Abstract

The increasing integration of sensing devices with smart technologies, deep learning algorithms, and robotics is profoundly transforming the agricultural sector in the context of Farming 4.0. These technological advancements constitute critical enablers for the development of customized, data-driven farming systems, offering potential solutions to the challenges of agricultural intensification while addressing societal concerns associated with the emerging paradigm of “farming by numbers”. The Precision Livestock Farming (PLF) systems enable the continuous, real-time, and individual sensing of livestock in order to detect subtle change in animals’ status and permit timely corrective actions. In addition, smart technology implementation within the housing environment leads the whole farming sector towards enhanced business rentability and food security as well as increased animal health and welfare conditions. Looking to the future, the collection, processing, and analysis of data with advanced statistic methods provide valuable information useful to design predictive models and foster the insight on animal welfare, environmental sustainability, farming productivity, and profitability. This review highlights the significant potential of implementing advanced sensing systems in livestock farming, examining the scientific foundations of PLF and analyzing the main technological applications driving the transition from traditional practices to more modern and efficient farming models.

1. Introduction

In the wake of the Industry 4.0 era, which has gradually transformed industrial systems worldwide, the need for technological solutions that drive the transition of agricultural sectors toward more sustainable scenarios is becoming crucial [1]. Industry 4.0 has introduced key technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics, which are now being adapted to the agricultural domain to optimize productivity while reducing environmental impact [2,3]. In addition, deepening the intricate link between sustainability and automated techno-digital solutions is of great importance in agricultural and livestock production, as sustainability is a key issue that may be addressed by harnessing the capabilities of high-efficiency technologies [4,5]. Nowadays, sustainable production models are regarded as a prerequisite for all production systems. These models are essential in agri-food and livestock systems where the interdependence among human, animal, and environmental health is emphasized and the interconnectedness of all living organisms bolsters the need for a comprehensive approach that supports the centrality of the concept of “One Health”. Notably, in the livestock sector, the “One Health” approach focuses on the importance of harmonized control measures for humans, animals, and the environment (Figure 1). Its combination with sustainable practices aims to promote system efficiency by addressing environmental, economic, and social needs in a holistic manner. This approach aligns with global sustainability goals, such as the United Nations Sustainable Development Goals (SDGs), which emphasize responsible consumption and production, climate action, and life on land [6]. The current environmental and social issues that affect the production system, from climate change to exponential population growth, from the progressive depletion of resources to rising production costs and poverty, are driving radical changes in the agri-food sector and require measures to ensure its survival and sustainability. Such complex and multifaceted challenges require advanced and precise approaches that encompass different scientific fields to achieve animal production goals and farm efficiency. In this context, digital technologies such as AI-driven predictive analytics, blockchain-based traceability, and smart sensors are becoming integral tools for optimizing resource use and ensuring transparency in the livestock sector [7].

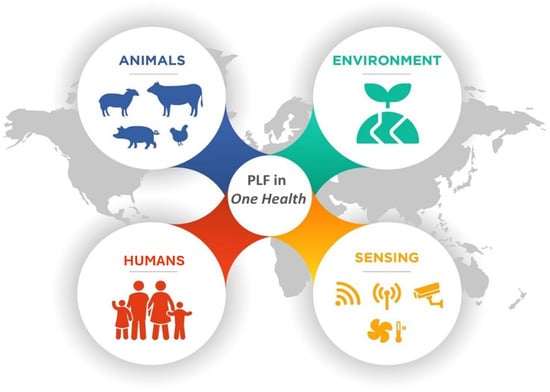

Figure 1.

Precision livestock farming (PLF) in the One Health approach integrates and reinforces the interconnected nature of animal health, environmental sustainability, human well-being, and technological sensing advancements in livestock farming.

The development of advanced models and engineering systems that contribute to sustainable food systems can be guided by the use of “sustainability indicators” in both farming and feeding strategies [8,9]. These indicators can help the industry address sustainability challenges more effectively by providing measurable benchmarks [10]. In this way, the introduction of emerging technologies may support stakeholders to improve efficiency and welfare through data collection and protocol design.

To date, Precision Livestock Farming (PLF) has been exploring technological solutions for everyday practices and routine operations to enhance sustainability [11,12,13]. Indeed, the core idea of PLF is that a high level of technological organization in livestock practices offers the opportunity to reshape animal husbandry, in both intensive and small-scale systems, by enabling a finer and earlier degree of precision in decision-making and management processes. It also bears the potential to be a powerful tool for remote collaboration between scientists and researchers, facilitating the collection of large and high-quality datasets that accelerate the understanding of the main patterns of animal physiology and production performance [11,12,13,14].

Furthermore, PLF is gaining increasing attention in policy frameworks aimed at digitalizing agriculture. For instance, the European Green Deal and the Farm to Fork strategy highlight the role of digital technologies in making food systems fairer, healthier, and more environmentally friendly [14]. These policies promote the adoption of precision livestock technologies to reduce greenhouse gas (GHG) emissions, improve animal welfare, and ensure traceability throughout the supply chain.

Livestock Industry 4.0 requires efficient and safe production that meets animal welfare, environmental and consumers standards. Thus, to achieve its full potential, PLF must consider these three pillars as part of a unique network, where technological platforms are integrated into a multi-layered structure. In the field of husbandry management, current trends confirmed that livestock welfare is not just a moral imperative, but also has economic implications, which may impact production efficiency goals in breeding systems. To improve the yield of milk, meat, and eggs and positively influence their quality it is essential to ensure high animal welfare standards and optimize husbandry techniques and handling practices [15]. For instance, advanced precision feeding systems have the potential to improve animal welfare, increase farm profitability, and reduce environmental pollution by continuously and automatically matching feed supply with animal nutrient requirements [16,17]. Moreover, real-time monitoring systems powered by AI and the IoT can predict animal health issues before they become critical, minimizing losses and improving overall farm resilience [18]. Ethical considerations encompass animal behavior as an integral aspect of the multifactorial framework of animal welfare. Monitoring behavioral patterns is essential to ensure that production practices align with environmental sustainability and respect both physiology and genetic of animals. Digital automated sensors allow for the monitoring of individual animals, even in large populations, and by integrating data from multiple sources, they provide a fully comprehensive picture of animal welfare and behaviors [19,20,21]. In addition, by combining recent sensing technologies, it is possible to detect subtle changes in behavior before physiological disruptions or visible symptoms occur, enabling early intervention and limiting the spread of diseases. Available data confirm that environmental management is a critical point directly influencing animal welfare and productivity. Animal and environmental data collected by automated precision technologies can improve overall health and welfare management, nutrition, reproduction, biosecurity, and greenhouse gas emissions [20,22]. As mentioned above, welfare, health, and environmental standards must be considered alongside consumer standards and demands. Recent research indicates that consumers increasingly value transparency in food production, with digital traceability systems playing a crucial role in meeting this expectation [23]. In order to enhance consumer perception of animal product quality, the standardization of precision livestock management could ensure both high standards of animal welfare [15] and transparency throughout the production process. For instance, blockchain-based livestock tracking systems have been proposed as a method to enhance consumer trust by ensuring food authenticity and safety [24,25].

Recognizing the importance of aligning research with day-to-day farming practices, this review aims to chart a clear path from current knowledge to the adoption of PLF strategies that can drive the transition of traditional farm management toward a modern and sustainable system. The ambition is not only to analyze the array of the main technological solutions, but also to establish meaningful relationships between the scientific principles underlying the development of PLF and the design of efficient tailor-made models for animal management and feeding strategies.

2. Review Criteria

In order to accurately draw up this review, multiple scientific databases (Scopus, Google Scholar, PubMed) were deeply explored to carry extensive bibliographic research between January and December 2024. Due to the breadth of the topic, the search criteria were first oriented to evaluate basic principles of PLF and precision feeding and, subsequently, to systematically classify the main technological devices to monitor environmental conditions and animal health and welfare. More specifically, the search terms used included: “PLF”, “Digital livestock farming”, “Precision feeding”, “Precision animal nutrition”, “environmental control”, and “air quality”. The search was extended to the following animal species: “dairy cow”, “beef cattle”, “sheep”, “goats”, “pigs”, “poultry” and/or “animal” and/or “livestock”. The following technologies were searched using: “biometric sensor”, “wearable sensor”, “biosensor”, “automatic behaviour analyser”, “image-based behaviour analyser”, “feeding behaviour analyser”, “ruminal bolus sensor”, “automatic drinker OR automatic waterer”, “automatic feeder”, “electronic feeding station”, “automatic milking system”, “activity sensor OR activity monitor”, “RFID”, “GPS”, “infrared thermometer”, “body-temperature sensor”, “automatic weigh scale”, “body condition score sensor OR automatic body condition score”, “oestrus detection systems”, “calving detection systems”, “mastitis detection system” “lameness sensor”, “automatic lameness detection”, “pressure mat OR force sensor”, “video monitoring”, “thermal camera”, “automatic sound analysis”, “vocalisation”, and “cough sensor OR cough monitor”. No Boolean operators were applied, except for “OR” and “AND”. An example of a search query is: livestock lameness sensor OR automatic lameness detection. Similarly, keywords combinations using AND were searched. The inclusion criteria for selecting papers were as follows: (1) inherence with the topic; (2) year of publication; (3) article relevance in terms of number of citations. The preferred timeframe for article selection was 2010–2024, assuming that studies within this timeframe are more likely to provide accurate and up-to-date information on the topic. However, older studies referenced in the selected literature were also included when deemed scientifically relevant.

3. Basic Principles of the PLF Approach

To date, novel ground-breaking technologies have emerged as promising solutions to drive the shift of traditional livestock systems toward modern production processes, paving the way for more efficient and sustainable husbandry practices [26,27,28]. Hence, the evolution of PLF and Industry 4.0 may be considered as overlapping processes since advancements in industrial technologies have in turn facilitated the adoption of innovative systems to refine the management of livestock farming [29,30].

While PLF primarily focuses on real-time data collection and monitoring, Digital Livestock Farming (DLF) represents a broader concept that incorporates advanced data analytics, artificial intelligence (AI), and machine learning (ML) to optimize decision-making and farm management strategies [21,31]. Clarifying this distinction helps in understanding the progressive digitalization of the livestock sector.

Electronic, robotic, and automatic on-line applications are revolutionizing the way we understand and manage livestock processes. Indeed, the adoption of precision technologies such as automatic monitoring farm devices and advanced techniques of data measurement can automatically collect and process daily information on the status of individual animals while monitoring the environment system [32]. In this context, PLF may be considered as an empowering tool where technology serves to foster animal welfare, environmental sustainability, productivity and profitability by automated, continuous, and real-time monitoring systems [33,34,35,36,37]. In addition, such management solutions act as automated “early warning systems” that help farmers in making timely decisions and simplify the management of a single animal [21,38,39]. In fact, the main goal of PLF is to provide the producers with devices that can facilitate management processes and reduce human workload.

The current availability of non-invasive technological developments that enable sound and image analysis such audio detectors, cameras, or monitors, together with biometric sensors, ensure that every process at every moment of animal life-cycle is controlled and measured. Moreover, the integration of the IoT into PLF systems allows real-time connectivity between different farm components, creating a smart environment where sensors, wearables, and automated devices work in synergy to improve efficiency and decision-making [31,40]. Therefore, PFL relies on the possibility of observing, collecting, and processing valuable data from these automated measurement systems.

To date, a well-designed data collection system requires: (i) continuous sensing of ‘animal-oriented’ and ‘environmental-oriented’ data, (ii) data storage, (iii) interpretation of measurements, and (iv) an online control system that automatically adjusts the animal microenvironment when critical variables exceeded the range of predetermined criteria of a process output, allowing to early intervention or proactive management strategies [41,42]. However, despite its potential, the large-scale adoption of PLF faces several challenges, including high implementation costs, the need for specialized training, and concerns over data privacy and security [43,44]. Addressing these barriers is crucial to ensuring equitable access to these technologies for both small and large-scale farmers. In this way, data storage and processing can also represent a useful tool for design prediction models that may delivers key information on farm processes, animal performance, environmental status, and other essential details. The models developed in this context, which are designed to proactively predict future events or trends, have the potential to optimize the use of critical resources such as feed and water. Additionally, by enabling continuous monitoring of animal health, these models can enhance the efficiency of livestock production processes and promote the adoption of more sustainable agricultural practices [28,45]. Leveraging predictive analytics powered by artificial intelligence (AI) and big data technologies can further support the early detection and prevention of diseases, improve the effectiveness of breeding programs, and enable precision feeding strategies. Collectively, these advancements contribute to a significant increase in overall livestock productivity [46,47]. Moreover, the evolution of PLF to the digital livestock farming introduces complex data and algorithms (e.g., big data analysis, artificial intelligence, machine learning, computer vision) allowing farmers and researchers to learn more about herd genetic potential, animal behavior and health, epidemiology, and territorial and rural development [28]. By leveraging these tools, predictive models can enable earlier detection of diseases, reducing reliance on antibiotics and improving overall herd health management [21,37]. In this way, these innovative approaches embody the complexity of the multidisciplinary aspect of PLF systems. According to early discussions, PLF implementation requires collaborative and interdisciplinary approaches [26,48]. In particular, farmers, researchers, veterinarians, physiologists, engineers, and information and communication technology (ICT) experts can together harness these technological skills and establish integrated application models to align technological advancements with practical farming needs, to ultimately foster the transition towards modern farming practices [21,31,44]. Such models are instrumental in facilitating the transition towards more advanced and sustainable agricultural practices [21,44]. Finally, livestock sector transition towards digitalization yields the ability to create values not only at farm level but could also facilitate the reshaping of broader socio-economic networks in which farmers are embedded [27,43]. This trend is supported by the advent of ICT and the IoT in the livestock industry, which has engendered a novel era of connectivity where things, people and animals are part of a connected multilayered data network [31]. By fostering real-time knowledge-sharing and improving decision-making at multiple levels, these interconnected systems can enhance efficiency, predict economic trends, and drive innovation in farm modernization and animal welfare [13,40,47].

4. PLF Reshapes the Intensive Livestock Industry

The livestock system is a dynamic reality of interfaced processes that entail a set of know-how and technologies related to physical, digital, and biological domains. The intensification of the agricultural and livestock sectors has driven the rise of such complexity in the in past decades. This resulted in mounting pressure on farmers which are currently challenged with the issue of providing consistent and specific care to an ever-increasing number of animals within their herds and flocks in a sustainable and cost-effective manner [49,50,51]. Nowadays, scaling up farms’ productivity and rentability without compromising individual animals caring stands as a core issue [48]. At the same time, intensification brings social concerns about the negative impacts of livestock management on animal welfare, public health, and environment [20,52,53,54]. Besides, the raised attention on food safety and human health have reinforced the interest on animal health and welfare.

As of 2020, the Food and Agricultural Organization (FAO) reported 16% increased units of cattle, buffalos, sheep, goats, and swine and a twofold increment of chicken numbers since 1990 [55,56]. In the same year, Okinda, et al. [57] detected a global number of 3535 million of animals bred in extensive and intensive systems, with an annual production of 798 and 3029 million tons of milk and meat, respectively [58,59]. The United States Department of Agriculture (USDA) defines any farm with more than 1000 cattle, 2500 pigs, or 125,000 chickens as a Concentrated Animal Feeding Operation (CAFO) or intensive farming system [60]. In the EU, the European Commission (2013) defined intensive farms as those carrying more than 40,000 chickens or 2000 pigs [61]. In the first quarter of the 21st century, the United States had 450,000 feedlots that raise chickens, cattle, pigs, and sheep, with about 24,000 of them being considered CAFOs. Due to the high number of animals per farm, intensive animal farming accounts for the vast majority of livestock raised for food in the USA [62]. As mentioned by [63] “in the future, a single farm (or animal city) could see 25,000 milking cows, 200,000 fattening pigs, or a few million broilers”; while in China the first pig “farm” of 300,000 fattening is already a reality [64]. Thus, in the coming years, one of the most significant challenges in livestock breeding will be to continuous monitoring of animal health and welfare within large groups, ensuring adequate care and food safety [26,45].

The “farming by numbers” philosophy that characterizes intensive livestock breeding has often conflicted with fundamental principles of animal health and welfare. Despite the clear benefits, concerns regarding the ethical implications and social acceptance of PLF remain. Public perception of intensive livestock farming is often negative, and the integration of advanced digital monitoring tools raises questions about data privacy, animal autonomy, and the role of farmers in decision-making [43,65]. In parallel to the public debate about animal rights and welfare, which advocates that animals are entitled to receive individual attentions [38,66], the global shift toward intensive animal rearing systems raises the question of the “good care” of animals considering the farmers difficulty to continuously pay attention to single animals [50,54]. In line with the actual vision of modern farming, “taking good care” may be considered a synonymous of “good practices” and it is the key for good productivity, health, and welfare. The adoption of effective monitoring methodologies is a way to foster symbiotic relationship between the farmers and their animals despite the challenge faced, and in turn ensure the enforcement of good practices in farm [67,68]. Within such framework, PLF technologies implementation aiding animal status monitoring within farm processes, seems an effort-effective starting point to comply with these goals [48,69]. Indeed, recent studies have indicated that PLF’s technological standards exceed the concept of “farming by number” [44] since the continuous, individual collection of basic data about the main physiological animal patterns permits the adoption of the opposite ‘per animal approach’ [70,71]. Additionally, the integration of latest digital solutions like the Internet of Things (IoT), Digital Twins in Livestock Farming (DTLF), Machine and Deep Learning (ML, DL), or Artificial Intelligence (AI) has the potential to bolster PLF instruments effectiveness, further support personalized animal management [23,28].

Sensors and biosensor devices, audio-video detectors or sensors displaced in the environment, can track in real-time data like body temperature, location, and animal behaviors, including feeding. Literature reports that sensing systems can monitor health conditions in dairy cows based on temperature and heart rate with an error rate of 0.6 °C and 3.5 beats per minute. Notably, detection systems can diagnose diseases in dairy cows with an accuracy rate of 90% [23]. Further, the application of DTLF led respectively to a 92 and 94% success rate in measuring the heart rate and the body temperature, and a 94% success rate in evaluating the humidity range in the environment [23]. The use of video monitoring and image analysis technologies in the poultry sector may detect poor welfare situations being useful in providing the opportunity to make timely improving corrective actions [57]. Similarly, an image analysis algorithm, namely Pig-ByteTrack, through the assessment of group-housed pigs’ behavior, may provide support to pig farmers in the monitor of health and welfare within big groups [72]. Additionally, the automation of routine tasks with precision feeding strategies allows for the optimization of feed and nutrient use, enhancing the efficiency and the sustainability of intensive husbandry [54,73]. PLF systems can contribute to reduce the environmental footprint of livestock farming by optimizing resource use, minimizing feed waste, and improving manure management. Studies have shown that data-driven farming practices can lead to a significant reduction in greenhouse gas emissions and nutrient runoff [15,48]. Motion tracking technologies, like Radio Frequency Identification (RFID) devices or accelerometers, can follow the movements or locate animals revealing, among others, in-depth insights of animal behaviors, such as eating, drinking, walking, resting, or ruminating. Moreover, they provide the possibility to locate animals as well as assess laying performance and behavior in hens, signs of heat or calving in cows [23,74,75,76]. These tools allow farmers to monitor animals more closely through real-time observation of health and stress indicators, behavioral changes, and productivity. Overall, data collected by automated devices can help identify patterns of animal behaviors and develop an animal’s digital fingerprint that can be used to create predictive models. These, in turn, could foretells animal’s response to a given situation and guide the adaptive decision-making [20,44,77]. Last but not least, PLF systems aid modern farmer to reduce the drudgery of repetitive farming tasks and overcome of additional animal handling stress that may influence accurate interpretations [20,78].

However, due to the complexity of livestock husbandry the relevance of a farmer centric approach in sustainable production models remains essential to our discourse [21,31,48,79]. Farmers expertise constitute the basis for PLF system adoption and its support is crucial to achieve the full potential of these technologies [47]. The symbiotic interplay between human and technologies may ensure the implementation of existing and new knowledge in husbandry practices. For instance, while digitalized technologies and sensor mechanisms offer real-time, comprehensive, and objective insights into animal welfare, it is the farmer’s deep-rooted knowledge of his herd and environment that should guide further actions. Hence, the purpose of these pioneering systems is not to replace human observations and experience, but rather to provide valuable support that makes producers more informed by aiding them take more proactive and productive decisions [80]. Moreover, the precision system should be flexible and responsive to changes in producer preferences and should offer solutions tailored to the farmers’ distinct needs, underlining the significance of a human-centric approach. Therefore, PLF may be regarded as both a disruptive concept and a multidisciplinary trade-off that, emphasizing the animal individuality, realizes a synergistic interplay among advanced technology, human expertise and traditional farming. Despite the promising potential of PLF, adoption remains uneven due to high initial costs, technological complexity, and the need for specialized training. Many small and medium-sized farms struggle to integrate these solutions into their management strategies [54,81].

5. Main Steps to Create a Tailor-Made Farming System with PLF Transition

The main objective of implementing a PLF system is to ensure that each process within a livestock enterprise, which can have an impact on productivity and profitability, is regularly checked and optimized to predefined criteria [45]. Briefly, through the control of animal health status and the optimal use of energy, feed and water, the system enables near optimum use of all resources, even in a highly variable environment, monitoring animal performance rates and environmental conditions under predetermined specifications. However, different farms have different layouts and animal management systems, and each type of livestock has its own welfare needs and distinct issues [20]. As outlined above, farm practices may be considered a set of interconnected processes, it is therefore important to select and use personalized models of precision technology supports that align with desired management goals and minimize performance gaps.

According to Wathes [82], PLF can be seen as an integrated systems approach, where modern technologies are used to steer farm processes along specific pathways to achieve the desired objectives [80]. For the effectiveness of PLF three key elements must be in place: firstly, the provision of all tools deemed essentials for the automatic measurement of system components; secondly, the introduction of measurement interpretation software and, lastly, the identification of critical measurement limits which move appropriate and timely corrective actions [35]. On this basis, the implementation of PLF systems requires the drawing of a “road map” document which analyzes the managing critical steps and aids in select appropriate tools to create a precise, tailor-made farm project [55]. The first critical step is to identify the performance gap that needs to be closed to ensure farm’s profitability optimization. This entails detecting the key processes that have a critical impact on farm management, such as the animal’s growth phase or physiological state. The second step in PLF implementation therefore implies the selection of precision measurement equipment that collect and integrate the data. Each measurement may provide relevant information about the status of a biological trait (e.g., cameras and image-analysis for body weight estimation), animal activity (e.g., about feed and water intake or estrus detection throughout cameras, global positioning system (GPS) tracking collars, sound-meters), or may detect information on the environmental status (e.g., thermometer and hygrometer for temperature and humidity). Environmental monitoring stands crucial to ensure proper living conditions to animals which affect their health, welfare and in turn productivity. Thus the use of sensor to keep them among determined ranges is common practice in confined animal rearing facilities [83,84,85,86,87]. Beyond optimizing livestock productivity, PLF technologies also contribute to environmental sustainability. By closely monitoring feed and water usage, farms can reduce waste and minimize their environmental footprint. For instance, smart feeding systems can significantly lower methane emissions from ruminants by ensuring optimized nutrient intake [15]. Humans, sensors, or robots may collect these data; so, the primary function of PLF is to simplify the process of collecting, processing and analyzing data to reduce the need for human input and the possibility of human error [41,88,89]. Otherwise, failure to assess the key processes or the available precision technologies that well fit with a specific production system may result in collecting inadequate data, management flaws, and financial loss [55]. In addition to management flaws, economic constraints often play a decisive role in the adoption of PLF technologies. While larger farms may afford the initial investment, smaller farms might struggle with the financial burden associated with purchasing, maintaining, and updating precision livestock equipment. Strategies such as cooperative investments or governmental subsidies could help bridge this gap and facilitate broader adoption [21,47]. Moreover, adequate data collection requires to determine the frequency of the measurement and the relative optimal range limits. The major outcome of data collection systems is to obtain information with sufficient frequency and to ensure that key processes on farms rest within the critical limits range. Consequently, the next critical steps involve data processing and interpreting, e.g., estimation criteria with a biological significance that can predict a dynamic outcome (bio-response). To conclude, an automated control system should be planned to apply coherent corrective actions when a critical measurement breaches the range limits and promptly bring it back within the set. The steps outlined lead to the development of tailor-made model systems that assist farmers to quickly identify problems along key processes of the production chain and to implement preventive measures to avoid critical failures. A crucial aspect of PLF adoption is ensuring that farmers and farm workers receive adequate training in using precision technologies. The complexity of data interpretation and system management requires continuous education and skill development. Without proper training, even the most advanced systems may fail to deliver their full potential [90], thus causing farmers to be reluctant to rely on PLF systems.

6. Assessing Animal Adaptative Bio-Responses Is Core to PLF

To achieve optimal levels of livestock monitoring and management through a PLF system, it is essential to gather specific evaluations of each key process of farm in order to close their performance gaps. The main variables that can be considered by PLF are livestock resource use (feed, water, land), feeding behaviors, health indicators (e.g., temperature, heart rate, respiratory rate), performances levels (e.g., milk yield, body weight), environmental conditions (e.g., temperature, humidity, pollutants) [67]. However, given the role of precision technology in the collection of relevant data on animal status, a holistic understanding of the main physiological patterns of animals emerges as a crucial point. Indeed, the animal is the most basic and most complex system to consider when formulating advanced precision strategies for livestock management and feeding [33].

Every living organism is defined as a CITD system, where CITD stands for: complex, individually different, time-varying, and dynamic [26,91]. This means that each animal is individually unique and will express a different response, in different time, to an environmental change or a stressor [26,63]. Furthermore, living organisms interact dynamically with the environment through innate and acquired regulatory mechanisms and adaptive response [92]. When these responses are overridden by environmental or internal perturbations a state of stress is reached and the ‘stress responsive systems’ are activated. Livestock must face the multifaceted challenge of physical, chemical, nutritional, and thermal stress [93]. The ‘stress system’ consists of neuroanatomical and functional structures that trigger adaptive bio-responses such as behavioral, physiological, and biochemical changes [39,94,95]. Monitoring and processing animals’ adaptive bio-responses are the starting point of any PLF system. However, they are also a crucial challenge requiring an in-depth knowledge of the main physiological and behavioral signals of the animal [71,96,97]. In this context, PLF can be seen as an animal-centred tool that places animal needs and requirements as the central part of farm processes, allowing for early-targeted interventions and confirming the direction of the per-animal approach [33,98].

The first step to achieve these goals is to identify the key indicators of the adaptive changes which mark how the animals respond to different stress conditions and that quantify the state or level of the animal health and welfare, environmental impact, or productivity. Scientific evidence underlines the pivotal role of animal welfare assessment as decisive indicator of conditions influencing livestock management. Animal welfare, therefore, has an effective impact on animal health and product quality, disease resistance, mortality, and morbidity rate [57,99,100,101,102]. Notably, animal welfare status includes a multifaceted set of indicators related to the physical, physiological, and behavioral aspects [65]. As an overlay, animal health indicators address the normal biological functioning and fitness of animals and serve as one of the most direct and immediate measures of animal well-being [103]. When internal or environmental alterations disrupt basal regulatory mechanisms, monitoring these indicators enables to detect the first signs of changes in physical or behavioral responses [13,104]. Hence, depending on the source, stress can have a serious impact on metabolic functions, basal and energetic metabolisms and overall animal health [94]. Then, farm animals may respond to stressors by altering a broad range of physiological parameters like body temperature, respiration rate (RR), heart rate (HR), but also with physical expressions such as drooling, panting, sweating, or modifying feeding or locomotion behaviors [78,105,106]. Animal health indicators, usually gathered by sensors or other technological tools (e.g., thermal camera), thanks to the IoT and devices connectivity are employed by data analysis techniques (AI, ML, or DL) to deliver information or alerts providing farmers with a more comprehensive picture regards their animal health status [107,108,109].

Already in 1980, Grandin [110] argued that comparing baseline levels of HR, RR and body temperature in animals under stress conditions is the simplest method to assess acute stress. Fluctuations in HR may be observed under stress, pain, respiratory, or other affections [107]. For example, change in HR is one of the physiological parameters used as indicator of acute stress when comparing stress levels between animals handled in poorly or well managed facilities [111]. Similarly to HR, RR increases not only during activity, but also in stressful situations or in consequence of heat stress [112]. Core body temperature is a very important parameter of animal physiological welfare. Apart from infectious diseases, factors influencing body temperature may be estrus, pregnancy, parturition, or lactation. Broadly, metabolic response to stress input may result in an increase of the body temperature. Such event has been documented in cattle and sheep, pigs, and poultry [113].

Lastly, stress exposure triggers several metabolic responses, resulting in changes in plasma concentrations of hormones, metabolites and enzymes [114]. Among others, cortisol level has been widely analyzed to assess short-term and long-term stress in experimental animals, by using saliva as matrix to measure health and welfare biomarkers due to its non-invasive collection. In farm animals, cortisol has been used to measure stress and pain related to management practices, transport, husbandry procedures, and disease [115].

As a result, the disruption of animal health and welfare due to stress factors affects animal products quality and quantity. The effects of stress on behavioral and physiological status in meat animals are widely documented [78,116]. Physiologically, the breakdown of metabolic functions due to stress response involves alterations in energy homeostasis, intracellular functions, protease activity, and muscle protein configuration, affecting the conversion of muscle into meat and potentially leading to a severe reduction in meat quality during the post-mortem biochemical changes [117]. Similarly, in broilers as well as in other animals reared for meat, poor handling or slaughtering practices will result in reduced quality or contaminated meat [118]. In the poultry sector, if laying hens are stressed or not adequately handled, the egg production will drop [119]. Infectious disease, metabolic disease, lameness, and mastitis all significantly impact on dairy production. For example, decreasing daily milk production due to mastitis ranges from 15 to 19% [120].

Continuous monitoring of animal-based parameters enables early intervention when a deviation from “normality” is detected, bridging the difficulty to assess the key indicators of animal status and different type and time-varying character of the response of each living organism [20,26,121]. For example, in pigs, the detection and analysis of animal’s likelihood to behavioral changes may unravel state of alteration linked to deviation in thermal comfort in infectious diseases [122,123].

Traditionally, quantitation of livestock physiological parameters has been carried by in-person visits assessment. However, in middle- and upper-scale farms, checking animal condition in the conventional way is not always an efficient solution [124]. Regrettably, some researchers sustain definitely that “human surveillance has ceased to be a viable solution in livestock monitoring” [102]. Certainly, these practices are time-consuming, subjective, and labor-intensive, making them unsuitable for a continuous and rational evaluation of animal welfare. Further, they also consist in invasive techniques that require animal constrain or close animal–human contact, increasing individual stress levels [78,125]. PLF technologies may additionally serve in reduce stressful situations related to handling of animals, for instance image analysis application to automate weight estimation of piglets proved high accuracy rates and may, in addition, help avoid the stress suffered by the animal [126].

Over the years, the mounting emphasis on the need of measuring animals’ health and welfare has driven the development of fully automated sensor-based technologies that can continuously monitor the adaptive physiology of farm animals [39,127]. Animal behavior, feed and water intake, temperature, and other environmental factors can all be detected using these systems [23]. Moreover, the implementation of PLF instruments with advanced statistical methods like big data analytics, ML or DL, AI algorithms, or IoT systems, has led to develop accurate predictive models that aid to identify in real-time the first signs of deviation from normality and enable the activation of early-warning signals in farm [127]. For example, several PLF technologies are used to assess porcine respiratory disease at an early stage so to ensure timely intervention, AI applied to sound analysis, HR and RR represent the most common and accurate ones [128].

In cattle, body temperature, activity and feeding behavior are the main parameters monitored for the detection of illness signs. These are important indicators to monitor because a rise in temperature or a sudden variation in the cattle’s movement, rumination or grazing behavior can be associated with common cattle diseases such as fever, lameness, or mastitis [129]. Other diseases, such as pneumonia, diarrhea, or milk fever, may be related to changes in parameters such as breath sounds, respiration and heart rate [130]. Early detection of stress or of improper feeding supply in livestock farming is of great value. Further, in cows stress can reduce feed intake and induce metabolic changes that affect digestive efficiency and alter microbial population and fermentation process in the rumen, leading to changes in methane production [131]. Recognizing stress at an early stage could, therefore, reduce methane emissions and greenhouse gas production. Similarly, precision feeding strategies optimizing feed formulation concur not only to increase feed efficiency, but also to curb methane emission per unit of meat or milk produced [132].

From the environmental point of view, intensive livestock sector relies on effective environmental control systems to optimize animal welfare and productivity and reduce farm environmental impact. Climate represents one of the main critical factors of production efficiency. PLF technologies enable continuous monitoring, at an appropriate frequency, of environmental parameters such barn’s temperature and humidity, air speed, solar radiation, and air quality. These management systems ensure on-site detection of thermal conditions or air quality problems and permit to take immediate actions. For example, application of thermal sensor within housing environment can aid to control heat stress, detecting the variations of temperature and humidity in relation to the optimal animal thermal zone. The temperature–humidity index (THI), which is calculated by using the ambient temperature and relative humidity, is one of the most important environmental parameters to ensure that the animals are in the thermal comfort zone [54]. In the last decades, due to climate change effects, the number of days per years identifiable as heat stressing are raised dramatically [133]. Thermal stress is a critical concern in modern livestock production, affecting performance, morbidity and mortality, and resulting in significant animal welfare concerns and economic losses [35]. Thus, thermal comfort is essential for animal wellbeing and among livestock, pigs are more sensitive to high temperature leading to behavioral changes like reduced feed intake which, in turn affects productivity. Hence, environment monitoring systems are key PLF tools in the swine sector to ensure animal welfare and productivity [71]. In laying hens, Lee et al. [134] designed a sound monitoring system to identify different stress-related vocalization patterns (thermal, physical, or mental discomfort) with a 96,2% accuracy when validated using real sound records. In dairy cattle, the environmental THI is a parameter largely used to evaluate heat stress [135] that, according to the classification made by Armstrong [136], began when THI exceed the value of 72. Cattle have developed several strategies to handle heat stress: by increasing respiratory rate and rectal temperature, sweating, panting, or by decreasing activity, reducing feed consumption, milk production, and fertility [137,138]. Research has shown that under heat stress, cow respiratory rate rises first rather than rectal temperature, and that as the THI value increases, the respiratory rate increases and the milk yield decreases [139,140]. During thermal stress response, dairy cows also change their behavior, e.g., by drinking more water, eating during cooler times of the day, standing more, seeking shade, and reducing their overall activity [77,138]. Recently, a predictive model was created to evaluate how cows respond to different environmental factors like air temperature, humidity, wind speed, and solar radiation. The results showed a mild correlation between environmental thermal conditions and cows’ skin and body temperature and respiratory rate [141]. Further, Antanaitis, et al. [142] examined the effect of heat stress on rumination, feeding, and locomotor activity in the first 30 days postpartum. The availability of automated monitoring of eating and rumination behavior permitted to deep investigate the interactions between disease, feed intake, and transition management in dairy cows [28]. Tullo et al. [77] found a correlation between environmental conditions (THI, solar radiation, air velocity, and rainfalls) and lying behavior of dairy cows. The authors developed a predictive model that identify in real-time deviation in cattle behavior according to climatic conditions.

Ultimately, to assure individualized care, researchers in PLF have developed automatic identification systems consisting of facial detection technologies and machine learning algorithms. These technologies analyze facial expression features and are able to identify individuals and monitor behavioral facial changes related to affective states [20]. Kumar, et al. [143] tested a face recognition system for cattle individual identification concluding that face detection can be done “in a friendlier, cost-effective and non-invasive way”. Further, since farm animals are often subjected to necessary management procedures such as dehorning, tail docking, and castration [144], specialists are developing a facial “grimace scales” to help stock-people in monitoring animal affective conditions detecting pain by using facial expressions [145]. Therefore, understanding how to achieve sustainable integration of PLF requires combining knowledge of the key principles that guide animal bio-response with knowledge of the wide range of the available technologies and applications that may be integrate into existing systems [55].

7. The Array of Precision Technologies in Livestock Farming

Technological advances are thoroughly remodelling the manner in which livestock rearing is approached, shaping the livestock industry in the context of Industry 4.0. The application of sensors, image and sound analysis in farms acts as low-labor tools designed to facilitate daily-run of farm operations and overcome limitations of traditional methods, delivering faster and more precise outcomes [146].

Research into the applications of PLF instruments has shown that the main data collected and analyzed with monitoring systems cover these fields:

- -

- Environmental conditions: instrumentation for controlling the environmental conditions and optimize the living environment in the barn such as temperature, humidity, pollutant, radiation, wind, etc.

- -

- Animal welfare and behavior: broad-range tools to control the behavioral aspects and the physiological mechanisms of stress responses of single animals and/or the relations among animals.

- -

- Animal health: monitoring tools used to detect early state of sub-optimal conditions or diseases among which measure animal health parameters or that detect sounds, images and other data.

- -

- Animal production: instrumentation to control productive variables (e.g., automatic milking systems) or innovative husbandry techniques such as feed formulation optimization, nutritional supplements, and development and application of rearing equipment.

The growing field of sensor technologies in PLF includes an array of tools, each with unique capabilities. They can be generally classified into biometric sensors (wearable sensors and biosensors), environmental sensors, and audio-visual technologies. In addition, PLF systems embrace automation technologies like automated feeding systems, milking robots, or waste disposal systems, which optimize labor-intensive tasks and overall livestock practices. Lastly, via mobile application or on-line interface, real-time data, notifications or alert can be sent to the farmer that, eventually, may manage from remote farm operations [132]. While sensor devices allow animals to be managed at the individual level supporting the shift toward a per-animal approach [147], the sound and image analysis systems have the advantage of being contactless and non-invasive. This enables the collection of data without animal manipulation, and since one camera or microphone can monitor a large group of animals, it avoids the need for human visual observations, thus reducing costs of manual labor-intensive tasks [148].

8. Sensor Devices

Sensor technologies play a pivotal role in PLF gathering real-time data on animal behavior, health status, and environmental conditions (Table 1). Moreover, customized multi-sensor systems are deemed essential for automating all stages of the farm processes, such as in cow management, where they have shown to reduce workloads and give animals a degree of autonomy, as has been seen with automatic milking systems (AMS) [20]. Indeed, AMS is considered not only one of the most significant PLF development in dairy sector [149,150], but also a holistic approach to manage dairy cow health and production efficiency [149,151]. This system combined robotic and sensor technologies through which is possible to monitor at once udder health, milk quality/quantity, reproductive status, feed intake, and body weight changes, providing a complete picture of each animal and each milking process. In fact, as well as enhance milk yield and quality, AMS improves different aspects of dairy sector such as animal health and welfare [152,153,154], herd management, and labor efficiency [155,156].

New generations of AMS may be considered crucial for improve both milking efficiency management and “animal–AMS” relationship [151]. Indeed, through voluntary milking systems, the cow elects her own milking time and interval, enabling milking to be spread over a 24 h cycle [157]. As reported in some studies, this system facilitates more than 2 milkings/day resulting in an increased milk production of 2 to 12% [149].

In conventional classifications, sensors may be located into or on the animals as portable or wearable devices, in barns or pastures as environmental monitoring systems, or as drones in the air. The basic concept of a sensor-based detection system is to automatically identify animal conditions from data delivered by one or more sensors installed in or around animals. Collected data are then analyzed using advanced statistical methods or processed by machine learning or AI algorithms, to identify and analyze patterns and/or anomalies [158]. These devices are designed to detect and react to various types of stimuli (physical and chemical), which are subsequently converted into measurable and analyzable bio-signals. The category of the sensor is usually defined by the nature of stimulus to which it responds; hence, temperature sensors measure temperature, motion sensors detect locomotion, and so on. Sensors can be furtherly divided into: (a) physical sensors and (b) biosensors. Both can be wearable, and the difference between the two is largely dictated by the type of the stimulus detected and how it is processed: sensors detect physio-chemical stimuli while, biosensors respond to biological stimuli using biological components.

As mentioned above, the PLF system prioritizes the health and welfare of each individual animal rather than focusing on groups. Sensors, by continuously and systematically assessing animal status at different stages of their lives, detect deviations from normal behavior and health at an individual level. This attitude leads to a per-animal approach and to welfare assessments that are based on a unique digital fingerprint of the animal that consent to build tailor-made farm practices.

Over the past decade, sensors have been developed around animals and are capable of effectively monitoring a variety of useful parameters for all livestock species. In particular, they can observe animal behavior such as movement and resting patterns, feeding behavior and social interactions between animals. Sensors can also provide to record real-time data on animal health status, as they detect physiological parameters such as body temperature [159], heart and respiratory rate, pH range [160], and activity levels [161] to early discover signs of disease or stress.

In terms of environmental conditions, they can monitor temperature, humidity, air quality, and light conditions in animal housing. In sheds, together with THI, air quality is also a critical factor. Suboptimal air quality affects livestock health; therefore, the accurate monitoring of pollutants like ammonia and particulate matter is essential for enable farmers to instantaneously detect air quality problems and to avoid repercussions on respiratory system, mostly for those closed in barns such as for pigs and poultry farms. Moreover, the control of the physical environment includes the measurement of pollutant emissions and odor transfer, thus reducing the environmental impact of intensive farms.

Among livestock species, the impact of the house environment in poultry production is one of the major issues, thus farm implementation with environmental sensors is the most investigated topic [35,83]. In this sector, the main monitored environmental inputs are temperature, air velocity, ventilation rate, litter quality, humidity, and gas concentrations, including carbon dioxide and ammonia [84,85,86,87]. Environmental conditions that exceed the established standard may result in reduced feed intake, slower growth [162], high-stress levels [163], and high mortality rates [164]. An example of how PLF technologies can be used to monitor and control the poultry house environment is through humidity sensors that manage this parameter via ventilation rate changes. Relative humidity is a crucial environmental aspect of a poultry house, as it can impact bird health [86,165]. Moreover, relative humidity levels are closely linked to the concentrations of ammonia and carbon dioxide gases and dusts level within the poultry house, which can further affect the well-being of birds [166]. The exposition to raised levels of these gases is known to decrease growth index, feed conversion rate, and immune response [167]. Jackman, et al. [168], combining data on broilers weight with temperature, relative humidity, carbon dioxide, and ammonia concentrations from sensor input, generated a prediction model to calculate the mean final bird weight with an accuracy considered as good to excellent and demonstrated the correlation between environmental factors and bird performance.

As aforementioned, wearables sensors comprise devices intended to be positioned over (e.g., collars, accelerometers, ear tags) or inside (e.g., boluses, microchips) the animal body, thus can monitor different health-related conditions such as body temperature and heart rate or behavior-related such movement and feeding behavior (e.g., animal activity, rumination, laying behavior).

For instance, behavioral-oriented sensors are used in order to avoid the need for continuous visual observations of typical activities related to the animal behavioral sphere. These indicators cover a wide range of behaviors, including eating and sleeping habits, social interactions, or other natural behaviors. Moreover, these valuable data may be useful to fuel innovative researches on animal behavioral and ethological models helping to deep understand the mental and emotional facets of animal welfare and providing a window into the animal sphere that reflect its comfort, stress, or frustration [21,169,170].

For the evaluation of animal behavior, one of the most notable wearable devices used in precision farming are motion trackers [130]. A few commonly used wearable locomotion devices for livestock farming are radio-frequency identification (RFID) tags, GPS (global positioning system), pedometers, accelerometers, and microelectromechanical (MEMS)-based activity sensors [171].

RFID (Radio Frequency Identification) devices may be embedded in ear tags and collars or implanted subcutaneously, to monitor a broad range of behaviors such as motion activity, eating, and drinking [172]. Barbari et al. [173], in pigs reared in open space, used a RFID collar to identify feeding, drinking, and resting behavior. In cattle, RFID transceivers implanted in the tailhead can be used for estrus, mating and calving activity detection [67]. The RFID application in laying hens may be useful to monitor laying behaviors [76].

Over the years, PLF mobility detectors like GPS, applied to grazing animals have permitted to better understand the behavioral distinctions between the animals, their organizational processes or their interfering ecological disturbances. By tracking location on pasture was made possible, for researchers and farmers, to observe animal migration or livestock use patterns on the landscape like grazing selection, pasture use, and changes in forage preference through time [23].

The number of steps each animal move daily can be measured objectively by a pedometer (step counter), and the distance covered can be estimated with the aid of an algorithm. Natural behavior modifications, such as estrus or calving manifestations, but also signs of stress or disease can be detected with this sensor. In the past, it was mainly used to detect estrus in cows [172,174]. Further, pedometers were also used to detect lame calves before clinical signs appeared. The efficiency of an ALT-pedometer (ALT: Activity, Lying behavior and Temperature) to record cattle movement activity and detect lameness was investigated by Alsaaod and Büscher [175]. Previously, Mazrier, et al. [176] concluded that pedometers can detect lame cows before clinical signs occur recognizing reduced hoof activity in 15% of cows examined several days before the start of clinical lameness.

Otherwise, currently, the main device used to track moving animals and behaviors are accelerometers [130]. These instruments detect leg movements and measure the acceleration of the animal using electromechanical signals; thus, they can follow in real-time movements and habits or assess locomotion problems [19]. Accelerometer devices may be mounted to wear as an ear tag, nose halter, neck collar or on leg [67,177]. Literature reports that the mounting position of a sensor using an accelerometer is crucial to detect a cow’s specific behavior [178]. Indeed, while a neck-mounted sensor detects more accurately feeding behaviors, a leg-mounted accelerometer is more suitable for lying detection [179]. Hendriks, et al. [180] analyzing the most proper use of accelerometers underlined the importance of an appropriate and firmly attachment on the hind limb of the cow for more accurate results in the monitoring of lying behavior. In beef cattle these sensors are used for long-term observation of mobility and behavior [181]. In grazing animals, location, posture, and movements, especially gait and jaw movement, are the most important parameters to monitor. The collection of data based on the position of cow’s head (up or down) recorded by an accelerometer combined with a GPS system, allowed to detect posture analysis and feeding related behaviors in grazing animals with an accuracy > 90% [182]. To calculate beef cattle’s grazing time, Raynor, et al. [183] measured the time an animal spent with its head in a downward posture. Further, continuous monitoring of jaw movements can reveal data about grazing habits, animal health status or pasture availability [182,184]. In dairy farming, a part for motion activity, accelerometers have been used to detect diseases or crucial reproductive phases such estrus, mating, and calving. For example, the detection of heat events in cattle can be revealed by the use of accelerometers as stated by [185]. The “Moocall” is a tailhead mounted accelerometer used for detecting calving time on the basis of tail position [67]. The “Moomonitor” is a collar device with an integrated 3-axis accelerometer, commercially available since 2000, which is used for detecting the standing behavior of dairy cows during estrous [186]. Following further development, this device has been applicated also for accurately record grazing and rumination time in dairy cows [187]. Lastly, in sheep, ear-mounted sensors identified grazing, standing, and walking with an accuracy respectively of 94, 95, and 99% [188].

In PLF, these devices are often designed as a multiple sensor system, collecting data on several health and welfare parameters at once also on a huge number of animals [67,108]. As concluded in a classification by Alipio and Villena [130], in cattle, the most commonly used devices are accelerometers and temperature sensors employed for detecting and measuring rumination and body temperature. In a study, Aswini, Santhya, Nandheni and Sukirthini [108] described a cattle health and environmental monitoring system using various types of sensors such as thermistor, heartbeat sensor and GPS fitted to the cattle. Modern remote monitoring systems are based on wireless devices connected by IoT technology. The basic idea of the IoT is to allow interactions among tools such as Radio-Frequency Identification (RFID) tags, sensors, mobile phones, etc., which interact each with other. A RFID-based locating system is a stationary sensor fixed in the environment that record animal behavior. These stations are placed near a feed bunk, a water point, or a mineral lick block and, combined with other wearable sensors, may identify animal water and feeding behaviors [189]. For example, to record drinking behavior and water intake in grazing heifers, Williams, et al. [190] proposed an automatic equipment that mixed three sensor technologies: a RFID panel annexed to the water point entry and exit, a neck-mounted accelerometers that detects drinking events and a water flow meter posed on trough that measure water intake. In addition, all cattle wore a RFID ear tag that consent to identify (by its ID) when each animal visit the water point. An IoT-based sensor technology may measure also body temperature and heart rate through wearable collars combined with a fixed base unit that measure environmental temperature [108,109]. Chaudhry et al. [107] proposed a customed IoT multi-sensor board composed with a collar embedded on animal that act as pulse sensor, temperature sensor and accelerometer, combined with a fixed based unit that measure ambient temperature and humidity. For pigs and poultry farming, Pan, et al. [191] referred about a system developed by The Big Dutchman company, the ‘BigFarmNet’, which combines all the controllers, computers, sensors and machinery in one system [192]. These systems are designed to set up and manage applications in a single barn or across the whole farm, and to exchange data among systems. For example, in poultry farms, literature reports the use of customed multi-sensor systems designed to monitor birds’ movement. This latter may be considered a direct indicator of welfare status in this rearing system, since housing conditions may limit freedom of movement due to the high stocking density and the relative space availability [167]. Zhang, et al. [193] used RFID tags and readers to monitor poultry movement and behavior as feeding and resting time. Again, Chien and Chen [76] designed a smart nest box to assess single hens’ laying performance and behavior. This was equipped with a RFID reader and a pressure sensor to monitor whether a hen was entering/exiting the nest or the presence of an egg. While, an electronic sensor placed under a mat and connected to a software that allow force recording, was used in a study of Nääs, et al. [194] to evaluate locomotion deficiency in broiler chickens.

In dairy cattle precision systems, feeding and rumination behavior, lying behavior, rumen pH and temperature, body temperature, animal activity or location are all available through customed wearable multi-sensors systems [147]. In particular, ingestive-related behaviors (lying, feeding and ruminating), may be considered the main indicators of health, productivity and welfare in this species [177]. Further, as previously stated, the advent of multi-sensor devices has led to a significant increase in research efforts aimed at fostering a thorough comprehension of animal feeding behavior and habits. Numerous investigations conducted over the past years have shown that the time a cow spends for lying, feeding and ruminating may be related to its health and welfare status [195,196,197]. For instance, accelerometers and GPS devices together can record valuable information on cattle lying behavior [174]. Collected data shown that lying time increases if cows are affected by metabolic disease, mastitis, metritis, lameness or are close to estrus or calving [75,77,198]. Similarly, cows lie less when animals stocking density or housing conditions are not appropriate [54]. Among others, feed-intake behavior and rumination time may be used to predict a plethora of health-related signs, such as the status of the reproductive cycle of cows (calving, estrus), metabolic disorders, hoof or udder pathologies [199,200,201,202]. For example, during clinical mastitis, Jaeger, et al. [203] observed in affected cows a decline in feeding and ruminating rates. In addition, they found that the feed intake parameter was more sensitive to diseases in respect of ruminating time. Similarly, Norring, et al. [204] found that feeding time was a suitable parameter for the early detection of lameness in cows. The ‘CowManager SensOor™ system’ (Agis Automatisering BV, Harmelen, the Netherlands) is a 3-dimensional accelerometer attached to RIFD that provides to real-time quantification of ear temperature and ingestive-related behaviors such as ruminating, feeding and general activity of milking cows [203]. Another sensor system is ‘RumiWatch’ (Itin + Hoch GmbH, Liestal, Switzerland), a pressure-based noseband sensor that monitors eating, drinking and rumination activity in stable-fed dairy cows. The system consists of an oil-filled silicone tube containing a pressure sensor which is attached to a collar over the cow’s nose [184,189,205]. Moreover, rumen functions may also be monitored by wireless intraruminal bolus sensors intended to detect ruminal temperature, pH, pressure or activity. This device is inserted orally in the reticulum and is equipped with an accelerometer combined with a temperature and a pH sensor, an internal battery and a transmitter [179].Changes in ruminal temperature or pH as well as modification of ruminal activity, measured by the amplitude and frequency of ruminal contractions, can help to assess metabolic disorders (rumen acidosis, subacute rumen acidosis or hypocalcemia) or other disease that cause increased body temperature, pain or anomalous behaviors [39,174]. Notably, rumen pH is a straightforward indicator of rumen physiology and fermentation. Optimal food fermentation and fibre absorption are achieved in a ruminal pH range of 6.0–6.4. By using a real-time reticulorumen bolus sensor, a temperature detection system, and a laser methane detector, Antanaitis, et al. [206] found relationships between rumen parameters and both methane emission and heat stress risk in cows. The authors stated that cows with higher rumen pH (6.22–6.42) can emit 46.18% more methane, than cows with lower ruminal pH.

Similarly to wearable devices, biosensors and immunosensors have the primarily purpose of monitoring livestock health conditions and detect early signs of illness or abnormality leading to a non-invasive diagnostic procedure. In particular, while wearable devices measure and record macroscopic parameters of an animal, biosensor recognizes in body fluids specific biochemical substances (e.g., cortisol, lactate, BHB) that produce a detectable and measurable electric signal and that may be referred on a physiological parameter or indicate stress or disease. They also provide to researchers many insights to better understand the behavioral or physiological responses of farm animals when subjected to stressors [207] or inadequate nutrition [208]. In addition, biosensors have the ability to precisely quantify these parameters and to detect specific analytes, thus showing selectivity [130]. For instance, beta-hydroxybutyrate (BHB) is a key biomarker for diagnosis of subclinical ketosis in cows and can produce useful information on stress response before external symptoms are observed. Weng, et al. [209] developed a quantum dots-based biosensor designed as a specific portable device for subclinical ketosis detection on farm. Advanced immunosensor kits conceived to detect BHB in dairy cattle have shown high specificity and sensibility in a study conducted by Tuteja, et al. [210]. Corticosteroid hormones are common biomarker of animal’s stress response and traditionally their level is measured on blood samples. Cook [211] reviewed in detail the current minimally invasive cortisol assays available. In addition, Yamaguchi, et al. [212] designed and tested a salivary cortisol immunosensor that shown to closely correspond to ELISA assay.

Table 1.

Main PLF sensor technologies, their applications, and benefits.

Table 1.

Main PLF sensor technologies, their applications, and benefits.

| Sensor Type | Function/Application | Specific Measurements | Benefits | References |

|---|---|---|---|---|

| Wearable Sensors | Monitor individual animal health and behavior through continuous data collection. | Body temperature, heart rate, physical activity, feeding behavior. | Provides real-time health monitoring, allows early disease detection, tracks physical fitness. | [20,130,159,160,161,172,174]. |

| RFID (Radio-Frequency Identification) | Track and identify individual animals for better management and health monitoring. | Feeding activity, movement patterns, social interactions, laying behavior. | Improves herd management, enhances record-keeping, supports individualized care. | [67,76,172,173] |

| GPS (Global Positioning System) | Monitor grazing patterns and movement of livestock in real-time. | Location coordinates, grazing duration, movement trajectories. | Aids in pasture management, enhances animal welfare by understanding grazing behavior. | [23] |

| Pedometers | Measure daily activity levels and detect deviations from normal behavior. | Steps taken, activity levels, rest periods. | Facilitates identification of health issues, encourages better physical activity. | [175,176]. |

| Accelerometers | Monitor animal movement patterns and behavior, detecting changes indicative of health issues. | Locomotor activity, feeding behavior, behavioral anomalies. | Enhances disease detection, tracks changes in activity levels, supports behavioral research. | [19,67,123,178,179,181]. |

| Biosensors | Analyze biological samples to detect specific health indicators or diseases. | Biomarkers in blood, saliva, or milk. | Enables early diagnosis of diseases, supports preventive health measures. | [207,208,209,210,212]. |

| Multi-Sensor Systems | Combine multiple sensors for comprehensive health and welfare monitoring. | Various health metrics, behavioral data. | Provides a holistic view of animal health, improves data accuracy and management efficiency. | [67,107,108,109,184,189] |

9. Audio Visual Technologies

As part of PLF technologies currently deployed in livestock farming sector also fall the audio-visual technologies (Table 2). These stand out as non-invasive nor intrusive technological tools to efficiently monitor animal health, welfare, and behavior.

9.1. Visual Analysis

Video-based PLF technologies entail surveillance cameras, easy to place in barns, used to evaluate a broad range of animal-based indicators. Imaging technologies can be used for individual identification (e.g., through facial detection, see above) or to assess animal heath, feeding behavior, animal weight, gait or posture, and social interactions [44]. Automated imaging systems can reduce the drudgery of routinary tasks, such as visual scoring or animal weighing, and reduce the stress associated with attachment of wearable sensors to monitor animals [213]. As for other monitoring devices, the introduction of advanced data processing methods such machine or deep learning systems, allows the analysis of large amounts of visual information and the design of accurate predictive models. For instance, algorithms have been developed to analyze video images that detect changes in posture, isolation behavior, locomotor activity and body weight in pigs [214,215,216].

In poultry rearing, PLF systems like digital imaging, vocalization analysis and thermal/infrared analysis, received increasing attention on a global scale and the majority of studies focused on improving animal health and welfare. These technologies may indeed enable efficient and continuous detection of abnormal behaviors, thermal stress or illnesses. In particular, in broiler farm more than 90% of problems (blocked feeder line, light program, water supply, climate, etc.) may be detected by camera-based systems; moreover, the PLF setup shown that 95% of all of these problems may be related to behavior patterns [26,68]. An example of advanced imaging sensing in broiler house is the PLF eYeNamic system: this real-time camera vision-based monitoring consists in 3 or 4 cameras mounted at the ceiling that analyze broilers’ behavior detecting pictures of the distribution of the birds in the flock. Moreover, the system permits to evaluate water ad feed intake by visualization of feeder lines. Based on collected data, continuous housing monitoring and real-time prediction of birds’ distribution allows for the detection of flaws in feeding, drinking, heating and fans systems with an accuracy of 95%, enabling faster and more effective corrective action to ensure health and welfare, microclimate control, and the maintenance of typical gaseous pollutants [166,217,218].

Advance in research has made possible to gain innovative imagining technology such as computer vision systems and thermal imaging technique. Computer vision is an innovative system that includes two-dimensional (2D) and three-dimensional (3D) vision systems combined to sensor devices [219,220]. Actually, 3D cameras are replacing 2D cameras since 3D cameras introduce the third dimension, or “the depth”, visualizing the bodies three-dimensionally. A comprehensive review of 2D and 3D image processing techniques used to detect cattle and pig behavior and characteristics was found by Nasirahmadi, et al. [221]. Objective details and measurements of livestock weight and body dimension can be extracted by 3D cameras. For example, in dairy and beef cattle rearing, these imagery systems have been used for body weight prediction [213,222,223]. A sharp change of body condition parameters can indicate improper management or the onset of disorder or disease [213,224].

Visual detection systems can also be used to detect lameness, abnormal gait or foot pad dermatitis (FPDs) in livestock. These affections are deeply associated with welfare [225,226,227], with reduced feed and water intake and overall poor animal health status. Nowadays, modern poultry breeds have genetically been selected to reach heavier slaughter weight more quickly [228]. However, the rapid growth rate, alongside other factors, may leads developmental abnormalities and related diseases, like skeletal problems and poor leg health, including lameness [229]. These affections flow in culling, mortality, decreased feed efficiency, and thus growth performance [230]. Common methods of lameness evaluation rely on visual locomotion scoring [231], thus are labor intense and time consuming. Nevertheless, PLF technology may come in handy with more practical and non-invasive image detection tools to enable continuous flock monitor [166,167]. In broilers, Aydin [232] proposed a lameness assessment method based on a combination of 3D cameras equipped with a depth sensor. Additionally, an image-processing algorithm was used to detect the number of laying events and the latency to lay down. Authors compared data collected on laying events and visual gait score obtained with the common reference method and found a correlation between these measures, detecting lameness with an average of 93%.