Precision Feeding on Pig Fattening Farms: Can Simplified Implementation Enhance Productivity and Reduce Pollutant Emissions?

Abstract

1. Introduction

2. Materials and Methods

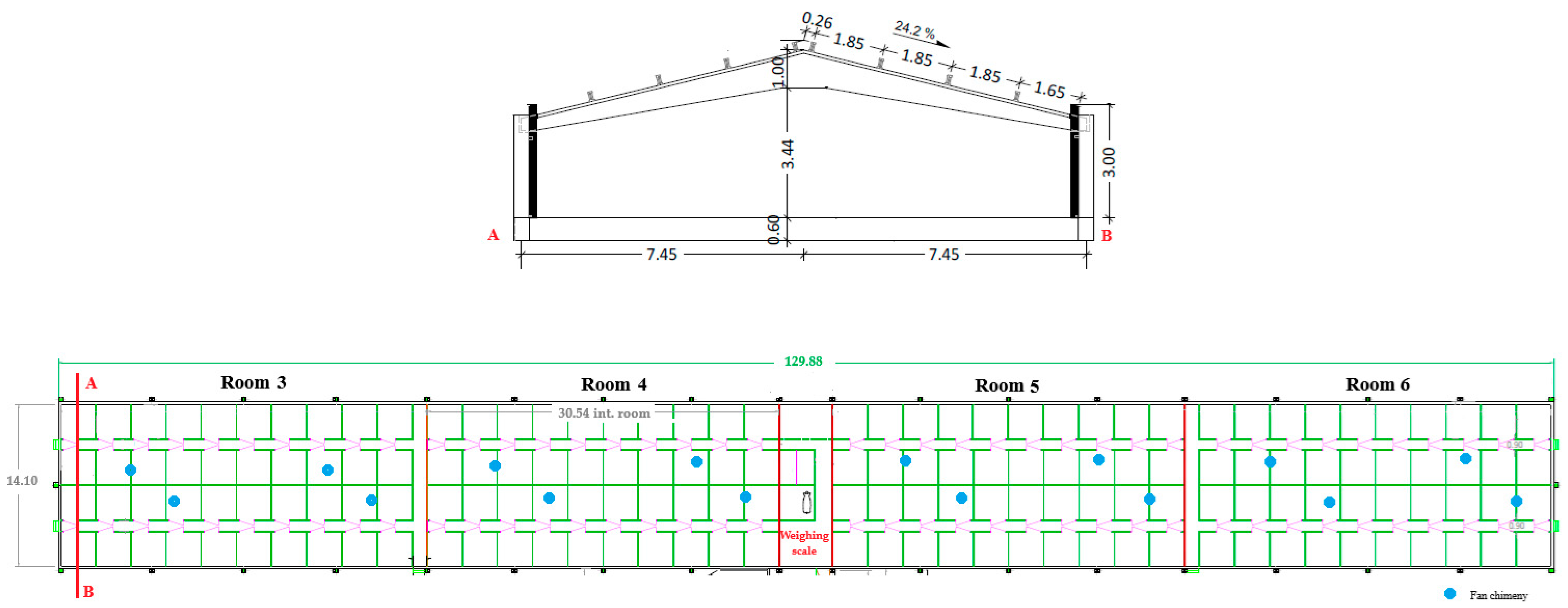

2.1. Experimental Facilities and Animals

2.2. Experimental Design

2.3. Diets

2.4. Productive Performance

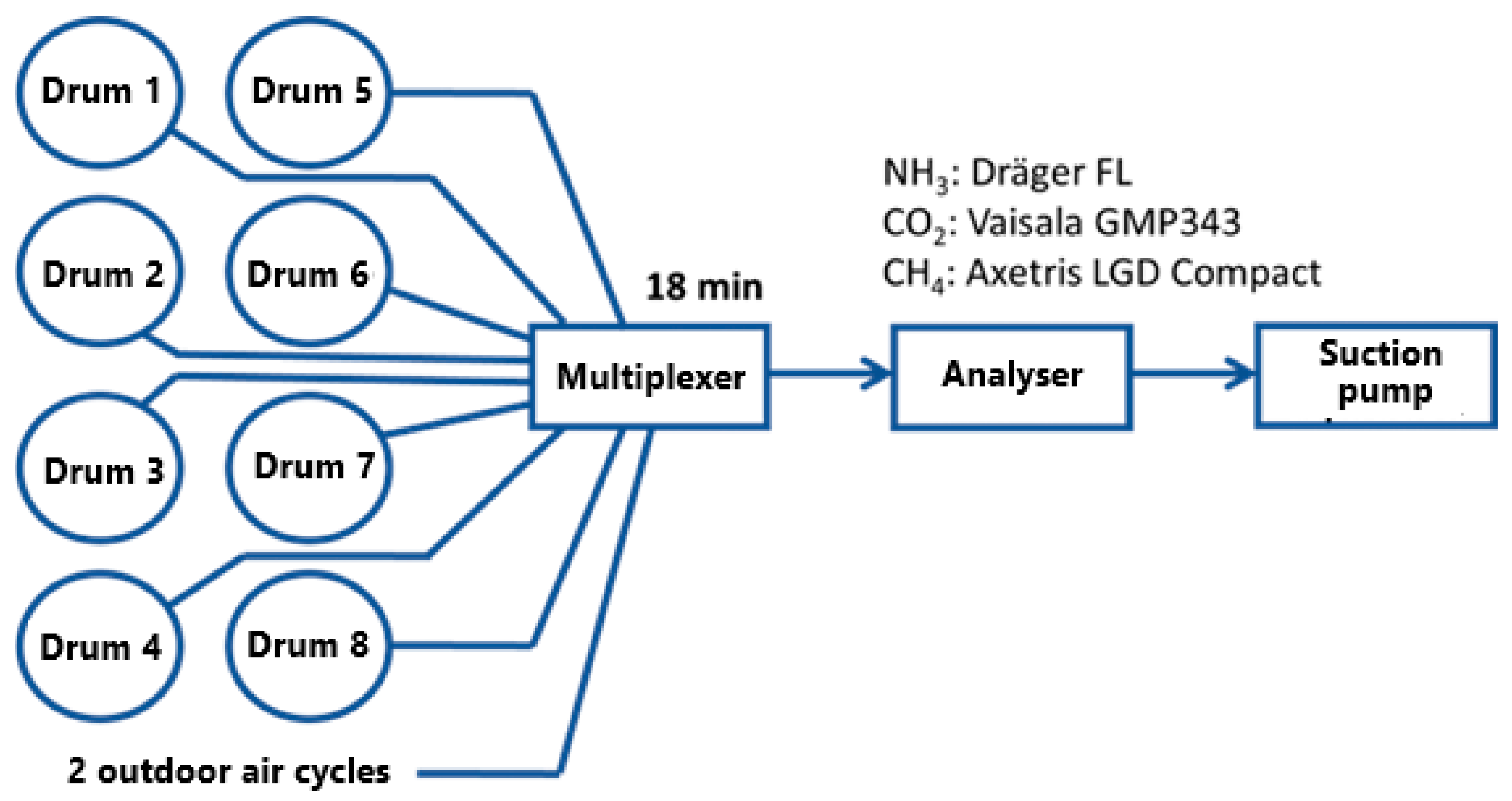

2.5. Slurry Controls and Gas Emissions

2.6. Nitrogen Balance

2.7. Feed Cost Calculations

2.8. Statistical Analysis

- Variable is the variable on which the effect is intended to be studied (emission, composition…);

- µ is the mean of the model;

- Treatmentj is the effect of the treatment (C or BF);

- Samplingj is the effect of the time of sampling (Intermediate vs. Final);

- Treatmenti × Samplingj is the effect of the interaction between the two previous variables;

- εij is the error of the model.

3. Results

3.1. Diets

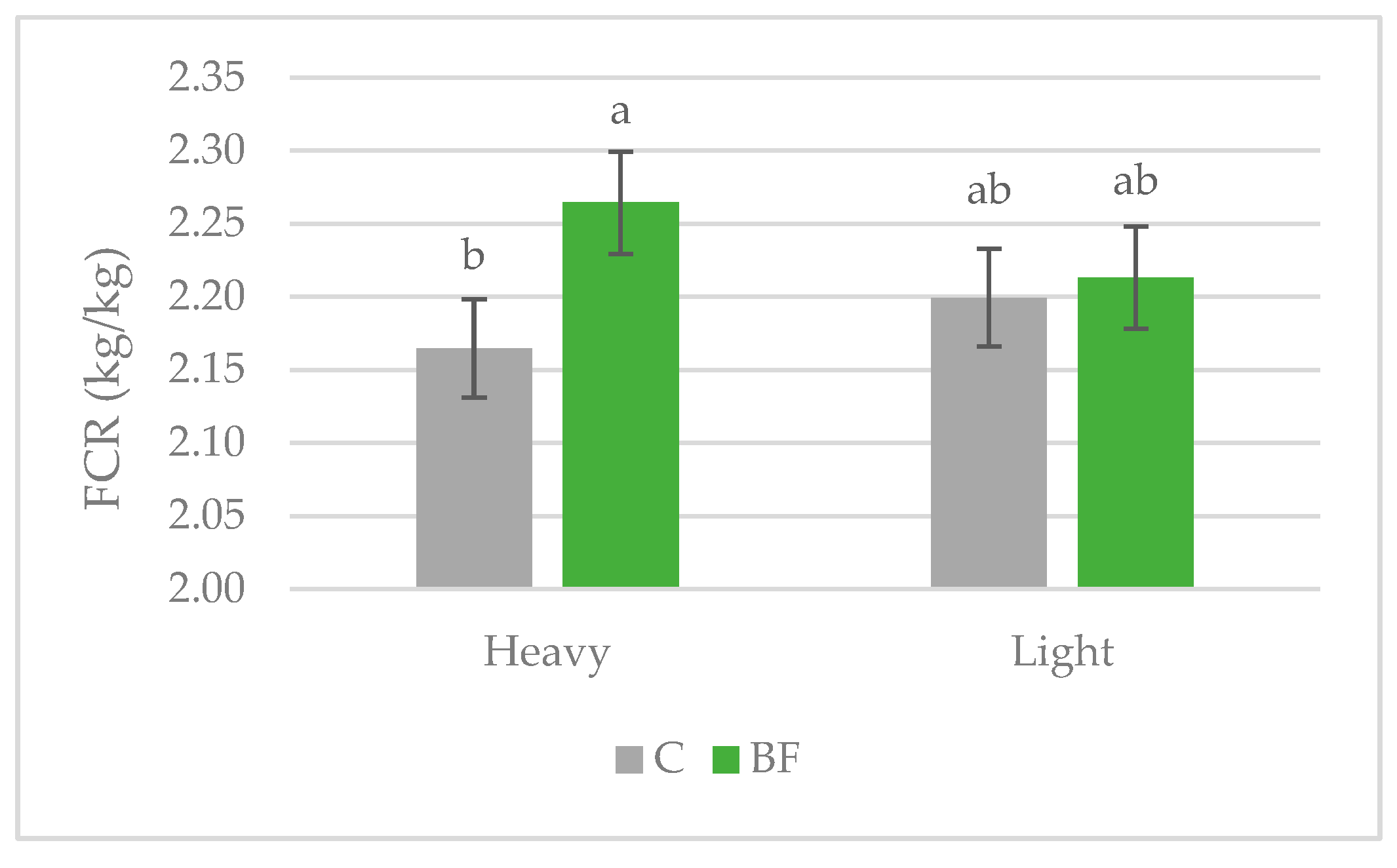

3.2. Animal Performance

3.3. Nitrogen Balance Results

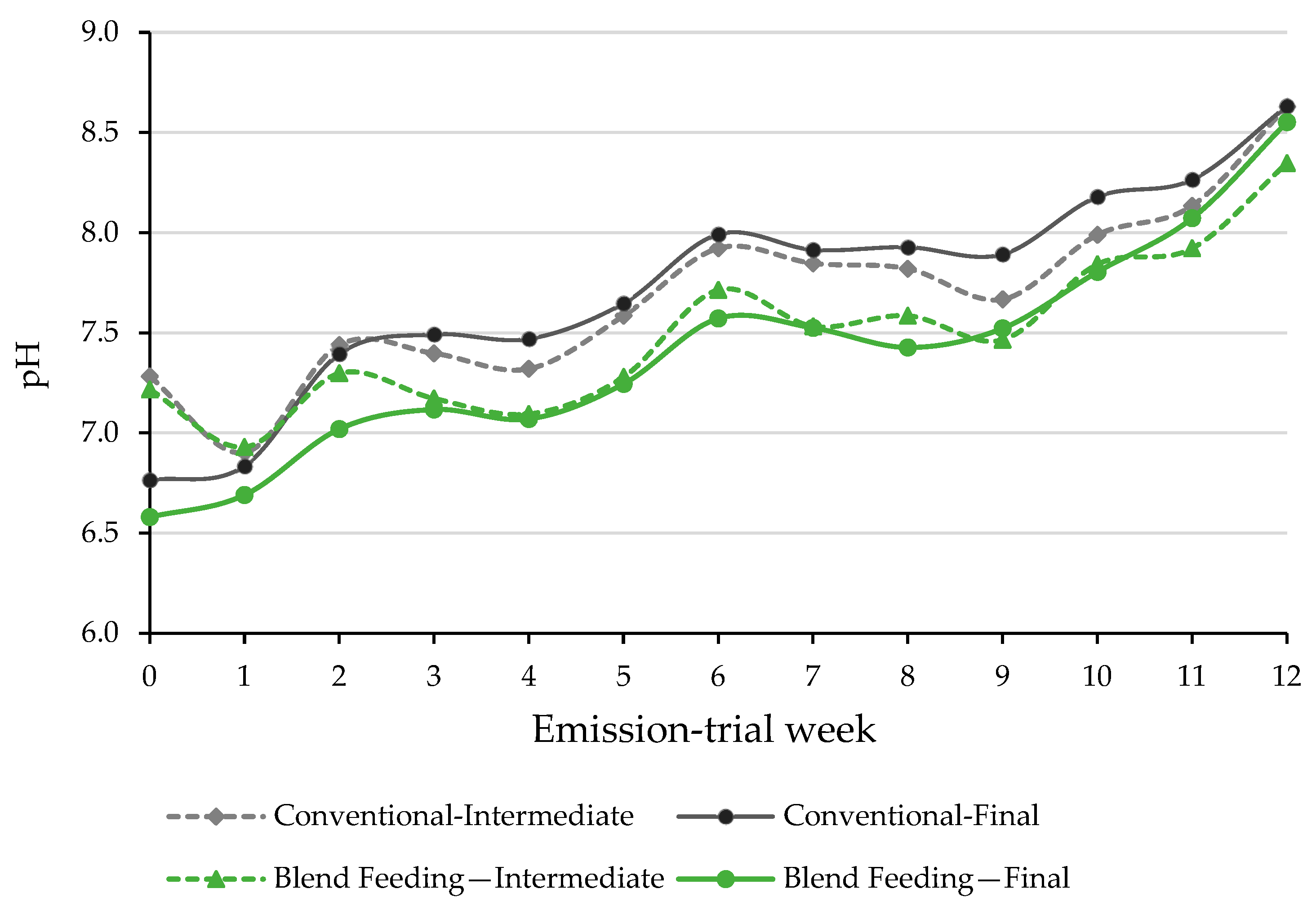

3.4. Slurry Composition

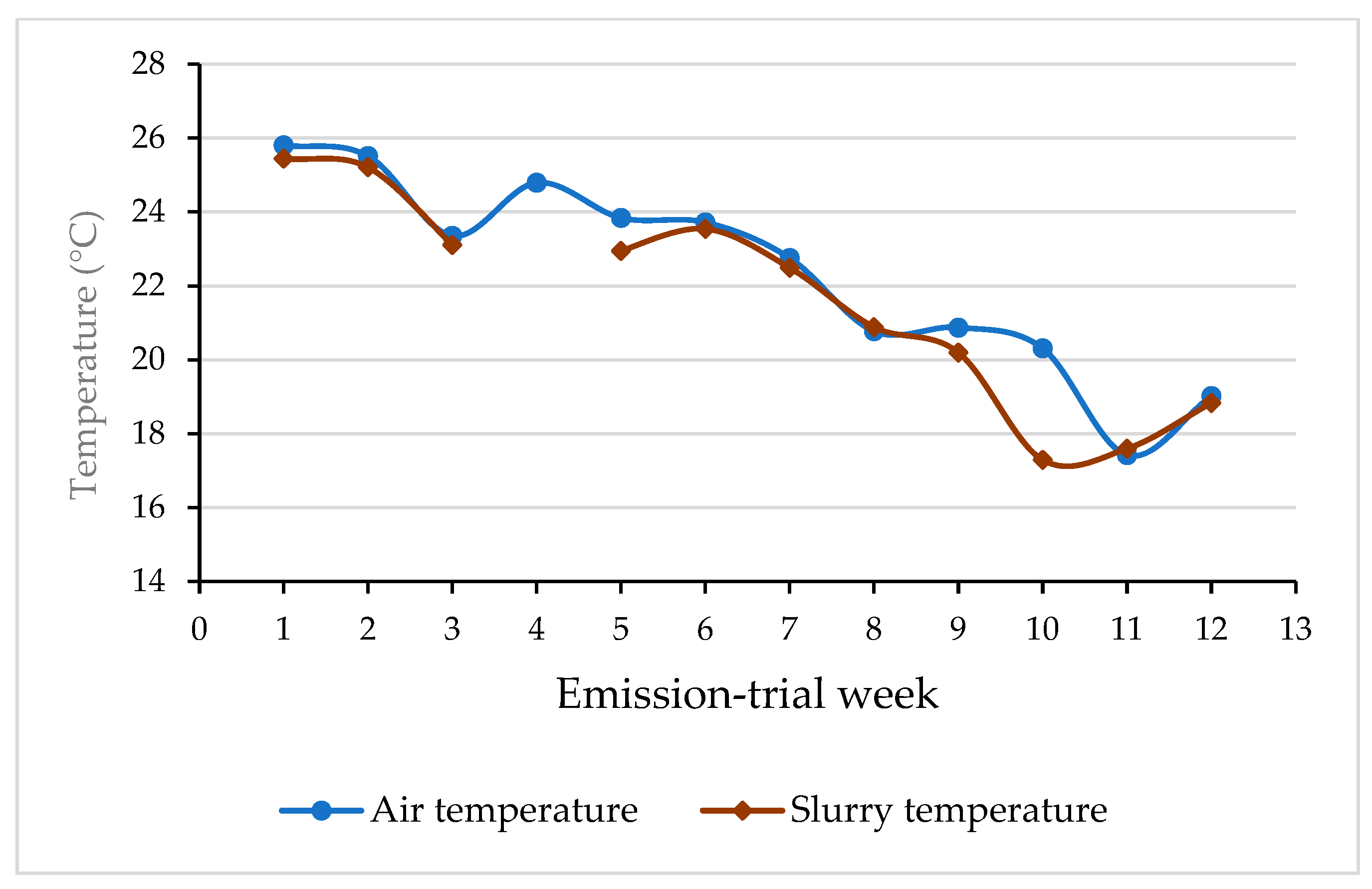

3.5. Temperature and Gas Emissions

3.6. Feed Cost

4. Discussion

4.1. Animal Performance

4.2. Nitrogen Balance and Slurry Composition

4.3. Gas Emissions

4.4. Economic Evaluation

4.5. Implications

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADFI | Average daily feed intake |

| ADG | Average daily gain |

| AI | Artificial intelligence |

| BF | Blend feeding |

| BW | Body weight |

| C | Control |

| CF | Crude fibre |

| CH4 | Methane |

| CO2 | Carbon dioxide |

| CP | Crude protein |

| DM | Dry matter |

| EC | Electrical conductivity |

| FAO | Food and Agricultural Organization of the United Nations |

| FCR | Feed conversion ratio |

| GHG | Greenhouse gases |

| H | Heavy pigs |

| IPCC | Intergovernmental Panel on Climate Change |

| IRPP-BREF | Best Available Techniques Reference Document for Intensive Rearing of Poultry/Pigs |

| L | Light pigs |

| Lys | Lysine |

| MCF | Methane conversion factor |

| N | Nitrogen |

| N2O | Nitrous oxide |

| NDF | Neutral detergent fibre |

| NH3 | Ammonia |

| N-NH3 | Ammoniacal nitrogen |

| NRC | Nutrient Requirements of Swine |

| OECD | Organisation for Economic Co-operation and Development |

| OM | Organic matter |

| PF | Precision feeding |

| SEM | Standard error of the mean |

| SID | Standardised ileal digestible |

| TKN | Total Kjeldahl nitrogen |

References

- OECD. Market Examinations in Mexico: Case Study of the Pork Meat Market 2019; OECD: Paris, France, 2019. [Google Scholar] [CrossRef]

- FAO. Livestock’s Long Shadow; FAO: Rome, Italy, 2006. [Google Scholar]

- National Research Council (NRC). Air Emissions from Animal Feeding Operations: Current Knowledge, Future Needs; National Academies Press: Washington, DC, USA, 2003. [Google Scholar] [CrossRef]

- Montalvo Bermejo, G.; Babot Gaspa, D.; Calvet Sanz, S.; Flotats Ripoll, X.; Gallart Arenal, R.; Herrero Encinas, M.; Higuera Pascual, M.Á.; Laínez Andrés, M. Sostenibilidad e Impacto Ambiental de las Explotaciones Porcinas, 1st ed.; Menéndez Carreño, M., Fuica Macías, E., Eds.; Grupo Asís Biomedia, S.L.: Zaragoza, Spain, 2024. [Google Scholar]

- Agostini, P.S.; Gasa, J.; Manzanilla, E.G.; Da Silva, C.A.; De Blas, C. Descriptive Study of Production Factors Affecting Performance Traits in Growing-Finishing Pigs in Spain. Span. J. Agric. Res. 2013, 11, 371–381. [Google Scholar] [CrossRef]

- Andretta, I.; Hauschild, L.; Kipper, M.; Pires, P.G.S.; Pomar, C. Environmental Impacts of Precision Feeding Programs Applied in Pig Production. Animal 2018, 12, 1990–1998. [Google Scholar] [CrossRef]

- Bourdon, D.; Dourmad, J.Y.; Henry, Y. Réduction Des Rejets Azotés Chez Le Porc En Croissance Par La Mise En Oeuvre de l’alimentation Multiphase, Associé à l’abaissement Du Taux Azoté. J. Rech. Porc. 1995, 27, 269–278. [Google Scholar]

- Giner Santonja, G.; Georgitzikis, K.; Maria Scalet, B.; Montobbio, P.; Roudier, S.; Delgado Sancho, L. Best Available Techniques (BAT) Reference Document for the Intensive Rearing of Poultry or Pigs—Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control); OECD: Paris, France, 2017. [Google Scholar] [CrossRef]

- Oenema, O.; Tamminga, S.; Menzi, H.; Aarnink, A.; Piñeiro Noguera, C.; Montalvo Bermejo, G. Livestock Feeding Strategies. In Options for Ammonia Mitigation: Guidance from the UNECE Task Force on Reactive Nitrogen; Bittman, S., Dedina, M., Howard, C.M., Oenema, O., Sutton, M.A., Eds.; Centre for Ecology and Hydrology (CEH): Edimburgh, Scotland, 2014; pp. 10–13. [Google Scholar]

- Le Bellego, L.; van Milgen, J.; Noblet, J. Effect of High Temperature and Low-Protein Diets on the Performance of Growing-Finishing Pigs1. J. Anim. Sci. 2002, 80, 691–701. [Google Scholar] [CrossRef]

- Rocha, G.C.; Duarte, M.E.; Kim, S.W. Advances, Implications, and Limitations of Low-Crude-Protein Diets in Pig Production. Animals 2022, 12, 3478. [Google Scholar] [CrossRef] [PubMed]

- Kerr, B.J.; Southern, L.L.; Bidner, T.D.; Friesen, K.G.; Easter, R.A. Influence of Dietary Protein Level, Amino Acid Supplementation, and Dietary Energy Levels on Growing-Finishing Pig Performance and Carcass Composition1. J. Anim. Sci. 2003, 81, 3075–3087. [Google Scholar] [CrossRef] [PubMed]

- Aparicio, M.; Yeste-Vizcaíno, N.; Morales, J.; Soria, N.; Isabel, B.; Piñeiro, C.; González-Bulnes, A. Use of Precision Feeding during Lactation Improves the Productive Yields of Sows and Their Piglets under Commercial Farm Conditions. Animals 2024, 14, 2863. [Google Scholar] [CrossRef] [PubMed]

- Pomar, C.; Hauschild, L.; Zhang, G.H.; Pomar, J.; Lovatto, P.A. Precision Feeding Can Significantly Reduce Feeding Cost and Nutrient Excretion in Growing Animals. In Modelling Nutrient Digestion and Utilisation in Farm Animals; Wageningen Academic Publishers: Wageningen, The Netherlands, 2011; pp. 327–334. [Google Scholar] [CrossRef]

- Andretta, I.; Pomar, C.; Rivest, J.; Pomar, J.; Lovatto, P.A.; Neto, J.R. The Impact of Feeding Growing-Finishing Pigs with Daily Tailored Diets Using Precision Feeding Techniques on Animal Performance, Nutrient Utilization, and Body and Carcass Composition 1. J. Anim. Sci. 2014, 92, 3925–3936. [Google Scholar] [CrossRef]

- Pomar, C.; Remus, A. Review: Fundamentals, Limitations and Pitfalls on the Development and Application of Precision Nutrition Techniques for Precision Livestock Farming. Animal 2023, 17, 100763. [Google Scholar] [CrossRef]

- Quiniou, N.; Noblet, J. Effect of the Dietary Net Energy Concentration on Feed Intake and Performance of Growing-Finishing Pigs Housed Individually1. J. Anim. Sci. 2012, 90, 4362–4372. [Google Scholar] [CrossRef]

- Horacio Santiago, R.; Luiz Fernando Teixeira, A.; Arele Arlindo, C.; Melissa Izabel, H.; Nilva Kazue, S.; Fenando Guilherme, P.; Gabriel Cipriano, R.; Alysson, S.; Márvio Lobão Teixeira de, A.; Jansller Luiz, G.; et al. Brazilian Tables for Poultry and Swine—Composition of Feedstuffs and Nutritional Requirements; Horacio Santiago, R., Luiz Fernando Teixeira, A., Eds.; Editora Scienza: Sao Carlos, Brazil, 2024. [Google Scholar] [CrossRef]

- De Blas, C.; Gasa, J.; Mateos, G.G. Necesidades Nutricionales Para Ganado Porcino. Normas FEDNA, 2nd ed.; FEDNA: Madrid, Spain, 2013. [Google Scholar]

- Mauch, E.D.; Young, J.M.; Serão, N.V.L.; Hsu, W.L.; Patience, J.F.; Kerr, B.J.; Weber, T.E.; Gabler, N.K.; Dekkers, J.C.M. Effect of Lower-Energy, Higher-Fiber Diets on Pigs Divergently Selected for Residual Feed Intake When Fed Higher-Energy, Lower-Fiber Diets1. J. Anim. Sci. 2018, 96, 1221–1236. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association, American Water Works Association, Water Environment Federation, Eds.; APHA: Washington, DC, USA, 2005. [Google Scholar]

- Babot Gaspa, D.; Coma, J.; Carrión, D. Bases Zootécnicas Para el Cálculo del Balance Alimentario de Nitrógeno y de Fósforo, 2nd ed.; Ministerio de Agricultura, Pesca y Alimentación, Eds.; Centro de Publicaciones del Ministerio de Agricultura y Pesca, Alimentación y Medio Ambiente: Madrid, Spain, 2024. [Google Scholar]

- SAS Institute Inc. SAS/STAT ® 9.1 User’s Guide; SAS Institute Inc.: Cary, NC, USA, 2004. [Google Scholar]

- Main, R.G.; Dritz, S.S.; Tokach, M.D.; Goodband, R.D.; Nelssen, J.L. Determining an Optimum Lysine:Calorie Ratio for Barrows and Gilts in a Commercial Finishing Facility. J. Anim. Sci. 2008, 86, 2190–2207. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Lee, S.D.; Yun, W.; Oh, H.J.; An, J.S.; Kim, I.H.; Cho, J.H. Effects of Different Standardized Ileal Digestible Lysine: Net Energy Proportion in Growing and Finishing Pigs. J. Anim. Sci. Technol. 2020, 62, 198–207. [Google Scholar] [CrossRef]

- Marçal, D.A.; Kiefer, C.; Tokach, M.D.; Dritz, S.S.; Woodworth, J.C.; Goodband, R.D.; Cemin, H.S.; Derouchey, J.M. Diet Formulation Method Influences the Response to Increasing Net Energy in Finishing Pigs. Transl. Anim. Sci. 2019, 3, 1349–1358. [Google Scholar] [CrossRef]

- IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Calvo Buendia, E., Tanabe, K., Kranjc, A., Baasansuren, J., Fukuda, M., Ngarize, S., Osako, A., Pyrozhenko, Y., Shermanau, P., Federici, S., Eds.; Intergovernmental Panel on Climate Change: Hayama, Japan, 2019. [Google Scholar]

- Hauschild, L.; Pomar, C.; Lovatto, P.A. Systematic Comparison of the Empirical and Factorial Methods Used to Estimate the Nutrient Requirements of Growing Pigs. Animal 2010, 4, 714–723. [Google Scholar] [CrossRef] [PubMed]

- dit Bailleul, P.J.; Bernier, J.F.; van Milgen, J.; Sauvant, D.; Pomar, C. The Utilization of Prediction Models to Optimize Farm Animal Production Systems: The Case of a Growing Pig Model. In Modelling Nutrient Utilization in Farm Animals; CABI Publishing: Wallingford, UK, 2000; pp. 379–392. [Google Scholar] [CrossRef]

- Niemi, J.K.; Sevón-Aimonen, M.L.; Pietola, K.; Stalder, K.J. The Value of Precision Feeding Technologies for Grow–Finish Swine. Livest. Sci. 2010, 129, 13–23. [Google Scholar] [CrossRef]

- Pomar, C.; Pomar, J.; Dubeau, F.; Joannopoulos, E.; Dussault, J.P. The Impact of Daily Multiphase Feeding on Animal Performance, Body Composition, Nitrogen and Phosphorus Excretions, and Feed Costs in Growing-Finishing Pigs. Animal 2014, 8, 704–713. [Google Scholar] [CrossRef]

- Aymerich, P.; Soldevila, C.; Bonet, J.; Gasa, J.; Coma, J.; Solà-Oriol, D. Increasing Dietary Lysine Impacts Differently Growth Performance of Growing Pigs Sorted by Body Weight. Animals 2020, 10, 1032. [Google Scholar] [CrossRef]

- Henry, Y. Dietary Factors Involved in Feed Intake Regulation in Growing Pigs: A Review. Livest. Prod. Sci. 1985, 12, 339–354. [Google Scholar] [CrossRef]

- Menegat, M.B.; Dritz, S.S.; Tokach, M.D.; Woodworth, J.C.; DeRouchey, J.M.; Goodband, R.D. A Review of Compensatory Growth Following Lysine Restriction in Grow-Finish Pigs1. Transl. Anim. Sci. 2020, 4, 531–547. [Google Scholar] [CrossRef]

- Beaulieu, A.D.; Williams, N.H.; Patience, J.F. Response to Dietary Digestible Energy Concentration in Growing Pigs Fed Cereal Grain-Based Diets1. J. Anim. Sci. 2009, 87, 965–976. [Google Scholar] [CrossRef] [PubMed]

- Daza, A.; Rodriguez, I.; Ovejero, I.; López-Bote, C.J. Effect on Pig Performance of Feed Restriction during the Growth Period. Span. J. Agric. Res. 2003, 1, 3–8. [Google Scholar] [CrossRef]

- Canh, T.T.; Sutton, A.L.; Aarnink, A.J.; Verstegen, M.W.; Schrama, J.W.; Bakker, G.C. Dietary Carbohydrates Alter the Fecal Composition and PH and the Ammonia Emission from Slurry of Growing Pigs. J. Anim. Sci. 1998, 76, 1887. [Google Scholar] [CrossRef]

- Lashkari, S.; Dalby, F.R.; Krogh, U.; Sattarova, E.; Børsting, C.F. Estimating the Influence of Dietary Composition and Management on Nutrient Intake and Excretion and Methane Emission in Different Pig Categories. PLoS ONE 2025, 20, e0323024. [Google Scholar] [CrossRef]

- Møller, H.B.; Sommer, S.G.; Ahring, B.K. Biological Degradation and Greenhouse Gas Emissions during Pre-Storage of Liquid Animal Manure. J. Environ. Qual. 2004, 33, 27–36. [Google Scholar] [CrossRef]

- Dalby, F.R.; Hafner, S.D.; Petersen, S.O.; VanderZaag, A.C.; Habtewold, J.; Dunfield, K.; Chantigny, M.H.; Sommer, S.G. Understanding Methane Emission from Stored Animal Manure: A Review to Guide Model Development. J. Environ. Qual. 2021, 50, 817–835. [Google Scholar] [CrossRef]

- Andretta, I.; Pomar, C.; Rivest, J.; Pomar, J.; Radünz, J. Precision Feeding Can Significantly Reduce Lysine Intake and Nitrogen Excretion without Compromising the Performance of Growing Pigs. Animal 2016, 10, 1137–1147. [Google Scholar] [CrossRef] [PubMed]

| Treatment | Number of Diets | Duration Pre-Growing | Duration Growing | Duration Finishing |

|---|---|---|---|---|

| Conventional (C) | 3 | 21 days Pre-grower feed | 56 days Grower feed | 20 days Finisher feed |

| Blend feeding (BF) | 2 diets mixed weekly | Pre-grower and a low-nutrient-density finisher feed mixed weekly according to lysine requirements | ||

| Ingredients (%) | Conventional (C) | Blend Feeding (BF) | |||

|---|---|---|---|---|---|

| Pre-Grower | Grower | Finisher | Pre-Grower | Finisher-BF | |

| Wheat | 35.0 | 37.5 | 37.5 | 35.0 | 20.0 |

| Barley | 30.0 | 25.0 | 25.0 | 30.0 | 30.0 |

| Soybean meal 47 | 13.3 | 11.4 | 5.6 | 13.3 | - |

| Cookie flour | 8.16 | 4.60 | 7.70 | 8.16 | 5.76 |

| Maize | 7.00 | 17.6 | 16.6 | 7.00 | 20.0 |

| Wheat middling | - | - | - | - | 10.0 |

| Sunflower meal 28 | - | - | - | - | 6.00 |

| Rapeseed meal | 3.00 | 1.25 | 5.00 | 3.00 | 5.30 |

| Animal fat | 1.03 | 0.250 | 0.250 | 1.03 | 0.500 |

| Salt | 0.500 | 0.500 | 0.500 | 0.500 | 0.400 |

| Mineral–vitamin premix 1 | 0.500 | 0.500 | 0.500 | 0.500 | - |

| L-lysine | 0.440 | 0.430 | 0.420 | 0.440 | 0.400 |

| Organic acid mix 1 | 0.300 | - | - | 0.300 | - |

| Liquid methionine | 0.220 | 0.200 | 0.160 | 0.220 | - |

| Monocalcium phosphate | 0.210 | 0.200 | 0.050 | 0.210 | 0.200 |

| Sodium bicarbonate | - | - | - | - | 0.200 |

| L-threonine | 0.190 | 0.180 | 0.160 | 0.190 | 0.070 |

| Calcium carbonate | 0.160 | 0.350 | 0.280 | 0.160 | 0.760 |

| Choline chloride 75% | - | - | - | - | 0.020 |

| Mineral mix 1 | - | - | 0.200 | - | - |

| Mineral–vitamin finisher premix 1 | - | - | - | - | 0.400 |

| Nutrients (%) | Conventional (C) | Blend Feeding (BF) | |||

|---|---|---|---|---|---|

| Pre-Grower | Grower | Finisher | Pre-Grower | Finisher-BF | |

| Net energy, kcal/kg | 2450 | 2450 | 2450 | 2450 | 2315 |

| Dry matter | 89.3 | 89.0 | 89.1 | 89.3 | 89.0 |

| Crude protein | 16.5 | 15.1 | 14.0 | 16.5 | 13.0 |

| Crude fat | 3.11 | 2.28 | 2.50 | 3.11 | 3.06 |

| Crude fibre | 3.59 | 3.22 | 3.47 | 3.59 | 5.56 |

| Starch | 47.0 | 50.6 | 51.4 | 47.0 | 46.0 |

| Crude ash | 4.00 | 3.77 | 3.67 | 4.00 | 4.43 |

| Neutral detergent fibre | 11.8 | 11.2 | 11.8 | 11.8 | 17.0 |

| Calcium | 0.360 | 0.410 | 0.440 | 0.360 | 0.520 |

| Phosphorus | 0.400 | 0.370 | 0.350 | 0.400 | 0.460 |

| Digestible Phosphorus | 0.290 | 0.280 | 0.250 | 0.290 | 0.220 |

| Magnesium | 0.150 | 0.140 | 0.140 | 0.150 | 0.150 |

| Sodium | 0.260 | 0.240 | 0.260 | 0.260 | 0.250 |

| Potassium | 0.660 | 0.600 | 0.530 | 0.660 | 0.560 |

| Chlorine | 0.530 | 0.500 | 0.520 | 0.530 | 0.430 |

| Lysine SID | 0.947 | 0.866 | 0.766 | 0.947 | 0.670 |

| Methionine SID | 0.311 | 0.286 | 0.259 | 0.311 | 0.193 |

| Methionine + Cysteine SID | 0.571 | 0.528 | 0.492 | 0.571 | 0.413 |

| Threonine SID | 0.651 | 0.597 | 0.532 | 0.651 | 0.407 |

| Tryptophane SID | 0.168 | 0.150 | 0.133 | 0.168 | 0.121 |

| Isoleucine SID | 0.543 | 0.494 | 0.430 | 0.543 | 0.373 |

| Valine SID | 0.640 | 0.585 | 0.525 | 0.640 | 0.483 |

| Day of Age/Day of Trial | Light Pigs | Heavy Pigs | ||

|---|---|---|---|---|

| Pre-Grower 1 | Finisher-BF 1 | Pre-Grower 1 | Finisher-BF 1 | |

| 63/1 | 100 | 0 | 100 | 0 |

| 70/8 | 100 | 0 | 100 | 0 |

| 77/15 | 100 | 0 | 91 | 9 |

| 84/22 | 93 | 7 | 85 | 15 |

| 91/29 | 90 | 10 | 75 | 25 |

| 98/36 | 81 | 19 | 63 | 37 |

| 105/43 | 70 | 30 | 54 | 46 |

| 112/50 | 62 | 38 | 46 | 54 |

| 119/57 | 56 | 44 | 39 | 61 |

| 126/64 | 50 | 50 | 33 | 67 |

| 133/71 | 45 | 55 | 27 | 73 |

| 140/78 | 33 | 67 | 15 | 85 |

| 147/85 | 30 | 70 | 10 | 90 |

| 154/92 | 27 | 73 | 4 | 96 |

| Variable | Feeding Strategy | BW Block | SEM | p-Value | ||||

|---|---|---|---|---|---|---|---|---|

| Conventional (C) | Blend Feeding (BF) | Heavy | Light | Strategy | BW Block | Strategy × BW Block | ||

| Day 63–84 | ||||||||

| BW d63, kg | 23.1 | 23.1 | 25.2 | 21.0 | 0.304 | 0.992 | <0.001 | 0.367 |

| ADG, kg/d | 0.588 | 0.584 | 0.621 | 0.551 | 0.018 | 0.813 | 0.024 | 0.909 |

| ADFI, kg/d | 1.13 | 1.14 | 1.18 | 1.08 | 0.030 | 0.656 | 0.081 | 0.468 |

| FCR, kg/kg | 1.95 | 1.95 | 1.91 | 2.00 | 0.028 | 0.995 | 0.090 | 0.966 |

| BW d84, kg | 35.5 | 35.4 | 36.2 | 34.7 | 0.376 | 0.756 | 0.022 | 0.989 |

| Day 84–140 | ||||||||

| ADG, kg/d | 0.825 | 0.821 | 0.804 | 0.841 | 0.012 | 0.736 | 0.086 | 0.168 |

| ADFI, kg/d | 1.78 | 1.79 | 1.76 | 1.80 | 0.038 | 0.564 | 0.307 | 0.978 |

| FCR, kg/kg | 2.16 | 2.18 | 2.19 | 2.14 | 0.043 | 0.167 | 0.169 | 0.036 |

| BW d140, kg | 82.0 | 81.9 | 82.4 | 81.6 | 0.974 | 0.928 | 0.650 | 0.541 |

| Day 140–161 | ||||||||

| ADG, kg/d | 1.015 | 0.980 | 0.992 | 1.004 | 0.030 | 0.217 | 0.824 | 0.289 |

| ADFI, kg/d | 2.45 | 2.52 | 2.45 | 2.51 | 0.044 | 0.086 | 0.430 | 0.785 |

| FCR, kg/kg | 2.43 | 2.59 | 2.49 | 2.53 | 0.074 | 0.023 | 0.762 | 0.260 |

| BW d161, kg | 102 | 101 | 102 | 101 | 1.14 | 0.506 | 0.647 | 0.336 |

| Day 63–161 | ||||||||

| ADG, kg/d | 0.812 | 0.801 | 0.803 | 0.809 | 0.010 | 0.244 | 0.757 | 0.107 |

| ADFI, kg/d | 1.77 | 1.79 | 1.78 | 1.78 | 0.032 | 0.286 | 0.941 | 0.916 |

| FCR, kg/kg | 2.18 | 2.24 | 2.22 | 2.21 | 0.031 | 0.007 | 0.829 | 0.039 |

| Variable | Strategy | BW Block | SEM | p-Value | ||||

|---|---|---|---|---|---|---|---|---|

| Conventional (C) | Blend Feeding (BF) | Heavy | Light | Strategy | BW Block | Strategy × BW Block | ||

| Ingested N (kg/pig) | 4.10 | 4.07 | 4.16 | 4.01 | 0.0248 | 0.306 | <0.001 | 0.044 |

| Excreted N (kg/pig) | 1.96 | 1.96 | 2.03 | 1.90 | 0.0230 | 0.858 | <0.001 | 0.057 |

| N efficiency 1 (kg/kg) | 0.513 | 0.510 | 0.505 | 0.518 | 0.005 | 0.158 | 0.083 | 0.414 |

| Sampling | Parameter | Conventional (C) | Blend feeding (BF) | SEM | p-Value | |||

|---|---|---|---|---|---|---|---|---|

| Intermediate | Final | Intermediate | Final | Strategy | Time | |||

| Start of the test, 2 September. | DM (%FM) | 2.08 | 2.47 | 3.88 | 4.99 | 1.86 | 0.312 | 0.708 |

| OM (%DM) | 52.3 | 69.0 | 62.9 | 71.1 | 7.90 | 0.470 | 0.191 | |

| pH | 7.28 | 6.76 | 7.22 | 6.58 | 0.16 | 0.486 | 0.024 | |

| EC (mS/cm) | 22.8 | 16.6 | 23.7 | 17.0 | 3.50 | 0.869 | 0.140 | |

| TKN (mg/L) | 2298 | 2075 | 3177 | 3246 | 899 | 0.318 | 0.935 | |

| N-NH3 (mg/L) | 1884 | 1621 | 2363 | 2108 | 460 | 0.353 | 0.603 | |

| End of the test, 22 November. | DM (%FM) | 2.97 | 2.84 | 3.20 | 5.76 | 1.99 | 0.473 | 0.575 |

| OM (%DM) | 51.0 | 61.7 | 50.1 | 65.8 | 8.60 | 0.861 | 0.200 | |

| pH | 8.63 | 8.63 | 8.34 | 8.55 | 0.24 | 0.496 | 0.696 | |

| EC (mS/cm) | ND | ND | ND | ND | ND | ND | ND | |

| TKN (mg/L) | 888 | 1150 | 2711 | 1645 | 977 | 0.301 | 0.534 | |

| N-NH3 (mg/L) | 498 | 607 | 1360 | 982 | 516 | 0.297 | 0.662 | |

| Gas | Conventional (C) | Blend Feeding (BF) | SEM | p-Value | ||||

|---|---|---|---|---|---|---|---|---|

| Intermediate | Final | Intermediate | Final | Strategy | Time | Strategy × Time | ||

| NH3 (mg/m3 per hour) | 2.01 | 1.91 | 2.46 | 1.88 | 0.181 | 0.245 | 0.060 | 0.177 |

| CH4 (mg/m3 per hour) | 0.48 | 1.36 | 0.95 | 2.36 | 0.166 | <0.001 | <0.001 | 0.112 |

| CO2 (mg/m3 per hour) | 11.8 | 13.7 | 16.6 | 17.1 | 1.20 | 0.001 | 0.344 | 0.571 |

| Ratio | Conventional (C) | Blend Feeding (BF) | SEM | p-Value | ||||

|---|---|---|---|---|---|---|---|---|

| Intermediate | Final | Intermediate | Final | Strategy | Time | Strategy × Time | ||

| N-NH3e /N-NH3 slurry | 0.750 | 0.850 | 0.780 | 0.690 | 0.130 | 0.667 | 0.993 | 0.529 |

| CH4e/Theoretical MCF | 0.320 | 0.610 | 0.360 | 0.600 | 0.200 | 0.937 | 0.258 | 0.885 |

| Variable | Strategy | BW Block | SEM | p-Value | ||||

|---|---|---|---|---|---|---|---|---|

| Control (C) | Blend Feeding (BF) | Heavy | Light | Strategy | BW Block | Treat × BW Block | ||

| Low feed costs | ||||||||

| EUR/pig | 50.5 | 48.8 | 49.6 | 49.7 | 0.470 | 0.012 | 0.929 | 0.575 |

| High feed costs | ||||||||

| EUR/pig | 57.9 | 55.9 | 56.8 | 56.9 | 0.539 | 0.011 | 0.891 | 0.562 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montalvo, G.; Rodríguez, M.; Piñeiro, C.; Calvet, S.; Sanz, M.J.; Garcia-Rebollar, P. Precision Feeding on Pig Fattening Farms: Can Simplified Implementation Enhance Productivity and Reduce Pollutant Emissions? Agriculture 2025, 15, 1935. https://doi.org/10.3390/agriculture15181935

Montalvo G, Rodríguez M, Piñeiro C, Calvet S, Sanz MJ, Garcia-Rebollar P. Precision Feeding on Pig Fattening Farms: Can Simplified Implementation Enhance Productivity and Reduce Pollutant Emissions? Agriculture. 2025; 15(18):1935. https://doi.org/10.3390/agriculture15181935

Chicago/Turabian StyleMontalvo, Gema, María Rodríguez, Carlos Piñeiro, Salvador Calvet, María J. Sanz, and Paloma Garcia-Rebollar. 2025. "Precision Feeding on Pig Fattening Farms: Can Simplified Implementation Enhance Productivity and Reduce Pollutant Emissions?" Agriculture 15, no. 18: 1935. https://doi.org/10.3390/agriculture15181935

APA StyleMontalvo, G., Rodríguez, M., Piñeiro, C., Calvet, S., Sanz, M. J., & Garcia-Rebollar, P. (2025). Precision Feeding on Pig Fattening Farms: Can Simplified Implementation Enhance Productivity and Reduce Pollutant Emissions? Agriculture, 15(18), 1935. https://doi.org/10.3390/agriculture15181935