with a chisel shank simulated using discrete element and finite element methods and validate by experiment. Biosyst. Eng. 2021, 209, 125–138. [Google Scholar] [CrossRef]

- Aikins, K.A.; Ucgul, M.; Barr, J.B.; Awuah, E.; Antille, D.L.; Jensen, T.A.; Desbiolles, J.M.A. Review of Discrete Element Method Simulations of Soil Tillage and Furrow Opening. Agriculture 2023, 13, 541. [Google Scholar] [CrossRef]

- Li, H.; Gao, F. Improvement design of separation and conveying machinery and equipment of potato excavator in heavy soil. Phys. Chem. Earth Parts A/B/C. 2023, 130, 103363. [Google Scholar] [CrossRef]

- Li, J.; Jiang, X.; Ma, Y.; Tong, J.; Hu, B. Bionic Design of a Potato Digging Shovel with Drag Reduction Based on the Discrete Element Method (DEM) in Clay Soil. Appl. Sci. 2020, 10, 7096. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Hu, B.; Gu, T.; Wang, Z.; Wang, H. Analysis of the resistance reduction mechanism of potato bionic digging shovels in clay and heavy soil conditions. Comput. Electron. Agric. 2023, 214, 108315. [Google Scholar] [CrossRef]

- Gai, X.; Xie, S.; Deng, W.; Lu, K.; Ji, X. Construction and parameter calibration of potato double-layer flexible bonding model based on discrete-element method. J. Food Process Eng. 2024, 47, e14602. [Google Scholar] [CrossRef]

- Liang, Z.; Huang, Y.; Li, D.; Wada, M.E. Parameter determination of a viscoelastic–plastic contact model for potatoes during transient collisions. Biosyst. Eng. 2023, 234, 156–171. [Google Scholar] [CrossRef]

- Ye, F.; Lu, T.; Xu, C. Digging characteristics of grab based on DEM-MBD simulation and experiment. Comput. Part. Mech. 2024. [Google Scholar] [CrossRef]

- Chen, M.; Liu, X.; Hu, P.; Zhai, X.; Han, Z.; Shi, Y.; Zhu, W.; Wang, D.; He, X.; Shang, S. Study on rotor vibration potato-soil separation device for potato harvester using DEM-MBD coupling simulation. Comput. Electron. Agric. 2024, 218, 108638. [Google Scholar] [CrossRef]

- Xie, S.; Zhang, Y.; Li, J.; Liu, F. Analysis of Breaking and Separating Characteristics of Potato-Soil Aggregates Based on the New Type of Swing Separation Sieve. Agronomy 2024, 14, 1272. [Google Scholar] [CrossRef]

- McRae, D.C. Improving the Quality of the Potato Crop. Outlook Agric. 1990, 19, 237–242. [Google Scholar] [CrossRef]

- Xie, S.; Wang, C.; Deng, W. Experimental study on collision acceleration and damage characteristics of potato. J. Food Process Eng. 2020, 43, e13457. [Google Scholar] [CrossRef]

- Shang, Z.; Wang, F.; Xie, S.; Deng, W.; Li, J.; Guo, Y.; Lu, K.; Gai, X.; Ji, X. Construction and analysis of the forced vibration model of separating screen under a dropped potato. J. Food Process Eng. 2023, 46, e14346. [Google Scholar] [CrossRef]

- Deng, W.; Wang, C.; Xie, S. Collision simulation of potato on rod separator. Int. J. Food Eng. 2020, 17, 435–444. [Google Scholar] [CrossRef]

- Dorokhov, A.; Didmanidze, O.; Aksenov, A.; Sibirev, A.; Sazonov, N.; Mosyakov, M.; Godyaeva, M. The Results of Studies on the Assessment of the Destruction of Soil Clods during Combine Harvesting of Potatoes. Agriculture 2022, 12, 2024. [Google Scholar] [CrossRef]

- Milne, F.N.J. The Canon of Potato Science: 34. Potato Harvesting. Potato Res. 2007, 50, 347–349. [Google Scholar] [CrossRef]

- Dorokhov, A.; Ponomarev, A.; Zernov, V.; Petukhov, S.; Aksenov, A.; Sibirev, A.; Sazonov, N.; Godyaeva, M. The Results of Laboratory Studies of the Device for Evaluation of Suitability of Potato Tubers for Mechanized Harvesting. Appl. Sci. 2022, 12, 2171. [Google Scholar] [CrossRef]

- Li, Y.; Fan, J.; Hu, Z.; Luo, W.; Yang, H.; Shi, L.; Wu, F. Calibration of Discrete Element Model Parameters of Soil around Tubers during Potato Harvesting Period. Agriculture 2022, 12, 1475. [Google Scholar] [CrossRef]

- Du, X.; Liu, J.; Zhao, Y.; Zhang, C.; Zhang, X.; Wang, Y. Design and Test of Discrete Element-Based Separation Roller Potato-Soil Separation Device. Agriculture 2024, 14, 1053. [Google Scholar] [CrossRef]

- Li, Y.; Hu, Z.; Gu, F.; Wang, B.; Fan, J.; Yang, H.; Wu, F. DEM-MBD Coupling Simulation and Analysis of the Working Process of Soil and Tuber Separation of a Potato Combine Harvester. Agronomy 2022, 12, 1734. [Google Scholar] [CrossRef]

- Yan, D.; Deng, W.; Xie, S.; Liu, C.; Ren, Z.; Zhao, H.; Cai, Y.; Zhao, Z. Discrete Element-Based Simulation Analysis and Research of Potato Soil Agglomerate Fragmentation and Separation. Appl. Sci. 2023, 13, 8416. [Google Scholar] [CrossRef]

- Zhao, H.; Deng, W.; Xie, S.; Zhao, Z. Performance Optimization and Experimental Study of Small-Scale Potato-Grading Device. Agriculture 2024, 14, 822. [Google Scholar] [CrossRef]

- Geng, J.; Wang, S.; Gao, Z.; Liu, Z.; Rao, X. Influence of initial orientations on potato conveyor trajectories by machine vision. Comput. Electron. Agric. 2019, 163, 104838. [Google Scholar] [CrossRef]

- Xie, H.K.; Gao, G.; Tian, B.; Li, B.; Zhang, S.; Huang, J. Optimization of Potato Soil Transportation Separation Mechanism Based on Discrete Element Method and TRIZ Theory. J. Phys. Conf. Ser. 2019, 1267, 012071. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H.; Sun, W.; Li, H.; Liu, X.; Sun, G.; Lu, Y.; Chen, Y.; Xing, W. Optimization of Potato Planter Soil Lifting Device Based on TRIZ Theory. Agriculture 2024, 14, 1695. [Google Scholar] [CrossRef]

- Sun, H.; Ma, H.; Zhao, Y. DEM investigation on conveying of non-spherical particles in a screw conveyor. Particuology 2022, 65, 17–31. [Google Scholar] [CrossRef]

- McRae, D.C. A potato harvester delivery conveyor with automatic discharge height control. Potato Res. 1974, 17, 138–151. [Google Scholar] [CrossRef]

- Torres-Serra, J.; Rodriguez-Ferran, A.; Romero, E. Study of grain-scale effects in bulk handling using discrete element simulations. Powder Technol. 2021, 382, 284–299. [Google Scholar] [CrossRef]

- Ren, H.; Meng, W.; Sun, X.; Zhao, Z.; Zhao, X. Discrete element analysis on dynamic characteristics of directional material flow driven by horizontal trough-free screw conveyor. Powder Technol. 2023, 418, 118276. [Google Scholar] [CrossRef]

- Shi, Q.; Sakai, M. Recent progress on the discrete element method simulations for powder transport systems: A review. Adv. Powder Technol. 2022, 33, 103664. [Google Scholar] [CrossRef]

- Dai, H.; Li, Y. Research on the Collection Characteristics of a Hydraulic Collector for Seafloor Massive Sulfides. J. Mar. Sci. Eng. 2024, 12, 1534. [Google Scholar] [CrossRef]

- Zhang, B.; Lu, H.; Yang, J.; Sun, P.; Deng, L. Numerical and experimental study on ore-collecting characteristics of deep-sea seafloor massive sulfide. Ocean Eng. 2024, 310, 118729. [Google Scholar] [CrossRef]

- Hou, J.; Ren, Z.; Liu, D.; Ma, Z.Y.; Liu, X.; Wang, W. Parameter Calibration of a Discrete Element Model for Three-Compartment Separation and Fragmentation of Castor Capsules During Harvesting. J. Biosyst. Eng. 2023, 48, 198–214. [Google Scholar] [CrossRef]

| Name | Technical Characteristics | Appearance | Place of Production |

|---|---|---|---|

| WM4000 Potato Harvester |

|  | French |

| 1710A Potato Harvester |

|  | China |

| 4TS-490 Potato Harvester |

|  | China |

| 4U-90LH Potato Harvester |

|  | China |

| 4U-170B Potato Harvester |

|  | China |

| 4UFD-1400 Potato Harvester |

|  | China |

| 4U-2-900 Potato Harvester |

|  | China |

| TPH179 Potato Harvester |

|  | Japan |

| SHI-1500 Potato Harvester |

|  | Korea |

| 4UL-170C Potato Harvester |

|  | China |

| Name | Technical Characteristics | Appearance | Place of Production |

|---|---|---|---|

| VARITRON 470 Potato Combine Harvester |

|  | Germany |

| VENTOR 4150 Potato Combine Harvester |

|  | Germany |

| Double-L 859 Potato Combine Harvester |

|  | America |

| AVRSpirit6200 Potato Combine Harvester |

|  | Belgium |

| Dewulf r3060-3 Potato Combine Harvester |

|  | Belgium |

| Ropa keiler classic 2 Potato Combine Harvester |

|  | Germany |

| Standen T3 |

|  | England |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yue, Y.; Zhang, Q.; Dong, B.; Li, J. Application of Discrete Element Method to Potato Harvesting Machinery: A Review. Agriculture 2025, 15, 315. https://doi.org/10.3390/agriculture15030315

Yue Y, Zhang Q, Dong B, Li J. Application of Discrete Element Method to Potato Harvesting Machinery: A Review. Agriculture. 2025; 15(3):315. https://doi.org/10.3390/agriculture15030315

Chicago/Turabian StyleYue, Yuanman, Qian Zhang, Boyang Dong, and Jin Li. 2025. "Application of Discrete Element Method to Potato Harvesting Machinery: A Review" Agriculture 15, no. 3: 315. https://doi.org/10.3390/agriculture15030315

APA StyleYue, Y., Zhang, Q., Dong, B., & Li, J. (2025). Application of Discrete Element Method to Potato Harvesting Machinery: A Review. Agriculture, 15(3), 315. https://doi.org/10.3390/agriculture15030315