Advances in Mechanized Harvesting Technologies and Equipment for Chili Peppers

Abstract

1. Introduction

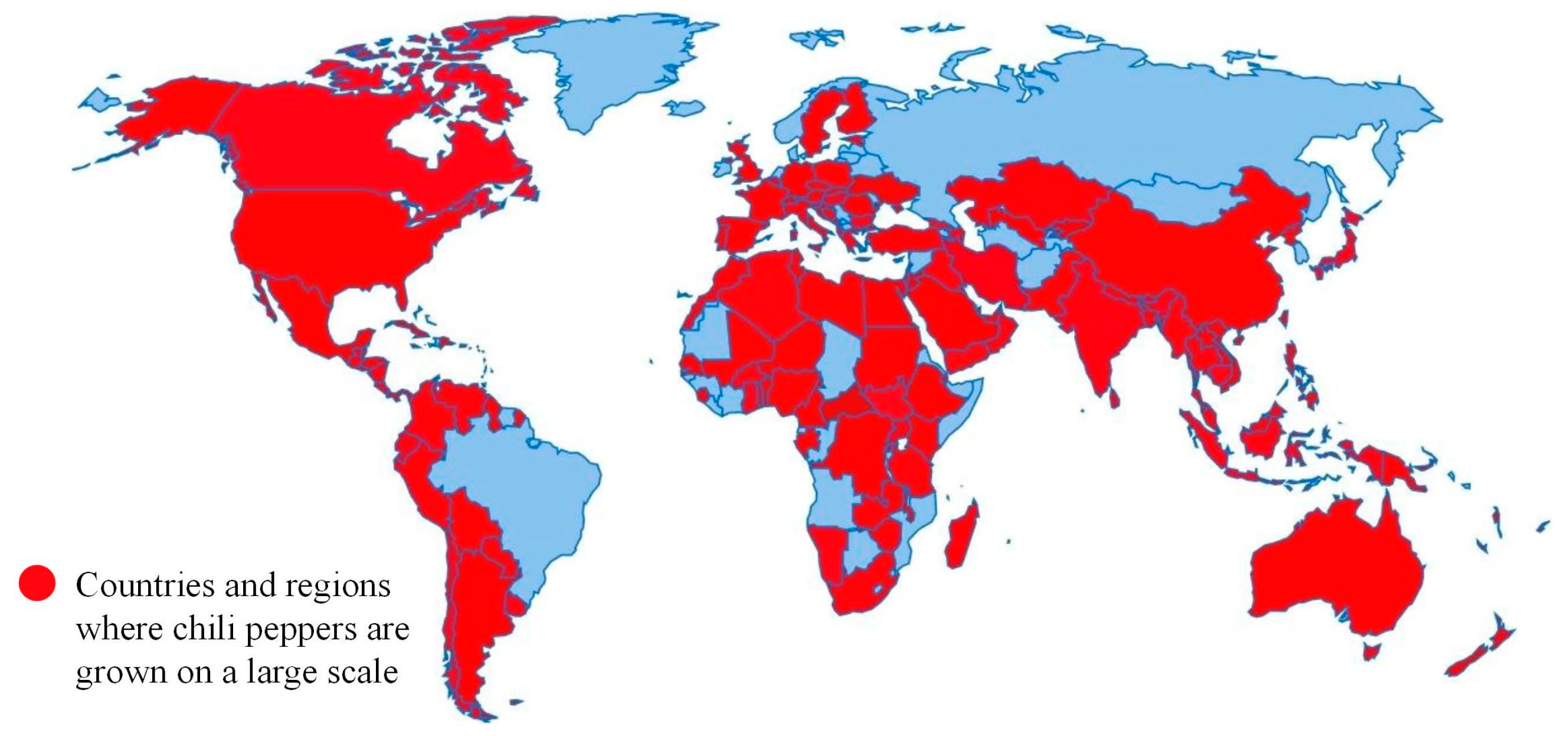

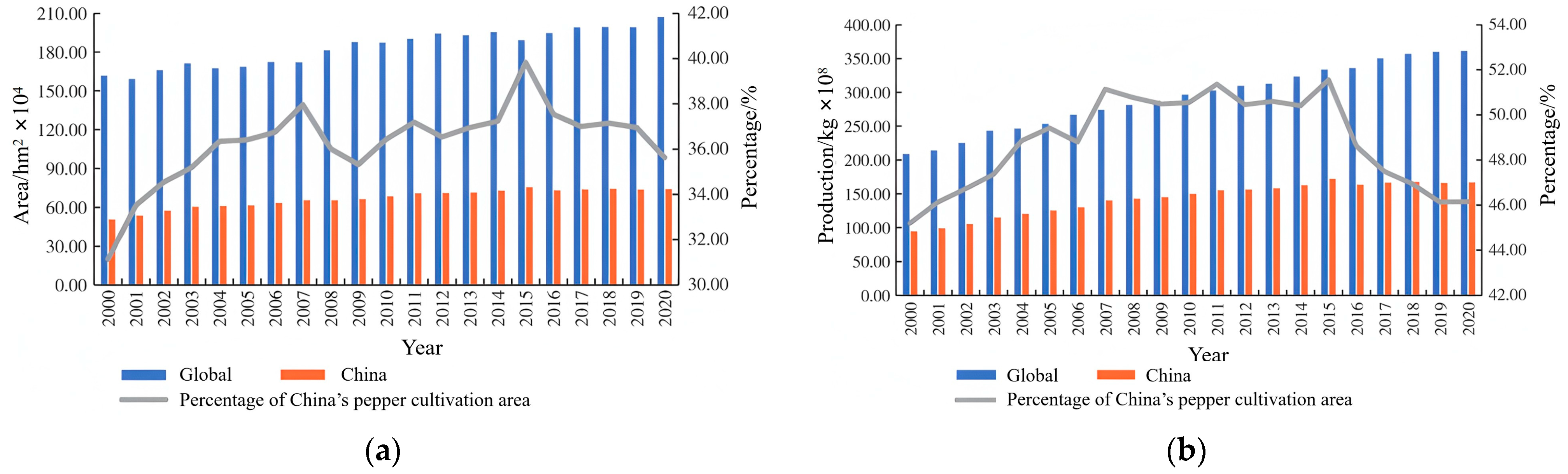

1.1. Pepper Planting Status and Variety Classification

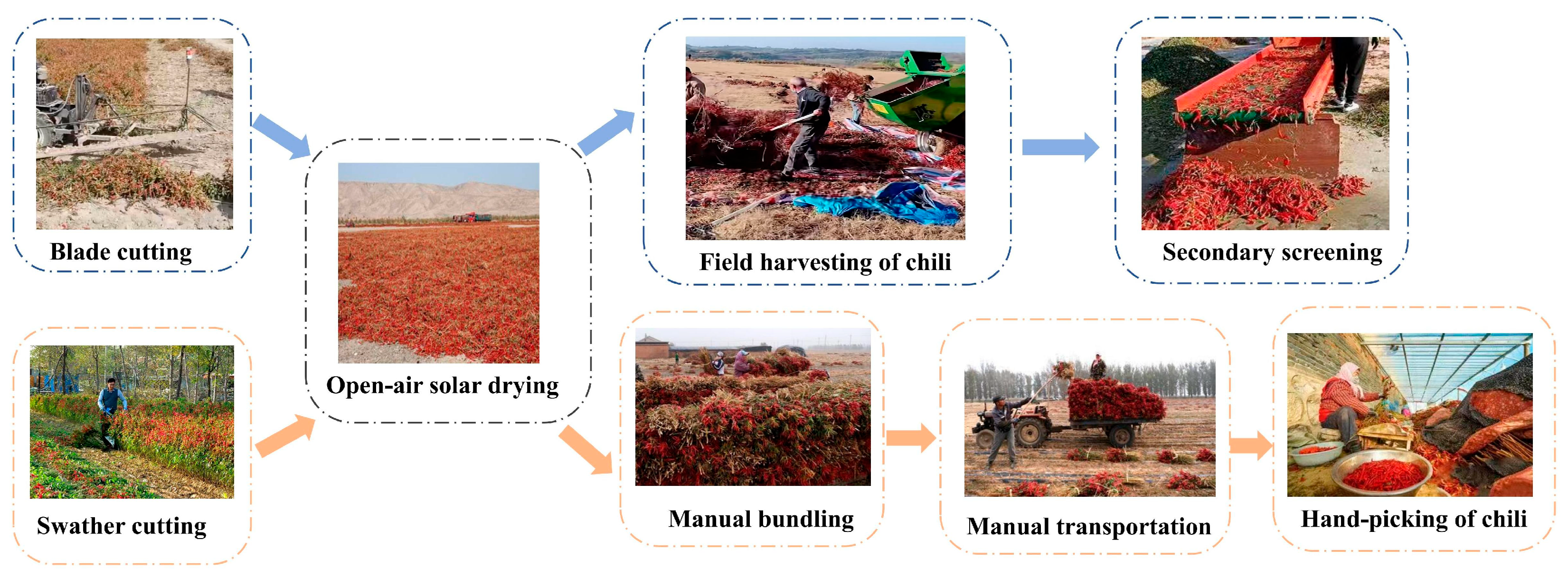

1.2. Existing Pepper Harvesting Methods and Their Characteristics

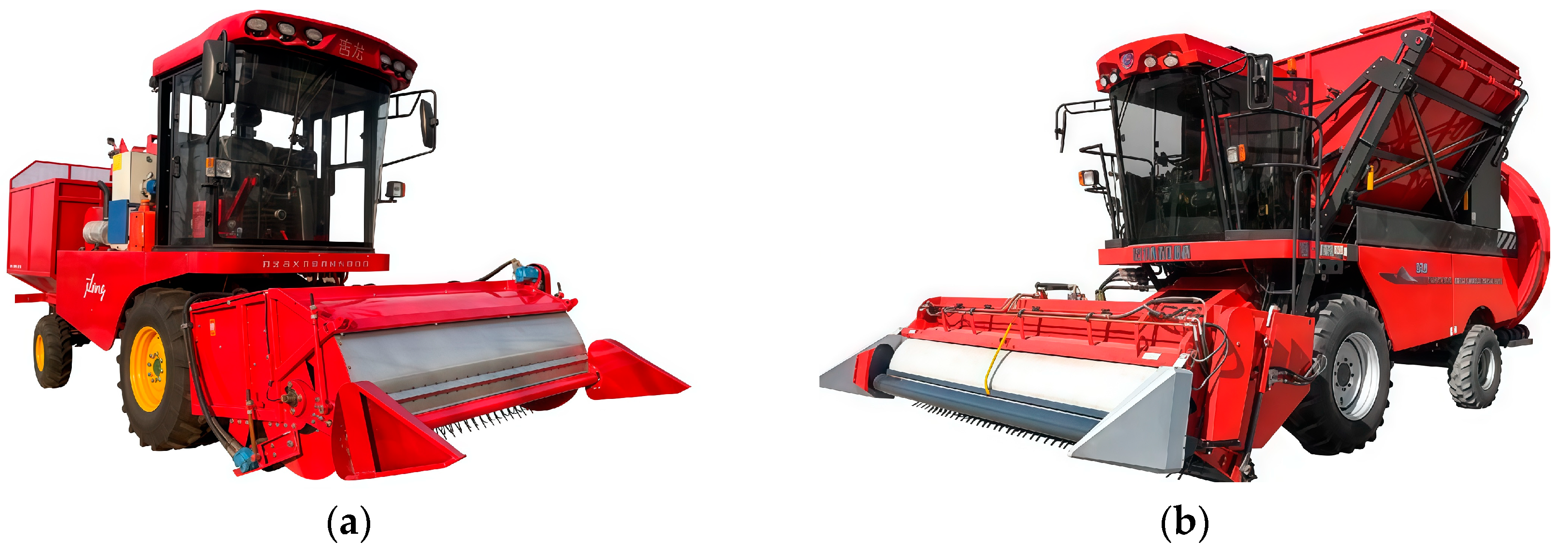

1.3. Current Status of Mechanized Chili Harvesting

2. Pepper Picking Technology and Devices

2.1. Current Harvesting Techniques

2.2. Current Application Status of Harvesting Technologies

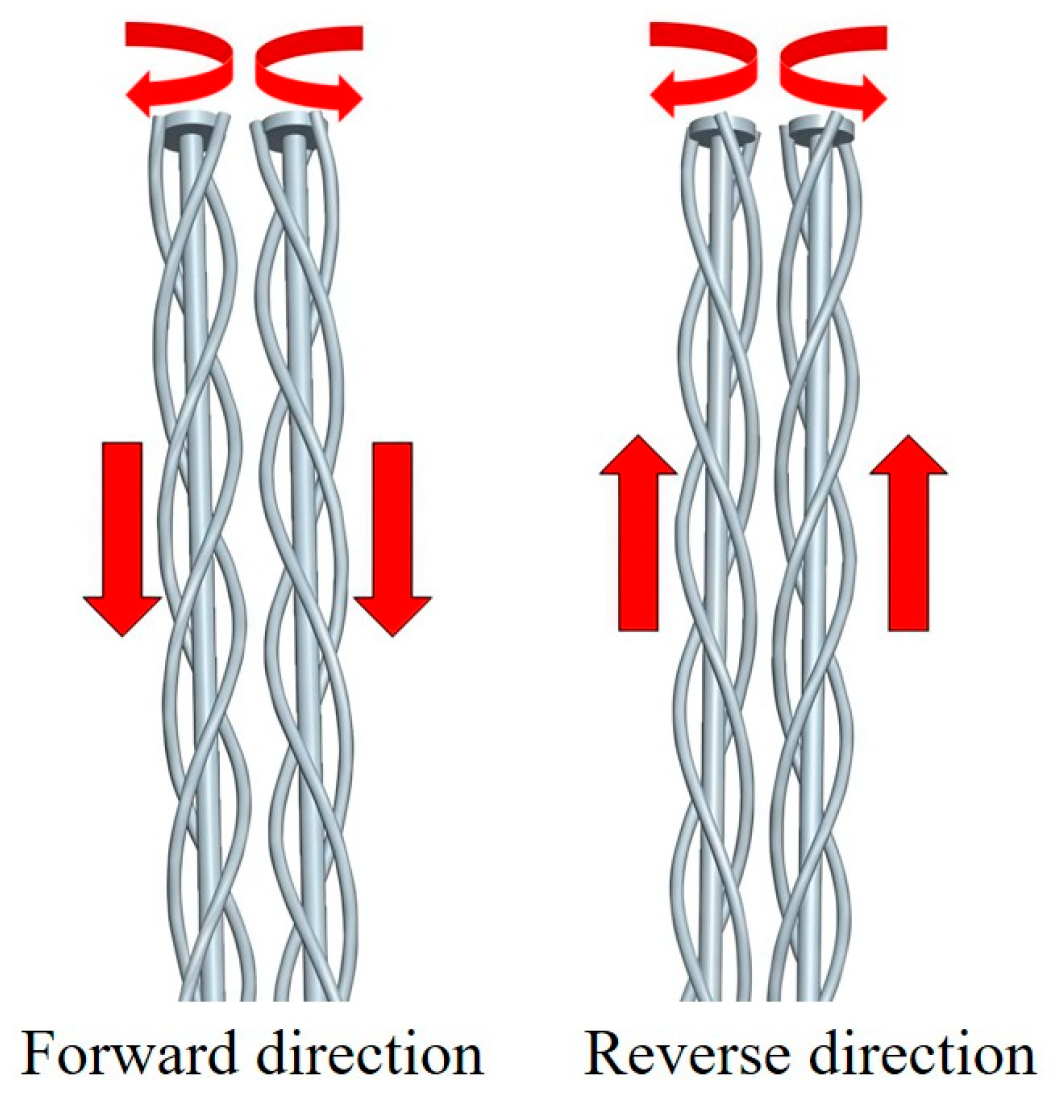

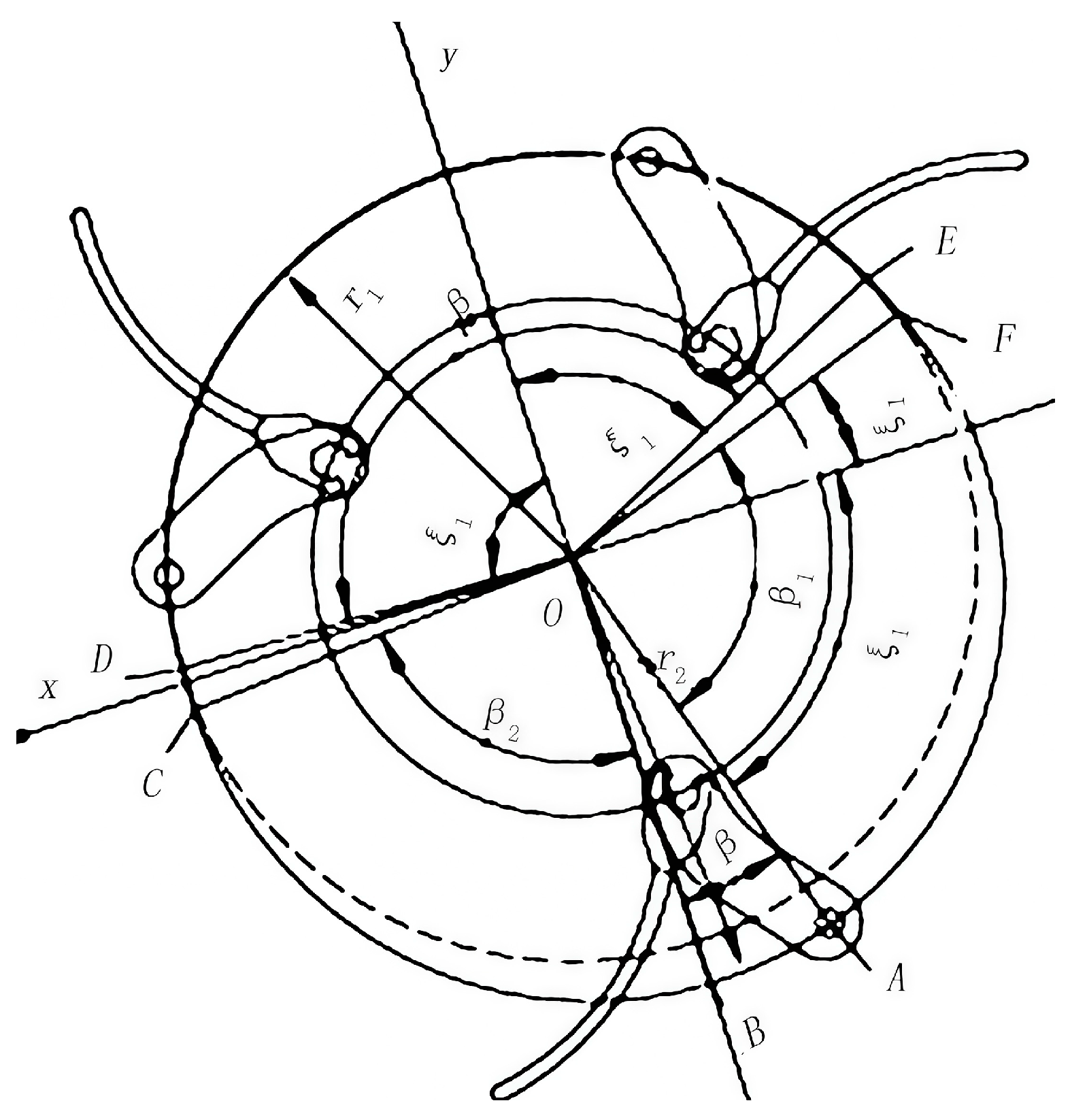

2.2.1. Dual-Helix Picking Device

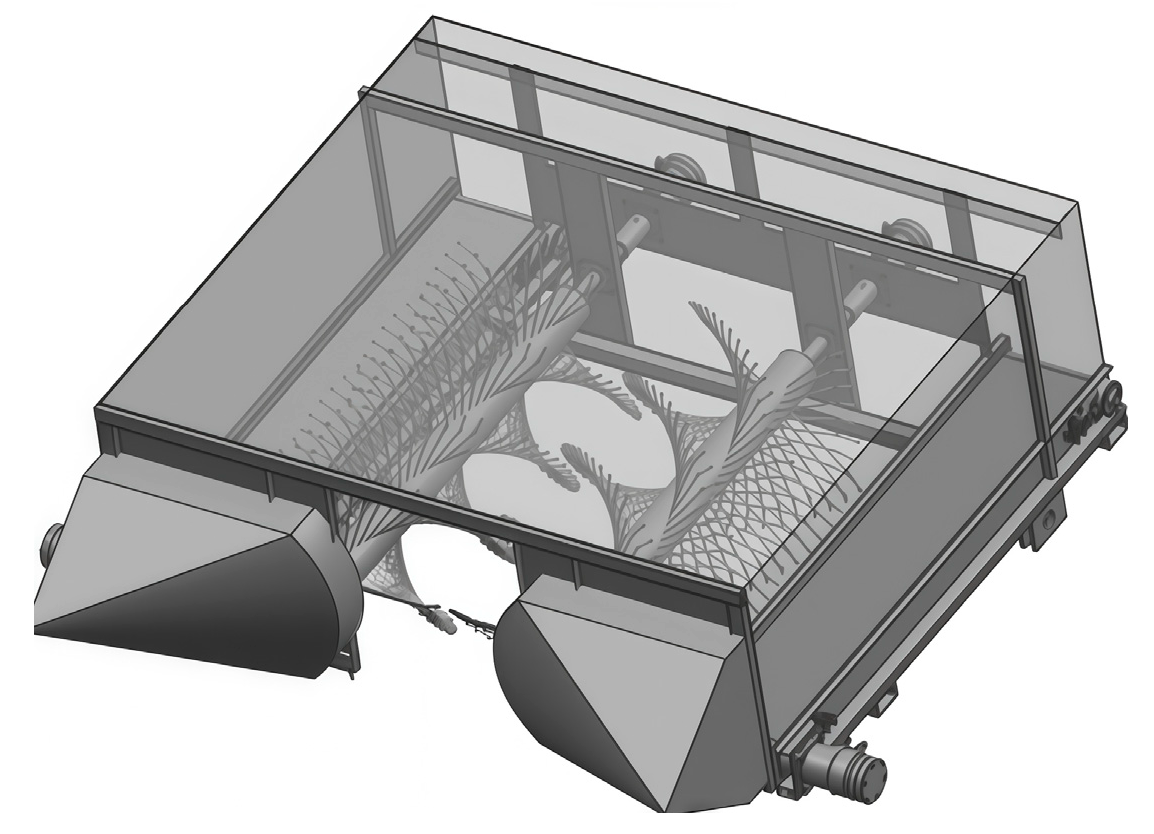

2.2.2. Roller Finger-Picking Device

2.2.3. Long-Rod Comb-Tooth-Type Harvesting Device

2.2.4. Belt-Type Comb-Tooth Harvesting Device

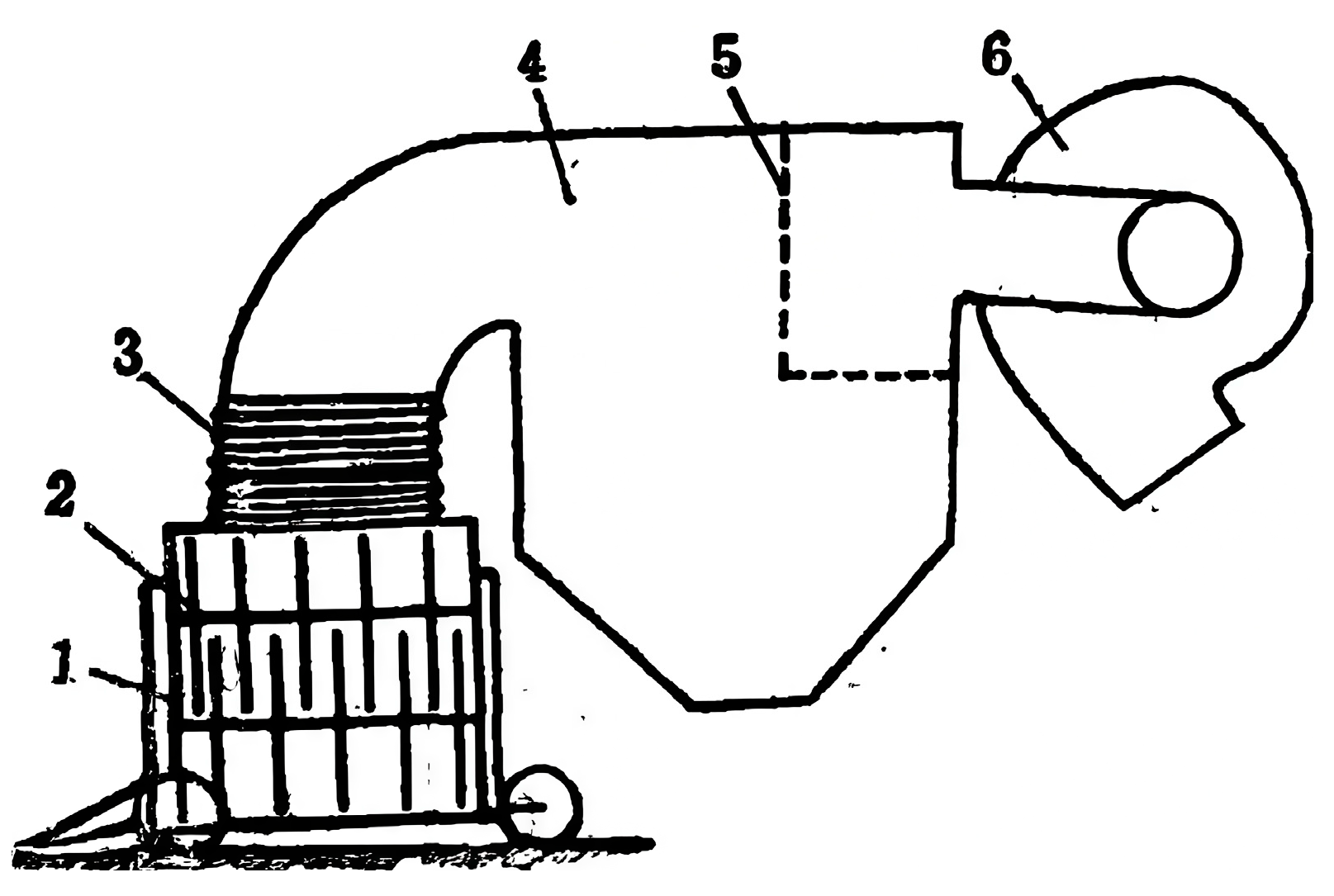

2.2.5. Chili Re-Threshing Device

2.2.6. Staged Harvesting Device

2.3. Development Trends in Picking and Harvesting Technology

3. Pepper Cleaning and Separation Technology and Device

3.1. Current Technology for Cleaning and Separating Chili Peppers

3.2. Current Status of Cleaning and Separating Devices

3.3. Development Trend of Scavenging and Separation Technology

4. Research on Other Devices of Chili Harvesters

5. Summary and Outlook

5.1. Current Issues in Chili Harvesting Equipment

5.2. Solutions to Mechanized Harvesting Questions

5.3. Intelligent Development Prospects for Chili Harvesting Equipment

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Mikula, K.; Izydorczyk, G.; Skrzypczak, D.; Mironiuk, M.; Moustakas, K.; Witek-Krowiak, A.; Chojnacka, K. Controlled release micronutrient fertilizers for precision agriculture—A review. Sci. Total Environ. 2020, 712, 136365. [Google Scholar] [CrossRef] [PubMed]

- Yost, M.A.; Kitchen, N.R.; Sudduth, K.A.; Massey, R.E.; Sadler, E.J.; Drummond, S.T.; Volkmann, M.R. A long-term precision agriculture system sustains grain profitability. Precis. Agric. 2019, 20, 1177–1198. [Google Scholar] [CrossRef]

- O’Brien, P.L.; Daigh, A.L. Tillage practices alter the surface energy balance–A review. Soil Tillage Res. 2019, 195, 104354. [Google Scholar] [CrossRef]

- Zhao, Y.; Gong, L.; Huang, Y.; Liu, C. A review of key techniques of vision-based control for harvesting robot. Comput. Electron. Agric. 2016, 127, 311–323. [Google Scholar] [CrossRef]

- Food Research and Development Service Center. 2025. Available online: https://yanfa.foodmate.net/news/show-237.html (accessed on 7 May 2025).

- Wei, Y.; Jin, L. Research progress on extraction methods and application of capsanthin. Chin. Condiment 2017, 42, 142–147. [Google Scholar]

- Liu, Y.; Hu, W.; Jiang, A.; Liu, C.; Bai, L. Research progress in the nutrition value and processing products of Chili. Sci. Technol. Food Ind. 2014, 35, 377–381. [Google Scholar]

- Zhang, D.; Sun, X.; Battino, M.; Wei, X.; Shi, J.; Zhao, L.; Liu, S.; Xiao, J.; Shi, B.; Zou, X. A comparative overview on chili pepper (capsicum genus) and sichuan pepper (zanthoxylum genus): From pungent spices to pharma-foods. Trends Food Sci. Technol. 2021, 117, 148–162. [Google Scholar] [CrossRef]

- Li, J.; Zuo, M.; Zhang, W.; Zou, X.; Sun, Z. Diazo coupling-based ultrasensitive SERS detection of capsaicin and its application in identifying gutter oil. Food Anal. Method. 2022, 15, 3468–3478. [Google Scholar] [CrossRef]

- Gao, L.; Li, Z.; Wei, X.; Hao, M.; Song, W.; Zou, X.; Huang, X. A cell-based electrochemical biosensor for the detection of capsaicin. J. Food Meas. Charact. 2024, 18, 9341–9352. [Google Scholar] [CrossRef]

- FAOSTAT. Food and Agriculture Organization of the United Nations: 2025. Available online: https://www.fao.org/faostat/zh/#data/qcl (accessed on 7 May 2025).

- Lin, Q.; Xin, Z.; Kong, L.; Wang, X.; Yang, X.; He, W. Current situation of pepper industry development and breeding countermeasures in China. J. China Agric. Univ. 2023, 28, 82–95. [Google Scholar]

- Walker, S.J.; Funk, P.; Joukhadar, I.; Place, T.; Havlik, C.; Tonnessen, B. ‘NuMex odyssey’, a New Mexico–type green Chile pepper for mechanical harvest. HortScience 2021, 56, 1605–1607. [Google Scholar] [CrossRef]

- Zou, X.; Yang, S.; Dai, X.; Hu, B.; Xu, H.; Zhu, F.; Pei, S.; Yuan, F. The rapid development of China’s chili pepper industry over the past 40 years. Acta Hortic. Sin. 2025, 52, 247–258. [Google Scholar]

- Wang, S.; Liu, X.; Liu, Y.; Li, B.; Dong, Y.; Wang, T. Investigation on present planting and harvesting situation of dry pepper in xinjiang. Xinjiang Agric. Mech. 2022, 03, 26–29. [Google Scholar]

- Jain, R.; Meena, M.L.; Dangayach, G.S.; Bhardwaj, A.K. Association of risk factors with musculoskeletal disorders in manual-working farmers. Arch. Environ. Occup. Health 2018, 73, 19–28. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, Y. Key Technologies and Equipment for Mechanized Chili Harvesting, 1st ed.; China Agricultural Science and Technology Pres: Beijing, China, 2018; pp. 5–40. [Google Scholar]

- BS ISO 8210:2021; Equipment for Harvesting—Combine Harvesters—Test Procedure and Performance Assessment. British Standards Institution: London, UK, 2021.

- KS B ISO 8210-2022; Equipment for Harvesting—Combine Harvesters—Test Procedure and Performance Assessment. Korean Agency for Technology and Standards: Seoul, Republic of Korea, 2022.

- ISO 8210:2021; Equipment for Harvesting—Combine Harvesters—Test Procedure and Performance Assessment. International Organization for Standardization: Geneva, Switzerland, 2021.

- Hu, S.; Chen, Y.; Yuan, Y.; Han, L. The present research and propect of pepper harvester. J. Agric. Mech. Res. 2011, 33, 237–240. [Google Scholar]

- Fan, S.; Sun, R.; Lou, H.; Cai, P.; Zhang, S.; Hao, Y. Current status and research strategies of mechanization technology for pepper harvesting in China. J. Zhongzhou Univ. 2023, 40, 116–120. [Google Scholar]

- Qiao, L.; Zhao, B.; Zong, Y.; Kou, C.; Dong, Y. Development Current Situation, Tendency, and Countermeasure for China’s Pepper Industry. China Veget. 2023, 11, 9–15. [Google Scholar]

- JB/T 12825-2016; Pepper Harvesters. China Machinery Industry Federation: Beijing, China, 2016.

- DG/T 114-2019; Pepper Harvesters. Ministry of Agriculture and Rural Affairs of the People’s Republic of China: Beijing, China, 2019.

- Q/ZS206-2017; Pepper Harvesters. Xinjiang Machinery Research Institute Co., Ltd.: Urumqi, China, 2017.

- Q/321181 SFH 051-2022; Technical Requirements for Environmental Protection Equipment. Jiangsu Ward Agricultural Machinery Co., Ltd.: Zhenjiang, China, 2022.

- Liu, Y.; Zhang, X.; Zhu, X.; Ma, S. Vibration Separation Mechanism and Experimental Study of Pigment of Chile. J. Agric. Mech. Res. 2022, 44, 7–13. [Google Scholar]

- Marshall, D.E. Mechanical pepper harvesting. Acta Hortic. 1995, 412, 285–292. [Google Scholar] [CrossRef]

- Eaton, F.E.; Wilson, C. Refinement and Testing of Mechanical Clearners for Red Chile; College of Agriculture and Home Economics: Las Cruces, NM, USA, 2005. [Google Scholar]

- Gentry, J.P.; Miles, J.A.; Hinz, W.W. Development of a chili pepper harvester. Trans. ASAE 1978, 21, 52–54. [Google Scholar] [CrossRef]

- Wilhoit, J.H.; Duncan, G.A.; Wells, L.G. Elliptical combing motion for harvesting bell peppers. Appl. Eng. Agric. 1990, 6, 673–678. [Google Scholar] [CrossRef][Green Version]

- Oren, D.U.; Gary, L.U.; Randy, L.U. Harvesting Apparatus. U.S. Patent 5287687, 22 February 1994. [Google Scholar]

- Lenker, D.H.; Nascimento, D.F. Mechanical harvesting and cleaning of chili peppers. Trans. ASAE 1982, 25, 42–0046. [Google Scholar] [CrossRef]

- Ke, B. Test Research on Air-Suction Type Pepper Harvest. J. Beijing Agric. Mech. Inst. 1984, 04, 43–51. [Google Scholar]

- Salton, J.R.; Wilson, C. Improving Chile Harvesting and Cleaning Technologies; New Mexico State University Chile Task Force Report 6; New Mexico State University: Las Cruces, NM, USA, 2003; Available online: https://pubs.nmsu.edu/research/horticulture/CTF6/index.html (accessed on 12 May 2025).

- Marshall, D.E. Designing a pepper for mechanical harvesting. Capsicum Eggplant Newsl. 1997, 16, 15–27. [Google Scholar]

- Palau, E.; Torregrosa, A. Mechanical harvesting of paprika peppers in Spain. JAER 1997, 66, 195–201. [Google Scholar] [CrossRef]

- Kim, T.H.; Kim, D.C.; Cho, Y. Performance comparison and evaluation of two small chili pepper harvester prototypes that attach to walking cultivators. Appl. Sci. 2020, 10, 2570. [Google Scholar] [CrossRef]

- Kang, S.; Kim, Y.; Park, H.; Woo, S.; Uyeh, D.D.; Ha, Y. Effect of planting distance on the mechanical harvesting of hot pepper. Agriculture 2021, 11, 945. [Google Scholar] [CrossRef]

- Kang, K.S.; Park, H.S.; Park, S.J.; Kang, Y.S.; Kim, D.C. Study on optimal working conditions for picking head of self-propelled pepper harvester by factorial test. J. Biosyst. Eng. 2016, 41, 12–20. [Google Scholar] [CrossRef]

- Joukhadar, I.S.; Walker, S.J.; Funk, P.A. Comparative mechanical harvest efficiency of six new mexico pod–type green chile pepper cultivars. Horttechnology 2018, 28, 310–318. [Google Scholar] [CrossRef]

- Gupta, C.; Tewari, V.K.; Machavaram, R. Evaluation of a laboratory-based prototype of a comb-type picking mechanism for chili pepper harvester. J. Biosyst. Eng. 2022, 47, 69–78. [Google Scholar] [CrossRef]

- Liu, G.; Lin, S.; Liang, Y.; Tang, Y.; Xu, W. Design of Inclined Double Spiral Comb Finger Type Pepper Harvesting Test Bed. J. Agric. Mech. Res. 2020, 42, 133–137. [Google Scholar]

- Yuan, X.; Yang, S.; Jin, R.; Zhao, L.; Daoerjicai, R.; Zheng, N.; Fu, W. Design and experiment of double helix pair roller pepper harvesting device. Trans. Chin. Soc. Agric. Eng. 2021, 37, 1–9. [Google Scholar]

- Wang, G.; He, B.; Han, D.; Zhang, H.; Wang, X.; Chen, Y.; Chen, X.; Zhao, R.; Li, G. Investigation of Collision Damage Mechanisms and Reduction Methods for Pod Pepper. Agriculture 2024, 14, 117. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Bai, J.; Fang, W.; Hong, T.; Zang, N.; Wang, G. Virtual parameter calibration of pod pepper seeds based on discrete element simulation. Heliyon 2024, 10, e31686. [Google Scholar] [CrossRef] [PubMed]

- Han, D.; Zhang, H.; Li, G.; Wang, G.; Wang, X.; Chen, Y.; Chen, X.; Wen, X.; Yang, Q.; Zhao, R. Development of a bionic picking device for high harvest and low loss rate pod pepper harvesting and related working parameter optimization details. Agriculture 2024, 14, 859. [Google Scholar] [CrossRef]

- Shandong Agricultural University. A Kind of Row Spacing Adjustable Self-Propelled Pepper Combine Harvester. Patent CN202411092021.0, 27 September 2024. [Google Scholar]

- Li, Q.; Xu, Y.; Shen, X. Design and Application of Cleaning Fan Pepper Harvester. Xinjiang Agric. Mech. 2022, 05, 11–12+48. [Google Scholar]

- Lei, M.; Kong, L.; Chen, Y.; Zhou, H.; Duan, Y.; Tian, K. Research on the Chili Picking Device of Spring Tooth Roller-Type. J. Chin. Agric. Mech. 2014, 35, 161–165. [Google Scholar]

- Lei, M.; Wang, F.; Wang, M.; Xue, F.; He, Y.; Chen, Y. Experimental Study on Performance of Chili Picking Device Based on Spring Tooth Roller–type. J. Agric. Mech. Res. 2018, 40, 142–146+152. [Google Scholar]

- Duan, Y.; Kong, L.; Chen, Y.; Lei, M.; Tian, K. Tine drum pepper picking device picking hot pepper me·chanical damage characteristics and mechanism. J. Chin. Agric. Mech. 2014, 35, 79–82. [Google Scholar]

- Kong, L.; Chen, Y. Design and mechanism analysis of the 4LZ-3.0 pepper harvester. J. Chin. Agric. Mech. 2015, 36, 16–19. [Google Scholar]

- Qin, X.; Chen, Y.; Zhang, F.; Liu, X.; Hu, S.; Xiong, Z.; Yuan, Y. Design and research of chili pepper harvester of the type of 4LZ-3.0. J. Agric. Mech. Res. 2012, 34, 53–56. [Google Scholar]

- Wu, L. Pepper-style works harvester and experimental research 4LZ-3.0-type self-propelled. J. Agric. Mech. Res. 2017, 39, 136–139. [Google Scholar]

- Shihezi University. A Parameter-Adjustable Multi-Data-Acquisition Chili Pepper Bullet-Tooth Drum Picking Test Stand. Patent CN202410715501.1, 23 August 2024. [Google Scholar]

- Yang, J.; Qin, X.; Lei, J.; Lu, L.; Zhang, J.; Wang, Z. Design and experiment of a crawler-type harvester for red cluster peppers in hilly and mountainous regions. Agriculture 2024, 14, 1742. [Google Scholar] [CrossRef]

- Song, Z.; Du, C.; Chen, Y.; Han, D.; Wang, X. Development and test of a spring-finger roller-type hot pepper picking header. J. Agric. Eng. 2024, 55, 3. [Google Scholar] [CrossRef]

- Zou, D.; Alimu, M.; Han, C.; Li, Q.; Li, Y.; Zhang, J. Design and experiment of picking table of pepper harvester. J. Agric. Mech. Res. 2022, 44, 105–109. [Google Scholar]

- Shen, X. Design and Experimental Study of Bouncing Pepper Picking Drum. Master’s Thesis, Xinjiang Agricultural University, Urumqi, China, 2023. [Google Scholar]

- Shen, X.; Alimu, M.; Jin, F.; Li, Q.; Xu, Y. Design and Experiment of Spring-tooth Type Pepper Picking Roller. J. Agric. Mech. Res. 2025, 47, 160–166. [Google Scholar]

- Shen, X.; Jin, F.; Li, Q.; Xu, Y. Design and Experiment of Eccentric Pepper Picking Poller. J. Agric. Mech. Res. 2024, 46, 90–95. [Google Scholar]

- Du, C.; Fang, W.; Han, D.; Chen, X.; Wang, X. Design and Experimental Study of a Biomimetic Pod-Pepper-Picking Drum Based on Multi-Finger Collaboration. Agriculture 2024, 14, 314. [Google Scholar] [CrossRef]

- Du, C.; Han, D.; Song, Z.; Chen, Y.; Chen, X.; Wang, X. Calibration of contact parameters for complex shaped fruits based on discrete element method: The case of pod pepper (Capsicum annuum). Biosyst. Eng. 2023, 226, 43–54. [Google Scholar] [CrossRef]

- Funk, P.A.; Marshall, D.E. Pepper Harvester Development; ASABE: Pittsburgh, PA, USA, 2010; p. 1. [Google Scholar]

- Massey, R.A.; Massey, B.F. Pepper Harvester. U.S. Patent Application No. 2005/0210853, 29 September 2004. [Google Scholar]

- Funk, P.A.; Walker, S.J. Green Chile Pepper Harvest Mechanization; American Society of Agricultural and Biological Engineers: Reno, NV, USA, 2009; p. 1. [Google Scholar]

- Funk, P.A.; Walker, S.J. Evaluation of five green Chile cultivars utilizing five different harvest mechanisms. Appl. Eng. Agric. 2010, 26, 955–964. [Google Scholar] [CrossRef]

- Funk, P.A.; Walker, S.J.; Herbon, R.P. A systems approach to chile harvest mechanization. Int. J. Veg. Sci. 2011, 17, 296–309. [Google Scholar] [CrossRef]

- Shooter, S.B.; Buffinton, K.W. Design and development of the pik rite chili pepper harvester: A collaborative project with the University, industry, and government. In Proceedings of the FIE’99 Frontiers in Education. 29th Annual Frontiers in Education Conference, San Juan, PR, USA, 10–13 November 1999. [Google Scholar]

- Chen, Y.; Hu, S.; Yuan, Y. Research of the comb-type picking device for chili pepper. In Proceedings of the 2012 International Conference on Agricultural Machinery (CSAM 2012), Hangzhou, China, 27 October 2012. [Google Scholar]

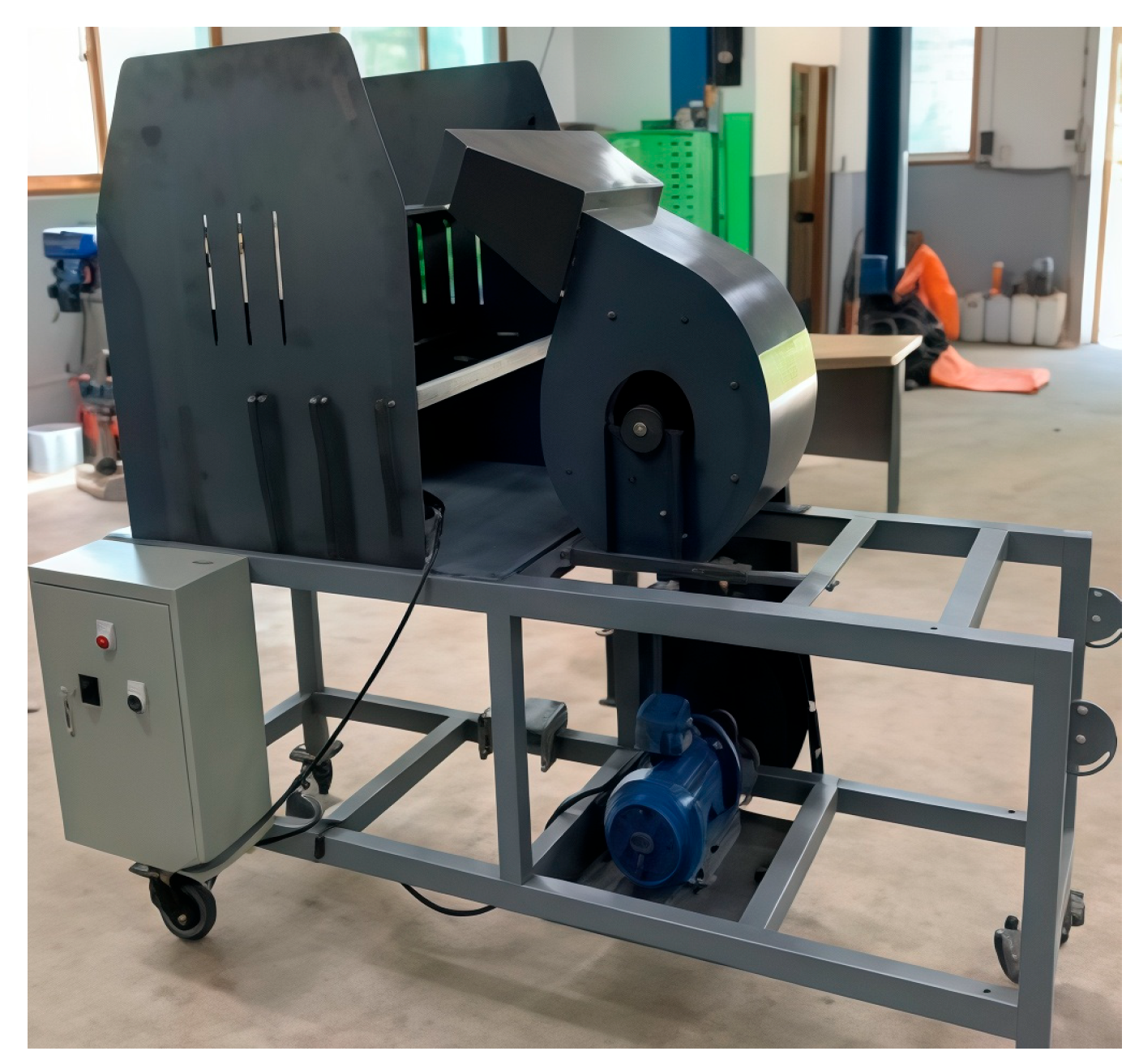

- Shin, S.Y.; Kim, M.H.; Cho, Y.; Kim, D.C. Performance testing and evaluation of drum-type stem-separation device for pepper harvester. Appl. Sci. 2021, 11, 9225. [Google Scholar] [CrossRef]

- Nam, J.S.; Kang, Y.S.; Kim, S.B.; Kim, D.C. Factorial experiment for drum-type secondary separating part of self-propelled pepper harvester. J. Biosyst. Eng. 2017, 42, 242–250. [Google Scholar]

- Zhao, Y.; Diao, X.; Chen, Y.; Fu, W.; Xiong, Z. Design of the divided no-till wheat planter. J. Agric. Mech. Res. 2018, 40, 105–110. [Google Scholar]

- Shen, X.; Alimu, M.; Li, Q.; Xu, Y.; Shi, Y. Design and experiment of pepper re-removal device. J. Chin. Agric. Mech. 2023, 44, 80–86. [Google Scholar]

- Jiangsu University. A Kind of Artichoke Bionic Picking Device and Self-Propelled Bionic Picking Artichoke Harvester. CN202011561266.5, 30 April 2021. [Google Scholar]

- Fang, W.; Wang, X.; Han, D.; Chen, X. Review of material parameter calibration method. Agriculture 2022, 12, 706. [Google Scholar] [CrossRef]

- Liang, Z.; Li, J.; Liang, J.; Shao, Y.; Zhou, T.; Si, Z.; Li, Y. Investigation into Experimental and DEM Simulation of Guide Blade Optimum Arrangement in Multi-Rotor Combine Harvesters. Agriculture 2022, 12, 435. [Google Scholar] [CrossRef]

- Ding, B.; Liang, Z.; Qi, Y.; Ye, Z.; Zhou, J. Improving cleaning performance of rice combine harvesters by DEM–CFD coupling technology. Agriculture 2022, 12, 1457. [Google Scholar] [CrossRef]

- Xu, L.; Li, Y.; Chai, X.; Wang, G.; Liang, Z.; Li, Y.; Li, B. Numerical simulation of gas–solid two-phase flow to predict the cleaning performance of rice combine harvesters. Biosyst. Eng. 2020, 190, 11–24. [Google Scholar] [CrossRef]

- Liang, Z.; Xu, L.; De Baerdemaeker, J.; Li, Y.; Saeys, W. Optimisation of a multi-duct cleaning device for rice combine harvesters utilising CFD and experiments. Biosyst. Eng. 2020, 190, 25–40. [Google Scholar] [CrossRef]

- Xu, L.; Hansen, A.C.; Li, Y.; Liang, Z.; Yu, L. Numerical and experimental analysis of airflow in a multi-duct cleaning system for a rice combine harvester. Trans. ASABE 2016, 59, 1101–1110. [Google Scholar]

- Urich. Harvesting Apparatus. Patent US5930987, 3 August 1999. [Google Scholar]

- Herbon, R. The Design, Prototype Development and Concept Validation of a Chile Sorting Machine. Ph.D. Dissertation, New Mexico State University, Las Cruces, NM, USA, 2003. [Google Scholar]

- Rasmussen. Pepper Station. Patent US820450, 28 June 1974. [Google Scholar]

- Rutt. Cleaning Apparatus. Patent US5427573, 27 June 1995. [Google Scholar]

- Boese. Pull Type Petter Harvester. Patent US7555888B1, 7 July 2009. [Google Scholar]

- Zhang, J.; Alimu, M.; Li, Q.; Li, Y.; Xu, Y.; Gao, S.; Gao, B. Design of Moshine 4JZ-3600A Self-propelled Pepper Harvester. Xinjiang Agric. Mech. 2020, 03, 5–7. [Google Scholar]

- Yuan, Y. Research of Separating Device for Pepper Harvester. Master’s Thesis, Shihezi University, Shihezi, China, 2012. [Google Scholar]

- Kong, L.; Chen, Y.; Lei, M.; Duan, Y.; Xu, C.; Li, J.; Ding, L. Measurement of Mate-rial properties based on line pepper’s mixture. J. Chin. Agric. Mech. 2014, 35, 95–97. [Google Scholar]

- Kong, L.; Chen, Y.; Ma, L.; Duan, Y. Research and design of line pepper’ cleaning and separating device, based on star wheel and airflow. J. Chin. Agric. Mech. 2013, 34, 102–105. [Google Scholar]

- Zou, D.; Zhou, W.; Ma, X.; Li, Q.; Han, C.; Li, Y.; Zhang, J. Design of cleaning system of pepper harvester. J. Agric. Mech. Res. 2022, 44, 129–132+137. [Google Scholar]

- Jo, Y.J.; Kang, Y.S.; Nam, J.S.; Choe, J.S.; Inoue, E.; Okayasu, T.; Kim, D.C. Performance analysis for a card cleaner type separating system of pepper harvester. J. Fac. Agric. Kyushu Univ. 2018, 63, 103–111. [Google Scholar] [CrossRef]

- Byum, J.H.; Nam, J.S.; Choe, J.S.; Inoue, E.; Okayasu, T.; KIM, D.C. Analysis of the separating performance of a card cleaner for pepper harvester using EDEM software. J. Fac. Agric. Kyushu Univ. 2018, 63, 347–354. [Google Scholar] [CrossRef]

- Shin, S.Y.; Kim, D.C.; Kang, Y.S.; Cho, Y. Factorial experiment for air blower of the pepper harvester. J. Biosyst. Eng. 2020, 45, 239–248. [Google Scholar] [CrossRef]

- Lee, M.H.; Kang, Y.S.; Kim, D.C.; Cho, Y.J. A Study on the performance improvement of foreign materials separating system for a pepper harvester. J. Agirc. Life Sci. 2020, 54, 111–120. [Google Scholar] [CrossRef]

- Nam, J.S.; Byun, J.H.; Kim, T.H.; Kim, M.H.; Kim, D.C. Measurement of mechanical and physical properties of pepper for particle behavior analysis. J. Biosyst. Eng. 2018, 43, 173–184. [Google Scholar]

- Zhang, D.; Tang, Y.; Zhang, J.; Lin, S.; Zhang, T.; Xu, W. Determination and simulation analysis of material properties of Chaotian pepper mixture. J. Chin. Agric. Mech. 2023, 44, 35–41+57. [Google Scholar] [CrossRef]

- Zhang, D.J.; Zhang, X.M.; Wu, D.; Lin, S.Y.; Zhang, T.H.; Xu, W.P. Simulation of pepper cleaning based on DEM-CFD coupling. J. Agric. Sci. Technol. 2023, 25, 87–96. [Google Scholar]

- Herbon, R.P.; Cillessen, D.E.; Gamillo, E.M.; Hyde, A.M. Engineering a Machine to Remove Stems from Chile Peppers—A Critical Need for the New Mexico Chile Industry; American Society of Agricultural and Biological Engineers: Reno, NV, USA, 2009. [Google Scholar]

- Liao, Y. Design and Test of Double Roller Differential Dry Pepper. Master’s Thesis, Shandong Agricultural University, Taian, China, 2022. [Google Scholar]

- Li, F.; Li, Z.; Wang, F. Experimental study on physical and mechanical characteristics of Xinjiang Honglong pepper. J. Chin. Agric. Mech. 2024, 45, 141–145+151. [Google Scholar]

- Wang, F.; Li, F.; Zhang, P.; Zhang, L.; Wang, H. Design and Experiment of Double Roller Dried Pepper Pedicel Removal Device. Trans. Chin. Soc. Agric. Mach. 2024, 55, 191–199. [Google Scholar]

- Shandong University of Technology. Straight and Curved Shank Multi-Removal Type Chili Pepper Stalk. Patent CN202311644138.0, 2024. [Google Scholar]

- Ji, X.; Tang, Y.; Lin, S.; Zhang, D.; Zhang, T.; Xu, W. Dynamic simulation and test of the tracked chassis of the mountainous self-propelled pepper harvester. J. Chin. Agric. Mech. 2022, 43, 72–80. [Google Scholar]

- Wu, L. Design and Analysis of Small Hand Supported Pepper Harvester. Master’s Thesis, Chengdu University, Chengdu, China, 2021. [Google Scholar]

- Wang, X.; Cao, Y.; Fang, W.; Sheng, H. Vibration Test and Analysis of Crawler Pepper Harvester under Multiple Working Conditions. Sustainability 2023, 15, 8112. [Google Scholar] [CrossRef]

- Li, Y.; Sun, P.; Pang, J.; Xu, L. Finite element mode analysis and experiment of combine harvester chassis. Trans. Chin. Soc. Agric. Eng. 2013, 29, 38–46. [Google Scholar]

- Li, Y.; Li, Y.; Xu, L.; Hu, B.; Wang, R. Structural parameter optimization of combine harvester cutting bench. Trans. Chin. Soc. Agric. Eng. 2014, 30, 30–37. [Google Scholar]

- Xu, L.; Li, Y.; Sun, P.; Pang, J. Vibration measurement and analysis of tracked-whole feeding rice combine harvester. Trans. Chin. Soc. Agric. Eng. 2014, 30, 49–55. [Google Scholar]

- Tang, Z.; Zhang, B.; Wang, M.; Zhang, H. Damping behaviour of a prestressed composite beam designed for the thresher of a combine harvester. Biosyst. Eng. 2021, 204, 130–146. [Google Scholar] [CrossRef]

- Nanjing Institute of Agricultural Mechanization, Ministry of Agriculture and Rural Affairs. A Kind of Chili Pepper Harvesting Pneumatic Auxiliary Conveying and Cleaning Device. Patent CN201910304098.2, 6 September 2024. [Google Scholar]

- Xu, Y.; Qi, C.; Alimu, M.; Li, Q. Design and experiment of anti-winding device for cutting table of pepper harvester. Xinjiang Agric. Mech. 2025, 01, 18–20. [Google Scholar]

- Liang, Z.; Li, Y.; Xu, L.; Zhao, Z. Sensor for monitoring rice grain sieve losses in combine harvesters. Biosyst. Eng. 2016, 147, 51–66. [Google Scholar] [CrossRef]

- Liang, Z.; Li, Y.; Xu, L.; Zhao, Z.; Tang, Z. Optimum design of an array structure for the grain loss sensor to upgrade its resolution for harvesting rice in a combine harvester. Biosyst. Eng. 2017, 157, 24–34. [Google Scholar] [CrossRef]

- Lu, E.; Xu, L.; Li, Y.; Tang, Z.; Ma, Z. Modeling of working environment and coverage path planning method of combine harvesters. Int. J. Agric. Biol. Eng. 2020, 13, 132–137. [Google Scholar] [CrossRef]

| Name | Picture | Features | Harvesting Methods |

|---|---|---|---|

| Cherry peppers |  | Chili peppers are round or oblate, resembling cherries or buttons. Varieties vary in their use for dried chili production, fresh consumption, and ornamental purposes. | Dried chilies are harvested using vibratory or air-suction harvesters, such as China’s 4JZ-1 model, while fresh varieties are manually harvested with handheld electric pickers. |

| Conical pepper |  | Conical or bullet-shaped chilies, such as Fresno Chili, are primarily for fresh consumption. Certain cultivars, like Serrano Pepper, undergo drying processes. | Fresh chilies are primarily handpicked, while varieties with concentrated ripeness use mechanical harvesters, like the US GH80 model. |

| Pod pepper |  | Pod peppers grow upright and are small in size. They can be categorized by single-stage or batch ripening, and are used for fresh consumption and dried chili production. | Pod peppers are mostly handpicked, while central pod peppers are harvested with chili pepper harvesters, such as China’s 4JZ-3600 model. |

| Bullhorn pepper |  | Bullhorn peppers are long and thick, with thick skins, and are shaped like cow or ram’s horns. They are mainly used for fresh consumption, e.g., Bulgarian ram’s horns peppers. | Most of the horn peppers are hand-picked due to their inconsistent ripening and primary use for fresh consumption. |

| Cayenne pepper |  | Cayenne peppers are linear, thin, slightly curved, and yield high, uniform maturity, making them ideal for dried chili production. | These peppers are primarily harvested for dried chili production using harvesters, such as the 4JZ-3150 model in China. |

| Bell pepper |  | Bell peppers are large, thick-fleshed, and lantern-shaped, with a variety of cultivars, primarily used for fresh consumption. | Mechanical harvesting can damage the peppers, so manual picking is predominantly used. |

| Standard | Type of Application | Loss Rate | Breakage Rate | Impurity Rate |

|---|---|---|---|---|

| JBT 12825-2016 [24] | Thread pepper harvester | ≤3.0% | ≤2.0% | ≤18% |

| DG T 114-2019 [25] | Comb-type chili harvester | ≤8% | ≤3% | ≤20% |

| Q/ZS206-2017 [26] | Harvester compatible with varieties including thread, Jinta, and American Red chili peppers | ≤6% | Thread ≤ 8% Jinta ≤ 10% American Red ≤ 15% | ≤20% |

| Q/321181 SFH 051-2022 [27] | Compact self-propelled chili harvester | ≤5% | ≤8% | ≤15% |

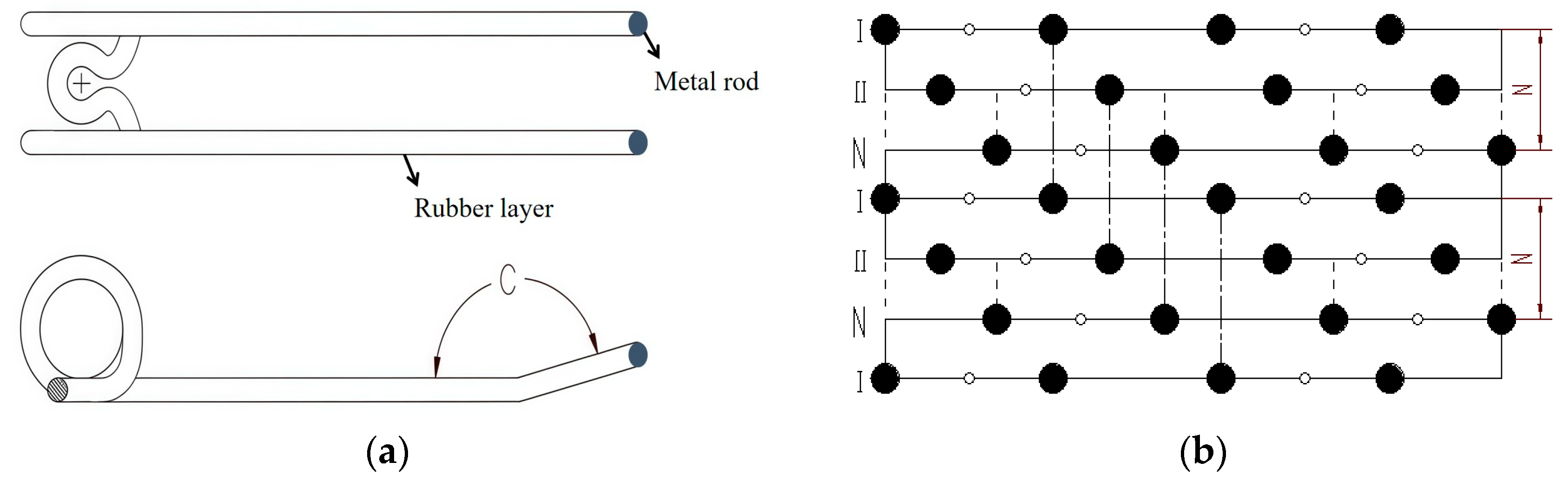

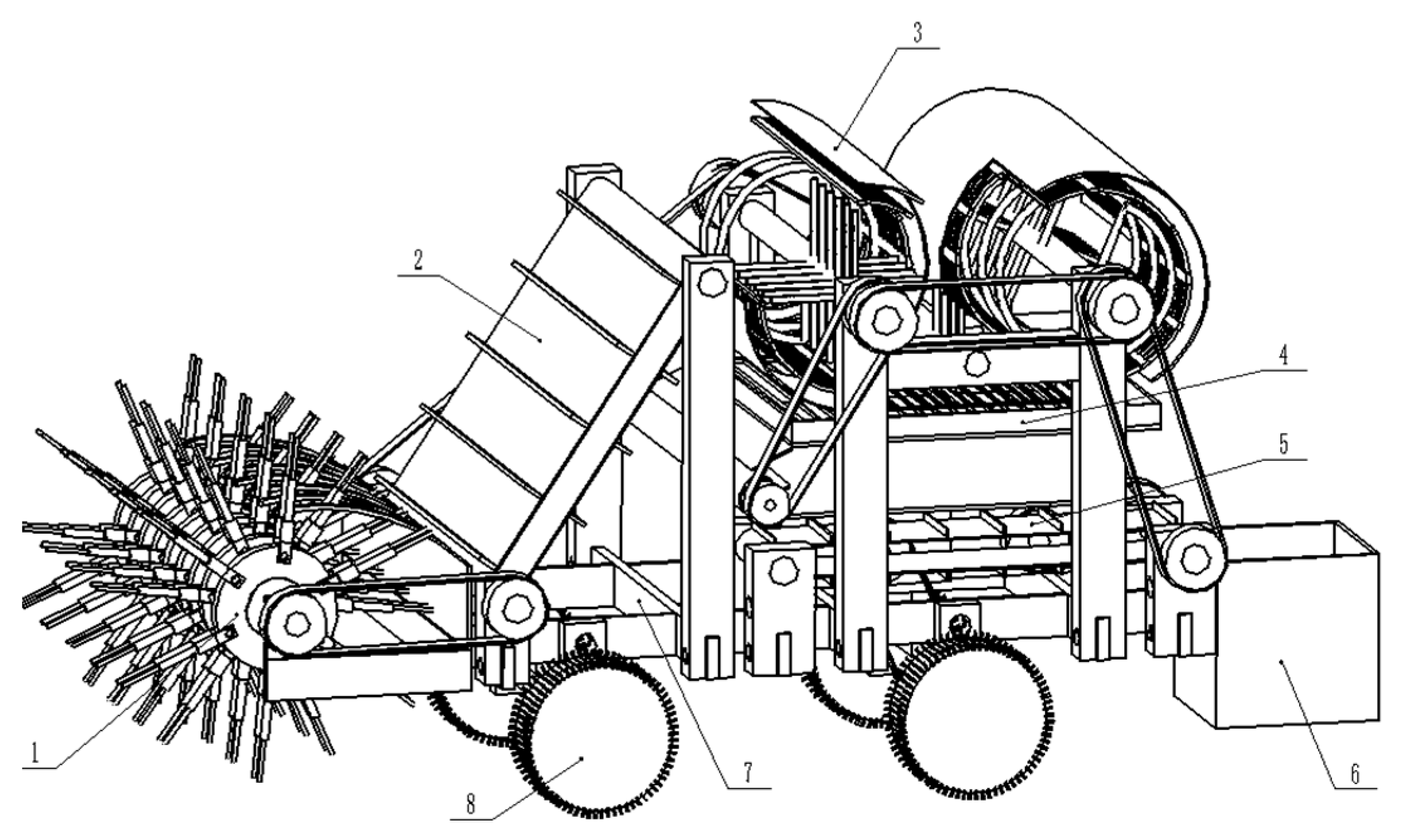

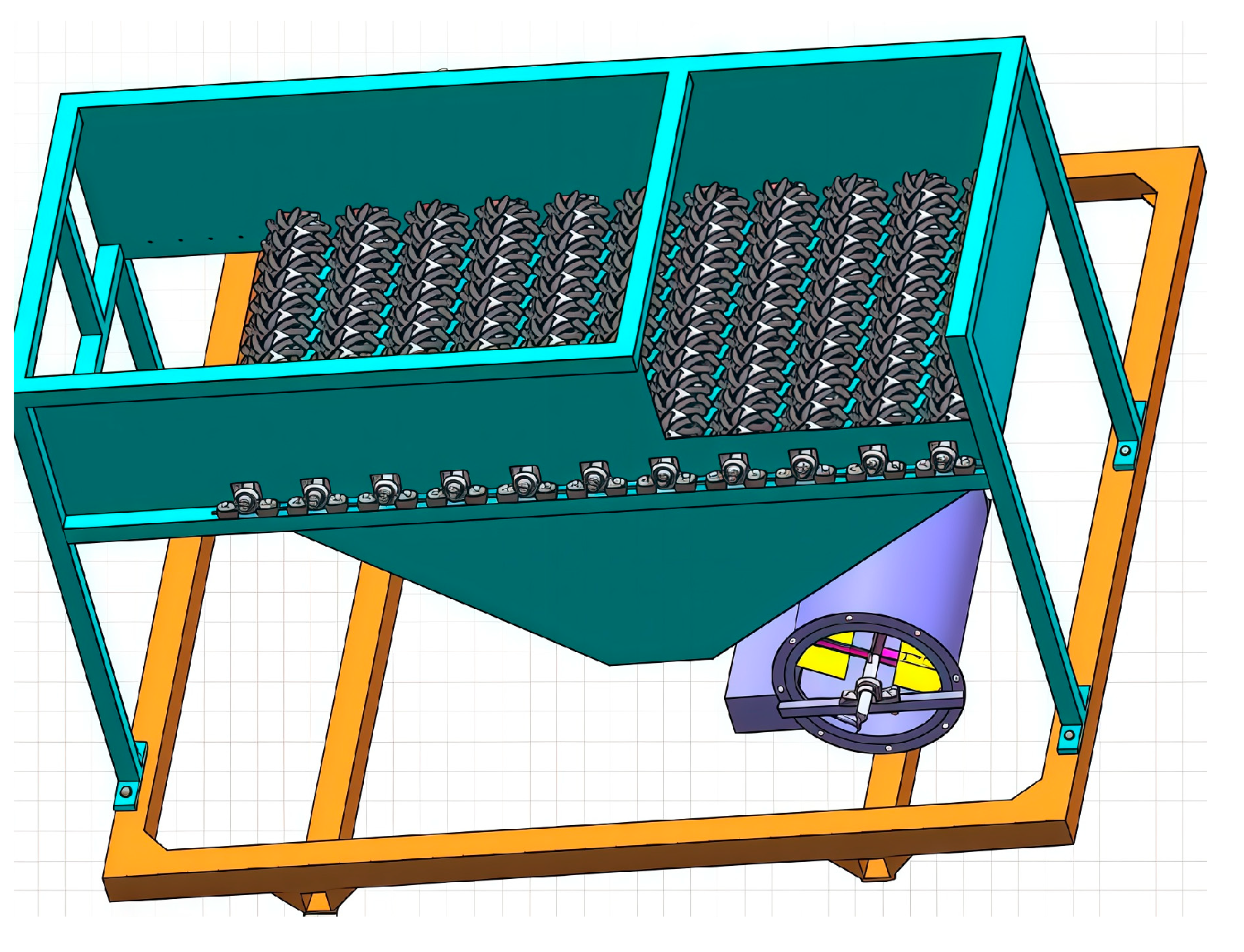

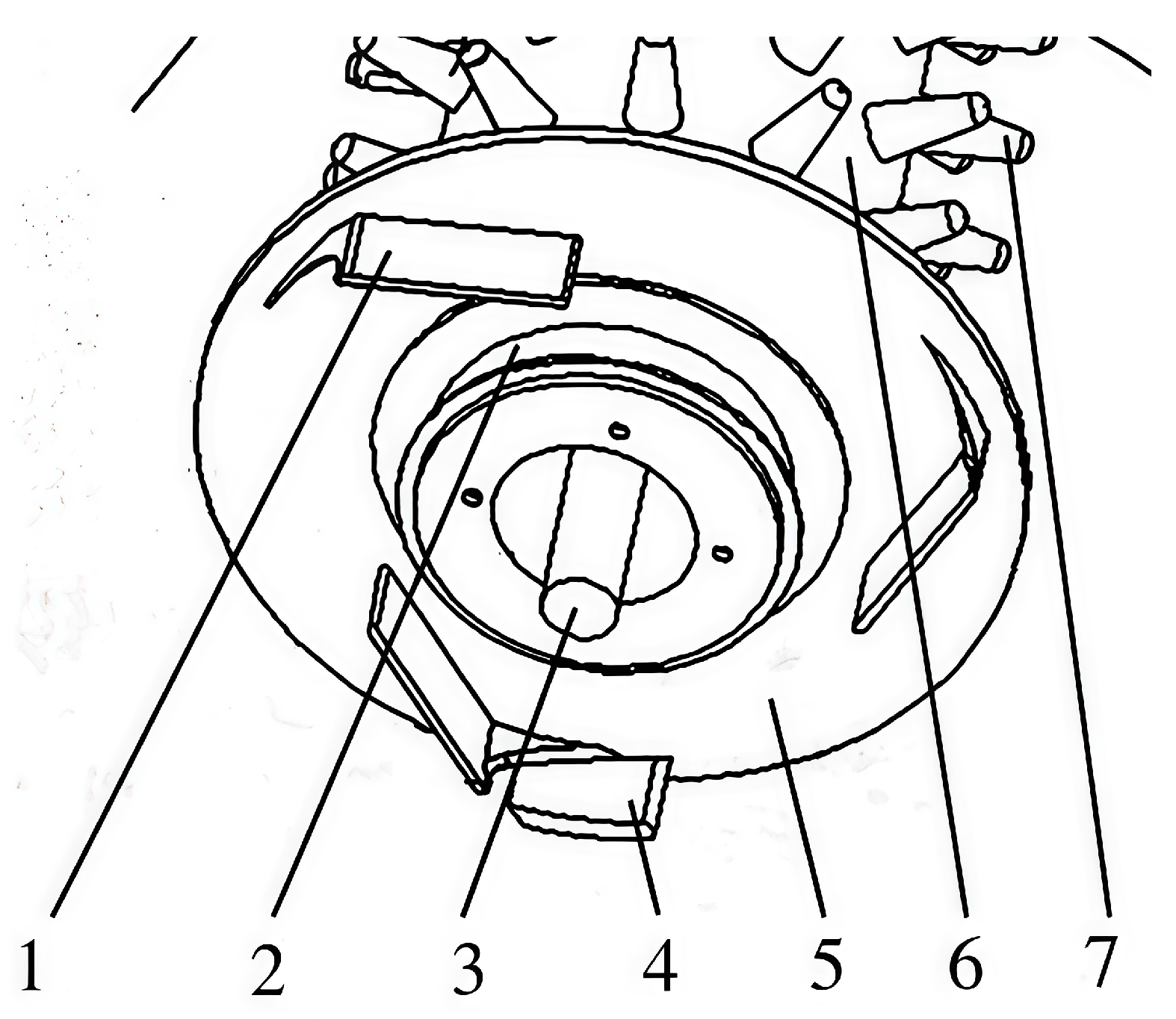

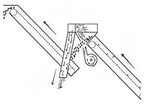

| Type | Working Schematic | Features | Suitable Varieties |

|---|---|---|---|

| Dual-helix picking mechanism |  | Simple structure and low failure rate. Low damage to peppers due to point contact, resulting in many impurities such as pepper leaves, and needs row-aligned harvesting. | Suitable for pepper varieties with low water content or dry stalks, such as bell peppers. |

| Roller finger snapping type |  | Can harvest without row spacing, making it highly adaptable to peppers with varying row distances. Effectively picks up peppers that have fallen to the ground. | Effective for harvesting clusters of peppers and dried peppers with fragile stems. |

| Rod and bar comb type |  | Requires harvesting in paired rows, with a continuous bottom-up impact on the peppers. High picking capacity, but causes significant damage to the peppers. | Suitable for chili varieties with concentrated pepper distribution. |

| Belt-type comb-tooth harvesting device |  | Requires opposite row harvesting, with two rotating belts moving in opposite directions from bottom to top. Effectively picks up peppers that have fallen to the ground. | Suitable for harvesting larger peppers, such as board peppers (a specific variety of goat horn pepper) and lantern peppers. |

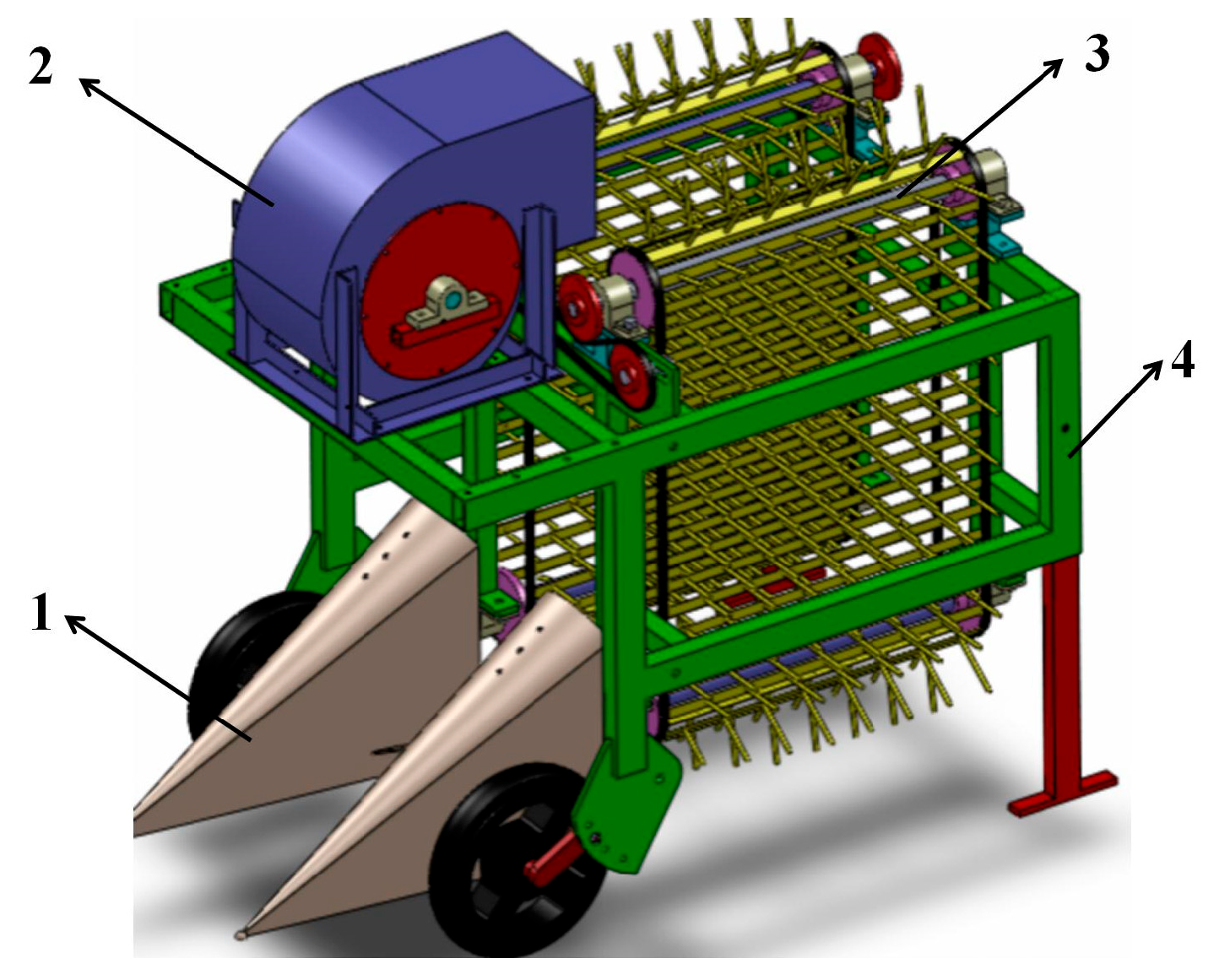

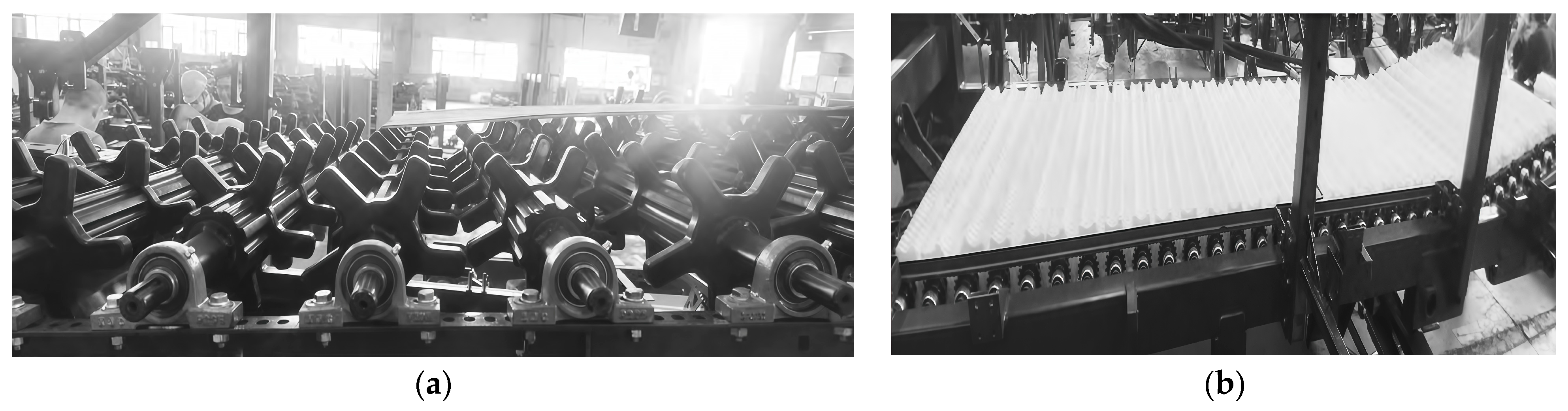

| Spiral Roller Types | Picture | Specificities |

|---|---|---|

| Unfolding Spiral Picking Roller |  | Point contact picking can effectively avoid damaging the peppers and is suitable for picking larger peppers such as bell peppers. Currently the most used picking roller. |

| Comb Finger Spiral Picking Roller |  | In comb finger picking, the picking effect is good but it is easy to damage peppers, so it is suitable for picking peppers growing in clusters. |

| Rigid–Flexible Coupling Comb Roller |  | Reduces the damage to the peppers by changing the material of the core components or adding flexible materials. |

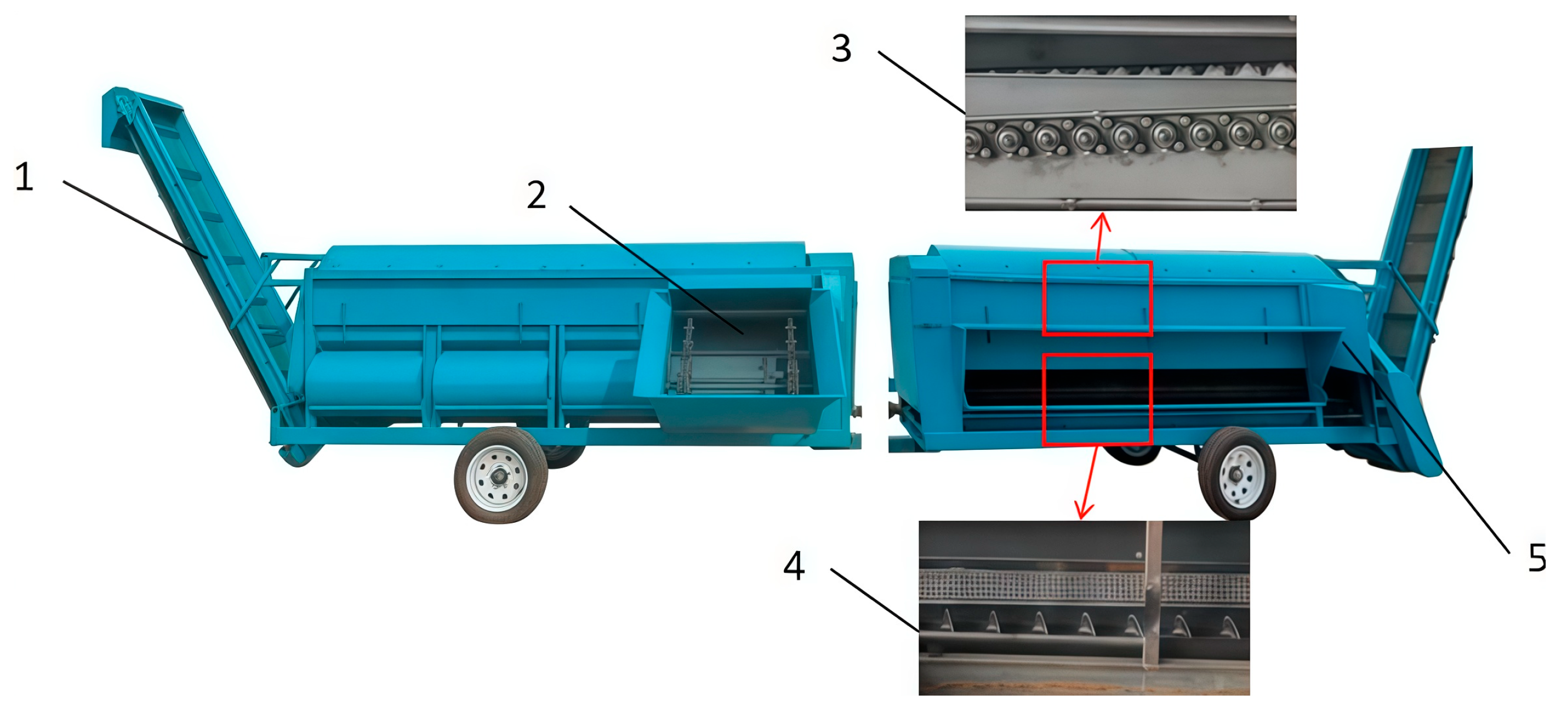

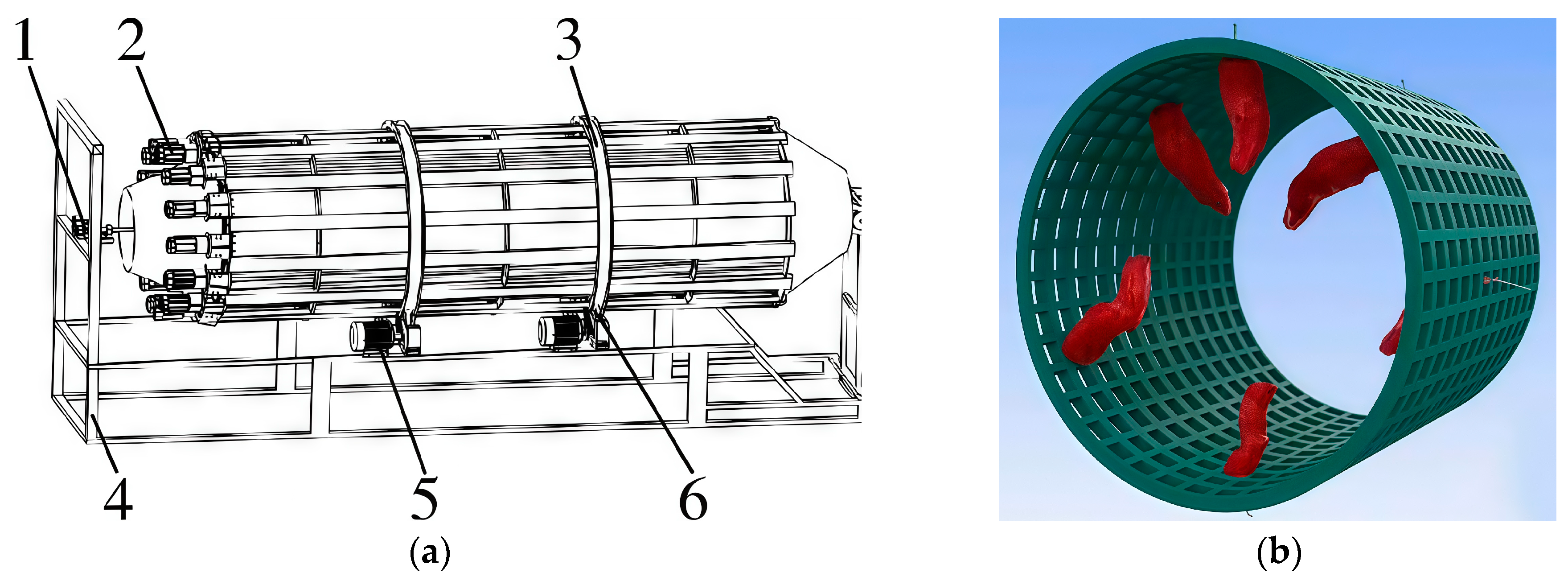

| Type | Schematic Diagram | Characteristics | Applicable Varieties |

|---|---|---|---|

| Pneumatic conveying system |  | The simple structure facilitates effective separation of pepper leaves but has poor performance in cleaning stems. It is suitable for peppers with larger volumes or higher masses. | Suitable for pepper varieties with fewer stems and more leaves. |

| Intermittent belt conveyor |  | Effective at separating long stems, but short stems and leaves tend to fall with the peppers. Excessive clearance increases impurity content, while insufficient clearance leads to blockage. | Suitable for pepper varieties with abundant stems and fewer leaves, particularly effective for small-sized peppers. |

| Rotary blade-pneumatic integrated system |  | The entire plant can be fed in for stem–leaf separation. However, the complex structure poses a risk of cutting peppers with blades. Frequent blade wear requires replacement. | Compatible with segmented harvesting methods and pepper varieties that require intricate picking operations. |

| Cylindrical drum mechanism |  | Excessive sieve bar clearance causes pepper leakage, while insufficient clearance leads to blockage. The separation efficiency for long stems is poor. | Suitable for cleaning large-sized peppers to prevent small peppers from leaking through gaps. |

| Star wheel-airflow coordinated device |  | Provides better clearing effects for both stems and leaves, but the fixed spacing between the star wheels limits its use to peppers of similar size. | Optimal for cleaning small-sized and dried peppers. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, D.; Wang, C.; Zhang, H.; Pang, H.; Wang, X.; Chen, X.; Wen, X. Advances in Mechanized Harvesting Technologies and Equipment for Chili Peppers. Agriculture 2025, 15, 1129. https://doi.org/10.3390/agriculture15111129

Han D, Wang C, Zhang H, Pang H, Wang X, Chen X, Wen X. Advances in Mechanized Harvesting Technologies and Equipment for Chili Peppers. Agriculture. 2025; 15(11):1129. https://doi.org/10.3390/agriculture15111129

Chicago/Turabian StyleHan, Dianlei, Congxu Wang, He Zhang, Hao Pang, Xinzhong Wang, Xuegeng Chen, and Xiangyu Wen. 2025. "Advances in Mechanized Harvesting Technologies and Equipment for Chili Peppers" Agriculture 15, no. 11: 1129. https://doi.org/10.3390/agriculture15111129

APA StyleHan, D., Wang, C., Zhang, H., Pang, H., Wang, X., Chen, X., & Wen, X. (2025). Advances in Mechanized Harvesting Technologies and Equipment for Chili Peppers. Agriculture, 15(11), 1129. https://doi.org/10.3390/agriculture15111129