Design and Experiment of a Handheld Vibration Harvesting Device for Camellia oleifera Fruits

Abstract

1. Introduction

2. Materials and Methods

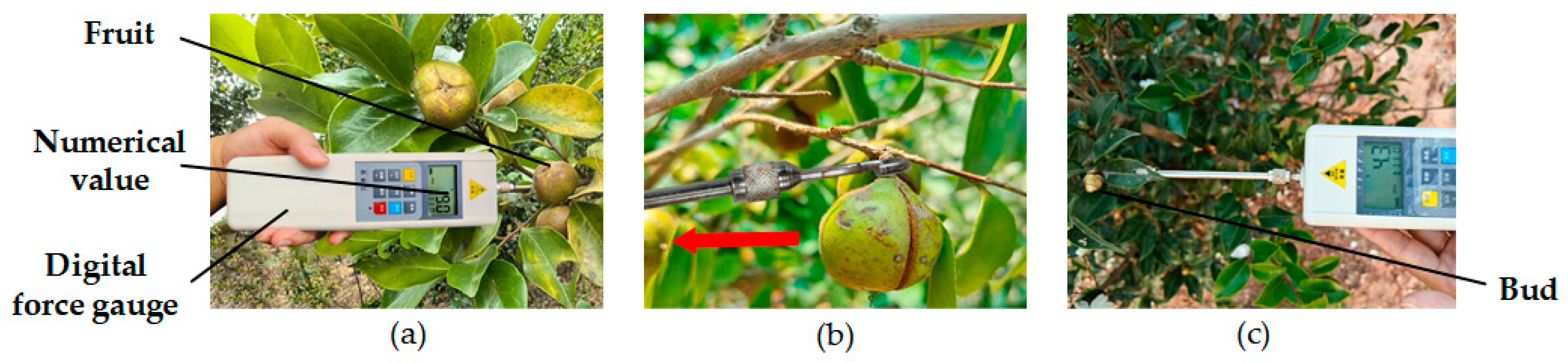

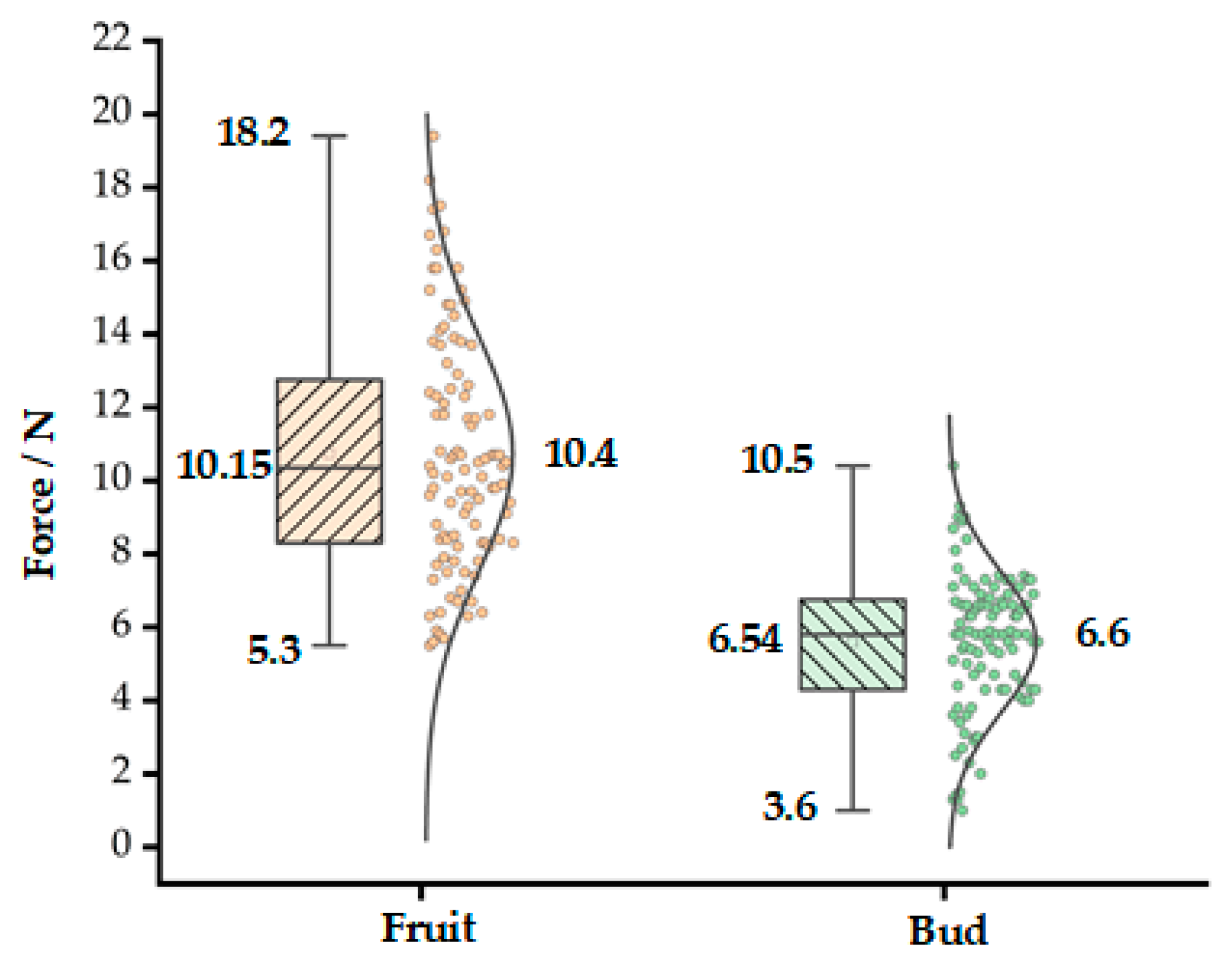

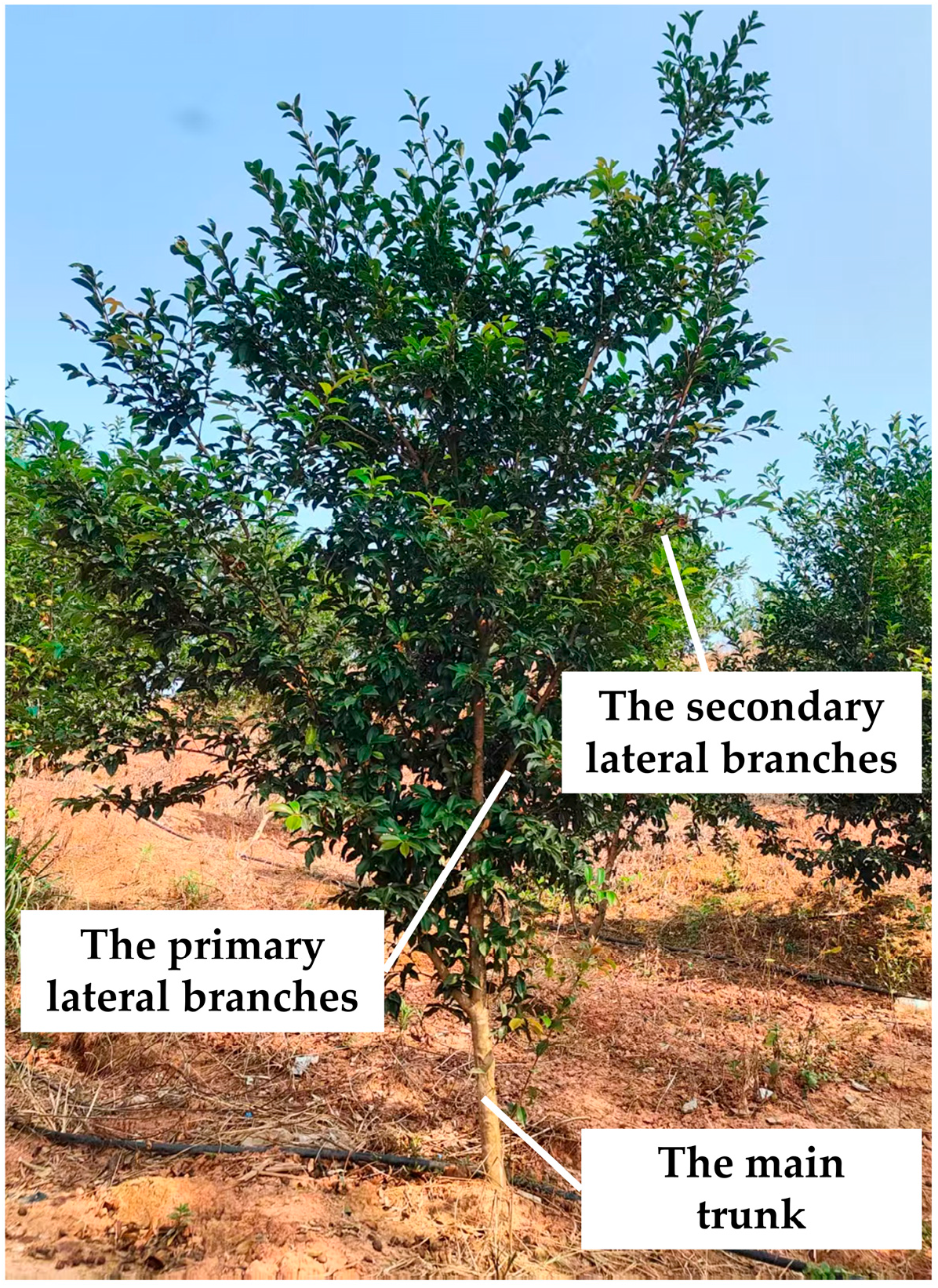

2.1. Study on the Mechanical Characteristics of CO Fruit Picking

2.1.1. Materials and Equipment

2.1.2. Analysis of Picking Characteristic Parameters

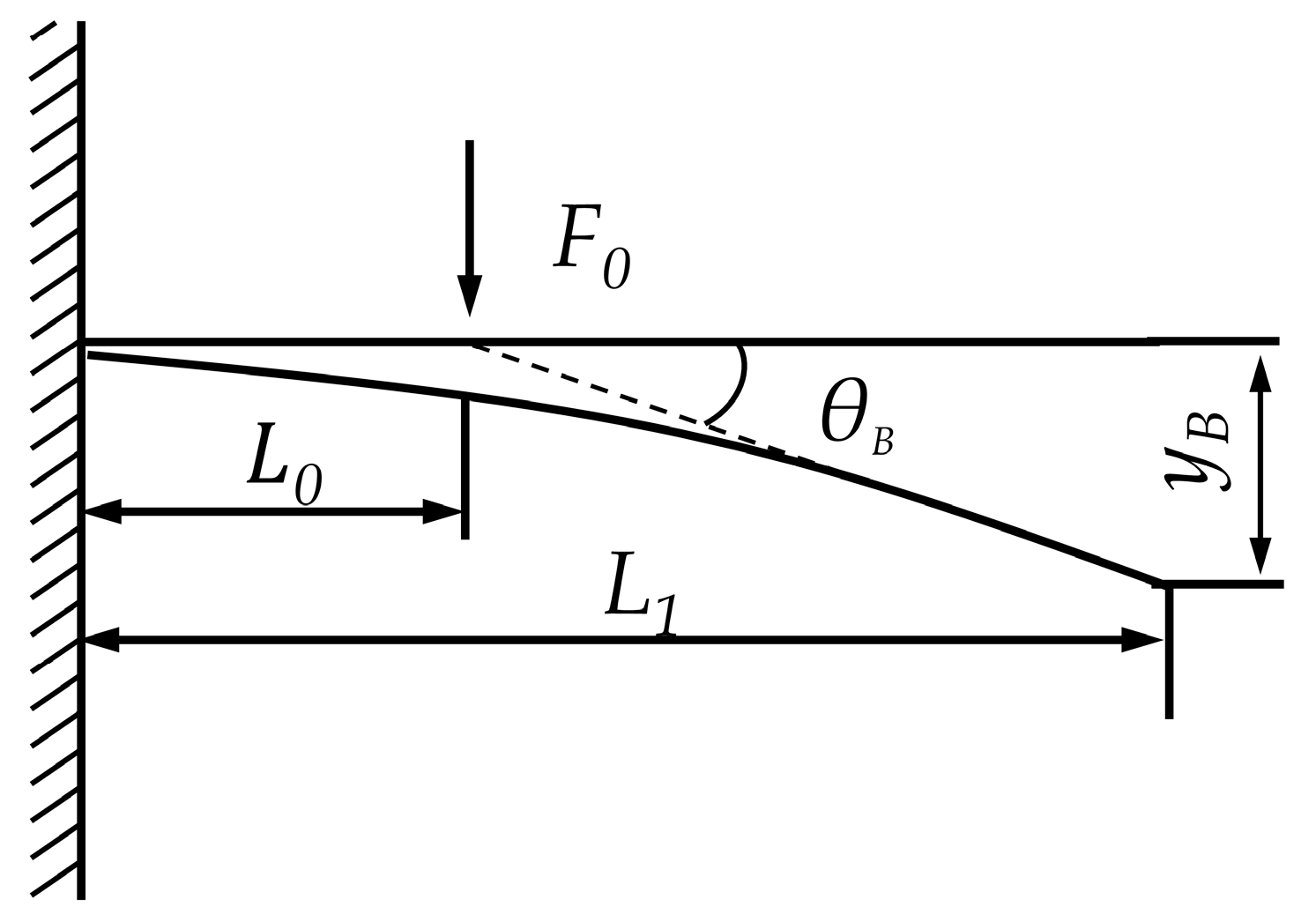

2.2. Analysis of Factors Affecting Forced Vibration Shedding of CO Fruits

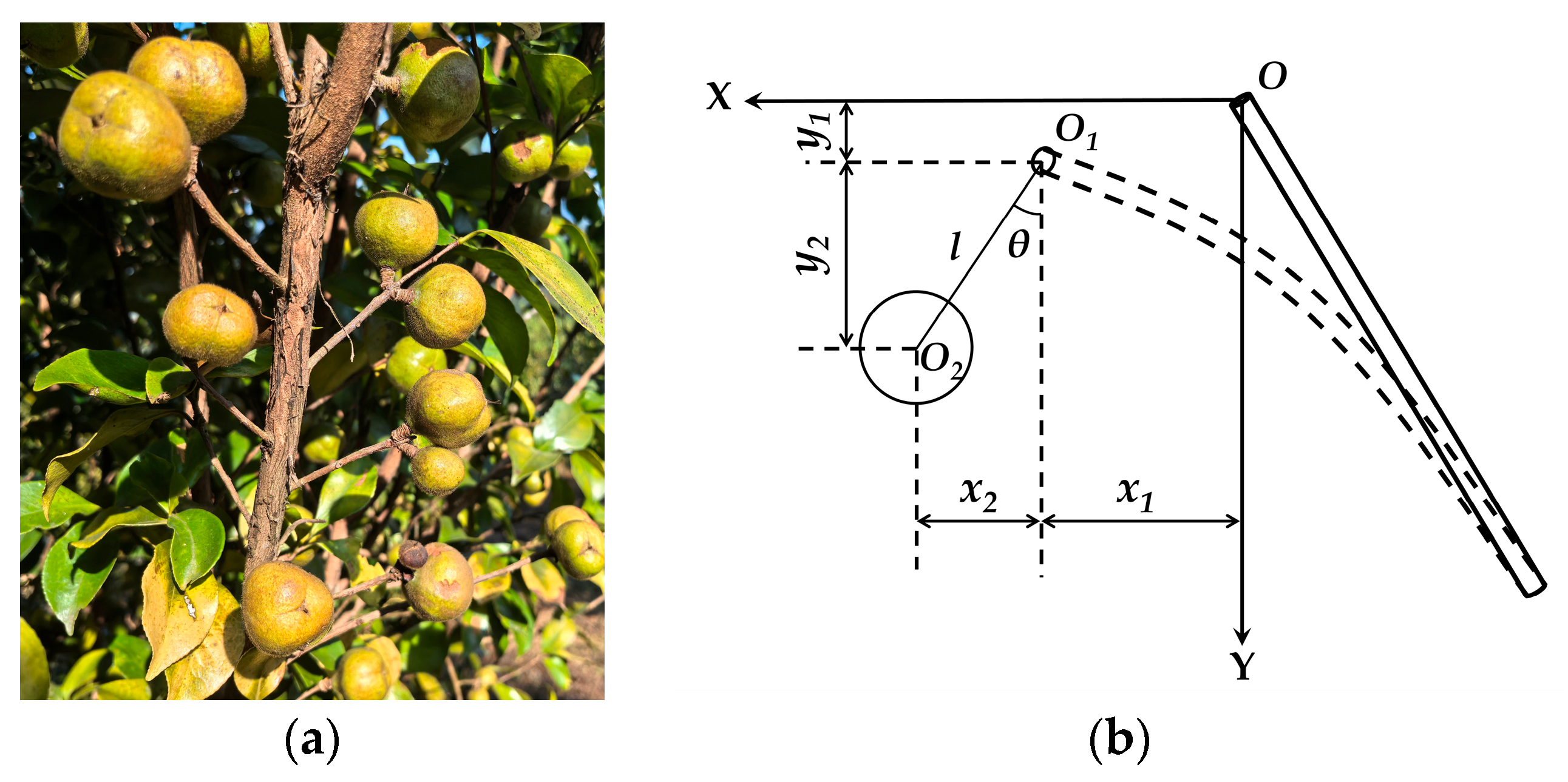

2.2.1. Establishment of a Single-Pendulum Dynamic Model for Fruit-Branch System

2.2.2. Solution of the Single-Pendulum Dynamic Model for CO Fruit

2.2.3. Analysis of Vibrational Shedding of the CO Fruits

2.3. Selection of Vibration Harvesting Parameters for CO Fruits

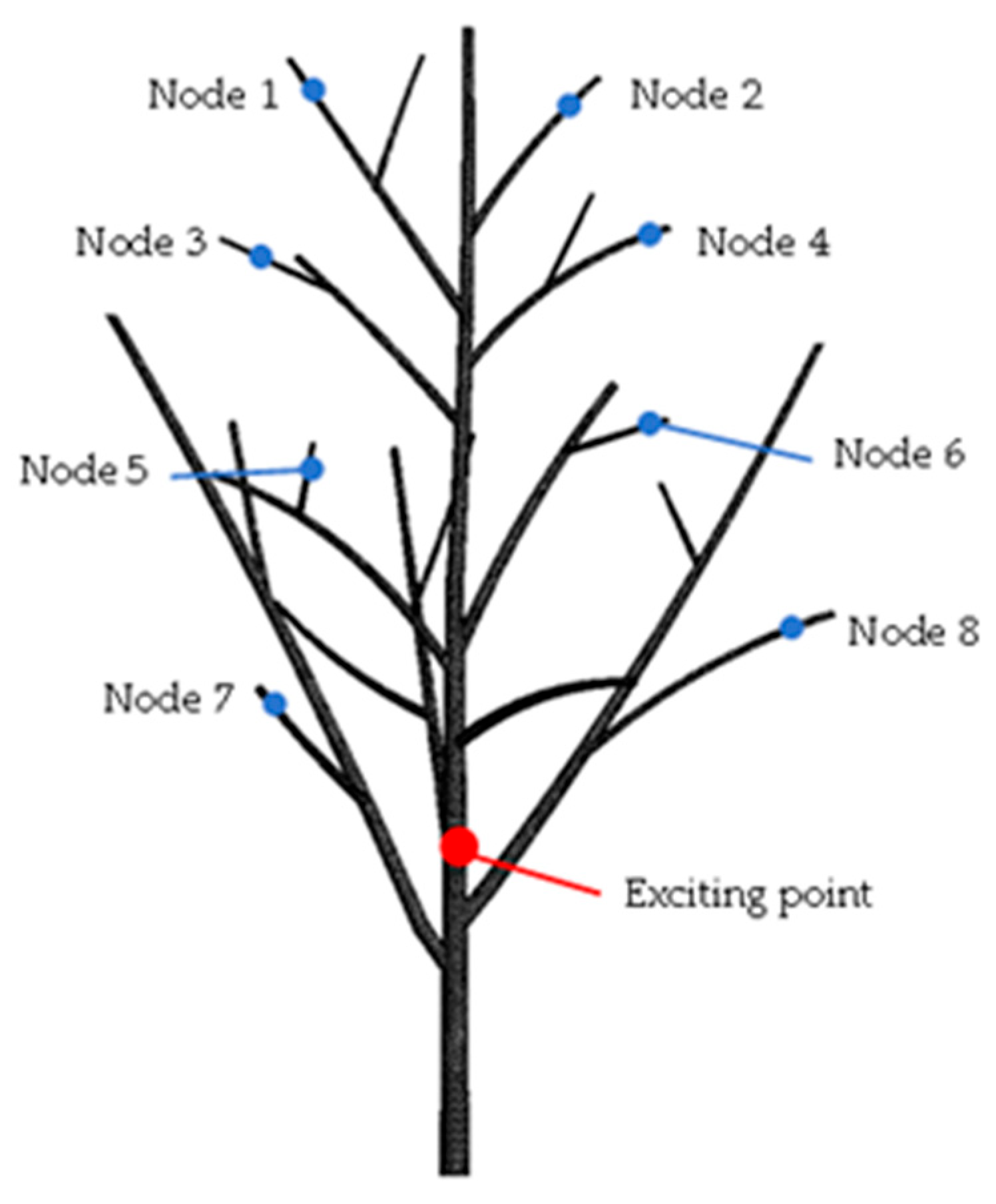

2.3.1. Finite Element Modeling of the CO Tree

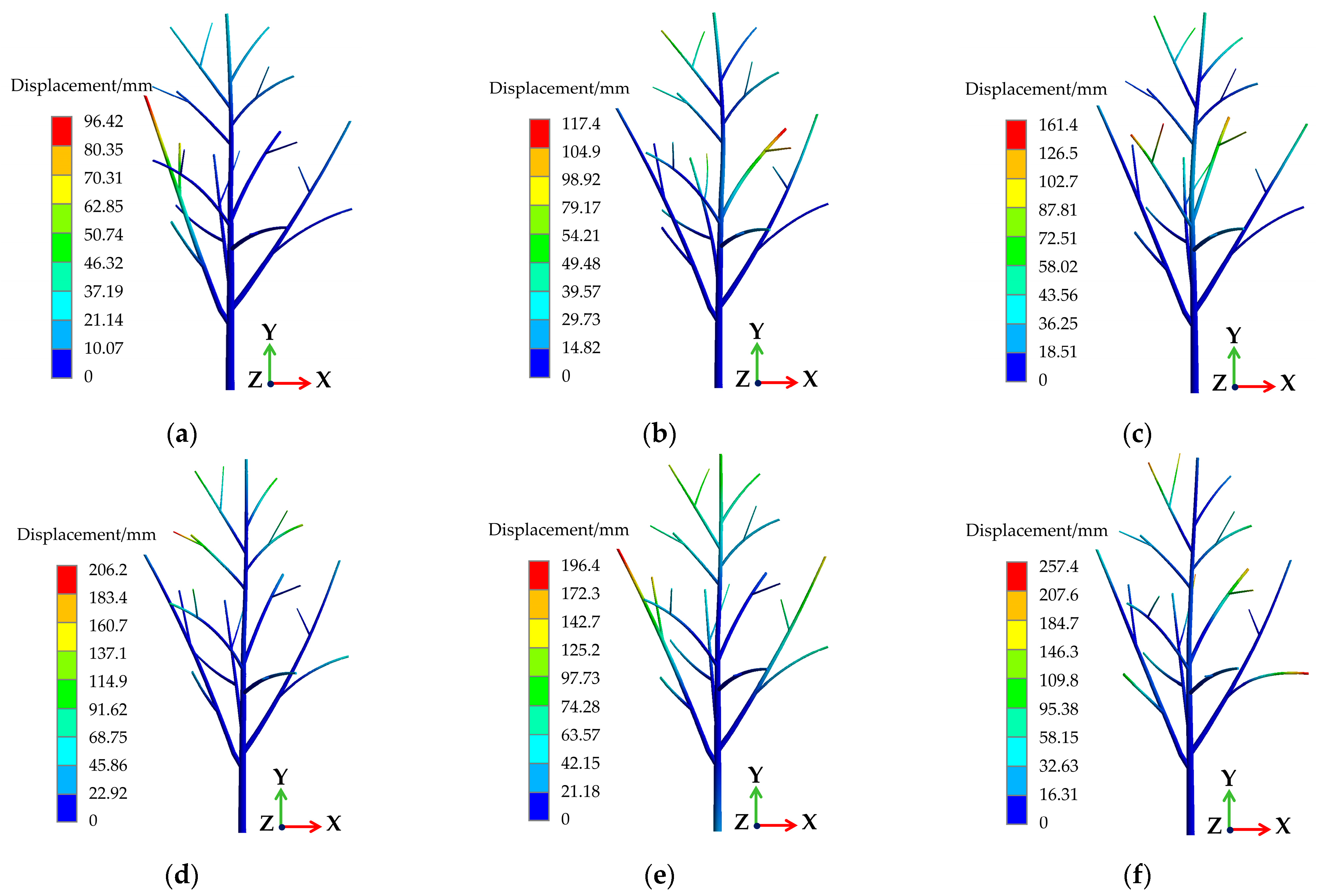

2.3.2. Finite Element Analysis

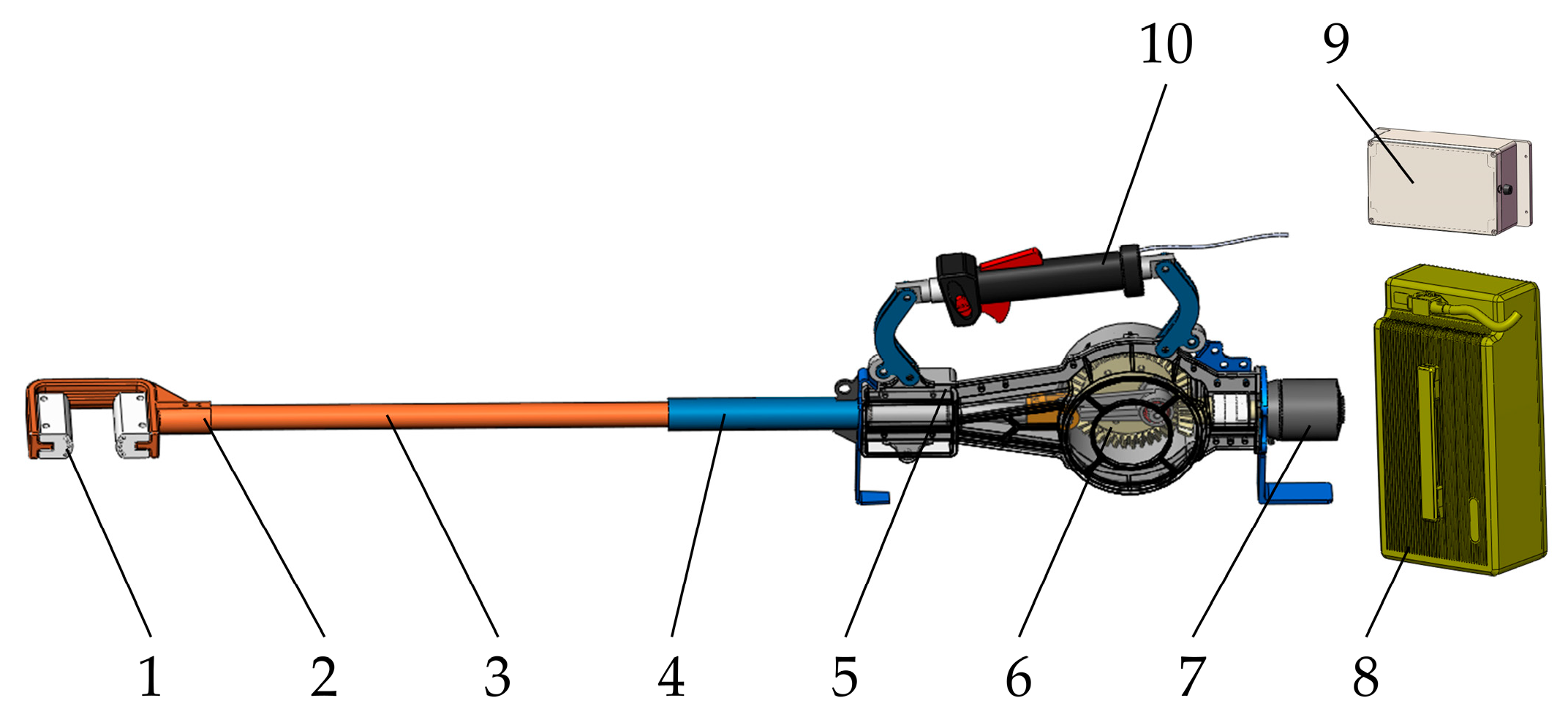

2.4. Design of the CO Vibration Harvesting Device

2.4.1. Structure and Working Principle of the Vibration Harvesting Device

2.4.2. Design of Vibrating Mechanism

2.4.3. Selection and Design of Related Devices

2.5. Rigid-Flexible Coupling Simulation of the CO Tree-Vibration Harvesting Device

2.6. Field Experiment

3. Results and Discussion

3.1. Modal Analysis of CO Tree

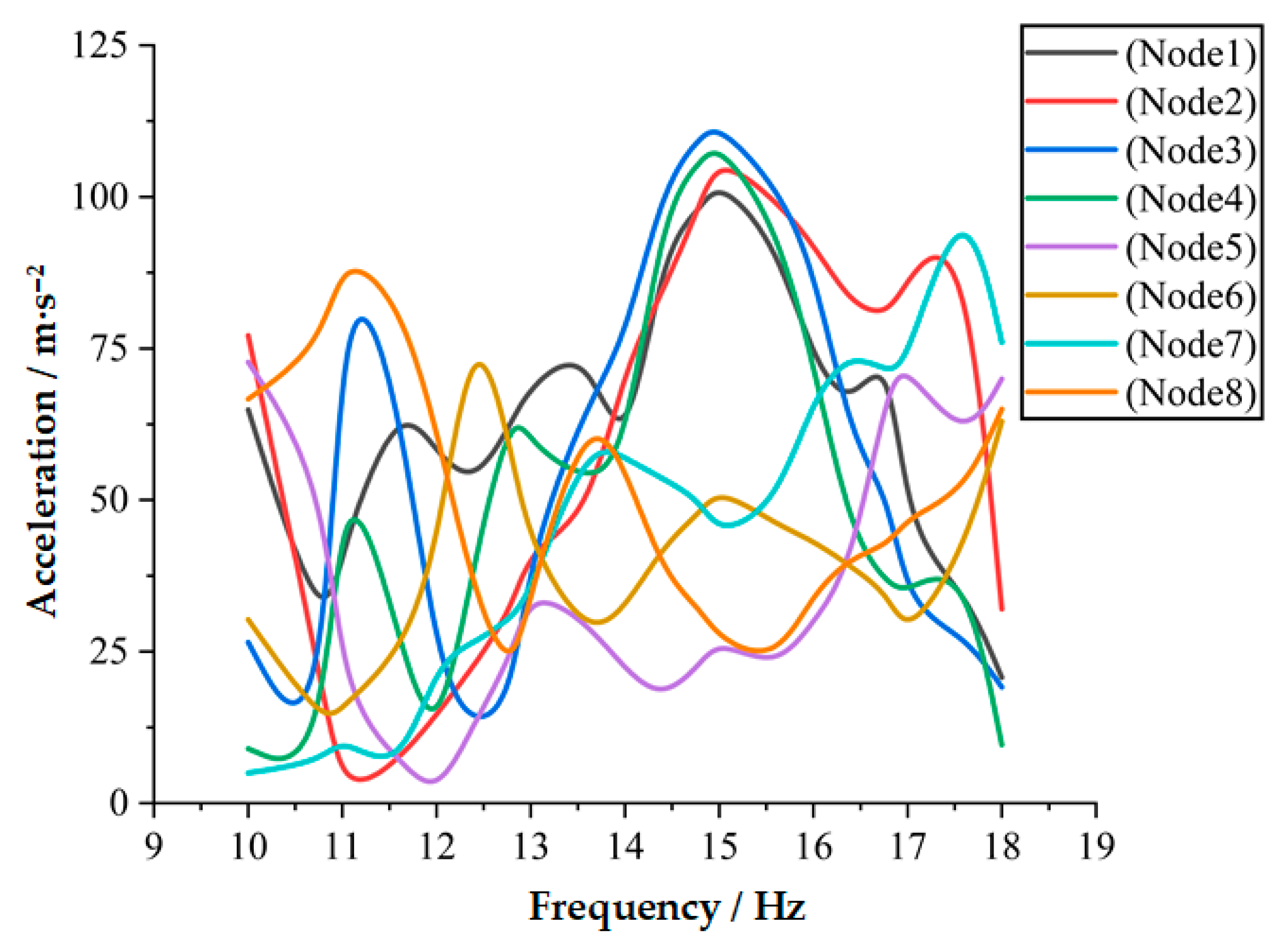

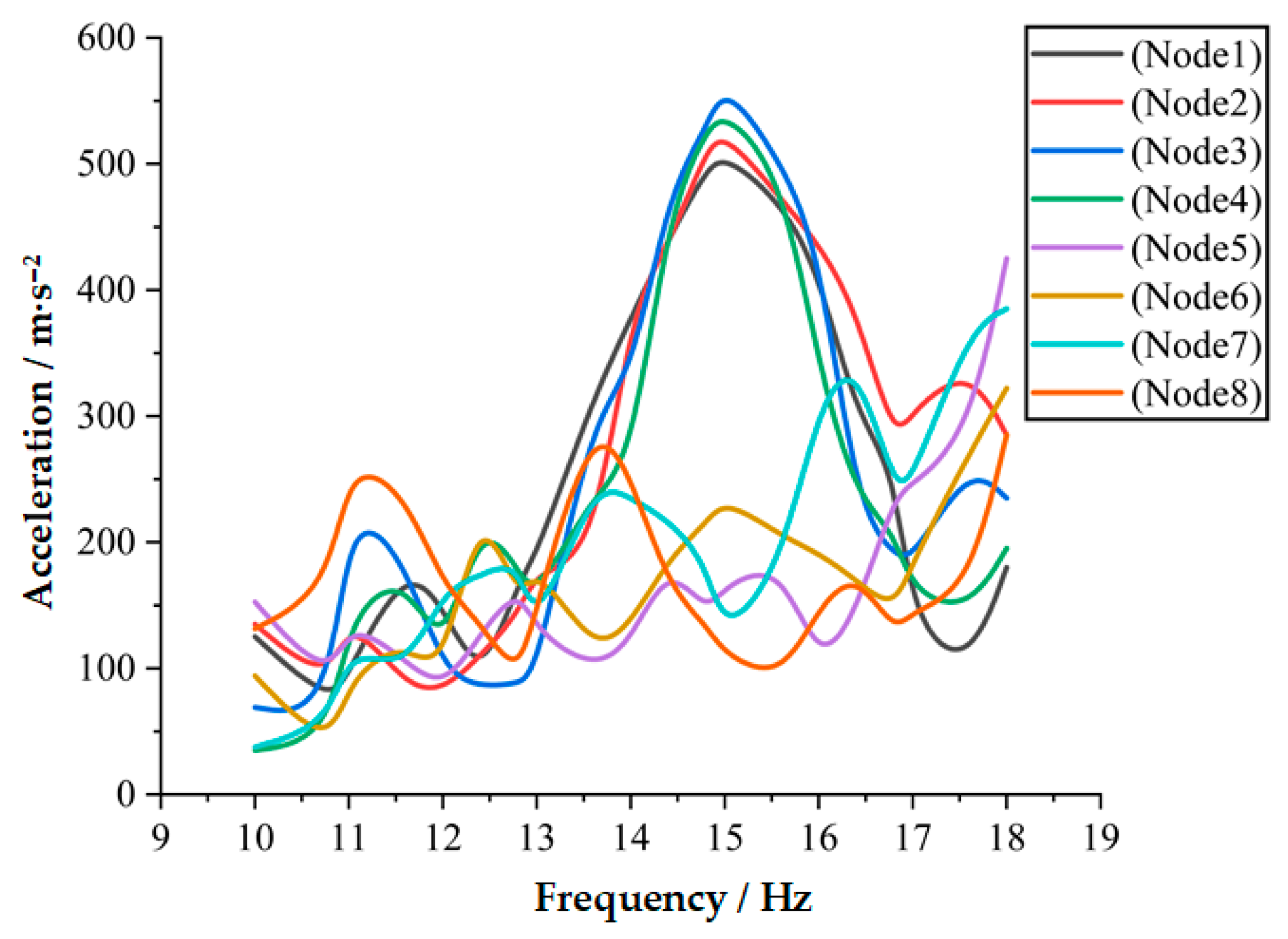

3.2. Harmonic Response Analysis of CO Tree

3.3. Rigid-Flexible Coupling Simulation Based on ADAMS

3.4. Field Experiment Results and Analysis

3.4.1. Experimental Results

3.4.2. Analysis of Experimental Results

3.4.3. Contribution Rate Analysis

3.4.4. Response Surface Analysis

3.4.5. Parameter Optimization

4. Conclusions

- (1)

- By solving the dynamic model of a simple pendulum, the tangential acceleration required for fruit detachment was determined to be 507.5 . The main factors influencing fruit shedding were identified as vibration frequency, amplitude, vibration duration, and vibration height.

- (2)

- Finite element analysis indicated that the optimal vibration frequency range for the CO tree lies between 10 Hz and 18 Hz. It was further found that an amplitude of 52.4 mm combined with a frequency of 15 Hz can generate the acceleration necessary for fruit detachment.

- (3)

- Rigid–flexible coupling simulations were conducted to verify the validity of the dynamic model and to assess the feasibility of the harvesting device; these simulations also revealed variations in lateral branch acceleration under different parameter settings.

- (4)

- The experimental results were optimized using the Response Optimization module in Design-Expert. The optimal parameter combination for the handheld CO vibration harvesting device was determined to be: vibration frequency of 14 Hz, vibration height of 980 mm, and vibration duration of 13 s. Under these conditions, the fruit-picking efficiency reached 95.22%, demonstrating an ideal harvesting performance that meets the requirements for CO fruit harvesting.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, J.Z. Current Status and Countermeasures of Oil Tea Industry Development in Guangxi. Rural Sci. Exp. 2024, 12, 124–126. [Google Scholar]

- Ren, W. Research on the Value of Camellia Oil Planting and the Plantation Technology. For. Sci. Technol. Inf. 2025, 57, 181–183. [Google Scholar]

- Wu, J.P.; Tang, Q.J.; Zhang, D.Q.; Luo, H.J. Research on Mechanized Planting of Camellia oleifera in Hilly and Mountainous Areas of China. South Forum 2025, 56, 1–6. [Google Scholar]

- Gao, Q.; Han, J.; Zeng, S.; Wang, Y.; Wei, W.; Wang, D.; Ye, H.; Lu, J.; Zeng, H. Performance Analysis and Operation Parameter Optimization of Shaker-Type Harvesting for Camellia Fruits. Agriculture 2024, 14, 1989. [Google Scholar] [CrossRef]

- Yu, Z.; Wu, J.; Jiang, F.; Xing, H.; Yan, L.; Yang, J. Kinematic Analysis of the Vibration Harvesting Process of Lycium barbarum L. Fruit. Agriculture 2024, 14, 1715. [Google Scholar] [CrossRef]

- Zhao, J.; Tsuchikawa, S.; Ma, T.; Hu, G.; Chen, Y.; Wang, Z.; Chen, Q.; Gao, Z.; Chen, J. Modal Analysis and Experiment of a Lycium barbarum L. Shrub for Efficient Vibration Harvesting of Fruit. Agriculture 2021, 11, 519. [Google Scholar] [CrossRef]

- Cetinkaya, C.; Polat, R.; Ozalp, A.F. Investigation of the Vibration Effect of Using Single or Double Eccentric Mass in the Trunk Shakers Used in Fruit Harvesting. Eng. Sci. Technol. Int. J. 2022, 35, 101228. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, J.; Zhao, J.; Wang, F.; Zhang, H.; Su, X.; Sun, Y.; Liu, J.; Zhao, D. Effects of Different Excitation Parameters on Mechanized Harvesting Performance and Postharvest Quality of First-Crop Organic Goji Berries in Saline-Alkali Land. Agriculture 2025, 15, 1377. [Google Scholar] [CrossRef]

- Bu, L.; Chen, C.; Hu, G.; Zhou, J.; Sugirbay, A.; Chen, J. Investigating the Dynamic Behavior of an Apple Branch-Stem-Fruit Model Using Experimental and Simulation Analysis. Comput. Electron. Agric. 2021, 186, 106224. [Google Scholar] [CrossRef]

- Zhou, J.; Xu, L.; Zhang, A.; Hang, X. Finite Element Explicit Dynamics Simulation of Motion and Shedding of Jujube Fruits Under Forced Vibration. Comput. Electron. Agric. 2022, 198, 107009. [Google Scholar] [CrossRef]

- Du, X.; Shen, T.; Zhao, L.; Zhang, G.; Hu, A.; Fang, S.; Cao, Y.; Yao, X. Design and Experiment of the Comb-Brush Harvesting Machine with Variable Spacing for Oil-Tea Camellia Fruit. Int. J. Agric. Biol. Eng. 2021, 14, 172–177. [Google Scholar] [CrossRef]

- Lyu, X.; Wang, H.; Xu, G.; Chu, C. Research on Fruit Picking Test of Blueberry Harvesting Machinery Under Transmission Clearance. Heliyon 2024, 10, e34740. [Google Scholar] [CrossRef]

- Hu, Y.; Zheng, Z.; Yu, C.; Feng, J.; Qiao, Y. Vibration Response Characteristics of Jujube Trees Based on Finite Element Method and Structure-from-Motion. Sci. Hortic. 2024, 331, 113125. [Google Scholar] [CrossRef]

- Cao, J.; Bai, X.; Xu, D.; Li, W.; Chen, C. Experiment and Analysis on Walnut (Juglans regia L.) Shedding Force Based on Low-Frequency Vibration Response. Ind. Crops Prod. 2023, 204, 117242. [Google Scholar] [CrossRef]

- Yu, Y.; Cao, Y.; Lai, Q.; Zhao, Q.; Sun, Z.; Zhou, S.; Song, D. Design and Operation Parameters of Vibrating Harvester for Coffea arabica L. Agriculture 2023, 13, 700. [Google Scholar] [CrossRef]

- Zhang, X.; Niu, Z.; Deng, J.; Mu, H.; Cui, Y. Vibration Simulation and Experiment of Three Open-Center Shape Olive Trees. Vibroeng. Procedia 2022, 41, 60–65. [Google Scholar] [CrossRef]

- Castro-García, S.; Blanco-Roldán, G.L.; Gil-Ribes, J.A.; Agüera-Vega, J. Dynamic Analysis of Olive Trees in Intensive Orchards Under Forced Vibration. Trees 2008, 22, 795–802. [Google Scholar] [CrossRef]

- Wang, R.; Fang, D.; Wu, C.; Wang, B.; Zhu, H.; Hu, T.; Wu, D. Dynamic Response of Camellia Oleifera Fruit-Branch Based on Mathematical Model and High-Speed Photography. Biosyst. Eng. 2024, 237, 232–241. [Google Scholar] [CrossRef]

- Hu, G.; Zhou, J.; Chen, Q.; Luo, T.; Li, P.; Chen, Y.; Zhang, S.; Chen, J. Effects of Different Picking Patterns and Sequences on the Vibration of Apples on the Same Branch. Biosyst. Eng. 2024, 237, 26–37. [Google Scholar] [CrossRef]

- Zhao, J.; Ma, T.; Inagaki, T.; Chen, Q.; Gao, Z.; Sun, L.; Cai, H.; Chen, C.; Li, C.; Zhang, S.; et al. Finite Element Method Simulations and Experiments of Detachments of Lycium barbarum L. Forests 2021, 12, 699. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, J.; Liu, Y.; Wang, T.; Wang, H.; Chen, S.; Zhou, J.; Zhao, D. Motion Trajectory of Different Fruiting Types of Camellia Oleifera Fruit Under Vibration: Theoretical and Experimental Studies. Ind. Crops Prod. 2025, 231, 121173. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R.; Al-Mahdouri, A. Effect on Physiological Properties of Banana Fruit Based on Pendulum Impact Test and Storage. Curr. Res. Food Sci. 2023, 7, 100640. [Google Scholar] [CrossRef]

- Mei, S.; Wang, J.; Song, Z.; Tang, D.; Shen, C. Mechanism and Experimental Study on the Fruit Detachment of Chinese Wolfberry Through Reciprocating Vibration. Int. J. Agric. Biol. Eng. 2024, 17, 47–58. [Google Scholar] [CrossRef]

- Fu, W.; Zhang, Z.; Liu, Y.; Pan, J.; Cui, J.; Ding, K.; Zhang, H. Simulation Experiment in Lab on Force Transfer Effect of Jujube Under Vibration Excitation. Trans. Chin. Soc. Agric. Eng. 2017, 33, 65–72. [Google Scholar]

- Wang, Y.; Xu, L.; Zhang, Y.; Zhu, Y.; Zhou, H.; Cui, W.; Zhang, A. Study of Vibration Patterns and Response Transfer Relationships in Walnut Tree Trunks. Sci. Hortic. 2024, 337, 113567. [Google Scholar] [CrossRef]

- Du, X.; Han, X.; Shen, T.; Meng, Z.; Chen, K.; Yao, X.; Cao, Y.; Castro-García, S. Natural Frequency Identification Model Based on BP Neural Network for Camellia Oleifera Fruit Harvesting. Biosyst. Eng. 2024, 237, 38–49. [Google Scholar] [CrossRef]

- Moravčík, Ľ.; Vincúr, R.; Rózová, Z. Analysis of the Static Behavior of a Single Tree on a Finite Element Model. Plants 2021, 10, 1284. [Google Scholar] [CrossRef]

- Bentaher, H.; Haddar, M.; Fakhfakh, T.; Mâalej, A. Finite Elements Modeling of Olive Tree Mechanical Harvesting Using Different Shakers. Trees 2013, 27, 1537–1545. [Google Scholar] [CrossRef]

- Burcham, D.C.; Au, S.-K. Identifying Modal Properties of Trees with Bayesian Inference. Agric. For. Meteorol. 2022, 316, 108804. [Google Scholar] [CrossRef]

- Castro-Garcia, S.; Sola-Guirado, R.R.; Gil-Ribes, J.A. Vibration Analysis of the Fruit Detachment Process in Late-Season ‘Valencia’ Orange with Canopy Shaker Technology. Biosyst. Eng. 2018, 170, 130–137. [Google Scholar] [CrossRef]

- Castro-García, S.; Blanco-Roldán, G.L.; Gil-Ribes, J.A. Vibrational and Operational Parameters in Mechanical Cone Harvesting of Stone Pine (Pinus pinea L.). Biosyst. Eng. 2012, 112, 352–358. [Google Scholar] [CrossRef]

- Láng, Z.; Csorba, L. A Two Degree of Freedom Damped Fruit Tree Model. Agric. Eng. Int. CIGR J. 2015, 17, 1–7. [Google Scholar]

- Dang, K.; Niu, Z.; Mu, H.; Lan, W.; Zhang, X.; Xin, D.; Zhang, J.; Cui, Y. Vibration Harvesting Process of Olive Trees Based on Response Surface Methodology and Rigid-Flexible Coupling Simulation. Int. J. Agric. Biol. Eng. 2025, 18, 25–36. [Google Scholar] [CrossRef]

- Tian, Y.; Jia, Y.; Zhang, J. New Method for Multibody Dynamics Based on Unknown Constraint Force. Sci. China Technol. Sci. 2024, 67, 791–808. [Google Scholar] [CrossRef]

- Dupuy, L.X.; Fourcaud, T.; Lac, P.; Stokes, A. A Generic 3D Finite Element Model of Tree Anchorage Integrating Soil Mechanics and Real Root System Architecture. Am. J. Bot. 2007, 94, 1506–1514. [Google Scholar] [CrossRef]

- Kim, Y.; Rahardjo, H.; Tsen-Tieng, D.L. Stability Analysis of Laterally Loaded Trees Based on Tree-Root-Soil Interaction. Urban For. Urban Green. 2020, 49, 126639. [Google Scholar] [CrossRef]

- Kanahama, T.; Chalermsin, C.L.; Sato, M. Mechanical Instability of Heavy Column with Rotational Spring. J. Mech. 2023, 39, 480–490. [Google Scholar] [CrossRef]

- Fan, P.; Yan, B.; Wang, M.; Lei, X.; Liu, Z.; Yang, F. Three-Finger Grasp Planning and Experimental Analysis of Picking Patterns for Robotic Apple Harvesting. Comput. Electron. Agric. 2021, 188, 106353. [Google Scholar] [CrossRef]

- Li, Q.; Kang, L.; Rao, H.; Liu, M. Design and experiment of multichannel camellia-fruit-picking device. Eng. Agríc. 2023, 43, e20220038. [Google Scholar] [CrossRef]

- Wu, D.; Ding, D.; Cui, B.; Jiang, S.; Zhao, E.; Liu, Y.; Cao, C. Design and Experiment of Vibration Plate Type Camellia Fruit Picking Machine. Biol. Eng. 2022, 15, 130–138. [Google Scholar] [CrossRef]

| Type | Mass/g | Diameter/mm |

|---|---|---|

| CO fruits | 20.5 ± 8.3 | 28.8 ± 5.5 |

| Flower buds | 0.5 ± 0.1 | 9.6 ± 1.6 |

| Number | The Main Trunk | The Primary Lateral Branches | The Secondary Lateral Branches | Canopy Spread | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Intial | End | Height | Intial | End | Height | Intial | End | Height | Length × Width | |

| 1 | 58 | 16 | 2700 | 27~38 | 10 | 1000 | 17~20 | 7 | 360 | 1400 × 2200 |

| 2 | 50 | 12 | 2800 | 23~30 | 8 | 700 | 14~16 | 5 | 450 | 1500 × 1800 |

| 3 | 48 | 18 | 3300 | 23~28 | 9 | 720 | 13~17 | 8 | 320 | 1800 × 2100 |

| 4 | 45 | 17 | 2300 | 25~28 | 11 | 850 | 15~19 | 8 | 430 | 1300 × 1800 |

| 5 | 42 | 14 | 2500 | 21~25 | 6 | 800 | 11~13 | 5 | 300 | 1600 × 2300 |

| 6 | 47 | 15 | 2200 | 29~32 | 7 | 775 | 17~19 | 6 | 340 | 1500 × 1900 |

| 7 | 45 | 11 | 2000 | 24~29 | 10 | 910 | 13~15 | 5 | 210 | 1200 × 1400 |

| 8 | 46 | 12 | 2550 | 19~22 | 8 | 1100 | 11~14 | 5 | 240 | 1700 × 2000 |

| Parameter | Value |

|---|---|

| Length/mm | 1400 |

| Motor power/kW | 1 |

| Working power supply/V | 48 |

| Frequency/Hz | 0~20 |

| Amplitude/mm | 52.4 |

| Weight/kg | 15 |

| Modal Frequency/Hz | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Order 1 | Order 3 | Order 8 | Order 10 | Order 12 | Order 13 | Order 15 | Order 18 | Order 20 | Order 26 | Order 32 | Order 40 |

| 2.3 | 3.9 | 10.6 | 11.4 | 12.2 | 13.7 | 14.5 | 15.4 | 17.2 | 21.3 | 26.3 | 33.5 |

| Encodings | Considerations | ||

|---|---|---|---|

| Vibration Frequency A/Hz | Vibration Height B/mm | Vibration Duration C/s | |

| −1 | 12 | 600 | 10 |

| 0 | 15 | 900 | 15 |

| 1 | 18 | 1200 | 20 |

| Serial Number | Considerations | P/% | ||

|---|---|---|---|---|

| A/Hz | B/mm | C/s | ||

| 1 | 12 | 1200 | 15 | 82.54 |

| 2 | 15 | 900 | 15 | 92.13 |

| 3 | 12 | 600 | 15 | 81.95 |

| 4 | 12 | 900 | 10 | 84.02 |

| 5 | 15 | 600 | 20 | 86.45 |

| 6 | 18 | 900 | 20 | 88.93 |

| 7 | 15 | 900 | 15 | 90.14 |

| 8 | 15 | 1200 | 20 | 88.21 |

| 9 | 18 | 600 | 15 | 83.85 |

| 10 | 18 | 1200 | 15 | 88.74 |

| 11 | 15 | 600 | 10 | 84.53 |

| 12 | 15 | 1200 | 10 | 88.31 |

| 13 | 15 | 900 | 15 | 90.14 |

| 14 | 15 | 900 | 15 | 92.87 |

| 15 | 15 | 900 | 15 | 91.74 |

| 16 | 18 | 900 | 10 | 86.42 |

| 17 | 12 | 900 | 20 | 83.51 |

| Source | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 255.86 | 9 | 28.43 | 741.60 | <0.0001 ** |

| A | 31.68 | 1 | 31.68 | 826.412 | <0.0001 ** |

| B | 15.15 | 1 | 15.15 | 395.27 | <0.0001 ** |

| C | 1.81 | 1 | 1.81 | 47.33 | 0.0002 ** |

| AB | 4.62 | 1 | 4.62 | 120.58 | <0.0001 ** |

| AC | 2.28 | 1 | 2.28 | 59.48 | 0.0001 ** |

| BC | 1.03 | 1 | 1.03 | 26.87 | 0.0013 ** |

| A2 | 100.20 | 1 | 100.20 | 2613.78 | <0.0001 ** |

| B2 | 58.45 | 1 | 58.45 | 1524.64 | <0.0001 ** |

| C2 | 21.81 | 1 | 21.81 | 568.84 | <0.0001 ** |

| Residual | 0.2683 | 7 | 0.0383 | ||

| Lack of Fit | 0.0146 | 3 | 0.0049 | 0.0769 | 0.9692 |

| Pure Error | 0.2537 | 4 | 0.0634 | ||

| Cor Total | 256.13 | 16 |

| Considerations | Δj |

|---|---|

| A | 2.9859 |

| B | 2.8541 |

| C | 2.7687 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Q.; Zeng, H.; Xin, Q.; Wang, D.; Huang, J.; Cai, Y.; Li, Y.; Jiang, Z.; Dun, Z. Design and Experiment of a Handheld Vibration Harvesting Device for Camellia oleifera Fruits. Agriculture 2025, 15, 2585. https://doi.org/10.3390/agriculture15242585

Gao Q, Zeng H, Xin Q, Wang D, Huang J, Cai Y, Li Y, Jiang Z, Dun Z. Design and Experiment of a Handheld Vibration Harvesting Device for Camellia oleifera Fruits. Agriculture. 2025; 15(24):2585. https://doi.org/10.3390/agriculture15242585

Chicago/Turabian StyleGao, Qiaoming, Haoxiang Zeng, Qingqing Xin, Dongxue Wang, Jianyou Huang, Ya Cai, Yuejuan Li, Zepeng Jiang, and Zhaofu Dun. 2025. "Design and Experiment of a Handheld Vibration Harvesting Device for Camellia oleifera Fruits" Agriculture 15, no. 24: 2585. https://doi.org/10.3390/agriculture15242585

APA StyleGao, Q., Zeng, H., Xin, Q., Wang, D., Huang, J., Cai, Y., Li, Y., Jiang, Z., & Dun, Z. (2025). Design and Experiment of a Handheld Vibration Harvesting Device for Camellia oleifera Fruits. Agriculture, 15(24), 2585. https://doi.org/10.3390/agriculture15242585