Design and Experiment of Axial Flow Threshing and Cleaning Device for Roller Brush Type Castor Harvesting Machine

Abstract

1. Introduction

2. Materials and Methods

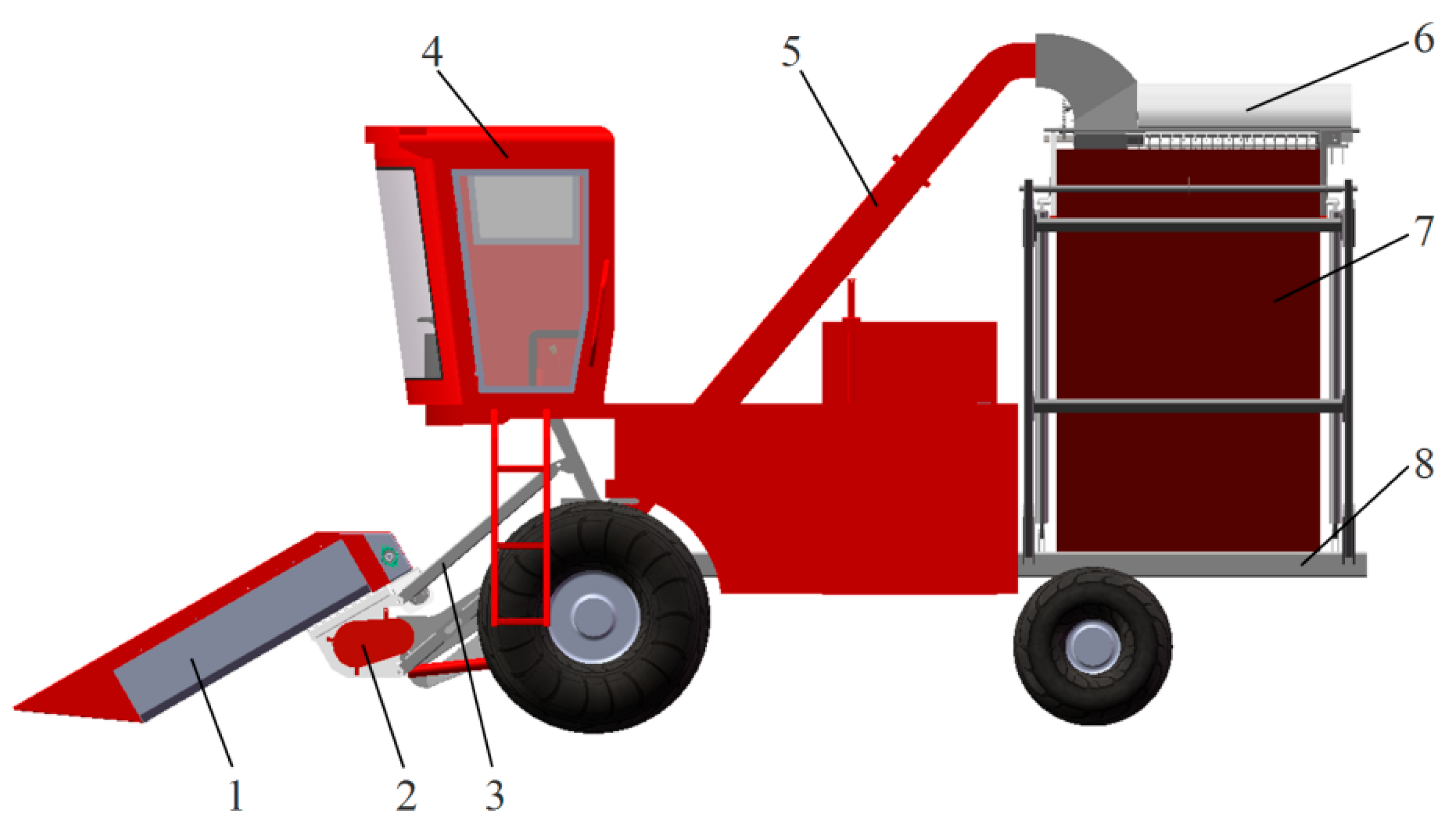

2.1. Machine Structure and Operating Principle

2.1.1. Overall Structure

2.1.2. Operating Principle of Threshing and Cleaning Device

2.2. Design and Calculation of Key Components

2.2.1. Design of Auger-Rod-Tooth Roller

- Spiral conveyor design

- 2.

- Rod-Tooth Structure Design

- 3.

- Force analysis of seed and rod tooth collision

2.2.2. Concave Sieve Design

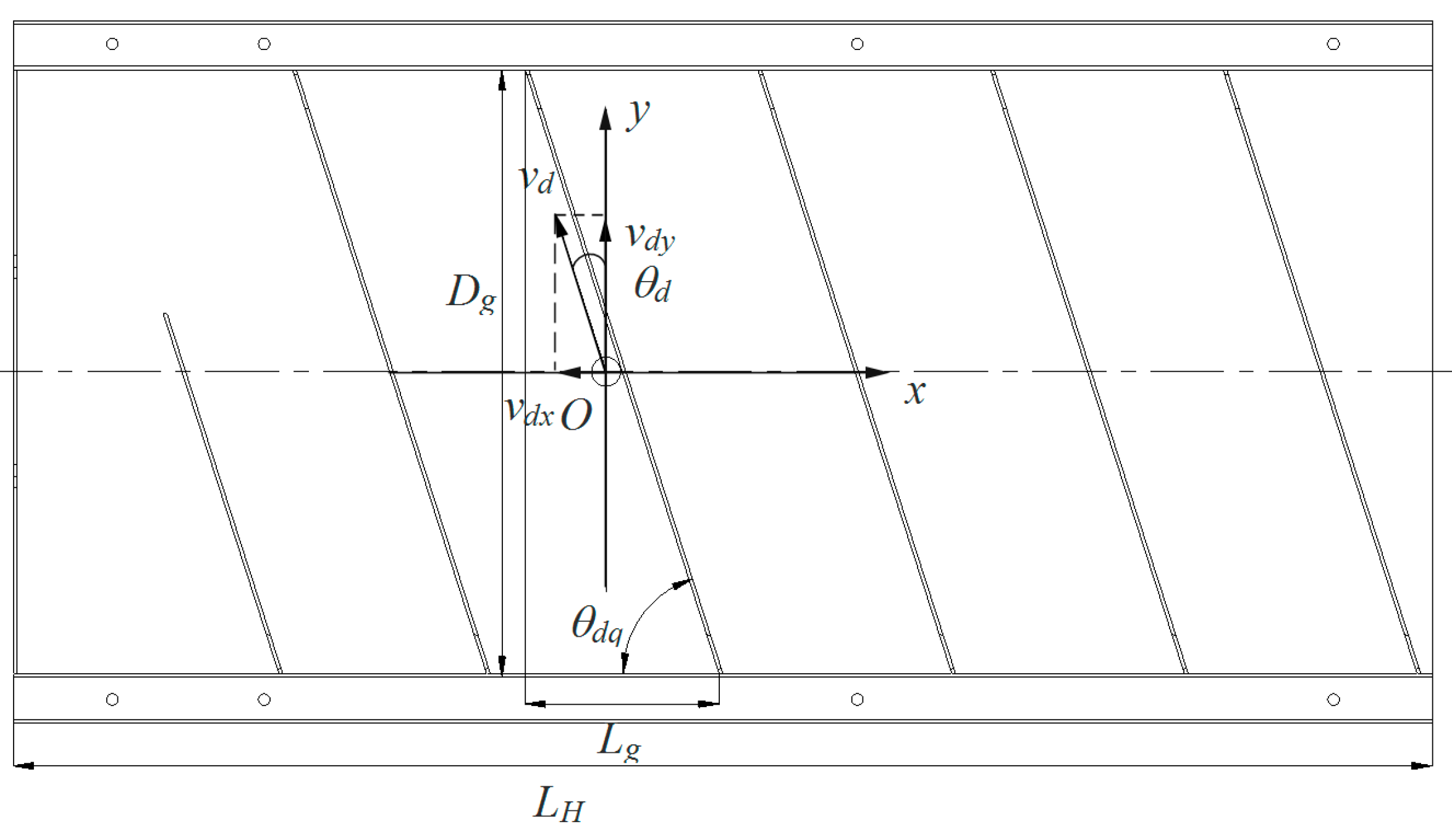

2.2.3. Deflector Design

2.3. Experimental Conditions, Factors, and Indicators

2.3.1. Experimental Conditions

2.3.2. Experimental Factors

2.3.3. Experimental Indicators

3. Results

3.1. Experiment Results

3.2. Regression Model Establishment and Significance Testing

3.3. Analysis of the Impact of Interaction Factors on Performance

3.4. Parameter Optimization and Validation Experiment

3.4.1. Parameter Optimization

3.4.2. Experimental Verification

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Merkouropoulos, G.; Kapazoglou, A.; Drosou, V.; Jacobs, E.; Krolzig, A.; Papadopoulos, C.; Hilioti, Z. Dwarf hybrids of the bioenergy crop Ricinus communis, suitable for mechanized harvesting reveal differences in morphophysiological characteristics and seed metabolic profiles. Euphytica 2016, 210, 207–219. [Google Scholar] [CrossRef]

- Wei, H.L.; Li, X.M.; Li, M.; Huang, H. Leaf shape simulation of castor bean and its application in nondestructive leaf area estimation. Int. J. Agric. Biol. Eng. 2019, 12, 135–140. [Google Scholar] [CrossRef]

- Kong, F.T.; Wu, T.; Zhang, B.; Zhao, H.Y.; Sun, Y.F.; Chen, C.L.; Xie, Q. Edge curve fitting and optimization of the wave-type cutting disc for castor. Trans. Chin. Soc. Agric. Eng. 2024, 40, 66–75. [Google Scholar] [CrossRef]

- Kong, F.T.; Wang, D.F.; Shi, L.; Wu, T.; Chen, C.L.; Sun, Y.F.; Xie, Q. Design and experiment of disc-cutting picking device of castor. Trans. Chin. Soc. Agric. Eng. 2021, 37, 1–9. [Google Scholar] [CrossRef]

- Liu, L.; Wu, T.; Kong, F.T.; Sun, Y.F.; Chen, C.L.; Xie, Q.; Shi, L. Optimized design and experiment of the picking mechanism for brush-roller castor harvesters. Trans. Chin. Soc. Agric. Eng. 2021, 37, 19–29. [Google Scholar] [CrossRef]

- Sun, Z.J.; LV, L.Y.; Wu, Y.P. Castor industry development: From cultivation to product exploitation. J. Chin. Agric. Univ. 2012, 17, 204–214. [Google Scholar] [CrossRef]

- Wu, T.; Kong, F.T.; Shi, L.; Xie, Q.; Sun, Y.F.; Chen, C.L. Power Consumption Influence Test of Castor Disc-Cutting Device. Agriculture 2022, 12, 1535. [Google Scholar] [CrossRef]

- Latterini, F.; Stefanoni, W.; Cavalaris, C.; Karamoutis, C.; Karamoutis, C.; Pari, L. Effectiveness of Three Terminating Products on Reducing the Residual Moisture in Dwarf Castor Plants: A Preliminary Study of Direct Mechanical Harvesting in Central Greece. Agronomy 2022, 12, 146. [Google Scholar] [CrossRef]

- Pari, L.; Suardi, A.; Stefanoni, W.; Latterini, F.; Palmieri, N. Environmental and Economic Assessment of Castor Oil Supply Chain: A Case Study. Sustainability 2020, 12, 6339. [Google Scholar] [CrossRef]

- Wu, T.; Kong, F.T.; Shi, L.; Chen, C.L.; Sun, Y.F.; Xie, Q. Analysis of the development status of Ricinus communis production technology. J. Chin. Agric. Mach. Chem. 2019, 40, 77–81. [Google Scholar] [CrossRef]

- Stefanoni, W.; Latterini, F.; Malkogiannidis, V.; Salpiggidis, V.; Alexopoulou, E.; Pari, L. Mechanical Harvesting of Castor Bean (Ricinus communis L.) with a Combine Harvester Equipped with Two Different Headers: A Comparison of Working Performance. Energies 2022, 15, 2999. [Google Scholar] [CrossRef]

- Xie, G.; Zhang, G.Z.; Fu, J.W.; Zhou, Y.; Wang, Y.; Gao, Y.; Wang, W.K.; Mohamed, A. Comparing power consumption of drum and cylindrical rod-tooth longitudinal axial flow threshing roller. J. Huazhong Agric. Univ. 2021, 40, 77–81. [Google Scholar] [CrossRef]

- Kang, J.X.; Wang, X.S.; Xie, F.P.; Luo, Y.; Li, Q.; Huang, X.J. Experiments and analysis of the differential threshing cylinder for soybean with different maturities. Trans. Chin. Soc. Agric. Eng. 2023, 39, 38–49. [Google Scholar] [CrossRef]

- Kang, J.X. Design and Mechanism Research on Threshing and Separation Device for Southern Soybean Combine Harvester. Ph.D. Thesis, Hunan Agricultural University, Changsha, China, 2022. [Google Scholar] [CrossRef]

- Teng, Y.J.; Jin, C.Q.; Chen, Y.P.; Liu, P.; Yin, X.; Wang, T.E.; Yu, K. Design and optimization of segmented threshing device of combine harvester for rice and wheat. Trans. Chin. Soc. Agric. Eng. 2020, 36, 1–12. [Google Scholar] [CrossRef]

- Li, Y.M.; Wang, J.P.; Xu, L.Z.; Tang, Z.; Xu, Z.H.; Wang, K.J. Design and experiment on adjusting mechanism of concave clearance of combine harvester cylinder. Trans. Chin. Soc. Agric. Mach. 2018, 49, 68–75. [Google Scholar] [CrossRef]

- Zhang, Z.Z.; Xie, F.P.; Tian, L.Q.; Liu, Z.H.; Looh, G.A.; Wang, X.S. Design and performance test of rotary grate concave threshing and separating unit of head-feeding combine harvester. Appl. Eng. Agric. 2022, 38, 303–312. [Google Scholar] [CrossRef]

- Li, Y.B.; Jiang, J.J.; Xu, Y.; Cui, T.; Su, Y.; Qiao, M.M. Preparation and threshing performance tests of rubber composite nail teeth under maize with high moisture content. Trans. Chin. Soc. Agric. Mach. 2020, 51, 158–167. [Google Scholar] [CrossRef]

- Chen, N.; Xiong, Y.S.; Chen, D.J.; Xu, J.D.; Zhao, Y. Design and test on the Coaxial differential-speed Axial-flow threshing rotor of combine harvester. Trans. Chin. Soc. Agric. Mach. 2010, 41, 67–71. Available online: http://www.j-csam.org/jcsam/article/abstract/20101041?st=article_issue (accessed on 3 December 2025).

- Wang, Z.M.; Lv, P.M.; Chen, N.; Li, H.; Liu, Z.H.; Chen, D.J. Design and experiment on axial-flow differential-speed threshing-separating-cleaning unit. Trans. Chin. Soc. Agric. Mach. 2016, 47, 53–61. [Google Scholar] [CrossRef]

- Lian, G.D.; Zong, W.Y.; Wei, W.; Ma, L.N.; Cheng, Y.F.; Wei, X.X. Design and experiment of cutting threshing integrated type header for harvesting of edible sunflower. Trans. Chin. Soc. Agric. Mach. 2023, 54, 122–131+154. [Google Scholar] [CrossRef]

- Hou, J.M.; Yao, E.C.; Li, J.P.; Bai, J.B.; Yang, Y.; Zhu, H.J. Motion analysis and experiment on shelling process of kneading and pressing castor shelling machine. Trans. Chin. Soc. Agric. Mach. 2020, 51, 220–232. [Google Scholar] [CrossRef]

- Xu, L.Z.; Li, Y.M.; Ding, L.F. Contacting mechanics analysis during impact process between rice and threshing component. Trans. Chin. Soc. Agric. Eng. 2008, 24, 146–149. Available online: https://kns.cnki.net/kcms2/article/abstract?v=QSPvTk9Jgi1ldbPOkoja5DkbicR9CzqiGWm7icJ1ZipDDU6hOFR-_BdTc3iGWz_zu1BhMKOO1UiNA1lny4NXghPs_iNUACp7_Nxtcpe7H7L1P96SEJCQFREGR7VxsAnbtQp-oCrEAcfgF1qsU5wjX1N1mxXjwxsksRbcK4-jwnLXgAGZOkwtTA==&uniplatform=NZKPT&language=CHS (accessed on 3 December 2025).

- Liu, W.R.; Zhou, Y.; Xu, H.M.; Fu, J.W.; Zhang, N.; Xie, G.; Zhang, G.Z. Optimization and experiments of the drum longitudinal axial threshing cylinder with rod tooth for rice. Trans. Chin. Soc. Agric. Eng. 2023, 39, 34–45. [Google Scholar] [CrossRef]

- Yang, G.; Chen, Q.M.; Xia, X.F.; Chen, J.N.; Song, Z.Y. Design and optimization of the key components for 4DL-5A faba bean combine harvester. Trans. Chin. Soc. Agric. Eng. 2021, 37, 10–18. [Google Scholar] [CrossRef]

- Xu, N.; Shang, S.Q.; Wang, D.W.; He, X.N.; Gao, Z.; Liu, J.Q.; Zhang, Y.D.; Guo, P. Design and research of spike tooth type peanut picking device with longitudinal axial flow. J. Agric. Mech. Res. 2020, 42, 197–201. [Google Scholar] [CrossRef]

- Hou, J.M.; Li, J.P.; Yao, E.C.; Bai, J.B.; Yang, Y.; Zhu, H.J. Calibration and analysis of discrete element parameters of typical castor. J. Shenyang Agric. Univ. 2019, 50, 565–575. Available online: https://kns.cnki.net/kcms2/article/abstract?v=X84Xx1LLloKoUrKvP8gRWbceCmj5NvpS9p9qQ64oHuQZELtMMV8YUy4GhgFiSPSIh_nqcED-9PSzhBqMfyUM0geIe8jURLQdTKEf4N3vlMadeg7Bchvmz275TR8Qt22OYb5cJTJ-2RFgIFcgpZyA5tBQBTy2aSwDJtL6zKMF7M33XhZ6cZmAqg==&uniplatform=NZKPT&language=CHS (accessed on 3 December 2025).

- NY/T 4365-2023; National Agricultural Industry Standards, Operating Quality for Castor Harvester. China Agricultural Publishing House: Beijing, China, 2023.

- GB/T 5262-2008; National Standard, Agricultural Machinery Testing Conditions-General Rules for Measuring Methods. Standards Press of China: Beijing, China, 2008.

- GB/T 8097-2008; National Standard, Equipment for Harvesting -Combine harvesters- Test Procedure. Standards Press of China: Beijing, China, 2008.

- Wang, B.L.; Hu, Z.C.; Gu, F.W.; Wu, F.; Cao, M.Z.; Sun, Y.J. Analysis and evaluation of the experimental effect of double-disc knife-cutting device for carrot combine harvester. Agriculture 2025, 15, 682. [Google Scholar] [CrossRef]

- Kang, J.X.; Wang, X.S.; Xie, F.P.; Hou, J.; Li, Q.; Liu, A.W. Optimization and experiment of oil sunflower combined harvester cleaning device. Trans. Chin. Soc. Agric. Eng. 2025, 41, 11–21. [Google Scholar] [CrossRef]

- Zhang, X.J.; Zhang, Y.H.; Shi, Z.L.; Ma, S.T.; Huang, S.; Cheng, J.P. Optimization and experiment of oil sunflower combined harvester cleaning device. Trans. Chin. Soc. Agric. Mach. 2022, 53, 103–113. Available online: http://www.j-csam.org/jcsam/article/abstract/20220811?st=search (accessed on 3 December 2025).

- Jin, C.Q.; Guo, F.Y.; Xu, J.S.; Li, Q.L.; Chen, M.; Li, J.J.; Yin, X. Optimization of working parameters of soybean combine harvester. Trans. Chin. Soc. Agric. Eng. 2019, 35, 10–22. [Google Scholar] [CrossRef]

- Severino, L.; Silva, C.; Oliveira, M. Seed quality and efficiency of mechanical harvest of castor crop at commercial scale. Ind. Crops Prod. 2025, 235, 121787. [Google Scholar] [CrossRef]

| Levels | Forward Speed x1 (m∙s−1) | Roller Rotational Speed x2 (r∙min−1) | Threshing Gap of Concave Sieve x3 (mm) |

|---|---|---|---|

| −1 | 0.6 | 400 | 15 |

| 0 | 0.8 | 475 | 25 |

| 1 | 1.0 | 550 | 35 |

| No. | Levels | Response Values | ||||

|---|---|---|---|---|---|---|

| Forward Speed X1/(m∙s−1) | Roller Rotational Speed X2/(r∙min−1) | Threshing Gap of Concave Sieve X3/(mm) | Impurity Rate Y1/(%) | Damage Rate Y2/(%) | Separation Loss Rate Y3/(%) | |

| 1 | −1 | −1 | 0 | 2.27 | 2.05 | 0.55 |

| 2 | 1 | −1 | 0 | 3.29 | 1.72 | 0.89 |

| 3 | −1 | 1 | 0 | 2.91 | 3.08 | 0.22 |

| 4 | 1 | 1 | 0 | 4.49 | 2.88 | 0.51 |

| 5 | −1 | 0 | −1 | 2.79 | 2.95 | 0.11 |

| 6 | 1 | 0 | −1 | 4.29 | 2.68 | 0.42 |

| 7 | −1 | 0 | 1 | 2.66 | 2.42 | 0.25 |

| 8 | 1 | 0 | 1 | 3.18 | 1.89 | 0.66 |

| 9 | 0 | −1 | −1 | 3.32 | 2.39 | 0.62 |

| 10 | 0 | 1 | −1 | 4.17 | 3.19 | 0.24 |

| 11 | 0 | −1 | 1 | 2.72 | 1.58 | 0.81 |

| 12 | 0 | 1 | 1 | 3.25 | 2.76 | 0.46 |

| 13 | 0 | 0 | 0 | 2.98 | 2.07 | 0.26 |

| 14 | 0 | 0 | 0 | 2.82 | 1.92 | 0.32 |

| 15 | 0 | 0 | 0 | 2.86 | 2.05 | 0.37 |

| 16 | 0 | 0 | 0 | 2.68 | 2.11 | 0.26 |

| 17 | 0 | 0 | 0 | 2.89 | 2.09 | 0.33 |

| Source | Impurity Rate Y1 | Damage Rate Y2 | Separation Loss Rate Y3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sum of Squares | Degree of Freedom | F Value | Significant Level p | Sum of Squares | Degree of Freedom | F Value | Significant Level p | Sum of Squares | Degree of Freedom | F Value | Significant Level p | |

| Model | 5.97 | 9 | 36.64 | <0.0001 ** | 3.89 | 9 | 79.90 | <0.0001 ** | 0.7550 | 9 | 57.26 | <0.0001 ** |

| X1 | 2.67 | 1 | 147.50 | <0.0001 ** | 0.2211 | 1 | 40.83 | 0.0004 ** | 0.2278 | 1 | 155.50 | <0.0001 ** |

| X2 | 1.30 | 1 | 71.65 | <0.0001 ** | 2.17 | 1 | 401.41 | <0.0001 ** | 0.2592 | 1 | 176.93 | <0.0001 ** |

| X3 | 0.9522 | 1 | 52.64 | 0.0002 ** | 0.8192 | 1 | 151.28 | <0.0001 ** | 0.0780 | 1 | 53.25 | 0.0002 ** |

| X1X2 | 0.0784 | 1 | 4.33 | 0.0759 | 0.0042 | 1 | 0.7802 | 0.4064 | 0.0006 | 1 | 0.4266 | 0.5345 |

| X1X3 | 0.2401 | 1 | 13.27 | 0.0083 ** | 0.0169 | 1 | 3.12 | 0.1206 | 0.0025 | 1 | 1.71 | 0.2327 |

| X2X3 | 0.0256 | 1 | 1.42 | 0.2730 | 0.0361 | 1 | 6.67 | 0.0364 * | 0.0002 | 1 | 0.1536 | 0.7068 |

| X12 | 0.0706 | 1 | 3.90 | 0.0887 | 0.1597 | 1 | 29.49 | 0.0010 ** | 0.0040 | 1 | 2.76 | 0.1405 |

| X22 | 0.2946 | 1 | 16.28 | 0.0050 ** | 0.1516 | 1 | 28.00 | 0.0011 ** | 0.1744 | 1 | 119.02 | <0.0001 ** |

| X32 | 0.2727 | 1 | 15.08 | 0.0060 ** | 0.2471 | 1 | 45.63 | 0.0003 ** | 0.0019 | 1 | 1.27 | 0.2974 |

| Residual | 0.1266 | 7 | 0.0379 | 7 | 0.0103 | 7 | ||||||

| Lack of fit | 0.0783 | 3 | 2.16 | 0.2354 | 0.0154 | 3 | 0.9149 | 0.5095 | 0.0012 | 3 | 0.1725 | 0.9097 |

| Pure error | 0.0483 | 4 | 0.0225 | 4 | 0.0091 | 4 | ||||||

| Total | 6.09 | 16 | 3.93 | 16 | 0.7652 | 16 | ||||||

| Items | Impurity Rate (%) | Damage Rate (%) | Separation Loss Rate (%) |

|---|---|---|---|

| Theoretical optimized values | 2.87 | 1.83 | 0.45 |

| Test average values | 2.95 | 1.75 | 0.49 |

| Relative error (%) | 2.71 | 4.57 | 8.16 |

| Standard values [28] | 7 | 2 | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, T.; Zhang, B.; Kong, F.; Sun, Y.; Xie, Q.; Zhao, H.; Zheng, S. Design and Experiment of Axial Flow Threshing and Cleaning Device for Roller Brush Type Castor Harvesting Machine. Agriculture 2025, 15, 2578. https://doi.org/10.3390/agriculture15242578

Wu T, Zhang B, Kong F, Sun Y, Xie Q, Zhao H, Zheng S. Design and Experiment of Axial Flow Threshing and Cleaning Device for Roller Brush Type Castor Harvesting Machine. Agriculture. 2025; 15(24):2578. https://doi.org/10.3390/agriculture15242578

Chicago/Turabian StyleWu, Teng, Bin Zhang, Fanting Kong, Yongfei Sun, Qing Xie, Huayang Zhao, and Shuhe Zheng. 2025. "Design and Experiment of Axial Flow Threshing and Cleaning Device for Roller Brush Type Castor Harvesting Machine" Agriculture 15, no. 24: 2578. https://doi.org/10.3390/agriculture15242578

APA StyleWu, T., Zhang, B., Kong, F., Sun, Y., Xie, Q., Zhao, H., & Zheng, S. (2025). Design and Experiment of Axial Flow Threshing and Cleaning Device for Roller Brush Type Castor Harvesting Machine. Agriculture, 15(24), 2578. https://doi.org/10.3390/agriculture15242578