Design and Performance Testing of a Multi-Variety Forage Grass Mixed-Sowing Seed Metering Device

Abstract

1. Introduction

2. Materials and Methods

2.1. Structure and Working Principle of the Mixed-Forage Seed Metering Device

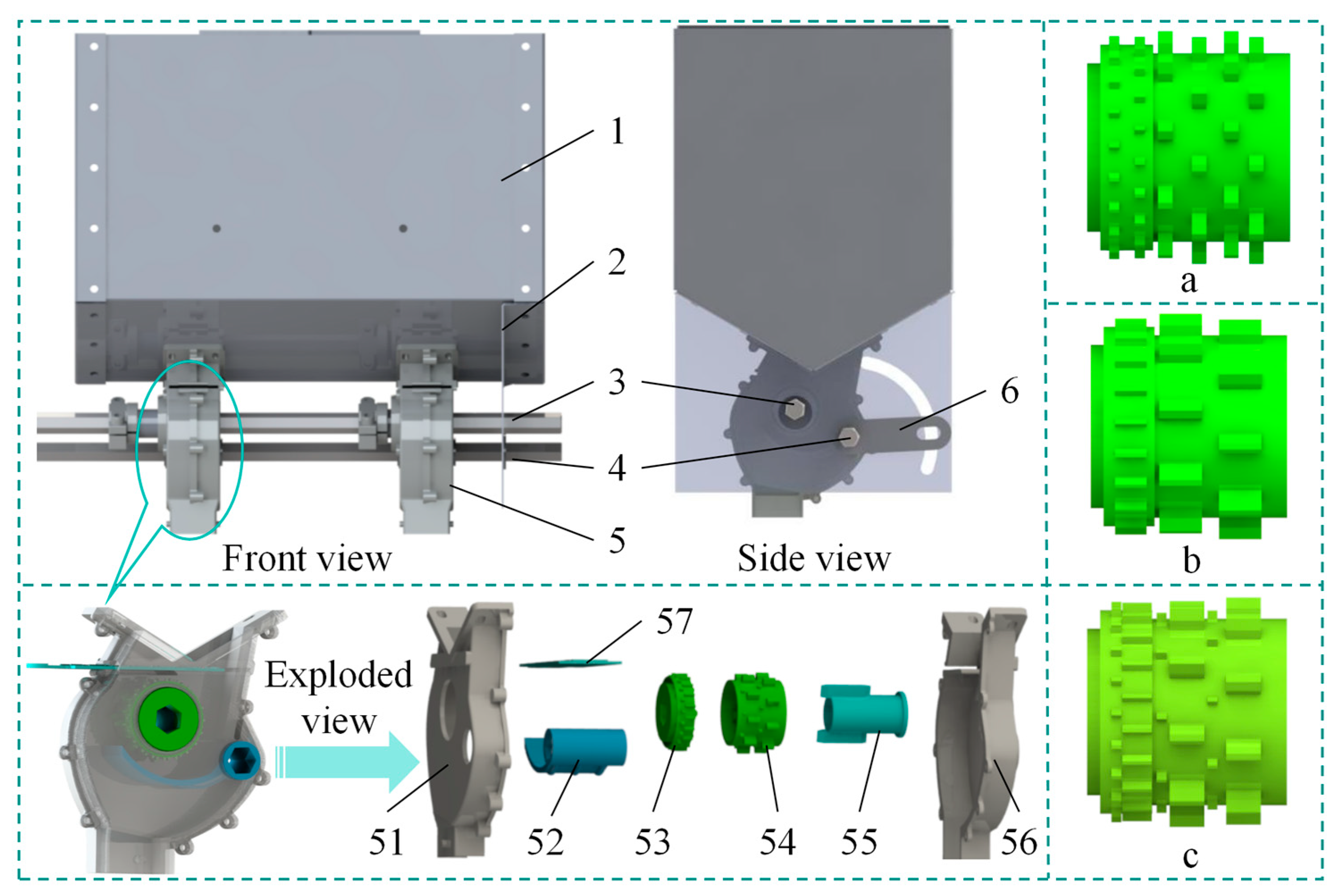

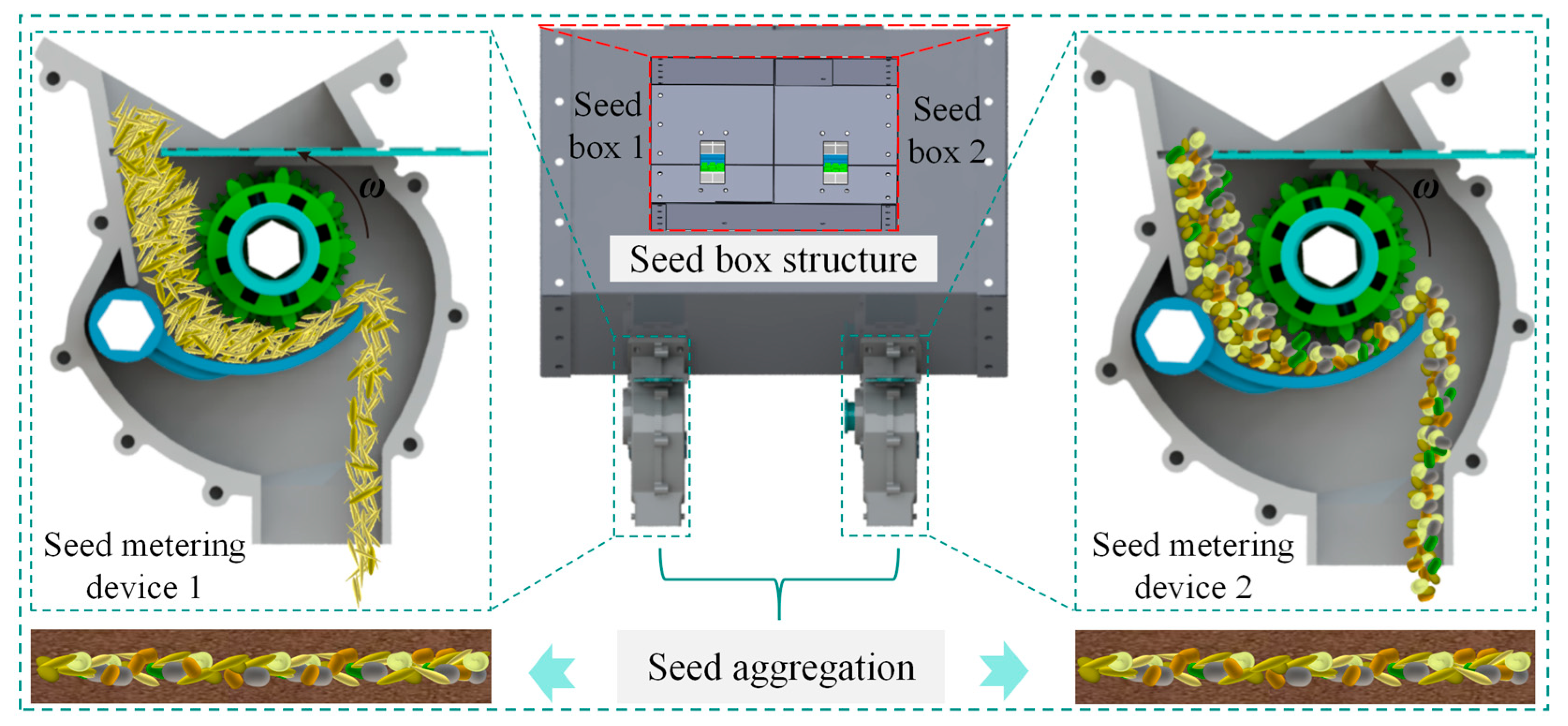

2.1.1. Structure of the Mixed-Forage Seed Metering Device

2.1.2. The Working Principle of the Mixed-Seeding Seed Metering Device

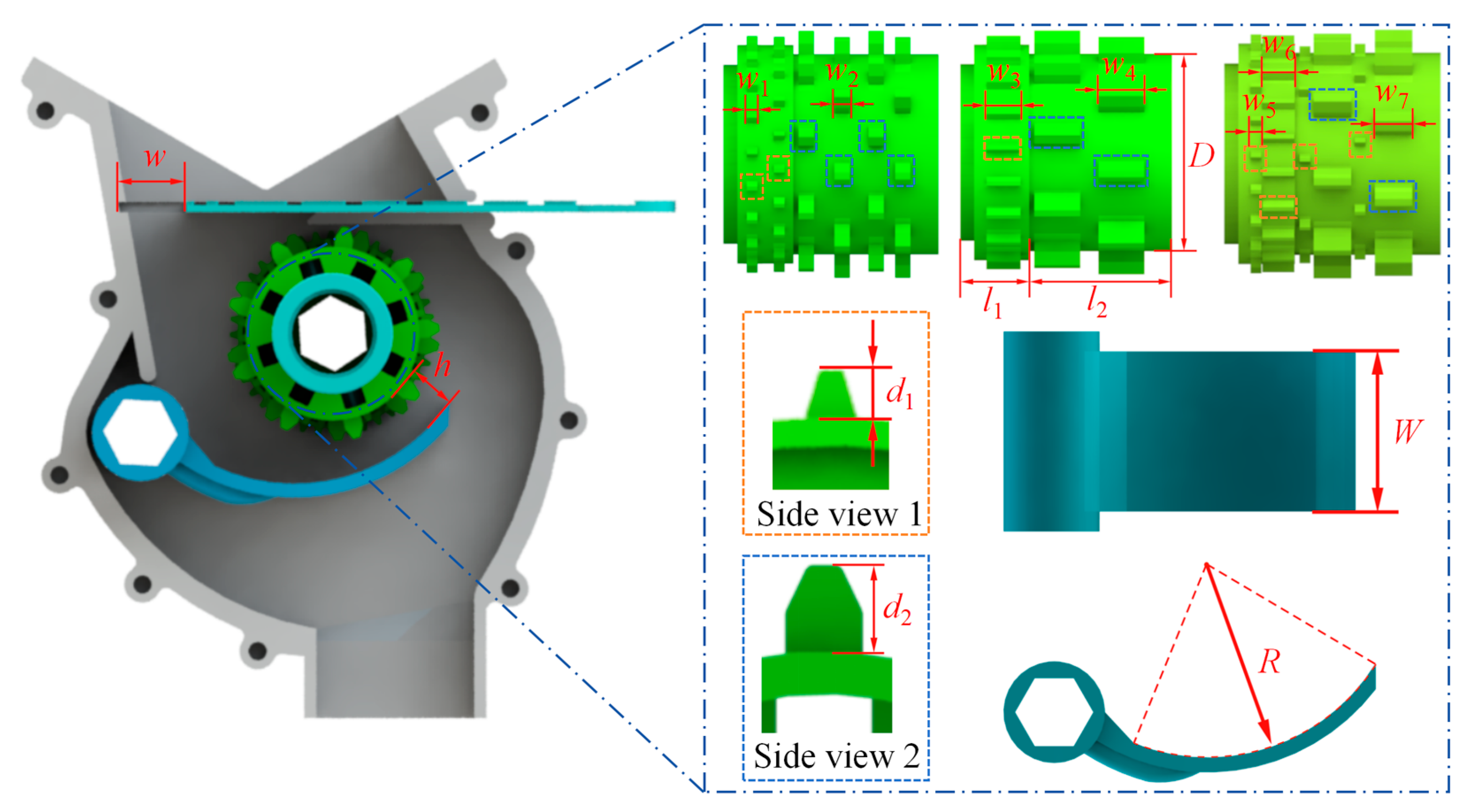

2.2. Design of Key Components

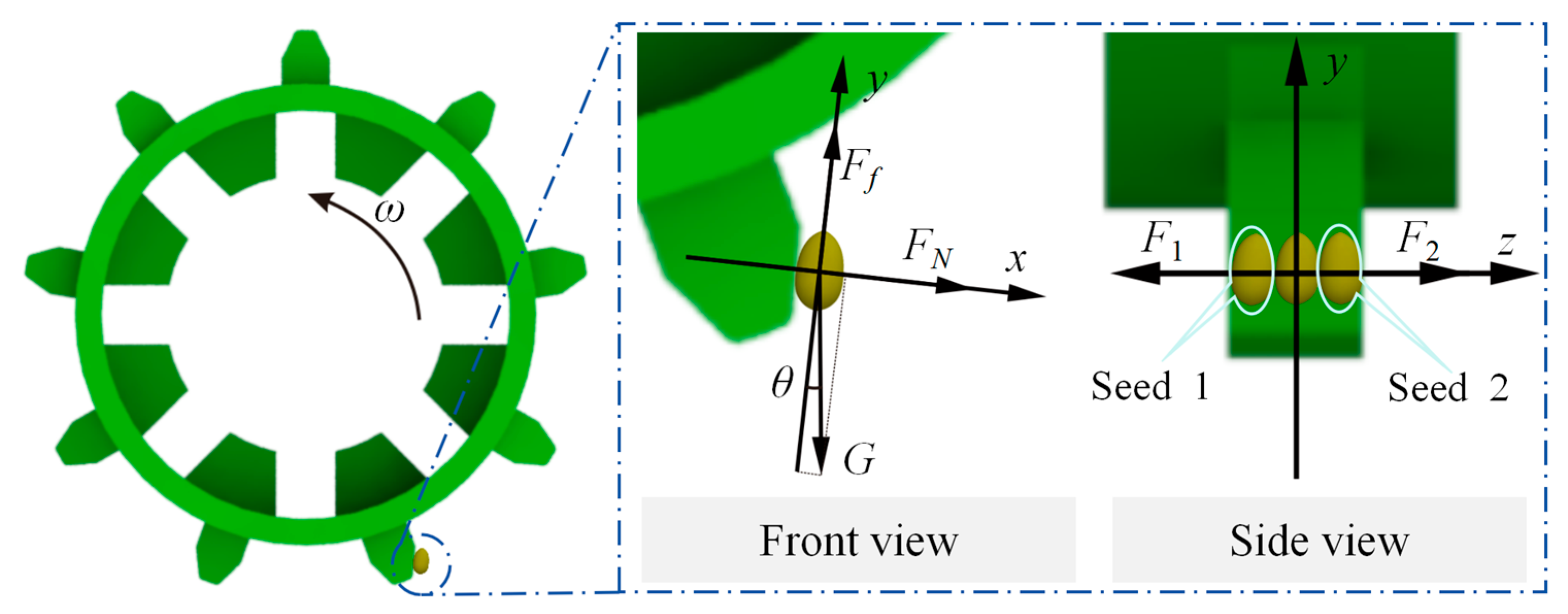

2.3. Force Analysis

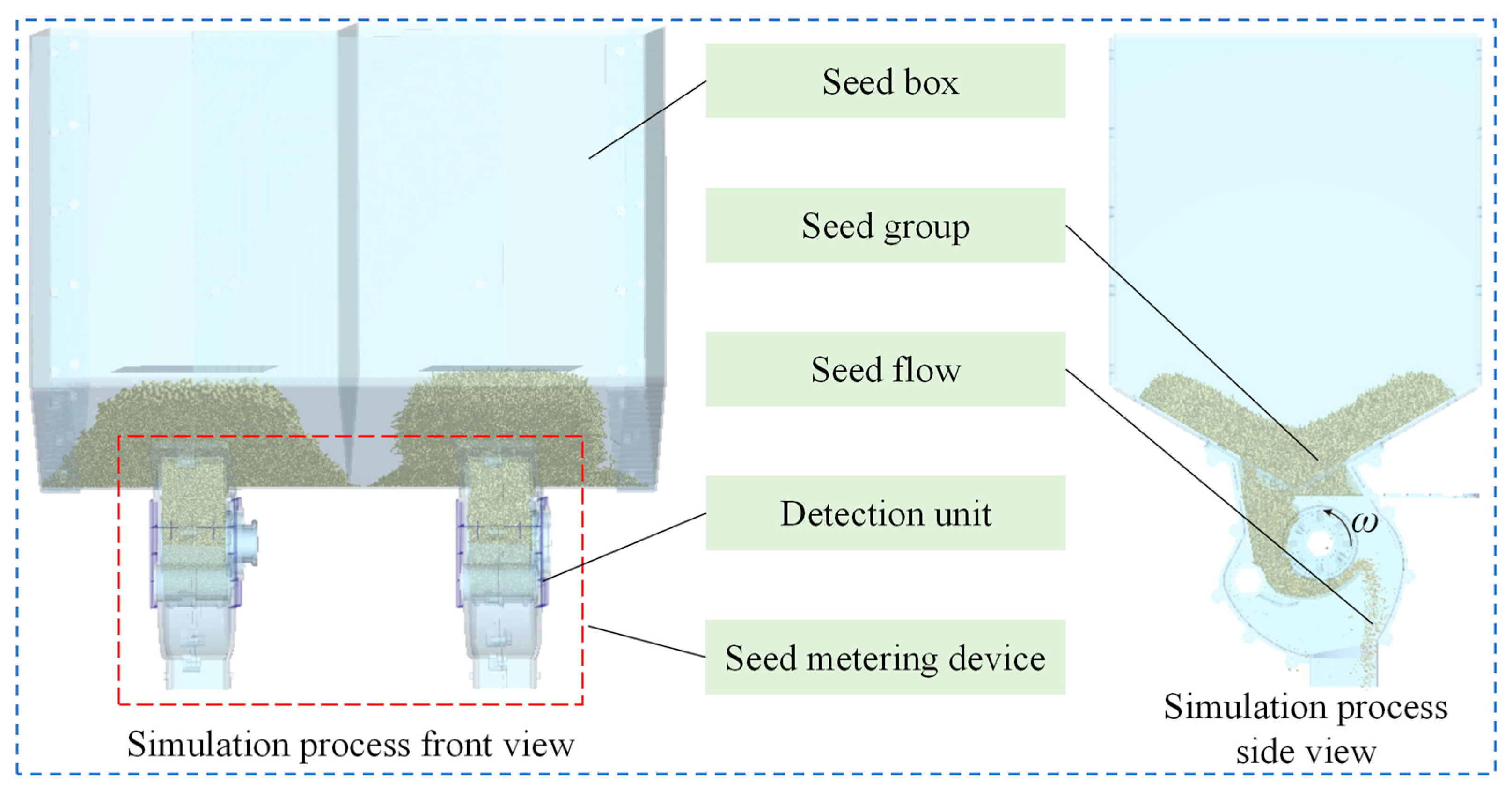

2.4. Simulation of the Seed Metering Device

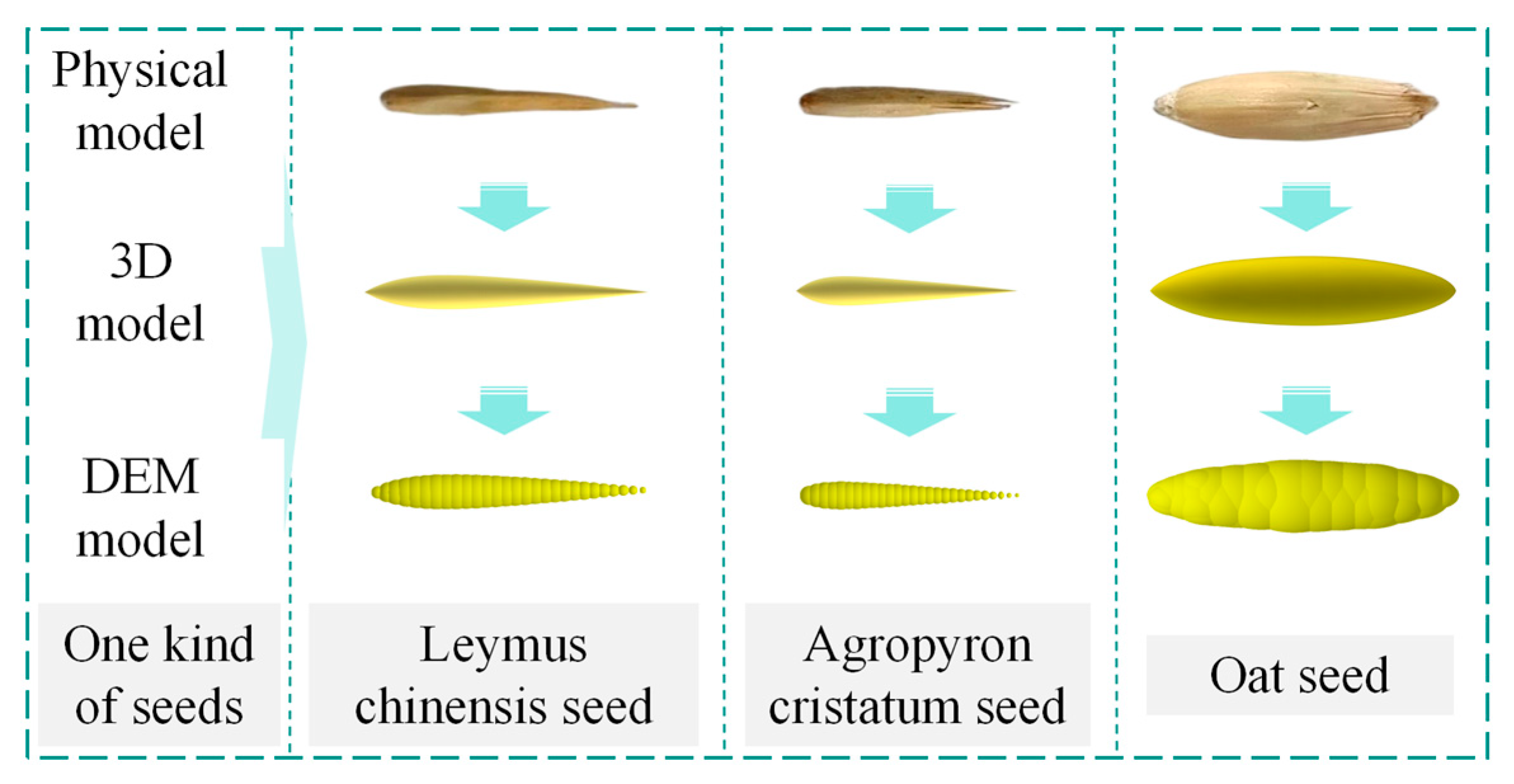

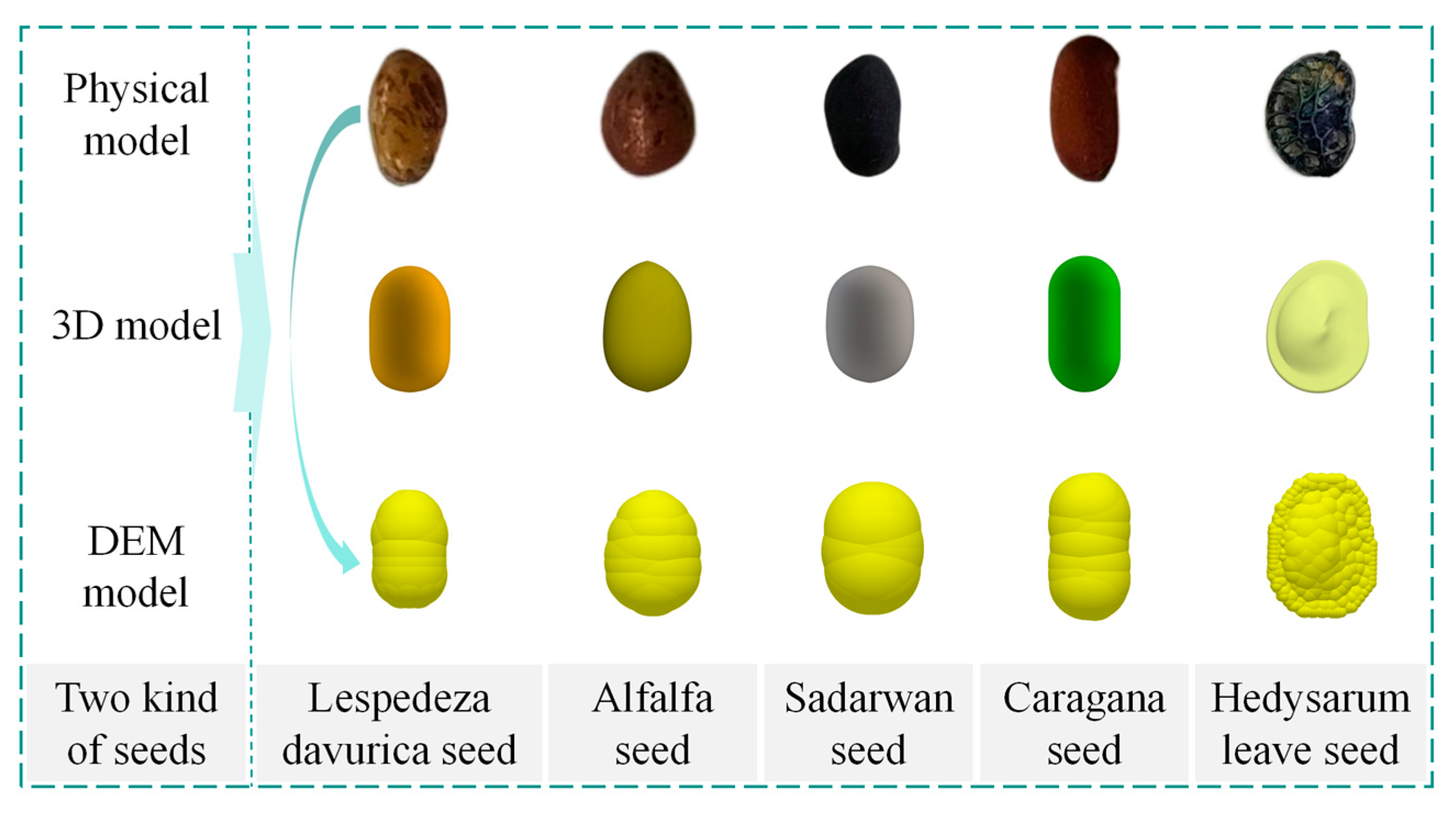

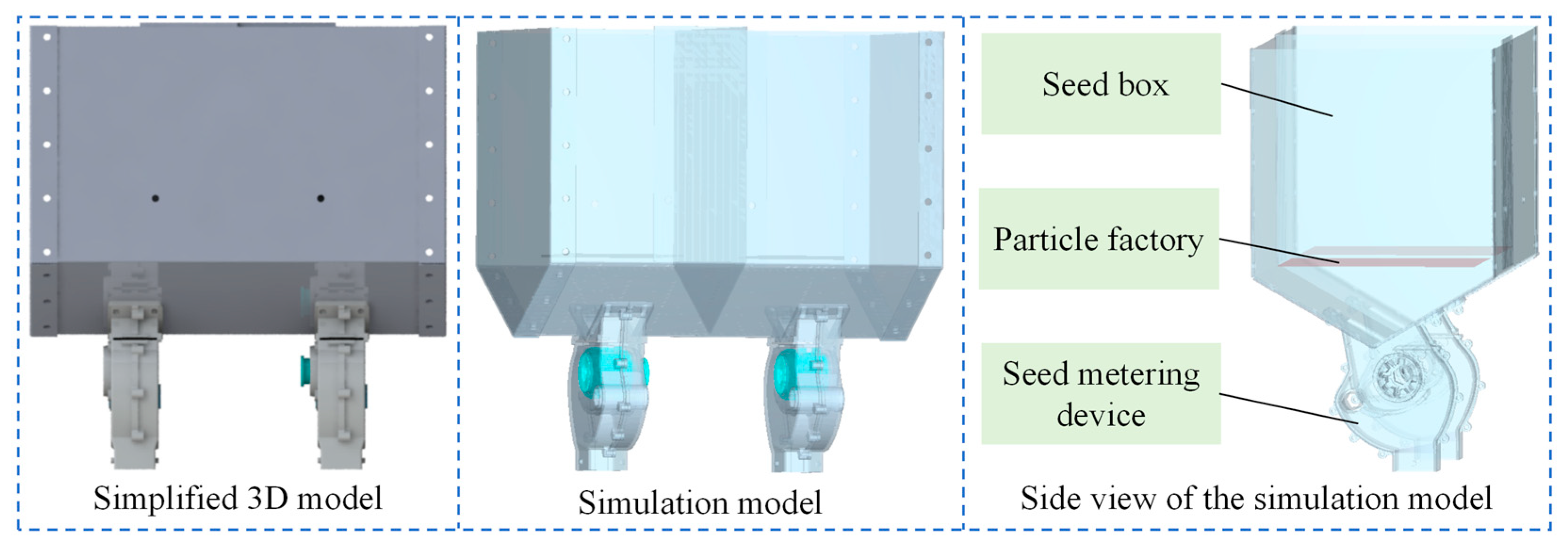

2.4.1. Modeling of the Seed Metering Device

2.4.2. Simulation Parameter Settings

2.4.3. One-Factor Experiment

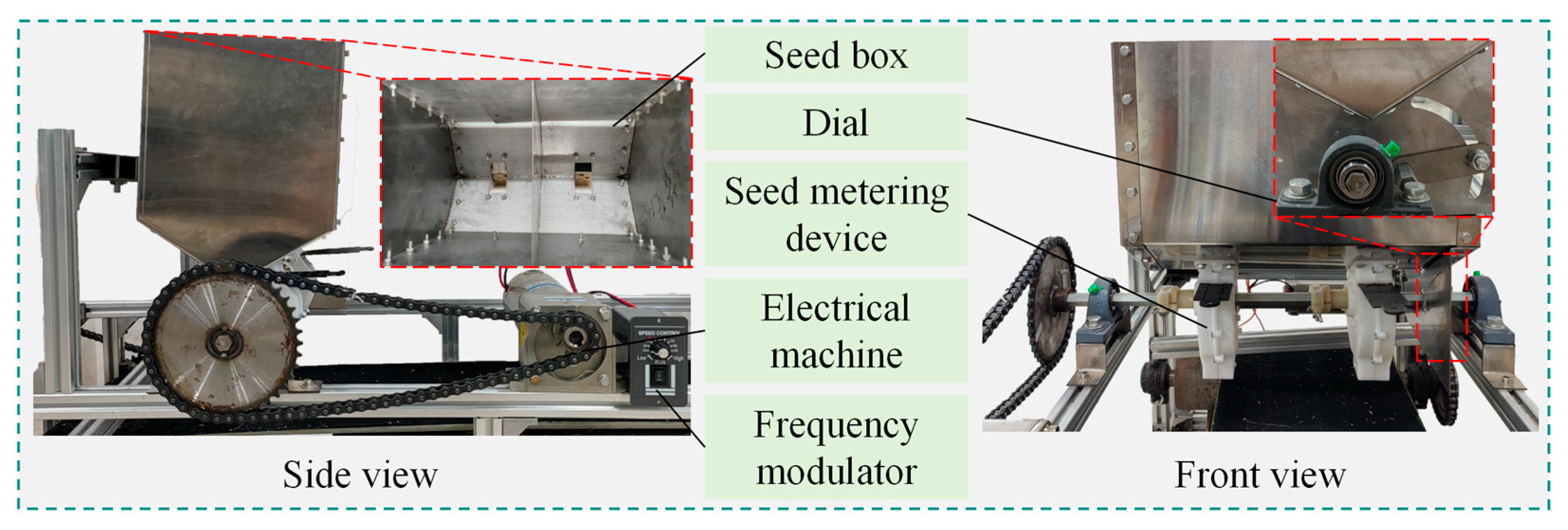

2.5. Bench Test

2.5.1. Test Method

2.5.2. Test Design

2.6. Field Test

3. Results and Discussion

3.1. Seed Metering Device Movement Process

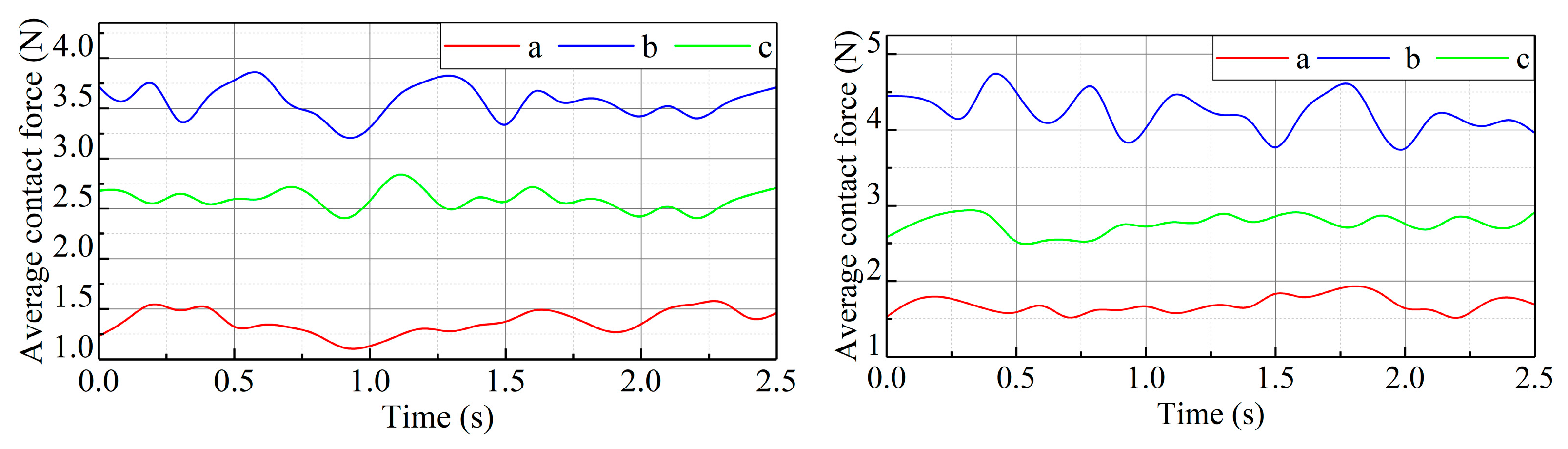

3.1.1. The Impact of the Seed Metering Wheel Structure on the Average Contact Force of the Seeds

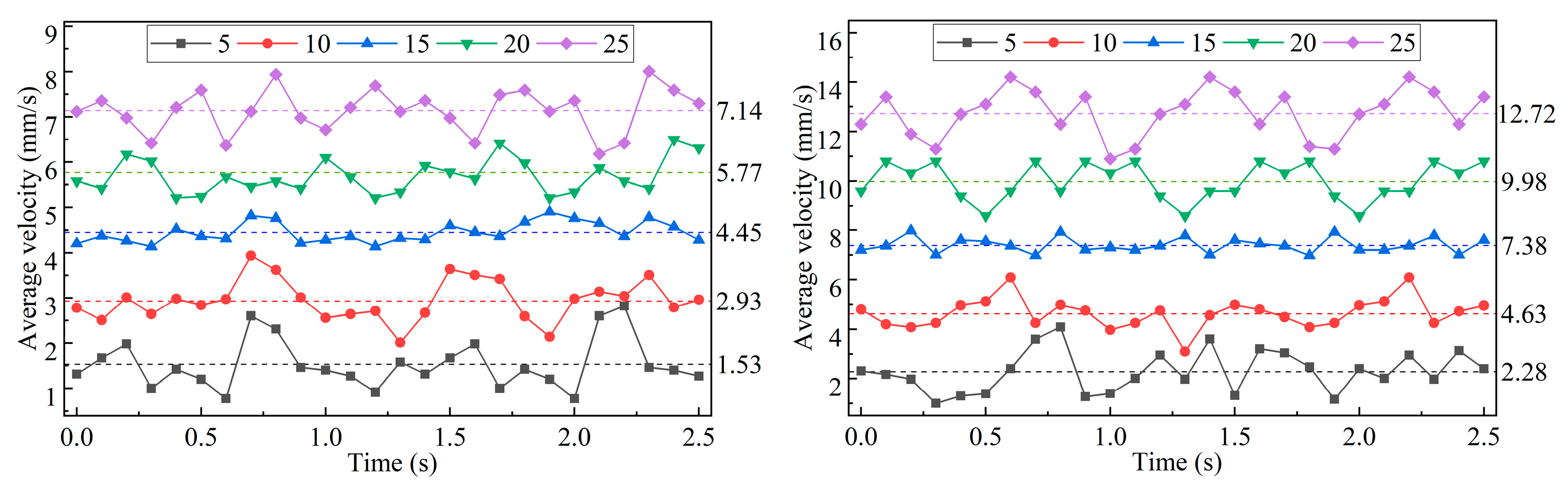

3.1.2. The Impact of the Metering Shaft Speed on the Movement State of the Seed Group

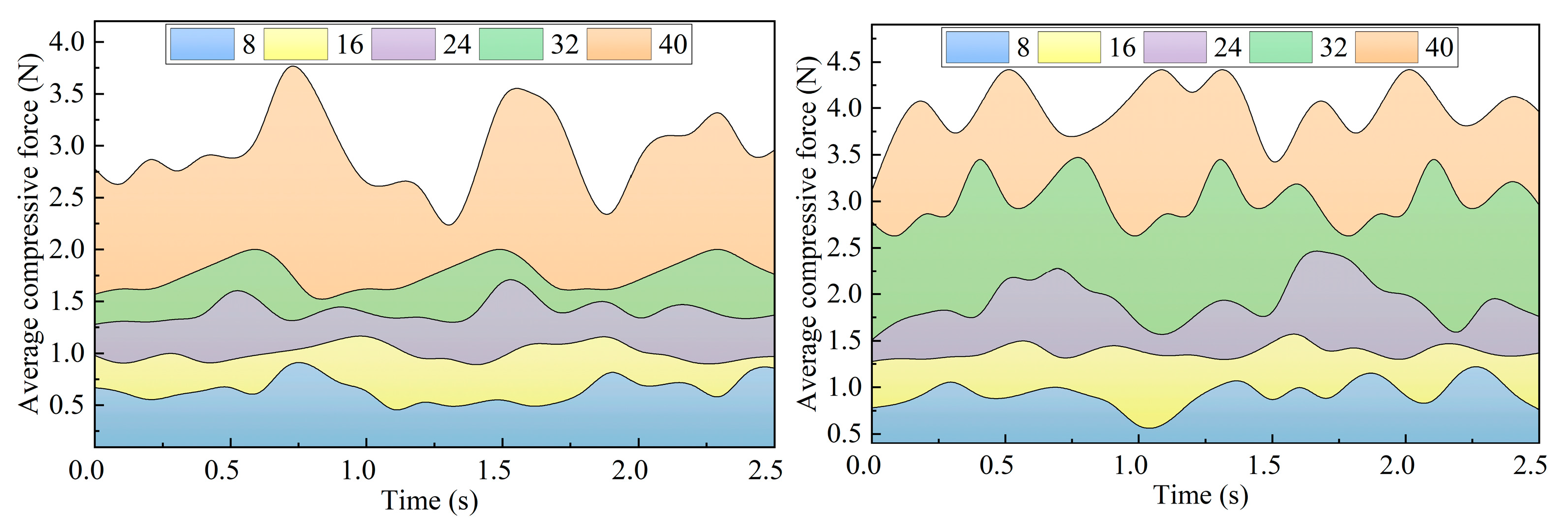

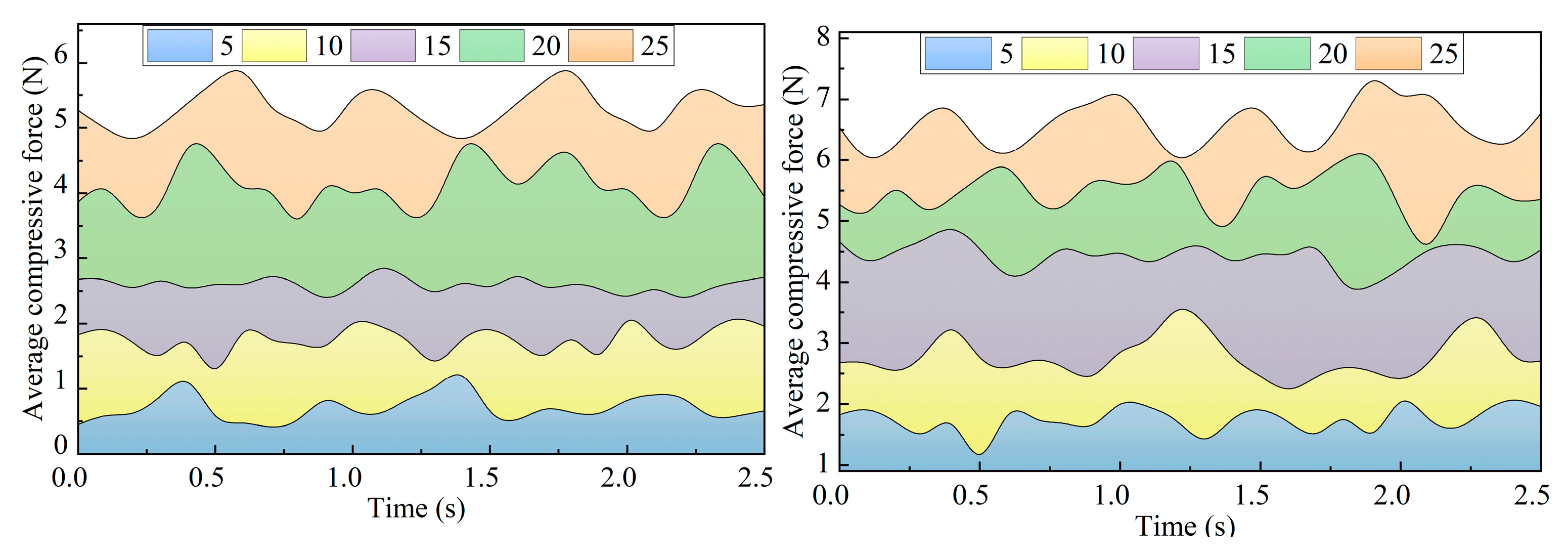

3.1.3. The Impact of the Seed Inlet Width on the Inter-Seed Compressive Force

3.1.4. The Impact of the Seed Outlet Height on the Inter-Seed Contact Force

3.2. Results of the Verification Test

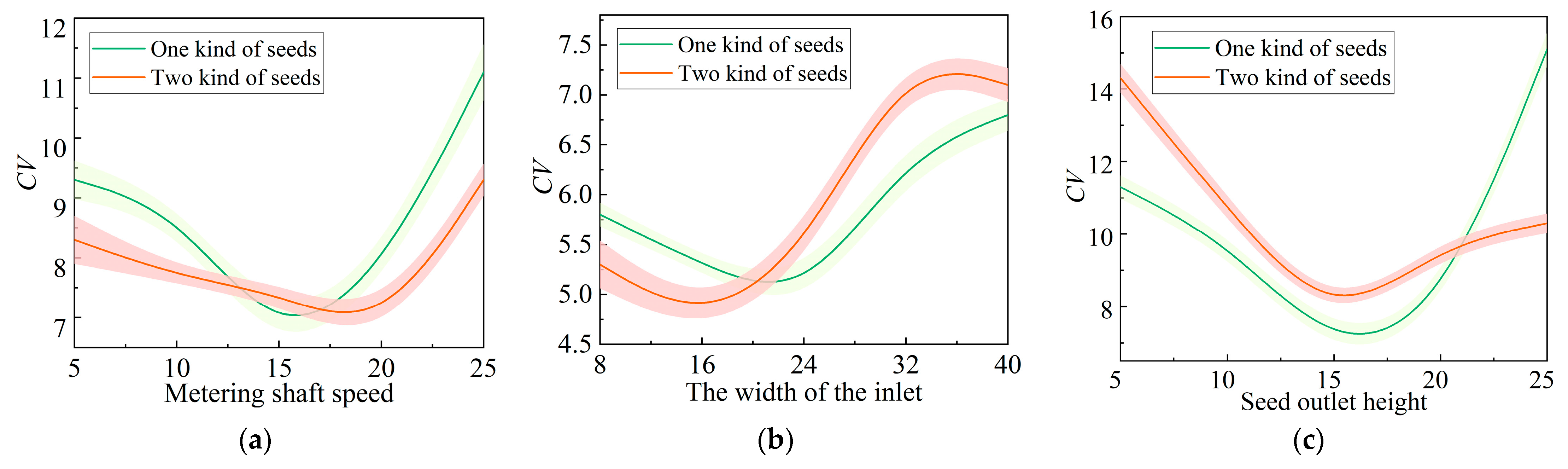

3.3. Results of the One-Way Test

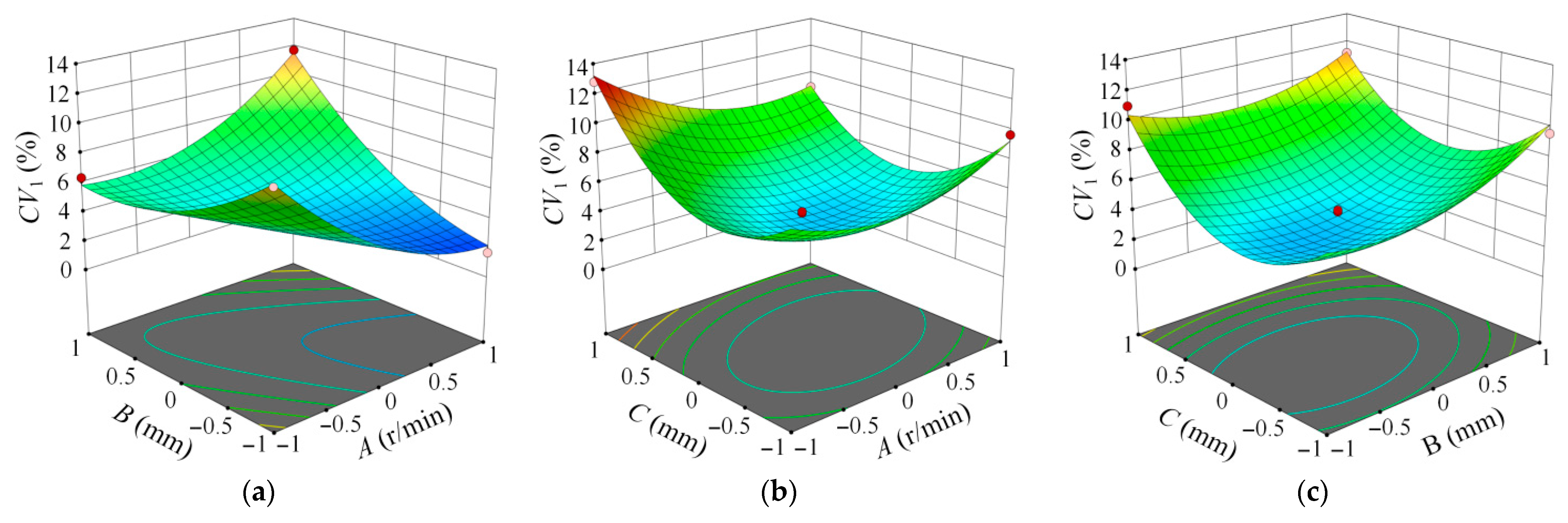

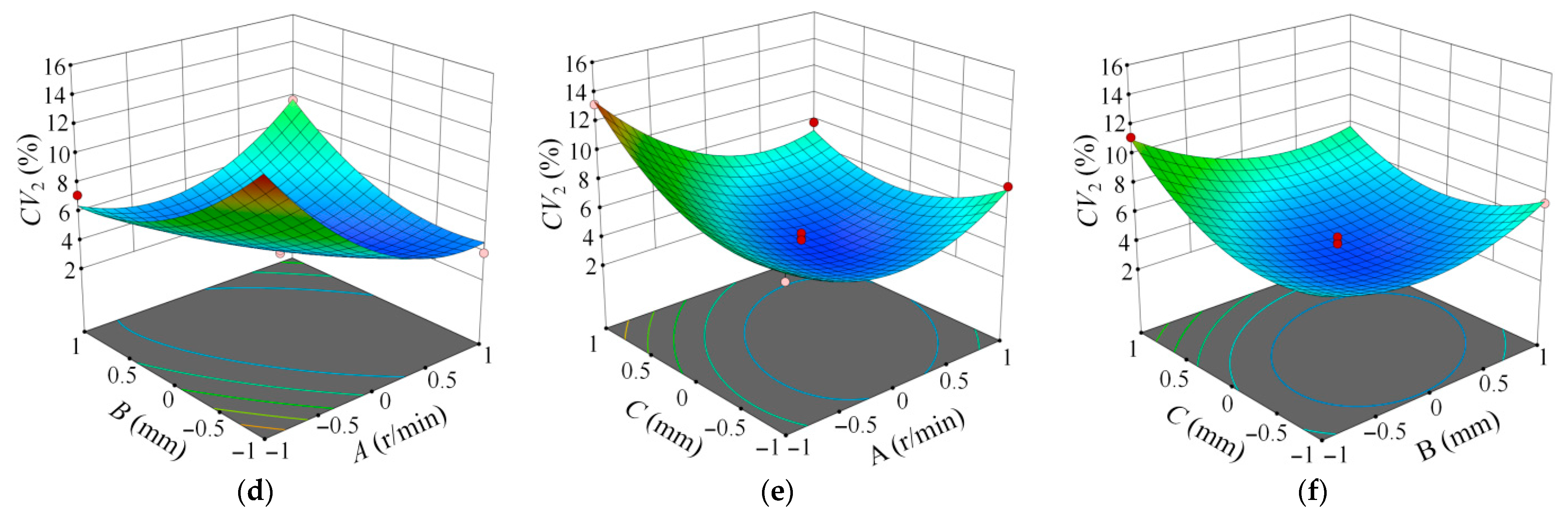

3.4. Response Surface Test Results

3.5. Field Validation Test Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, D.W.; You, Y.; Zhang, X.N.; Wang, X.F.; Wang, D.C. Review of the improvement techniques and equipment development fordegraded grassland. Trans. Chin. Soc. Agric. Eng. 2024, 40, 17–33. [Google Scholar] [CrossRef]

- Sun, L.L.; Meng, X.; Xie, K.Y.; Yan, A.; Liu, W.; Yang, L.; Cui, H.T.; Zhao, Y.; Chu, H.Q. Effect of different mixed sowing patterns on yield and nutritional value of grass in sowing year. Acta Agrestia Sin. 2024, 32, 340–348. [Google Scholar] [CrossRef]

- Li, Y.M.; Li, D.N.; Wang, B.; Li, X.Y.; Shen, X.T.; Cao, L.J.; Ni, W.; Wang, T.F.; Lan, J. The effect of mixed sowing and sowing rate of different alfalfa varieties on the yield and quality of forage. Acta Agrestia Sin. 2022, 31, 61–75. [Google Scholar] [CrossRef]

- Zhu, Y.Q.; Guan, Z.X.; Zhen, W.; Wang, X. Effect of species diversity and community structure on nitrogen use efficiency of mixed legume grass pastures. Acta Agrestia Sin. 2018, 27, 1–14. [Google Scholar] [CrossRef]

- Yang, H.Y.; Tian, S.N.; Pan, Z.H.; Zhang, L.; Yu, H.Y. Development Status of Grassland Agricultural Machinery. J. Agric. Mech. Res. 2025, 47, 1–8+17. [Google Scholar] [CrossRef]

- Yu, C.Y.; Chen, Z.; Chen, L.Q. Design and Test of Electronic Control Seeding System for Wheat Plot Drill. Trans. Chin. Soc. Agric. Mach. 2023, 54, 75–83. [Google Scholar] [CrossRef]

- Cheng, X.P.; Li, H.W.; Lu, C.Y.; He, J.; Wang, Q.J.; Wang, C.; Yu, C.C.; Wei, Z.C.; Wang, C.L. Parameter optimization and experiment of centrifugal seed dispenser in wheat plot drill. Trans. Chin. Soc. Agric. Eng. 2019, 35, 1–9. [Google Scholar] [CrossRef]

- Shang, S.Q.; Wu, X.F.; Yang, R.B.; Li, G.Y.; Yang, X.L.; Chen, B.Q. Research Status and Prospect of Plot-sowing Equipment and Technology. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–20. [Google Scholar] [CrossRef]

- Zhao, L.T.; Xian, Y.Y.; Liu, G.M.; Jiang, H.X.; Liao, P.Q.; Zhao, C.; Wang, W.L.; Huo, Z.Y. Effects of different mechanized tillage and sowing modes on the seedling quality and yield of winter wheat. Trans. Chin. Soc. Agric. Eng. 2021, 37, 31–38. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Du, R.C.; Diao, P.S.; Yang, S.D.; Wang, Z.W. Design and experiment of wide band seeding rice seeder with reversed stubble cleaning and anti-blocking. Trans. Chin. Soc. Agric. Eng. 2017, 33, 7–13. [Google Scholar] [CrossRef]

- Yu, Y.C.; Li, M.Z.; Liu, X.W. Improvement of composition of the outer groove-wheel seed meter. J. Henan Agric. Univ. 2002, 36, 85–88+95. [Google Scholar]

- Li, M.S.; Ye, J.; Li, D.; Yang, S.; Zeng, B.G.; Liu, J. Design and test of a seed metering device for buckwheat seeder based on the discrete element method. J. Southwest Univ. 2019, 41, 78–85. [Google Scholar] [CrossRef]

- Yin, W.Q.; Zhao, L.; Li, H.; Hu, F.; Yu, H.M. Design and Experiment on Suction Nozzle Type Hole of Pneumatic-sheave Combined Vegetable Precision Metering Device. Trans. Chin. Soc. Agric. Mach. 2019, 50, 68–76. [Google Scholar] [CrossRef]

- Zhen, J.; Lai, H.Y.; Li, T.; Li, T.Y.; Liao, Q.X.; Liao, Y.T. Design and Test of Precision Seed Metering Device for Wheat Wide Seedling Belt with Air Suction. Trans. Chin. Soc. Agric. Mach. 2024, 55, 165–176. [Google Scholar] [CrossRef]

- Zheng, Z.H. Design and Experiment of the Precision Metering Device with Staggered Convex Teeth and Wide Seedling Belt for Wheat. Master’s Thesis, Hei Fei Anhui Agric University, Hefei, China, 2023. [Google Scholar] [CrossRef]

- Zhang, C.L.; Liu, T.; Zheng, Z.H.; Fang, J.; Xie, X.D.; Chen, L.Q. Design and test of the precision seeding dispenser with the staggered convex teeth for wheat sowing with wide seedling belt. Trans. Chin. Soc. Agric. Eng. 2024, 40, 47–59. [Google Scholar] [CrossRef]

- Zhang, R.F.; Jiao, W.; Zhou, J.L.; Qi, B.; Liu, H.; Xia, Q.Q. Parameter Calibration and Experiment of Rice Seeds Discrete Element Model with Different Filling Particle Radius. Trans. Chin. Soc. Agric. Mach. 2020, 51, 227–235. [Google Scholar] [CrossRef]

- Horabik, J.; Wiacek, J.; Parafiniuk, P.; Banda, M.; Kobylka, R.; Stasiak, M.; Molenda, M. Calibration of discrete-element-method model parameters of bulk wheat for storage. Biosyst. Eng. 2020, 200, 298–314. [Google Scholar] [CrossRef]

- Sun, K.; Yu, J.Q.; Liang, L.S.; Wang, Y.; Yan, D.X.; Zhou, L.; Yu, Y.J. A DEM-based general modelling method and experimental verification for wheat seeds. Powder Technol. 2022, 401, 117353. [Google Scholar] [CrossRef]

- Dong, W.; Zhang, A.; Liu, F.; Zhao, X.; Ren, Y.; Bai, H.; Xuan, D.; Kong, X.; Yang, S.; Yang, X. Design and Performance Test of Variable-Capacity Spoon-Type Oat Precision Hill Seeder. Agriculture 2025, 15, 986. [Google Scholar] [CrossRef]

- Yu, Q.X.; Liu, Y.; Chen, X.B.; Sun, K.; Lai, Q.H. Simulation parameter calibration and experiment of Panax notoginseng seeds based on discrete element. Trans. Chin. Soc. Agric. Mach. 2020, 51, 123–132. [Google Scholar] [CrossRef]

- Wang, X.L.; Zhong, X.K.; Geng, Y.L.; Wei, Z.C.; Hu, H.; Geng, D.Y.; Zhang, X.C. Construction and parameter calibration of the nonlinear elastoplastic discrete element model for no-tillage soil compaction. Trans. Chin. Soc. Agric. Eng. 2021, 37, 100–107. [Google Scholar] [CrossRef]

- Yang, L.; Li, J.W.; Lai, Q.H.; Zhao, L.L.; Li, J.J.; Zeng, R.H.; Zhang, Z.H. Discrete element contact model and parameter calibration for clayey soil particles in the Southwest hill and mountain region. J. Terramechanics 2024, 111, 73–87. [Google Scholar] [CrossRef]

- Li, Z.; Zhong, J.; Gu, X.; Zhang, H.; Chen, Y.; Wang, W.; Zhang, T.; Chen, L. DEM Study of Seed Motion Model-Hole-Wheel Variable Seed Metering Device for Wheat. Agriculture 2023, 13, 23. [Google Scholar] [CrossRef]

- Wang, J.; Sun, W.; Simionescu, P.A.; Ju, Y. Optimization of the Fluted Force-Feed Seeder Meter with the Helical Roller Using the Discrete Element Method and Response Surface Analysis. Agriculture 2023, 13, 1400. [Google Scholar] [CrossRef]

- Dong, J.; Wu, J.; Zhu, Y.; Gao, X. Investigation on Seed-Filling Effect of Quantitative Precision Filling High-Speed Seed-Metering Device for Maize. Agriculture 2025, 15, 1517. [Google Scholar] [CrossRef]

- Dun, G.; Wei, Y.; Ji, X.; Gao, S.; Pei, Y.; He, Y.; Ma, C. Design and Test of the Outside-Filling Chinese Chive Adjustable-Capacity Precision Seed-Metering Device. Agronomy 2025, 15, 622. [Google Scholar] [CrossRef]

- Zheng, G.; Qi, B.; Zhang, W.; Shao, W.; Zhang, L.; Wang, Y.; Ding, Y. Engineering Discrete Element Method-Based Design and Optimization of the Key Components of a Spoon-Wheel Spinach Seed-Metering Device. Agronomy 2024, 14, 2096. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, S.; Wang, W.; Lv, H.; Chen, Y.; Zhou, L.; Li, M.; Zhao, J. Design and Testing of Soybean Double-Row Seed-Metering Device with Double-Beveled Seed Guide Groove. Agriculture 2024, 14, 1595. [Google Scholar] [CrossRef]

- Dong, W.X.; Li, N.; Liu, F.; Zhao, X.; Wang, L.H.; Xuan, D.Z.; Zhong, W.D.; Hu, H.T.; Meng, X.Y.; Li, M.Y.; et al. Study on vibration adsorption characteristics of small-particle-size seeds based on DEM. INMATEH-Agric. Eng. 2023, 71, 406–418. [Google Scholar] [CrossRef]

- Liu, M.; Hou, Z.F.; Ma, X.J.; Dai, N.Z.; Zhang, X.W. Discrete Element Method-based Simulation Parameter Calibration and Testing of Alfalfa Seeds. Jiangsu Agric. Sci. 2022, 50, 168–175. [Google Scholar] [CrossRef]

- Chen, S.; Li, Y.; Wei, B.; Shi, M.; Zou, X.; Huang, X. Establishment of a Discrete-Element Model and Verification of a Seeder Bench Experiment for Sesbania Seeds. Appl. Sci. 2025, 15, 4710. [Google Scholar] [CrossRef]

- Hu, M.; Xia, J.; Zhou, Y.; Luo, C.; Zhou, M.; Liu, Z. Measurement and Calibration of the Discrete Element Parameters of Coated Delinted Cotton Seeds. Agriculture 2022, 12, 286. [Google Scholar] [CrossRef]

- Tang, H.; Xu, F.D.; Xu, C.S.; Zhao, J.L.; Wang, Y.J. The influence of a seed drop tube of the inside-filling air-blowing precision seed-metering device on seeding quality. Comput. Electron. Agric. 2023, 204, 107555. [Google Scholar] [CrossRef]

- Luo, W.; Chen, X.; Guo, K.; Qin, M.; Wu, F.; Gu, F.; Hu, Z. Optimization and Accuracy Analysis of a Soil–Planter Model during the Sowing Period of Wheat after a Rice Stubble Based Discrete Element Method. Agriculture 2023, 13, 2036. [Google Scholar] [CrossRef]

| Parameters | Numerical Value | Parameters | Numerical Value |

|---|---|---|---|

| Poisson’s ratio for Leymus chinensis | 0.40 | Poisson’s ratio for hedysarum leave | 0.42 |

| Shear modulus for Leymus chinensis/(Pa) | 5.1 × 107 | Shear modulus for hedysarum leave/(Pa) | 5.2 × 107 |

| Density for Leymus chinensis/(g·cm−3) | 0.50 | Density for hedysarum leave/(g·cm−3) | 0.59 |

| Poisson’s ratio for Agropyron cristatum | 0.35 | Poisson’s ratio for seed metering device | 0.46 |

| Shear modulus for Agropyron cristatum/(Pa) | 4.7 × 107 | Shear modulus for seed metering device/(Pa) | 3.5 × 109 |

| Density for Agropyron cristatum/(g·cm−3) | 0.46 | Density for seed metering device/(g·cm−3) | 2.56 |

| Poisson’s ratio for oat | 0.20 | First kind of seed–seed metering device collision recovery coefficient | 0.38 |

| Shear modulus for oat/(Pa) | 3.9 × 108 | First kind of seed–seed metering device coefficient of static friction | 0.30 |

| Density for oat/(g·cm−3) | 0.87 | First kind of seed–seed metering device coefficient of rolling friction | 0.24 |

| Poisson’s ratio for Lespedeza davurica | 0.50 | First kind of seed–first kind of seed collision recovery coefficient | 0.17 |

| Shear modulus for Lespedeza davurica/(Pa) | 1.8 × 108 | First kind of seed–first kind of seed coefficient of static friction | 0.49 |

| Density for Lespedeza davurica/(g·cm−3) | 1.14 | First kind of seed–first kind of seed coefficient of rolling friction | 0.37 |

| Poisson’s ratio for alfalfa | 0.35 | First kind of seed–second kind of seed collision recovery coefficient | 0.25 |

| Shear modulus for alfalfa/(Pa) | 2.9 × 108 | First kind of seed–second kind of seed coefficient of static friction | 0.47 |

| Density for alfalfa/(g·cm−3) | 0.26 | First kind of seed–second kind of seed coefficient of rolling friction | 0.27 |

| Poisson’s ratio for sadarwan | 0.50 | Second kind of seed–seed metering device collision recovery coefficient | 0.14 |

| Shear modulus for sadarwan/(Pa) | 1.7 × 108 | Second kind of seed–seed metering device coefficient of static friction | 0.24 |

| Density for sadarwan/(g·cm−3) | 1.07 | Second kind of seed–seed metering device coefficient of rolling friction | 0.22 |

| Poisson’s ratio for caragana | 0.42 | Second kind of seed–second kind of seed collision recovery coefficient | 0.24 |

| Shear modulus for caragana/(Pa) | 1.6 × 108 | Second kind of seed–second kind of seed coefficient of static friction | 0.46 |

| Density for caragana/(g·cm−3) | 1.11 | Second kind of seed–second kind of seed coefficient of rolling friction | 0.40 |

| Factor | Level of Factors | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Metering shaft speed (r/min) | 5 | 10 | 15 | 20 | 25 |

| Seed inlet width (mm) | 8 | 16 | 24 | 32 | 40 |

| Seed outlet height (mm) | 6 | 9 | 12 | 15 | 18 |

| Encodings | Level of Factors | ||

|---|---|---|---|

| Metering Shaft Speed A (r/min) | Seed Inlet Width B (mm) | Seed Outlet Height C (mm) | |

| 1 | 10 | 8 | 10 |

| 0 | 15 | 16 | 15 |

| −1 | 20 | 24 | 20 |

| Type | Seed Type | Theoretical Seeding Rate (kg) | Actual Seeding Rate (kg) | CV (%) |

|---|---|---|---|---|

| a | First kind of seed | 0.0096 | 0.0083 | 10.8 |

| Second kind of seed | 0.0144 | 0.0136 | 9.2 | |

| b | First kind of seed | 0.0096 | 0.0094 | 7.6 |

| Second kind of seed | 0.0144 | 0.0147 | 8.3 | |

| c | First kind of seed | 0.0096 | 0.0132 | 9.4 |

| Second kind of seed | 0.0144 | 0.0157 | 7.8 |

| Test Number | Test Factors | Test Indicators | |||

|---|---|---|---|---|---|

| A | B | C | CV1–Y1 (%) | CV2–Y2 (%) | |

| 1 | −1 | 0 | 1 | 12.8 | 13.2 |

| 2 | 0 | 0 | 0 | 3.3 | 4.7 |

| 3 | −1 | −1 | 0 | 10.6 | 14.1 |

| 4 | −1 | 1 | 0 | 6.4 | 7.2 |

| 5 | 0 | 0 | 0 | 3.9 | 3.7 |

| 6 | −1 | 0 | −1 | 8.2 | 7.3 |

| 7 | 1 | 0 | −1 | 9.7 | 8.3 |

| 8 | 0 | −1 | 1 | 10.4 | 11.2 |

| 9 | 0 | −1 | −1 | 6.7 | 7.2 |

| 10 | 1 | 1 | 0 | 11.7 | 9.7 |

| 11 | 1 | 0 | 1 | 9.0 | 7.8 |

| 12 | 1 | −1 | 0 | 4.6 | 3.9 |

| 13 | 0 | 1 | 1 | 11.2 | 7.2 |

| 14 | 0 | 0 | 0 | 3.9 | 4.3 |

| 15 | 0 | 1 | −1 | 9.6 | 7.4 |

| 16 | 0 | 0 | 0 | 4.3 | 4.2 |

| 17 | 0 | 0 | 0 | 4.2 | 3.5 |

| Source of Variance | Qualified Rate Y1 (%) | |||||

|---|---|---|---|---|---|---|

| Sum of Squares | Freedom | Mean Square | F-Value | p-Value | Significance | |

| Model | 162.60 | 9 | 18.07 | 100.93 | <0.0001 | ** |

| A | 1.13 | 1 | 1.13 | 6.28 | 0.0406 | * |

| B | 5.44 | 1 | 5.44 | 30.42 | 0.0009 | ** |

| C | 10.58 | 1 | 10.58 | 59.11 | 0.0001 | ** |

| AB | 31.92 | 1 | 31.92 | 178.34 | <0.0001 | ** |

| AC | 7.02 | 1 | 7.02 | 39.23 | 0.0004 | ** |

| BC | 1.10 | 1 | 1.10 | 6.16 | 0.0421 * | * |

| A2 | 24.81 | 1 | 24.81 | 138.61 | <0.0001 | ** |

| B2 | 16.47 | 1 | 16.47 | 91.98 | <0.0001 | ** |

| C2 | 53.89 | 1 | 53.89 | 301.05 | <0.0001 | ** |

| Residuals | 1.25 | 7 | 0.1790 | |||

| Fail to fit | 0.6450 | 3 | 0.2150 | 1.41 | 0.3619 | |

| Error | 0.6080 | 4 | 0.1520 | |||

| Total | 163.85 | 16 | ||||

| Source of Variance | Multiple Rate Y2 (%) | |||||

| Sum of Squares | Freedom | Mean Square | F-Value | p-Value | Significance | |

| Model | 164.08 | 9 | 18.23 | 36.25 | <0.0001 | ** |

| A | 18.30 | 1 | 18.30 | 36.39 | 0.0005 | ** |

| B | 3.00 | 1 | 3.00 | 5.97 | 0.0446 | * |

| C | 10.58 | 1 | 10.58 | 21.04 | 0.0025 | ** |

| AB | 40.32 | 1 | 40.32 | 80.18 | <0.0001 | ** |

| AC | 10.24 | 1 | 10.24 | 20.36 | 0.0028 | ** |

| BC | 4.41 | 1 | 4.41 | 8.77 | 0.0211 | * |

| A2 | 32.37 | 1 | 32.37 | 64.35 | <0.0001 | ** |

| B2 | 14.76 | 1 | 14.76 | 29.35 | 0.0010 | ** |

| C2 | 22.23 | 1 | 22.23 | 44.19 | 0.0003 | ** |

| Residuals | 3.52 | 7 | 0.5029 | |||

| Fail to fit | 2.59 | 3 | 0.8642 | 3.72 | 0.1182 | |

| Error | 0.9280 | 4 | 0.2320 | |||

| Total | 167.60 | 16 | ||||

| Number | Seed Type | Theoretical Seeding Rate (kg) | Actual Seeding Rate (kg) | CV (%) |

|---|---|---|---|---|

| 1 | First kind of seed | 0.0096 | 0.0079 | 4.1 |

| Second kind of seed | 0.0144 | 0.0147 | 2.9 | |

| 2 | First kind of seed | 0.0096 | 0.0102 | 4.7 |

| Second kind of seed | 0.0144 | 0.0131 | 2.7 | |

| 3 | First kind of seed | 0.0096 | 0.0081 | 3.8 |

| Second kind of seed | 0.0144 | 0.0148 | 3.1 | |

| 4 | First kind of seed | 0.0096 | 0.0108 | 4.5 |

| Second kind of seed | 0.0144 | 0.0139 | 3.8 | |

| 5 | First kind of seed | 0.0096 | 0.0089 | 3.7 |

| Second kind of seed | 0.0144 | 0.0152 | 2.4 | |

| Average | First kind of seed | 0.0096 | 0.0092 | 4.16 |

| Second kind of seed | 0.0144 | 0.0143 | 2.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, Q.; Dong, W.; Zhang, A.; Liu, F.; Wu, Y.; Qi, Y.; Ren, Y. Design and Performance Testing of a Multi-Variety Forage Grass Mixed-Sowing Seed Metering Device. Agriculture 2025, 15, 1788. https://doi.org/10.3390/agriculture15161788

Wan Q, Dong W, Zhang A, Liu F, Wu Y, Qi Y, Ren Y. Design and Performance Testing of a Multi-Variety Forage Grass Mixed-Sowing Seed Metering Device. Agriculture. 2025; 15(16):1788. https://doi.org/10.3390/agriculture15161788

Chicago/Turabian StyleWan, Qihao, Wenxue Dong, Anbin Zhang, Fei Liu, Yingsi Wu, Yin Qi, and Yuxing Ren. 2025. "Design and Performance Testing of a Multi-Variety Forage Grass Mixed-Sowing Seed Metering Device" Agriculture 15, no. 16: 1788. https://doi.org/10.3390/agriculture15161788

APA StyleWan, Q., Dong, W., Zhang, A., Liu, F., Wu, Y., Qi, Y., & Ren, Y. (2025). Design and Performance Testing of a Multi-Variety Forage Grass Mixed-Sowing Seed Metering Device. Agriculture, 15(16), 1788. https://doi.org/10.3390/agriculture15161788