Design and Experimental Research on an Automated Force-Measuring Device for Plug Seedling Extraction

Abstract

1. Introduction

2. Materials and Methods

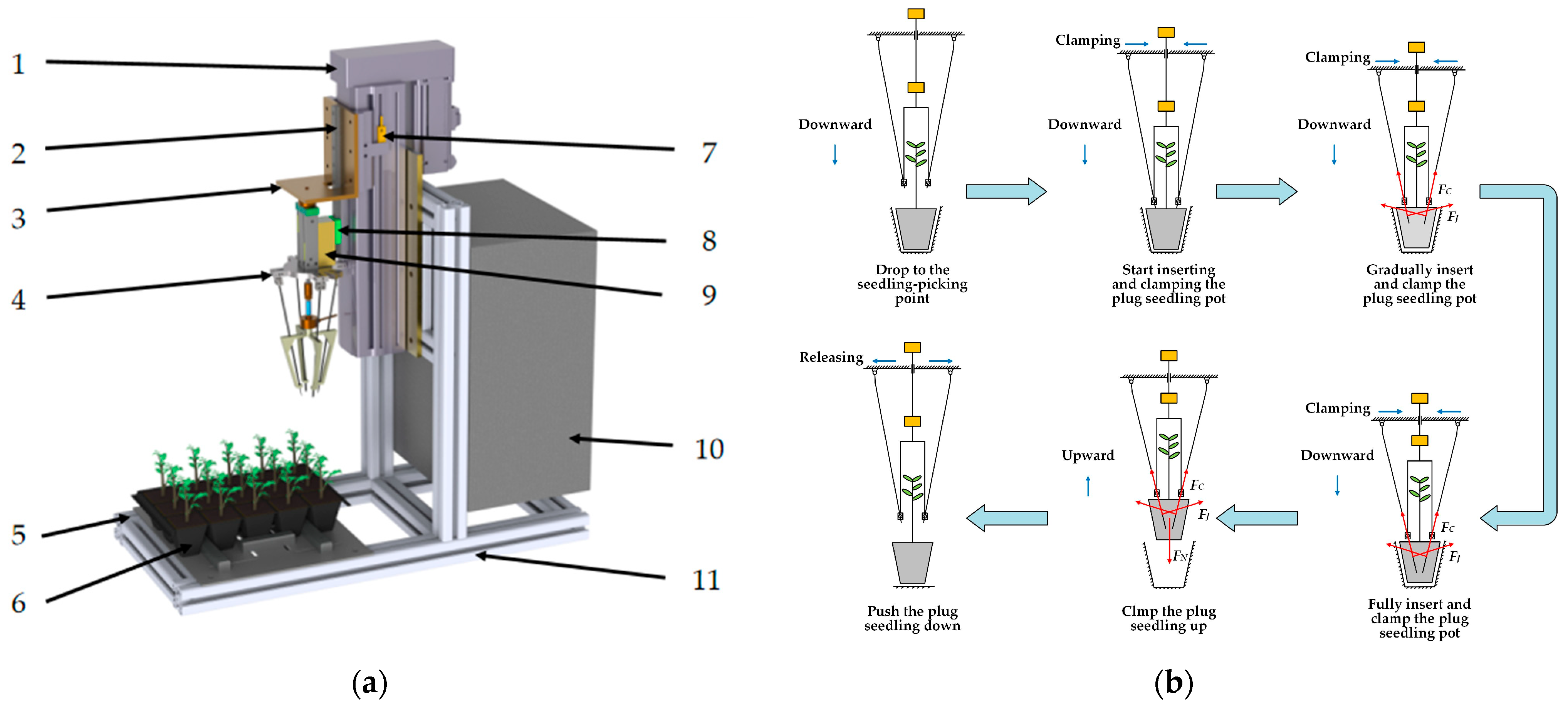

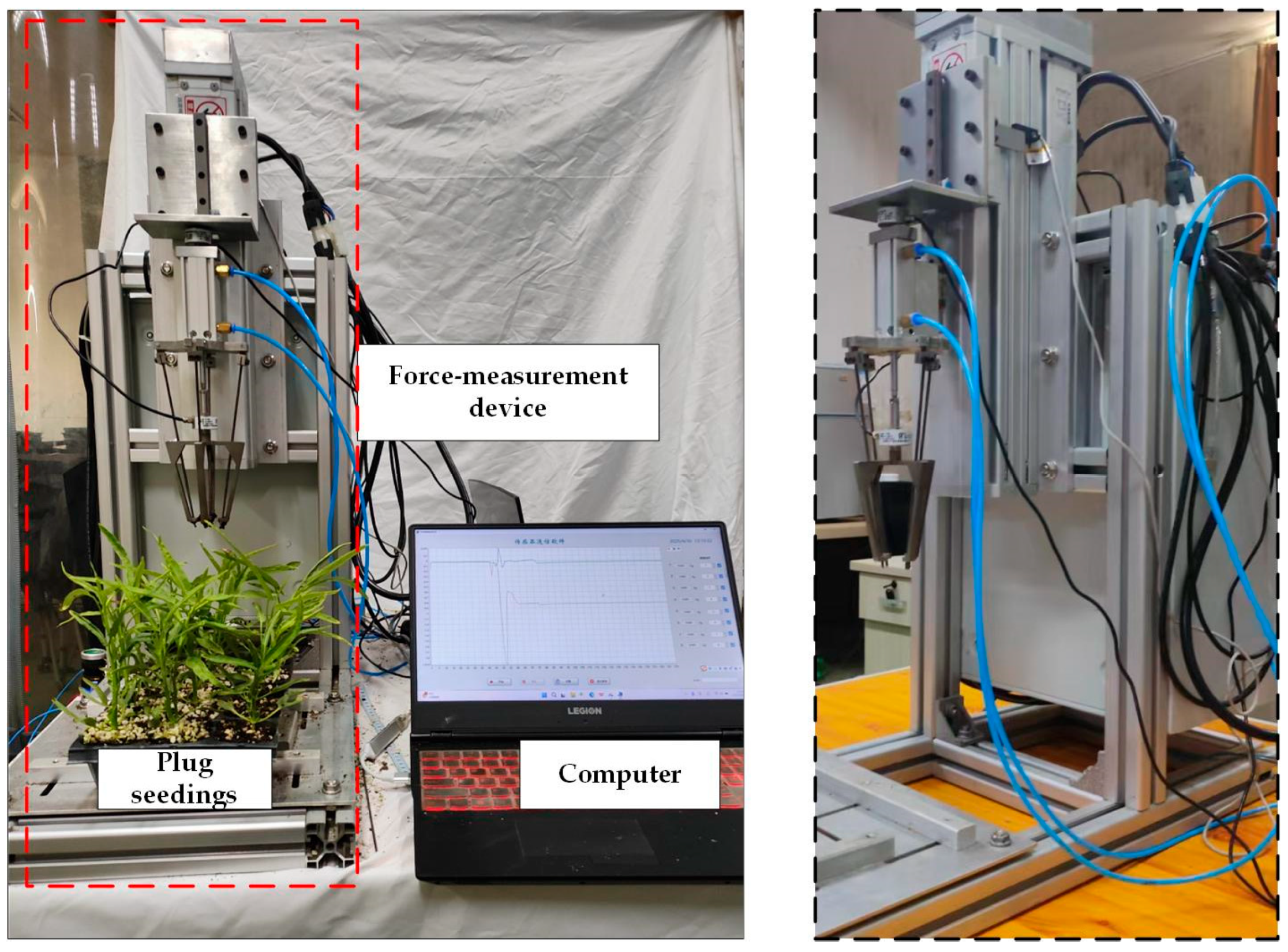

2.1. Design of Force-Measuring Device

2.1.1. The Overall Structure of the Force-Measuring Device

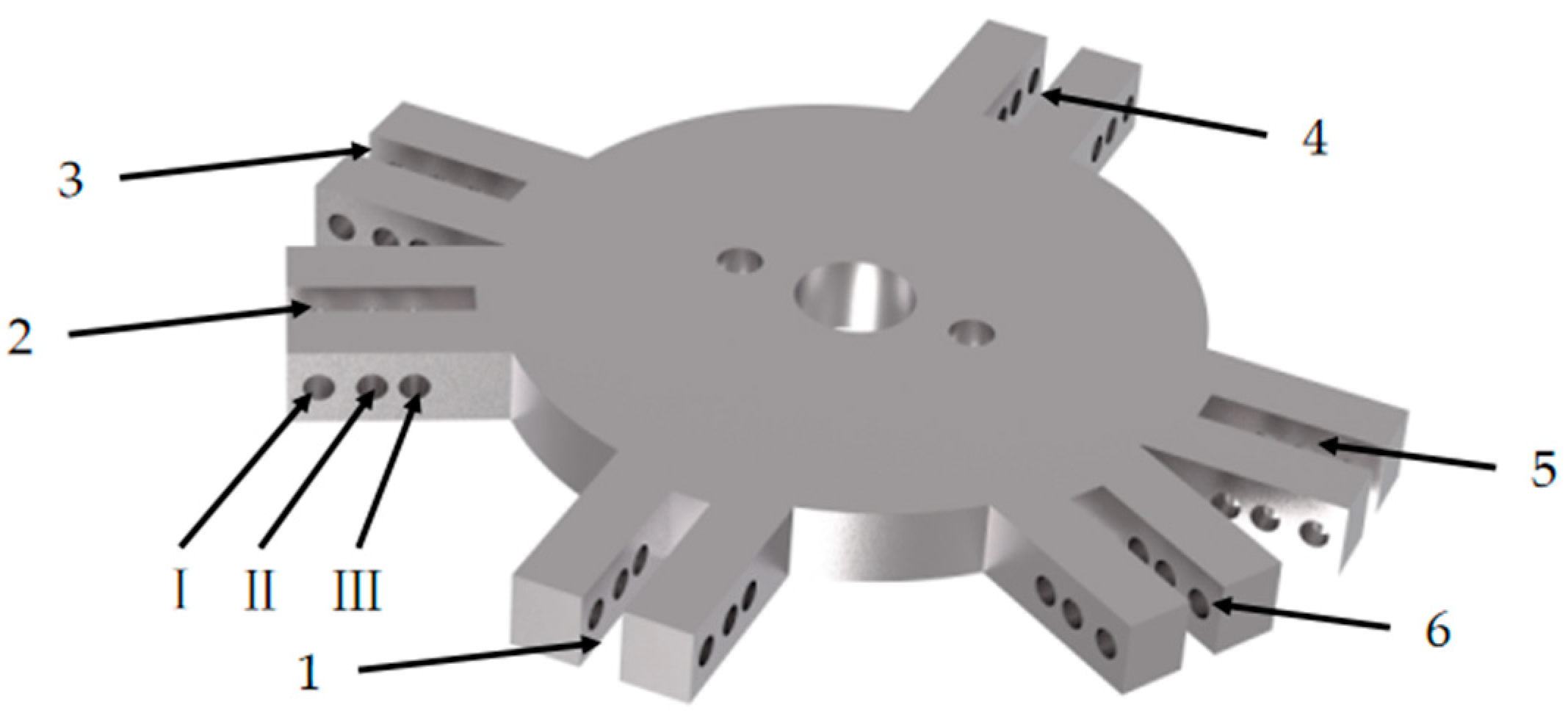

2.1.2. Universal Design of Force-Measuring Device

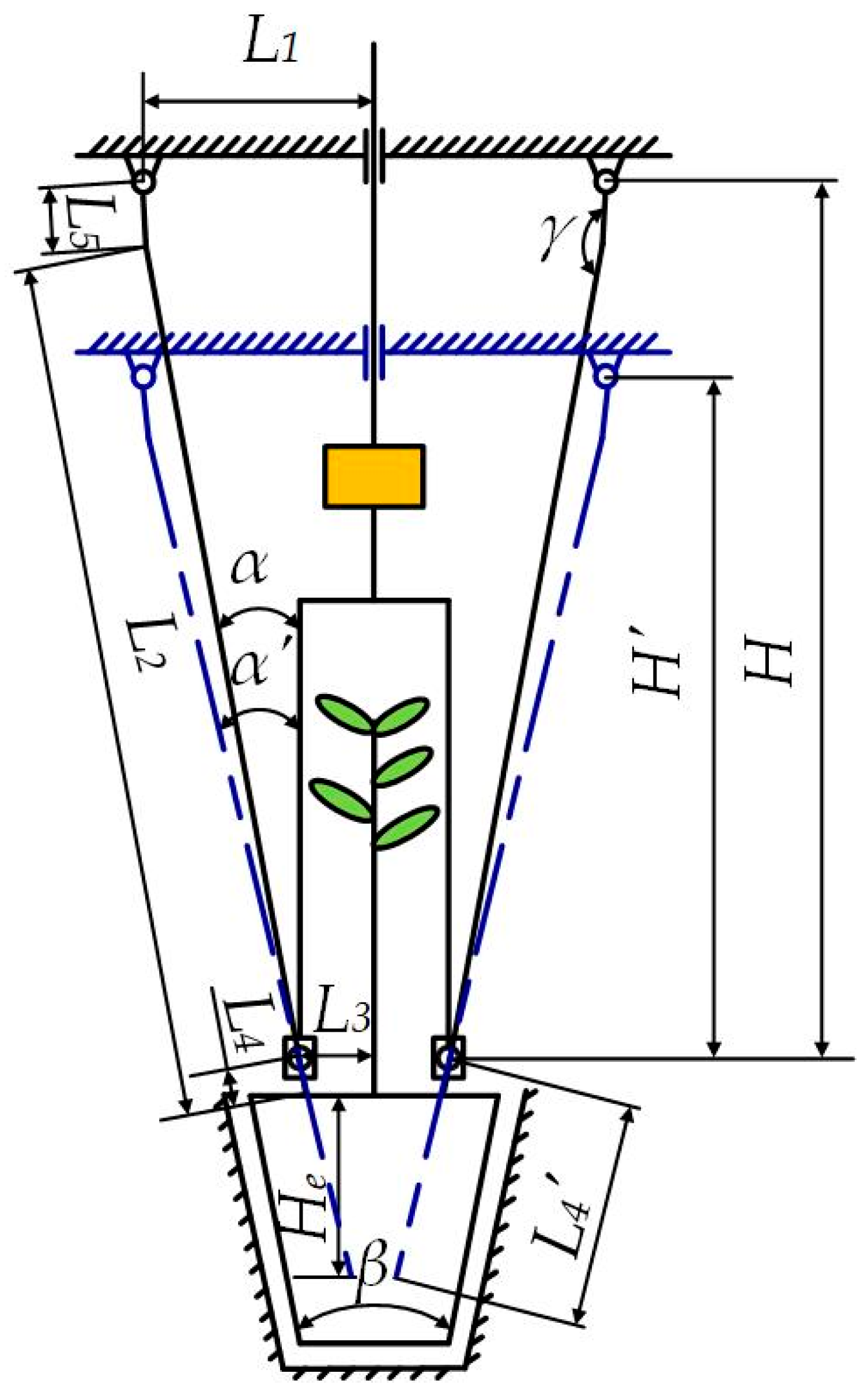

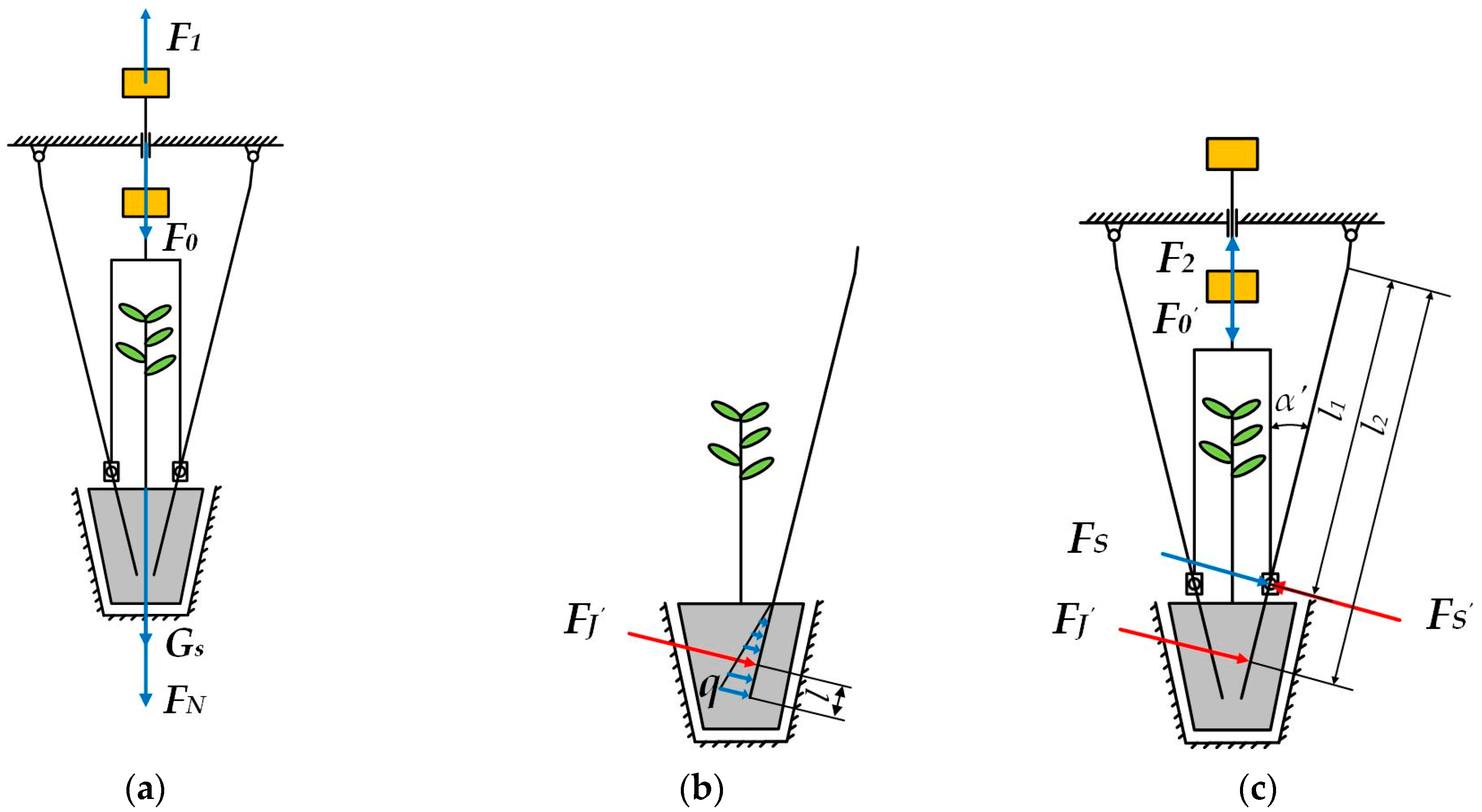

2.1.3. The Structural Parameter Model of Seedling-Picking Force-Measuring Component

2.2. Dynamic Analysis of Seedling-Picking Motion

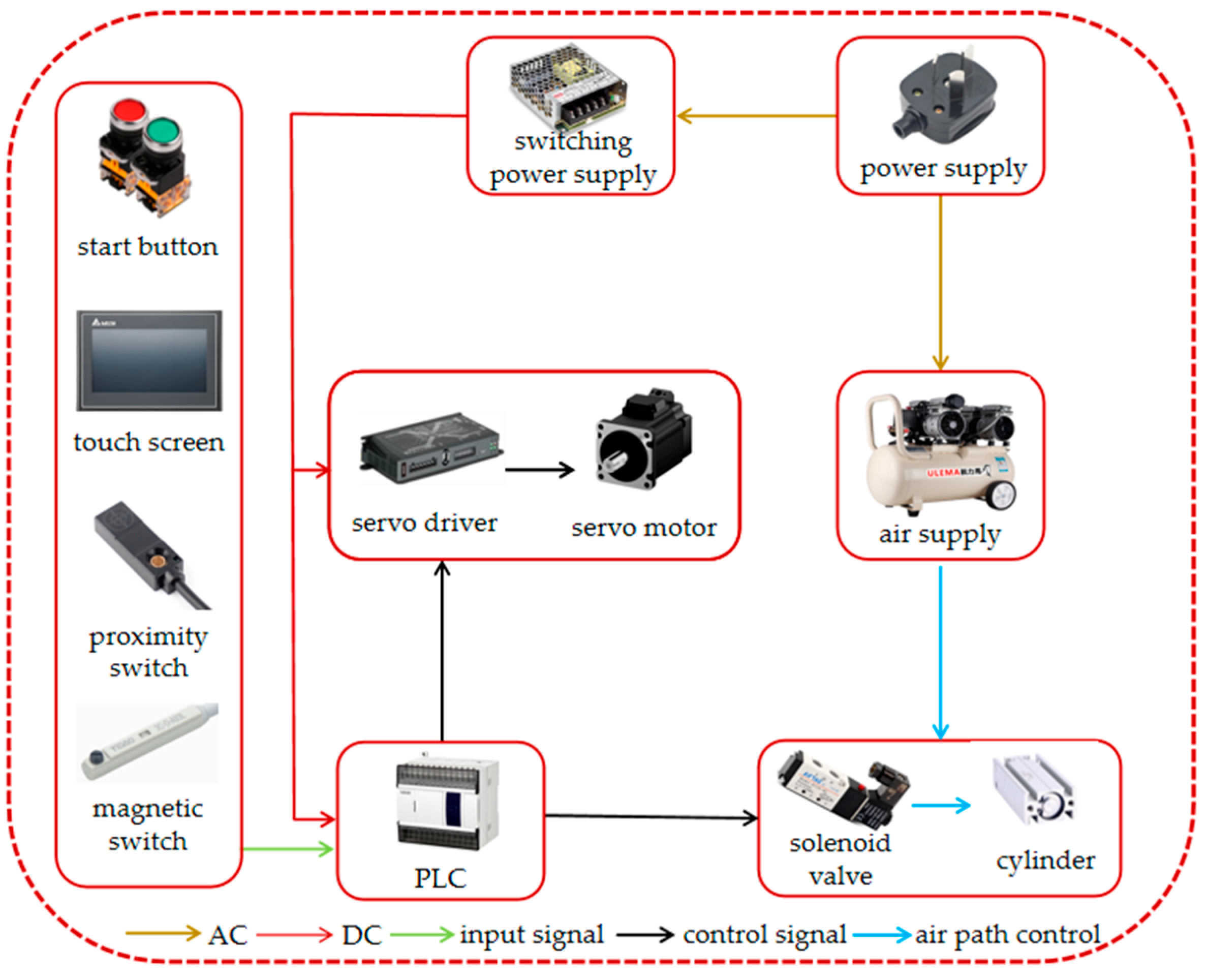

2.2.1. Control of Seedling-Picking Motion Parameters

- Servo motor—MF3H-60CS (CM) 30BZ1-504;

- Servo driver—DF3E-0410Z;

- Proximity switch—Omron TL-W3MC1;

- Solenoid valve—AIRTAC 4V210-08B (two-position five-way);

- Cylinder magnetic switch—AIRTAC CMSG020.

2.2.2. Dynamic Coupling Simulation of Seedling-Picking Motion via EDEM-RecurDyn

2.3. Force-Measuring Experimental Verification

2.3.1. Design of Experiment

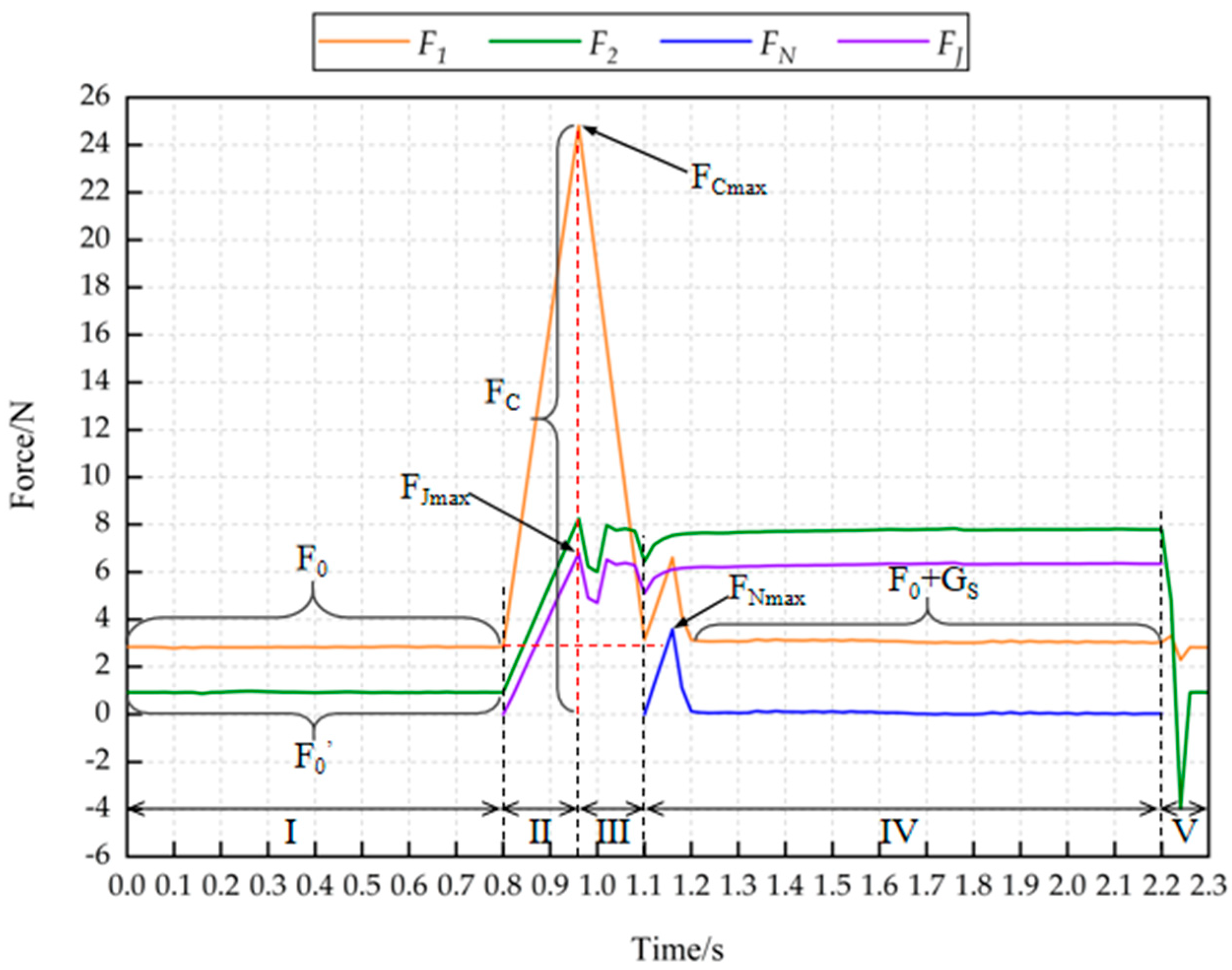

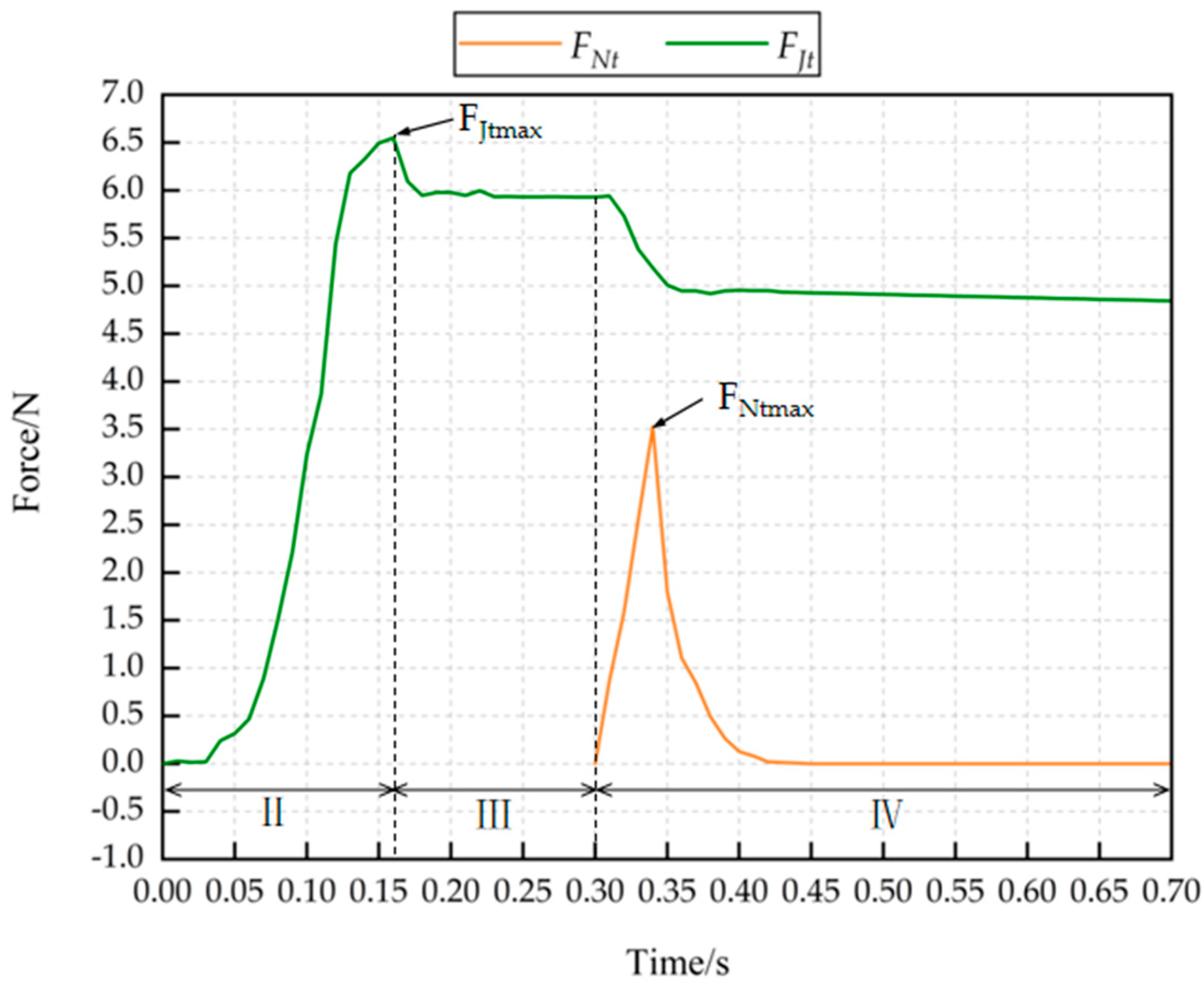

2.3.2. The Measured Mechanical Curve Transformation

3. Results

3.1. Functional Analysis of Force-Measuring Device

3.2. Applicability Analysis of Force-Measuring Device

3.3. Universality Analysis of Force-Measuring Device

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jin, X.; Yuan, Y.; Ji, J.; Zhao, K.; Li, M.; Chen, K. Design and implementation of anti-leakage planting system for transplanting machine based on fuzzy information. Comput. Electron. Agric. 2020, 169, 105204. [Google Scholar] [CrossRef]

- Zhou, M.; Shan, Y.; Xue, X.; Yin, D. Theoretical analysis and development of a mechanism with punching device for transplanting potted vegetable seedlings. Int. J. Agric. Biol. Eng. 2020, 13, 85–92. [Google Scholar] [CrossRef]

- Ma, G.; Mao, H.; Bu, Q.; Han, L.; Shabbir, A.; Gao, F. Effect of compound biochar substrate on the root growth of cucumber plug seedlings. Agronomy 2020, 10, 1080. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, S.; Li, N.; Faheem, M.; Zhou, T.; Cai, W.; Zhao, M.; Zhu, X.; Li, P. Development and field test of an autonomous strawberry plug seeding transplanter for use in elevated cultivation. Appl. Eng. Agric. 2019, 35, 1067–1078. [Google Scholar] [CrossRef]

- Zhou, M.; Xu, T.; Wang, G.; Dong, H.; Yang, S.; Wang, Z. Design of a 2R Open-Chain Plug Seedling-Picking Mechanism and Control System Constrained by a Differential Non-Circular Planetary Gear Train. Agriculture 2024, 14, 1576. [Google Scholar] [CrossRef]

- Khadatkar, A.; Sawant, C.P.; Magar, A.P. Agricultural robots and automated machinery for handling of nursery seedlings with special reference to the transplanting devices. Discov. Appl. Sci. 2025, 7, 916. [Google Scholar]

- Magar, A.P.; Nandede, B.M.; Khadatkar, A.; Sawant, C.P.; Pandirwar, A.P.; Chaudhary, V.P. Optimization, development and evaluation of vegetable seedlings transplanter using inclined magazine-type metering device for cylindrical paper pot seedlings. Agric. Res. 2024. [Google Scholar] [CrossRef]

- Ma, G.; Mao, H.; Han, L.; Liu, Y.; Gao, F. Reciprocating mechanism for whole row automatic seedling picking and dropping on a transplanter. Appl. Eng. Agric. 2020, 36, 751–766. [Google Scholar] [CrossRef]

- Khadatkar, A.; Mathur, S.M.; Gaikwad, B.B. Automation in transplanting: A smart way of vegetable cultivation. Curr. Sci. 2018, 115, 1884–1892. [Google Scholar] [CrossRef]

- Zhou, B.; Miao, H.; Guan, C.S.; Ji, X.; Wang, X.C. Design and Test of Seedling-Picking Mechanism of Fully Automatic Transplanting Machine. Appl. Sci. 2024, 14, 9235. [Google Scholar] [CrossRef]

- Yin, J.; Wang, Z.; Zhou, M.; Wu, L.; Zhang, Y. Optimized design and experiment of the three-arm transplanting mechanism for rice potted seedlings. Int. J. Agric. Biol. Eng. 2021, 14, 56–62. [Google Scholar] [CrossRef]

- Ye, B.; Zeng, G.J.; Deng, B.; Yang, C.L.; Liu, J.K.; Yu, G.H. Design and tests of a rotary plug seedling pick-up mechanism for vegetable automatic transplanter. J. Int. J. Agric. Biol. Eng. 2020, 13, 70–78. [Google Scholar] [CrossRef]

- Ji, D.; Tian, S.; Wu, H.; Zhao, B.; Gong, Y.; Ma, J.; Zhou, M.; Liu, W. Design and experimental verification of an automatic transplant device for a self-propelled flower transplanter. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 420. [Google Scholar] [CrossRef]

- Cui, J.; Li, X.; Zeng, F.; Bai, H. Study on Contact Stress Distribution Characteristics and Damage of Plug Seedlings Based on Flexible Pressure Sensor. Sensors 2023, 23, 8175. [Google Scholar] [CrossRef]

- Yang, Y.; Ting, K.C.; Giacomelli, G.A. Factors affecting performance of sliding-needles gripper during robotic transplanting of seedlings. Appl. Eng. Agric. 1991, 7, 493–498. [Google Scholar] [CrossRef]

- Tong, J.; Jiang, H.; Jiang, Z.; Cui, D. Experiment on Parameter Optimization of Gripper Needles Clamping Seedling Plug for Automatic Transplanter. Trans. Chin. Soc. Agric. Eng. 2014, 30, 8–16. [Google Scholar]

- Jiang, Z.; Hu, Y.; Jiang, H.; Tong, J. Design and force analysis of end-effector for plug seedling transplanter. PLoS ONE 2017, 12, e0180229. [Google Scholar]

- Kang, T.G.; Kim, Y.K.; Jun, H.J.; Choi, L.S. Analysis of pick-up mechanism for automatic transplanter (I). J. Agric. Life Sci. 2017, 51, 187–192. [Google Scholar] [CrossRef]

- Jin, X.; Suo, H.; Zhang, H.; Ji, J.; Zhang, B.; Lin, C. Development and Experiment of Integrated Vegetable Pot Seedling Picking Jaw Clamping Force Detection Sensor. Trans. Chin. Soc. Agric. Mach. 2023, 54, 175–183. [Google Scholar]

- Tian, Z.; Ma, W.; Yang, Q.; Yao, S.; Guo, X.; Duan, F. Design and experiment of gripper for greenhouse plug seedling transplanting based on EDM. Agronomy 2022, 12, 1487. [Google Scholar] [CrossRef]

- Han, L.; Wang, Y.; Du, X.; Xu, Q.; Ma, G. Design and test analysis of the seedling pick-up mechanical equipment for automatic transplanting. Trans. Chin. Soc. Agric. Eng. 2025, 41, 47–55. [Google Scholar]

- Magar, A.P.; Nalawade, S.M.; Walunj, A.A. Development and optimization of an automatic transplanting device for plug tray vegetable seedlings using embedded system. Sci. Rep. 2025, 15, 22483. [Google Scholar] [CrossRef]

- Zhang, N.; Zhang, G.; Liu, H.; Liu, W.; Wei, J.; Tang, N. Design of and Experiment on Open-and-Close Seedling Pick-Up Manipulator with Four Fingers. Agriculture 2022, 12, 1776. [Google Scholar] [CrossRef]

- Hu, J.; Pan, J.; Chen, F. Simulation and Optimization Design of Finger-clamping Seedling Picking Claw Based on EDEM-RecurDyn. Trans. Chin. Soc. Agric. Mach. 2022, 53, 75–85+301. [Google Scholar]

- Han, L.; Xiang, D.; Xu, Q.; Du, X.; Ma, G.; Mao, H. Development of Simplified Seedling Transplanting Device for Supporting Efficient Production of Vegetable Raw Materials. Appl. Sci. 2023, 13, 10022. [Google Scholar] [CrossRef]

- Jin, X.; Li, D.; Ma, H.; Ji, J.; Zhao, K.; Pang, J. Development of single row automatic transplanting device for potted vegetable seedlings. Int. J. Agric. Biol. Eng. 2018, 11, 67–75. [Google Scholar] [CrossRef]

- Mao, H.; Ma, G.; Han, L.; Hu, J.; Gao, F.; Liu, Y. A whole row automatic pick-up device using air force to blow out vegetable plug seedlings. Span. J. Agric. Res. 2021, 18, e0211. [Google Scholar] [CrossRef]

- Choi, W.C.; Kim, D.C.; Ryu, I.H.; Kim, K.U. Development of a seedling pick-up device for vegetable transplanters. Trans. Am. Soc. Agric. Eng. 2002, 45, 13–19. [Google Scholar]

- Mao, H.; Liu, Y.; Han, L.; Sheng, B.; Ma, G.; Li, Y. X-ray Computerized Tomography for Characterization of Pick-up Destruction and Pick-up Parameter Optimization of Tomato Root Lumps. Span. J. Agric. Res. 2019, 17, e0202. [Google Scholar] [CrossRef]

- Yue, R.; Hu, J.; Liu, Y.; Yao, M.; Zhang, T.; Shi, J. Design and Working Parameter Optimization of Pneumatic Reciprocating Seedling-Picking Device of Automatic Transplanter. Agriculture 2022, 12, 1989. [Google Scholar] [CrossRef]

- Liu, W.; Jiang, W.; Zhang, H.; Liu, X.; Liu, H.; Zheng, W. DEM simulations of spherical particle–particle collisions. Can. J. Chem. Eng. 2023, 101, 984–995. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Q.; Jiang, H. Design and optimisation of end effector for loose substrate grasping based on discrete element method. Biosyst. Eng. 2024, 241, 43–55. [Google Scholar] [CrossRef]

- Cui, J.; Li, X.; Zeng, F.; Bai, H.; Zhang, Y. Parameter Calibration and Optimization of a Discrete Element Model of Plug Seedling Pots Based on a Collision Impact Force. Appl. Sci. 2023, 13, 6278. [Google Scholar] [CrossRef]

- Zhao, X.; Yan, H.; Bie, Q.; An, H.; Wang, Y.; Xie, G. Calibration of Seedling Pot Particle Parameters and Simulation and Experimentation of Seedling Picking Claw Based on EDEM-RecurDyn. Trans. Chin. Soc. Agric. Mach. 2024, 55, 197–206. [Google Scholar]

- Mao, H.; Han, L.; Hu, J.; Kumi, F. Development of a pincette-type pick-up device for automatic transplanting of greenhouse seedlings. Appl. Eng. Agric. 2014, 30, 547–556. [Google Scholar]

- Han, L.; Francis, K.; Mao, H.; Hu, J. Design and Tests of a Multi-pin Flexible Seedling Pick-up Gripper for Automatic. Appl. Eng. Agric. 2019, 6, 949–957. [Google Scholar] [CrossRef]

| Seeding Plug Specification | Hole Upper Part Opening Size/mm | Hole Lower Part Opening Size/mm | Hole Height Size/mm | Hole Cone Angle/° |

|---|---|---|---|---|

| 50-hole | 50 × 50 | 24 × 24 | 48 | 15.15 |

| 72-hole | 40 × 40 | 22 × 22 | 42 | 12.09 |

| 128-hole | 32 × 32 | 14 × 14 | 44 | 11.56 |

| Seedling Plug Specification | He/mm | α′/° | α/° | L1/mm | L4/mm | L4′/mm | H′/mm |

|---|---|---|---|---|---|---|---|

| 50-hole | 42.5 | 15.5 | 11.71 | 51 | 5.11 | 49.29 | 135.0 |

| 72-hole | 36 | 12.5 | 10.05 | 47.5 | 5.08 | 41.99 | 142.5 |

| 128-hole | 38 | 12.0 | 9.41 | 44 | 5.07 | 43.96 | 140.5 |

| Item | Attribute | Value/Unit |

|---|---|---|

| Particle | Poisson’s ratio | 0.364 |

| Solids density | 425 kg/m3 | |

| Shear modulus | 1.6 × 106 Pa | |

| Seeding plug | Poisson’s ratio | 0.38 |

| Solids density | 1400 kg/m3 | |

| Shear modulus | 8.66 × 108 Pa | |

| Clamping needle | Poisson’s ratio | 0.288 |

| Solids density | 7810 kg/m3 | |

| Shear modulus | 8.0 × 1010 Pa | |

| Particle–Particle | Coefficient of restitution | 0.12 |

| Coefficient of static friction | 0.65 | |

| Coefficient of rolling friction | 0.345 | |

| Normal stiffness per unit area | 1 × 108 | |

| Shear stiffness per unit area | 5 × 107 | |

| Critical normal stress | 3 × 104 Pa | |

| Critical shear stress | 1.5 × 104 Pa | |

| Bonded disk radius | 0.6 mm | |

| Particle–Seedling plug | Coefficient of restitution | 0.4 |

| Coefficient of static friction | 0.2 | |

| Coefficient of rolling friction | 0.002 | |

| Surface energy | 1.513 J/m2 | |

| Particle–Clamping needle | Coefficient of restitution | 0.6 |

| Coefficient of static friction | 0.397 | |

| Coefficient of rolling friction | 0.261 |

| Sensor Name | Technical Parameter | Parameter Calibration |

|---|---|---|

| pull-pressure sensor-1 | Range: 10 kg; Composite precision: ±0.05%; sensitivity: 1.12 ± 0.05 mV/V | F1 = 1.9996X1 − 0.0008 R2 = 0.999 |

| pull-pressure sensor-2 | Range: 3 kg; Composite precision: ±0.05%; sensitivity: 0.90 ± 0.04 mV/V | F2 = 0.5999X2 + 0.0038 R2 = 1.000 |

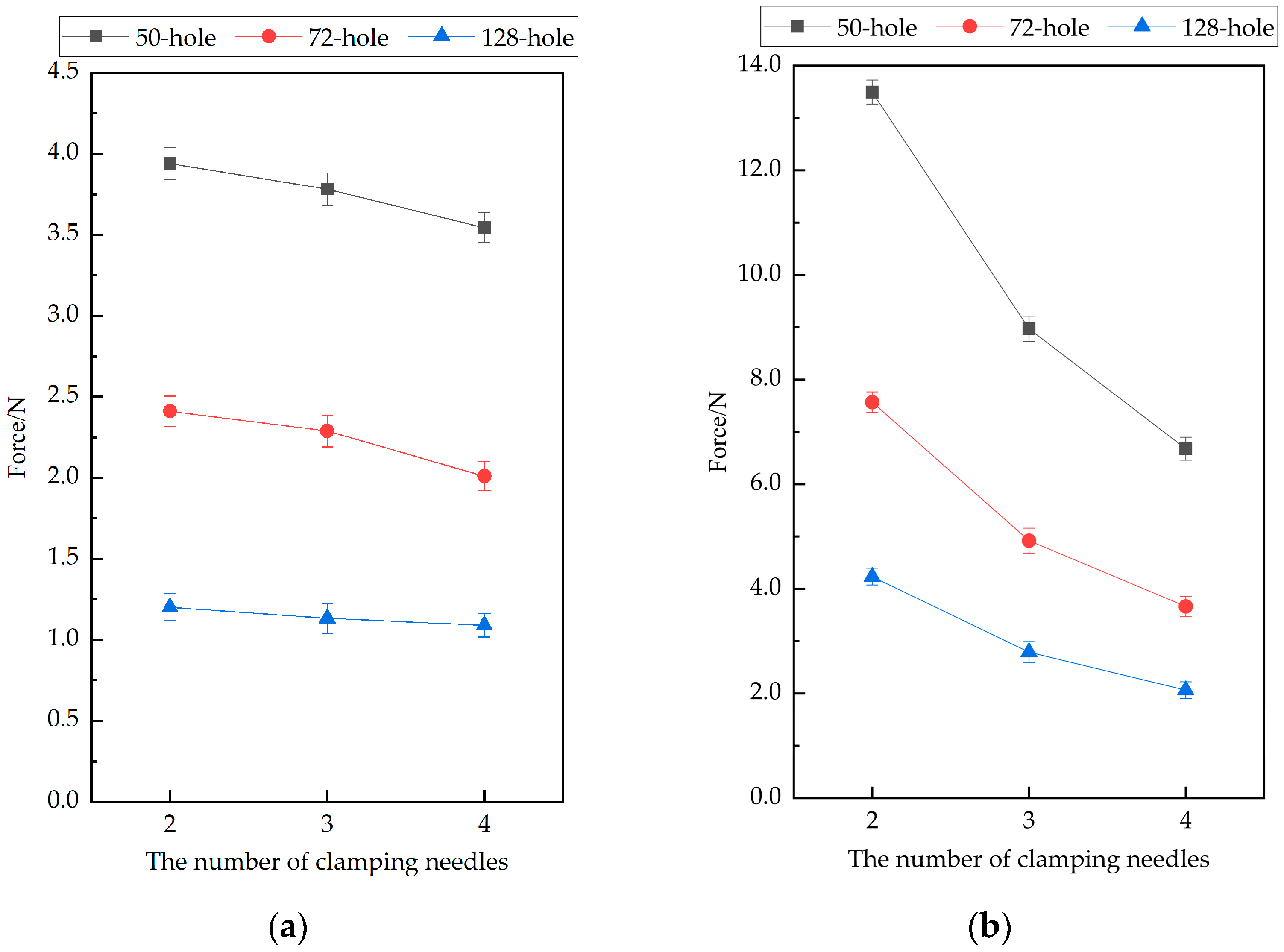

| Force | Source | Sum of Squares | Freedom | Mean Square | F Value | p Value | Significance |

|---|---|---|---|---|---|---|---|

| FNmax | Seedling plug specification | 310.107 | 2 | 155.053 | 18,350.197 | 0.000 | ** |

| The number of clamping needles | 4.199 | 2 | 2.100 | 248.476 | 0.000 | ** | |

| FJmax | Seedling plug specification | 2069.470 | 2 | 1034.735 | 24,272.779 | 0.000 | ** |

| The number of clamping needles | 862.124 | 2 | 431.062 | 10,111.837 | 0.000 | ** |

| Seedling Plug Specification | The Number of Clamping Needles | M1/g | M2/g | IR/% |

|---|---|---|---|---|

| 50-hole | 2 | 34.25 | 33.28 | 97.17 |

| 3 | 33.93 | 32.86 | 96.85 | |

| 4 | 35.62 | 34.34 | 96.41 | |

| 72-hole | 2 | 20.97 | 20.47 | 97.62 |

| 3 | 22.43 | 21.77 | 97.06 | |

| 4 | 21.62 | 20.91 | 96.72 | |

| 128-hole | 2 | 13.25 | 13.06 | 98.56 |

| 3 | 13.12 | 12.88 | 98.17 | |

| 4 | 12.47 | 12.16 | 97.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, T.; Chen, X.; Hu, J.; Liu, W.; Lv, J.; Tan, Y.; Li, F. Design and Experimental Research on an Automated Force-Measuring Device for Plug Seedling Extraction. Agriculture 2025, 15, 1939. https://doi.org/10.3390/agriculture15181939

Hou T, Chen X, Hu J, Liu W, Lv J, Tan Y, Li F. Design and Experimental Research on an Automated Force-Measuring Device for Plug Seedling Extraction. Agriculture. 2025; 15(18):1939. https://doi.org/10.3390/agriculture15181939

Chicago/Turabian StyleHou, Tengyuan, Xinxin Chen, Jianping Hu, Wei Liu, Junpeng Lv, Youheng Tan, and Fengpeng Li. 2025. "Design and Experimental Research on an Automated Force-Measuring Device for Plug Seedling Extraction" Agriculture 15, no. 18: 1939. https://doi.org/10.3390/agriculture15181939

APA StyleHou, T., Chen, X., Hu, J., Liu, W., Lv, J., Tan, Y., & Li, F. (2025). Design and Experimental Research on an Automated Force-Measuring Device for Plug Seedling Extraction. Agriculture, 15(18), 1939. https://doi.org/10.3390/agriculture15181939