Hot Pots: Container Color Has a Greater Cooling Effect than Micro-Sprinkler Frequency in Nursery Production

Abstract

1. Introduction

2. Materials and Methods

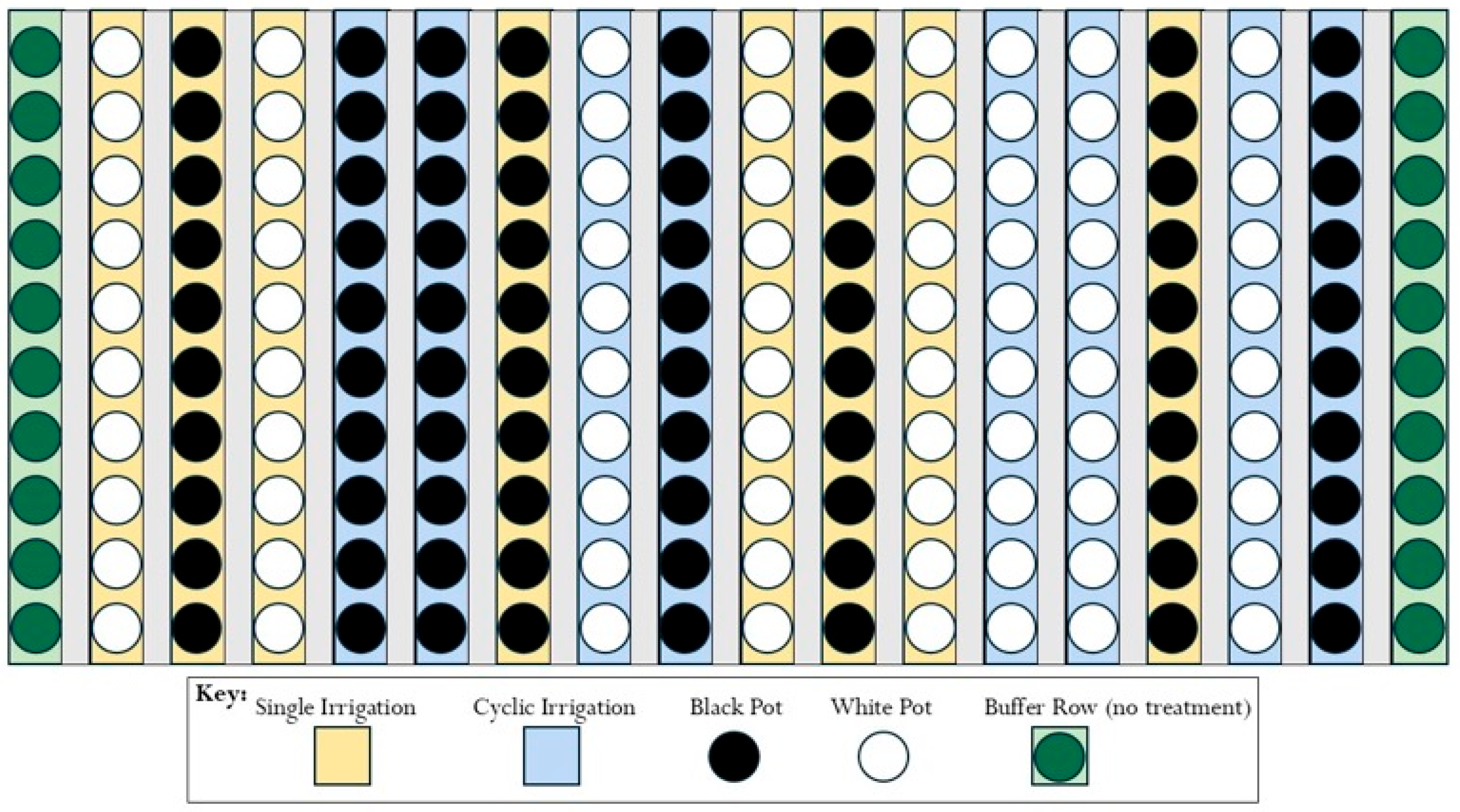

2.1. Plant Material and Experimental Setup

2.2. Irrigation Treatments

2.3. Data Collection

2.4. Statistical Analyses

3. Results

3.1. Weather Conditions

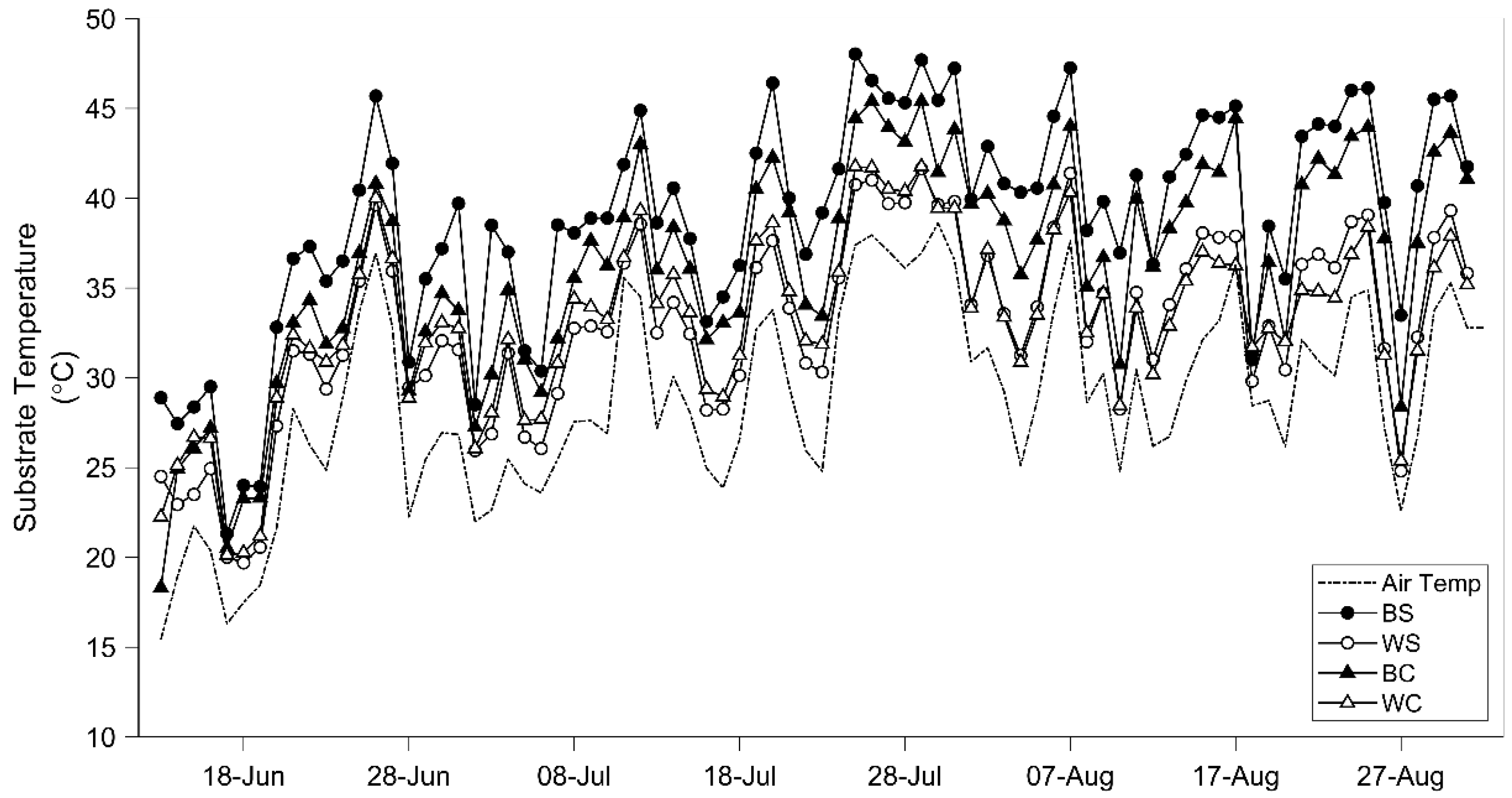

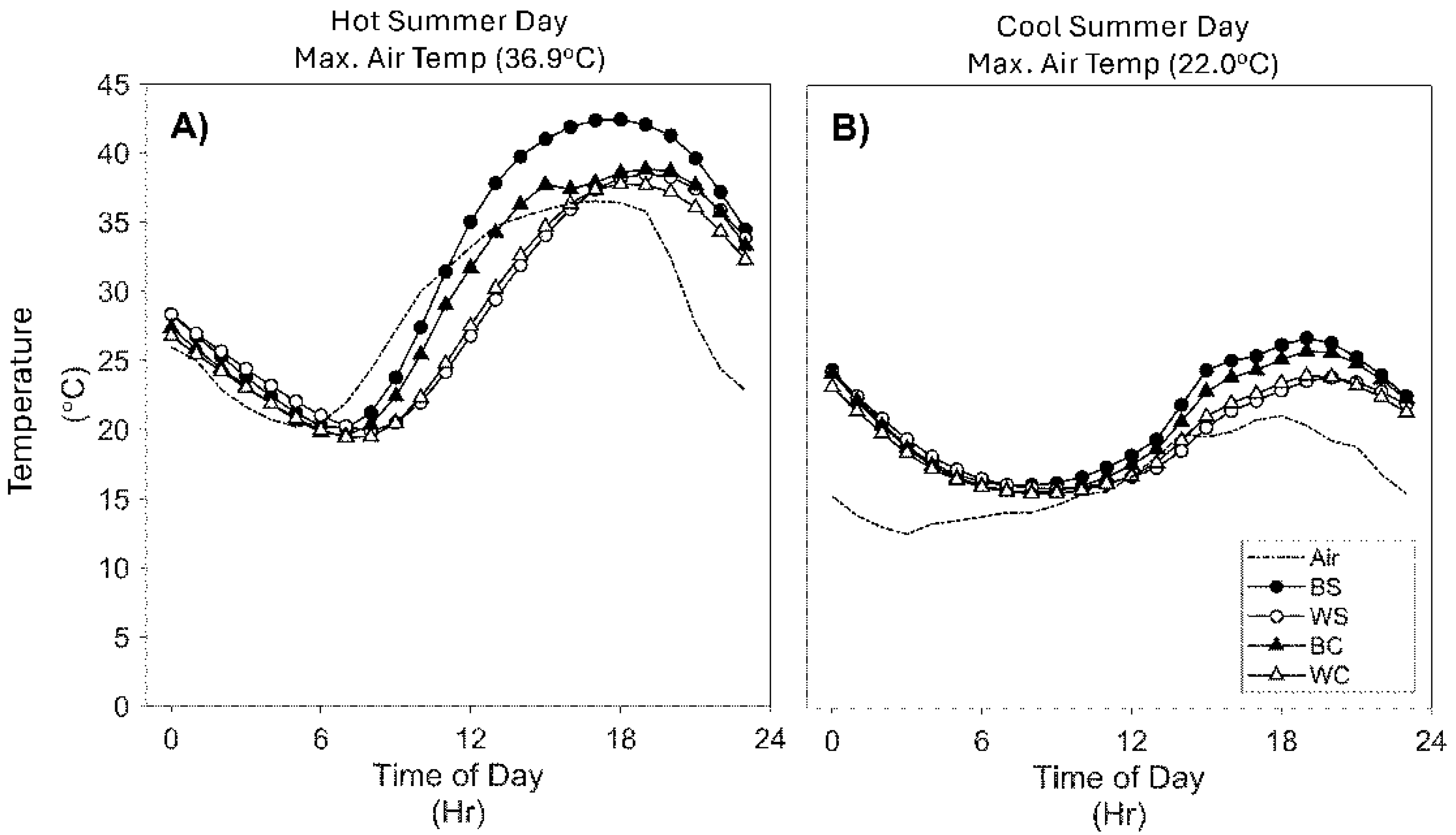

3.2. Container Temperature

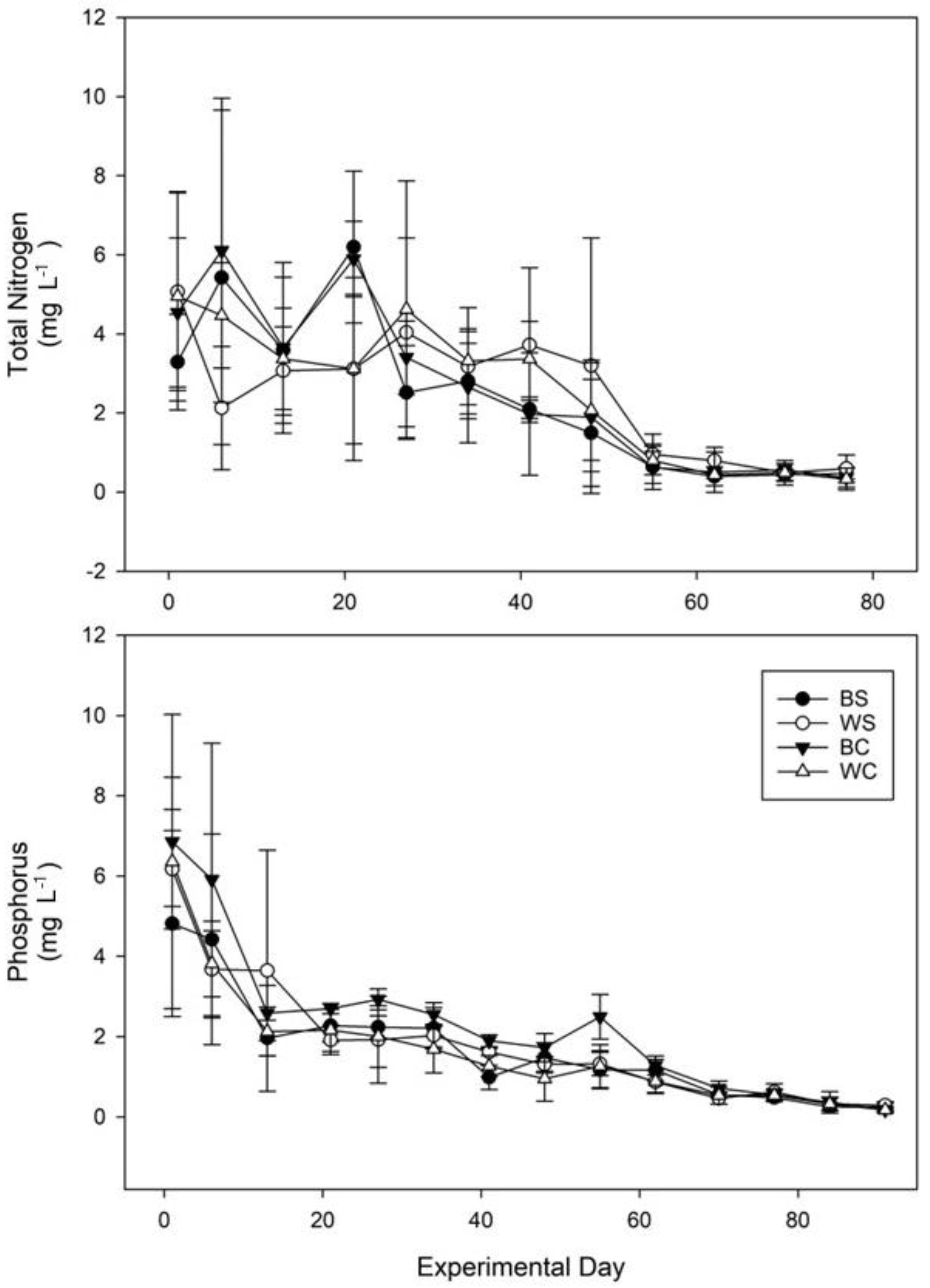

3.3. Nutrient Leaching

3.3.1. Nitrogen

3.3.2. Phosphorus

3.4. Plant Growth Index (PGI)

4. Discussion

4.1. Pot Color and Plant Growth

4.2. Nutrient Concentrations and Runoff

4.3. Implications for Sustainable Nursery Practices

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LMM | Linear mixed-effect model |

| PGI | Plant growth index |

| RZT | Root zone temperature |

| CRF | Control release fertilizer |

References

- Nackley, L.; McCauley, D.; Scagel, C.F. Hot Mess: Heatwave Effects on Controlled-Release Fertilizer. HortScience 2023, 58, 1459–1460. [Google Scholar] [CrossRef]

- Ingram, D.L.; Ruter, J.M.; Martin, C.A. Review: Characterization and Impact of Supraoptimal Root-Zone Temperatures in Container-Grown Plants. HortScience 2015, 50, 530–539. [Google Scholar] [CrossRef]

- Witcher, A.L.; Pickens, J.M.; Blythe, E.K. Container Type and Substrate Affect Root Zone Temperature and Growth of ‘Green Giant’ Arborvitae. Horticulturae 2020, 6, 22. [Google Scholar] [CrossRef]

- Fields, J.S.; Owen, J.S.; Lamm, A.; Altland, J.; Jackson, B.; Oki, L.; Samtani, J.B.; Zheng, Y.; Criscione, K.S. Surveying North American Specialty Crop Growers’ Current Use of Soilless Substrates and Future Research and Education Needs. Agriculture 2023, 13, 1727. [Google Scholar] [CrossRef]

- Kingston, P.H.; Scagel, C.F.; Bryla, D.R. Suitability of Sphagnum Moss, Coir, and Douglas Fir Bark as Soilless Substrates for Container Production of Highbush Blueberry. HortScience 2017, 52, 1692–1699. [Google Scholar] [CrossRef]

- Dickson, R.W.; Machesney, L.M.; Henderson, E.O. Forcing Temperature Effects on Plant Development for Containerized Blackberry Grown Using Long-Cane Techniques. Horticulturae 2023, 9, 1090. [Google Scholar] [CrossRef]

- Linnemannstöns, L. Substrate Cultivation of Raspberry in Germany. Acta Hortic. 2020, 1277, 165–172. [Google Scholar] [CrossRef]

- Young, R.E.; Bachman, G.R. Temperature Distribution in Large, Pot-in-Pot Nursery Containers. J. Environ. Hortic. 1996, 14, 170–176. [Google Scholar] [CrossRef]

- Bartusek, S.; Kornhuber, K.; Ting, M. 2021 North American Heatwave Amplified by Climate Change-Driven Nonlinear Interactions. Nat. Clim. Chang. 2022, 12, 1143–1150. [Google Scholar] [CrossRef]

- Cross, J.F.; Owen, J.S.; Shreckhise, J.H.; Fields, J.S.; Nackley, L.; Altland, J.E.; Drewry, D.T. Parsimonious Models of Root Zone Temperature in Soilless Substrates through Ensemble Machine Learning. Smart Agric. Technol. 2025, 12, 101289. [Google Scholar] [CrossRef]

- Bonachela, S.; López, J.C.; Granados, M.R.; Magán, J.J.; Hernández, J.; Baille, A. Effects of Gravel Mulch on Surface Energy Balance and Soil Thermal Regime in an Unheated Plastic Greenhouse. Biosyst. Eng. 2020, 192, 1–13. [Google Scholar] [CrossRef]

- Martin, C.A.; Ingram, D.L. Container Dimension Affects Rooting Medium Temperature Patterns. HortScience 1993, 28, 18–19. [Google Scholar] [CrossRef]

- Nambuthiri, S.; Hagen, E.; Fulcher, A.; Geneve, R. Evaluating a Physiological-Based, On-Demand Irrigation System for Container-Grown Woody Plants with Different Water Requirements. HortScience 2017, 52, 251–257. [Google Scholar] [CrossRef]

- Mathers, H.M.; Lowe, S.B.; Scagel, C.; Struve, D.K.; Case, L.T. Abiotic Factors Influencing Root Growth of Woody Nursery Plants in Containers. HortTechnology 2007, 17, 151–162. [Google Scholar] [CrossRef]

- Ruter, J.M.; Ingram, D.L. High Root-Zone Temperatures Influence RuBisCO Activity and Pigment Accumulation in Leaves of ‘Rotundifolia’ Holly. J. Am. Soc. Hortic. Sci. 1992, 117, 154–157. [Google Scholar] [CrossRef]

- Kerbler, S.M.; Wigge, P.A. Temperature Sensing in Plants. Annu. Rev. Plant Biol. 2023, 74, 341–366. [Google Scholar] [CrossRef]

- Ingram, D.L. Modeling High Temperature and Exposure Time Interactions on Pittosporum Tobira Root Cell Membrane Thermostability. J. Amer. Soc. Hort. Sci. 1985, 110, 470–473. [Google Scholar] [CrossRef]

- Adams, C.; Frantz, J.; Bugbee, B. Macro- and Micronutrient-release Characteristics of Three Polymer-coated Fertilizers: Theory and Measurements. J. Plant Nutr. Soil Sci. 2013, 176, 76–88. [Google Scholar] [CrossRef]

- Ransom, C.J.; Jolley, V.D.; Blair, T.A.; Sutton, L.E.; Hopkins, B.G. Nitrogen Release Rates from Slow- and Controlled-Release Fertilizers Influenced by Placement and Temperature. PLoS ONE 2020, 15, e0234544. [Google Scholar] [CrossRef]

- Majsztrik, J.C.; Fernandez, R.T.; Fisher, P.R.; Hitchcock, D.R.; Lea-Cox, J.; Owen, J.S.; Oki, L.R.; White, S.A. Water Use and Treatment in Container-Grown Specialty Crop Production: A Review. Water Air Soil Pollut. 2017, 228, 151. [Google Scholar] [CrossRef]

- Yazdi, M.N.; Sample, D.J.; Scott, D.; Owen, J.S.; Ketabchy, M.; Alamdari, N. Water Quality Characterization of Storm and Irrigation Runoff from a Container Nursery. Sci. Total Environ. 2019, 667, 166–178. [Google Scholar] [CrossRef]

- Lobell, D.B.; Bonfils, C.J.; Kueppers, L.M.; Snyder, M.A. Irrigation Cooling Effect on Temperature and Heat Index Extremes. Geophys. Res. Lett. 2008, 35, 2008GL034145. [Google Scholar] [CrossRef]

- Million, J.B.; Yeager, T.H. Production of Thuja (T. standishii x T. plicata) Using an Automated Micro-Irrigation System and Routine Leaching Fraction Testing in a Container Nursery1. J. Environ. Hortic. 2018, 36, 140–145. [Google Scholar] [CrossRef]

- Ammons, A.; LeBude, A.V.; Owen, J.S.; McGinnis, M. Effect of Irrigation, Fertilizer Rate and Placement, and Two Substrates on Growth of Rose and Hydrangea. J. Environ. Hortic. 2022, 40, 123–128. [Google Scholar] [CrossRef]

- Mack, R.; Owen, J.S.; Niemiera, A.X.; Sample, D.J. Validation of Nursery and Greenhouse Best Management Practices through Scientific Evidence. HortTechnology 2019, 29, 700–715. [Google Scholar] [CrossRef]

- Warren, S.L.; Bilderback, T.E. More Plant per Gallon: Getting More out of Your Water. HortTechnology 2005, 15, 14–18. [Google Scholar] [CrossRef]

- Fare, D.C.; Gilliam, C.H.; Keever, G.J.; Olive, J.W. Cyclic Irrigation Reduces Container Leachate Nitrate-Nitrogen Concentration. HortScience 1994, 29, 1514–1517. [Google Scholar] [CrossRef]

- Tyler, H.H.; Warren, S.L.; Bilderback, T.E. Cyclic Irrigation Increases Irrigation Application Efficiency and Decreases Ammonium Losses. J. Environ. Hortic. 1996, 14, 194–198. [Google Scholar] [CrossRef]

- Warren, S.L.; Bilderback, T.E. Timing of Low Pressure Irrigation Affects Plant Growth and Water Utilization Efficiency. J. Environ. Hortic. 2002, 20, 184–188. [Google Scholar] [CrossRef]

- Ingram, D.L. Characterization of Temperature Fluctuations and Woody Plant Growth in White Poly Bags and Conventional Black Containers1. HortScience 1981, 16, 762–763. [Google Scholar] [CrossRef]

- McBrayer, R.H.; Pickens, J.M.; Witcher, A.L.; Wells, D.E.; Sibley, J.L. Effects of Nursery Container Color and Spacing on Root Zone Temperatures of ‘Soft Touch’ Holly. Agriculture 2022, 12, 2165. [Google Scholar] [CrossRef]

- Witcher, A.L.; Pickens, J.M.; Blythe, E.K. Container Color and Compost Substrate Affect Root Zone Temperature and Growth of “Green Giant” Arborvitae. Agronomy 2020, 10, 484. [Google Scholar] [CrossRef]

- Markham, J.W.; Bremer, D.J.; Boyer, C.R.; Schroeder, K.R. Effect of Container Color on Substrate Temperatures and Growth of Red Maple and Redbud. HortScience 2011, 46, 721–726. [Google Scholar] [CrossRef]

- Parke, J.L.; Grünwald, N.J. A Systems Approach for Management of Pests and Pathogens of Nursery Crops. Plant Dis. 2012, 96, 1236–1244. [Google Scholar] [CrossRef] [PubMed]

- Weiland, J.E. The Challenges of Managing Phytophthora Root Rot in the Nursery Industry. Plant Health Prog. 2021, 22, 332–341. [Google Scholar] [CrossRef]

- Scagel, C.F.; Bi, G.; Fuchigami, L.H.; Regan, R.P. Effects of Irrigation Frequency and Nitrogen Fertilizer Rate on Water Stress, Nitrogen Uptake, and Plant Growth of Container-Grown Rhododendron. HortScience 2011, 46, 1598–1603. [Google Scholar] [CrossRef]

- Mishra, S.; Spaccarotella, K.; Gido, J.; Samanta, I.; Chowdhary, G. Effects of Heat Stress on Plant-Nutrient Relations: An Update on Nutrient Uptake, Transport, and Assimilation. Int. J. Mol. Sci. 2023, 24, 15670. [Google Scholar] [CrossRef]

- Shreckhise, J.H.; Owen, J.S.; Eick, M.J.; Niemiera, A.X.; Altland, J.E.; White, S.A. Dolomite and Micronutrient Fertilizer Affect Phosphorus Fate in Pine Bark Substrate Used for Containerized Nursery Crop Production. Soil Sci. Soc. Am. J. 2019, 83, 1410–1420. [Google Scholar] [CrossRef]

- Tolman, D.A.; Niemiera, A.X.; Wright, R.D. Influence of Plant Age on Nutrient Absorption for Marigold Seedlings. HortScience 1990, 25, 1612–1613. [Google Scholar] [CrossRef]

- Warsaw, A.L.; Fernandez, R.T.; Cregg, B.M.; Andresen, J.A. Container-Grown Ornamental Plant Growth and Water Runoff Nutrient Content and Volume Under Four Irrigation Treatments. HortScience 2009, 44, 1573–1580. [Google Scholar] [CrossRef]

- Cabrera, R.I. Comparative Evaluation of Nitrogen Release Patterns from Controlled-Release Fertilizers by Nitrogen Leaching Analysis. HortScience 1997, 32, 669–673. [Google Scholar] [CrossRef]

- Goodwin, P.B.; Murphy, M.; Melville, P.; Yiasoumi, W. Efficiency of Water and Nutrient Use in Containerised Plants Irrigated by Overhead, Drip or Capillary Irrigation. Aust. J. Exp. Agric. 2003, 43, 189. [Google Scholar] [CrossRef]

- Rathier, T.M.; Frink, C.R. Nitrate in Runoff Water from Container Grown Juniper and Alberta Spruce Under Different Irrigation and N Fertilization Regimes. J. Environ. Hortic. 1989, 7, 32–35. [Google Scholar] [CrossRef]

| Month | Total Solar Radiation (kJ/m2) | Total ET (cm) | Total Precip. (cm) | Mean RH (%) | Min Temp (°C) | Mean Temp (°C) | Max. Temp (°C) |

|---|---|---|---|---|---|---|---|

| May | 597,275 | 11.4554 | 9.5504 | 78.91 ± 8.40 | 7.27 ± 2.97 | 12.20 ± 2.96 | 17.48 ± 3.84 |

| June | 636,662 | 15.24 | 10.3886 | 74.50 ± 16.17 | 11.56 ± 2.72 | 16.99 ± 3.84 | 22.82 ± 5.43 |

| July | 817,497 | 20.3962 | 0.3556 | 66.71 ± 8.40 | 14.24 ± 2.49 | 21.67 ± 3.64 | 29.80 ± 5.33 |

| August | 502,786 | 18.2372 | 0.0254 | 65.80 ± 7.40 | 14.25 ± 2.27 | 21.96 ± 2.21 | 30.31 ± 3.64 |

| September | 502,815 | 11.9634 | 0.4826 | 67.08 ± 13.93 | 11.88 ± 2.50 | 18.99 ± 2.36 | 26.69 ± 3.91 |

| Treatment | >25 °C (h) | >30 °C (h) | >35 °C (h) | >38 °C (h) | >45 °C (h) |

|---|---|---|---|---|---|

| BS | 974.90 ± 23.13 | 610.60 ± 56.30 | 286.11 ± 97.61 | 154.5 ± 87.5 | 8.7 ± 14.1 |

| WS | 771.72 ± 30.18 | 343.40 ± 49.93 | 89.24 ± 35.86 | 21.8 ± 17.1 | 0 ± 0 |

| BC | 927.89 ± 59.99 | 523.85 ± 81.06 | 178.96 ± 81.36 | 73 ± 77.6 | 0.6 ± 1.6 |

| WC | 769.76 ± 39.51 | 333.57 ± 38.78 | 73.35 ± 25.04 | 12.3 ± 16.5 | 0 ± 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nackley, L.; McCauley, D.; Owen, J., Jr.; Shreckhise, J.; Fields, J. Hot Pots: Container Color Has a Greater Cooling Effect than Micro-Sprinkler Frequency in Nursery Production. Agriculture 2025, 15, 2185. https://doi.org/10.3390/agriculture15212185

Nackley L, McCauley D, Owen J Jr., Shreckhise J, Fields J. Hot Pots: Container Color Has a Greater Cooling Effect than Micro-Sprinkler Frequency in Nursery Production. Agriculture. 2025; 15(21):2185. https://doi.org/10.3390/agriculture15212185

Chicago/Turabian StyleNackley, Lloyd, Dalyn McCauley, James Owen, Jr., Jacob Shreckhise, and Jeb Fields. 2025. "Hot Pots: Container Color Has a Greater Cooling Effect than Micro-Sprinkler Frequency in Nursery Production" Agriculture 15, no. 21: 2185. https://doi.org/10.3390/agriculture15212185

APA StyleNackley, L., McCauley, D., Owen, J., Jr., Shreckhise, J., & Fields, J. (2025). Hot Pots: Container Color Has a Greater Cooling Effect than Micro-Sprinkler Frequency in Nursery Production. Agriculture, 15(21), 2185. https://doi.org/10.3390/agriculture15212185