1. Introduction

The shift to alternative energy sources driven by climate change is increasing the demand for biofuels, making soil fertility in the EU critical for achieving energy independence. Given the EU’s growing dependence on energy resources and concerns about energy security, it increasingly focuses on renewable energy production. In the face of energy shortages, biofuel production has become a strategic focus for energy independence [

1]. It is worth noting that the feasibility of researching the use of progressive crop rotations for the development of biofuel production is highly relevant [

2]. Most of the studies that have been presented focus on short-term crop rotations or monoculture cultivation.

Simultaneously, individual studies do not consider the synergy between biofuel production and food security. This study aims to fill this gap by comprehensively assessing the potential of a 10-field crop rotation to ensure energy and food security and, consequently, as a basis for the development of bioenergy. In response to the growing need for alternative energy sources and the fight against the consequences of climate change, biofuel production has become a key area of research and development [

3].

Current research in this area has several significant gaps that require attention to fully unlock the potential of the circular economy in the agricultural sector. First, there is a lack of a long-term assessment of the cumulative impact of digestate, including its impact on soil physicochemical properties and the economic efficiency of its application within multiple crop rotations. Second, there is an absence of integrated “green logistics” models for optimizing the collection and transportation of biomass and digestate application to minimize overall CO2 emissions and logistics costs. Third, there is limited research on the regional adaptation of proposed crop rotation models, hindering their scalability and practical application in the specific soil, climatic, and economic conditions of various regions of the European Union. Finally, there is poor integration of research data with the financial and legal environment, resulting in a lack of well-developed mechanisms to stimulate investment in green infrastructure and the circular economy.

Simultaneously, the depletion of soil resources and the decline in soil fertility due to imperfect farming technologies and the use of monoculture rotations cannot ensure the comprehensive preservation of soil fertility and the formation of balanced food supplies. In this context, developing progressive crop rotation systems is particularly significant as a tool for optimizing agricultural production and ensuring energy security. Therefore, the use of a 10-field crop rotation system is a justified decision for increasing biofuel production because (1) implementing the appropriate crop rotation will allow for the efficient use of soil nutrients, reducing the need for mineral fertilizers in the short term; (2) this crop rotation contributes to the preservation of soil fertility, prevents water and wind erosion, and also improves the water and physical properties of the soil, which collectively reduce the negative impact of intensive agriculture on the environment.

Notably, a 10-field crop rotation synergizes biofuel and food crop production. This, in turn, allows for the creation of stable agroecosystems and ensures food and energy security without harming the environment. Based on these considerations, the study of the feasibility and effectiveness of a 10-field crop rotation system for biofuel production is relevant and crucial for developing sustainable agriculture and bioenergy. Simultaneously, using a 10-field crop rotation will allow for the diversification of raw material sources for biofuels, significantly reducing the European continent’s dependence on fossil fuels. Including energy crops (such as sugar beets, corn, and rapeseed) in crop rotations ensures stable bioethanol and biodiesel production. An appropriate crop rotation system can optimize land use, increase crop yields, and reduce costs for fertilizers and pesticides. This renders biofuel production more economically viable and sustainable.

The 10-field crop rotation system maintains and improves soil fertility, while the monoculture strategy can lead to soil degradation and a significant reduction in food crop yields. The rotation of energy and food crops (wheat, barley, sunflower, and soybeans) allows for the stable production of food and biofuels. Therefore, the relevant system avoids competition for land resources between biofuel and food producers, which is a key aspect of food security and energy security.

Macro-level modeling of biofuel resource potential in Ukraine, integrated with strict environmental and agronomic criteria for raw material extraction, can provide a reliable and practically applicable assessment for the national energy strategy, which differs significantly from idealized estimates based only on yield.

The study aims to address several key challenges related to integrated biofuel production and ensuring food and energy security in Ukraine and the EU through a 10-field crop rotation system. The main tasks completed within the scope of this study involved addressing the following key research questions (RQ):

RQ 1. To justify the environmental and energy feasibility of increasing biofuel production using a 10-field crop rotation system.

RQ 2. To analyze trends in the sown area and yields of Ukraine’s main agricultural crops from 2020 to 2024.

RQ 3. To assess the potential for biofuel production and identify opportunities for diversifying biofuel sources, including energy crops (sugar beet, corn, and rapeseed).

RQ 4. To study the impact of using by-products, particularly digestate residues and other by-products, on increasing agricultural yields.

This study will comprehensively assess the feasibility and effectiveness of a 10-field crop rotation system and identify its significant potential as a basis for increasing biofuel production.

3. Materials and Methods

3.1. Study Area

This study examines integrated land use policies for biofuel cultivation in Europe, using the case of Ukraine. In this context, the EU actively promotes a circular bioeconomy model that effectively integrates agricultural resources into biofuel production. This European strategy provides a policy framework for all member states, including Ukraine and its neighbors.

Farmland in the EU covers approximately 154 million hectares, accounting for approximately 38% of the EU’s total land area [

26]. Renewable energy sources (solar, wind, and biofuels) account for approximately 27% of energy production. The largest share in EU biofuel production is held by solid biomass (around 70% of all bioenergy), while liquid biofuels (biodiesel and bioethanol) account for over 20%, and biogas (including biomethane) is about 10% of the total bioenergy production [

27].

This study did not involve the use of laboratory equipment. All calculations related to the assessment of projected annual productivity, energy potential, and yield improvement in Ukraine were performed using Microsoft Excel (Microsoft Corporation). Although the total area of agricultural land in Ukraine has not officially decreased, due to temporary occupation and military action, a significant portion of this land will not be used for its intended purpose. It would not have contributed to the national economy in 2022 and 2024 (

Table 1).

In the field of biofuel production, Ukraine’s economy is showing growth, but it is significantly lagging behind the EU in terms of speed. Specifically, the production of biofuels in Ukraine (equivalent to 0.6 million tons of oil in 2024) is insignificant compared to that of the EU (equivalent to 20.9 million tons of oil), indicating an underutilization of the available potential (primarily agricultural) for biofuel production. Simultaneously, martial law conditions and Ukraine’s refusal to accept energy resources from Russia have spurred an increase in the share of renewable energy sources in Ukraine’s total energy consumption from 9.2% to 10.7%.

The study was conducted in Ukraine, which, being located in the temperate climate zone, is primarily characterized by a temperate continental climate, notable for its distinct seasonality, warm summers, and relatively cold winters, alongside a gradual increase in continentality and decrease in precipitation from west to east.

This geographic and climatic uniformity is coupled with internal differentiation, as the country’s territory is distinctly divided into three main natural and climatic zones—the humid Polissya in the north; the transitional, optimally watered Forest Steppe in the central part; and the arid Steppe in the south—with each of these zones possessing unique and specific soil cover characteristics, ranging from the sod-podzolic soils of Polissya to the highly fertile chernozem (Black Earths) and less humic chestnut soils of the Steppe, which is a determining factor for assessing agricultural potential and conducting research.

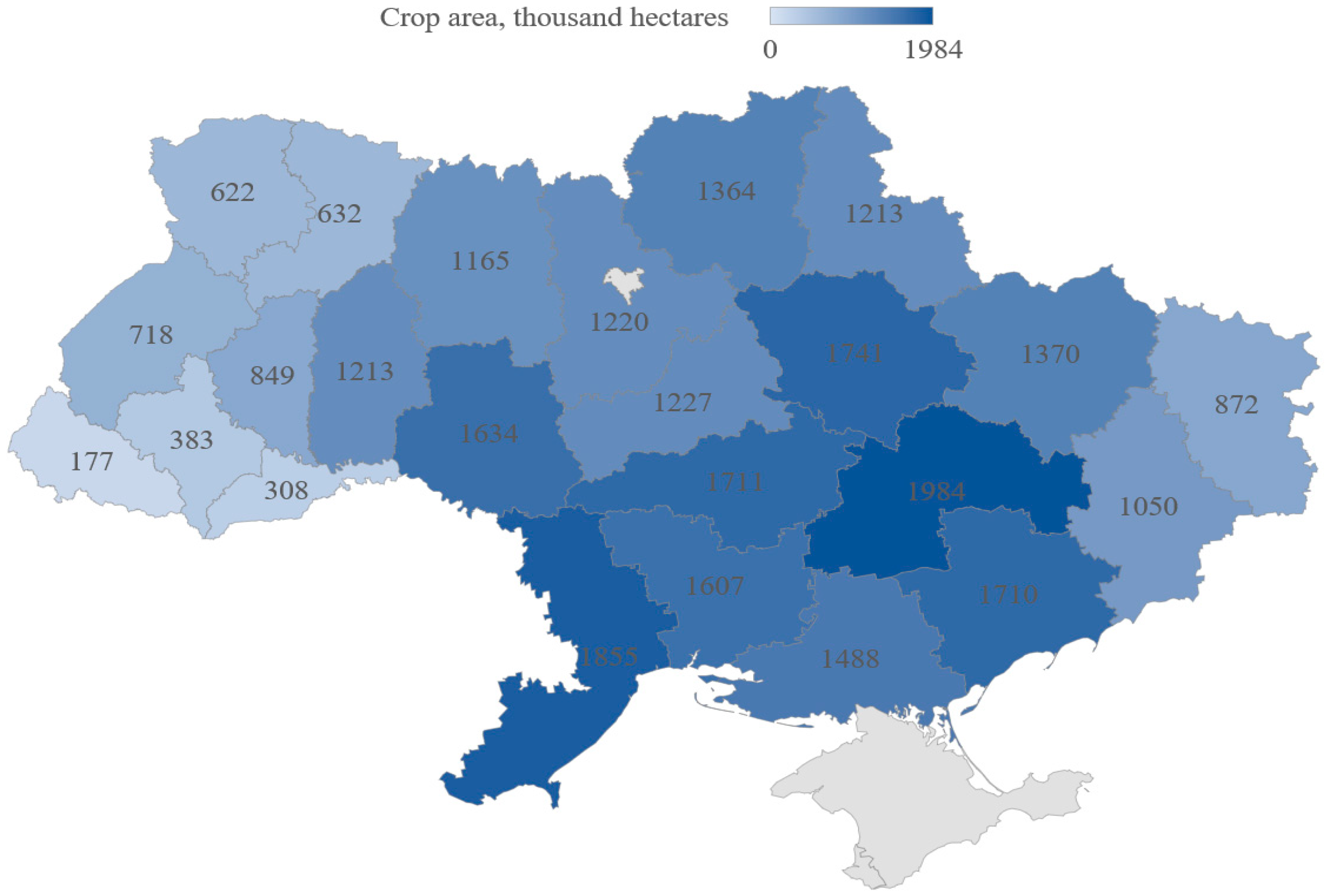

As of 2025, over 28.5 million hectares of land were in agricultural use, and the total area, including temporarily occupied territories, is over 32.4 million hectares (

Figure 1) [

28].

Simultaneously, an analysis of Ukraine’s soil cover shows a clear zonality that shapes its agronomic properties. The podzolic soils of the Polissya region were formed under conditions of excessive moisture and forest vegetation. The primary process of their formation is podzolization, which involves the intensive leaching of nutrients from the upper horizon, making it poor and light in color [

30].

The soils under investigation have a pronounced acidic reaction (pH less than 5.5), resulting from the constant leaching regime of the region. It is worth noting that the humus content in this type of soil is extremely low, usually not exceeding 1–2%, which significantly reduces its natural fertility. They are also characterized by a light granulometric composition, predominantly sandy and loamy sand, which ensures high water permeability but dries out rapidly.

Simultaneously, chernozem soils are widespread in the Forest Steppe and Steppe zones and are the most fertile soils. They are characterized by a neutral or slightly alkaline reaction (6.5–7.5 pH), which creates favorable conditions for the growth of most crops. These soils have the highest humus content in the world, reaching 9% or more in typical chernozems, providing a high concentration of nutrients and natural prerequisites for high yields. Their granular or crumbly structure is ideal for agriculture because it provides high air and water permeability and resistance to erosion.

The humus content in other soils is significantly lower than that in chernozems, ranging from 1.5 to 4%. They are characterized by a weakly developed structure in the upper horizons, which can lead to compaction. To improve their properties, irrigation and the application of organic fertilizers are important, which, according to the present study, contribute to normalizing acidity.

The use of scientifically sound crop rotations seems appropriate based on the great diversity of soils within the study area. This will increase yields and soil fertility and is an important tool for erosion control and pest and disease management in agriculture. Currently, 7–9-field systems are the most widespread; however, this study focuses on applying a 10-field crop rotation for biofuel production and suggests that this method is the most justified and rational.

A 10-field crop rotation maximizes the efficient use of agricultural resources, minimizes environmental impacts, and ensures a stable raw material supply. The key advantages of a 10-field crop rotation, identified in the study, are as follows:

- -

Justification of the benefits of perennial crop rotation, which allows for the alternation of cereals, legumes, oilseeds, and industrial crops, contributing to soil fertility restoration, disease, pest, and weed control, and consequently reducing the need for mineral fertilizers and pesticides, which is an important step towards the development of organic production.

- -

The proposed crop rotation will ensure the development of an integrated biofuel production system, including nitrogen-fixing crops (e.g., legumes), using by-products as organic fertilizers.

- -

Ensuring the sustainable cultivation of a wide range of raw materials for biofuel production, including grain for bioethanol, oilseeds for biodiesel, and plant biomass for biogas, is critically important for energy security in Europe.

- -

An extended crop rotation cycle will help prevent soil depletion, preserve its structure and microflora, and reduce the risk of erosion, which is important for sustainable agricultural practices [

19].

3.2. Experimental Design

This study aimed to justify the use of 10-field crop rotation systems for biofuel production. The subject of this research is the effectiveness and feasibility of the proposed crop rotation system for strengthening energy and food security on the European continent. The study considered and described the main variable factors that can influence the effectiveness of this crop rotation, namely the dynamics of sown areas and yields of major crops in the study area, the gross harvest of the corresponding crops, the possibility of using by-products, particularly digestate, and, based on changes in yields and areas, the potential production of various types of biofuel (bioethanol, biodiesel, biogas, and solid biofuels), as well as the impact of digestate on the yields of individual crops.

This study collected data to determine the leading indicators for using a 10-field crop rotation. The following dataset was used:

Yield determination was based on the assessment of statistical data calculated in tons per hectare.

The mass of post-harvest residues was determined by calculating coefficients from available studies, which were converted to by-products (separation of residues from the main crop).

Soil chemical analysis data (determination of acidity by potentiometry, humus content by the Tyurin method, and macronutrients—nitrogen, phosphorus, and potassium).

This study clearly distinguished between independent and dependent variables. The independent variables were the factors that the researchers changed to assess their impact on the study results:

A 10-field system was used, a key experimental factor influencing all other indicators.

The type of crop, as different agricultural crops included in the crop rotation, was studied.

The dependent variables were those indicators that were measured and analyzed owing to the influence of the independent factors.

Crop yields.

Biofuel quality was based on its physicochemical properties.

Waste energy potential was calculated based on its mass and calorific value.

Production costs were a key economic indicator.

The diagram presented in

Figure 2 outlines a comprehensive research plan to demonstrate how a 10-field crop rotation can provide Ukraine with raw materials for biofuels, while simultaneously improving soil health.

The central part of the study focuses on the scientific and theoretical justification for using a 10-field crop rotation system to ensure biofuel production, where the independent variables are the crop rotation system itself, crop types, and the use of digestate (DS). In contrast, the dependent variables were yield, soil quality, biofuel volume, and production cost.

The data were analyzed using statistical and proprietary methods to calculate the production potential of biogas, bioethanol, biodiesel, and solid biofuels. The findings aim to quantify the potential for replacing fossil fuels with various biofuels.

The key factor in this study was the justification for using a 10-field crop rotation as the basis for optimizing resource utilization, minimizing negative environmental consequences, and ensuring a stable raw material base for producing bio-briquettes. We took data from a study at Uman National University of Horticulture, which lasted from 1964 to 2014. This analysis allowed for identifying and assessing trends in sown areas and yields over the following periods.

3.3. Data Sources and Methodological Approaches

This study is based on complex materials, including data from:

The State Statistics Service of Ukraine for 2020–2024, specifically information on sown areas, yields, and gross harvests of major crops. This allowed for a retrospective agricultural sector analysis.

Statistical data and forecasts from international organizations (International Energy Agency, IEA; Organisation for Economic Co-operation and Development, OECD) and Ukrainian analytical centers specializing in fuel and bioenergy markets.

The results of field research on the implementation of a 10-field crop rotation system and the effectiveness of using biofuel production by-products (particularly digestate) as organic fertilizers are presented later in this article.

System analysis, mathematical modeling, statistical analysis, and physicochemical calculations were used for data processing.

Correlation analysis was performed to identify relationships between different indicators, such as the dependence of yield on the amount of digestate applied or soil quality.

Trend analysis, which was used to assess the dynamics of sown area reduction and yield growth over the period 2020–2024, allowed for identifying all-around trends in Ukrainian agriculture.

Multivariate analysis was used to comprehensively assess the influence of several independent variables (crop rotation system and crop type) on the dependent variables (yield and biofuel quality).

A methodology for calculating biogas production potential was developed based on the potential yield of biomethane from organic raw materials generated within a 10-field crop rotation, specifically from post-harvest residues and livestock waste.

The volume of biomethane was calculated as the sum of the products of the mass of each type of raw material multiplied by an empirical conversion factor, which determines the yield of biomethane from 1 ton of raw material (1).

The methodology for calculating the bioethanol production potential was based on the potential gross harvest of corn and wheat, which are suitable for cultivation within the proposed crop rotation.

The total volume of bioethanol (Vbioethanol) was calculated as the product of the total crop mass (Mcrop) and the grain-to-bioethanol conversion factor (Kconversion).

A method for calculating the biodiesel production potential, considering the potential yield of oil crops (rapeseed and soybeans), is as follows:

The volume of biodiesel (Vbiodiesel) can be calculated as the product of the total mass of oilseeds (Moil) and the biodiesel yield coefficient per 1 ton of raw material (Kyield). A methodology for calculating the production potential of solid biofuels, which considers the possibility of using organic waste as a raw material that can be utilized for energy purposes, is proposed. This includes the use of wood, livestock waste, and crop residues (straw).

The biomass potential (

P) was calculated using the basic formula:

Here, Ai is the average cultivated area of crop (ha); Yi is the average yield of crop (t/ha); Ri is the harvest-to-residue ratio coefficient (based on data from the literature); Ki is the availability/removal coefficient, which accounts for ecological limitations; and Econv is the energy conversion coefficient (MJ/t).

Key assumptions (coefficients

Ri and

Econv) were compared with data obtained from Eurostat and European Bioenergy Outlook reports to increase reliability. Additionally, a sensitivity analysis was conducted by modeling ‘optimistic’ (coefficients + 10%) and ‘pessimistic’ (coefficients −10%) scenarios, allowing the possible range of results to be estimated. In accordance with modern agronomic requirements (regarding the maintenance of soil organic matter content, erosion prevention, and the preservation of soil biodiversity), the model assumes that no more than 30% (a maximum availability coefficient

Ki = 0.3) of the total mass of post-harvest residues may be used for biofuel production. The remaining 70% of the biomass must be left in the field for maintaining the soil carbon balance, reducing water and wind erosion, and reserving the habitat for soil biota [

31,

32].

The developed methodologies allowed us to assess the potential for biogas, bioethanol, biodiesel, and solid biofuel production based on the use of a 10-field crop rotation system and quantitatively confirmed the feasibility of their production on the European continent. It is important to note that there may be errors in the assessment of biofuel production potential, as the assessment is based on statistical data and calculations that may not fully account for all the nuances of actual production, including logistical costs, losses during harvesting and processing, and market price fluctuations. The geographical representativeness of the study is limited because it was conducted in specific areas, which may restrict its applicability within the EU. The results may not fully reflect the situation in the occupied regions of Ukraine.

4. Results

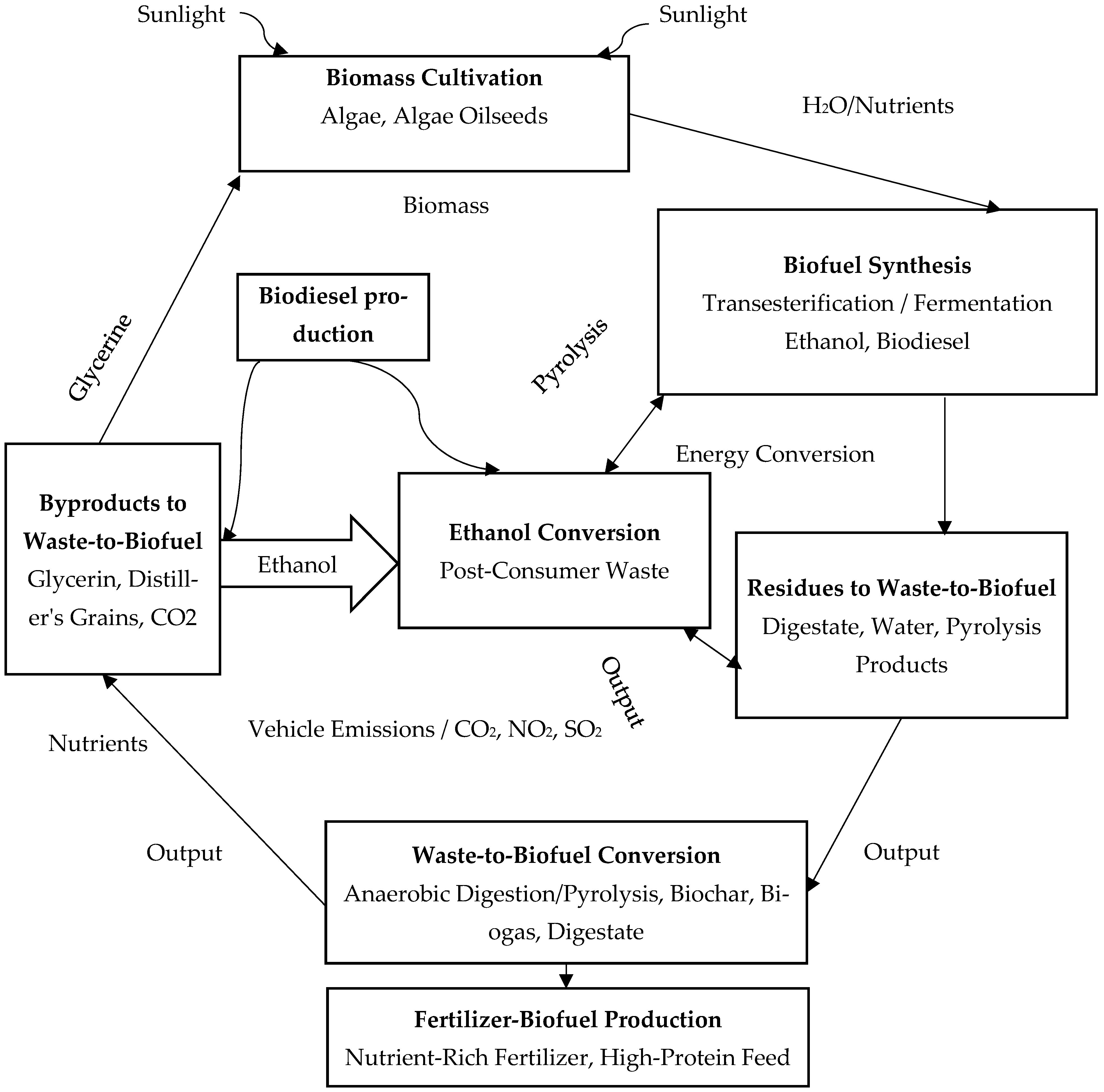

The circular economy is key to promoting sustainable agriculture, ensuring environmental sustainability, and improving biofuel production (

Figure 3 illustrates this process). Proper biomass processing of crops such as corn, sugarcane, and algae is essential for producing biofuels (bioethanol and biodiesel). Composting and recycling biofuel production waste (such as organic matter or agricultural residues) into fertilizers establishes a link between food production, biofuel production, and waste management, which is crucial for the long-term sustainability of the agricultural sector.

The production and yield of the main crops were analyzed to assess the feasibility of using a 10-field crop rotation system. Overall, a significant reduction in sown areas is worth noting, which is a consequence of complex economic and geopolitical factors (primarily the occupation of part of Ukraine’s territory) (

Table 2).

The area sown with sunflowers decreased by 1.44 million hectares (from 6.46 million hectares to 5.02 million hectares) over the period under review, indicating a shift in producers’ goals toward soybeans. Simultaneously, the areas sown with sugar beets showed positive dynamics, increasing by 34 thousand hectares (from 220 thousand hectares to 254 thousand hectares). This is due to the growth in domestic demand and the relative stability of the sugar market. Areas sown with vegetables, potatoes, and fruits also tended to decrease, which is detrimental to food security.

The production of major food crops decreased between 2020 and 2024 due to disruptions in irrigation and marketing problems. The main reason for the decline in production was the occupation of a significant part of Ukraine’s territory as a result of the military aggression of the Russian Federation (

Table 3).

At the same time, the total sugar beet harvest is steadily increasing, growing from 9.1 million tons in 2020 to 12.8 million tons in 2021. This trend correlates with an increase in sown areas and indicates the stabilization of the sugar market and the development of the confectionery industry. The crops most critical for domestic consumption were the most affected. Overall production volumes significantly declined, especially potato production. Meanwhile, potato production in Ukraine decreased by 17.03 million tons, dropping from 20.8 million tons to 3.8 million tons.

This was the most significant reduction among the analyzed crops. This is primarily because these crops were cultivated in the south of Ukraine, a region largely under occupation, especially the Kherson and Zaporizhzhia regions, and due to the destruction of the Kakhovka dam by military formations.

The main reasons for the decline in production were the reduction in planted areas and the lack of reliable data on some agricultural projects. The gross harvest of vegetable crops decreased by 8.62 million tons and of fruit and berry crops by 1.71 million tons. This decline is linked to the destruction of infrastructure, logistical difficulties, and the destruction of part of the production capacity of agricultural processing enterprises.

It is worth noting that there have also been changes in crop yields, with grain and leguminous crops showing a positive trend towards increased yields, from 42.5 quintals per hectare in 2020 to 50.6 quintals per hectare in 2024. The peak yield level was reached in 2023, amounting to 55.2 centners per hectare, which indicates the use of more intensive cultivation technologies (

Table 4).

Sugar beet yields also show steady growth, from 416 quintals per hectare in 2020 to 505 quintals per hectare in 2024, with the maximum yield recorded in 2022 at 541 quintals/hectare. Sunflower yields increased significantly, from 20.2 quintals per hectare in 2020 to 24.5 quintals per hectare in 2023. However, there was a slight decrease to 21.8 quintals per hectare in 2024 owing to less favorable weather conditions. Potatoes have shown stable but moderate yield growth, increasing from 157 quintals per hectare in 2020 to 177 quintals per hectare in 2023, followed by a sharp rise to 252 quintals per hectare in 2024. The overall deviation was 95 quintals per hectare. Vegetable crops show significant yield growth, increasing from 207 quintals per hectare in 2020 to 372 quintals per hectare by 2024. This was the most significant increase among all the crops analyzed, amounting to 165 quintals per hectare.

Fruit and berry production was an exception to the overall upward trend. Yields peaked in 2023 at 119.0 centners per hectare, but declined to 93.1 centners per hectare in 2024. Unfortunately, this decline was directly related to a significant reduction in production area due to the occupation of southern Ukraine. An analysis of the tabular data indicates an overall increase in agricultural productivity in Ukraine between 2020 and 2024, which is evidence of improved efficiency in agricultural production due to more advanced cultivation technology (

Table 5).

In the first year of crop rotation, it is recommended that perennial grasses be sown to improve soil fertility. From the fifth to the eighth year, legumes (peas and soybeans) and green manure should be sown to strengthen and enrich the soil structure with nitrogen. For biodiesel production, it is recommended that sunflowers be sown in the sixth year, and winter rapeseed in the second.

Winter wheat should be sown in the third year, corn in the fourth, and sugar beets in the seventh. For bioethanol production, it is recommended that striped millet and/or miscanthus be added to the crop rotation in the ninth and tenth years. By-products such as rapeseed and sunflower meal, sugar beet pulp, and corn can be used as animal feed in the livestock industry. Ukraine can use 11–12 million hectares and has proposed using 11.5 million hectares for a 10-field crop rotation focused on producing energy crops with a sowing volume of 11.5 million hectares [

11]. It should be noted that the total area of agricultural land in Ukraine is approximately 32.5 million hectares. Therefore, the proposed areas can be fully used to produce biofuels and maintain soil fertility owing to perennial grasses, soybeans, and peas in the crop rotation, which will be used for food purposes. In

Table 6, yield calculations were made for various crops, considering the average yield values for 2020–2024.

This allowed us to obtain a weighted estimate that minimized the impact of extreme weather conditions or other anomalies that may have occurred in a particular year and showed an average trend.

The proposed 10-field crop rotation system is suitable for organizing the production of raw materials for biofuel production, as it combines the cultivation of traditional energy crops (corn, rapeseed, and sunflower) and specialized energy crops (miscanthus and switchgrass) (

Table 7). This allows the diversification of supply sources for biofuel production from biomass and maximizes the overall volume of biofuel obtained, including the use of both the main product and crop residues. It is appropriate to state that this approach is economically viable and aligns with current trends in bioenergy development. Based on research [

37], we assumed that the average oil yield of soybeans was 20%, providing a biodiesel yield of 0.573 million tons when using this crop rotation. The average oil yield from rapeseed is 40% of the volume of rapeseed grown, which, in the case of the proposed crop rotation, would be 1.292 million tons of rapeseed [

38]. The average bioethanol yield is 360 liters per 1 ton of winter wheat in the case of the proposed system of 2.072 million tons [

39]. Bioethanol yields 416 liters per ton of corn and 100 L per ton of sugar beets [

40]. The systematized average oil yield from sunflowers is 500 liters, which, in the future, if the proposed crop rotation is used, will allow for the production of 1.294 million tons of biodiesel [

41,

42].

Thus, the total biodiesel production potential will be over 3.159 million tons, and the total bioethanol production over 11.095 million tons. To calculate the production potential of solid biofuels from miscanthus and switchgrass, as well as crop residues presented in

Table 8, it is advisable to calculate their production in terms of million tons of oil equivalent (Mtoe), excluding sugar beet residues, as this type of residue is suitable for use as a component of the substrate for biogas production. The coefficients were calculated using generally accepted values for the calorific value of biomass:

Straw (wheat, rapeseed): 14 MJ/kg.

Corn and sunflower stalks: 13 MJ/kg.

Soybean stalks: 15 MJ/kg.

Miscanthus and switchgrass: 8 MJ/kg [

40].

It was assumed that 1 million tons of oil equivalent (toe) is 41.868 PJ (petajoules).

The conversion factor for the bioenergy potential of post-harvest residues was calculated using the following formula:

where

—conversion factor (bioenergy potential.

—crop residue mass, million tons.

Cvalue—calorific value of biomass, MJ/kg.

Thus, the total energy potential of post-harvest residues is approximately 5.64 million tons of oil equivalent in the form of solid biofuels (pellets and briquettes). Approximately 3888,637 m

3 of wood are used annually in Ukraine, equivalent to 1.05 thousand tons of oil equivalent (toe) [

24]. The export potential of solid fuel is over 4.59 thousand toe.

Given the high cost of biogas production equipment, solid fuel briquettes can serve as an affordable alternative to traditional firewood, coal, and natural gas. The advantage of this type is that it can be produced from straw and other crop residues, which are common on private farms. The cost of pellet production equipment for a single rural household is much lower compared to the cost of a small-scale biogas reactor, amounting to USD 400–500, which makes it possible to process crop residues from household activities into solid biofuel. In contrast, the price of a low-power biogas reactor ranges from USD 4 to 5 thousand. The biogas yield from 1 ton of sugar beet tops is 0.2 thousand m

3 [

46]. Based on the calculations presented in

Table 7, the yield of sugar beet post-harvest residues in tops will be 43.7 million tons, from which 8.74 billion m

3 of biogas can potentially be obtained. An agricultural animal population data analysis from 2020 to 2025 indicates a steady downward trend in livestock numbers. Over the specified period, livestock numbers have significantly decreased across all major species, indicating profound structural changes and economic challenges (

Table 9).

The total cattle population decreased by 1090.4 thousand heads (from 3092.0 thousand in 2020 to 2001.6 thousand in 2025). This decrease was approximately 35.3%. The number of cows, a key indicator of the dairy industry, also decreased by 633,800 heads (35.4%). This dynamic indicates a severe crisis in livestock farming in the country. Between 2020 and 2025, livestock numbers declined significantly.

Pig numbers fell by 21.1% (over 1.2 million heads). Sheep and goat numbers declined significantly, leading to a 30% decline in the overall livestock population. These alarming trends may indicate a general decline in small-scale livestock production, traditionally based on smallholder farming.

The number of birds, which is the largest meat production sector by volume, decreased by 32.9 million heads (from 220.5 million heads in 2020 to 187.6 million heads by 2025). This drop is approximately 14.9%, indicating problems with logistics, sales, and the stability of production. This trend could seriously affect food security, the domestic export market, and the country’s potential for growth. The decrease in the cow population is particularly alarming for the dairy industry and was caused by the destruction of some facilities due to military actions.

Table 10 presents the calculations of the total volume of manure (in thousands of tons) and the potential biogas production (in millions of m

3) for each animal species. The normative values for biogas yield were systematized based on established data. Biogas production from 1 ton of pig manure is 60 m

3, while cattle manure is 50 m

3 [

47]. Regarding methane yield per ton, poultry manure ranks highest at 65 m

3 of biogas, followed by goat and sheep manure at 54 m

3. Each head of cattle produces 5 tons of manure annually [

48,

49]. The daily pig manure production is approximately 10 kg, or 0.365 tons per year [

50]. For sheep, the annual manure output per head is 1.5 tons [

50], whereas for poultry it is 0.05 tons per year [

51].

Therefore, the total potential for biogas production from livestock waste was 1.566 billion m3. Considering the potential of sugar beet tops in the volume of 8.74 billion m3, the total potential for biogas production through the use of livestock waste and sugar beet tops grown in the 10-field crop rotation we proposed will be over 10.3 billion m3, which, when converted to biomethane, will be 6.18 billion m3. As mentioned above, the use of a 10-field crop rotation for biofuel production, in parallel with biogas production from livestock waste, will make it possible to increase crop yields and partially replace natural gas with biomethane.

Considering that the yield of digestate from processing the organic fraction of waste will be 85–90% of the raw material volume, and the raw material itself is 71.782 million tons, it is believed there could be 61.1–64.61 million tons of digestate obtained [

49]. The conversion rate of digestate to organic fertilizer is 1–12. Considering that the crop rotation we propose involves the use of 11.5 million hectares of agricultural land, and based on a rate of 5 tons per hectare for processing post-harvest residues and livestock industry waste, the required rate can be achieved with a total volume of 57.5 million tons. Therefore, the processing of sugar beet post-harvest residues and organic waste from the livestock industry using the proposed crop rotation will make it possible to meet the needs of these areas for organic fertilizers. Additionally, 3.6 to 7.11 million tons of digestate can be utilized for crops grown in other areas (providing organic fertilization for approximately 0.72 to 1.42 million hectares). Studies (50) indicate that Excel modeling is an accessible tool for evaluating workflows to provide a reasonable basis for building reliability models through factor analysis. Therefore, it was appropriate to develop a model for estimating the yield growth of major agricultural crops using Microsoft Excel tools, which had the following form:

where

Y—predicted crop yield (t/ha).

β0—constant representing the baseline yield in the absence of other factors (analogous to the intercept in a linear model).

X1—amount of digestate applied (t/ha).

X2—soil type (e.g., loam, black soil, etc.), represented as a categorical variable with values from 0.25 to 1.0 according to the bonitet score.

X3—crop predecessor (e.g., cereals and legumes), also treated as a categorical variable.

X4—soil pH level after digestate application.

β1, β2, β3,…—regression coefficients indicating the change in yield per one-unit change in the corresponding factor, assuming all other factors remain constant.

ϵ — model error accounting for uncontrolled variables and random fluctuations (e.g., force majeure events, climatic conditions, and military actions).

To characterize the fertility of the soil cover of Ukraine, the study used generalized indicators of humus content, acidity, and quality assessment of the main types of soils (

Table 11), which can provide an idea of the potential suitability and suitability for agriculture.

Table 12 presents the vision of the relevant coefficients for determining the forecast yield of agricultural crops. The average yield of the relevant crops, according to

Table 6, was considered a constant. Other weighting coefficients were estimated based on their impact on yield, starting from the amount of digestate applied and ending with the predecessor.

Simultaneously, based on the data presented in

Table 13, it can be concluded that Ukraine has significant resources for the production of biofuels that can replace traditional energy sources, namely the potential for the production of biomethane obtained as a result of the processing of post-harvest residues and organic waste from livestock farming, which could produce over 6.18 billion m

3 of biomethane per year, which would cover 31.2% of the total natural gas consumption in Ukraine, which in 2024 amounted to 19.8 billion m

3. The potential for the production of bioethanol from corn, wheat, and sugar beet is estimated at 11.1 million tons per year, which is 4.44 times higher than the actual consumption of gasoline in 2024. Such an excess volume of potential production can create opportunities not only for the complete replacement of gasoline but also for the development of exports. The annual production of biodiesel from rapeseed could reach 3.16 million tons, which would cover 63.2% of the total gas oil consumption in Ukraine, which in 2024 was approximately 5.0 million tons.

Conducting a comprehensive analysis of implementing a 10-field crop rotation in the context of biofuel production (

Table 14) would facilitate the implementation of a comprehensive model that will reduce the country’s dependence on fossil fuel imports through the production of biofuels. Using by-products of biofuel production, especially organic fertilizers (digestate), will allow farmers to significantly optimize costs, thereby reducing the overall cost of agricultural products.

The transition to biofuels is critical for the environment, because it significantly reduces the overall carbon footprint and contributes to climate change mitigation. Furthermore, using plant residues, which were previously considered waste, to produce solid biofuels allows for the most efficient use of crops and land.

Further development and improvement of the proposed system will require ongoing scientific research and analysis. This will contribute to new job opportunities for researchers studying the effectiveness of crop rotations and novel biomass processing technologies. There are also opportunities for consultants to help agricultural enterprises implement innovative solutions and develop business plans. Thus, it is a comprehensive system that creates a multiplier effect through crop rotation and biofuel production, stimulating employment in the agricultural sector and the processing, energy, and scientific industries.

5. Discussion

Implementing a 10-field crop rotation makes biofuel production economically viable and sustainable. This is achieved through land use optimization, increased yields, and reduced costs for inorganic fertilizers and pesticides. Additionally, this system creates strong synergy between biofuel, food, and feed production, contributing to developing a sustainable agro-ecosystem. In this context, it is important to note that in the future, “green logistics” [

54] will no longer be considered a separate process but will become a vital component of integrating and coordinating environmental, social, and economic aspects within a regional logistics system for environmentally oriented logistics management in the region.

At the same time, using digestate as a byproduct of biogas production increases the yield of major crops by 53–83%, changes soil acidity from slightly acidic to almost neutral in the short term, and enhances the competitiveness of organic farming products. However, implementing such large-scale projects requires a solid economic foundation. At the same time, Ukraine needs financial and tax legislation that stabilizes its economic development, investment attractiveness, and the reliability of investments in its economy [

55]. This is critical for successfully implementing large-scale infrastructure projects, such as the transition to biofuels, which requires significant capital investment in logistics and processing facilities [

56,

57,

58].

Based on this research, a 10-field crop rotation has significant potential to supply the bioenergy sector with raw materials for biofuel production. Implementing this model will contribute to strengthening the energy and food security of Ukraine and the European Union. It allows for the diversification of feedstock sources for the sustainable production of bioethanol, biodiesel, and solid biofuels. Introducing a 10-field crop rotation makes biofuel production economically viable and sustainable. This is achieved by optimizing land use, increasing yields, and reducing the cost of inorganic fertilizers and pesticides. Furthermore, this system creates strong synergies between biofuel, food, and feed production, facilitating the development of a sustainable agroecosystem. The use of by-products such as digestate not only increases yields and reduces the cost of agricultural production but also effectively addresses the pressing issue of agricultural waste disposal in Ukraine. The use of a 10-field crop rotation is a justified decision for sustainable production based on circular economy principles. Its use will help preserve soil fertility and prevent water and wind erosion of the soil. Including legumes promotes biological nitrogen fixation, reducing the need for mineral fertilizers.

Differentiated fertilizer application, organic amendments, mulching, and 10-field crop rotation contribute to preserving soil organic carbon. Simultaneously, using digestate as a by-product of biogas production increases the yield of major crops by 53–83%, changes soil acidity from slightly acidic to almost neutral in the short term, and increases the competitiveness of organic farming products. Research has focused on short-term crop rotations or monoculture cultivation. This study utilized the findings of the effectiveness of a 10-field crop rotation for preserving soil fertility, as well as research demonstrating the positive impact of digestate on crop yields and soil restoration.

This study is based on data from 2020 to 2024, which reflect the specific climatic conditions and agricultural practices of certain regions of Ukraine. Changes in climate, soil, or growing technologies in other regions could have influenced the results and their economic viability. The prospects for further research are as follows: a comprehensive assessment of the potential of a 10-field crop rotation for sustainable agriculture and bioenergy; studying the impact of by-products, such as digestate, on increasing yields and reducing costs; and establishing synergy between biofuel and food production.

Despite the significant potential for biofuel production, the limitations of this study should be noted: firstly, the assessment of biofuel production potential is based on statistical data and calculations that may not account for all the nuances of actual production, including logistical costs, losses during harvesting and processing, and fluctuations in market prices; secondly, the geographical representativeness of the study is limited, as it was conducted in specific regions of Ukraine based on data from 2020 to 2024, which may narrow its applicability in other parts of the EU. Specifically, changes in climate, soil, or cultivation technologies in other regions could affect the economic viability of the results. Additionally, the obtained results may not fully reflect the situation in the temporarily occupied territories of Ukraine due to the lack of reliable data and the impossibility of full-fledged economic activity.