Research on the Design of an Omnidirectional Leveling System and Adaptive Sliding Mode Control for Tracked Agricultural Chassis in Hilly and Mountainous Terrain

Abstract

1. Introduction

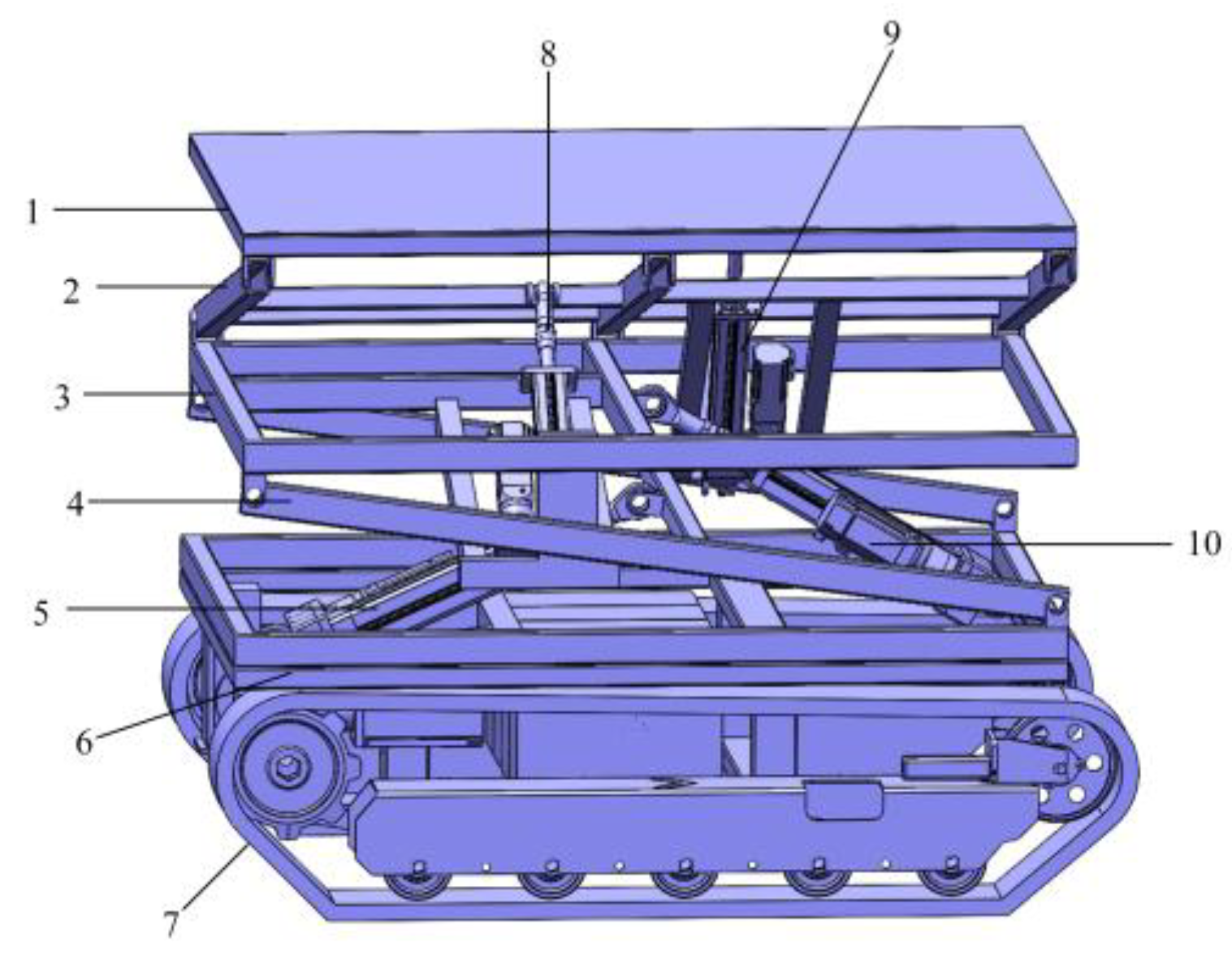

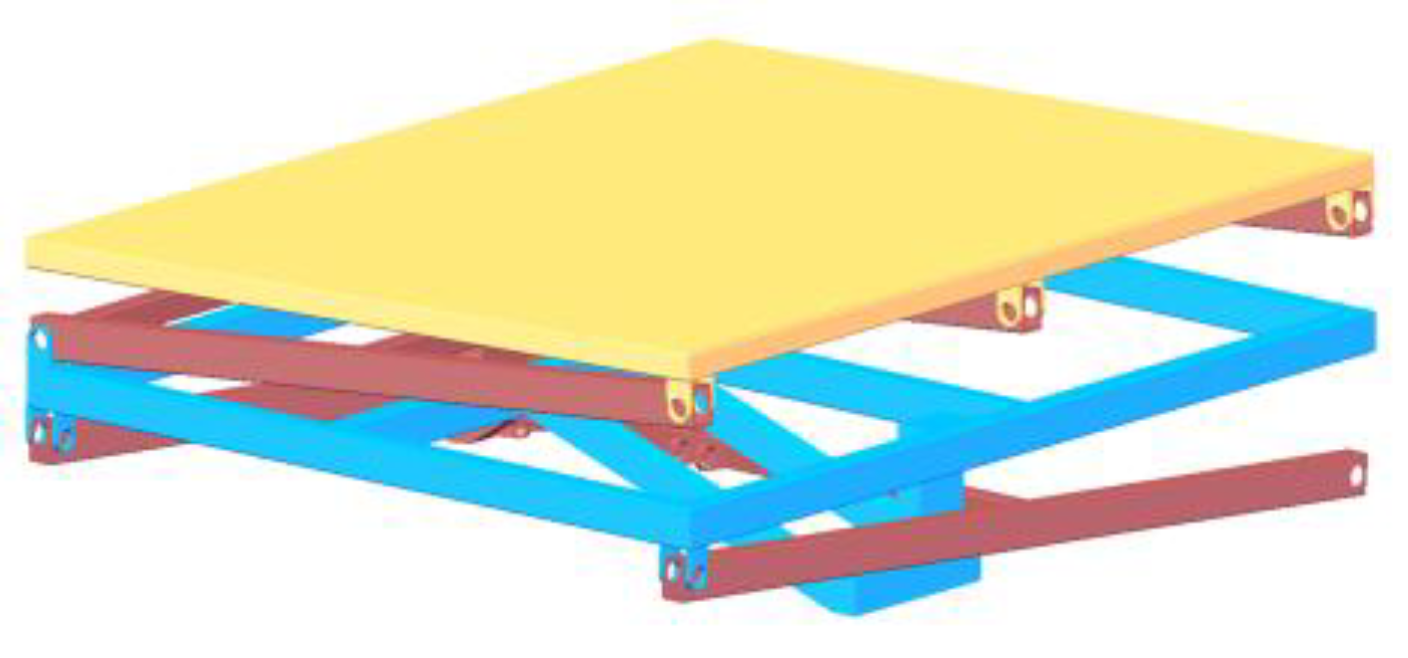

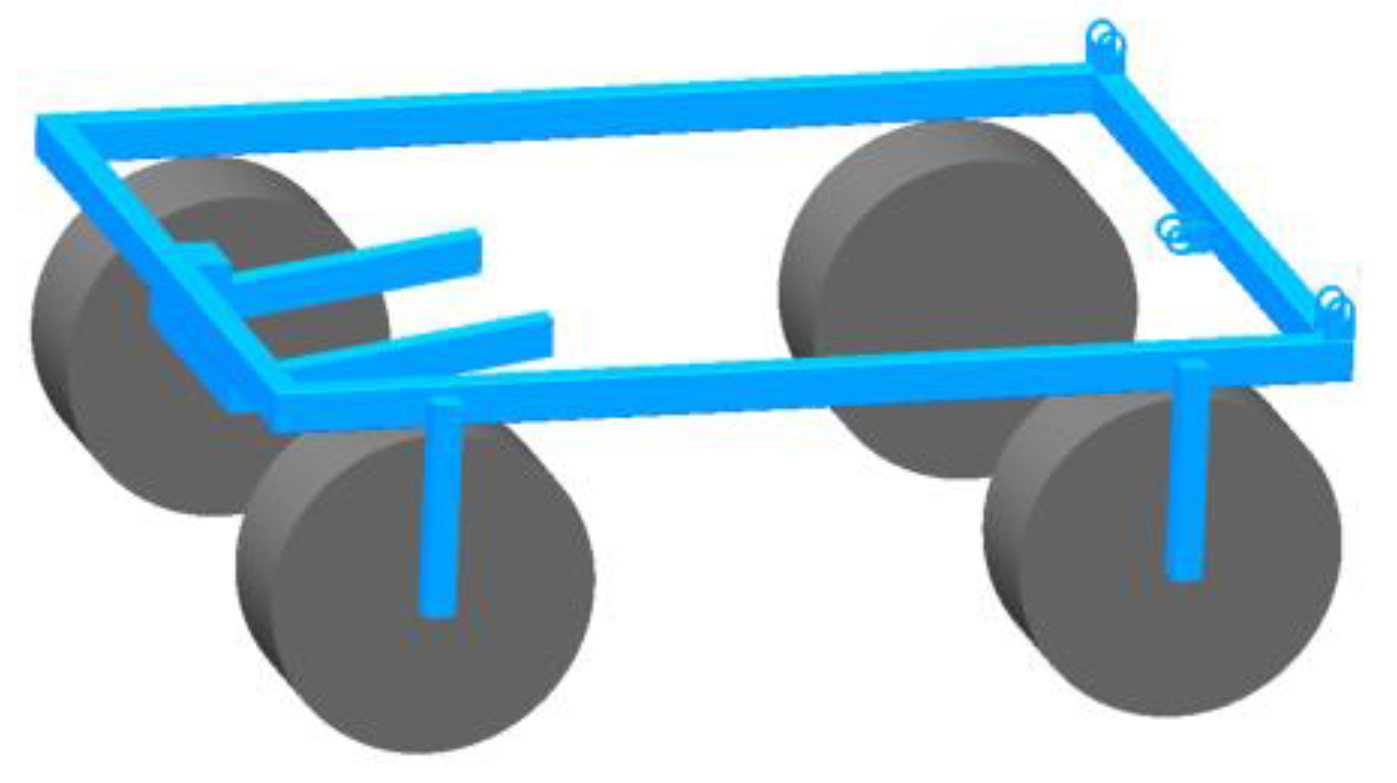

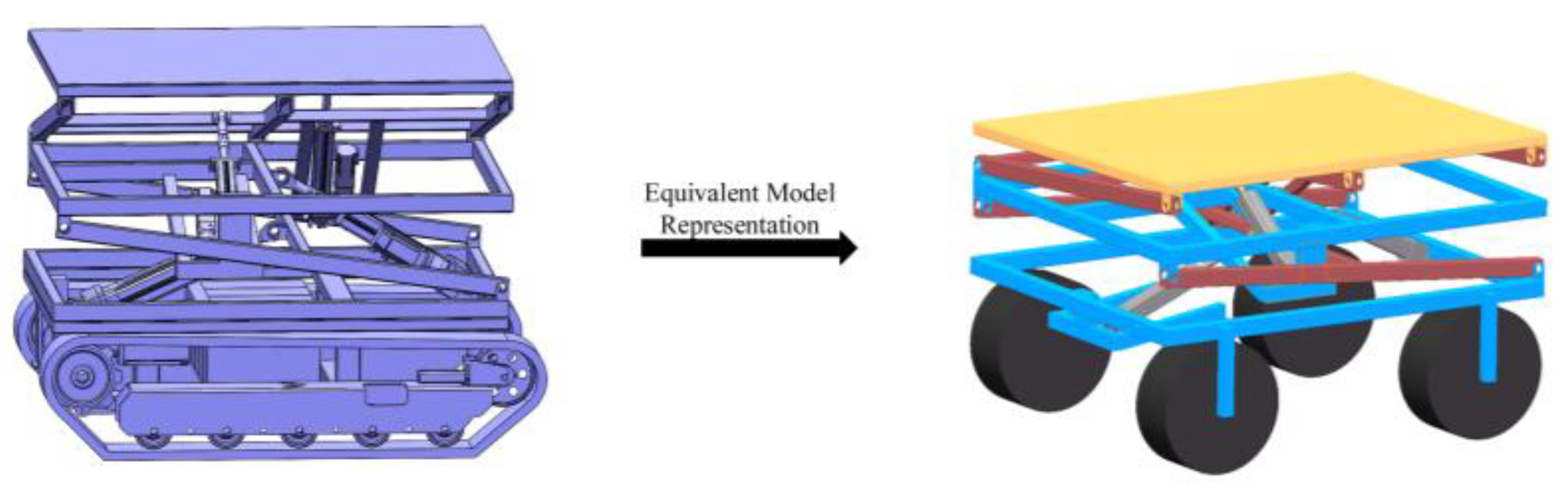

2. Design of an Omnidirectional Leveling System for Crawler-Type Agricultural Chassis

2.1. Design Requirements and Proposed Solutions

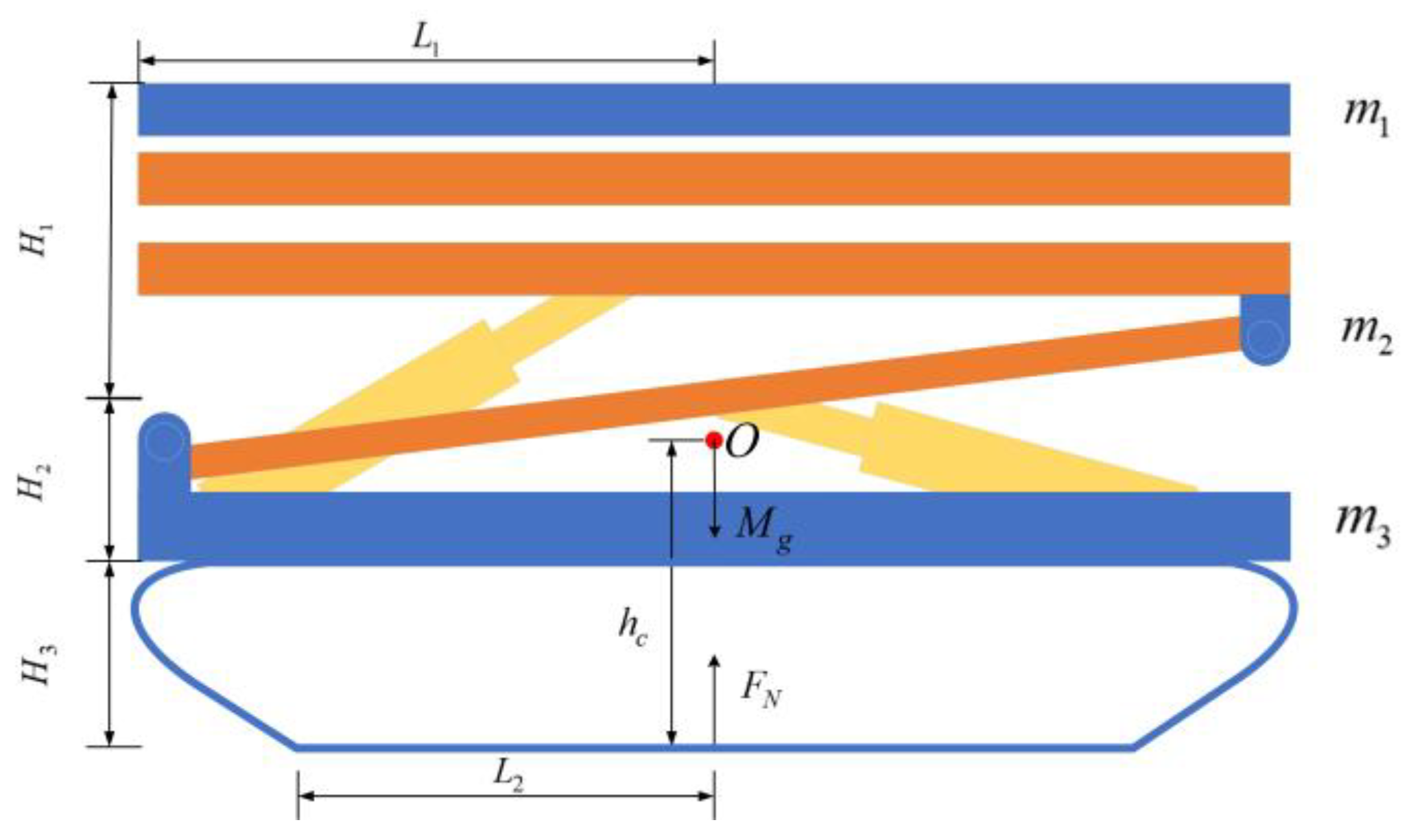

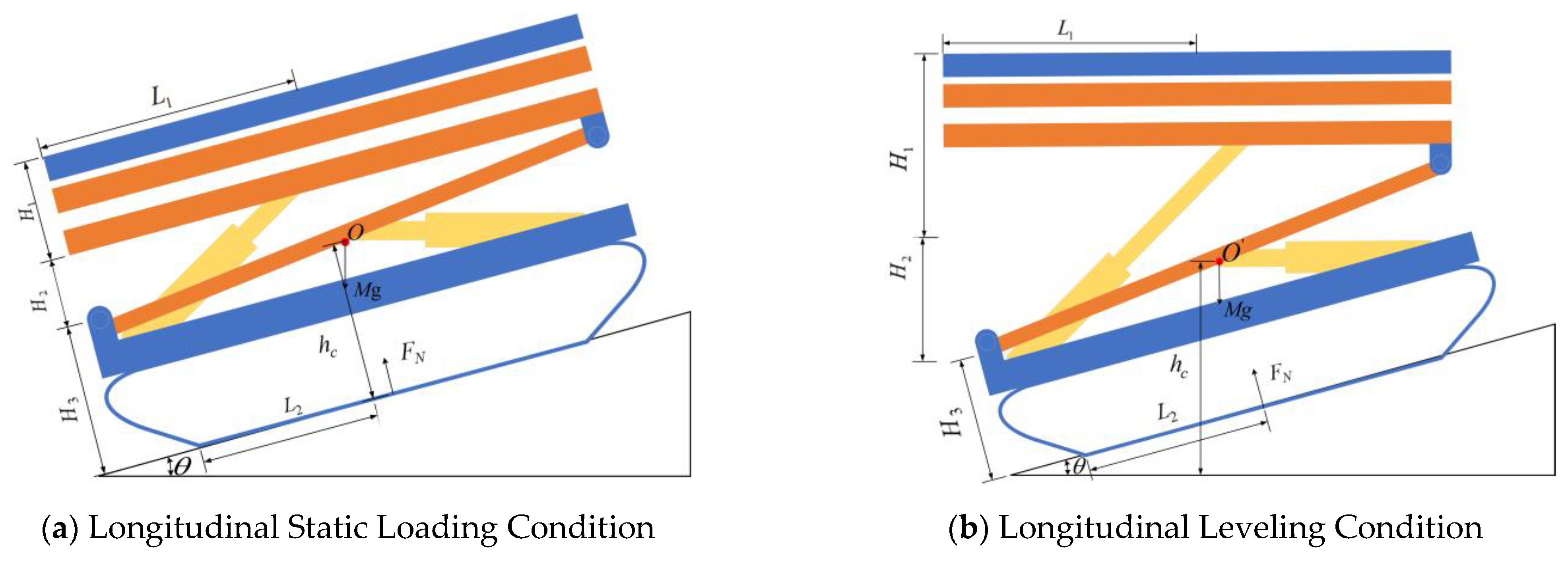

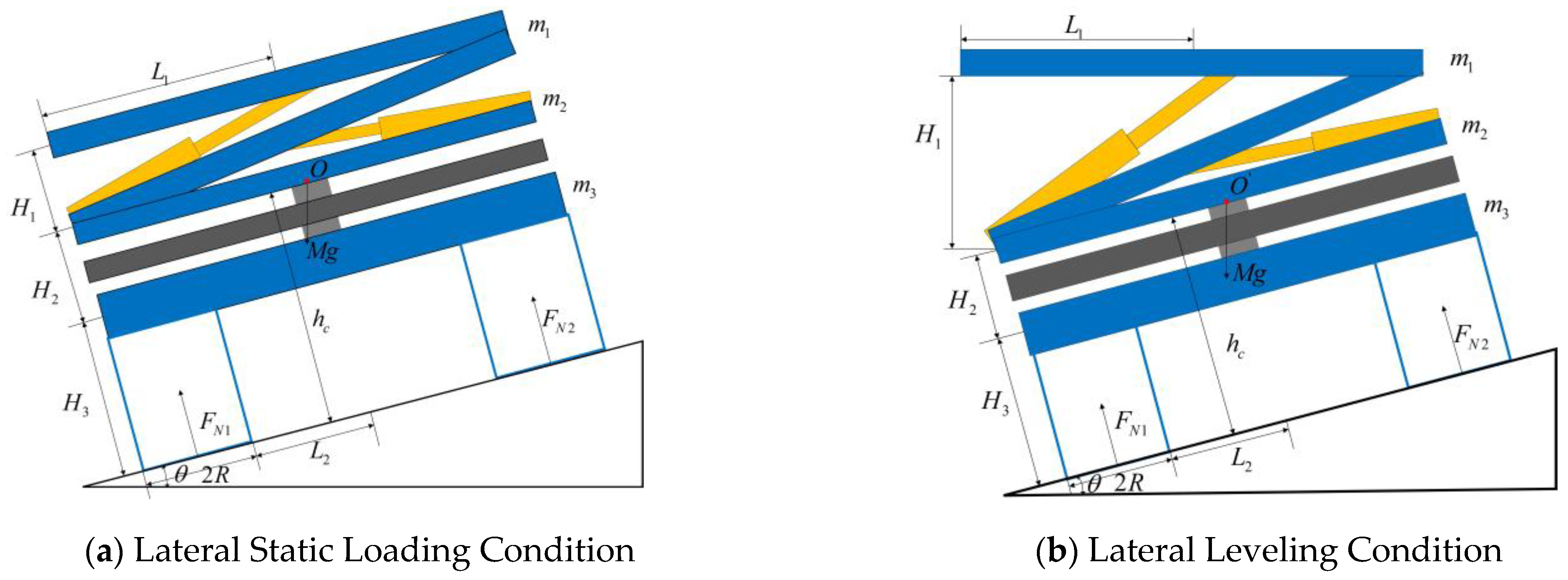

2.2. Structural Stability Analysis

2.2.1. Calculation of the Center of Gravity Position

2.2.2. Longitudinal Stability Analysis

2.2.3. Lateral Stability Analysis

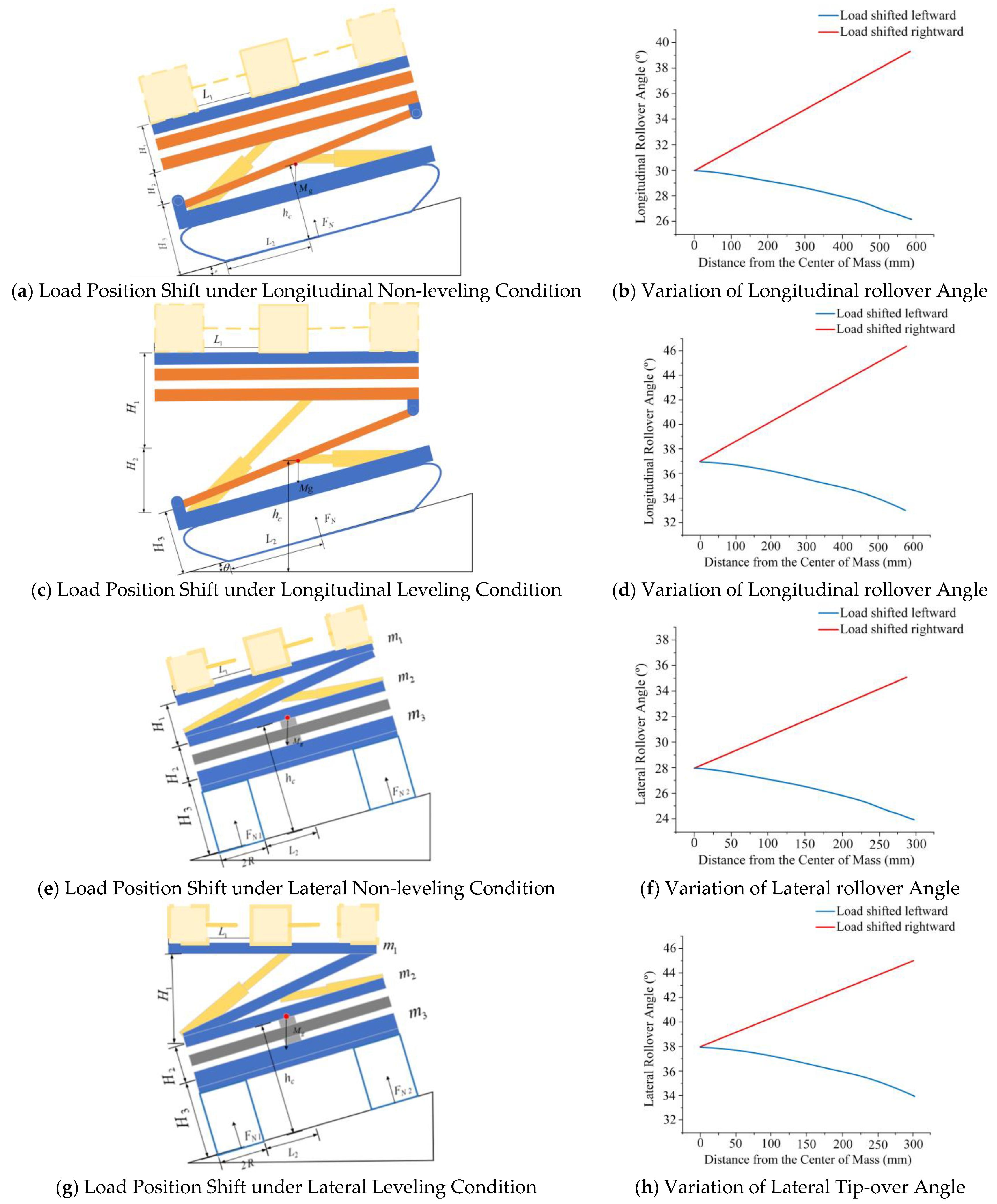

2.2.4. Load Stability Analysis

3. Design of Adaptive Sliding Mode Control Strategy

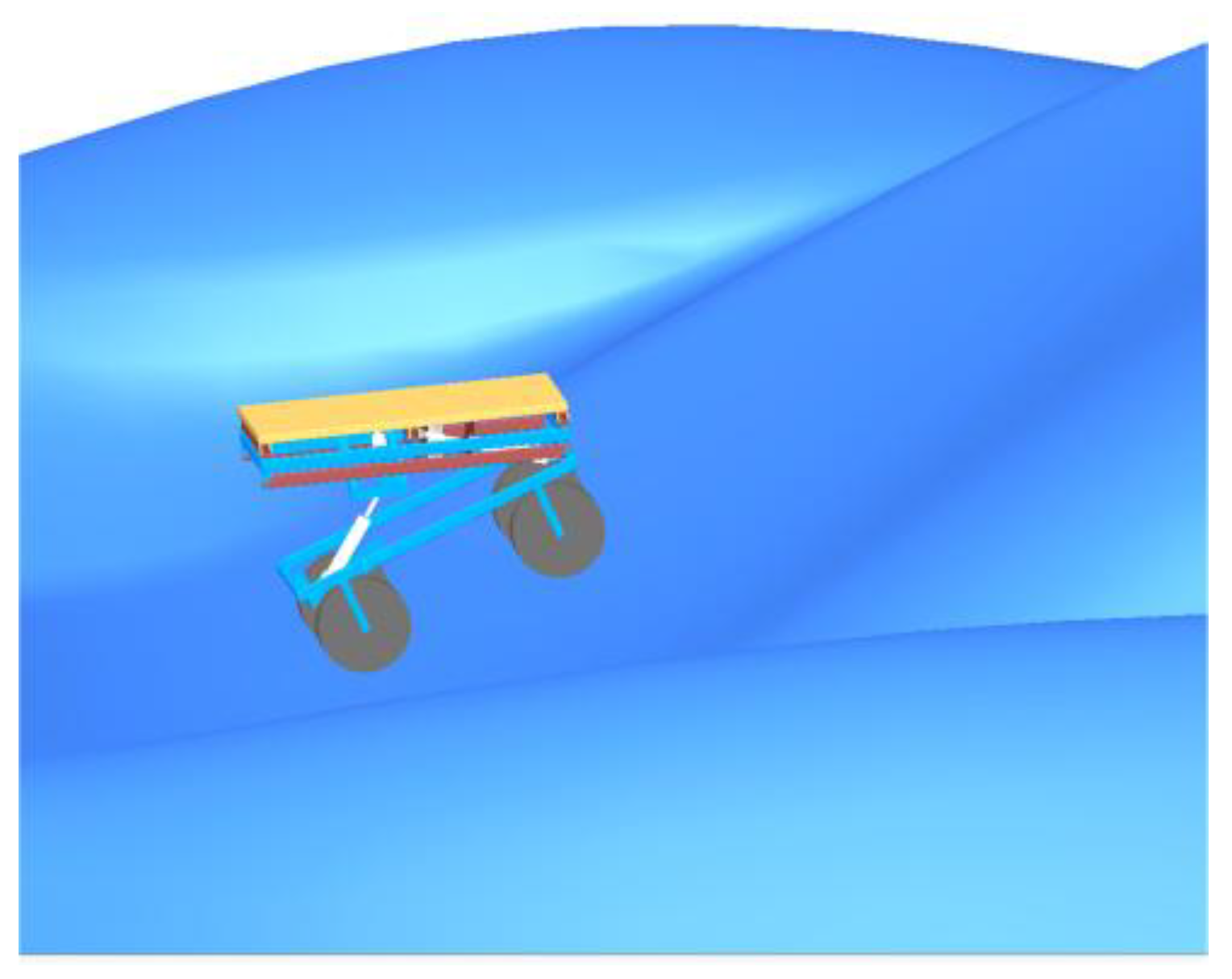

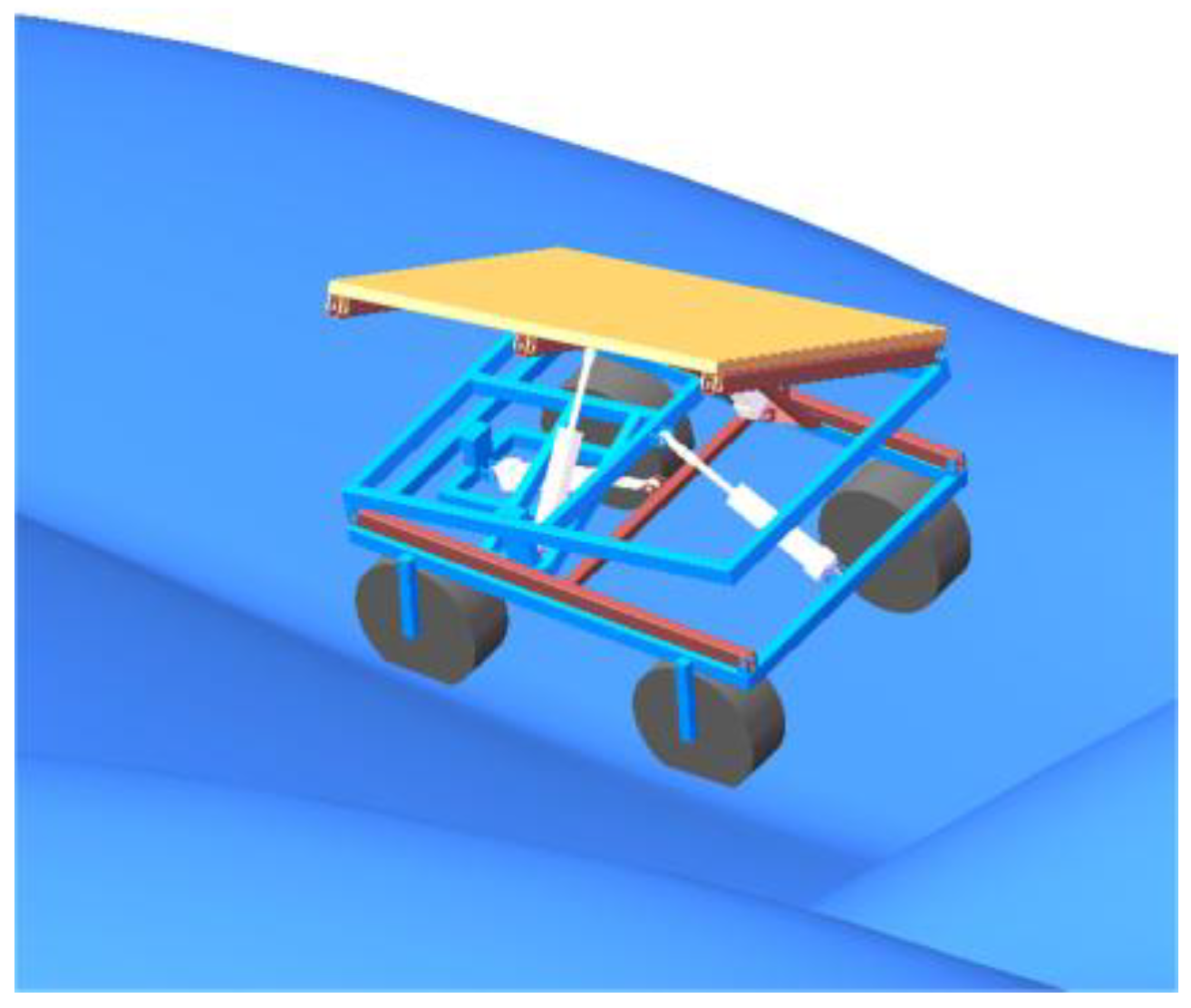

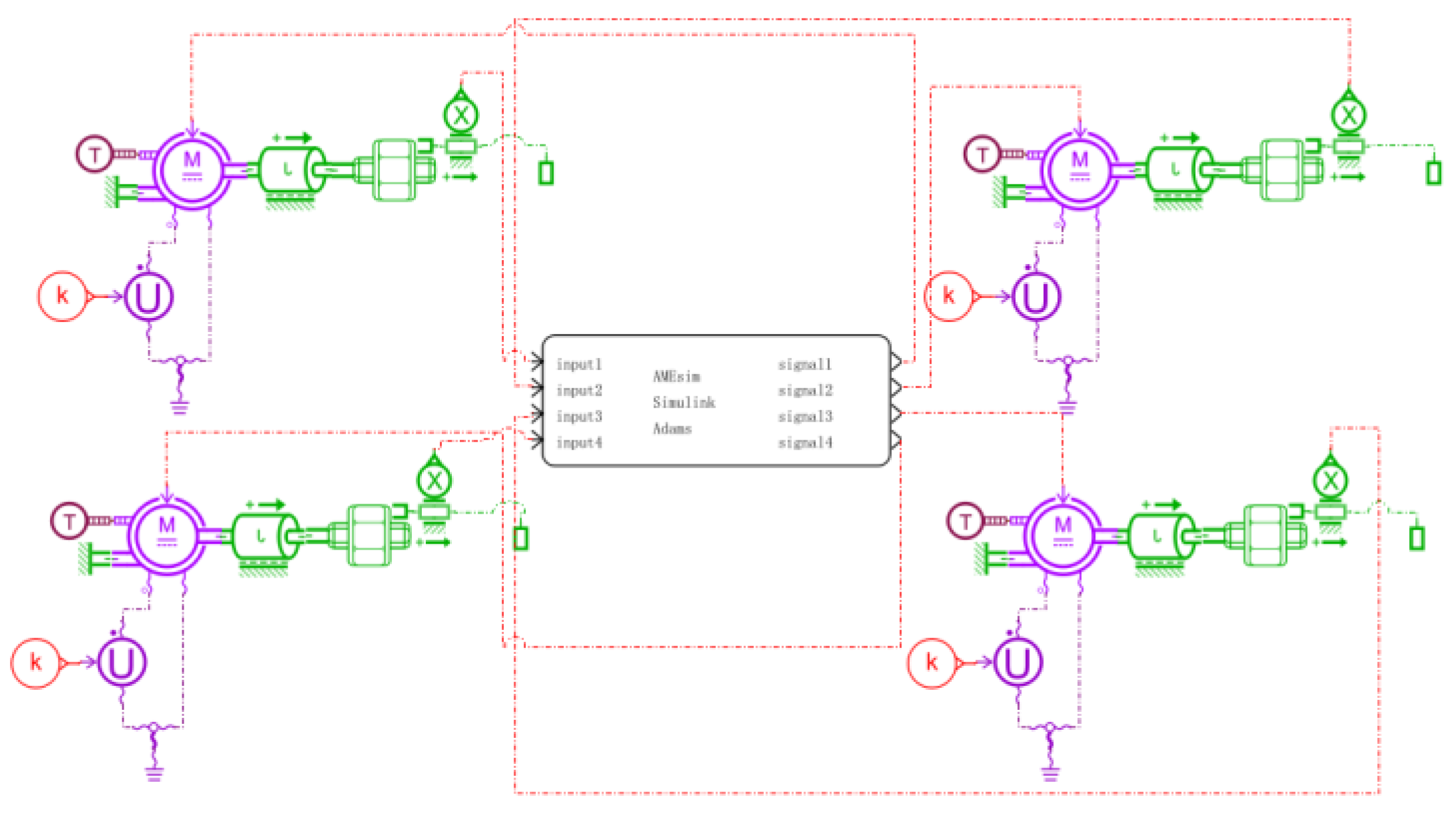

3.1. Virtual Prototype Model

3.1.1. Three-Dimensional Model of the Entire Machine

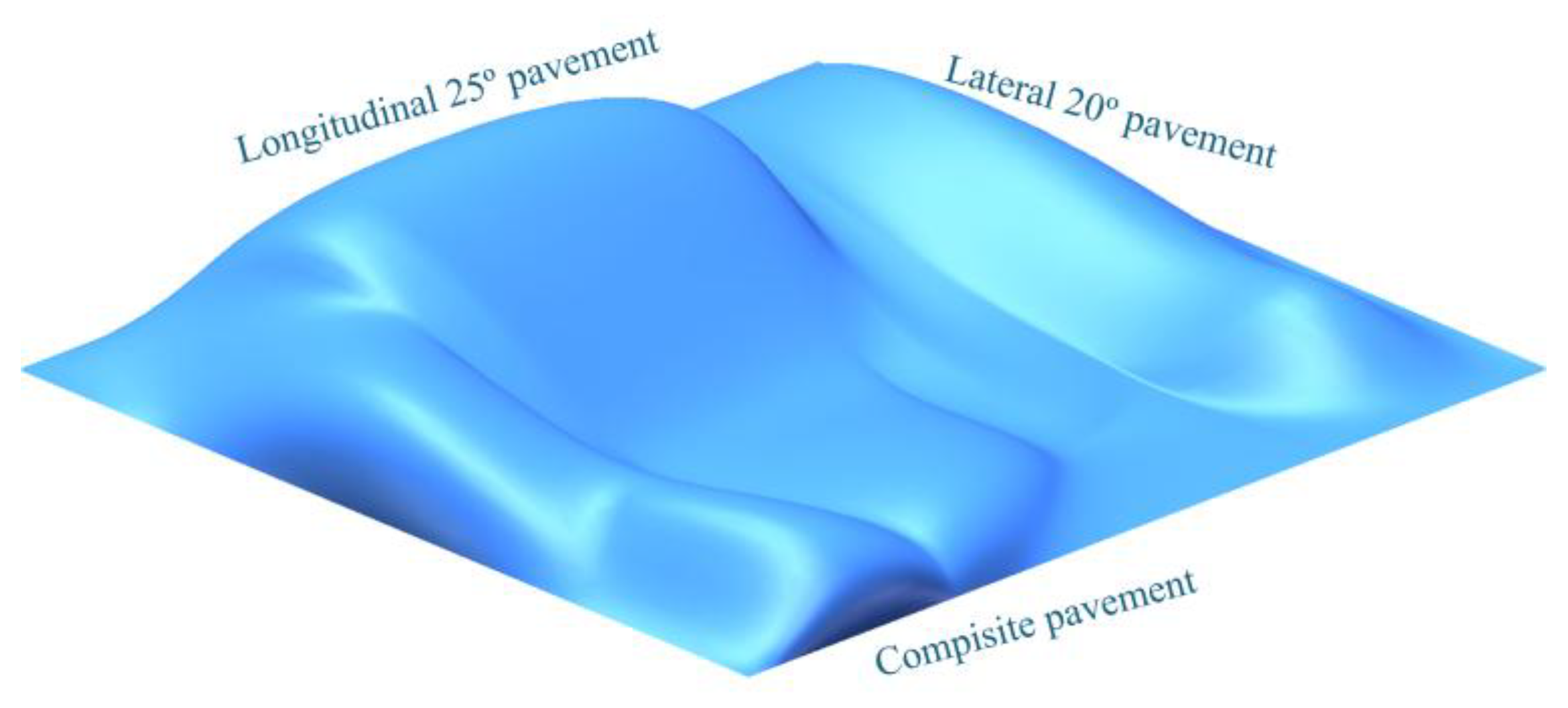

3.1.2. Hilly Road Surface Model

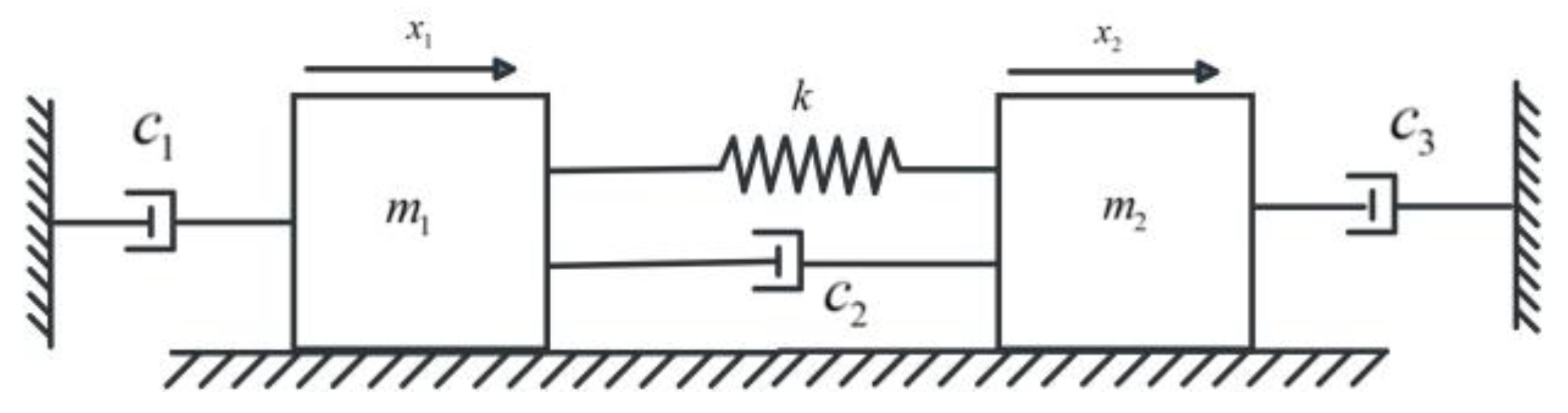

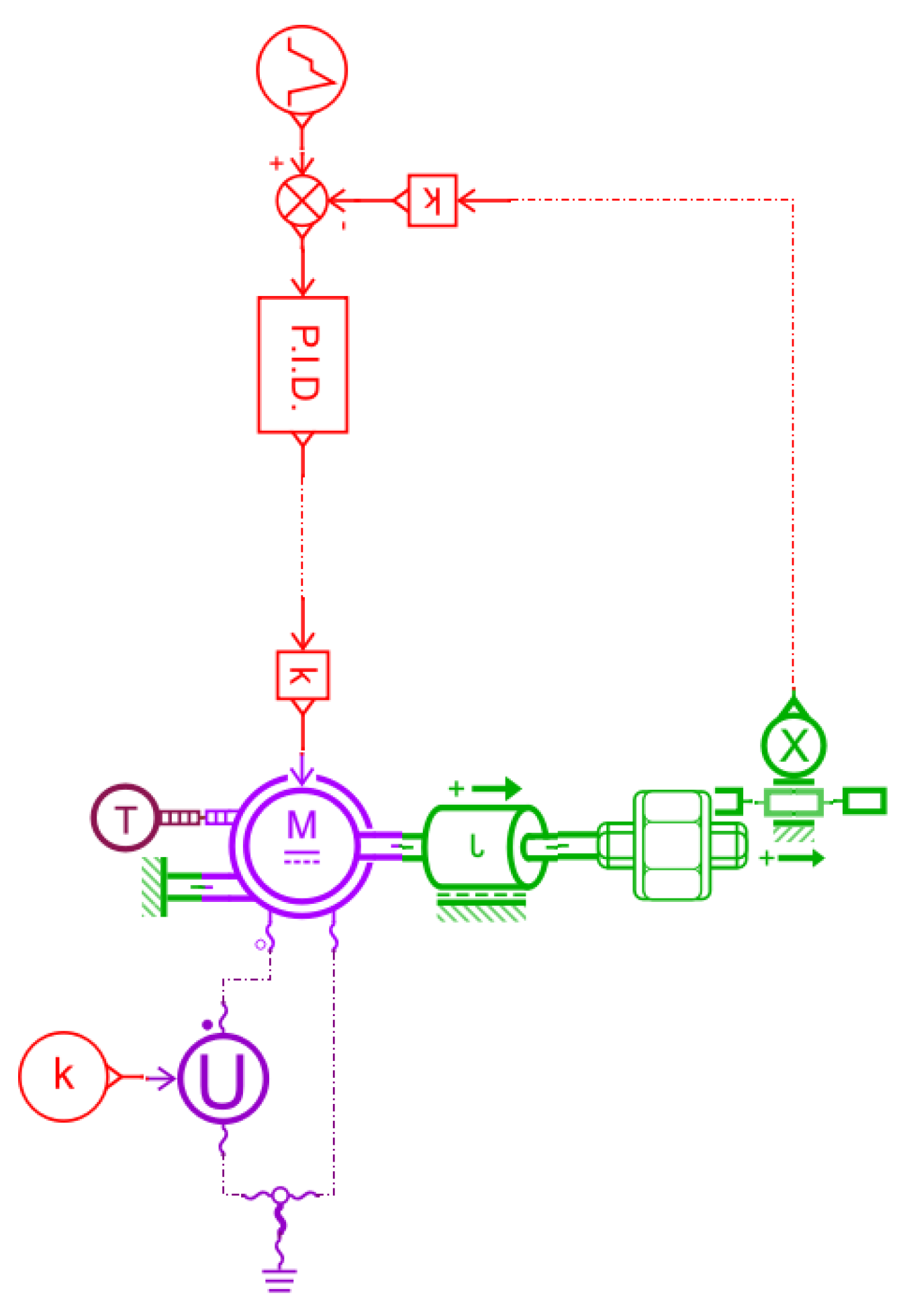

3.2. Mathematical Model for the Servo-Electric Cylinder

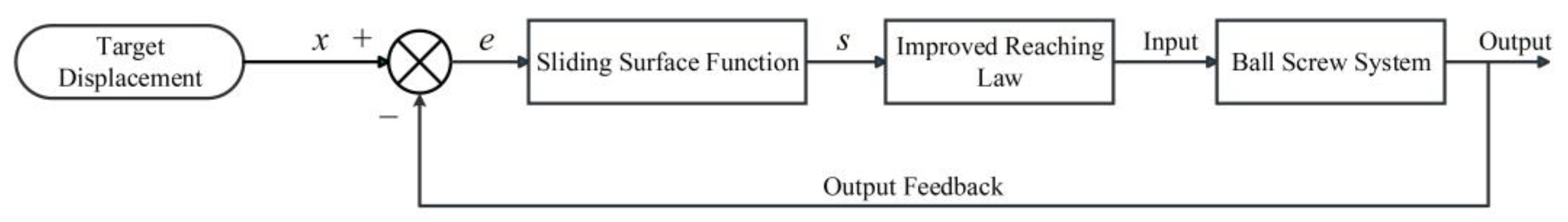

3.3. Design of an Adaptive Sliding Mode Control Strategy

3.3.1. Design of a Sliding Mode Controller

3.3.2. System Stability Verification

3.4. Performance Analysis and Validation

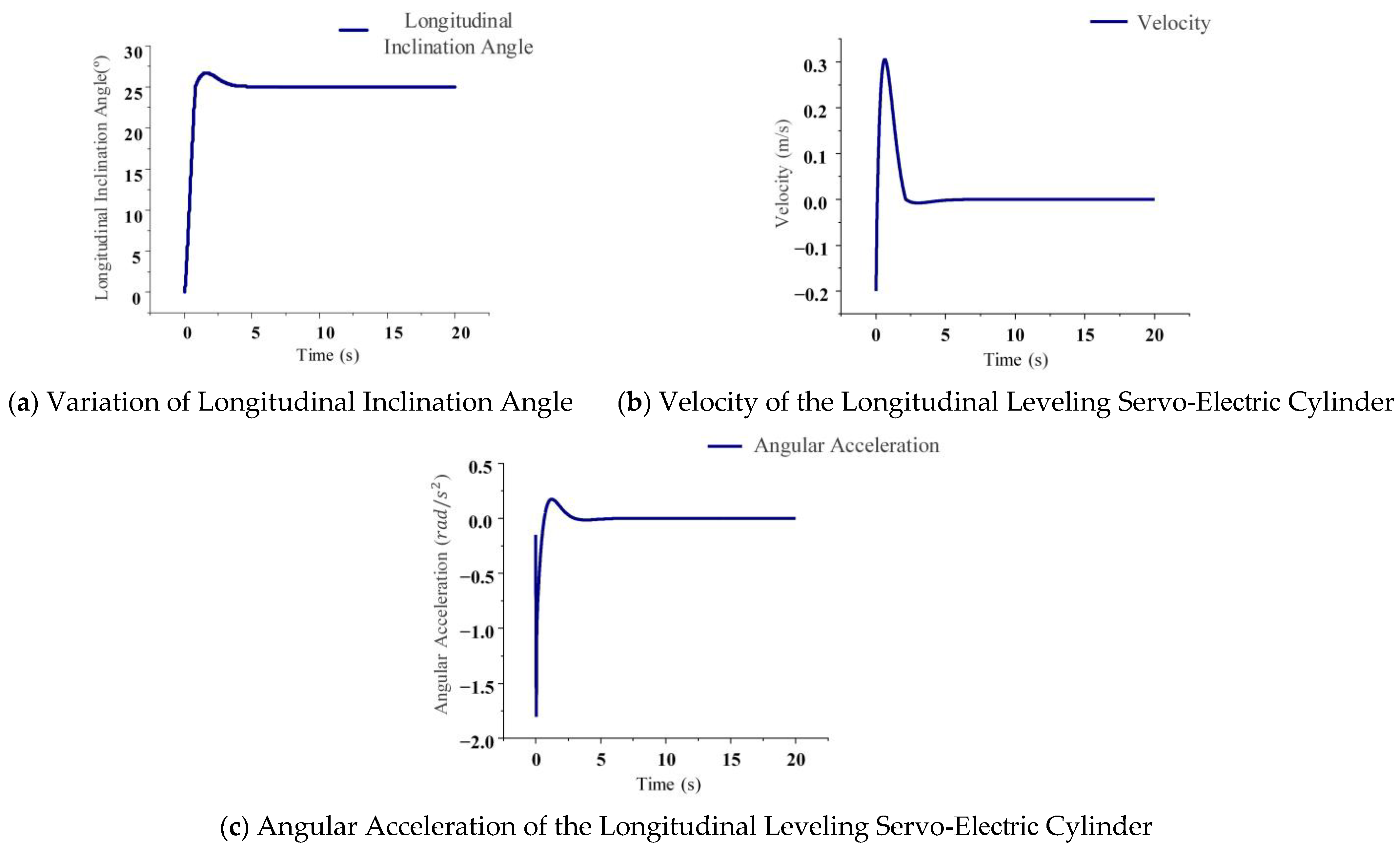

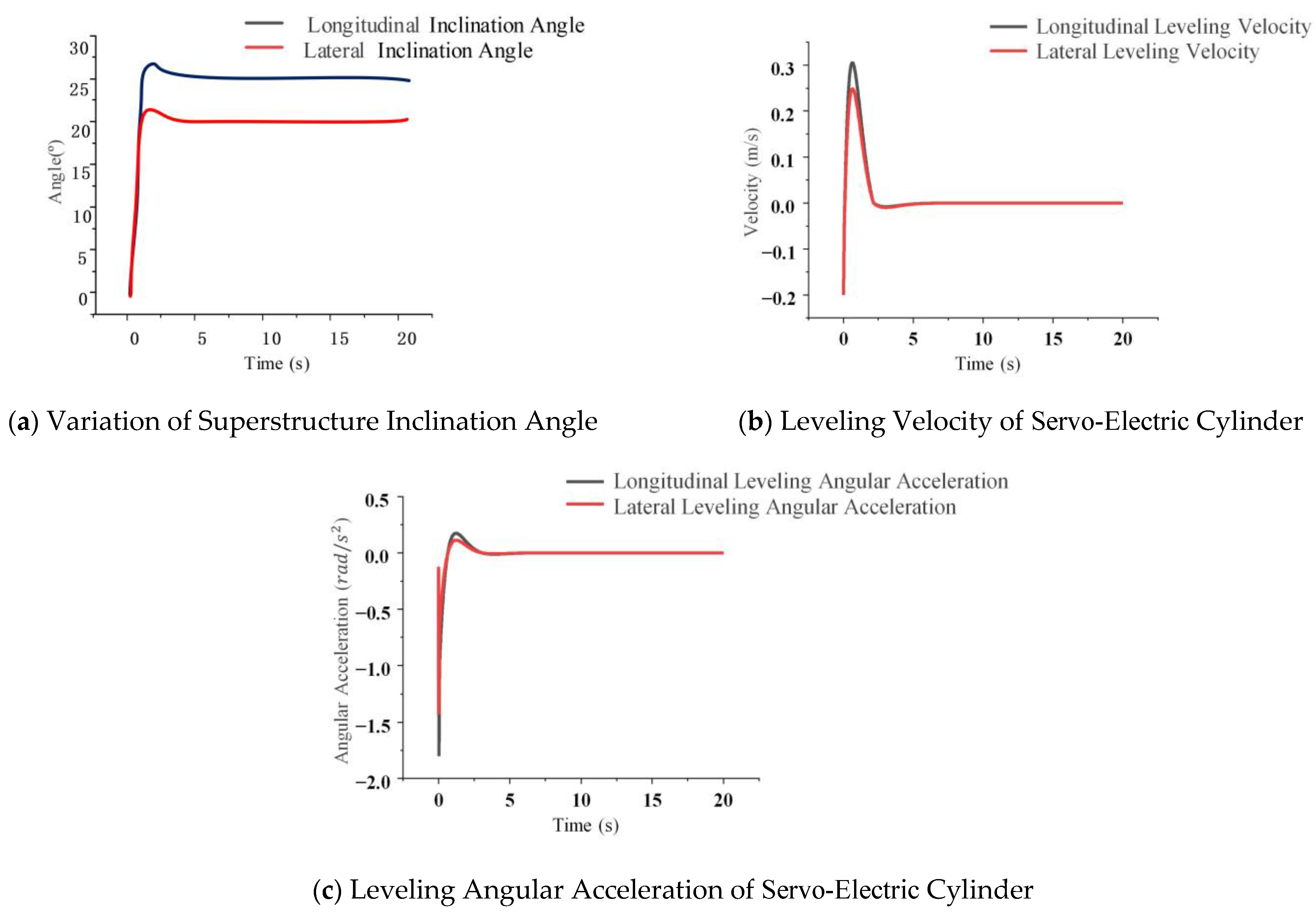

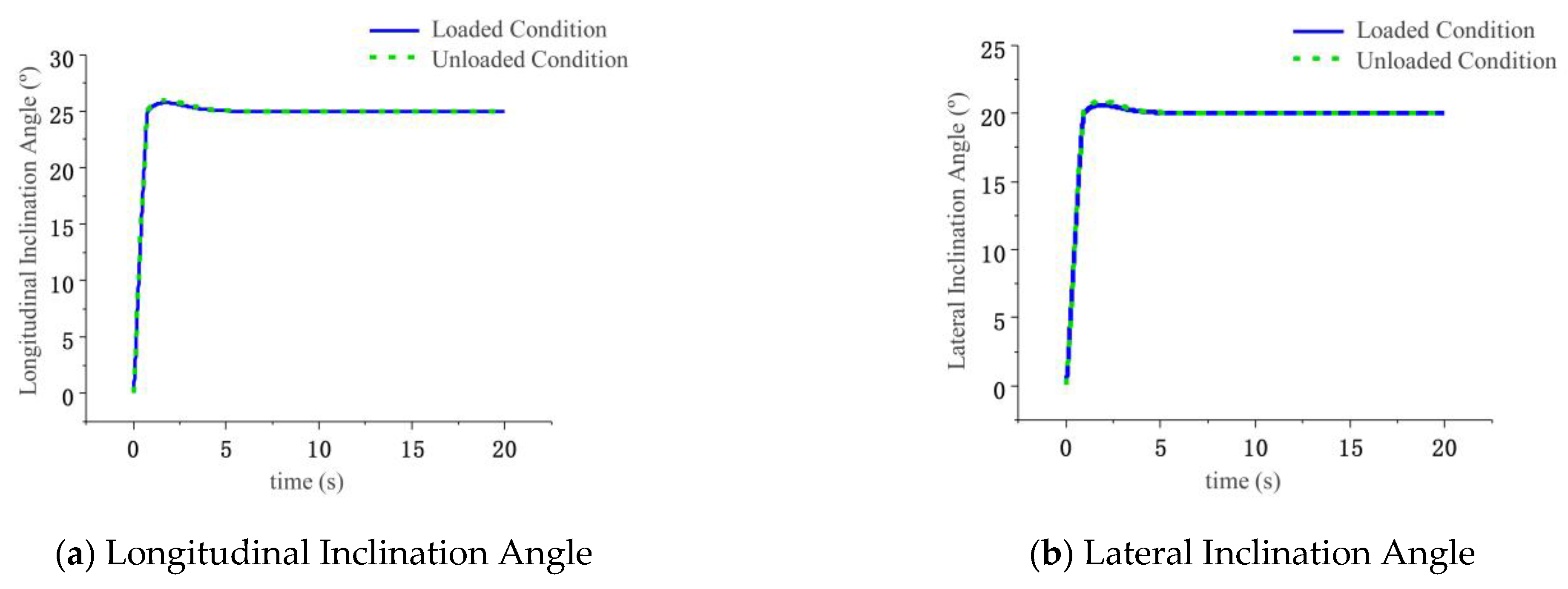

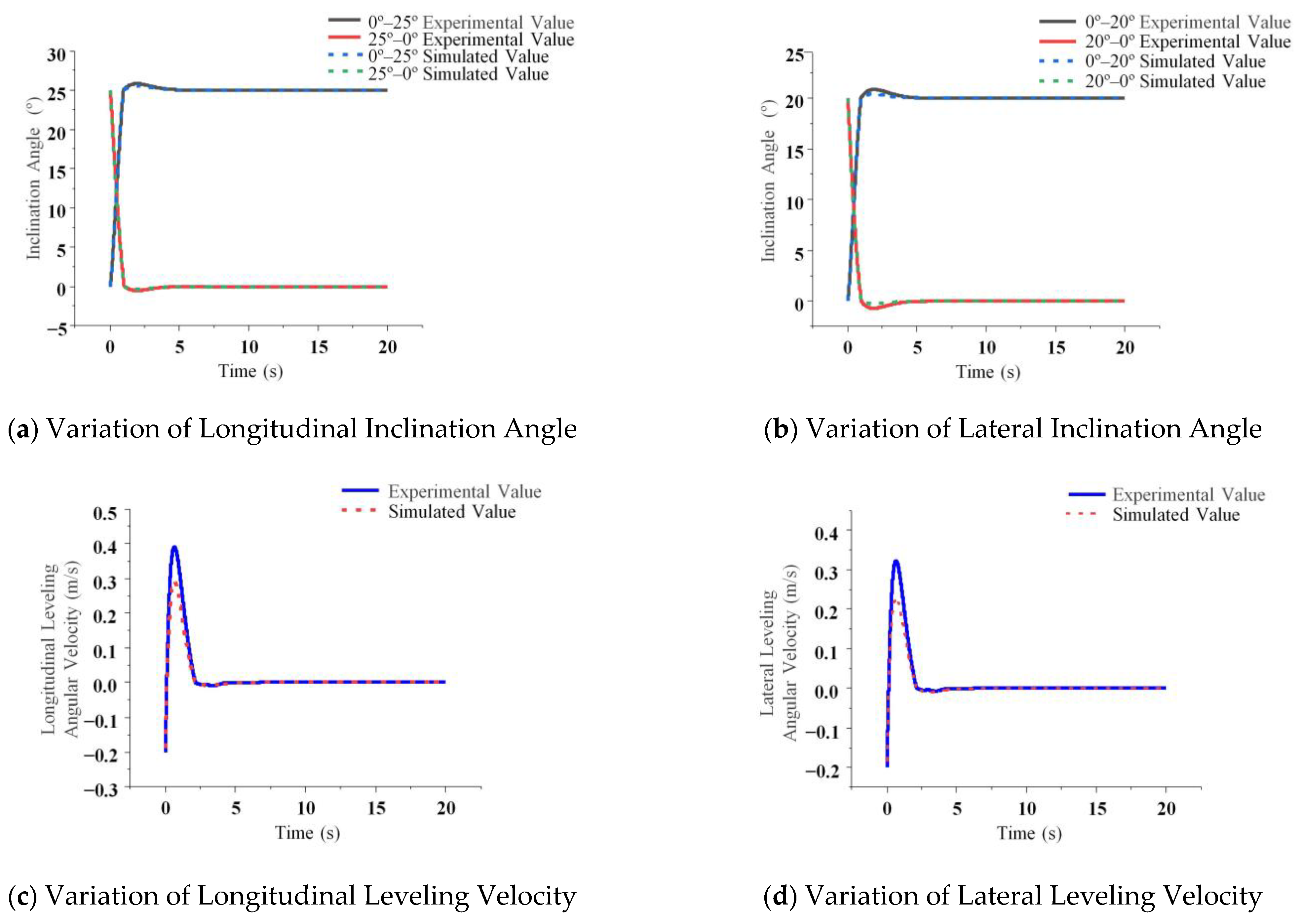

3.4.1. Verification of Omnidirectional Leveling Performance for Crawler-Type Agricultural Chassis

3.4.2. Comparative Performance Analysis of the Omnidirectional Leveling System for Tracked Agricultural Chassis

4. Experimental Verification

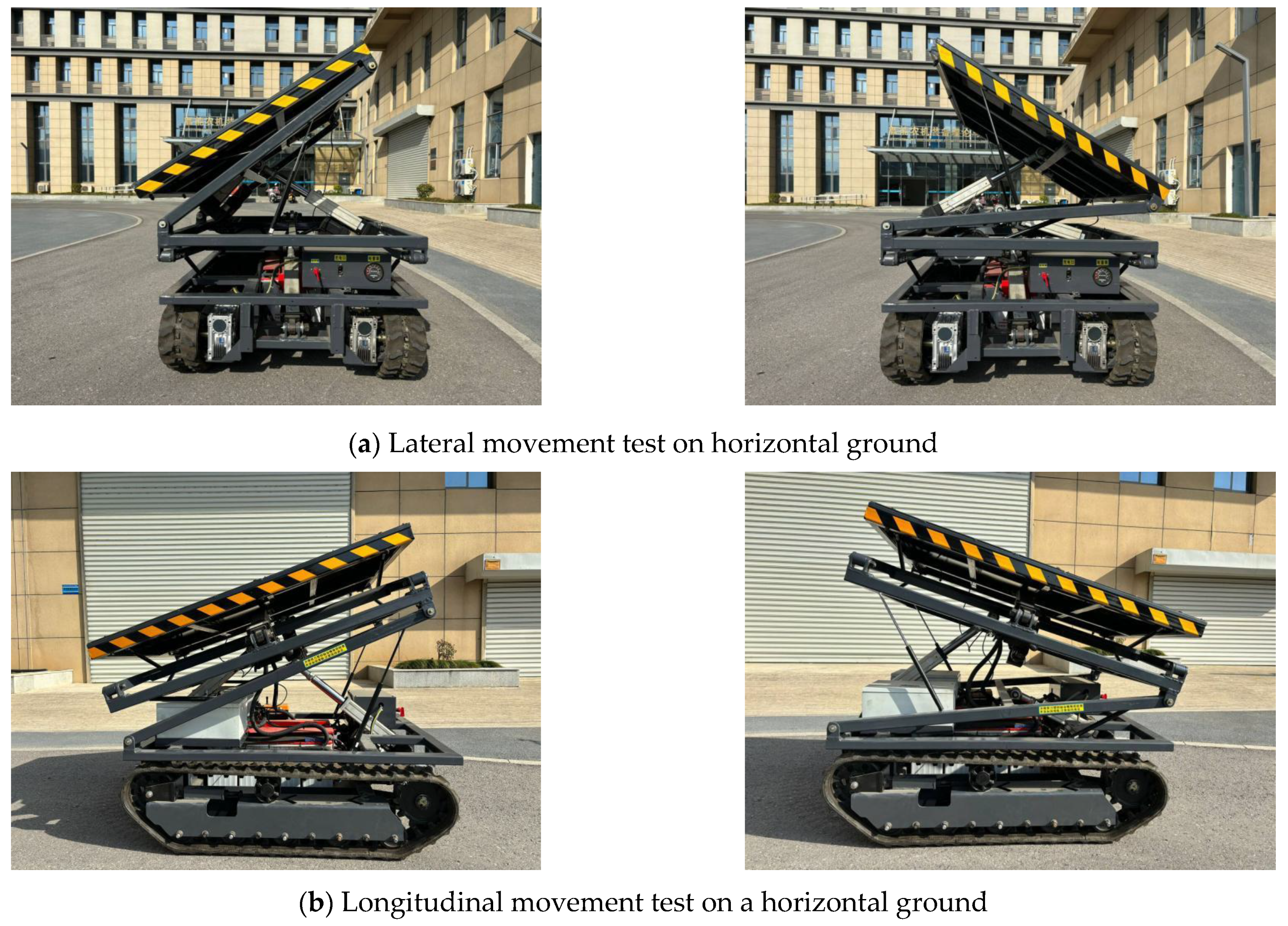

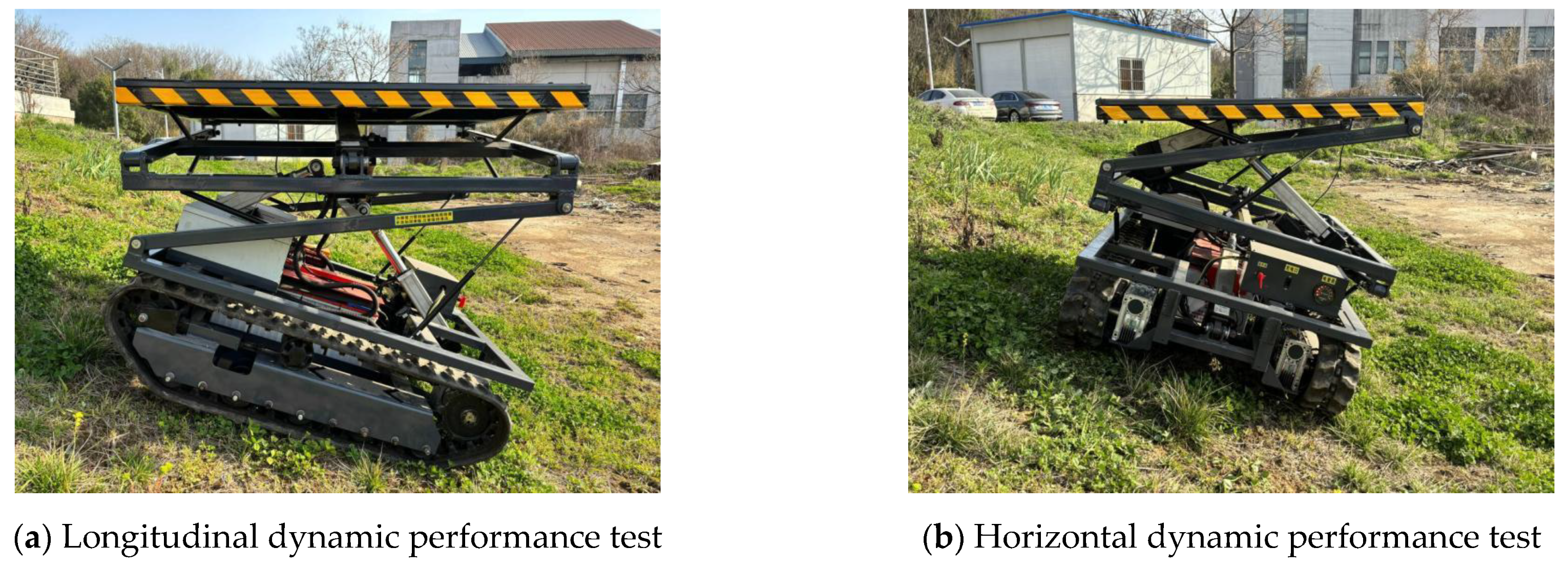

4.1. Test Equipment and Protocol

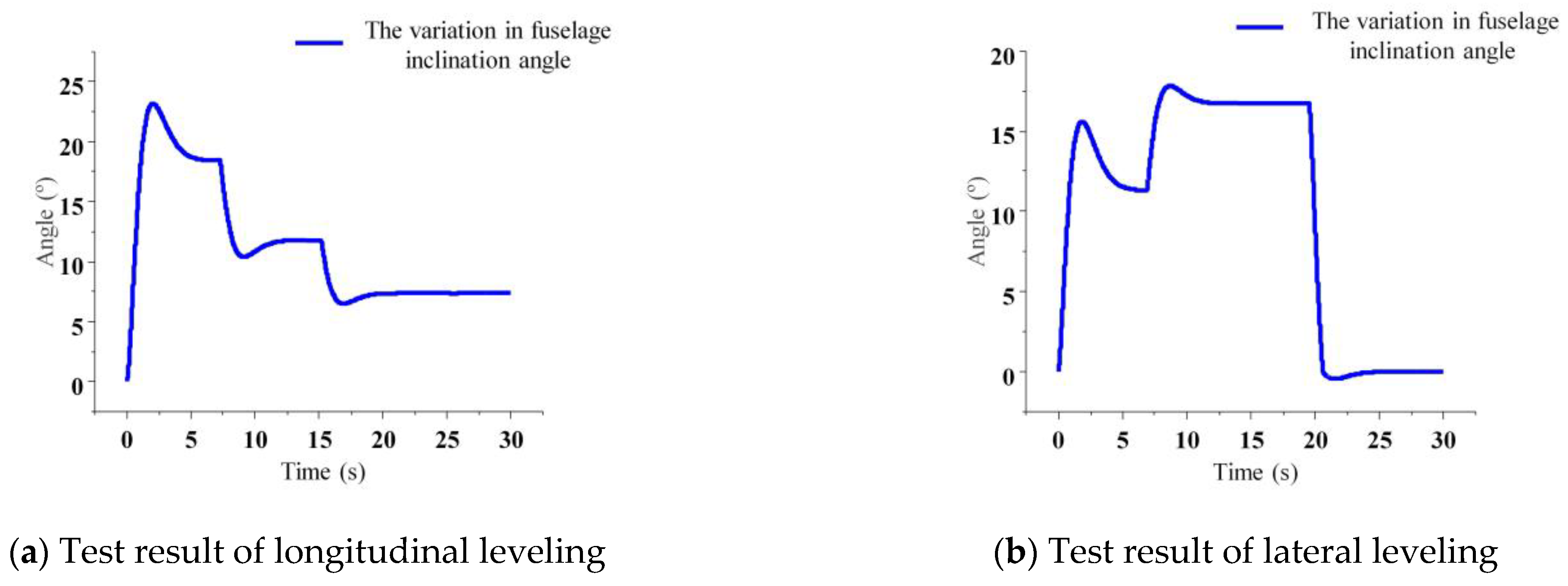

4.2. Static Leveling Tests

4.3. Dynamic Leveling Tests

4.3.1. One-Way Leveling Test

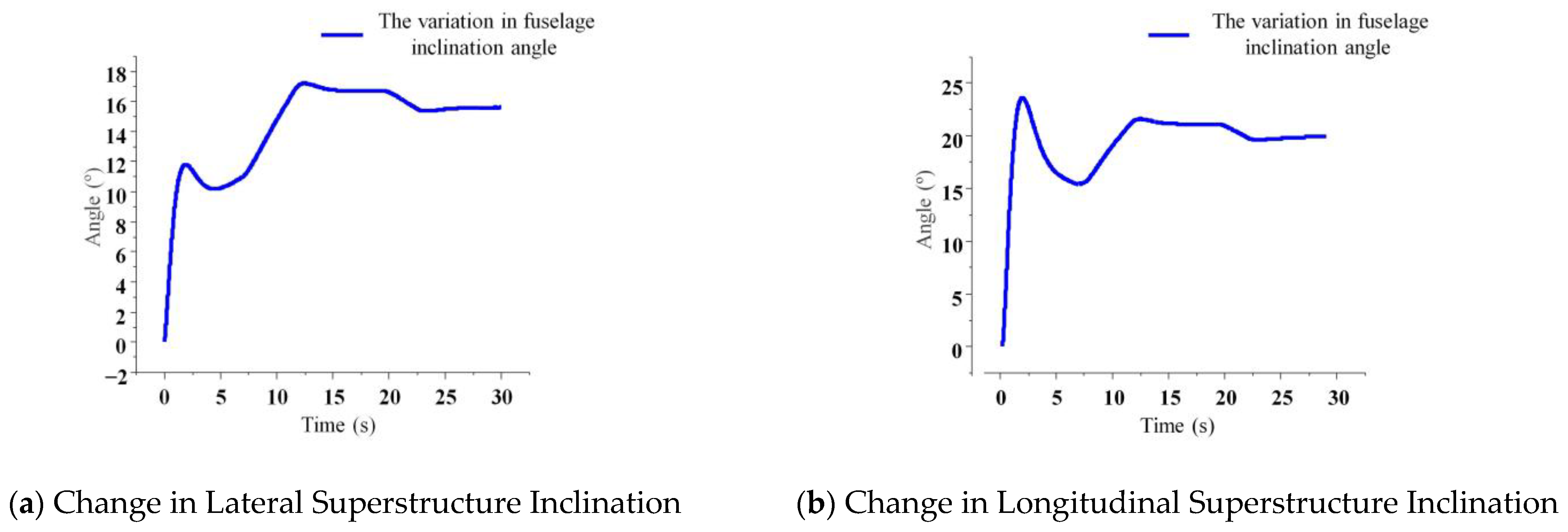

4.3.2. Omnidirectional Dynamic Performance Test

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, J.; Liu, Z.; Yang, F.; Sun, Q.; Liu, Q.; Luo, P. Research Review of Agricultural Equipment and Slope Operation Key Technologies in Hilly and Mountains Region. Nongye Jixie Xuebao Trans. Chin. Soc. Agric. Mach. 2023, 54, 1–18. [Google Scholar] [CrossRef]

- Li, H.; Chen, L.; Zhang, Z. A Study on the Utilization Rate and Influencing Factors of Small Agricultural Machinery: Evidence from 10 Hilly and Mountainous Provinces in China. Agriculture 2023, 13, 51. [Google Scholar] [CrossRef]

- Yang, M.; Li, M.; Luo, X. 50 Years of Agricultural Mechanization in China. AMA-Agric. Mech. Asia Afr. Lat. Am. 2020, 51, 86–92. [Google Scholar]

- Wang, B.; Du, X.; Wang, Y.; Mao, H. Multi-Machine Collaboration Realization Conditions and Precise and Efficient Production Mode of Intelligent Agricultural Machinery. Int. J. Agric. Biol. Eng. 2024, 17, 27–36. [Google Scholar] [CrossRef]

- Zhang, F.; Teng, S.; Wang, Y.; Guo, Z.; Wang, J.; Xu, R. Design of Bionic Goat Quadruped Robot Mechanism and Walking Gait Planning. Int. J. Agric. Biol. Eng. 2020, 13, 32–39. [Google Scholar] [CrossRef]

- Jin, Y.; Liu, J.; Xu, Z.; Yuan, S.; Li, P.; Wang, J. Development Status and Trend of Agricultural Robot Technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, G.; Tang, Z.; Cao, Y.; Zhao, Y. Structural Form and Field Operation Effect of Crawler Type Broccoli Harvester. Eng. Agric. 2023, 43, e20230132. [Google Scholar] [CrossRef]

- Yuan, L.; Tang, Z.; Liu, S.; Wang, T.; Ding, Z. Design for Copying Grouser and Bionic Convex Hull Patterns on Track Surfaces of Crawler Combine Harvesters. Agriculture 2024, 14, 1079. [Google Scholar] [CrossRef]

- Ding, R.; Qi, X.; Chen, X.; Mei, Y.; Li, A. The Current Development Status of Agricultural Machinery Chassis in Hilly and Mountainous Regions. Appl. Sci. 2025, 15, 7505. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, R.; Ding, R.; Sun, Z.; Jiang, Y.; Liu, W. Research Review of Agricultural Machinery Power Chassis in Hilly and Mountainous Areas. Agriculture 2025, 15, 1158. [Google Scholar] [CrossRef]

- Sun, J.; Meng, C.; Zhang, Y.; Chu, G.; Zhang, Y.; Yang, F.; Liu, Z. Design and Physical Model Experiment of an Attitude Adjustment Device for a Crawler Tractor in Hilly and Mountainous Regions. Inf. Process. Agric. 2020, 7, 466–478. [Google Scholar] [CrossRef]

- Jiang, L.; Xu, B.; Husnain, N.; Wang, Q. Overview of Agricultural Machinery Automation Technology for Sustainable Agriculture. Agronomy 2025, 15, 1471. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, L.; Wang, R.; Xu, X.; Shen, Y.; Liu, Y. Modeling and Test on Height Adjustment System of Electrically-Controlled Air Suspension for Agricultural Vehicles. Int. J. Agric. Biol. Eng. 2016, 9, 40–47. [Google Scholar] [CrossRef]

- Bałchanowski, J. Modelling and Simulation Studies on The Mobile Robot with Self-Leveling Chassis. J. Theor. Appl. Mech. 2016, 54, 149. [Google Scholar] [CrossRef][Green Version]

- Jia, X.; Shi, Z.; Li, R.; Zhang, G.; Geng, D.; LLan, Y.; Wang, B. Design and Test of Automatic Leveling System for Chassis of Small Agricultural Machinery in Hilly and Mountainous Areas. Nongye Jixie Xuebao Trans. Chin. Soc. Agric. Mach. 2024, 55, 108–115. [Google Scholar]

- Denis, D.; Thuilot, B.; Lenain, R. Online Adaptive Observer for Rollover Avoidance of Reconfigurable Agricultural Vehicles. Comput. Electron. Agric. 2016, 126, 32–43. [Google Scholar] [CrossRef]

- Gonzalez, D.; Martin-Gorriz, B.; Berrocal, I.; Hernandez, B.; Garcia, F.; Sanchez, P. Development of an Automatically Deployable Roll over Protective Structure for Agricultural Tractors Based on Hydraulic Power: Prototype and First Tests. Comput. Electron. Agric. 2016, 124, 46–54. [Google Scholar] [CrossRef]

- Wang, B.; Zhu, J.; Chai, X.; Liu, B.; Zhang, G.; Yao, W. Research Status and Development Trend of Key Technology of Agricultural Machinery Chassis in Hilly and Mountainous Areas. Comput. Electron. Agric. 2024, 226, 109447. [Google Scholar] [CrossRef]

- Wang, R.; Jiang, Y.; Ding, R.; Sun, Z.; Xu, K. Omnidirectional levelling control of electromechanical machine using BP neural network PID. Trans. Chin. Soc. Agric. Eng. 2024, 40, 52–62. [Google Scholar] [CrossRef]

- Guo, J.; Lu, Z.; Cui, B.; Xie, Y. Design and Test of Adaptive Leveling System for Orchard Operation Platform. Sensors 2025, 25, 1319. [Google Scholar] [CrossRef]

- Guo, H.; Lu, H.; Gao, G.; Wu, T.; Chen, H.; Qiu, Z. Design and Test of a Levelling System for a Mobile Safflower Picking Platform. Appl. Sci. 2023, 13, 4465. [Google Scholar] [CrossRef]

- Sun, Y.; Xu, L.; Jing, B.; Chai, X.; Li, Y. Development of a Four-Point Adjustable Lifting Crawler Chassis and Experiments in a Combine Harvester. Comput. Electron. Agric. 2020, 173, 105416. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, K.; Ding, R.; Jiang, Y.; Jiang, Y. A Novel Hydraulic Interconnection Design and Sliding Mode Synchronization Control of Leveling System for Crawler Work Machine. Agriculture 2025, 15, 137. [Google Scholar] [CrossRef]

- Chai, X.; Hu, J.; Ma, T.; Liu, P.; Shi, M.; Zhu, L.; Zhang, M.; Xu, L. Construction and Characteristic Analysis of Dynamic Stress Coupling Simulation Models for the Attitude-Adjustable Chassis of a Combine Harvester. Agronomy 2024, 14, 1874. [Google Scholar] [CrossRef]

- Hu, J.; Pan, J.; Dai, B.; Chai, X.; Sun, Y.; Xu, L. Development of an Attitude Adjustment Crawler Chassis for Combine Harvester and Experiment of Adaptive Leveling System. Agronomy 2022, 12, 717. [Google Scholar] [CrossRef]

- Tan, H.; Wang, G.; Zhou, S.; Jia, H.; Zou, Z.; Qu, M. Development of a Crawler Chassis Attitude Adjustment Device for a Self-Propelled Maize Harvester and Experiment of Fuselage Leveling. Int. J. Agric. Biol. Eng. 2024, 17, 111–120. [Google Scholar] [CrossRef]

- Sun, J.; Chu, G.; Pan, G.; Meng, C.; Liu, Z.; Yang, F. Design and Performance Test of Remote Control Omnidirectional Leveling Hillside Crawler Tractor. Nongye Jixie Xuebao Trans. Chin. Soc. Agric. Mach. 2021, 52, 358–369. [Google Scholar]

- Dettù, F.; Corno, M.; D’Ambrosio, D.; Acquistapace, A.; Taroni, F.; Savaresi, S. Modeling, Control Design and Experimental Automatic Calibration of a Leveling System for Combine Harvesters. Control Eng. Pract. 2023, 132, 105411. [Google Scholar] [CrossRef]

- Jiang, Y.; Sun, Z.; Wang, R.; Ding, R.; Ye, Q. Design and Control of a New Omnidirectional Levelling System for Hilly Crawler Work Machines. Comput. Electron. Agric. 2024, 218, 108661. [Google Scholar] [CrossRef]

- Yang, F.; Niu, H.; Sun, J.; Liu, Z.; Li, Y.; Zhu, H. Design and Experiment of Attitude Cooperative Control System of Mountain Crawler Tractor and Farm Tools. Nongye Jixie Xuebao Trans. Chin. Soc. Agric. Mach. 2022, 53, 414–422. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, J.; Zhong, Y.; Zhang, C.; Gao, Y. Study on Chassis Leveling Control of a Three-Wheeled Agricultural Robot. Agronomy 2024, 14, 1765. [Google Scholar] [CrossRef]

- Peng, H.; Ma, W.; Wang, Z.; Yuan, Z. Leveling Control of Hillside Tractor Body Based on Fuzzy Sliding Mode Variable Structure. Appl. Sci. 2023, 13, 6066. [Google Scholar] [CrossRef]

- Jin, C.; Yang, T.; Liu, G.; Wang, T.; Chen, M.; Liu, Z. Design and Test of Posture Controlled Chassis for Caterpillar Combine. Nongye Jixie Xuebao Trans. Chin. Soc. Agric. Mach. 2020, 51, 393–402. [Google Scholar]

- Liu, P.; Wang, C.; Li, H.; Zhang, M.; Wei, W.; Zhang, S. Terrain Adaptive and Dynamic Leveling Agricultural Chassis for Hilly Area. Nongye Jixie Xuebao Trans. Chin. Soc. Agric. Mach. 2018, 49, 74–81. [Google Scholar]

- Wang, J.; Tang, H.; Shen, H.; Bai, H.; Na, M. Design and experiment of high clearance roll-waist multifunctionalpower chassis for paddy field. Trans. Chin. Soc. Agric. Eng. 2017, 33, 32–40. [Google Scholar]

- Zhu, Y.; Kan, J. Prediction of the Lateral Stability of a Forestry Chassis with an Articulated Body and Fitted with Luffing Wheel-Legs. Biosyst. Eng. 2022, 224, 143–160. [Google Scholar] [CrossRef]

- Sun, Z.; Zhang, D.; Li, Z.; Shi, Y.; Wang, N. Optimum Design and Trafficability Analysis for an Articulated Wheel-Legged Forestry Chassis. J. Mech. Des. 2022, 144, 013301. [Google Scholar] [CrossRef]

- Yin, C.; Gao, J.; Xu, G.; Song, J.; Xie, F.; Wu, X.; Wang, K. Key technologies on the rollover protection and anti-rollover control for agricultural tractors. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2024, 40, 1–11. [Google Scholar]

- Tang, Z.; Li, Y.; Zhou, Y.; Zhang, H. Inertial Vibration Characteristics of Track Chassis Caused by Reciprocating Motion of Crank Slider. Shock Vib. 2019, 2019, 4378138. [Google Scholar] [CrossRef]

- Tang, Z.; Ren, H.; Li, X.; Liu, X.; Zhang, B. Structure Design and Bearing Capacity Analysis for Crawler Chassis of Rice Combine Harvester. Complexity 2020, 2020, 7610767. [Google Scholar] [CrossRef]

- Geng, D.; Sun, Y.; Li, H.; Mou, X.; Zhang, G.; Wang, Z.; Lu, X. Design and experiment of crawler corn harvester for sloping fields. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2021, 37, 11–19. [Google Scholar]

- Sun, J.; Wang, Z.; Ding, S.; Xia, J.; Xing, G. Adaptive Disturbance Observer-Based Fixed Time Nonsingular Terminal Sliding Mode Control for Path-Tracking of Unmanned Agricultural Tractors. Biosyst. Eng. 2024, 246, 96–109. [Google Scholar] [CrossRef]

- Li, J.; Shang, Z.; Li, R.; Cui, B. Adaptive Sliding Mode Path Tracking Control of Unmanned Rice Transplanter. Agriculture 2022, 12, 1225. [Google Scholar] [CrossRef]

- Lu, E.; Xue, J.; Chen, T.; Jiang, S. Robust Trajectory Tracking Control of an Autonomous Tractor-Trailer Considering Model Parameter Uncertainties and Disturbances. Agriculture 2023, 13, 869. [Google Scholar] [CrossRef]

| Longitudinal Static Rollover Angle | Longitudinal Leveling Rollover Angle |

|---|---|

| 38.9° | 42.9° |

| Lateral Static Rollover Angle | Lateral Leveling Rollover Angle |

|---|---|

| 31.2° | 38.3° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, R.; Qi, X.; Chen, X.; Mei, Y.; Li, A.; Wang, R.; Guo, Z. Research on the Design of an Omnidirectional Leveling System and Adaptive Sliding Mode Control for Tracked Agricultural Chassis in Hilly and Mountainous Terrain. Agriculture 2025, 15, 1920. https://doi.org/10.3390/agriculture15181920

Ding R, Qi X, Chen X, Mei Y, Li A, Wang R, Guo Z. Research on the Design of an Omnidirectional Leveling System and Adaptive Sliding Mode Control for Tracked Agricultural Chassis in Hilly and Mountainous Terrain. Agriculture. 2025; 15(18):1920. https://doi.org/10.3390/agriculture15181920

Chicago/Turabian StyleDing, Renkai, Xiangyuan Qi, Xuwen Chen, Yixin Mei, Anze Li, Ruochen Wang, and Zhongyang Guo. 2025. "Research on the Design of an Omnidirectional Leveling System and Adaptive Sliding Mode Control for Tracked Agricultural Chassis in Hilly and Mountainous Terrain" Agriculture 15, no. 18: 1920. https://doi.org/10.3390/agriculture15181920

APA StyleDing, R., Qi, X., Chen, X., Mei, Y., Li, A., Wang, R., & Guo, Z. (2025). Research on the Design of an Omnidirectional Leveling System and Adaptive Sliding Mode Control for Tracked Agricultural Chassis in Hilly and Mountainous Terrain. Agriculture, 15(18), 1920. https://doi.org/10.3390/agriculture15181920