Study on the Fracture Characteristics and Mechanism of Used Drip Irrigation Tape Under Different Stretching Speeds

Abstract

1. Introduction

2. Materials and Methods

2.1. Drip Irrigation Tape Samples

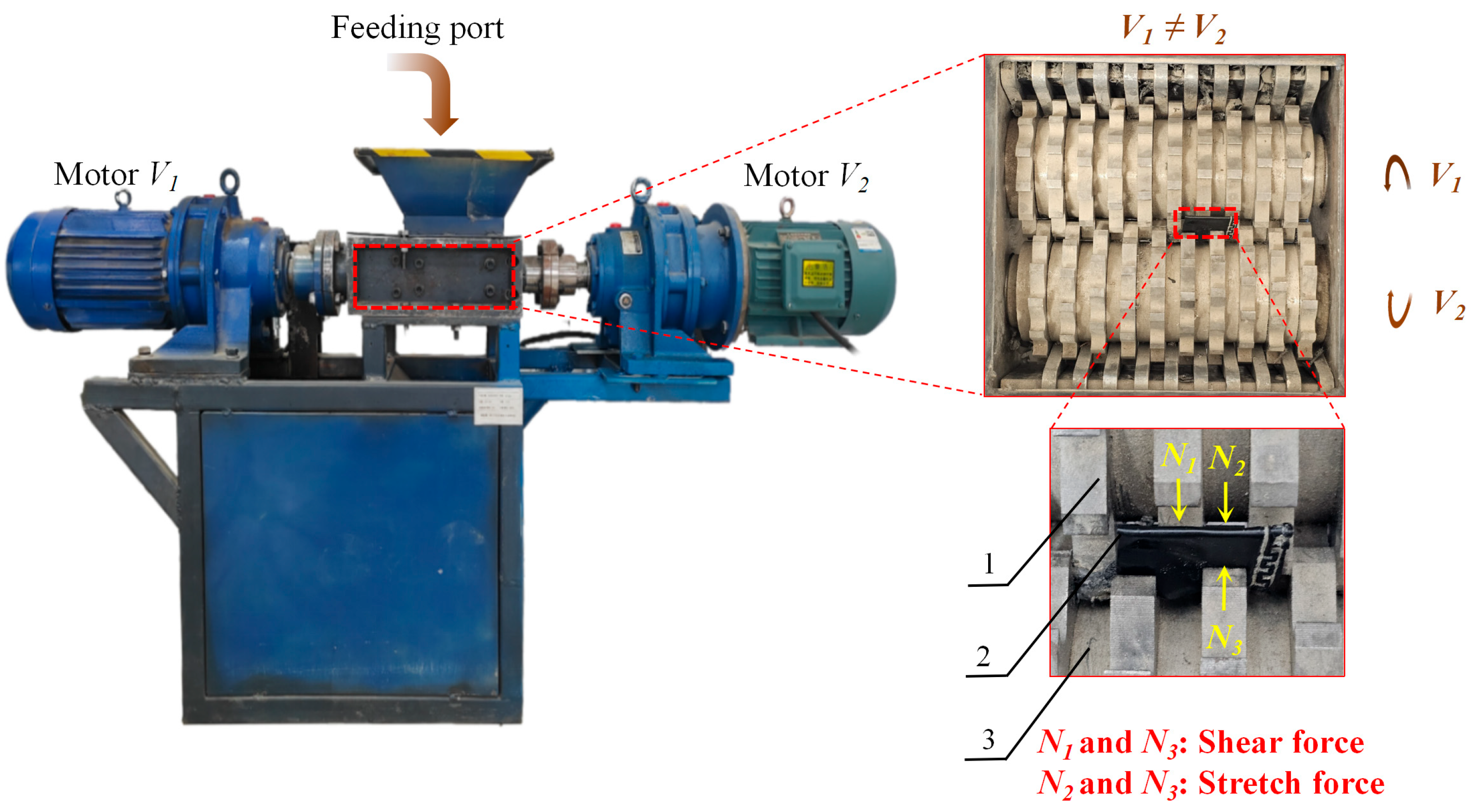

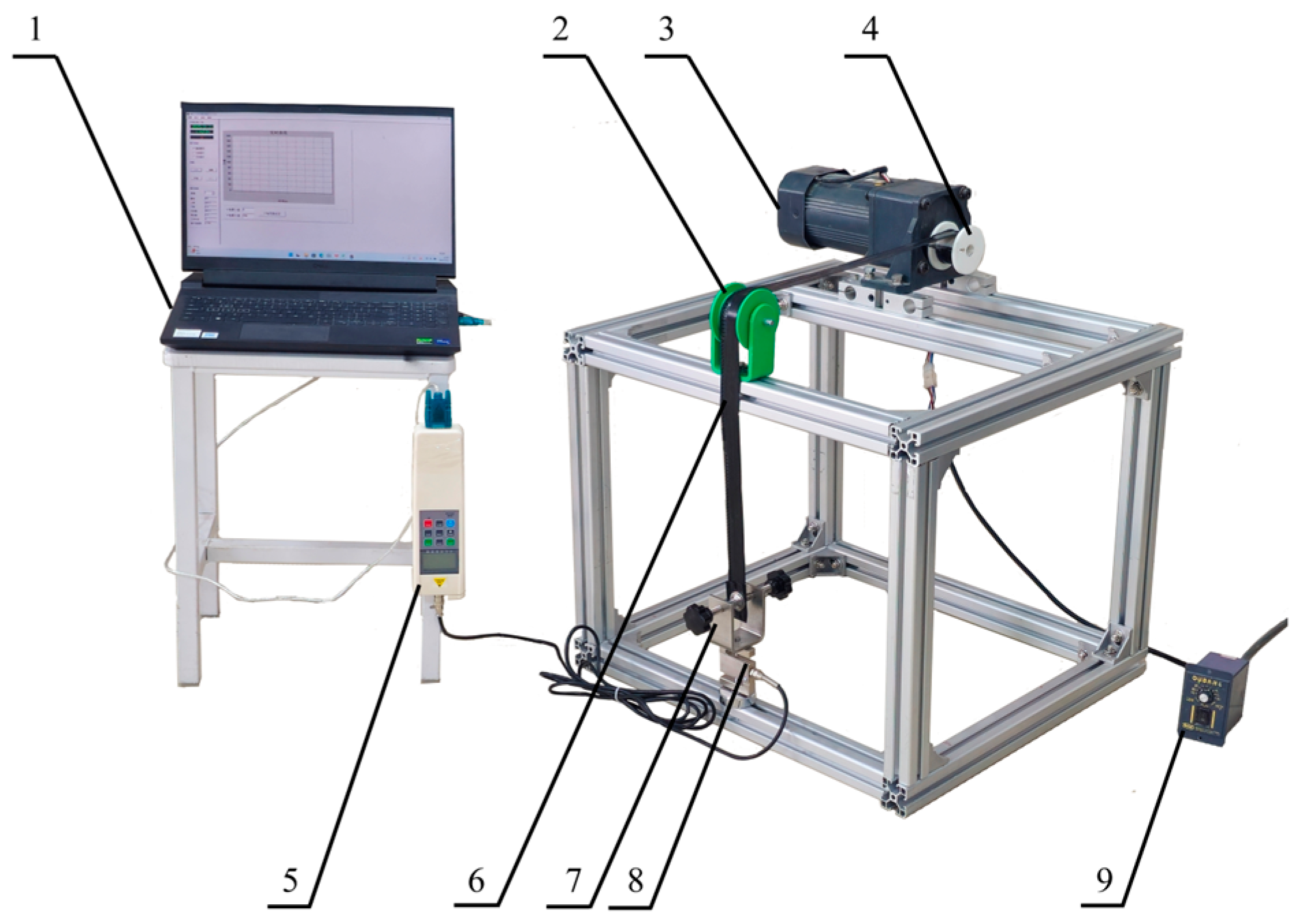

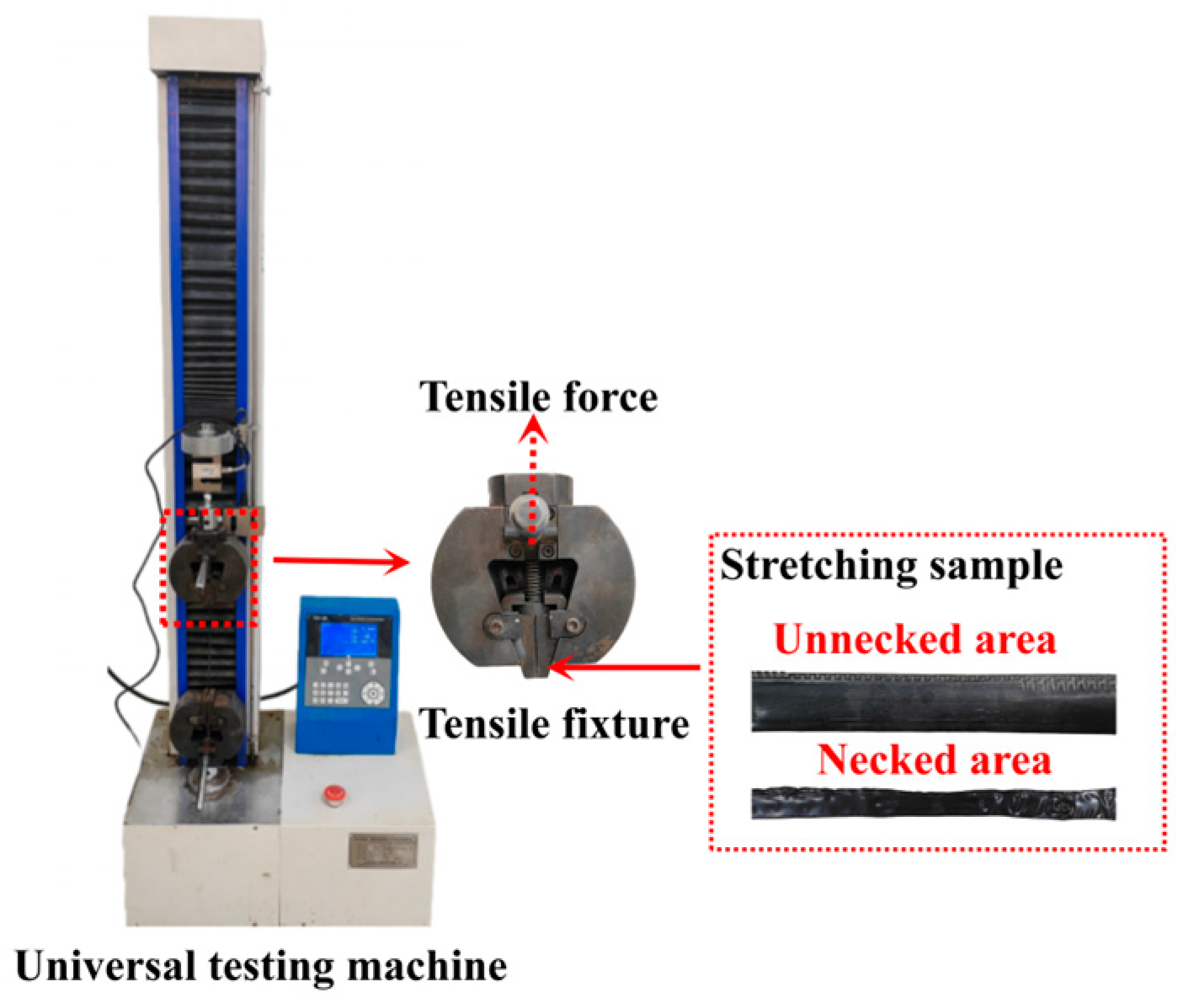

2.2. Experiment Apparatus

2.3. Stretch Test

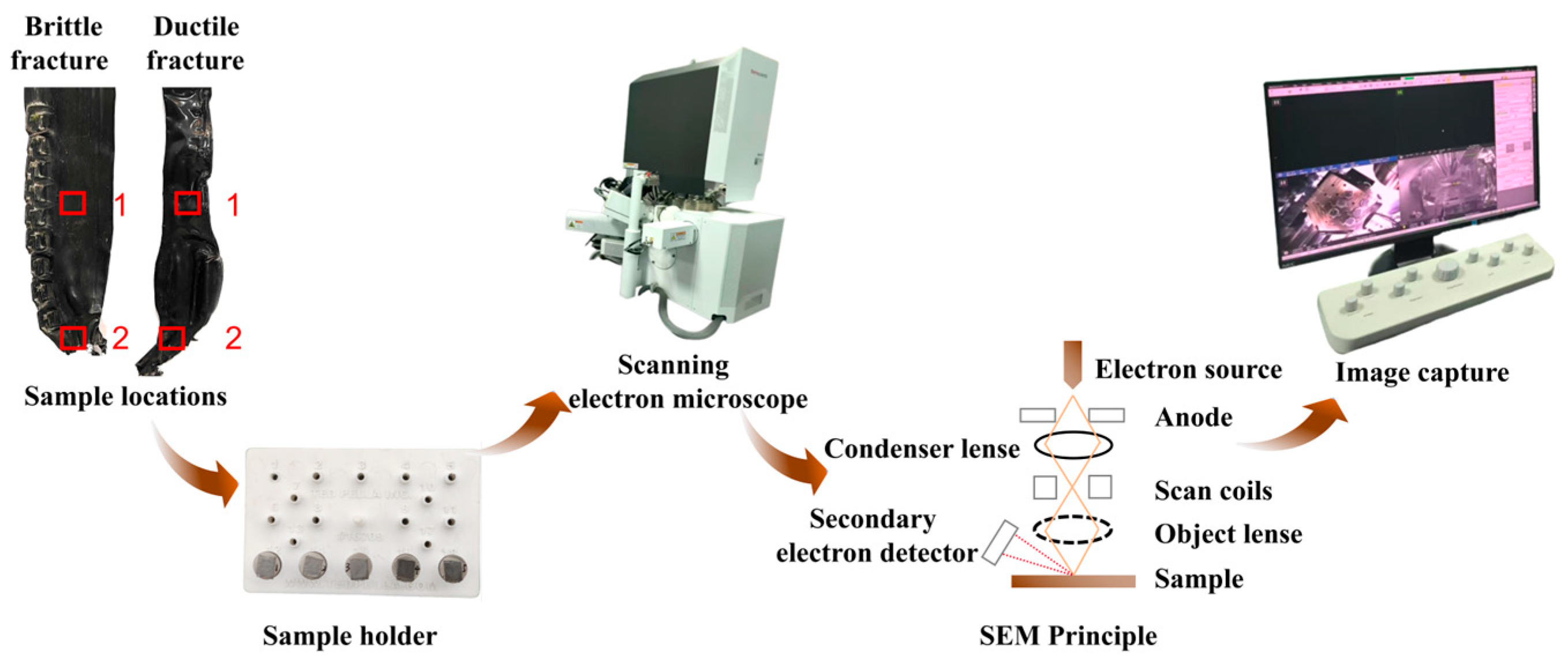

2.4. Scanning Electron Microscope Test of Used Drip Irrigation Tape

2.5. Stretch Test of Necked and Non-Necked Used Drip Irrigation Tape

2.6. Data Processing

3. Results and Discussion

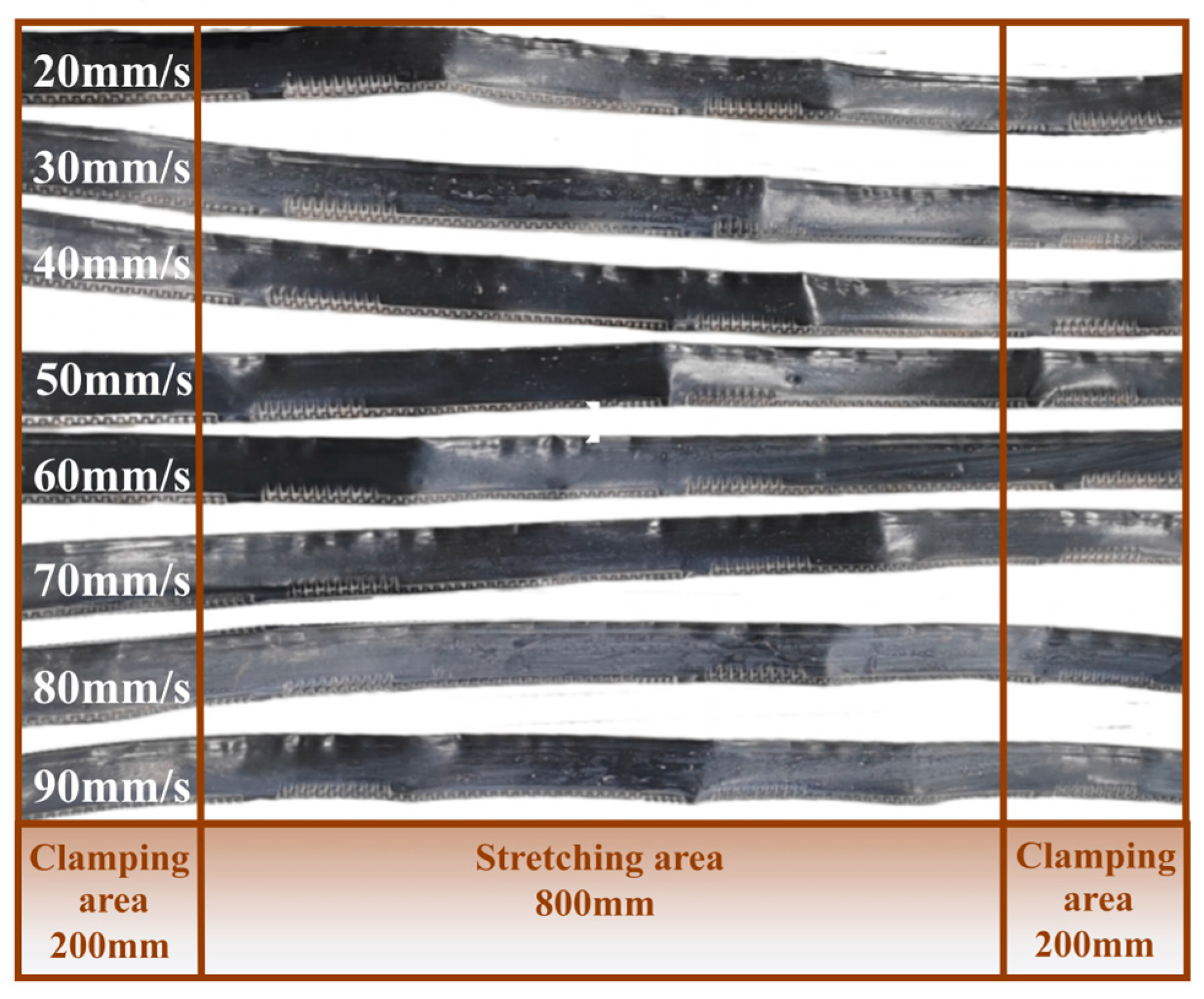

3.1. Fracture Characteristics Analysis

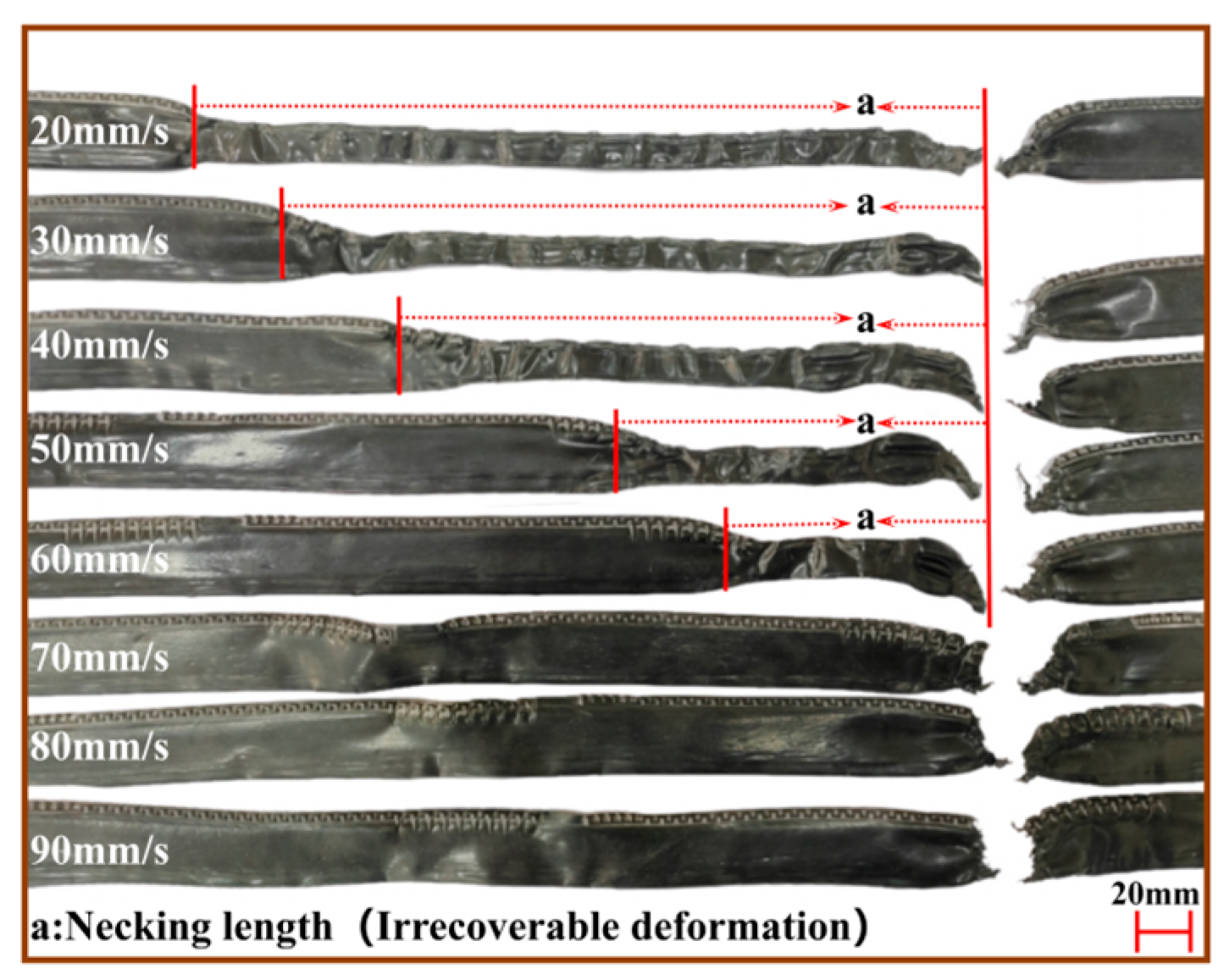

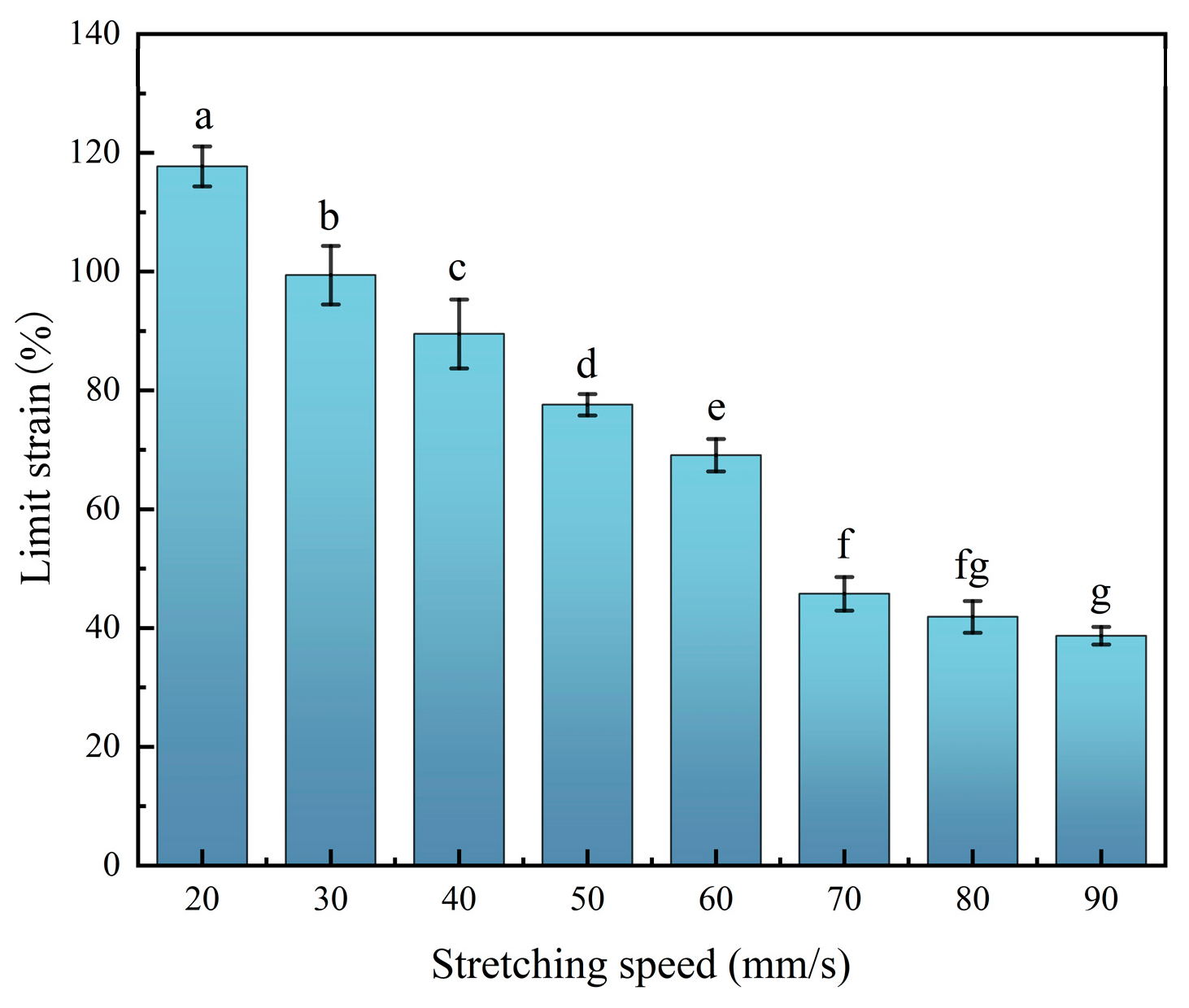

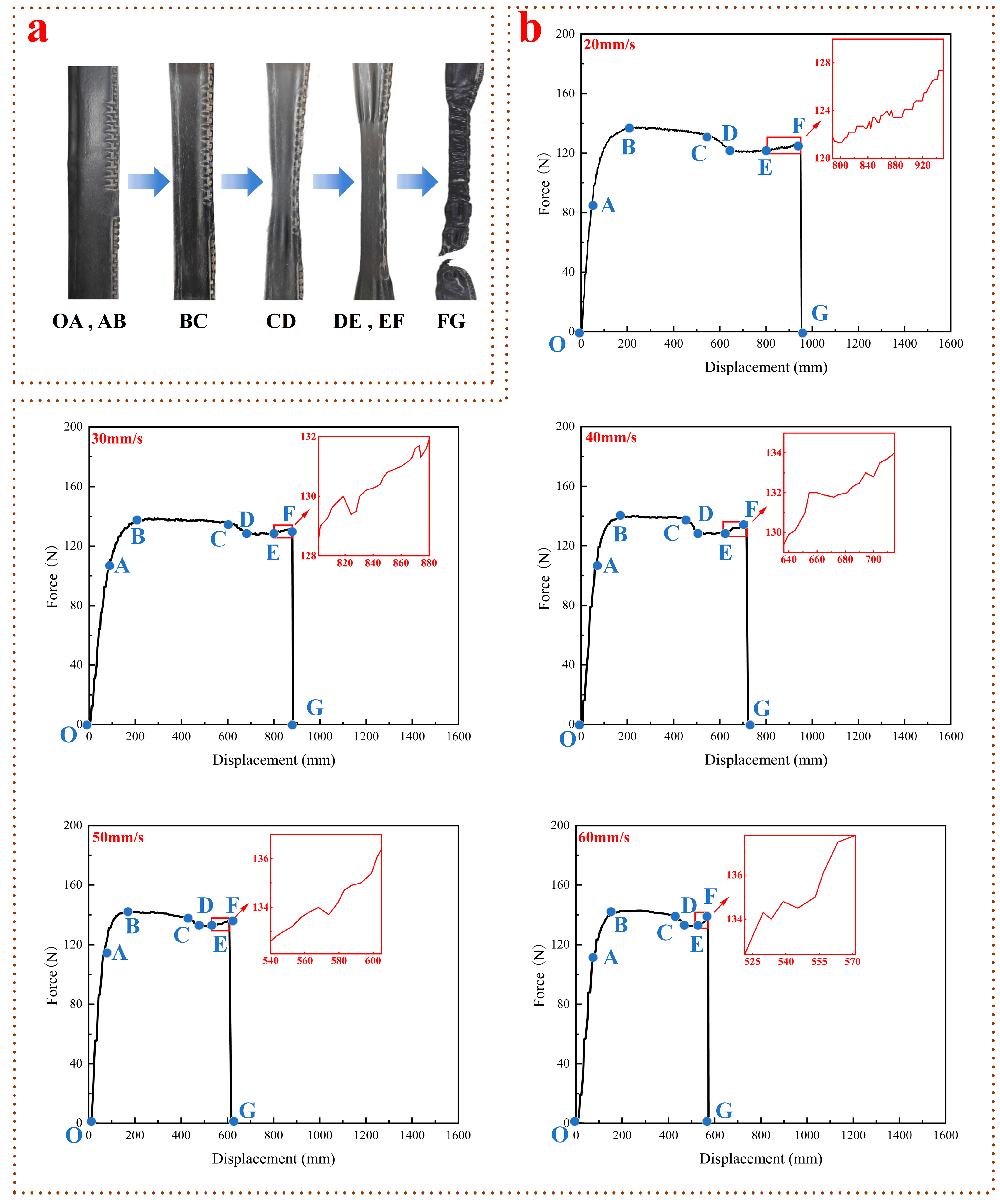

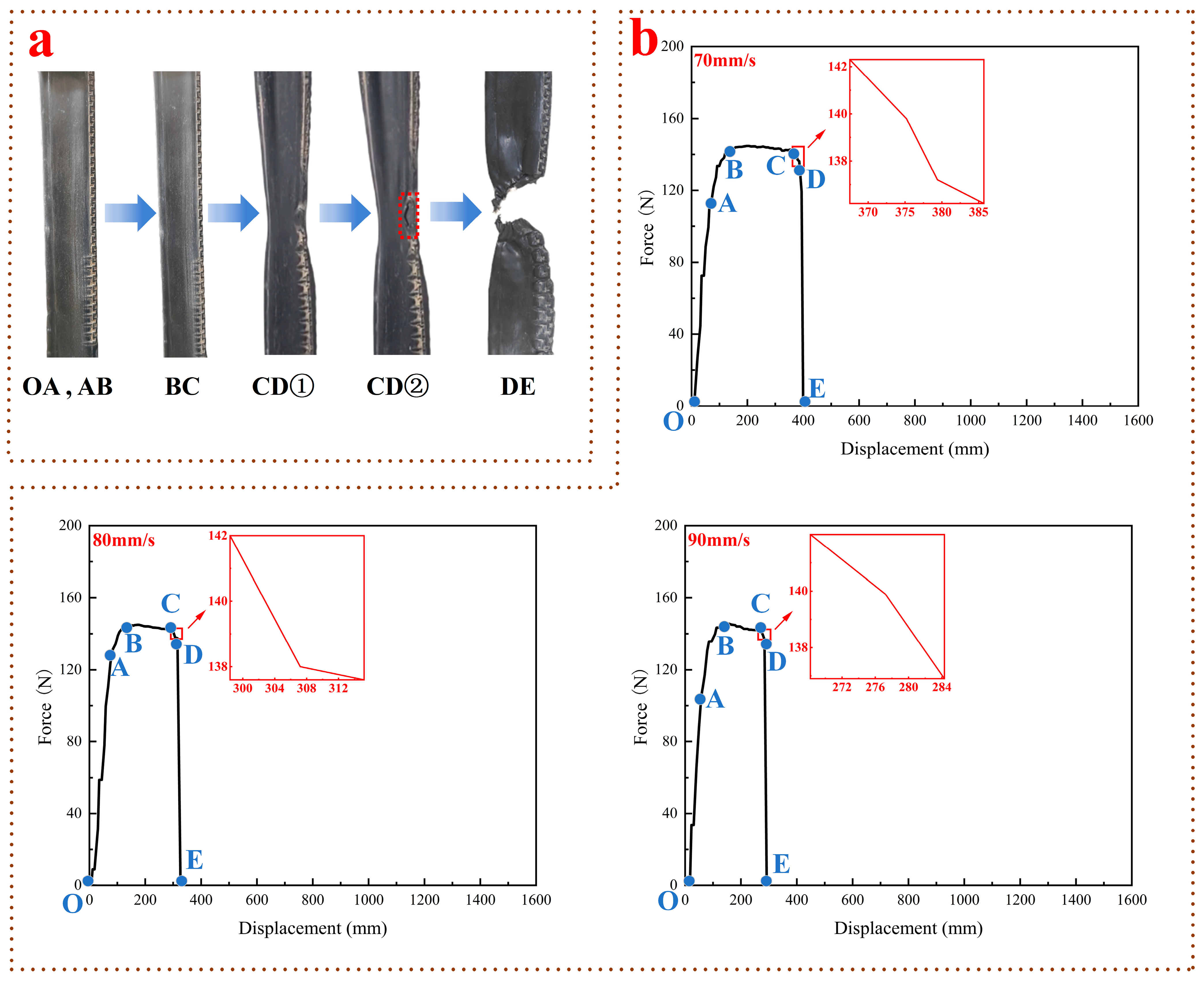

3.1.1. Effect of Stretching Speed on Fracture Characteristics

3.1.2. Effect of Stretching Speed on Mechanical Response

3.2. Analysis of the Fracture Mechanism

3.2.1. Effect of Stretching Speed on Energy Density

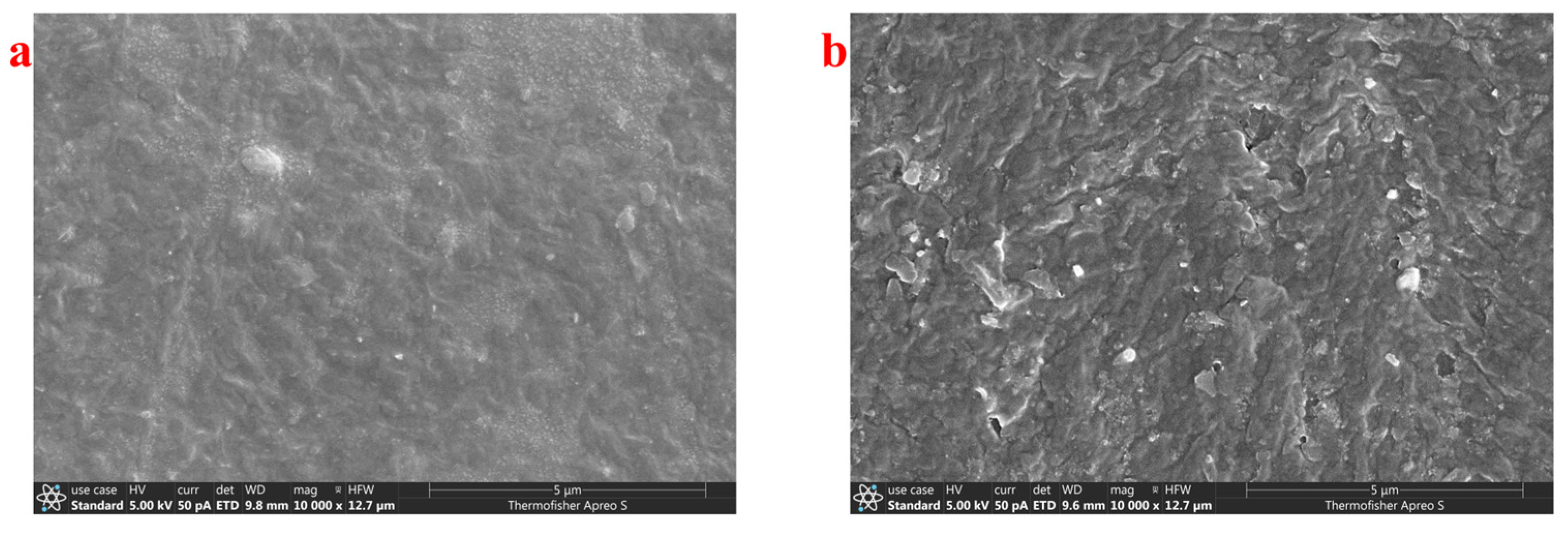

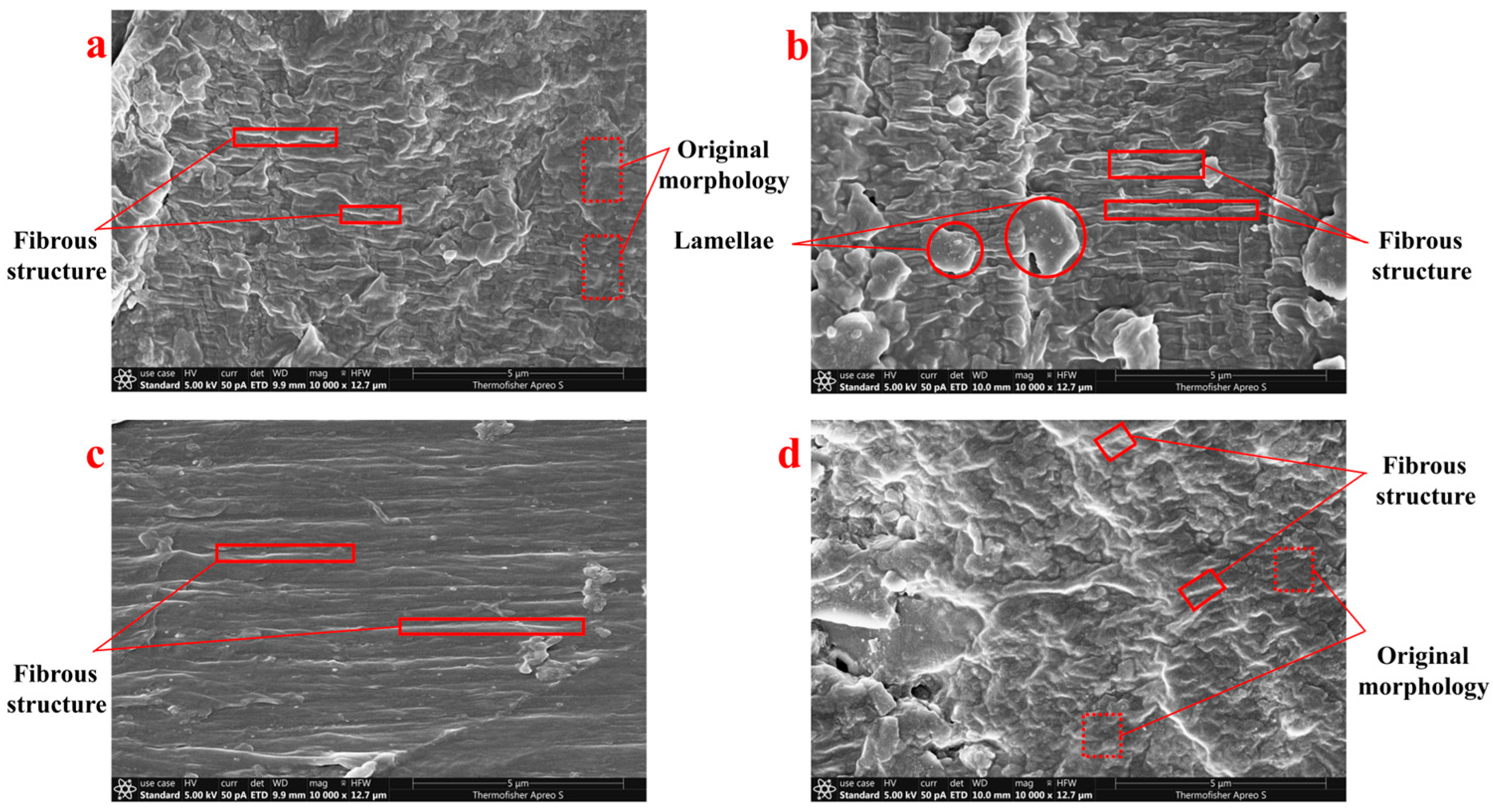

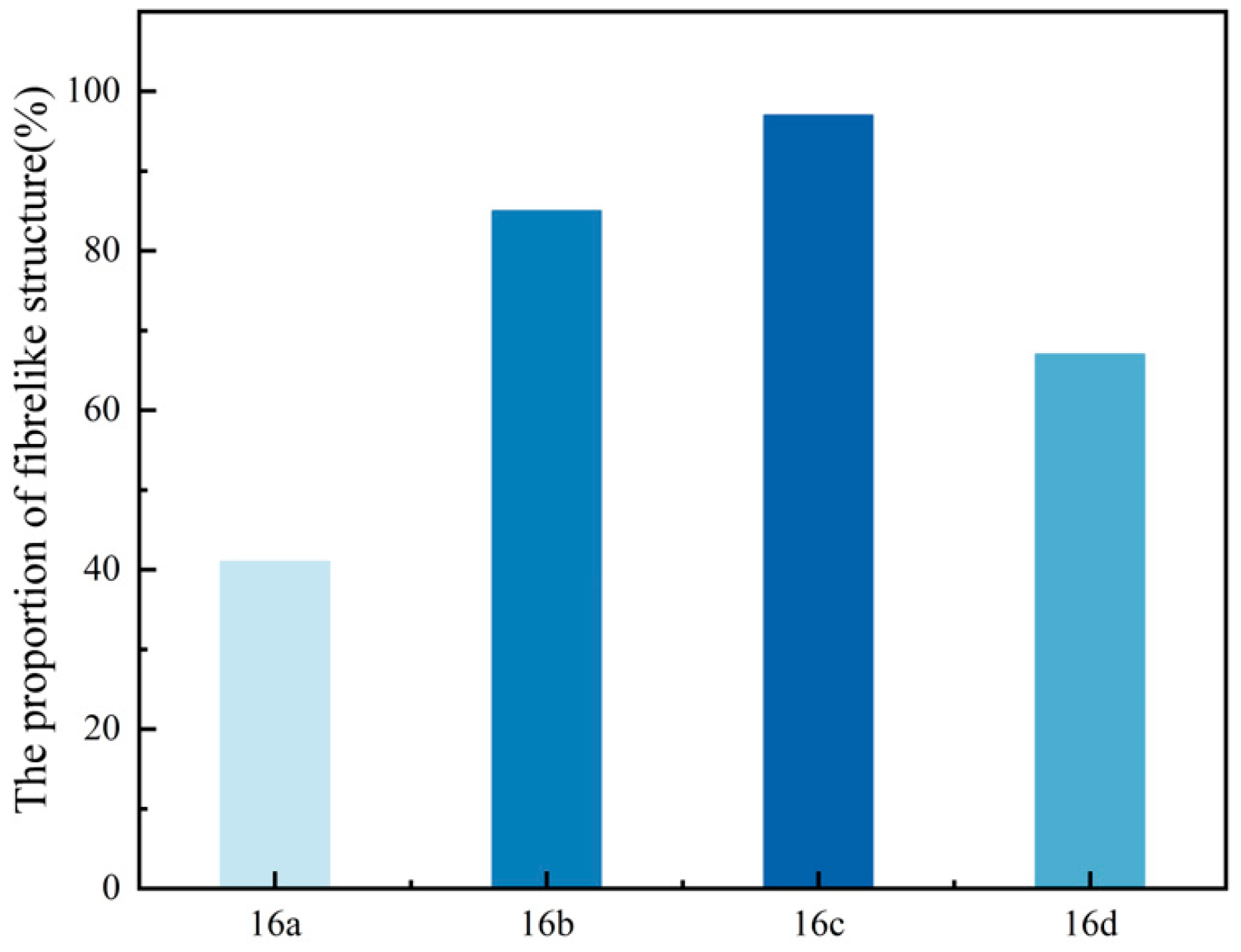

3.2.2. Microstructural Analysis of Used Drip Irrigation Tape

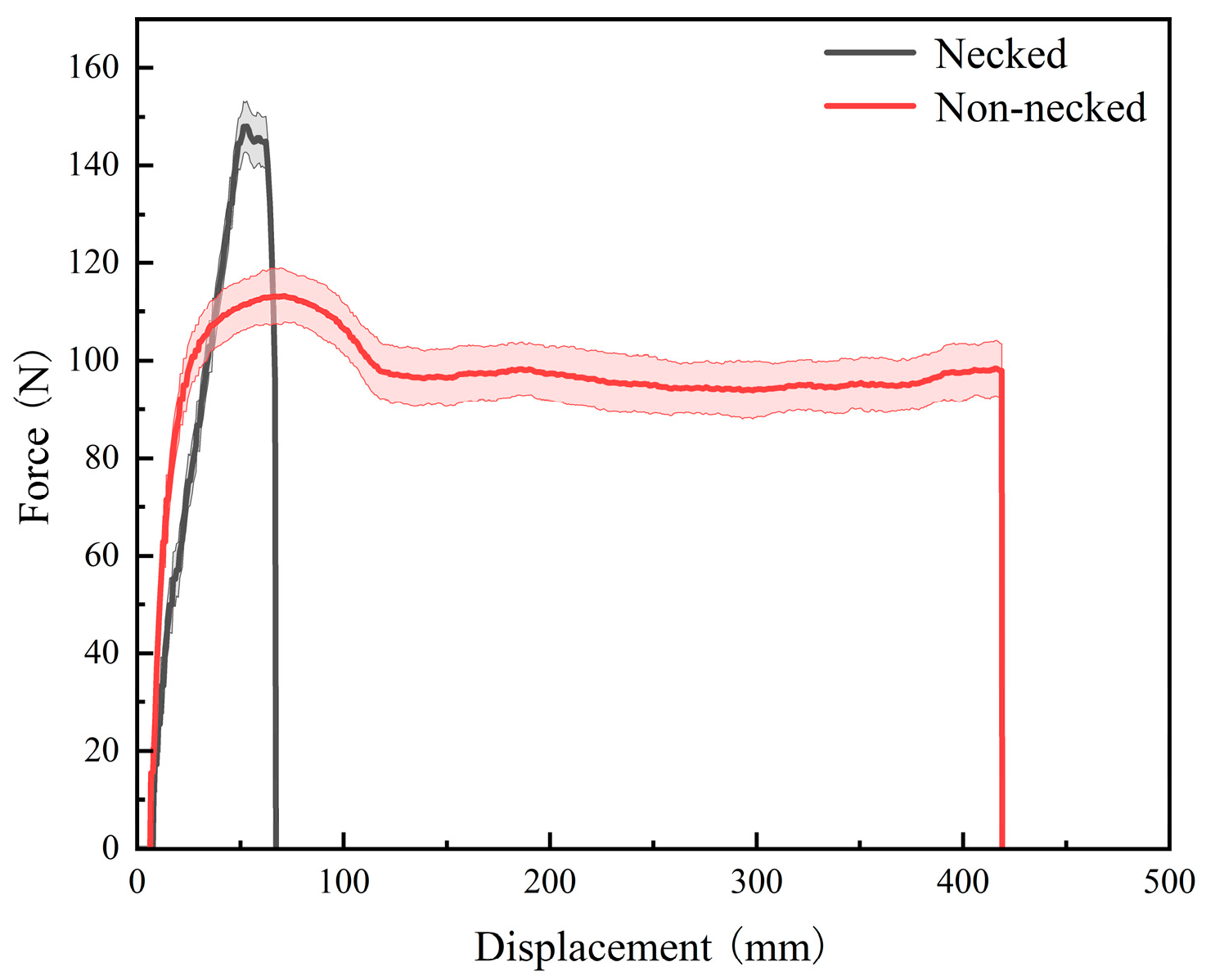

3.2.3. Analysis of the Mechanical Characteristics of the Necked and Non-Necked Drip Irrigation Tapes

3.3. Prospect

4. Conclusions

- As the stretching speed increases, the limit strain decreases from 117.7% to 38.7%, the fracture location consistently occurs at the junction between the necked area and the non-necked area, the fracture mode transitions from ductile fracture to brittle fracture, and the deformation mode changes from predominantly elastoplastic deformation to predominantly elastic deformation. When the stretching speed increases from 60 mm/s to 70 mm/s, there is a noticeable jump in the macroscopic fracture mode, mechanical characteristics, fracture energy density, and microstructural features.

- As the stretching speed increases, the mechanical response curve transitions from the elastic stage, yield stage, strain softening stage, cold drawing stage, and strain hardening stage to the elastic stage, yield stage, and strain softening stage.

- As the stretching speed increases, both the yield energy density and fracture energy density show a decreasing trend, while the proportion of elastic energy density increases. The fracture energy density decreased from 1.29 × 10−2 J/mm3 to 0.39 × 10−2 J/mm3, the yield energy density decreased from 1.02 × 10−2 J/mm3 to 0.23 × 10−2 J/mm3, and the proportion of elastic energy density increased from 21.03% to 40.95%. As the speed increases, the energy absorbed by the used drip irrigation tape decreases, and its ability to recover its original length after unloading increases. Due to the energy absorbed during brittle fracture, which is consumed in the disintegration and fracture of lamellae in the spherulites at the fracture surface, the microstructure of brittle fracture shows a significant increase in lamellae and fibrous stretching structures in the area adjacent to the brittle fracture surface, compared to the brittle fracture extension area. Energy absorption during ductile fracture occurs in the extension of the fibrous structure. The ductile fracture microstructure in the extension area exhibits a densely packed and highly fibrous state, which leads to the enhancement of the mechanical properties in the necked area. The stretching test further demonstrates that the mechanical properties of necked used drip irrigation tape are improved compared to those of non-necked used drip irrigation tape, which results in the fracture location consistently occurring at the junction between the necked and non-necked area.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ran, J.; Song, Z.; Zhang, Q.; Guo, W.; Wang, X. Design of a New Drip Irrigation Belt Recovery Machine with Anti Breakage Function. Agriculture 2024, 14, 421. [Google Scholar] [CrossRef]

- Ran, J.; Ren, Y.; Guo, W.; Hu, C.; Wang, X. Aging characteristics of drip irrigation belt in Xinjiang cotton fields and their effects on its recovery and recycling. Sci. Rep. 2023, 13, 16948. [Google Scholar] [CrossRef]

- Guo, B.; Wu, S.; Zhu, D. Effect of Additives on the Mechanical Properties of Recycling Material of Waste PE Drip Tape. Water. Sav. Irrig. 2016, 2, 47–50. [Google Scholar] [CrossRef]

- Ran, J.; Guo, W.; Wang, X. Analysis of research progress on mechanized recovery technology and equipment of drip irrigation belt. Xinjiang Agric. Mech. 2024, 6, 49–53. [Google Scholar] [CrossRef]

- Behera, K.; Yadav, M.; Chiu, F.-C.; Rhee, K.Y. Graphene Nanoplatelet-Reinforced Poly(vinylidene fluoride)/High Density Polyethylene Blend-Based Nanocomposites with Enhanced Thermal and Electrical Properties. Nanomaterials 2019, 9, 361. [Google Scholar] [CrossRef]

- Brandalise, R.N.; Zeni, M.; Martins, J.D.N.; Forte, M.M. Morphology, mechanical and dynamic mechanical properties of recycled high density polyethylene and poly(vinyl alcohol) blends. Polym. Bull. 2009, 62, 33–43. [Google Scholar] [CrossRef]

- Luo, W.B.; Liu, Y.P.; Yin, B.Y.; Li, Y.; Liu, X. Creep Lifetime Assessment of Pressure-Tight Pe100 Pipes Based on a Slow Fatigue Crack Growth. Strength Mater. 2018, 50, 781–787. [Google Scholar] [CrossRef]

- El-Bagory, T.M.; Sallam, H.E.; Younan, M.Y. Effect of strain rate, thickness, welding on the J–R curve for polyethylene pipe materials. Theor. Appl. Fract. Mech. 2014, 74, 164–180. [Google Scholar] [CrossRef]

- Reis, J.; Pacheco, L.; Mattos, H.d.C. Influence of the temperature and strain rate on the tensile behavior of post-consumer recycled high-density polyethylene. Polym. Test. 2013, 32, 1576–1581. [Google Scholar] [CrossRef]

- Lin, Y.; Li, X.; Chen, X.; An, M.; Zhang, Q.; Wang, D.; Chen, W.; Yin, P.; Meng, L.; Li, L. Deformation mechanism of hard elastic polyethylene film during uniaxial stretching: Effect of stretching speed. Polymer 2019, 178, 121579. [Google Scholar] [CrossRef]

- Ebrahimian, A.; Ward, P.; Ben Jar, P. Deep stretch of polyethylene by transverse loading: Finite element simulation to characterize the influence of indenter size and loading speed on the stress development and distribution. Polym. Eng. Sci. 2021, 61, 2349–2363. [Google Scholar] [CrossRef]

- Liu, Z.; Zhou, Z.; Ming, Y.; Zhang, S.; Hao, T.; Nie, Y. Molecular dynamics simulations of nucleation details in stretched polyethylene. Polymer 2020, 195, 122442. [Google Scholar] [CrossRef]

- Tang, X.; Yang, J.; Tian, F.; Xu, T.; Xie, C.; Chen, W.; Li, L. Flow-induced density fluctuation assisted nucleation in polyethylene. J. Chem. Phys. 2018, 149, 224901. [Google Scholar] [CrossRef] [PubMed]

- Parsons, M.; Stepanov, E.V.; Hiltner, A.; Baer, E. The damage zone ahead of the arrested crack in polyethylene resins. J. Mater. Sci. 2001, 36, 5747–5755. [Google Scholar] [CrossRef]

- Pritchard, R.; Dunn, T.; Kelly, P. Effects of morphology and molecular structure on tensile impact behavior of linear polyethylene. J. Appl. Polym. Sci. 2010, 8, 1751–1762. [Google Scholar] [CrossRef]

- Gosch, A.; Arbeiter, F.J.; Berer, M.; Vojtek, T.; Hutař, P.; Pinter, G. Fatigue characterization of polyethylene under mixed mode I/III conditions. Int. J. Fatigue 2020, 145, 106084. [Google Scholar] [CrossRef]

- Yeh, I.-C.; Lenhart, J.L.; Rutledge, G.C.; Andzelm, J.W. Molecular Dynamics Simulation of the Effects of Layer Thickness and Chain Tilt on Tensile Deformation Mechanisms of Semicrystalline Polyethylene. Macromolecules 2017, 50, 1700–1712. [Google Scholar] [CrossRef]

- Li, R.; Yang, G.-X.; Qin, Y.-N.; Liu, L.; Jiang, Z.-Y. Molecular Mobility in the Amorphous Phase Determines the Critical Strain of Fibrillation in the Tensile Stretching of Polyethylene. Chin. J. Polym. Sci. 2019, 38, 740–747. [Google Scholar] [CrossRef]

- Jiang, Z.; Tang, Y.; Rieger, J.; Enderle, H.-F.; Lilge, D.; Roth, S.V.; Gehrke, R.; Heckmann, W.; Men, Y. Two Lamellar to Fibrillar Transitions in the Tensile Deformation of High-Density Polyethylene. Macromolecules 2010, 43, 4727–4732. [Google Scholar] [CrossRef]

- Guadarrama-Medina, T.D.J.; Pérez-González, J.; De Vargas, L. Enhanced melt strength and stretching of linear low-density polyethylene extruded under strong slip conditions. Rheol. Acta 2005, 44, 278–286. [Google Scholar] [CrossRef]

- Xiong, B.; Lame, O.; Chenal, J.; Rochas, C.; Seguela, R.; Vigier, G. In-situ SAXS study and modeling of the cavitation/crystal-shear competition in semi-crystalline polymers: Influence of temperature and microstructure in polyethylene. Polymer 2013, 54, 5408–5418. [Google Scholar] [CrossRef]

- Kumar, M.; Ravi, K.; Singh, S.S. Temperature and strain rate effects on ultra-high-molecular-weight-polyethylene compression: An experimental and modeling approach. Polym. Eng. Sci. 2024, 64, 2214–2229. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Liu, X.; Luo, W.; Yang, B.; Li, M. A Time Dependent Process Zone Model for Slow Crack Growth of Polyethylene Pipe Material. J. Phys. Conf. Ser. 2020, 1634, 012140. [Google Scholar] [CrossRef]

- Frank, A.; Arbeiter, F.J.; Berger, I.J.; Hutař, P.; Náhlík, L.; Pinter, G. Fracture Mechanics Lifetime Prediction of Polyethylene Pipes. J. Pipeline Syst. Eng. Pract. 2019, 10, 04018030. [Google Scholar]

- Almomani, A.; Mourad, A.-H.I.; Deveci, S.; Wee, J.-W.; Choi, B.-H. Recent advances in slow crack growth modeling of polyethylene materials. Mater. Des. 2023, 227, 111720. [Google Scholar] [CrossRef]

- Luo, X.; Lu, S.; Shi, J.; Li, X.; Zheng, J. Numerical simulation of strength failure of buried polyethylene pipe under foundation settlement. Eng. Fail. Anal. 2015, 48, 144–152. [Google Scholar] [CrossRef]

- Frank, A.; Freimann, W.; Pinter, G.; Lang, R.W. A fracture mechanics concept for the accelerated characterization of creep crack growth in PE-HD pipe grades. Eng. Fract. Mech. 2009, 76, 2780–2787. [Google Scholar] [CrossRef]

- Huang, B.; Li, X.; Zeng, Z.; Yang, N. Study on Viscoelastic Behavior During Slow Crack Growth of Medium Density Polyethylene Pipes. Trans. Indian Inst. Met. 2016, 69, 1257–1265. [Google Scholar] [CrossRef]

- Kratochvilla, T.R.; Frank, A.; Pinter, G. Determination of slow crack growth behaviour of polyethylene pressure pipes with cracked round bar test. Polym. Test. 2014, 40, 299–303. [Google Scholar] [CrossRef]

- Robledo, N.; Domínguez, C.; García-Muñoz, R.A. Alternative accelerated and short-term methods for evaluating slow crack growth in polyethylene resins with high crack resistance. Polym. Test. 2017, 62, 366–372. [Google Scholar] [CrossRef]

- Wee, J.-W.; Chudnovsky, A.; Deveci, S.; Choi, B.-H. Mechano-chemical degradation effects on slow crack growth in polyethylene pipes with multiple cracks. Int. J. Mech. Sci. 2024, 281, 109575. [Google Scholar] [CrossRef]

- Nasiri, S.; Khosravani, M.R. Failure and fracture in polyethylene pipes: Overview, prediction methods, and challenges. Eng. Fail. Anal. 2023, 152, 107496. [Google Scholar] [CrossRef]

- Lei, Z.; Zhang, X.; Wang, L.; Zhu, X. Study on artificial UV aging and thermal aging performance of non-reusable drip tape with labyrinth on one side. China Plast. 2023, 37, 37–42. [Google Scholar] [CrossRef]

- Chen, C.; Hou, H.; Su, M.; Wang, S.; Jiao, C.; Zhao, Z. Feasibility of Nonlinear Ultrasonic Method to Characterize the Aging Degree of Polyethylene Pipes. J. Mater. Eng. Perform. 2023, 32, 5514–5522. [Google Scholar] [CrossRef]

- Audouin-Jirackova, L.; Papet, G.; Verdu, J. Effect of radiochemical ageing on the tensile properties of high density polyethylene. Eur. Polym. J. 1989, 25, 181–186. [Google Scholar] [CrossRef]

- GB/T 19812.1-2017; Plastic Equipment for Water Saving Irrigation—Part 1: Drip Tape with Labyrinth on One Side. China Standards Press: Beijing, China, 2017.

- Meng, Q. Design and Experiment of Residual Film Mixture Crushing and Kneading Device. Master’s Thesis, Xinjiang Agricultural University, Urumqi, China, 2024. [Google Scholar] [CrossRef]

- Miles, K.B.; Maerz, T.; Matthew, H.W.T. Scalable MSC-Derived Bone Tissue Modules: In Vitro Assessment of Differentiation, Matrix Deposition, and Compressive Load Bearing. Acta Biomater. 2019, 95, 395–407. [Google Scholar] [CrossRef] [PubMed]

- Fung, T.-M.; Lazo, C.G.; Smith, A.M. Elasticity and energy dissipation in the double network hydrogel adhesive of the slug Arion subfuscus. Philos. Trans. R. Soc. B Biol. Sci. 2019, 374, 20190201. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Dai, Q.; Guo, C.; Feng, L. Influence of pre strain on the mechanical properties of TA2 and the establishment of constitutive mode. Iron Steel Vanadium Titanium 2024, 45, 83–90. [Google Scholar] [CrossRef]

- Peng, J.; Li, K.; Dai, Q. Mechanical properties of pre-strained austenitic stainless steel from the view of energy density. Results Phys. 2018, 10, 187–193. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A. A critical comparison of various data processing methods in simple uni-axial compression testing. Mater. Des. 2011, 32, 2797–2802. [Google Scholar] [CrossRef]

- Luo, L. Tensile Strain Hardening Behavior and Strength Failure of Polyethylene Pipes. Master’s Thesis, Xiangtan University, Xiangtan, China, 2019. [Google Scholar] [CrossRef]

- Lv, M.; Qu, B.; Huang, F.; Wu, R. Uniaxial tensile properties testing and re-yield behavior of polypropylene. Sci. Technol. Eng. 2023, 23, 5500–5506. [Google Scholar]

- Dasari, A.; Duncan, S.J.; Misra, R.D.K. Microstructural aspects of tensile deformation of high density polyethylene. Mater. Sci. Technol. 2003, 19, 244–252. [Google Scholar] [CrossRef]

- Yan, N.; Xia, H.; Zhan, Y.; Fei, G. New Insights into Fatigue Crack Growth in Graphene-Filled Natural Rubber Composites by Microfocus Hard-X-Ray Beamline Radiation. Macromol. Mater. Eng. 2013, 298, 38–44. [Google Scholar] [CrossRef]

- Li, X.-Y.; Ding, J.-J.; Liu, Y.-P.; Tian, X.-Y. A new small-angle X-ray scattering model for polymer spherulites with a limited lateral size of the lamellar crystals. IUCrJ 2019, 6, 968–983. [Google Scholar] [CrossRef] [PubMed]

- Liao, T.; Yang, X.; Zhao, X.; Tang, Y.; Jiang, Z.; Men, Y. Gaussian and Non-Gaussian Distributions of Fracture Properties in Tensile Stretching of High-Density Polyethylene. Macromolecules 2021, 54, 8860–8874. [Google Scholar] [CrossRef]

| USE CASE | High Voltage (HV) | Current (curr) | Detector (det) | Working Distance (WD) | Magnification (mag) | High-Wide Field (HWF) | Scale Bar |

|---|---|---|---|---|---|---|---|

| Standard | 5.00 kV | 50 pA | ETD (Secondary electron detection) | 9.9 mm | 10,000× | 12.7 μm | 5 μm |

| F | Significance | t | Degrees of Freedom | Significance (Two-Tailed) | Mean Difference | Standard Error Difference | |

|---|---|---|---|---|---|---|---|

| Assuming equal variances | 306.52 | <0.001 | −3.37 | 586 | <0.001 | −10.34 | 3.06 |

| Not assuming equal variances | −1.77 | 85.17 | 0.081 | −10.34 | 5.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Lan, H.; Yang, X.; Li, K.; Hu, Z.; Chu, S.; Li, S.; Ouyang, L.; Zhang, T.; Zhang, H.; et al. Study on the Fracture Characteristics and Mechanism of Used Drip Irrigation Tape Under Different Stretching Speeds. Agriculture 2025, 15, 2038. https://doi.org/10.3390/agriculture15192038

Liu H, Lan H, Yang X, Li K, Hu Z, Chu S, Li S, Ouyang L, Zhang T, Zhang H, et al. Study on the Fracture Characteristics and Mechanism of Used Drip Irrigation Tape Under Different Stretching Speeds. Agriculture. 2025; 15(19):2038. https://doi.org/10.3390/agriculture15192038

Chicago/Turabian StyleLiu, Haiyang, Haipeng Lan, Xirui Yang, Kun Li, Zhanjun Hu, Shengyou Chu, Shuya Li, Long Ouyang, Tian Zhang, Hong Zhang, and et al. 2025. "Study on the Fracture Characteristics and Mechanism of Used Drip Irrigation Tape Under Different Stretching Speeds" Agriculture 15, no. 19: 2038. https://doi.org/10.3390/agriculture15192038

APA StyleLiu, H., Lan, H., Yang, X., Li, K., Hu, Z., Chu, S., Li, S., Ouyang, L., Zhang, T., Zhang, H., & Chen, P. (2025). Study on the Fracture Characteristics and Mechanism of Used Drip Irrigation Tape Under Different Stretching Speeds. Agriculture, 15(19), 2038. https://doi.org/10.3390/agriculture15192038