Design of a Seed-Pressing Mechanism for Precision Peanut Planters and Verification of Optimal Operating Parameters Under High-Speed Seeding Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

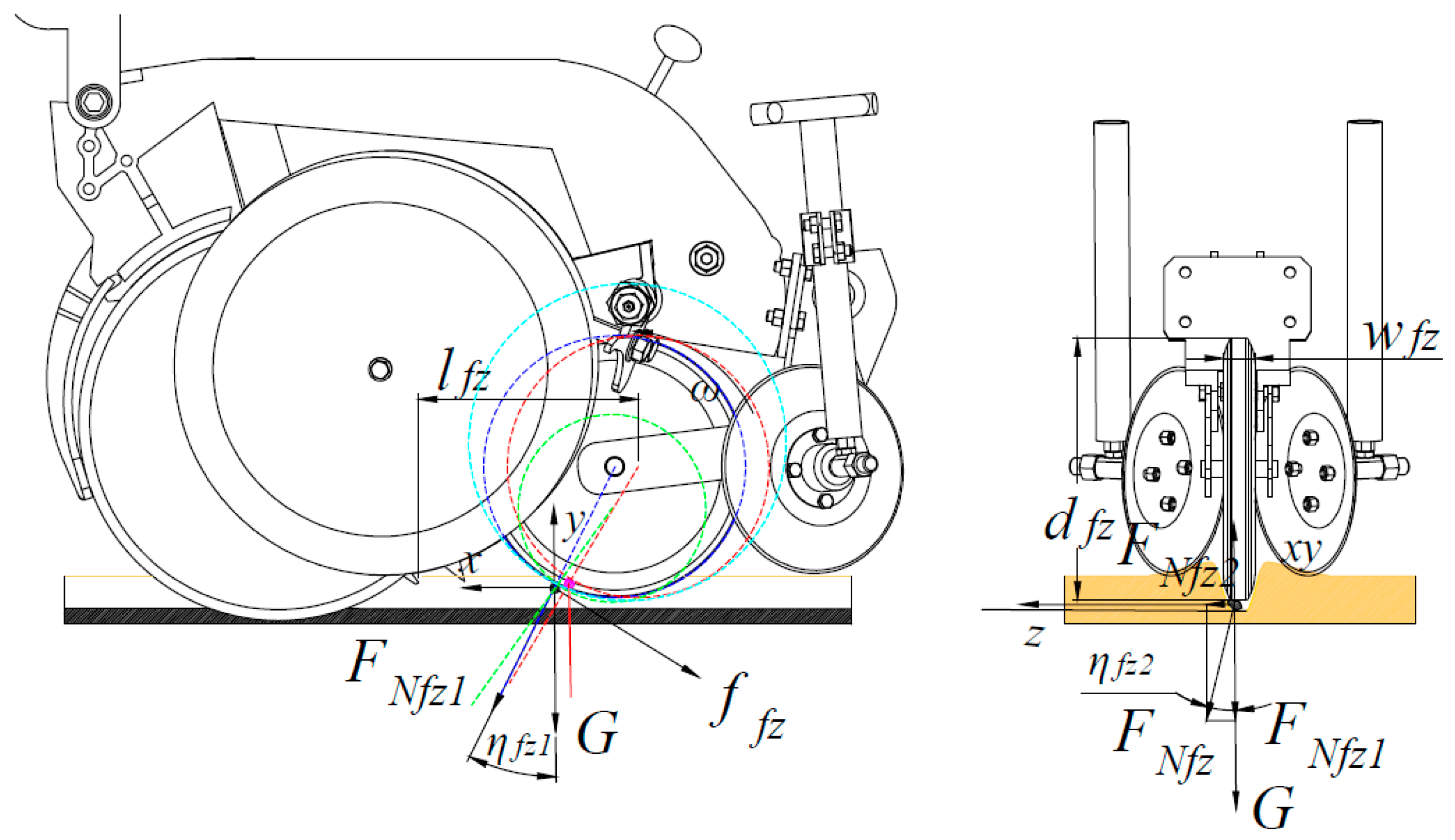

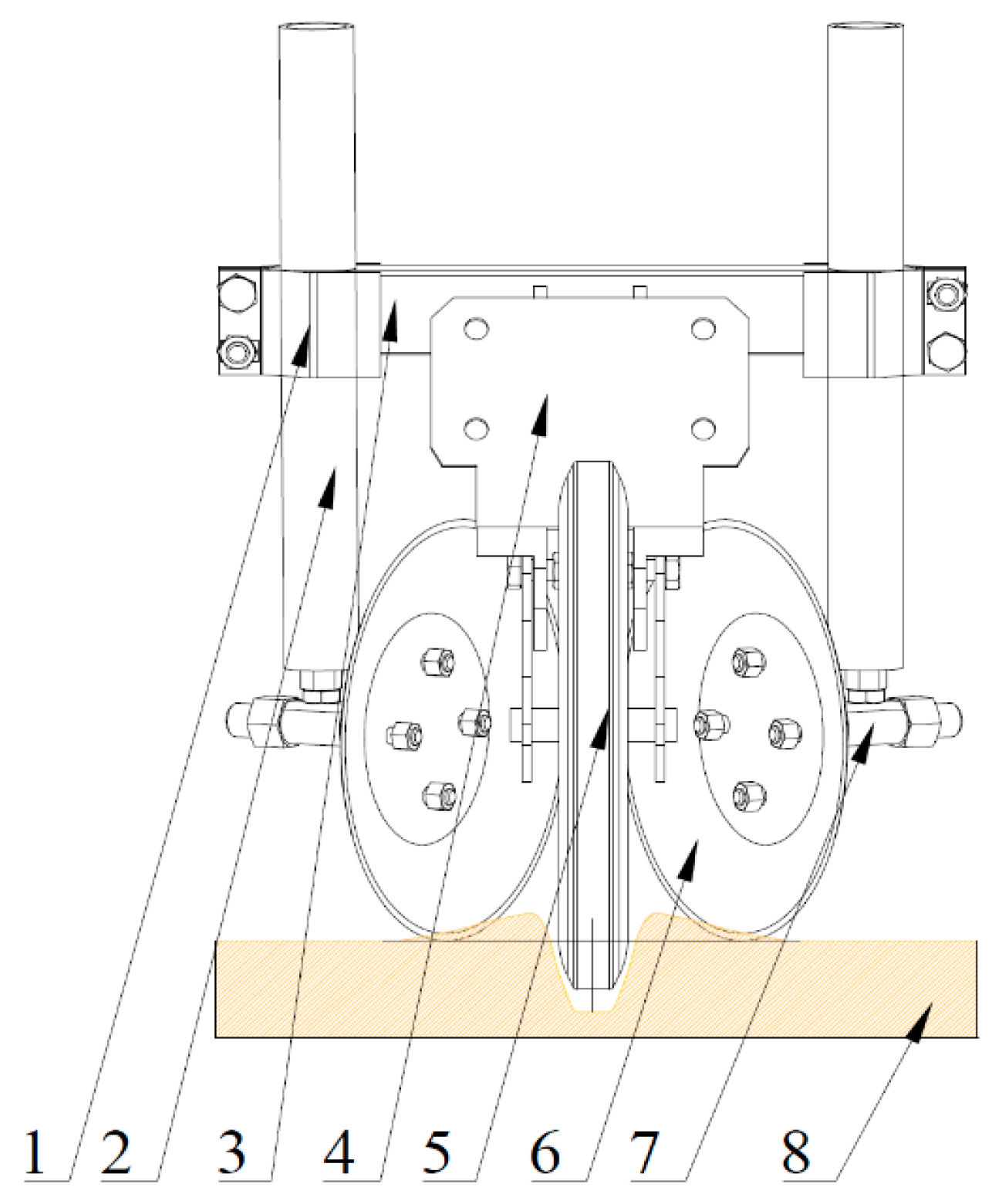

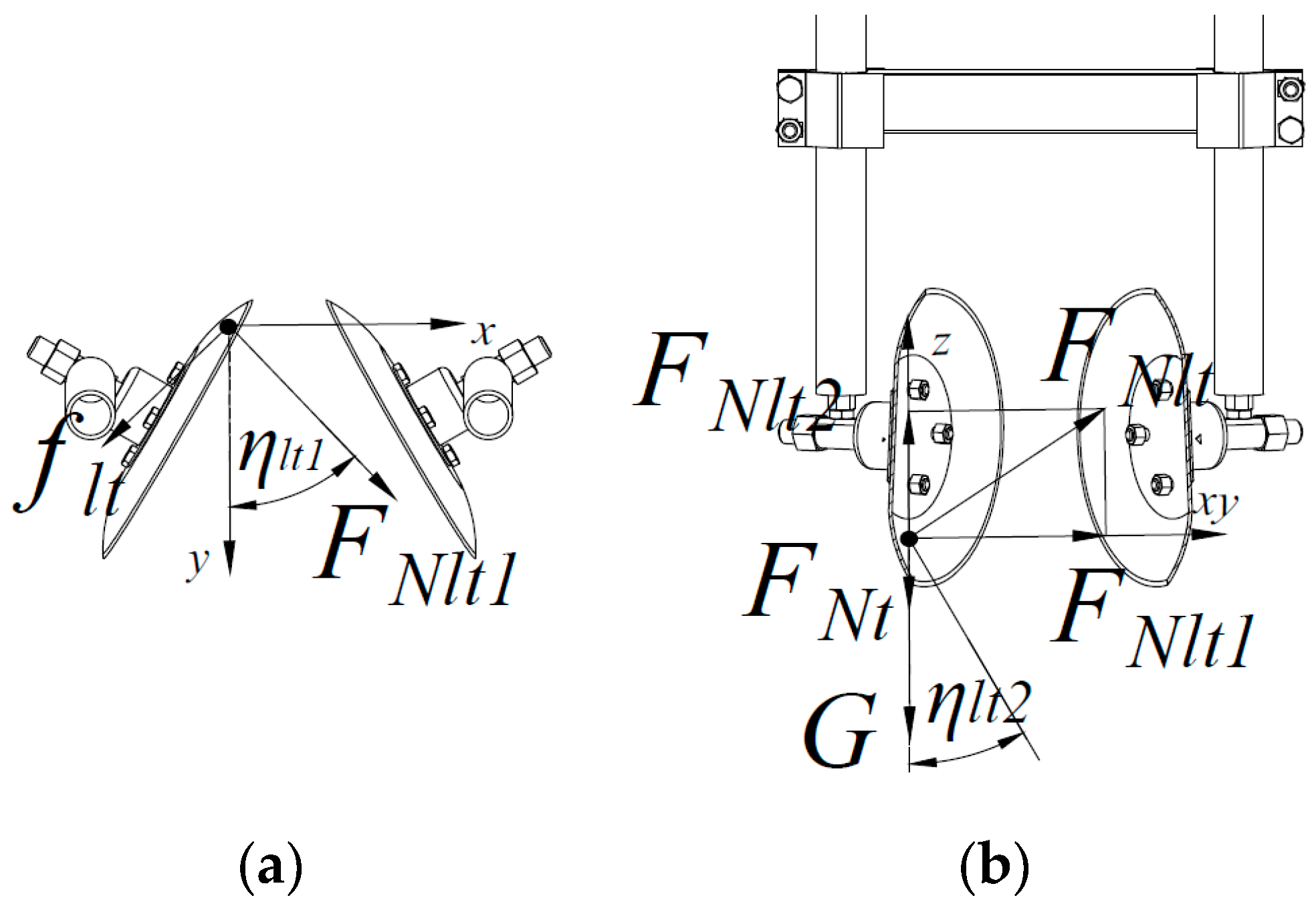

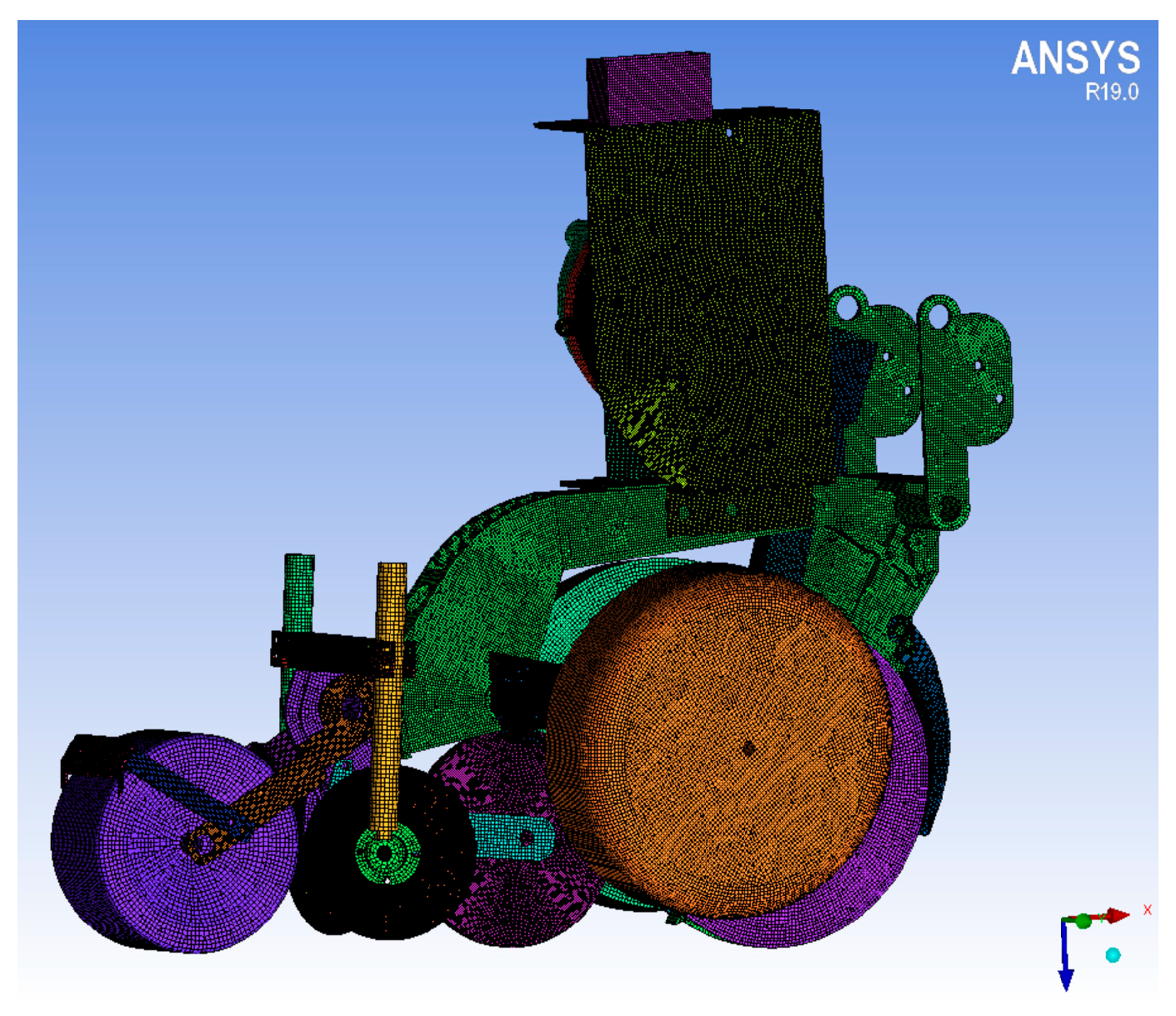

2.1.1. Seed-Pressing and Soil-Covering Mechanisms

2.1.2. Working Process

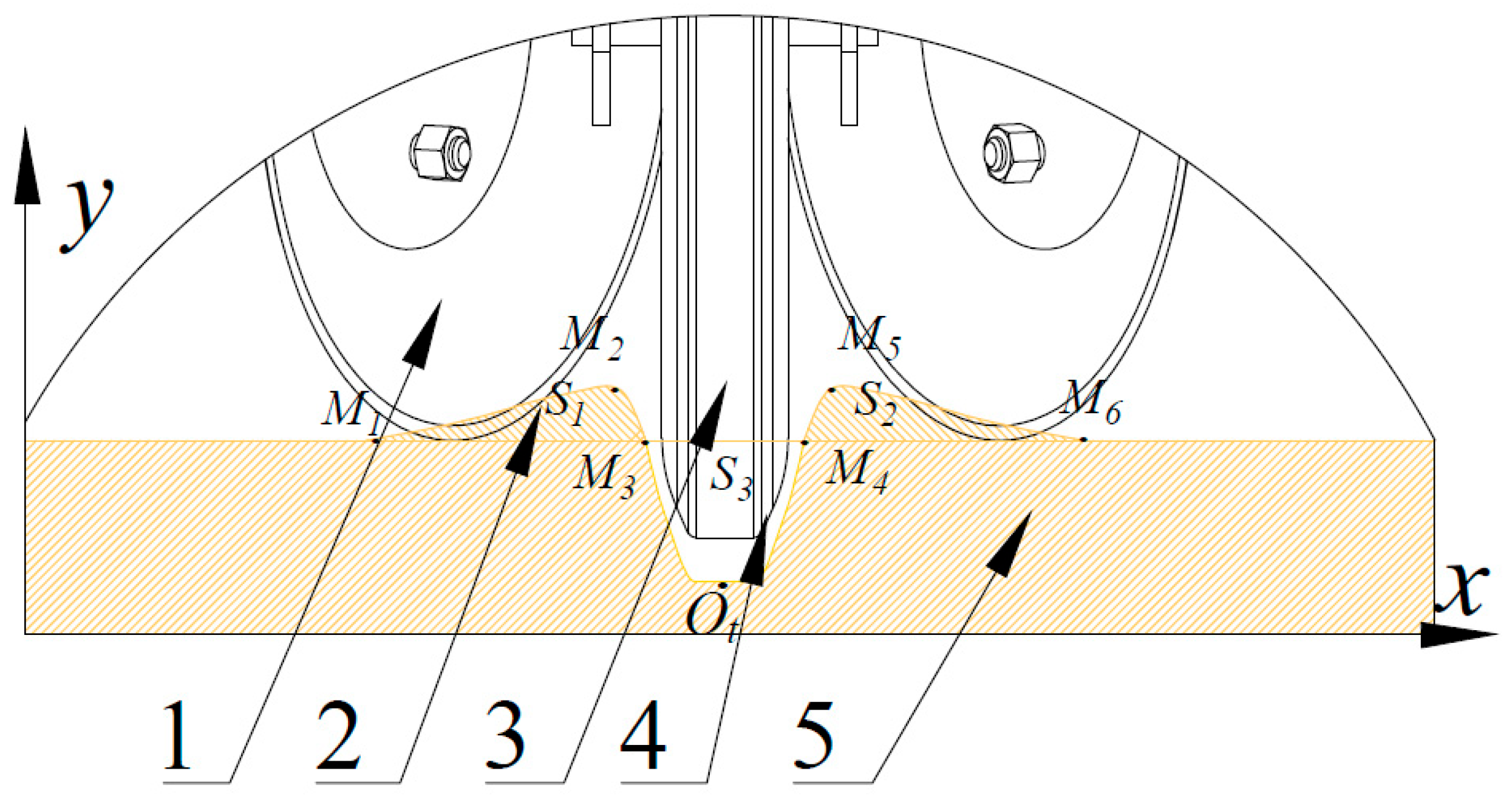

2.1.3. Key Parameters

Seed-Pressing Mechanism

Backfilling Device

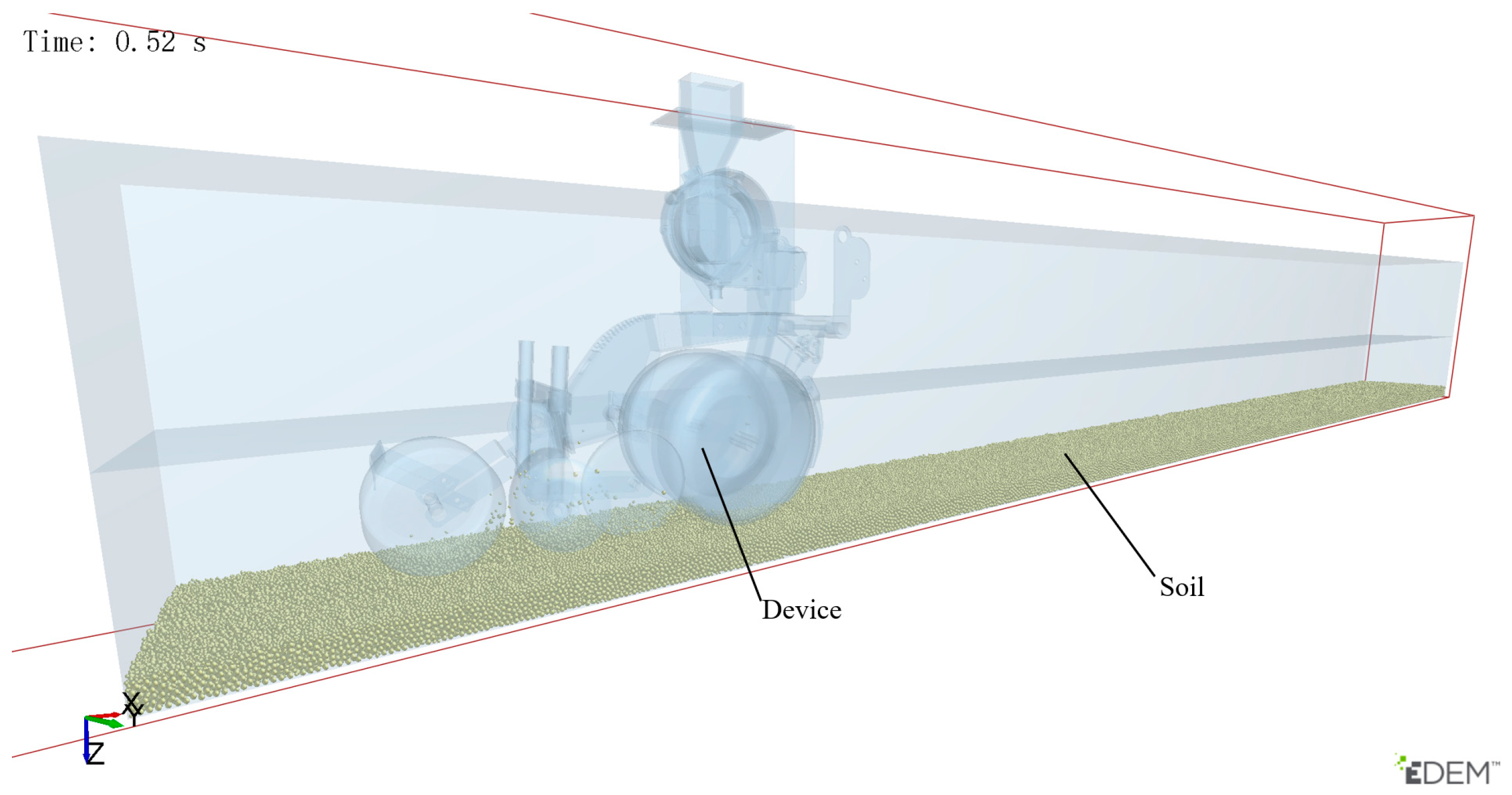

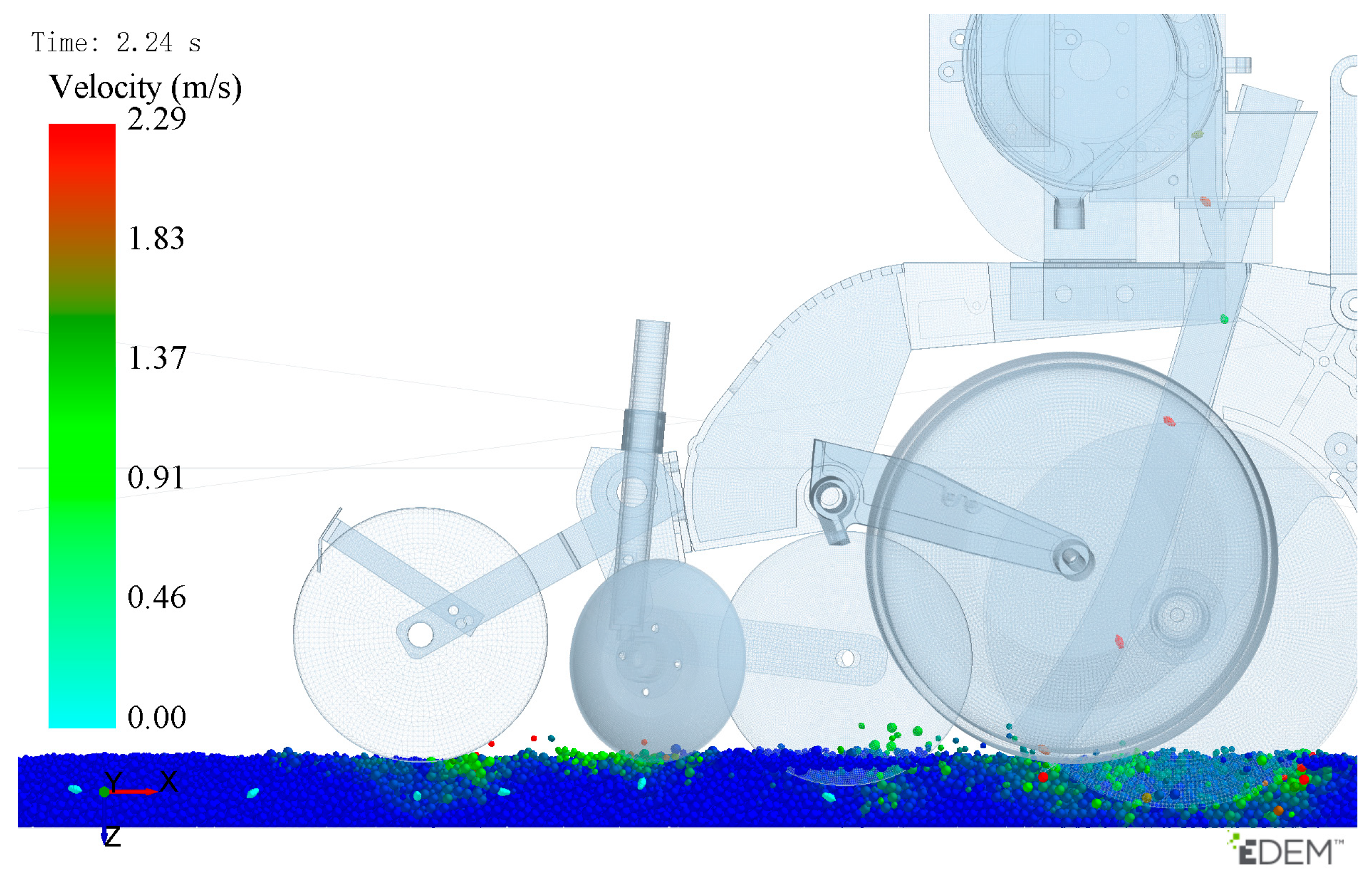

2.2. Simulation Model and Boundary Conditions

2.2.1. Soil-Particle Modeling

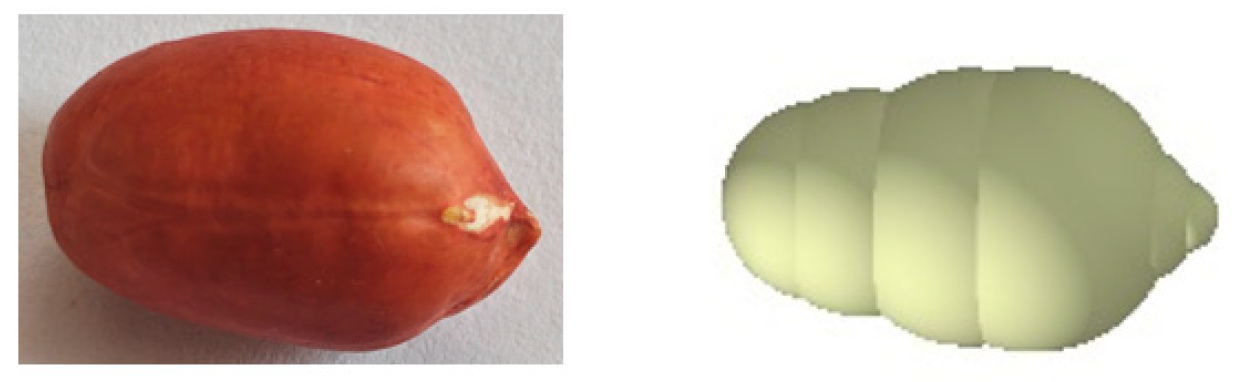

2.2.2. Seed-Particle Modeling

2.2.3. Geometric Modeling

2.2.4. Calculation Conditions and Parameters

2.3. Experimental Program

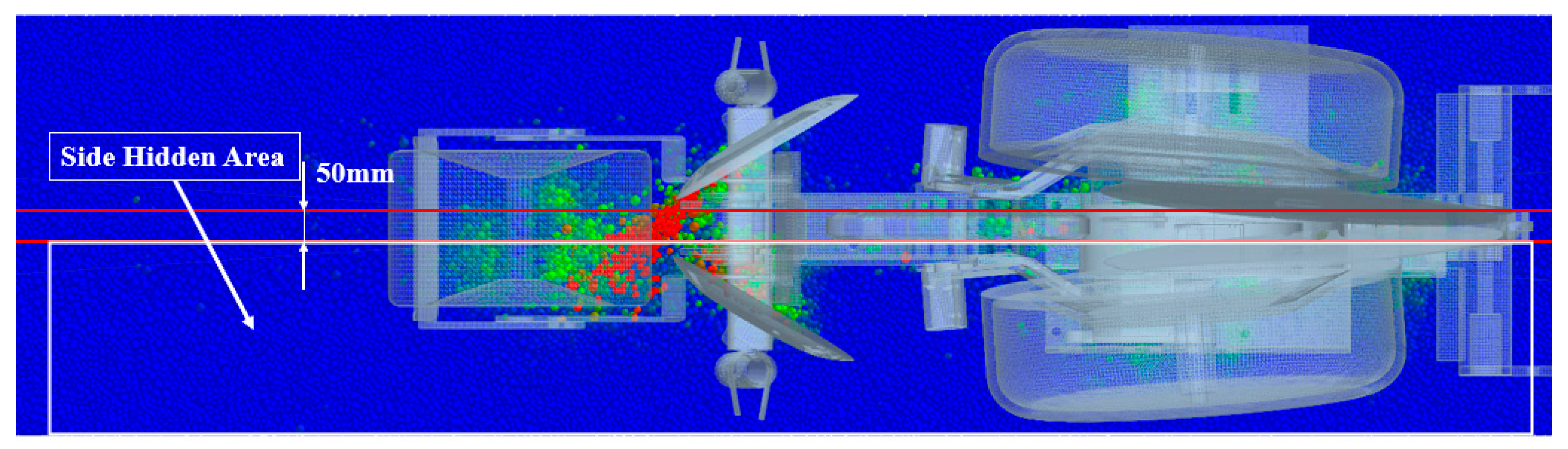

2.3.1. Coupled Simulation Experimental Design

2.3.2. Experimental Design

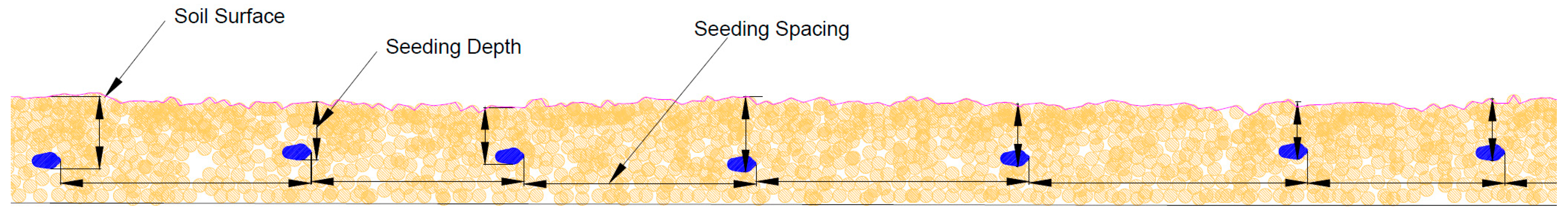

2.3.3. Test Indicators and Measurement Methods

3. Results and Discussion

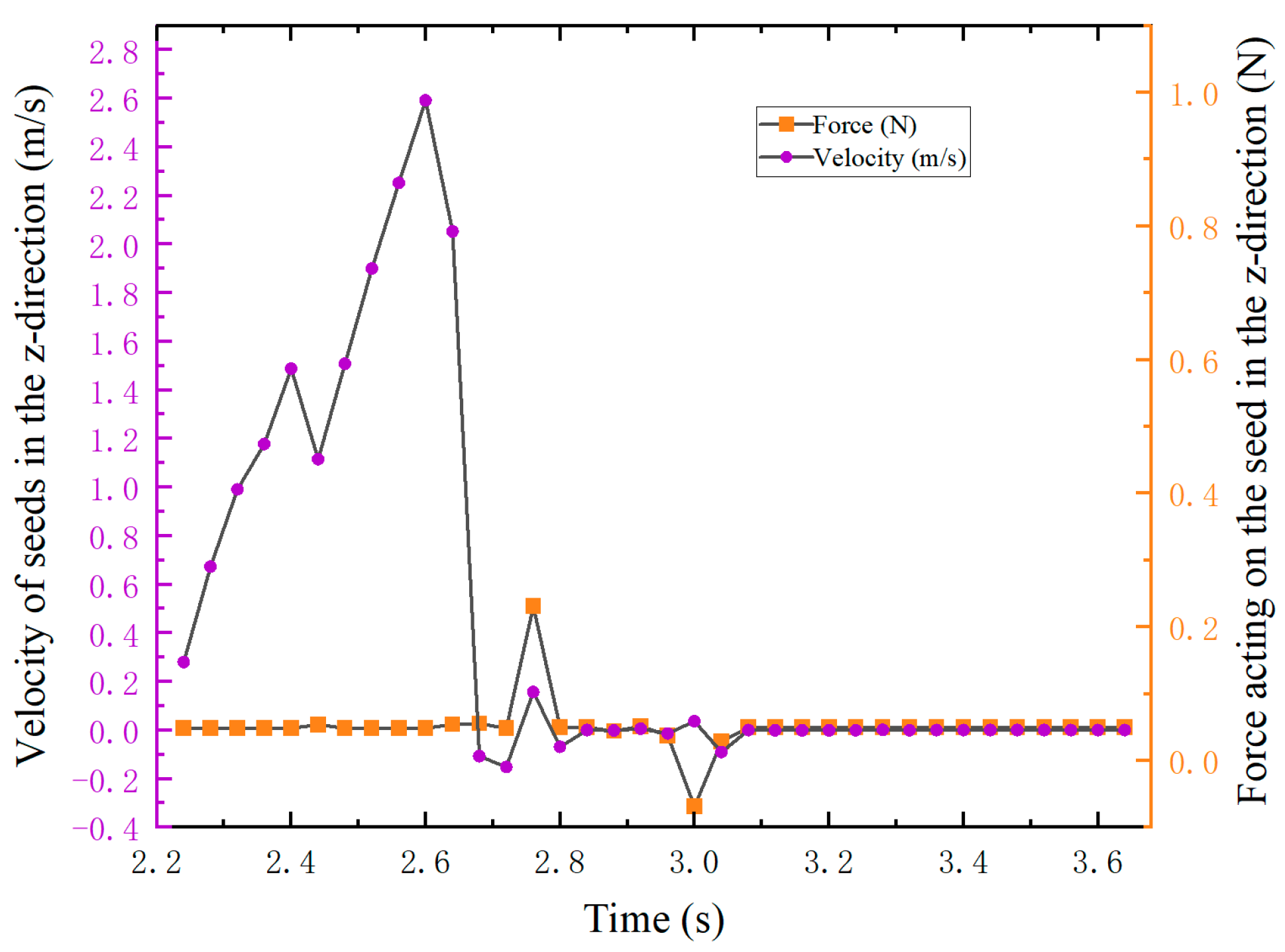

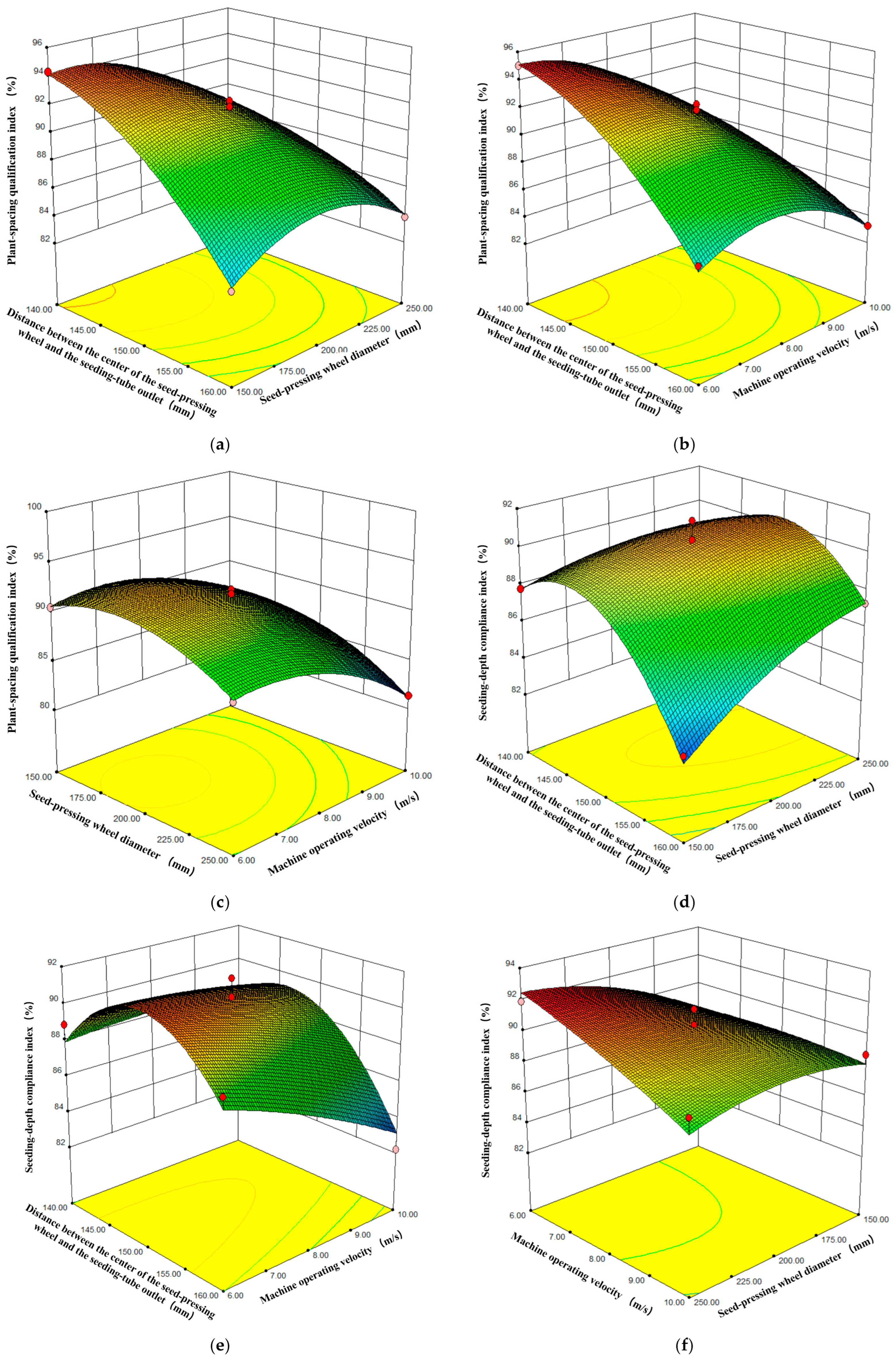

3.1. Discrete Element Simulation Results and Analysis

3.2. Validation Experiment

4. Conclusions

- (1)

- Theoretical analysis of the seed-pressing and soil-covering mechanisms identified the key structural parameters of both components. Three primary factors influencing the plant-spacing qualification and seeding-depth compliance indices were determined: DCSPW-STO, the seed-pressing wheel diameter, and the machine operating velocity.

- (2)

- Experimental analysis using the discrete element method with three factors and three levels revealed the effects of the DCSPW-STO, the seed-pressing wheel diameter, and the operational velocity on peanut-seeding performance. An optimization model was then established to determine the best parameter combination: the optimal DCSPW-STO was 146.13 mm, the optimal seed-pressing wheel diameter was 198.13 mm, and the optimal machine operating velocity was 6.45 km h−1. With these settings, the seeding effect was favorable.

- (3)

- Field trials validated the optimized results, demonstrating that the improved seed-pressing mechanism and operational parameters meet agronomic requirements for precision peanut seeding.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, X.S.; Ran, W.J.; Hao, J.J.; Bai, W.J.; Yang, X.L. Design and experiment of the double-seed hole seeding precision seed metering device for peanuts. Int. J. Agri. Biol. Eng. 2022, 15, 107–114. [Google Scholar] [CrossRef]

- Wang, S.Y.; Hu, Z.C.; Chen, Y.Q.; Wu, H.C.; Wang, Y.W.; Wu, F.; Gu, F.W. Integration of agricultural machinery and agronomy for mechanised peanut production using the vine for animal feed. Biosyst Eng. 2022, 219, 135–152. [Google Scholar] [CrossRef]

- He, S.N.; Chen, Y.; Xiang, W.; Chen, X.W.; Wang, X.L.; Chen, Y. Carbon and nitrogen footprints accounting of peanut and peanut oil production in China. J. Clean. Prod. 2021, 291, 125964. [Google Scholar] [CrossRef]

- Guo, P.; Zheng, X.S.; Wang, D.W.; Hou, J.L.; Zhao, Z. Design and Experiment of Precision Seed Metering Device with Pneumatic Assisted Seed-filling for Peanut. Trans. Chin. Soc. Agric. Mach. 2024, 55, 64–74. [Google Scholar]

- Yin, X.W.; Yang, L.; Zhang, D.X.; Cui, T.; Han, D.D.; Zhang, T.L.; Yu, Y.M. Design and experiment of balance and low-loss air allotter in air pressure maize precision planter. Trans. Chin. Soc. Agri. Eng. 2016, 32, 9–17. [Google Scholar] [CrossRef]

- Wang, Y.B.; Li, H.W.; Hu, H.N.; He, J.; Wang, Q.J.; Lu, C.Y.; Liu, P.; He, D.; Lin, X. DEM–CFD coupling simulation and optimization of a self-suction wheat shooting device. Powder Technol. 2021, 393, 494–509. [Google Scholar] [CrossRef]

- Wang, D.W.; Ji, R.Q.; He, X.N.; Guo, P.; Shi, Y.X.; Zhang, C.X. Drive-guided Combination Slot-assisted Seed-attached Air-absorbing Peanut High-speed Precision Seed Meter. Trans. Chin. Soc. Agri. Mach. 2023, 54, 59–70+149. [Google Scholar] [CrossRef]

- Li, Y.H.; Yang, L.; Zhang, D.X.; Cui, T.; Ding, L.; Wei, Y.N. Design and Experiment of Pneumatic Precision Seed-metering Device with Single Seed-metering Plate for Double-row. Trans. Chin. Soc. Agric. Mach. 2019, 50, 61–73. [Google Scholar] [CrossRef]

- Xing, H.; Cao, X.M.; Zhong, P.; Wan, Y.K.; Lin, J.J.; Zang, Y.; Zhang, G.Z. DEM-CFD coupling simulation and optimisation of rice seed particles seeding a hill in double cavity pneumatic seed metering device. Comput. Electr. Agri. 2024, 224, 109075. [Google Scholar] [CrossRef]

- Fang, Z.H.; Zhang, J.; Chen, J.C.; Pan, F.; Wang, B.W.; Ji, C. Design and Experimental Analysis of an Air-Suction Wheat Precision Hill-Seed Metering Device. Agriculture 2024, 14, 1931. [Google Scholar] [CrossRef]

- Liu, R.; Liu, Z.J.; Liu, L.J.; Li, Y.H. Design and Experiment of Corn High Speed Air Suction Seed Metering Device with Disturbance Assisted Seed-filling. Trans. Chin. Soc. Agri. Mach. 2022, 53, 50–59. [Google Scholar] [CrossRef]

- Zang, Y.; Huang, Z.S.; Qin, W.; He, S.Y.; Qian, C.; Jiang, Y.C.; Tao, W.Y.; Zhang, M.L.; Wang, Z.M. Design of hybrid rice air-suction single seed metering device. Trans. Chin. Soc. Agri. Eng. 2024, 40, 181–191. [Google Scholar] [CrossRef]

- Ding, L.; Yuan, Y.C.; Dou, Y.F.; Li, C.X.; He, Z.; Guo, G.M.; Zhang, Y.; Chen, B.J.; Li, H. Design and Experiment of Air-Suction Maize Seed-Metering Device with Auxiliary Guide. Agriculture 2024, 14, 169. [Google Scholar] [CrossRef]

- Liu, J.X.; Wang, Q.J.; Li, H.W.; He, J.; Lu, C.Y. Design and seed suction performance of pinhole-tube wheat precision seeding device. Trans. Chin. Soc. Agric. Eng. 2019, 35, 10–18. [Google Scholar] [CrossRef]

- Jiang, Y.Z.; Hou, X.X.; Zhao, Y.M.; Hu, B.; Luo, X.; Chen, Y.; Zhang, H. Design and experiment of air suction drum precision metering device for air blowing and seeding. J. Gansu Agric. Univ. 2022, 38, 31–41. [Google Scholar] [CrossRef]

- Huang, X.M.; Zhang, S.; Zhu, Y.Z.; Liu, Y. Seeding process analysis and test of the air conveying rapeseed aerial seeding device. Trans. Chin. Soc. Agric. Eng. 2022, 38, 31–41. [Google Scholar] [CrossRef]

- Wang, L.B.; Yang, H.Y.; Wang, Q.J.; Lu, C.Y.; Wang, C.; He, J. Design and Experiment of Air-assisted Linear Seeding Device for Wheat. Trans. Chin. Soc. Agric. Mach. 2024, 55, 111–120. [Google Scholar]

- Lü, J.Q.; Yang, Y.; Shang, Q.Q.; Li, Z.H.; Li, J.C.; Liu, Z.Y.; Wang, Y.B. Performance optimization test on air-suction potato seed metering device with positive pressure airflow and zero-speed seeding. Trans. Chin. Soc. Agric. Eng. 2016, 32, 40–48. [Google Scholar] [CrossRef]

- Siemens, M.C.; Gayler, R.R. Improving Seed Spacing Uniformity of Precision Vegetable Planters. Appl. Eng. Agric. 2016, 32, 579–587. [Google Scholar] [CrossRef]

- Wang, C.; Li, H.W.; He, J.; Wang, Q.J.; Lu, C.Y.; Wang, J.X. Design and Experiment of Pneumatic Wheat Precision Seed Casting Device in Rice-wheat Rotation Areas. Trans. Chin. Soc. Agric. Mach. 2020, 51, 43–53. [Google Scholar] [CrossRef]

- Lu, Q.; Zhao, J.H.; Liu, L.J.; Liu, Z.J.; Wang, C.L. Design and Experiment of a Soil-Covering and -Pressing Device for Planters. Agriculture 2024, 14, 1040. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhang, W.Y.; Yan, W.; Qi, B. Design and Experiment of Seed Pressing Device for Precision Seeder Based on Air Flow Assisted Seed Delivery. Trans. Chin. Soc. Agric. Mach. 2020, 51, 69–76. [Google Scholar] [CrossRef]

- Ma, F.Y.; Wang, L.B.; Wang, C.; Wang, Q.J.; Lu, C.Y. Study on Impact Soil Movement Experiments on Wheat Seeds Based on EDEM. Agriculture 2025, 15, 400. [Google Scholar] [CrossRef]

- Zhang, T.; Tang, X.L.; Dai, C.; Ren, G.Y. Operating parameter optimization and experiment of spiral outer grooved wheel seed metering device based on discrete element method. Sci. Rep. 2025, 15, 30762. [Google Scholar] [CrossRef]

- Guo, P.; Sun, B.; Shang, S.Q.; Hou, J.L.; Wang, D.W.; Zhao, Z.; Elshafie, A.; Zheng, X.S.; Eltoum, F. Effect of Auxiliary Air-Suction Seed-Filling Structure on Seed Discharge Performance of Peanut High-Speed Seed-Metering Machine. Agriculture 2025, 15, 1678. [Google Scholar] [CrossRef]

- Chen, Y.G.; Wu, N.; Lin, D.Z.; Yu, Z.Y.; You, Z.Y.; Hu, Z.C. Study on Recovery Coefficient and Friction Coefficient of Peanut Kernels. Jiangsu Agric. Sci. 2016, 44, 386–390. [Google Scholar] [CrossRef]

- Zhao, S.H.; Gu, Z.Y.; Yuan, Y.W.; Lü, J.Q. Bionic Design and Experiment of Potato Curved Surface Sowing Furrow Opener. Trans. Chin. Soc. Agric. Mach. 2021, 52, 32–42+64. [Google Scholar] [CrossRef]

- Zhang, H.; Pan, F.; Han, D.L.; Liu, J.B.; Ji, C. Design and Test of a Crawler-Type On-Film Precision Cotton Seeding. Agriculture 2024, 14, 962. [Google Scholar] [CrossRef]

- Wu, M.C.; Cong, J.L.; Yan, Q.; Zhu, D.; Peng, X.Y.; Wang, Y.S. Calibration and experiments for discrete element simulation parameters of peanut seed particles. Trans. Chin. Soc. Agri. Eng. 2020, 36, 30–38. [Google Scholar] [CrossRef]

- Wei, S.; Zhang, C.H.; Zhan, Z.Y.; Nong, F.; Ding, Y.C. Simulation and Optimization Test of Imitation Furrowing Process of Cotton Direct Seeding MachineBased on DEM-MBD Coupling. Trans. Chin. Soc. Agric. Mach. 2025, 56, 275–289+341. [Google Scholar] [CrossRef]

- Xia, J.F.; Zhang, P.; Yuan, H.W.; Du, J.; Zheng, K.; Li, Y.F. Calibration and Verification of Flexible Rice Straw Model by Discrete Element Method. Trans. Chin. Soc. Agric. Mach. 2024, 55, 174–184. [Google Scholar] [CrossRef]

- Ma, S.; Xu, L.M.; Yuan, Q.C.; Niu, C.; Zeng, J.; Chen, C.; Wang, S.S.; Yuan, X.T. Calibration of discrete element simulation parameters of grapevine antifreezing soil and its interaction with soil-cleaning components. Trans. Chin. Soc. Agri. Eng. 2020, 36, 30–38. [Google Scholar] [CrossRef]

- GB/T 6973-2005; Testing Methods of Single Seed Drills (Precision Drills). China Standards Press: Beijing, China, 2005.

| Physical Property | Parameter |

|---|---|

| Average size of three axes (mm) | 15 × 10 × 8.5 |

| Density (kg·m−3) | 1049 |

| Moisture content (%) | 8.87 |

| Materials | Parameters | Peanuts | Steel | Soil | Rubber | Nylon Plastic |

|---|---|---|---|---|---|---|

| Poisson’s ratio | 0.362 | 0.31 | 0.41 | 0.46 | 0.38 | |

| Shear modulus (Pa) | 5.06 × 107 | 7.85 × 1010 | 1.31 × 106 | 0.6 × 106 | 3.11 × 109 | |

| Density (kg m−3) | 1040 | 7850 | 2320 | 1200 | 1130 | |

| Seeds and Materials | Restitution coefficient | 0.501 | 0.63 | 0.34 | 0.18 | 0.519 |

| Static friction coefficient | 0.213 | 0.33 | 0.24 | 0.31 | 0.441 | |

| Rolling friction coefficient | 0.035 | 0.26 | 0.07 | 0.25 | 0.126 | |

| Soil and Materials | Restitution coefficient | 0.34 | 0.35 | 0.35 | 0.61 | / |

| Static friction coefficient | 0.24 | 0.60 | 0.35 | 0.48 | / | |

| Rolling friction coefficient | 0.07 | 0.10 | 0.26 | 0.23 | / | |

| Time step (s) | 1 × 10−5 | |||||

| Forward Speed of the Machine (km h−1) | Particle Factory Production Rate per Second | Initial Velocity of Generated Particles (m s−1) |

|---|---|---|

| 6 | 11 | 0.2 |

| 8 | 15 | 0.266 |

| 10 | 19 | 0.333 |

| Level Code | Experimental Factors | ||

|---|---|---|---|

| Distance Between the Center of the Seed-Pressing Wheel and the Seeding-Tube Outlet (mm) | Seed-Pressing Wheel Diameter (mm) | Machine Operating Velocity (km h−1) | |

| −1 | 140 | 150 | 6 |

| 0 | 150 | 200 | 8 |

| 1 | 160 | 250 | 10 |

| Number | Machine Operating Velocity (km h−1) | Seed-Tray Rotation Speed (rpm) |

|---|---|---|

| 1 | 6 | 19.09 |

| 2 | 8 | 25.38 |

| 3 | 10 | 31.79 |

| Experimental Factors | Plant-Spacing Qualification Index | Seeding-Depth Compliance Index | |||

|---|---|---|---|---|---|

| X1 | X2 | X3 | Y1% | Y2% | |

| 1 | 0 | −1 | −1 | 90.53 | 87.3 |

| 2 | 0 | 0 | 0 | 91.24 | 91.5 |

| 3 | −1 | −1 | 0 | 94.31 | 87.8 |

| 4 | 0 | 0 | 0 | 90.63 | 90.3 |

| 5 | 0 | −1 | 1 | 86.26 | 88.7 |

| 6 | −1 | 0 | −1 | 95.02 | 88.9 |

| 7 | 1 | 1 | 0 | 83.84 | 87.3 |

| 8 | −1 | 1 | 0 | 86.69 | 86.7 |

| 9 | 0 | 1 | −1 | 87.72 | 91.9 |

| 10 | 0 | 0 | 0 | 91.84 | 90.5 |

| 11 | 1 | 0 | 1 | 83.26 | 82.2 |

| 12 | 1 | 0 | −1 | 85.44 | 88.6 |

| 13 | 1 | −1 | 0 | 83.77 | 83.1 |

| 14 | 0 | 1 | 1 | 81.33 | 88.8 |

| 15 | 0 | 0 | 0 | 92.25 | 89.6 |

| 16 | 0 | 0 | 0 | 91.39 | 89.9 |

| 17 | −1 | 0 | 1 | 85.32 | 87.4 |

| Source | Plant-Spacing Qualification Index | Seeding-Depth Compliance Index | ||||||

|---|---|---|---|---|---|---|---|---|

| Sum of Squares | Degrees of Freedom | F | p | Sum of Squares | Degrees of Freedom | F | p | |

| Model | 274.4636 | 9 | 102.4545 | <0.0001 ** | 99.51682 | 9 | 10.34509 | 0.0028 ** |

| X1 | 78.31261 | 1 | 263.0999 | <0.0001 ** | 11.52 | 1 | 10.77787 | 0.0134 * |

| X2 | 29.22301 | 1 | 98.17793 | <0.0001 ** | 7.605 | 1 | 7.115076 | 0.0321 * |

| X3 | 63.50645 | 1 | 213.3569 | <0.0001 ** | 11.52 | 1 | 10.77787 | 0.0134 * |

| X1X2 | 14.78403 | 1 | 49.66856 | 0.0002 ** | 7.0225 | 1 | 6.570102 | 0.0374 * |

| X1X3 | 14.1376 | 1 | 47.49683 | 0.0002 ** | 6.0025 | 1 | 5.615811 | 0.0496 * |

| X2X3 | 1.1236 | 1 | 3.774858 | 0.0931 | 5.0625 | 1 | 4.736367 | 0.0660 |

| 13.02401 | 1 | 43.75559 | 0.0003 ** | 44.95392 | 1 | 42.05793 | 0.0003 ** | |

| 27.56716 | 1 | 92.61493 | <0.0001 ** | 3.168658 | 1 | 2.964529 | 0.1288 | |

| 25.29948 | 1 | 84.99639 | <0.0001 ** | 0.424447 | 1 | 0.397104 | 0.5486 | |

| Residual | 2.083575 | 7 | 7.482 | 7 | ||||

| Lack of fit | 0.573375 | 3 | 0.506224 | 0.6987 | 5.37 | 3 | 3.390152 | 0.1345 |

| Errors | 1.5102 | 4 | 2.112 | 4 | ||||

| Total | 276.5472 | 16 | 106.9988 | 16 | ||||

| Type | Machine Operating Velocity (km h−1) | Plant-Spacing Qualification Index (%) | Seeding-Depth Compliance Index (%) |

|---|---|---|---|

| Seed pressing | 6.45 | 90.31 | 89.18 |

| No seed pressing | 6.45 | 86.97 | 85.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, P.; Shang, S.; Zheng, X.; Hou, J.; Zhang, J.; Yan, H.; Ding, Y.; Eltom, F.; Wang, D. Design of a Seed-Pressing Mechanism for Precision Peanut Planters and Verification of Optimal Operating Parameters Under High-Speed Seeding Conditions. Agriculture 2025, 15, 2246. https://doi.org/10.3390/agriculture15212246

Guo P, Shang S, Zheng X, Hou J, Zhang J, Yan H, Ding Y, Eltom F, Wang D. Design of a Seed-Pressing Mechanism for Precision Peanut Planters and Verification of Optimal Operating Parameters Under High-Speed Seeding Conditions. Agriculture. 2025; 15(21):2246. https://doi.org/10.3390/agriculture15212246

Chicago/Turabian StyleGuo, Peng, Shuqi Shang, Xiaoshuai Zheng, Jialin Hou, Jing Zhang, Haipeng Yan, Yu Ding, Farid Eltom, and Dongwei Wang. 2025. "Design of a Seed-Pressing Mechanism for Precision Peanut Planters and Verification of Optimal Operating Parameters Under High-Speed Seeding Conditions" Agriculture 15, no. 21: 2246. https://doi.org/10.3390/agriculture15212246

APA StyleGuo, P., Shang, S., Zheng, X., Hou, J., Zhang, J., Yan, H., Ding, Y., Eltom, F., & Wang, D. (2025). Design of a Seed-Pressing Mechanism for Precision Peanut Planters and Verification of Optimal Operating Parameters Under High-Speed Seeding Conditions. Agriculture, 15(21), 2246. https://doi.org/10.3390/agriculture15212246