Study and Testing of a Front-Blowing and Rear-Suction Enhanced Cleaning Technology for Grain Combine Harvesters

Abstract

1. Introduction

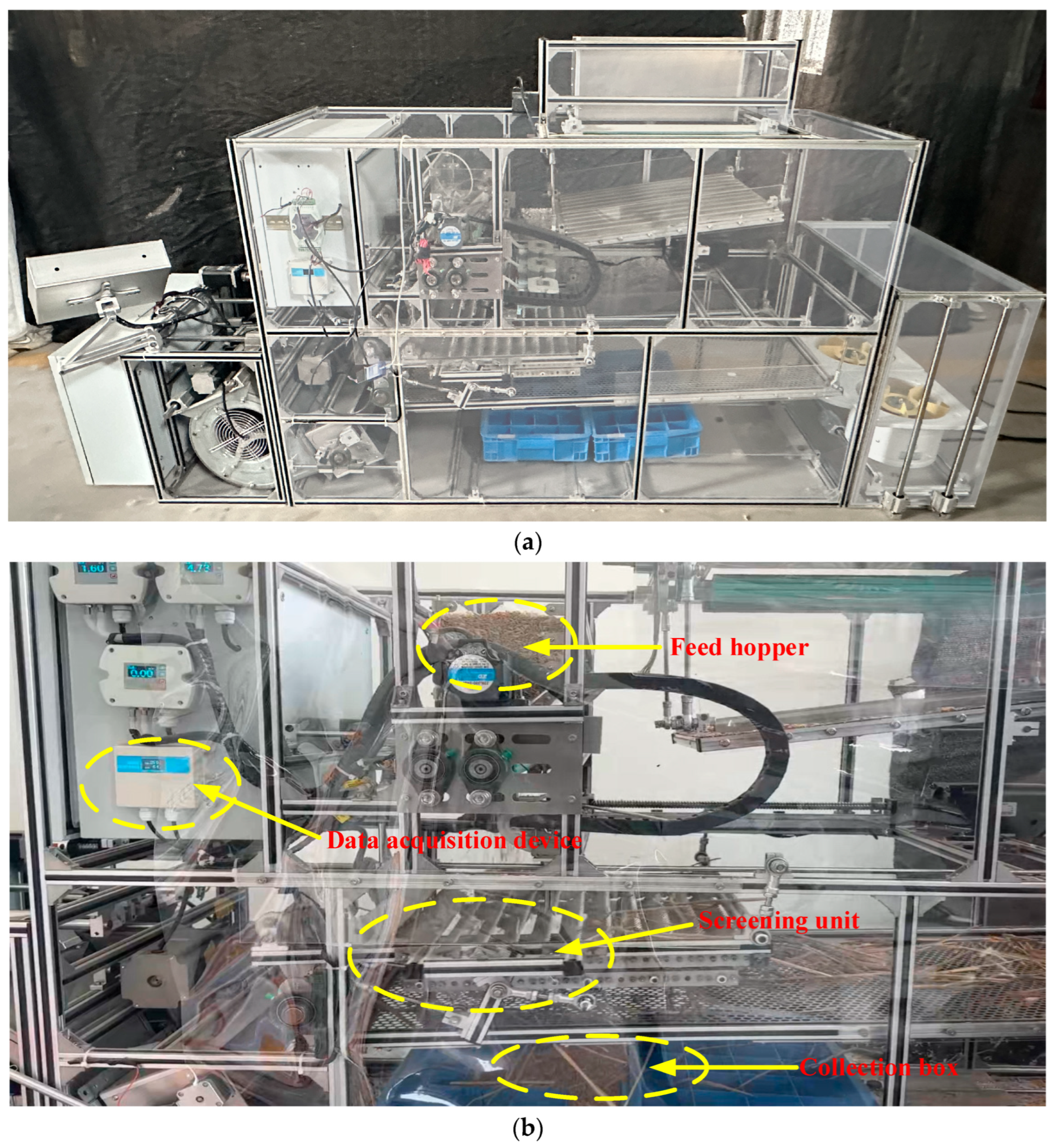

2. Materials and Methods

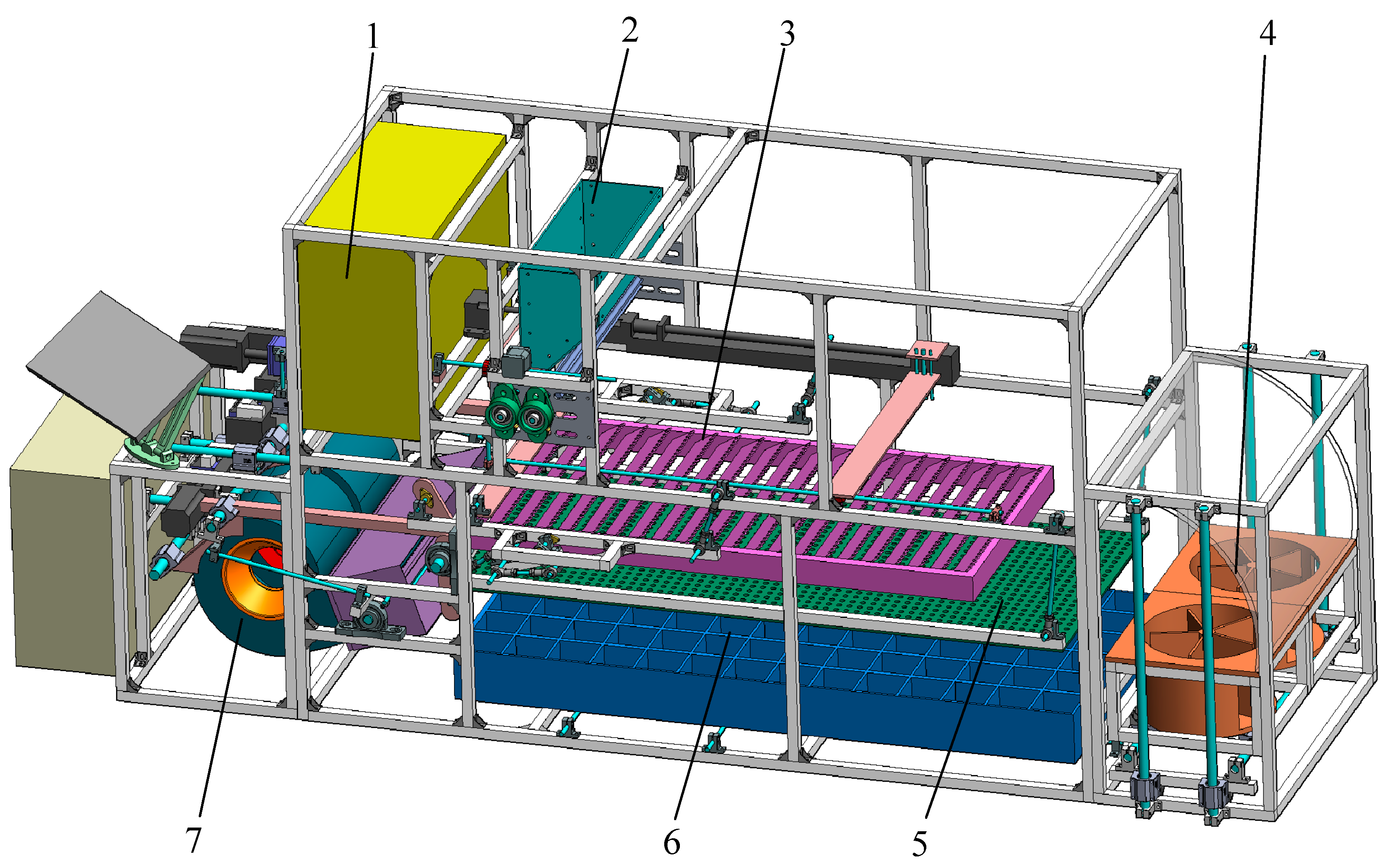

2.1. Operating Principle of the Cleaning System

2.2. Construction of the Airflow Velocity Model in the Cleaning Chamber

2.2.1. Investigation into the Flow Behavior of Cleaning Airflow

- (1)

- The light impurities are entrained and transported by the airflow, and their velocity is assumed to be equal to the airflow velocity within the cleaning chamber.

- (2)

- The vertical and horizontal components of the airflow velocity are assumed to be independent, and the airflow at the rear of the cleaning chamber is considered to be in a laminar flow state.

- (3)

- The density and pressure of the airflow in the cleaning chamber are assumed to remain constant. The density is equal to that of air under standard atmospheric conditions, and the static pressure is considered to be zero.

- (4)

- The light impurities are assumed to be uniform spherical particles with a diameter of (i.e., a radius of ), and the windward area is .

- (5)

- The threshed materials falling from the concave screen onto the cleaning sieve are assumed to be uniformly distributed within the cleaning chamber, with an average windward area denoted as .

2.2.2. Study on the Airflow Velocity Variation Model of the “Front-Blowing and Rear-Suction” Air-Sieve Combined Cleaning Technology

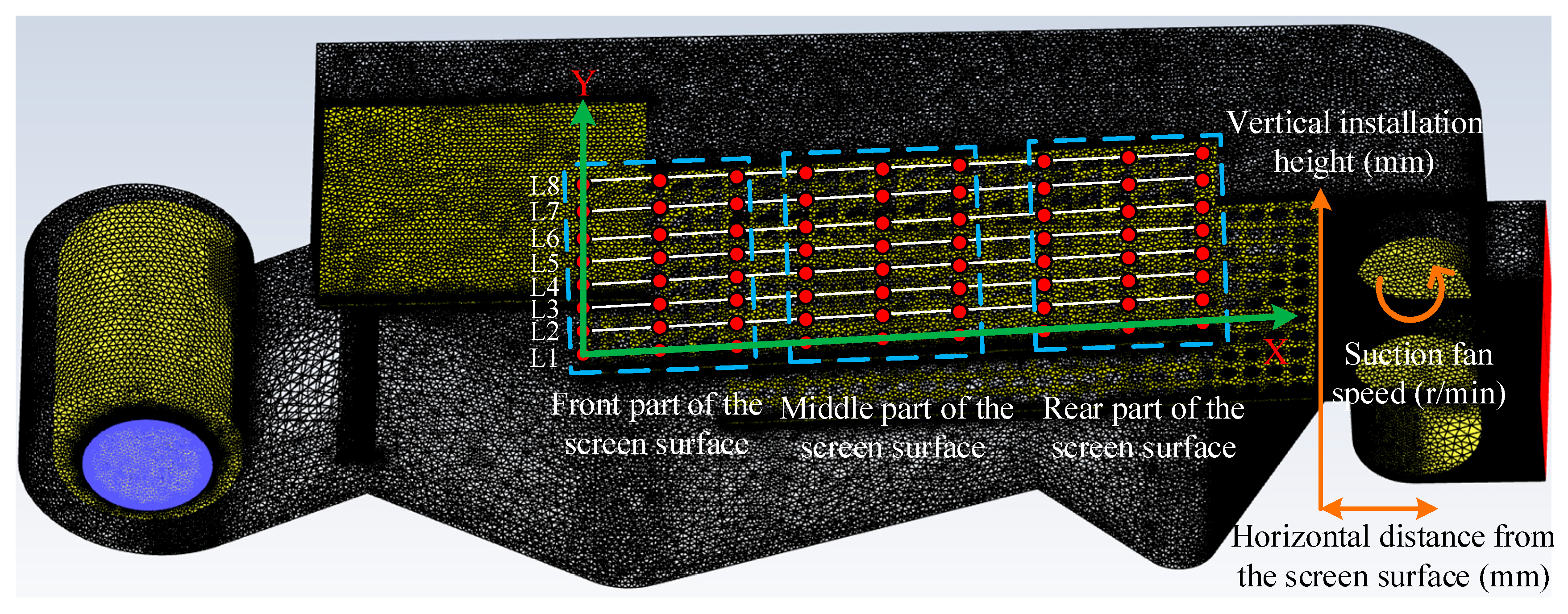

2.3. Construction of the Airflow Field Simulation Model for the Cleaning Device

2.4. Design of Simulation Experiments for Airflow Field Structure

2.5. Evaluation Indicators for Airflow Field Structure

3. Results and Discussion

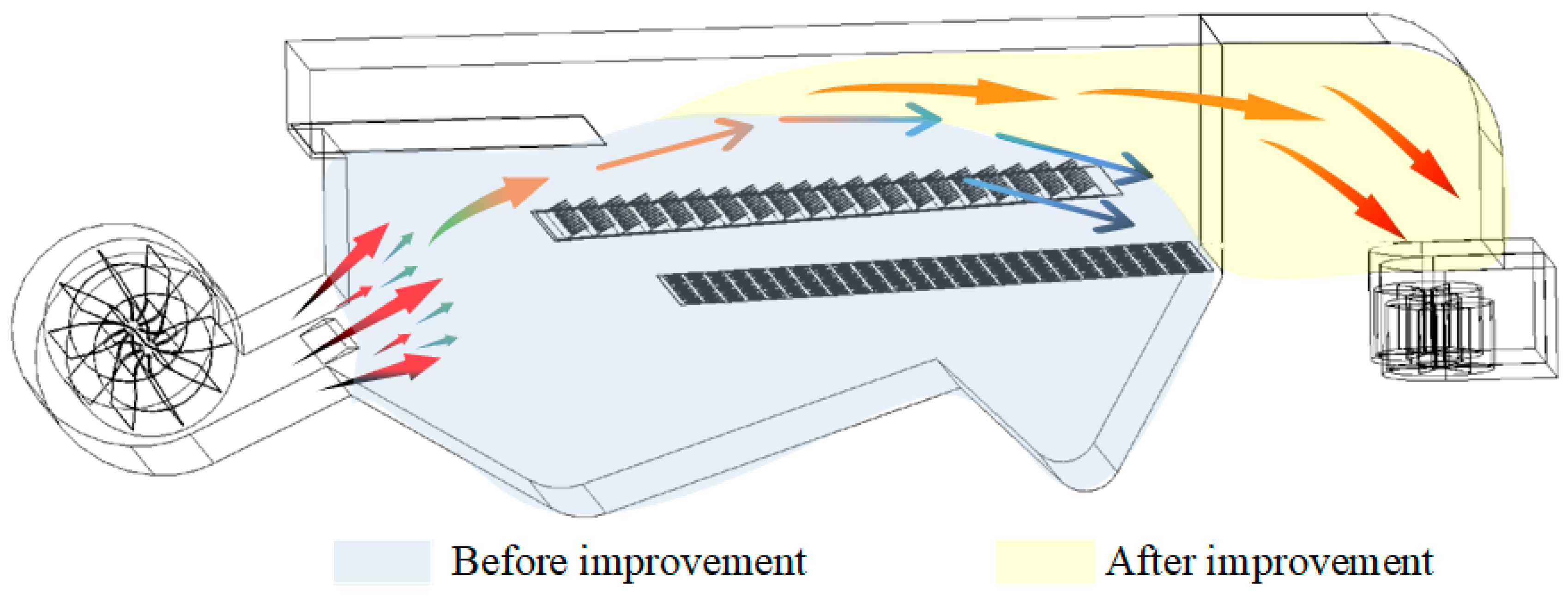

3.1. Analysis of the Airflow Field Distribution in the Cleaning Chamber Before and After Improvement

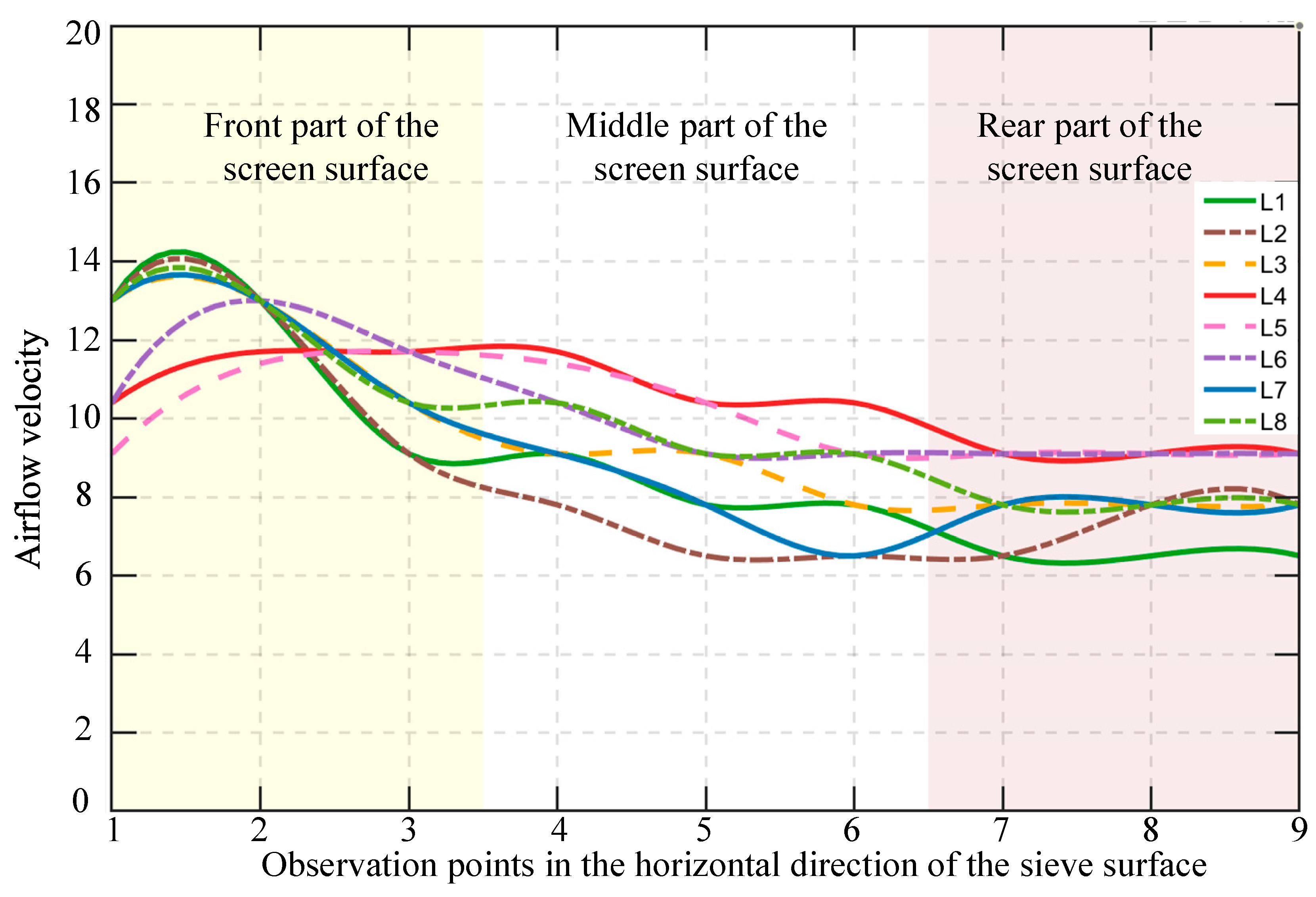

3.1.1. Analysis of the Airflow Field Structure in the Cleaning Chamber Before Improvement

3.1.2. Analysis of the Airflow Field Structure in the Cleaning Chamber After Improvement

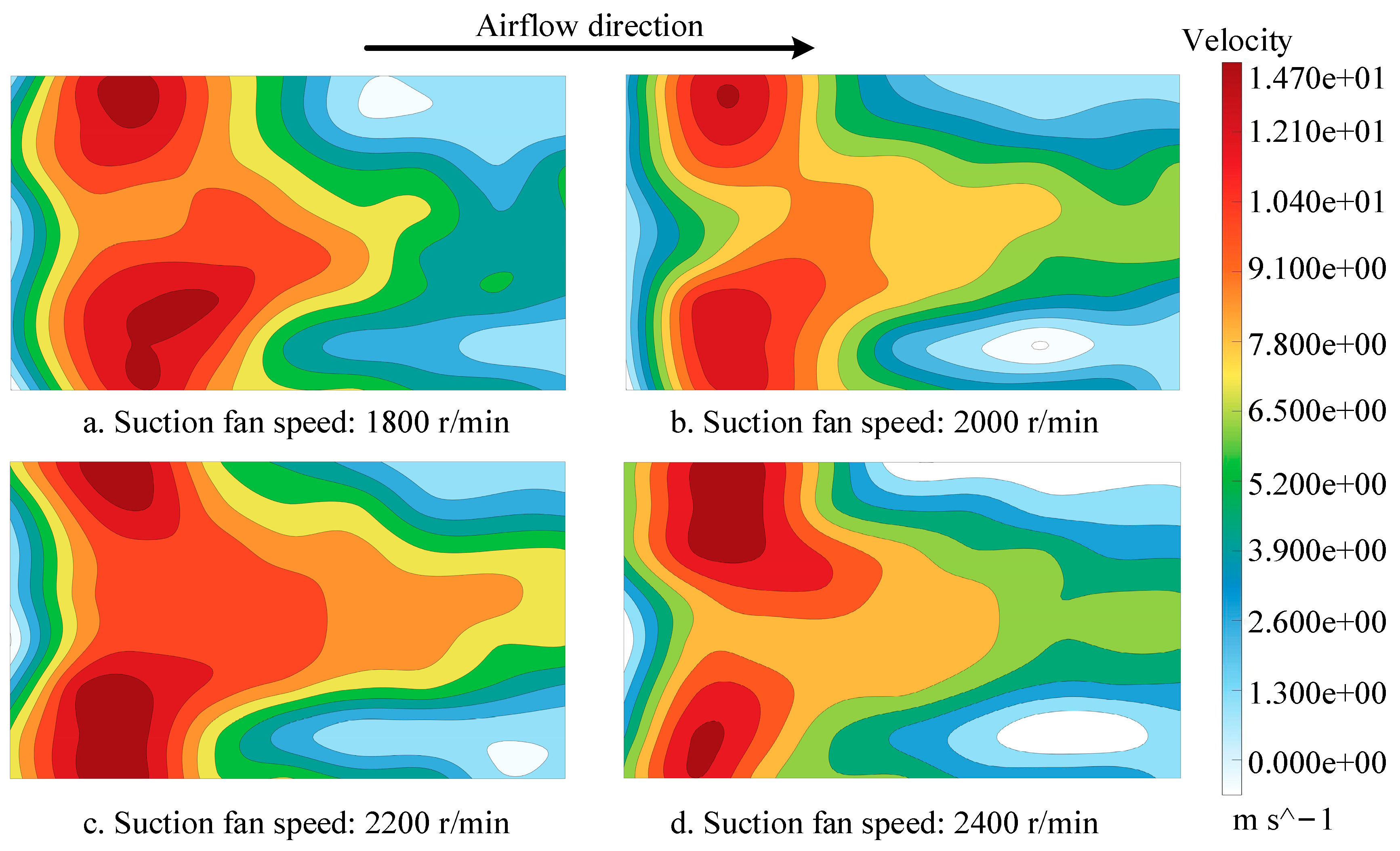

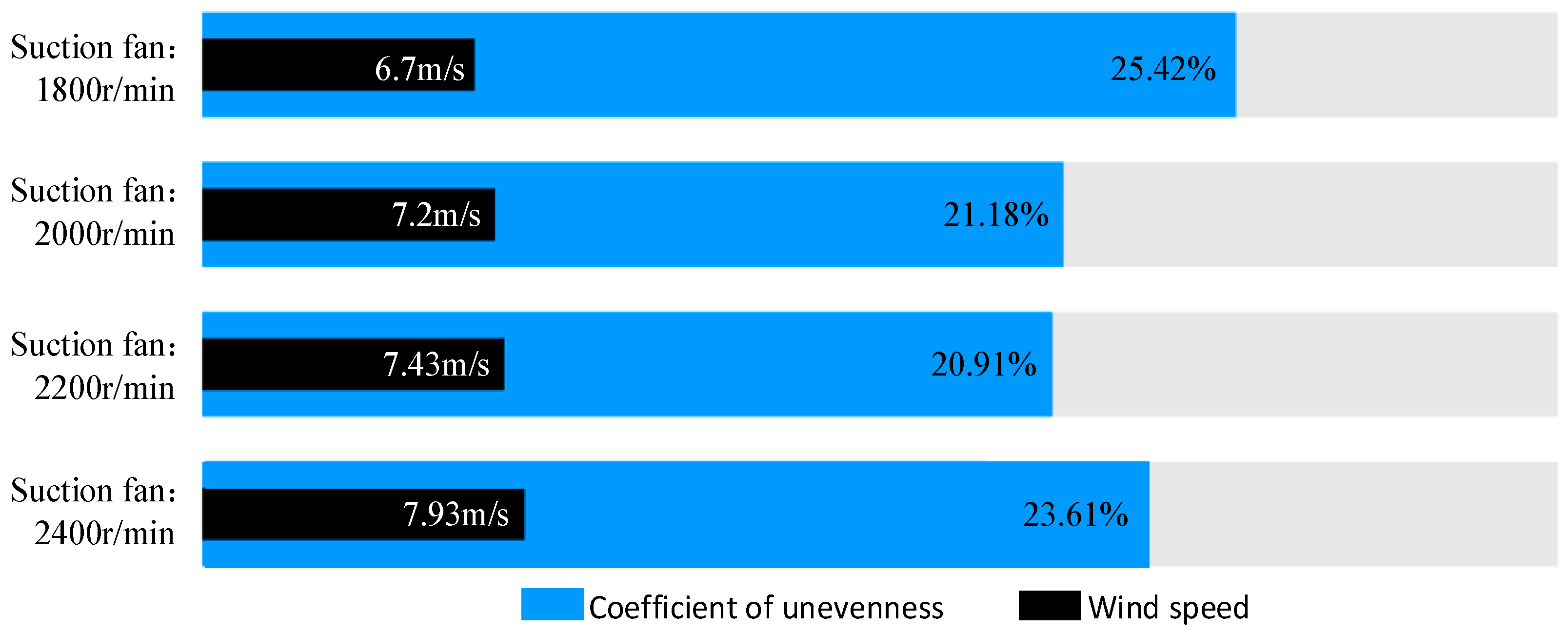

3.2. Simulation and Optimization Analysis of Induced Draft Fan

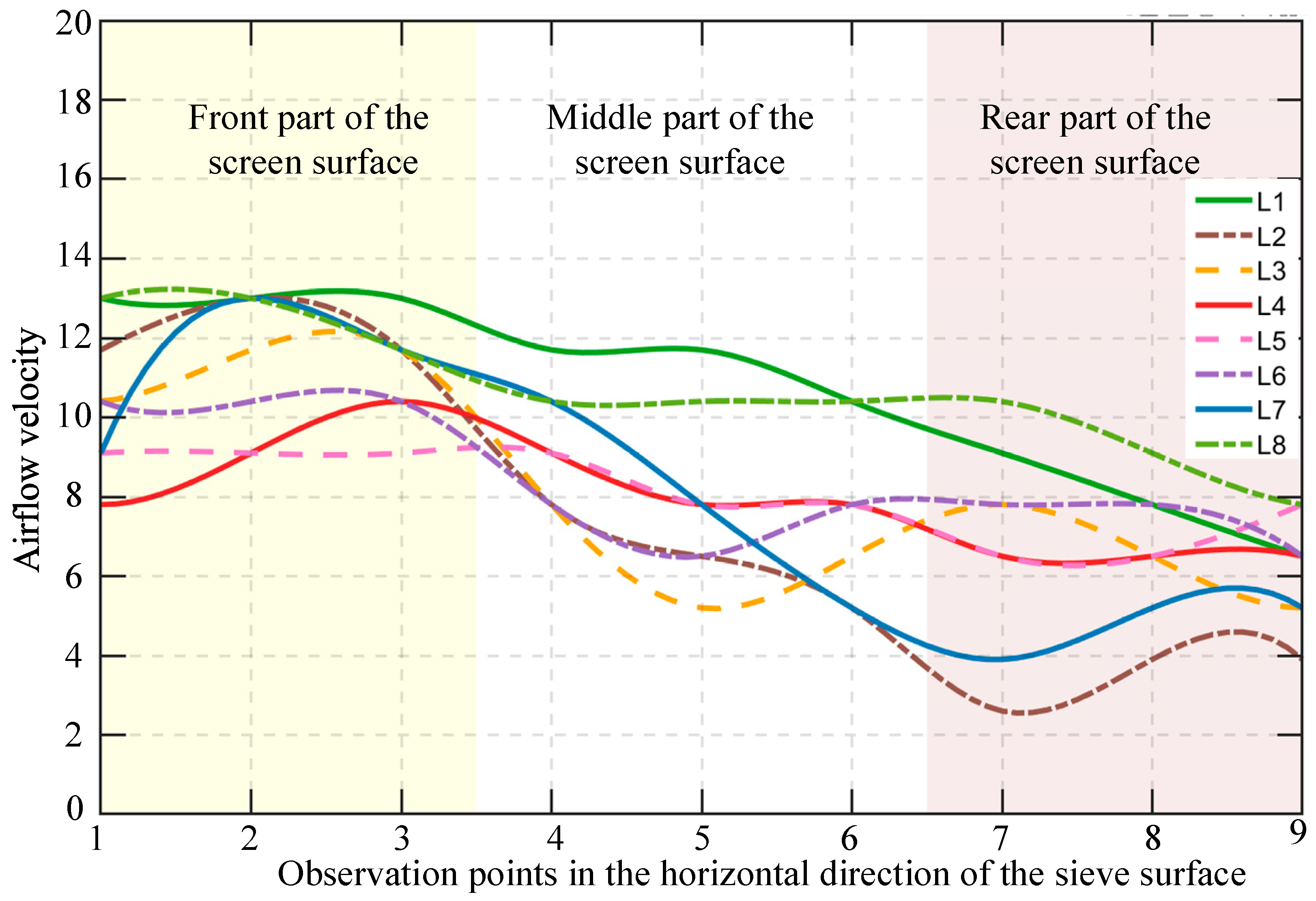

3.2.1. Effect of Induced Draft Fan Speed on the Airflow Field in the Cleaning Chamber

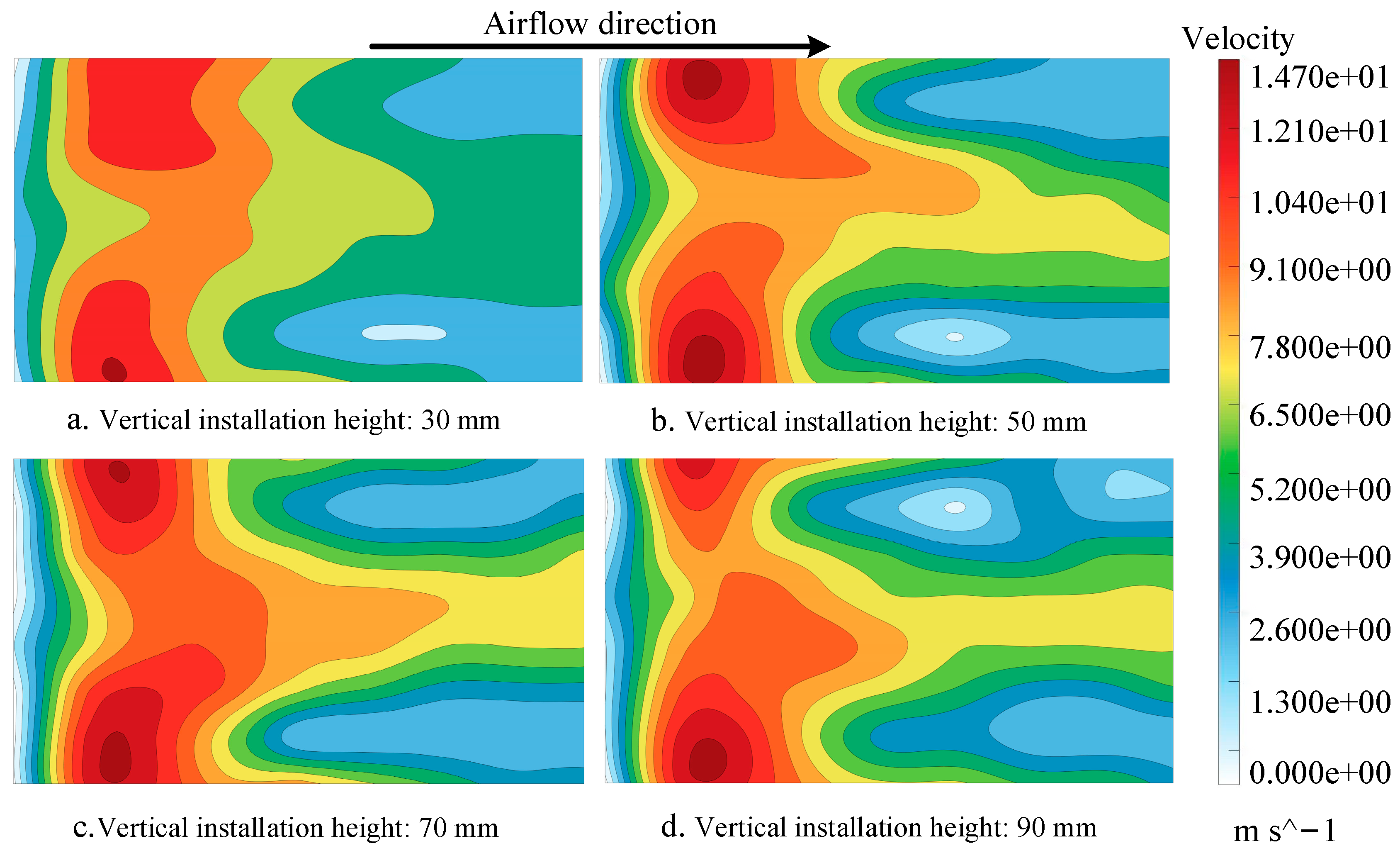

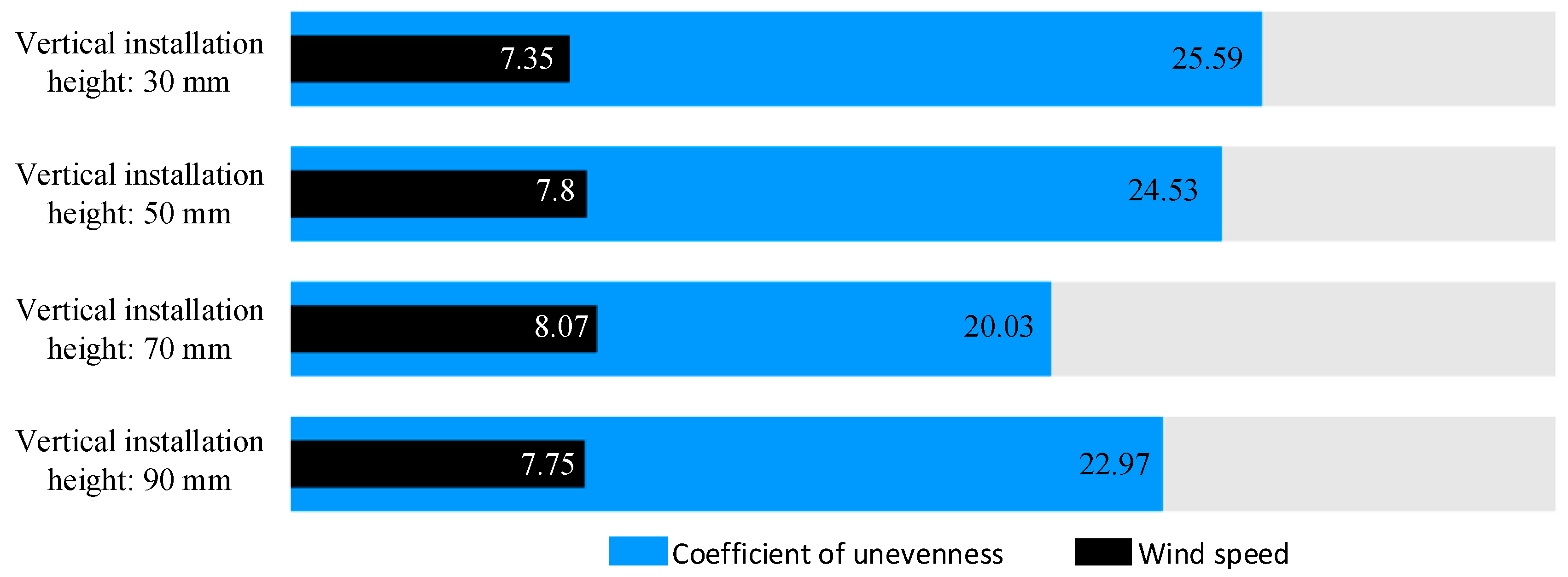

3.2.2. Influence of the Vertical Installation Position of the Induced Draft Fan on the Airflow Field in the Cleaning Chamber

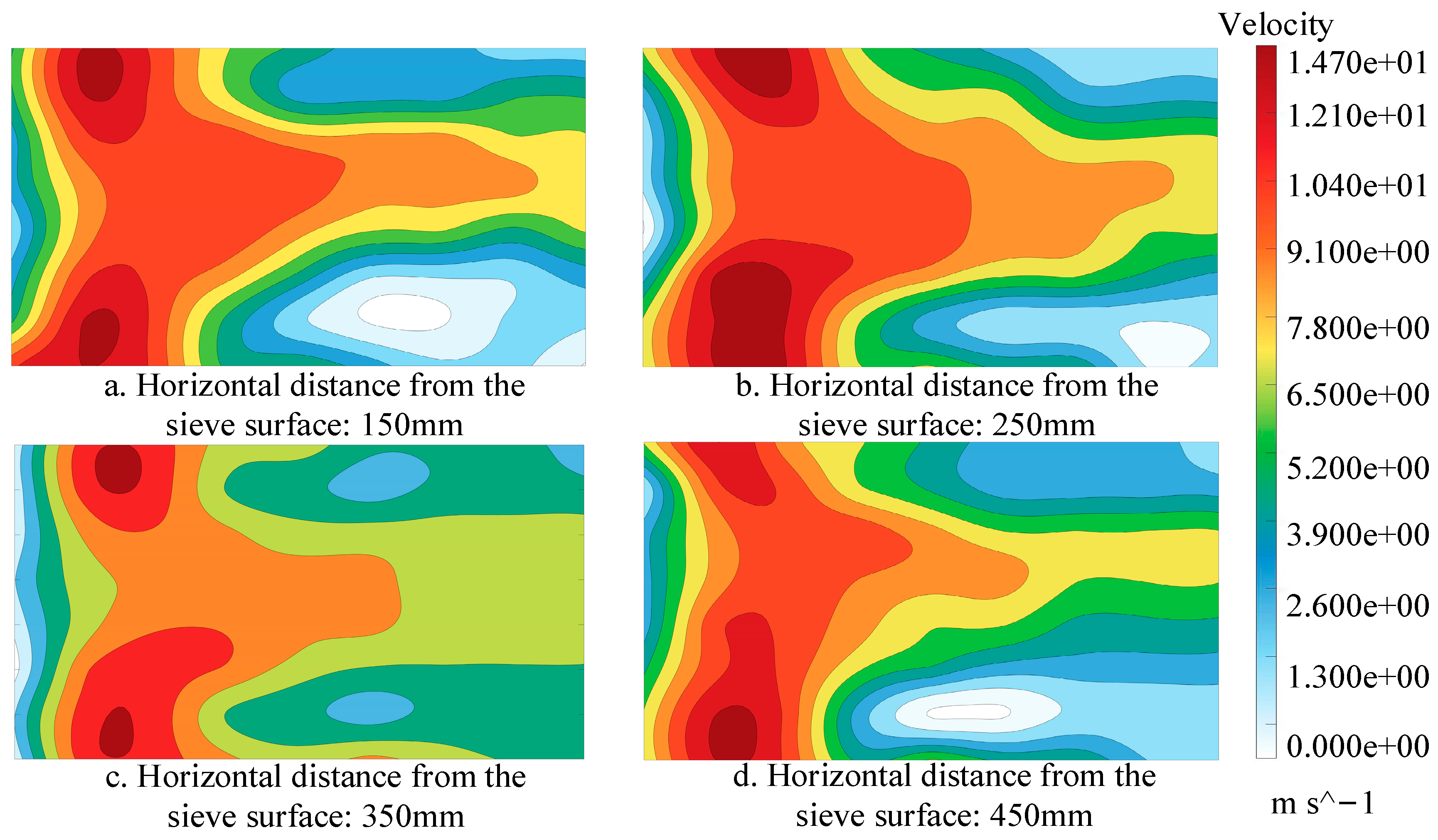

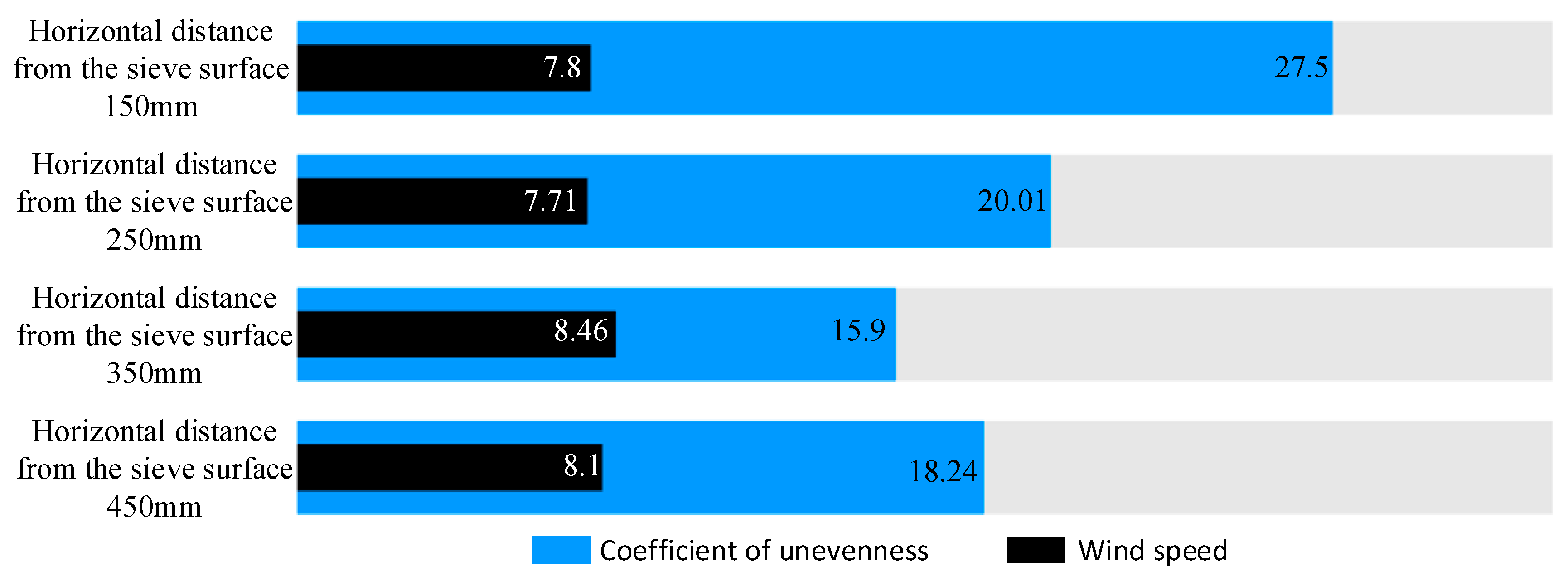

3.2.3. Influence of the Horizontal Distance Between the Induced Draft Fan and the Sieve Surface on the Airflow Field in the Cleaning Chamber

3.3. Structural Parameter Optimization of the Induced Draft Fan Cleaning Device

3.3.1. Experimental Design

3.3.2. Analysis of Experimental Results

3.3.3. Parameter Optimization and Experimental Verification

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, W.; Zeng, S.; Chen, X. Design and experiment of spiral step cleaning device for ratooning rice based on CFD-DEM coupling. Comput. Electron. Agric. 2024, 224, 109207. [Google Scholar] [CrossRef]

- Chai, X.; Zhou, Y.; Xu, L.; Li, Y.; Li, Y.; Lv, L. Effect of guide strips on the distribution of threshed outputs and cleaning losses for a tangential-longitudinal flow rice combine harvester. Biosyst. Eng. 2020, 198, 223–234. [Google Scholar] [CrossRef]

- Shao, W.; Feng, J.; Zhang, F.; Wang, S.; Li, Y.; Lv, J. Aerodynamic performance optimization of centrifugal fan blade for air system of self-propelled cotton-picking machine. Agriculture 2023, 13, 1579. [Google Scholar] [CrossRef]

- Liang, Y.; Tang, Z.; Zhang, H.; Li, Y.; Ding, Z.; Su, Z. Cross-flow fan on multi-dimensional airflow field of air screen cleaning system for rice grain. Int. J. Agric. Biol. Eng. 2022, 15, 223–235. [Google Scholar] [CrossRef]

- Dai, F.; Xu, P.; Yuan, Z.; Shi, R.; Zhao, Y.; Song, X.; Zhao, W. Simulation and optimization experiment: Working process of a cleaning device for flax combine harvester. Agriculture 2023, 13, 2123. [Google Scholar] [CrossRef]

- Liang, Z.; Li, D.; Li, J.; Tian, K. Effects of fan volute structure on airflow characteristics in rice combine harvesters. Span. J. Agric. Res. 2021, 18, e0209. [Google Scholar] [CrossRef]

- Gebrehiwot, M.G.; De Baerdemaeker, J.; Baelmans, M. Numerical and experimental study of a cross-flow fan for combine cleaning shoes. Biosyst. Eng. 2010, 106, 448–457. [Google Scholar] [CrossRef]

- Gebrehiwot, M.G.; De Baerdemaeker, J.; Baelmans, M. Effect of a cross-flow opening on the performance of a centrifugal fan in a combine harvester: Computational and experimental study. Biosyst. Eng. 2010, 105, 247–256. [Google Scholar] [CrossRef]

- Badretdinov, I.; Mudarisov, S.; Khasanov, E.; Nasyrov, R.; Tuktarov, M. Operation technological process research in the cleaning system of the grain combine. J. Agric. Eng. 2021, 52. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, L.; Guo, B.; Dang, H. Simulation and experiment of rice cleaning in air-separation device based on DEM-CFD coupling method. Int. J. Agric. Biol. Eng. 2020, 13, 226–233. [Google Scholar] [CrossRef]

- Liang, Z.; Xu, L.; De Baerdemaeker, J.; Li, Y.; Saeys, W. Optimisation of a multi-duct cleaning device for rice combine harvesters utilising CFD and experiments. Biosyst. Eng. 2020, 190, 25–40. [Google Scholar] [CrossRef]

- Zhang, C.; Geng, D.; Xu, H.; Li, X.; Ming, J.; Li, D.; Wang, Q. Experimental study on the influence of working parameters of centrifugal fan on airflow field in cleaning room. Agriculture 2023, 13, 1368. [Google Scholar] [CrossRef]

- Chai, X.; Xu, L.; Sun, Y.; Liang, Z.; Lu, E.; Li, Y. Development of a cleaning fan for a rice combine harvester using computational fluid dynamics and response surface methodology to optimise outlet airflow distribution. Biosyst. Eng. 2020, 192, 232–244. [Google Scholar] [CrossRef]

- Xu, L.; Hansen, A.C.; Li, Y.; Liang, Z.; Yu, L. Numerical and experimental analysis of airflow in a multi-duct cleaning system for a rice combine harvester. Trans. ASABE 2016, 59, 1101–1110. [Google Scholar] [CrossRef]

- Wan, X.; Yuan, J.; Yang, J.; Liao, Y.; Liao, Q. Effects of working parameters on the performance of cyclone separator for rapeseed combine harvester based on CFD. Int. J. Agric. Biol. Eng. 2023, 16, 128–135. [Google Scholar] [CrossRef]

- Chu, K.W.; Wang, B.; Yu, A.B.; Vince, A. CFD-DEM modelling of multiphase flow in dense medium cyclones. Powder Technol. 2009, 193, 235–247. [Google Scholar] [CrossRef]

- Younsi, M.; Bakir, F.; Kouidri, S.; Rey, R. Influence of impeller geometry on the unsteady flow in a centrifugal fan: Numerical and experimental analyses. Int. J. Rotating Mach. 2007, 2007, 34901. [Google Scholar] [CrossRef]

- Hussain, S.; Jianjun, H.; Yong, C.; Ali, A.; Song, H.; Zheng, D.; Farid, M.U.; Ghafoor, A.; Ahmed, M. CFD study of self-cleaning system of multi-stage tangential roller threshing unit for precise buckwheat breeding. Heliyon 2024, 10, e27180. [Google Scholar] [CrossRef] [PubMed]

- Pan, Y.; Chen, C. Exploring the relationship between particle deposition and near-wall turbulence quantities in the built environment. Build. Environ. 2021, 196, 107814. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Q.; Zhou, H.; Zhang, C.; Jiang, X.; Lv, X. CFD analysis and RSM-based design optimization of axial air-assisted sprayer deflectors for orchards. Crop Prot. 2024, 184, 106794. [Google Scholar] [CrossRef]

- Yuan, J.; Wu, C.; Li, H.; Qi, X.; Xiao, X.; Shi, X. Movement rules and screening characteristics of rice-threshed mixture separation through a cylinder sieve. Comput. Electron. Agric. 2018, 154, 320–329. [Google Scholar] [CrossRef]

- Liu, P.; Wang, X.; Jin, C. Bench test and analysis of cleaning parameter optimization of 4 L-2.5 wheat combine harvester. Appl. Sci. 2022, 12, 8932. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, H.; Hu, X.; Luo, M.; Wang, G.; Li, X.; Zhu, Y. Measurement of airflow pattern induced by ceiling fan with quad-view colour sequence particle streak velocimetry. Build. Environ. 2019, 152, 122–134. [Google Scholar] [CrossRef]

- Köhler, H.; Liebmann, V.; Golla, C.; Fröhlich, J.; Rüdiger, F. Modeling and CFD-simulation of cleaning process for adhesively detaching film-like soils with respect to industrial application. Food Bioprod. Process. 2021, 129, 157–167. [Google Scholar] [CrossRef]

- Xingyu, W.; Jiacheng, Y.; Qingxi, L.; Chongyou, W.; Min, Z.; Zhuohuai, G.; Haitong, L. Computational fluid dynamics analysis of the airflow field inside a cyclone of a combine harvester with adjustable blocks. Biosyst. Eng. 2023, 230, 205–218. [Google Scholar] [CrossRef]

- Chen, X.; Wang, D.; Wang, Y.; Lv, W.; Lei, D.; Zhang, Y.; Xia, L.; Sun, X.; Guo, Y.; Su, D.; et al. CFD design and testing of an air flow distribution device for microwave infrared hot-air rolling-bed dryer. Biosyst. Eng. 2024, 246, 204–218. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Overall dimensions of the test platform frame/mm | 2200 × 600 × 1000 |

| Impeller diameter of the centrifugal fan/mm | 300 mm |

| Outlet width of the centrifugal fan/mm | 540 mm |

| Impeller diameter of the induced draft fan/mm | 250 mm |

| Vertical distance from induced draft fan to sieve surface/mm | 150 mm |

| Dimensions of fish-scale sieve (Length × Width)/mm | 1000 mm × 500 mm |

| Inclination angle of the fish-scale sieve/° | 23° |

| Dimensions of perforated sieve (Length × Width)/mm | 1200 mm × 500 mm |

| Level | Factors | ||

|---|---|---|---|

| Induced Draft Fan Speed A/r·min−1 | Vertical Installation Position of the Induced Draft Fan B/mm | Horizontal Distance from the Screen Surface to the Induced Draft Fan C/mm | |

| 1 | 2000 | 50 | 250 |

| 2 | 2200 | 70 | 350 |

| 3 | 2400 | 90 | 450 |

| Test Number | Induced Draft Fan Speed A/r·min−1 | Vertical Installation Position of the Induced Draft Fan B/mm | Horizontal Distance from the Screen Surface to the Induced Draft Fan C/mm | Airflow Non-Uniformity Coefficient in the Rear Section Y/% |

|---|---|---|---|---|

| 1 | 2200 | 70 | 350 | 10.96 |

| 2 | 2200 | 70 | 350 | 11.09 |

| 3 | 2400 | 50 | 350 | 12.96 |

| 4 | 2000 | 90 | 350 | 14.2 |

| 5 | 2000 | 50 | 350 | 16.32 |

| 6 | 2200 | 50 | 450 | 12.53 |

| 7 | 2000 | 70 | 250 | 15.63 |

| 8 | 2200 | 90 | 250 | 12.94 |

| 9 | 2400 | 90 | 350 | 12.31 |

| 10 | 2200 | 90 | 450 | 12.51 |

| 11 | 2400 | 70 | 250 | 12.96 |

| 12 | 2200 | 50 | 250 | 15.26 |

| 13 | 2000 | 70 | 450 | 13.92 |

| 14 | 2200 | 70 | 350 | 10.57 |

| 15 | 2400 | 70 | 450 | 11.92 |

| 16 | 2200 | 70 | 350 | 11.33 |

| 17 | 2200 | 70 | 350 | 11.62 |

| Index | Source | Sum of Squares | Degrees of Freedom | Mean Square | F | p |

|---|---|---|---|---|---|---|

| Airflow Non-uniformity Coefficient in the Rear Section | Model | 44.91 | 9 | 4.99 | 49.26 | <0.0001 |

| A | 12.3 | 1 | 12.3 | 121.43 | <0.0001 | |

| B | 3.26 | 1 | 3.26 | 32.22 | 0.0008 | |

| C | 4.37 | 1 | 4.37 | 43.1 | 0.0003 | |

| BC | 1.32 | 1 | 1.32 | 13.06 | 0.0086 | |

| A2 | 10.32 | 1 | 10.32 | 101.87 | <0.0001 | |

| B2 | 6.77 | 1 | 6.77 | 66.83 | <0.0001 | |

| C2 | 3.63 | 1 | 3.63 | 35.8 | 0.0006 | |

| Residual | 0.7091 | 7 | 0.1013 | |||

| Lack of Fit | 0.0862 | 3 | 0.0287 | 0.1845 | 0.9018 | |

| Pure Error | 0.6229 | 4 | 0.1557 | |||

| Total Error | 45.62 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, J.; Cui, Y.; Zha, Z.; Yu, Q.; Guan, P.; Wang, Y.; Wang, X.; Geng, D. Study and Testing of a Front-Blowing and Rear-Suction Enhanced Cleaning Technology for Grain Combine Harvesters. Agriculture 2025, 15, 1722. https://doi.org/10.3390/agriculture15161722

Yin J, Cui Y, Zha Z, Yu Q, Guan P, Wang Y, Wang X, Geng D. Study and Testing of a Front-Blowing and Rear-Suction Enhanced Cleaning Technology for Grain Combine Harvesters. Agriculture. 2025; 15(16):1722. https://doi.org/10.3390/agriculture15161722

Chicago/Turabian StyleYin, Jianning, Yipeng Cui, Zehao Zha, Qiming Yu, Pengxuan Guan, Yang Wang, Xinxin Wang, and Duanyang Geng. 2025. "Study and Testing of a Front-Blowing and Rear-Suction Enhanced Cleaning Technology for Grain Combine Harvesters" Agriculture 15, no. 16: 1722. https://doi.org/10.3390/agriculture15161722

APA StyleYin, J., Cui, Y., Zha, Z., Yu, Q., Guan, P., Wang, Y., Wang, X., & Geng, D. (2025). Study and Testing of a Front-Blowing and Rear-Suction Enhanced Cleaning Technology for Grain Combine Harvesters. Agriculture, 15(16), 1722. https://doi.org/10.3390/agriculture15161722